wheel alignment AUDI TT ROADSTER 2008 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2008Pages: 316, PDF Size: 70.1 MB

Page 251 of 316

__________________________________________________ T_ ir_e _ s_ a_ n _ d_ w_ h_ e_ e_ls _ ____. 111111

Unbalanced wheels must be rebalanced to avoid excessive wear on

steering, suspension and tires. A wheel must also be rebalanced

when a new tire is installed.

Incorrect wheel alignment

Incorr ect wheel alignment can cause excessive tire wear, impairing

the safety of the vehicle. If tires show excessive wear, have the

wheel alignment checked by an authorized Audi dealer or qualified

workshop.

All Wheel Drive

Vehicles with quattro ® must always have tires of the same size,

construction and tread type. For details see

=> page 191.

& WARNING

Sudden tire failure can lead to loss of control, a crash and serious

personal injury!

• Never drive a vehicle when the tread on any tire is worn down

to the wear indicators .

• Worn tires are a safety hazard, they do not grip well on wet

roads and increase your risk of "hydroplaning" and loss of control .

• Always keep chemicals that can cause tire damage, such as

grease, oil, gasoline and brake fluid away from tires .

• Tires age even if they are not being used and can fail suddenly,

especially at high speeds . Tires that are more than 6 years old can

only be used in an emergency and then with special care and at

lower speeds.

• Never mount used tires on your vehicle if you are not sure of

their "previous history ." Old used tires may have been damaged

even though the damage cannot be seen that can lead to sudden

tire failure and loss of vehicle control. •

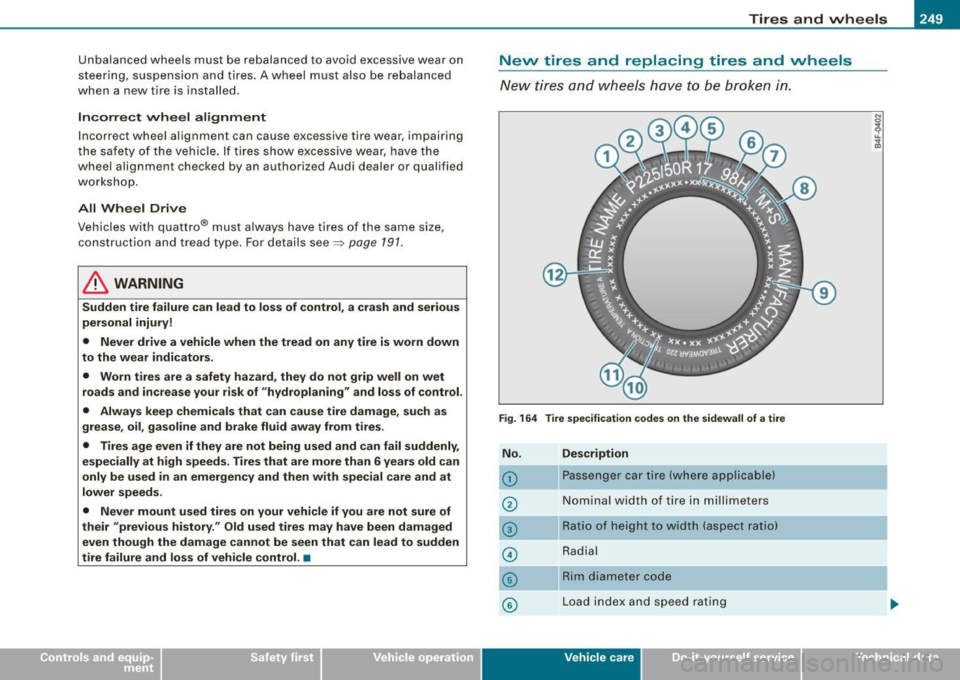

New tires and replacing tires and wheels

New tires and wheels have to be broken in.

Fig. 164 Tire specification codes on the sidewall of a tire

No.

©

0

©

©

©

©

Description

Passenger car tire (where app licable)

Nominal width of tire in mi llimeters

Ratio of height to width (aspect ratio)

Radial

ii Rim diameter code

Load index and speed rating

Vehic le care

I I irechnical data

Page 264 of 316

11111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ vv_ ? ______________________________________________ _

What do I do now?

Trunk escape handle

In case of an emergency, the rear lid can be opened from

the inside using the trunk escape handle.

F ig . 165 Lug gag e

co mp artm ent: T runk

escape handl e

- To open the trunk lid pull the hand le down as indicated

by t h e -arrow -~ fig. 165.

The trunk escape handle inside the storage compartment is made

of fluorescent materia l to glow in the dark.

& WARNING

The tr un k es cap e handl e is to b e use d onl y in an em ergen cy. •

Vehicle tool kit

The tools are st ored underneath the floor panel in the

luggage c ompartment.

Fi g. 16 6 Lugga ge

co mpa rtm ent : ve hic le

t o ol kit

- Sw ing the luggage compartment floo r upwards .

- Remove the ve hicle tool kit .

The onboard tool ki t includes:

• Hook for removing wheel covers *

• Plastic clip to remove wheel bolt covers*

• Wheel bolt wrench

• Alignment pin for changing wheels

• Screwdriver wi th reversible blade

• Replacement bit (r eve rsible Torx bit for changing lamps)

• Open ended wrench 10 x 13

• Towing eye

Note: some of the on board items listed above are prov ided on

certain models only or a re optional extras.

Page 272 of 316

1111...__W_ h_ a _ t_d_ o_ l _d _o_ n_ o_ w_ ? ______________________________________________ _

& WARNING

• You or your passengers could be injured while changing a

wheel if you do not follow safety precautions:

-Mounting the jack under the vehicle at any other place than

indicated above may damage the vehicle or may result in

personal injuries.

- A soft or unstable surface under the jack may cause the

vehicle to slip off the jack. Always provide a firm base for the

jack on the ground.

If necessary, use a sturdy board under the

jack.

- On hard, slippery surface (such as tiles) use a rubber mat or

similar to prevent the jack from slipping.

• To help prevent injury to yourself and your passengers: -Do not raise the vehicle until you are sure the jack is securely

engaged.

- Passengers must not remain in the vehicle when it is jacked

up.

- Make sure that passengers wait in a safe place away from

the vehicle and well away from the roadway and traffic.

- Make sure jack position is correct, adjust as necessary and

then continue to raise the jack.

0 Note

A floor jack or the pads on the hoist arms must not be positioned at

the points shown~

page 269, fig . 174 -arrows -. •

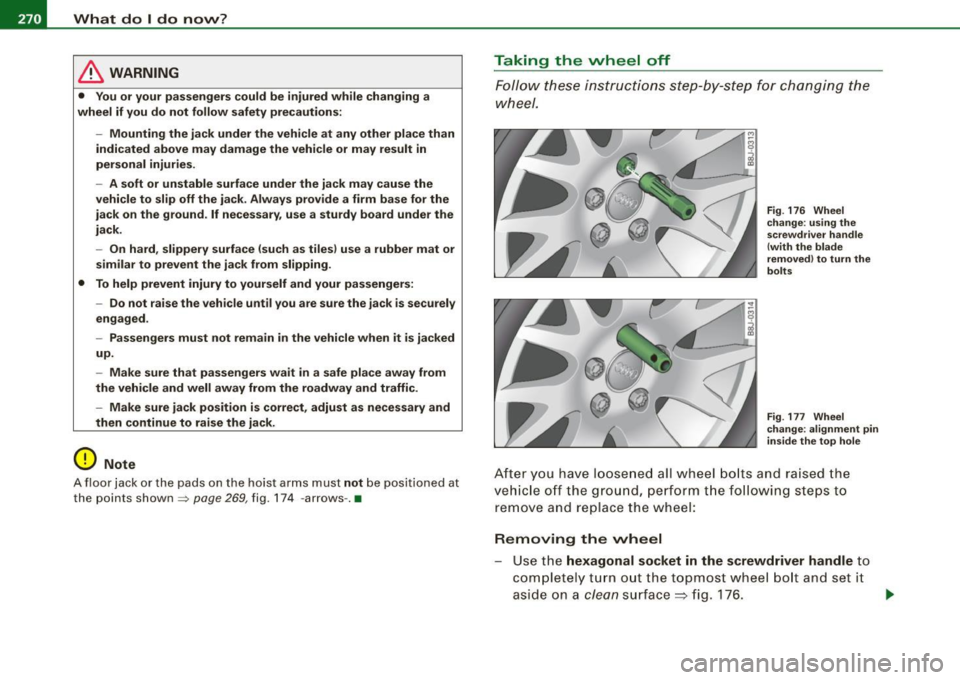

Taking the wheel off

Follow these instructions step-by-step for changing the

wheel.

Fig . 176 Wheel

change : using the

screwdriver handle

(with the blade

removed) to turn the

bolts

Fig. 177 Wheel

change : alignment pin

inside the top hole

After you have loosened all wheel bolts and raised the

vehicle off the ground, perform the following steps to

remove and replace the wheel:

Removing the wheel Use the hexagonal socket in the screwdriver handle to

completely turn out the topmost wheel bolt and set it

as ide on a

clean surface => fig. 176. ~

Page 273 of 316

What do I do now? -

----------------

•

-Screw the threaded end of the alignment pin from the

tool kit hand-tight into the now vacant bolt hole

=:> page 270, fig. 177.

- Then completely unscrew the other wheel bolts as

described above.

- Take off the wheel leaving the alignment pin in the bolt

hole.

Putting on the wheel

- Lift the spare wheel and carefully slide it over the align

ment pin to guide it in place.

- Use the hexagonal socket in the screwdriver handle to

screw in and tighten all wheel bolts slightly.

- Unscrew the alignment pin and insert and tighten the

remaining wheel bolt slightly like the rest.

- Turn the jack handle counter -clockwise to lower the

vehicle until the jack is fully released.

- Use the wheel bolt wrench to tighten all wheel bolts

firmly =:> page 268. Tighten them crosswise, from one

bolt to the (approximately) opposite one, to keep the

wheel centered.

[ i J Tips

Never use the hexagonal socket in the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reversible blade from the screwdriver before you use the

hexagonal socket in the handle to turn the wheel bolts.

• When mounting tires with

unidirectional tread design make sure

the tread pattern is pointed the right way~

page 272.

• The wheel bolts should be clean and easy to turn. Check for dirt

and corrosion on the mating surfaces of both the wheel and the

hub . Remove all dirt from these surfaces before remounting the

wheel. •

Notes on wheel change

Please read the information~ page 249, "New tires and replacing

tires and wheels", if you are going to use a spare tire which is

different from the tires on your vehicle.

After you change a tire:

• Check the tire pressure on the spare immediately after

mounting.

• Have the wheel bolt tightening torque checked with a torque

wrench as soon as possible by your authorized Audi dealer or a qualified service station .

• With steel and alloy wheel rims, the wheel bolts are correctly

tightened at a torque of 90 ft lb (120 Nml.

• If you notice while changing a tire that the wheel bolts are

corroded and difficult to turn, then they should be replaced before

you check the tightening torque.

• Replace the flat tire with a new one and have it installed on your

vehicle as soon as possible. Remount the wheel cover.

Until then, drive with extra care and at reduced speeds.

& WARNING

• If you are going to equip your vehicle with tires or rims which

differ from those which were factory installed, then be sure to read

the information

~ page 249, "New tires and replacing tires and

wheels".

• Always store the tools securely in luggage compartment.

Otherwise, in an accident or sudden maneuver they could fly

forward, causing injury to passengers in the vehicle.

Do-it-yourself service