warning AUDI TT ROADSTER 2015 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2015, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2015Pages: 244, PDF Size: 60.74 MB

Page 208 of 244

206 What do I do now ?

@ For the sake of the environment

Used sealant bottles can be dropped off at

a recycling facility .

@ Tips

- If sealant has run out, allow it to dry.

Then you can peel it off.

- Have the tire se alant replaced every 4

years at a dea lership .

Preliminary steps

Applies to vehicles: with Tire Mobil ity System

Some preliminary steps are necessary for tire

repair.

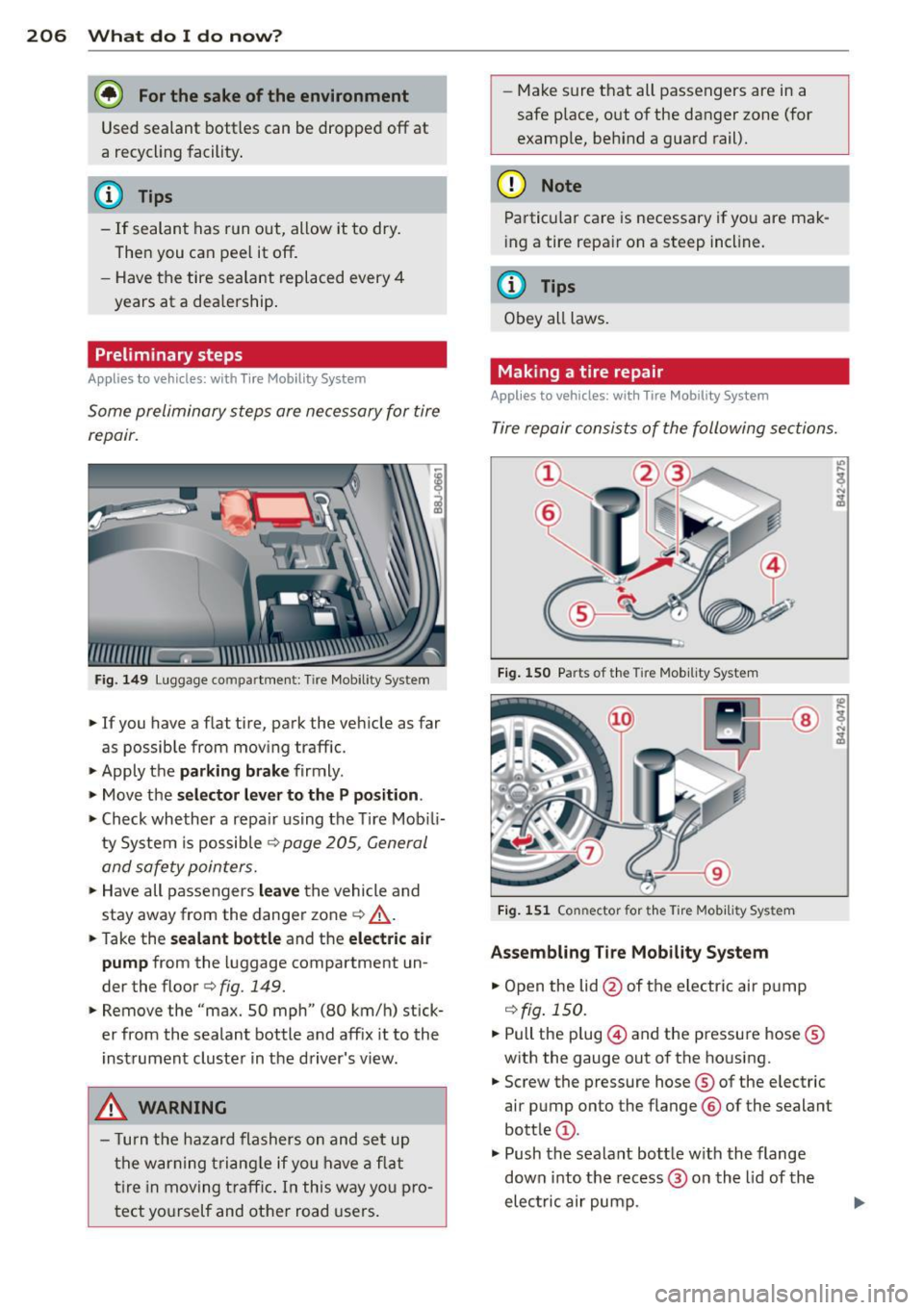

Fig. 149 Luggage co mpa rtment : T ir e Mobil ity System

.. If you have a flat tire, park the ve hicle as far

as possible from mov ing traffic .

.. Apply the parking brake firmly .

.. Move the selector lever to the P po sition .

.. Check whether a repa ir using the T ire Mob ili

ty System is possib le

~ page 205 , General

and safety pointers .

.. Have all passengers leave the vehicle and

stay away from the danger zone

c:> /.1. .

.. Take the sealant bottle and the electric air

pump from the luggage compartment un

der the floor

c:> fig. 149 .

.. Remove the "max. 50 mph" (80 km/ h) stick

er from the sealant bottle and aff ix it to the

instrument cluster in the driver's view.

A WARNING

- T urn the ha zard flashers on and set up

t he w arning t ria ng le if you have a fla t

t ire in moving traffic. In this way you pro

tect yo urself and other road users .

-

-Make sure that all passengers are in a

safe place, out of the danger zone (for

example, beh ind a guard rail).

(D Note

Particular care is necessary if you are mak

ing a tire repa ir on a steep incline.

(D Tips

Obey all laws.

Making a tire repair

Appl ies to vehicles: with Tire Mob ility System

Tire repair consists of the following sec tion s.

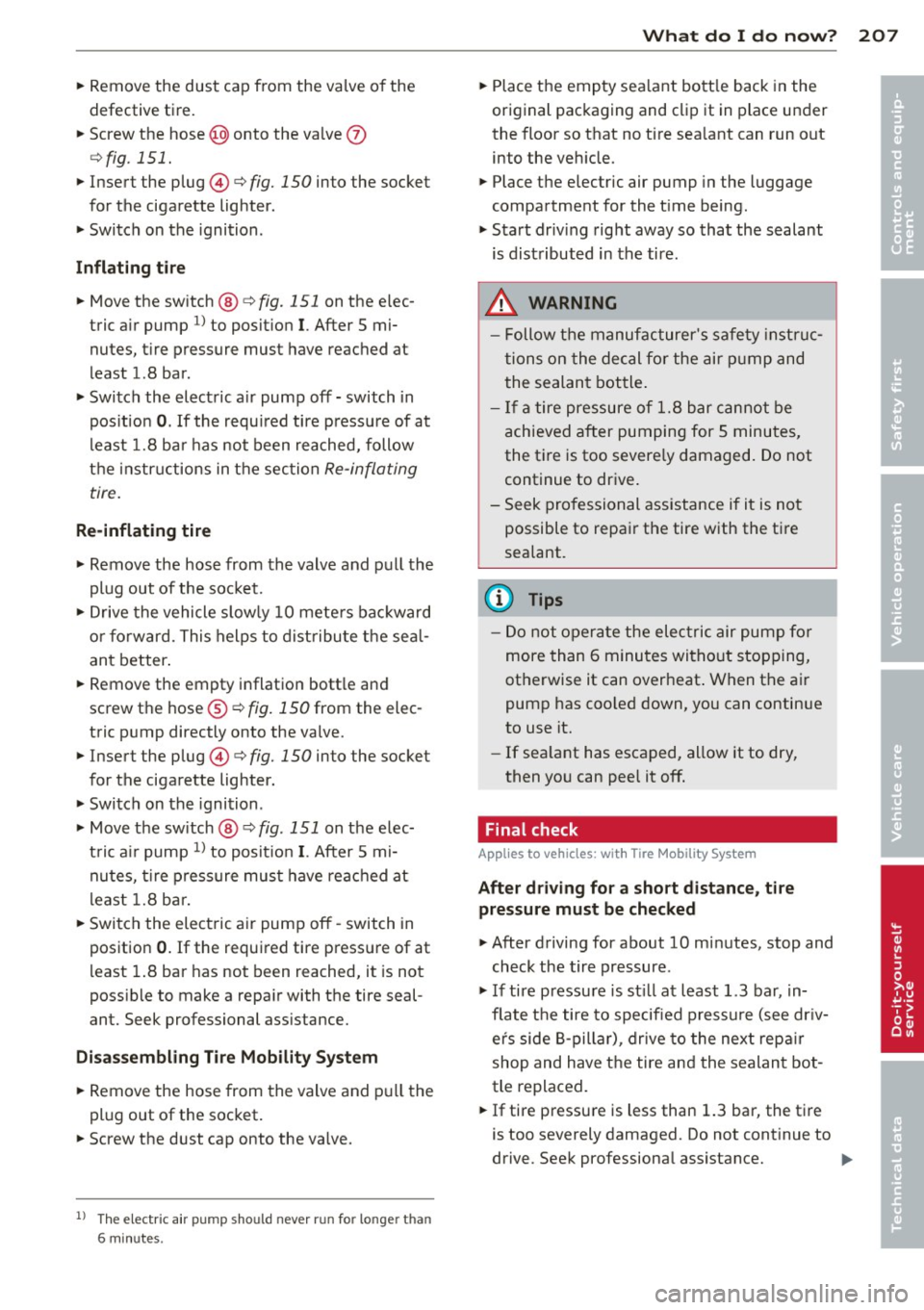

F ig. 1 50 Parts of t he T ire Mob ility System

Fig. 1 51 Conn ector for th e Tire Mob ility System

As sembling Ti re Mobility System

.. Open the lid@ of the electric air p ump

c:> fig.150 .

.. Pull the plug @) and the pressure hose ®

with the gauge out of the housing .

.. Screw the pressure hose ® of the electric

air pump onto the flange @ of the sealant

bott le @ .

"' Push the sealant bottle w ith the flange

down into the recess @ on the lid of the

elec tric air pump. ..,.

Page 209 of 244

~ Remove the dust cap from the valve of the

defective tire.

~ Screw the hose@) onto the va lve 0

¢ fig . 151.

~ Inser t the plug @¢ fig. 150 into the socket

for the cigarette lighter.

~ Switch on the ignition.

Inflating t ire

~ Move the switch@¢ fig. 151 on the e lec

tric a ir pump

l ) to posit ion I. After 5 mi

nutes, t ire pressure must have reached at

least 1.8 bar .

~ Switch the electric a ir pump off -switch in

pos ition

0 . If the requ ired tire pressure of at

least 1.8 bar has not been reached, follow

the i nstructions in the sec tion

Re-inflating

tire.

Re -inflating tire

~ Remove the hose from the valve and pull the

plug out of the socket.

~ Drive the vehicle slow ly 10 mete rs bac kward

or forward. This helps to dist ribu te t he sea l

ant better .

~ Remove the empty inflation bott le and

screw the hose®¢

fig. 150 from the elec

tric pump directly onto the valve.

~ I nsert the plug@¢ fig. 150 into the socket

for the ciga rette lighter.

~ Switch on the ignition .

~ Move the switch @¢ fig. 151 on the elec

t ric a ir pump

ll to pos it io n I. After 5 mi

nutes, t ire pressure mus t have reached at

least 1.8 b ar.

~ Switch the electric a ir pump off -switch in

position

0 . If the required tire pressure of at

l east 1.8 bar has not been reached, it is not

poss ib le to make a repa ir with the tire seal

ant. Seek professional ass istance.

Disas sembling Tire Mobility System

~ Remove the hose from the valve and p ull the

plug out of the soc ket .

~ Screw the d ust cap onto the va lve.

l ) The e lectr ic a ir pu m p sho uld never r un for lo ng er than

6 m in utes.

What do I do now? 207

~ Place the empty sea lant bott le back in the

original packaging and clip it in place under

the floor so that no tire sea lant can run out

into the veh icle.

~ Place the electric air pump in the luggage

compartment for the t ime being .

~ Start driv ing right away so that the sealant

is dist ributed in the tire.

.&_ WARNING

- Follow the manufacturer 's safe ty inst ru c

tions on the de cal for the ai r pump and

the sealan t bottle .

- If a tire pressure of 1.8 bar cannot be

achieved after pumping for 5 minutes,

the ti re is too severe ly damaged. Do not

continue to drive .

- Seek pro fessional assistance if it is not

possible to repa ir the tire with the t ire

sealant.

(D Tips

- Do not opera te the elec tric air pump fo r

more than 6 minutes without stopping,

otherwise it can overheat . When the ai r

pump has coo led down, you can continue

to use it.

- If sea lant has escaped, allow it to dry,

then yo u can peel it off.

Final check

App lies to vehicles : wi th Tire Mobility Sys tem

After d riv ing for a short d istance , tir e

pressure must be checked

~ After driving for about 10 mi nutes, stop and

check the tire pressure .

~ If tire pressu re is st ill at least 1.3 bar, in

flate the tire to specified press ure (see dr iv

er's side B-pillar), drive to the next repa ir

shop and have the tire and the sealant bot

tle replaced.

~ If tire pressu re is less than 1.3 bar, the t ire

is too severely damaged. Do not continue to

drive . Seek professional assistance. ..,.

•

•

Page 210 of 244

208 What do I do now ?

A WARNING

If tire pressure is less than 1.3 bar after

driving for 10 m inutes, the tire is too se

verely damaged . Do not continue to d rive .

Seek professional assistance .

@ Tips

After a tire repair, have the sealant bo ttle

replaced at a dealersh ip. This restores full

functionality to t he Tire Mob ility System .

What should I be

aware of when

changing a tire?

General information

The fo llow ing se ctions will prov ide yo u with

importa nt information o n how to change a

tire using the vehicle tool kit .

H oweve r, we recomme nd that you have a

q uali fied servi ce center change t he tire and

perform all work associated with changi ng it.

Wheels with cap-covered wheel bolts

Applies to vehicles: with cap-covered wheel bolts

The caps must be removed first from the

wheel bolts before the bolt s can be un

screwed .

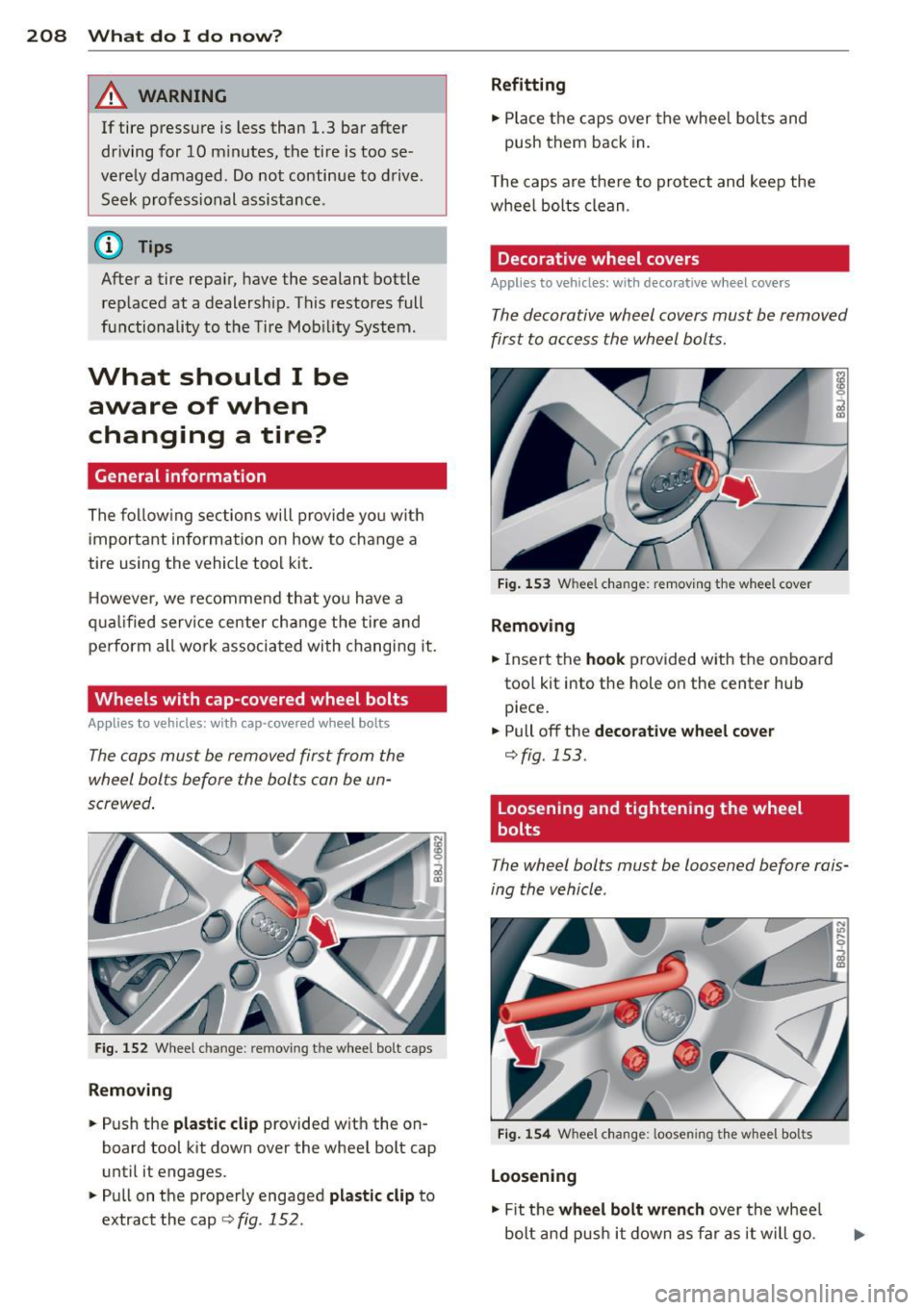

Fig. 152 W hee l chan ge: remo ving th e whee l b o lt c aps

R em oving

.. Push the plastic cl ip provided w it h the on

bo ard tool k it down over the wheel bolt cap

until i t engages .

.,. Pull on the properly engaged

plastic clip to

extract the cap

r:> fig . 152 .

Refitting

.,. Place the caps over the whee l bolts and

push them back in.

T he caps are the re to protect and keep the

whee l bolts clean .

Decorative wheel covers

Applies to vehicles: with decorative wheel covers

The d ecorative wheel covers must be remov ed

first to acc ess the wheel bolts.

Fi g. 1 53 Wheel c hang e: re moving t he wh eel c over

Removing

.. Insert the hook provided with the o n board

too l kit into the hole on the center hub

piece .

.. Pull off the

decor ative wheel cover

r:>fig.153 .

Loosening and tightening the wheel

bolts

T he wheel bolts mus t be loosened before rais

ing the vehicle .

Fig . 1 54 Whee l cha nge: loose ning t he whee l bol ts

Loosening

., Fit t he whe el bolt wren ch over the whee l

bolt an d pus h it down as far a s it will go .

Page 211 of 244

.. Close your grip around the end of the

wrench handle for maximum torque and

turn the wheel bolts

c ounter-clockwis e

about one single turn in the direct ion of ar

row

r:> fig . 154.

Tightening

.. Fit the wheel bol t wrench over the wheel

bolt and push it down as far as it will go .

.. Close your grip around the

end of the

wrenc h handle for maximum torque and

turn each wheel bolt

cl ock wis e unt il it sits

t ight .

A WARNING

-Us ing fo rce without control to speed the

wheel change up can cause the veh icle to

slip off the jack and ca use se rious pe r

sonal in juries.

-Do not loosen the wheel bolts more than

one turn

before you ra ise the veh icle with

the jack. -Risk of inj ury!

(1) Tips

- N ever t ry and use the hexagona l socket

i n the handle of the screwdriver to loos

en or tighte n the wheel bolts .

- If a whee l bolt sits very t ight, you may

find i t easie r to loosen by carefully p ush

i ng down on the end of the whee l bolt

wrench with

one foot only . As you do,

ho ld on to the car to keep yourse lf stable

and ta ke care not to slip .

Raising the vehicle

The vehicle must be lifted with the jack first

before the wheel can be removed .

..

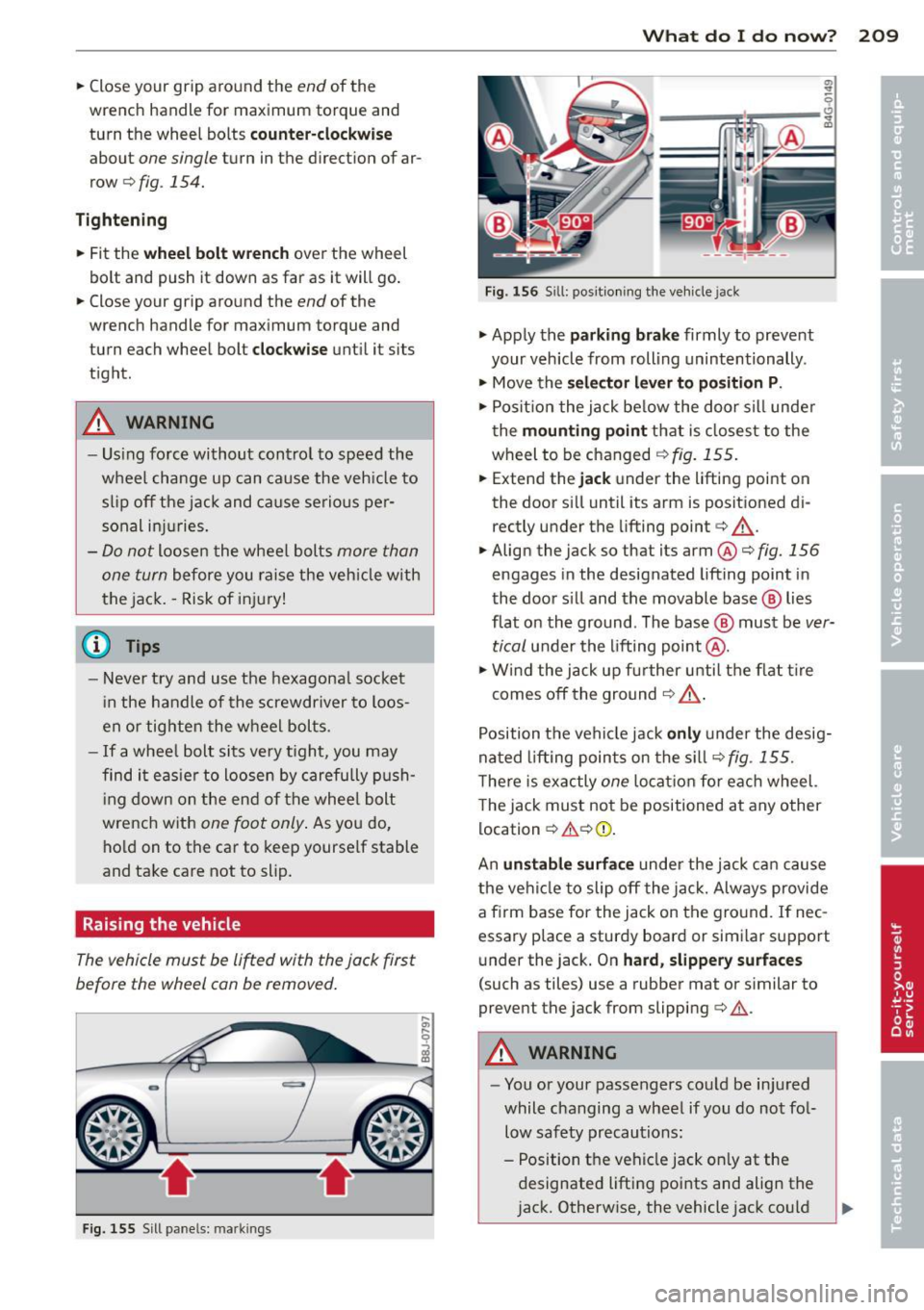

Fig. 155 Sill p ane ls: m arkin gs

What do I do now ? 209

Fig. 1 56 Sill : pos itio ning the ve hicle jac k

.. App ly the pa rkin g brake firmly to prevent

your veh icle from rolling unintentionally .

.. Move the

se lect or lever to p osition P .

.. Posit io n the jack be low the door sill unde r

t he

m ounting point tha t is closest to the

wheel to be changed

r=> fig. 155 .

.. Extend the jack under the lifting point on

the door s ill until its arm is positioned di

rectly under the lifting point

c> ,& .

.. Align the jack so that its arm@¢ fig. 156

engages in the designated lift ing point in

the door s ill and the movable base ® lies

flat on the ground . The base @ must be

ver

tical

under the lifting point @ .

.. Wi nd the jack up fu rther u ntil t he f lat t ire

comes off the ground

c> ,& .

Position t he vehicle jack only under the desig

na ted lifting points on the s ill

r:>fig . 155.

T he re is exactly one locat io n for eac h wheel.

T he jack must not be positioned at any other

location ¢

,&¢(D .

An unstable surfa ce unde r the jack ca n cause

the ve hicl e to slip off the jack. Always provide

a firm base for the jack on the gro und . If nec

essary place a sturdy board or s im ilar support

u nder the jack. On

hard , slippery surf aces

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping ¢

.&.

A WARNING

-You or your passengers cou ld be in jured

while changing a wheel if you do not fo l

low safety precautions:

- Position the veh icle jack on ly at the

designated lifting poi nts and align the

j ack. Otherwise, the vehicle jack co uld

Page 213 of 244

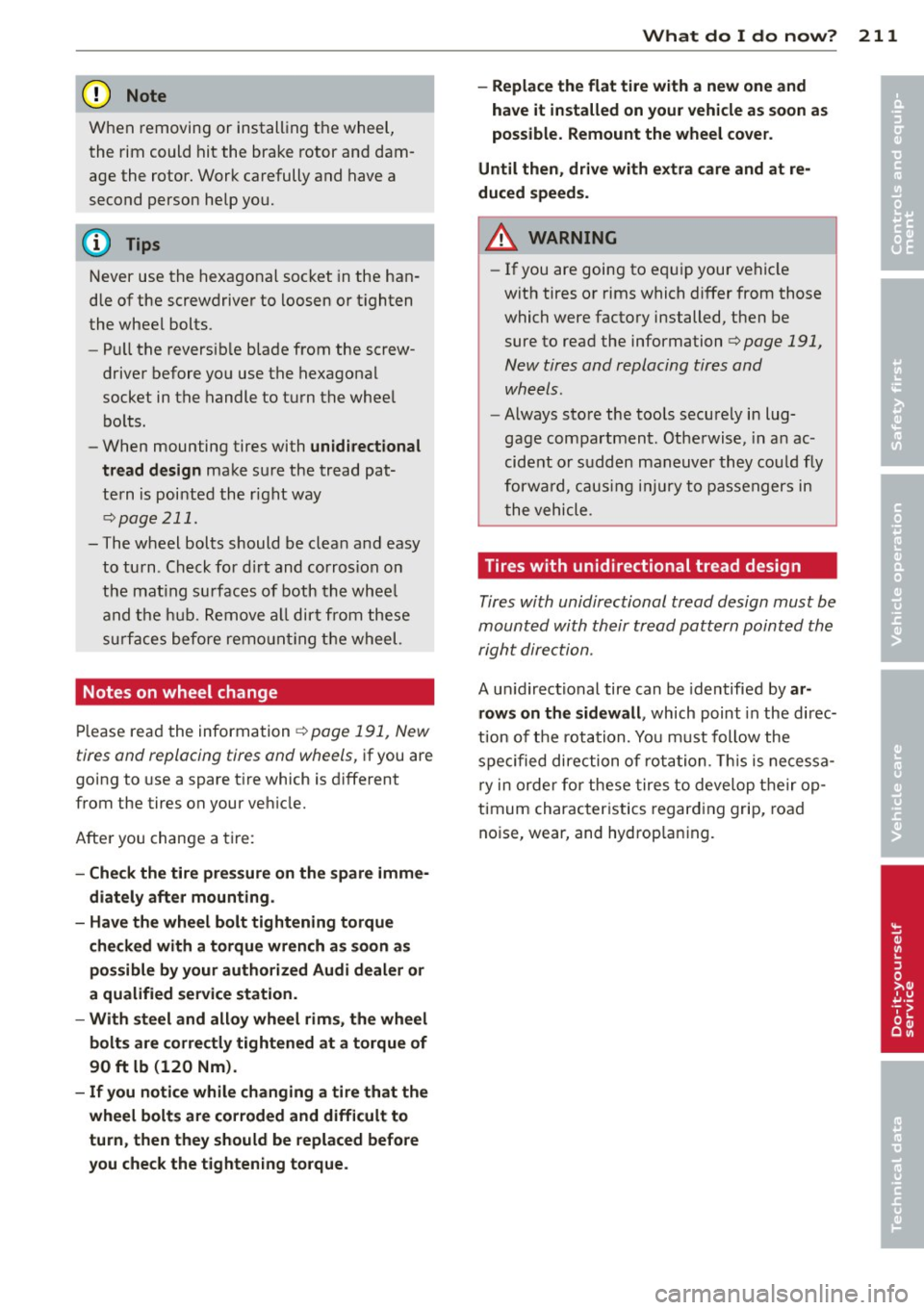

(D Note

When removing or installing the wheel,

the rim could hit the bra ke rotor and dam

age the rotor . Wor k carefully and have a

second person help you.

N ever use the hexa gonal s ocket in the ha n

d le of the screwdriver to loosen or t ighten

the wheel bolts.

- Pull the reversib le blade from the screw

drive r before yo u use the hexagonal

socket in t he handle to t urn the whee l

bo lts .

- When mounting tires with

unid irectional

tread design

make s ure the tread pat

te rn is poi nte d the r ight way

¢pag e 211.

- The wheel bolts should be clea n and easy

to tu rn . Ch eck for dirt and corros ion on

the mat ing su rfaces of both the whee l

a nd th e hu b. Remove a ll dir t fro m these

s ur fa ces before remo unting the wheel.

Notes on wheel change

Pl ease rea d the information ¢ page 191, New

tires and replacing tires and wheels,

i f you are

going to use a spare t ire which is different

from the tires on your ve hicle.

Afte r you change a tire:

- Check the tire pressure on the spare imme

diately after mounting .

- Have the wheel bolt tightening torque

che cked with a torque wrench as soon as

possible by your authorized Audi dealer or

a qualified service station.

- With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of

90 ft lb (120 Nm) .

- If you notice while changing a tire that the

wheel bolt s are co rroded and diffi cult to

turn , then they should be replaced before

you check the t ightening torque.

What do I do now? 211

- Replace the flat tire with a new one and

have it installed on your vehicle as soon as

possible. Remount the wheel cover .

Until then , drive with extra care and at re

duced speeds.

A WARNING

-

- If you are go ing to e quip your ve hicl e

wit h tires o r rims which differ from those

which were factory installed, t hen be

sure to read the information¢

page 191,

New tires and replacing tires and

wheels .

-Always sto re the tools secu rely in lug

gage compartment. Othe rwise, in a n ac

cident o r su dd en maneuv er they cou ld fly

forwa rd, causi ng injury to passe ngers in

the vehicle.

Tires with unidirectional tread design

Tires with unidirectional tr ead design must be

mounted with their tread pattern pointed the

right dire ction.

A u nidirectional tire can be identified by ar

rows on the sidewall,

which point in the direc

tion of t he rota tion. Yo u m ust follow the

s p ecifie d direction of rot ation. This i s nece ssa

r y in order fo r these tires to develop t heir op

timum charac ter istics regard ing grip, road

no ise, wear, and hydrop la ning.

•

•

Page 214 of 244

212 Fuses and bulbs

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through .

Fig. 159 End face of instrument panel: rem ov ing cover

p la te to access fuses

Fig. 160 Left side of eng ine compart men t: fuse cove r

Fuse cover on the left end face of the

inst rument pane l

.. Switch off the ignition and the electrical

component affected.

.. Carefully pry the fuse cover off the instru

ment panel using the ignition key or a

screwdriver

c;::> fig. 159 .

.. Check the fuse list ing on the next pages to

find out which fuse belongs to the compo

nent which has failed

o page 213, Fuse Lo

cation, Instrument Panel left .

.. Remove the blown fuse with the plastic clip

provided. The cl ip is located on the holder in

the fuse box .

.. Replace a blown fuse (recognizable by the

melted metal str ip ins ide) with a fuse of the

same amperage .

.. Firmly snap the cover back onto the instru

ment pane l face .

Fuse cover in engine compartment

.. Switch the ignit ion and the affected con

sumer off .

.. Unlatch the fuse cover , push the two slides

forward

c;::> fig. 160.

.. Find out which fuse belongs to the equip

ment which stopped working

c;::> page 214,

Fuse location , le~ side of engine compart

ment .

.. Remove the plastic from its retainer in the

fuse box cover (left face end of the instru

ment panel), place it on the fu se in question

and pull it out .

.. If the fuse is burned out (recognizable by

melted strips of metal), replace it with a

new fuse

of the same rating.

.. Replace the fuse cover .

.. Push the two slides to the rear

o fig. 160.

Install the fuse cover carefully to prevent

water from enter ing .

The various electrical circuits are protected by

fuses. The fuses are clustered in a centralized unit. The unit is located behind the face panel

at the end of the instrument panel.

You are well advised to keep a supply of spare

fuses in your vehicle. Fuses with the proper

ampere ratings are available at your author

ized Audi dealer.

A WARNING -

Do not repa ir fuses and never replace a

blown fuse with one that has a higher amp

rating. This can cause damage to the elec

trica l system and a fire.

(D Note

If a new fuse burns out again after shortly

have you have installed it, have the electri

ca l system checked by your authorized

Audi dealer.

Page 216 of 244

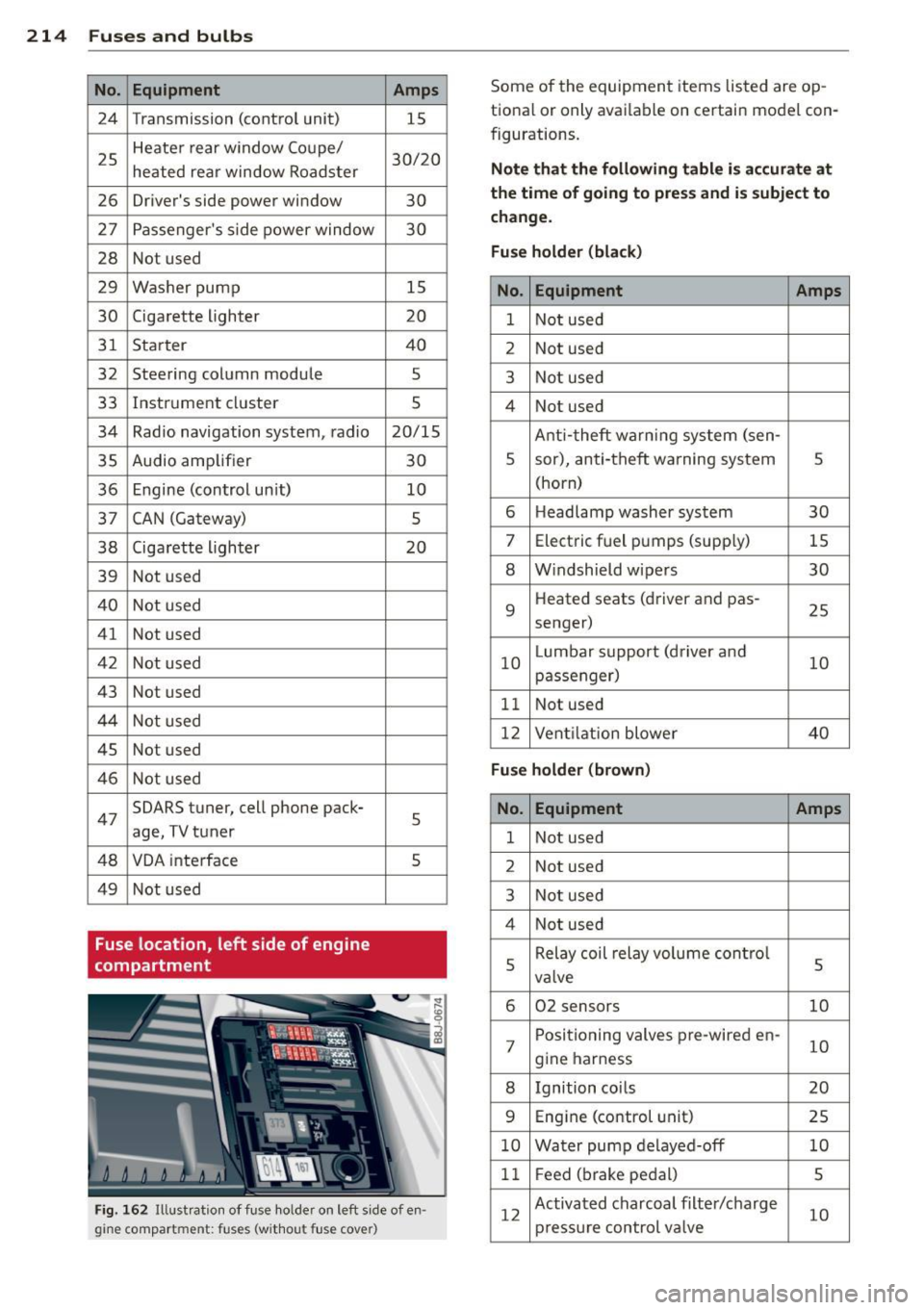

214 Fuses and bulb s

No. Equipment

24 Transmi ssion (contro l un it)

25 Heate

r rear window Coupe /

heated rear window Roadster

26 Driver'

s side power window

27 Passenger's s ide power window

28 No

t used

29 Washer pump

30 Cigarette lighter

31 Start er

32 Steering column module

33 Instrument clust er

34 Radio navigation system , radio

35 Aud io amplifi er

36 Engine (control un it)

37 CAN (Gat

eway)

38 Ciga

rette lighter

39 Not us ed

40 Not used

4 1 Not u sed

42 Not used

43 No t used

44 Not used

45 No

t used

46 Not used

47 SOARS tuner, cell phone pack-

age,

TV tuner

48 VOA interface

49 Not used

Fuse location, left side of engine

compartment Amps

15

30/ 20

30 30

15

20

40 5

5

20/15

30 10

5

20

5 5

Fi g. 162 Ill ustra tion of fus e ho lde r on l eft side o f en·

gi ne compar tment: fuse s (withou t fuse c over)

Some of the equipment items listed are op

tiona l or only avai lable on c ertain mod el con

figurations.

Note tha t the foll owing table i s ac cur ate at

the time of going to pre ss and is subject to

change .

Fus e holder (bla ck )

No . Equipment Amps

1 Not used

2 Not used

3 Not used

4 No t used

Anti- theft warning system (sen -

5 sor), ant

i-theft warn ing system

5

(horn)

6 Headlamp washer system

30

7 Elec

tric fuel pumps (supp ly)

15

8 W

indshield wipers

30

9 H

eat ed seats (dr iver and pas-

25

senger)

10 L

umbar support (d river and

10

passenger)

11 Not u sed

12 Vent ilation blower 40

Fus e holder (brown )

No. Equipment Amps

1 Not used

2 Not used

3 Not used

4 Not used

5 Relay coil

relay volume cont ro l

5

va lve

6 02

sensors

10

7 P

ositioning valves pre-wired en-

10

gine harness

8 Ignition coi ls 20

9 Eng

in e (cont rol unit)

25

10 Water pump de layed-off 10

1 1 F

e e d (brak e pedal)

5

1 2 Activated charcoal filter/charge

10

p ress ure control va lve

Page 217 of 244

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace burned

out bulbs for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in many cases, other parts of the car must first

be removed before you are able to get to the

bu lb. This appl ies especially to the light bu lbs

in the front of your car which you can on ly

reach through the engine compartment .

Sheet metal and bulb ho lde rs can have sharp

edges that can cause ser ious cuts, and parts

must be correctly taken apart and then prop

erly put back together to help prevent break

age of parts and long term damage from wa

ter that can enter housings that have not been

properly resealed.

F or your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you, since your dealer has the proper tools,

the correct bu lbs and the expertise.

G as disc harge la mp s (X enon li ght s)*:

Due to the high electrical voltage, have the

bu lbs rep laced by a qualified technician.

H eadlights with Xenon l ight can be ident ified

by the high voltage sticker .

A WARNING

Contact with hig h-voltage components of

the electrica l system and improper re

placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death .

- Xenon bulbs are pressurized and can ex plode when be ing changed.

- Chang ing Xenon lamps requires the spe

c ial train ing, instructions and equip

ment.

- Only an authorized Aud i dea ler or other

qualified workshop should change the

bulbs in gas discharge lamps .

Fuses and bulb s 215

A WARNING

There are parts with sharp edges on the

openings and on the bulb holders that can

cause ser ious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dealer or other qualified work

shop. Ser ious personal i nju ry may result

from imprope rly perfo rmed wo rk.

(D Tips

- If you must replace the light bulbs your

self, always remember that the eng ine

compartment of any vehicle is a hazard

ous area to work in. A lways read and

heed a ll WARN INGS

°* page 164, Work

ing in the engine comportment"*&. .

- It is best to ask your authorized Audi

dealer whenever yo u need to change a

bulb .

• -

•

Page 218 of 244

216 Emergency situations

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equ ipment to

perform these ope rations.

Starting by pushing or

towing

Q;) Note

Vehicle s with an automati c transmission

cannot be started by pushing or towing .

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discha rged or wea k batte ry, the battery can be

connected to the battery o f

another vehicle,

using a

pair of jumper cables to start the en

g ine .

Jumper cables

Use only jumper cab les of sufficiently

large cross section to safely carry the starter

cur rent. Refer to the manufacturer's specifica

ti ons.

Use on ly jumper cables which have

insulated

termina l clamps and are properly marked for

d istinction :

plus(+) cable in most cases colo red red

minu s(-) cable

in most cases colo red black .

_& WARNING

Batterie s contain elec trici ty, a cid, and ga s.

Any of th ese c an cause ve ry seri ous or f ata l

inju ry . Follow the instructions below fo r

safe han dling of your ve hicle's battery.

- Alw ays s hield yo ur eyes and avoid lean

ing over the batte ry w henever possib le . -

A discharged battery can a lready freeze

at temperatures just be low 32 °F (0 °C).

Before connect ing a jumper cab le, the

frozen battery must be thawed com

p letely, othe rwise it cou ld explode .

- Do not allow batte ry acid to contact eyes

or skin . Fl ush any contacted a rea wi th

water immediat ely .

- Imp roper use of a booster battery to

s tart a vehicle may cause an explosion.

- Vehicle batter ies generate explosive gas

es . Keep sparks, flame and lighted ciga

rettes away from ba tte ries .

- Do not try to jump start a ny ve hicle w ith

a low ac id leve l in the battery .

- The vo ltage of the booster batte ry m ust

a lso have a 12-Vo lt rat ing . The capacity

(A h) of the booster batte ry should not b e

lowe r than that of the discharged bat

tery . U se o f batt erie s of d iffe ren t voltage

or subs tanti ally diffe ren t "Ah" rat ing

may c ause an exp losion and person al in

ju ry .

- N ever ch arge a fr ozen bat te ry. Gas t rap

ped in the ice may ca use an ex plosion .

- N ever ch arge o r use a batt ery th at has

been fro zen. T he battery case may have

be weakened.

- Us e of batt erie s of di ffere nt vo lta ge or

substan tially differen t ca pa city (Ah) rat

i ng may cause an exp losion and injury.

T he capac ity (Ah) of the booster battery

should not be lower than that of the dis

charged batte ry.

- Before you check anything in the engine

compartment, always read and heed a ll

W ARNI NGS

c::;,page 164, Working in the

engine compartment .

@ Note

-App lying a hig her voltage booster ba t

tery will cause expens ive damage to se n

sitive electronic components, such as

cont ro l units , relays, rad io, etc.

- There must be no electrical contact be

twee n the vehicles as otherwise current

cou ld already start to flow as soo n as th e

posi tive (+) term inals are connect ed. ""

Page 219 of 244

@ Tips

The discharged battery must be properly connected to the vehicle's electrical sys

tem.

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

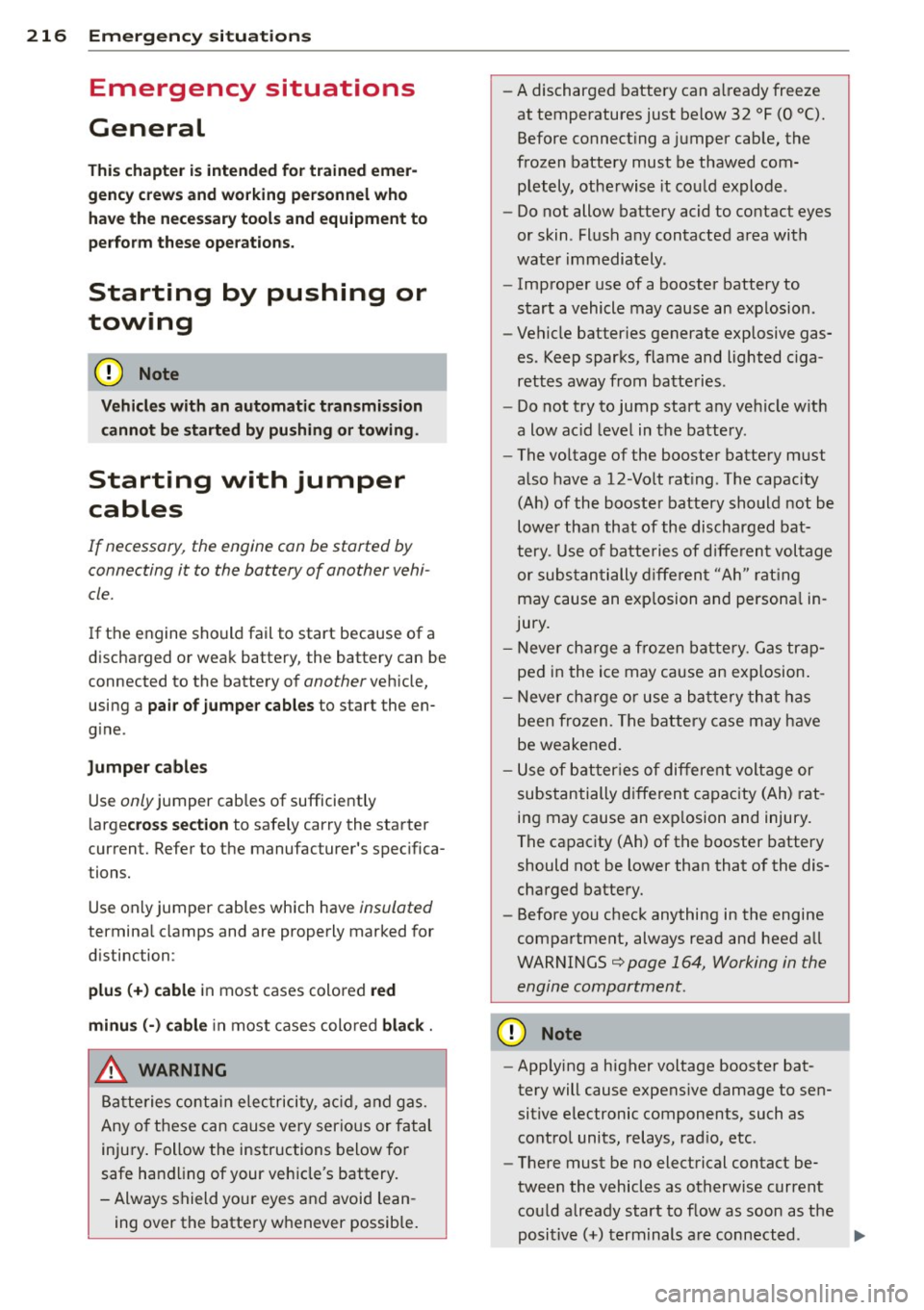

Fig. 163 Eng ine compartme nt: Co nnecto rs for jumper

cables and charger

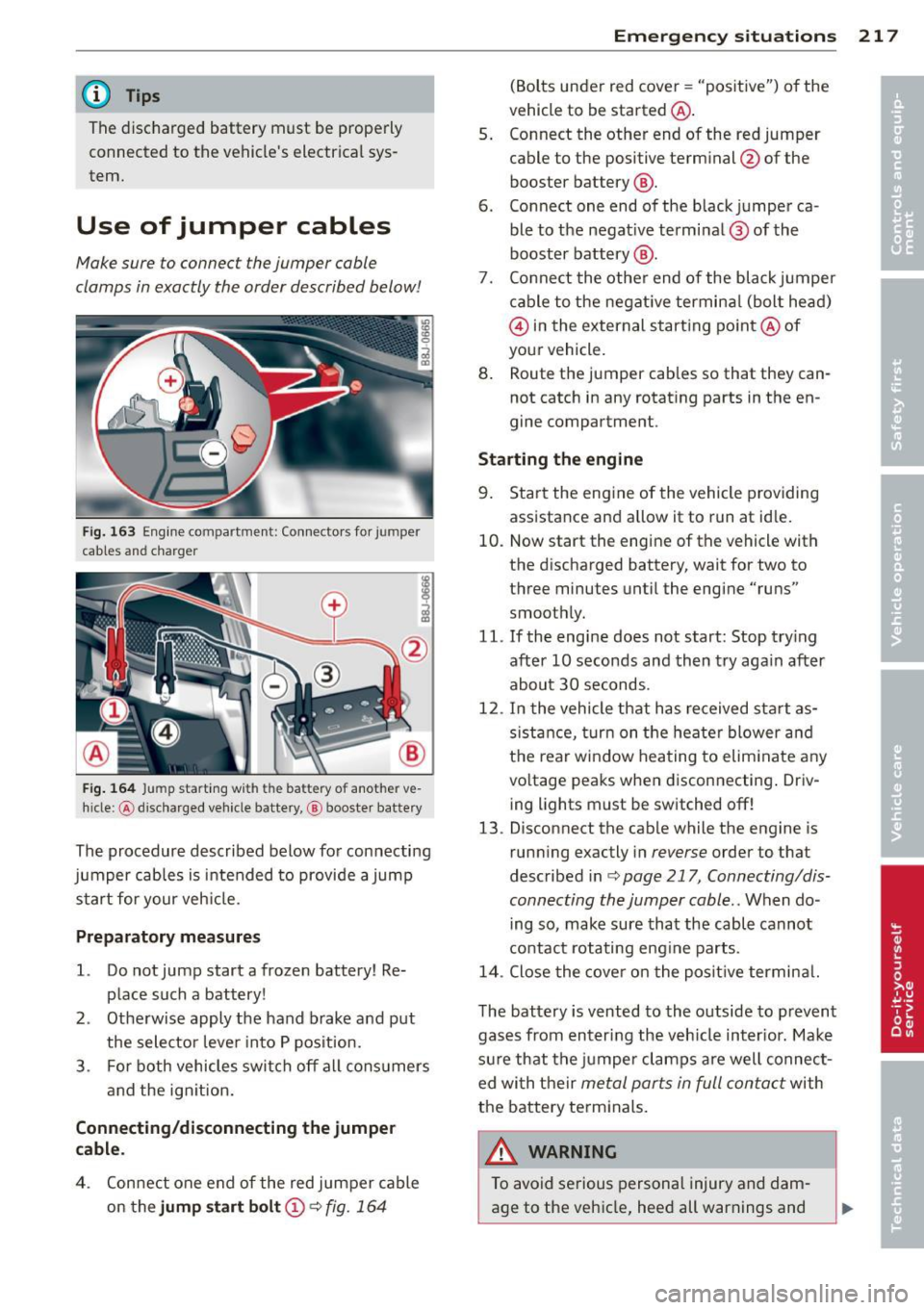

F ig . 164 Jump start ing with the battery of another ve

h icle: @discharged ve hicle batte ry, @ booste r battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle.

Preparatory me asures

1. Do not jump start a frozen battery! Re

place such a battery!

2 . Otherwise apply the hand brake and put

the selector leve r into P pos ition.

3. For both vehicles swi tch off all cons umers

and the ignit ion.

Conn ecting /disconnecting the jumper

cable .

4. Con nect one end of the red jumper cable

on the

jump st a rt bo lt @ ¢ fig. 164

Emergenc y situ ation s 21 7

(Bolts under red cover = "positive") o f the

vehicle to be started @.

5 . Connect the other end of the red jumper

cable to the positive terminal @ofthe

booster battery @.

6 . Connect one end of the black jumper ca

ble to the negat ive terminal ® of the

booster battery @.

7. Co nnect the othe r end of the black jumper

c able to the negat ive termina l (bolt head)

@ in the external starting po int @ of

your vehicle.

8 . Route the jumper cables so that they can

not catch in any rotat ing parts in the en

gine compartment.

Sta rting th e engine

9. Sta rt the eng ine of the vehicle providing

assistance and allow it to run at idle.

10. Now start the engine of the vehicle with

the discharged battery, wait for two to

three minutes until the engine "runs"

smooth ly.

11. If the eng ine does not start: Stop try ing

after 10 seconds and then try aga in after

about 30 seconds.

12 . In the vehicle that has received sta rt as

s istance, tur n on the heate r blower and

the rear window hea ting to elim inate a ny

vo ltage peaks when disconnecting . Driv

ing lights must be switched off!

13 . Disconnect the cable while the engine is

runn ing exactly in

reverse order to that

described in<=>

page 217, Connecting/dis

connecting the jumper coble ..

When do

ing so, make sure that the cable cannot

contact rotating eng ine parts.

14 . Close the cove r on the posit ive termina l.

T he battery is vented to the outside to p revent

gases from enter ing the veh icle inter ior. Make

s ur e that the jumper clamps a re well connec t

ed with their

me tal parts in full contact with

the battery terminals.

A WARNING

To avoid serious personal injury and dam

age to the vehicle, heed all warnings and