AUDI TT ROADSTER 2019 Owners Manual

Manufacturer: AUDI, Model Year: 2019, Model line: TT ROADSTER, Model: AUDI TT ROADSTER 2019Pages: 304, PDF Size: 80.77 MB

Page 271 of 304

8S8012721BA

Emergency assistance

— The tire sealant must not come in contact

with skin, eyes, or clothing.

— If tire sealant comes into contact with your

eyes or your skin, thoroughly rinse the af-

fected area immediately with clean water.

— Do not inhale the fumes.

— If you swallow any of the tire sealant, thor-

oughly rinse your mouth immediately and

drink a lot of water. Do not induce vomiting.

Seek medical attention immediately.

— Change your clothing immediately if it

comes into contact with tire sealant.

— If an allergic reaction occurs, seek medical

attention immediately.

— Keep the tire sealant away from children.

G) Tips

— If sealant leaks, allow it to dry in place. You

can then peel it off like a sticker.

— Note the expiration date on the sealant bot-

tle. Replace the tire sealant at an authorized

Audi dealer or authorized Audi Service Fa-

cility.

— Radio reception can be interrupted when

operating the compressor.

— Follow the legal regulations that are appli-

cable in the country where you are operating

the vehicle.

Fate ma cry

Applies to: vehicles with tire mobility kit

RAZ-0213]

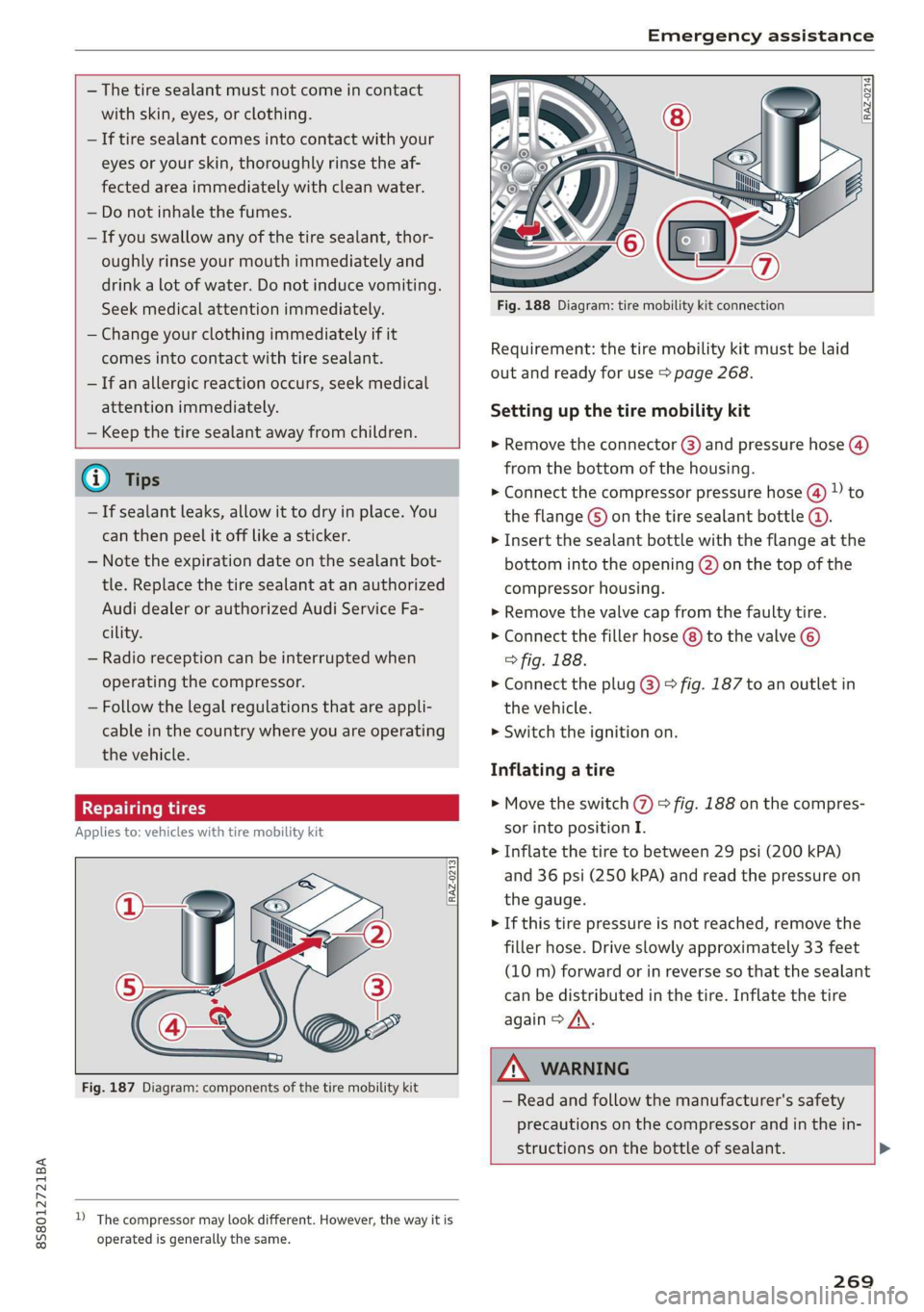

Fig. 187 Diagram: components of the tire mobility kit

D_ The compressor may look different. However, the way it is

operated is generally the same.

mo FP

aa Z, (Fy

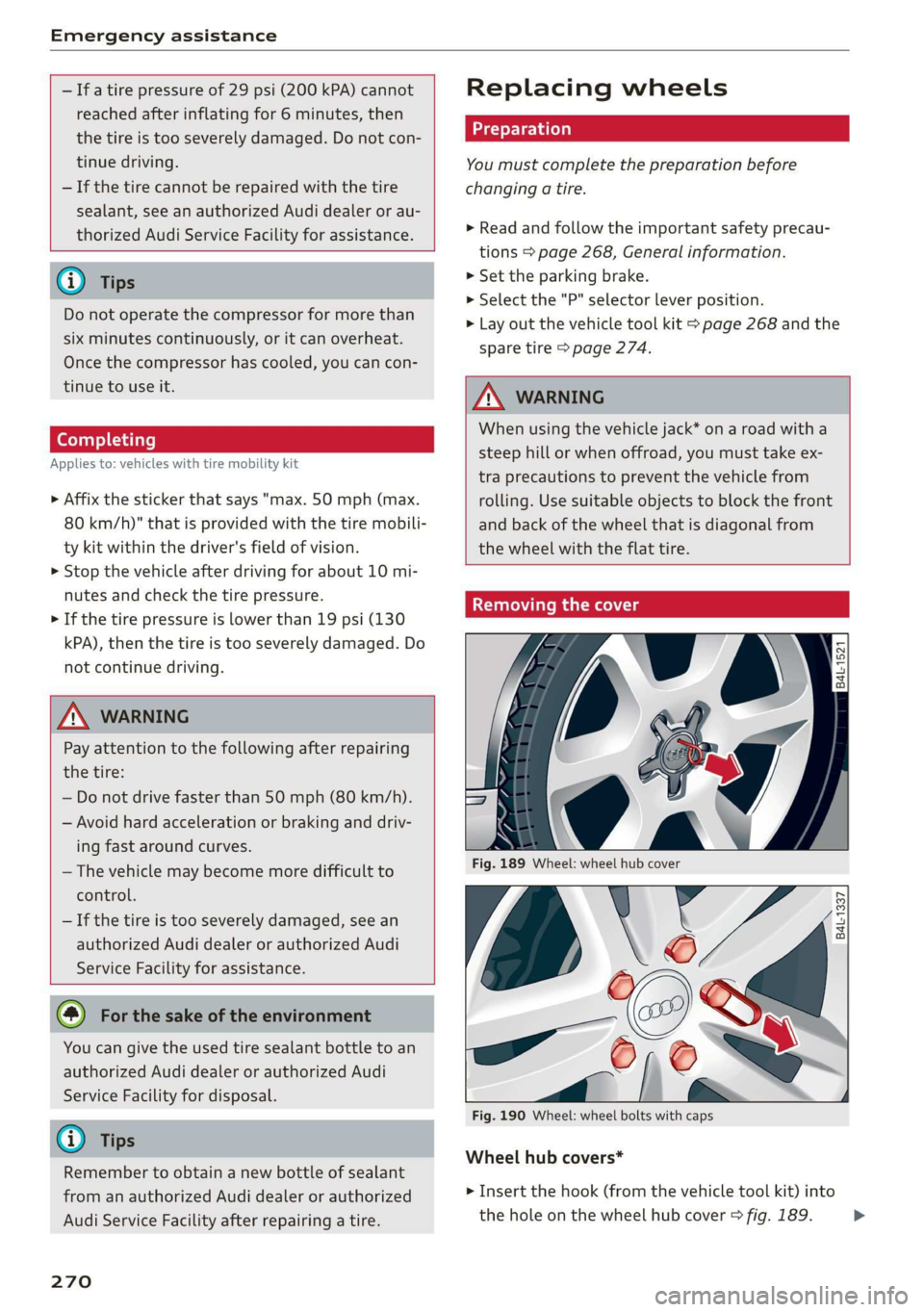

Fig. 188 Diagram: tire mobility kit connection

Requirement: the tire mobility kit must be laid

out and ready for use > page 268.

Setting up the tire mobility kit

» Remove the connector @) and pressure hose (4)

from the bottom of the housing.

> Connect the compressor pressure hose (4) ) to

the flange ©) on the tire sealant bottle @.

> Insert the sealant bottle with the flange at the

bottom into the opening (2) on the top of the

compressor housing.

> Remove the valve cap from the faulty tire.

> Connect the filler hose (8) to the valve ©)

> fig. 188.

> Connect the plug @) > fig. 187 to an outlet in

the vehicle.

> Switch the ignition on.

Inflating a tire

> Move the switch (7) > fig. 188 on the compres-

sor into position I.

> Inflate the tire to between 29 psi (200 kPA)

and 36 psi (250 kPA) and read the pressure on

the gauge.

> If this tire pressure is not reached, remove the

filler hose. Drive slowly approximately 33 feet

(10 m) forward or in reverse so that the sealant

can be distributed in the tire. Inflate the tire

again > A\.

ZA WARNING

— Read and follow the manufacturer's safety

precautions on the compressor and in the in-

structions on the bottle of sealant. >

269

Page 272 of 304

Emergency assistance

— Ifa tire pressure of 29 psi (200 kPA) cannot

reached after inflating for 6 minutes, then

the tire is too severely damaged. Do not con-

tinue driving.

— If the tire cannot be repaired with the tire

sealant, see an authorized Audi dealer or au-

thorized Audi Service Facility for assistance.

@) Tips

Do not operate the compressor for more than

six minutes continuously, or it can overheat.

Once the compressor has cooled, you can con-

tinue to use it.

fey CLL)

Applies to: vehicles with tire mobility kit

> Affix the sticker that says "max. 50 mph (max.

80 km/h)" that is provided with the tire mobili-

ty kit within the driver's field of vision.

> Stop the vehicle after driving for about 10 mi-

nutes and check the tire pressure.

> If the tire pressure is lower than 19 psi (130

kPA), then the tire is too severely damaged. Do

not continue driving.

ZA WARNING

Pay attention to the following after repairing

the tire:

— Do not drive faster than 50 mph (80 km/h).

— Avoid hard acceleration or braking and driv-

ing fast around curves.

— The vehicle may become more difficult to

control.

— If the tire is too severely damaged, see an

authorized Audi dealer or authorized Audi

Service Facility for assistance.

@ For the sake of the environment

You can give the used tire sealant bottle to an

authorized Audi dealer or authorized Audi

Service Facility for disposal.

@ Tips

Remember to obtain a new bottle of sealant

from an authorized Audi dealer or authorized

Audi Service Facility after repairing a tire.

270

Replacing wheels

You must complete the preparation before

changing a tire.

> Read and follow the important safety precau-

tions > page 268, General information.

> Set the parking brake.

> Select the "P" selector lever position.

> Lay out the vehicle tool kit > page 268 and the

spare tire > page 274.

ZA WARNING

When using the vehicle jack* on a road with a

steep hill or when offroad, you must take ex-

tra precautions to prevent the vehicle from

rolling. Use suitable objects to block the front

and back of the wheel that is diagonal from

the wheel with the flat tire.

Removing the cover

B4L-1521

Fig. 189 Wheel: wheel hub cover

V6

Es

al

Fig. 190 Wheel: wheel bolts with caps

B4L-1337

@

Wheel hub covers*

> Insert the hook (from the vehicle tool kit) into

the hole on the wheel hub cover > fig. 189. >

Page 273 of 304

8S8012721BA

Emergency assistance

> Remove the wheel hub cover.

Wheel bolts with caps*

> Slide the plastic clip from the vehicle tool kit

onto the cap until it engages > fig. 190.

> Remove the cap with the plastic clip.

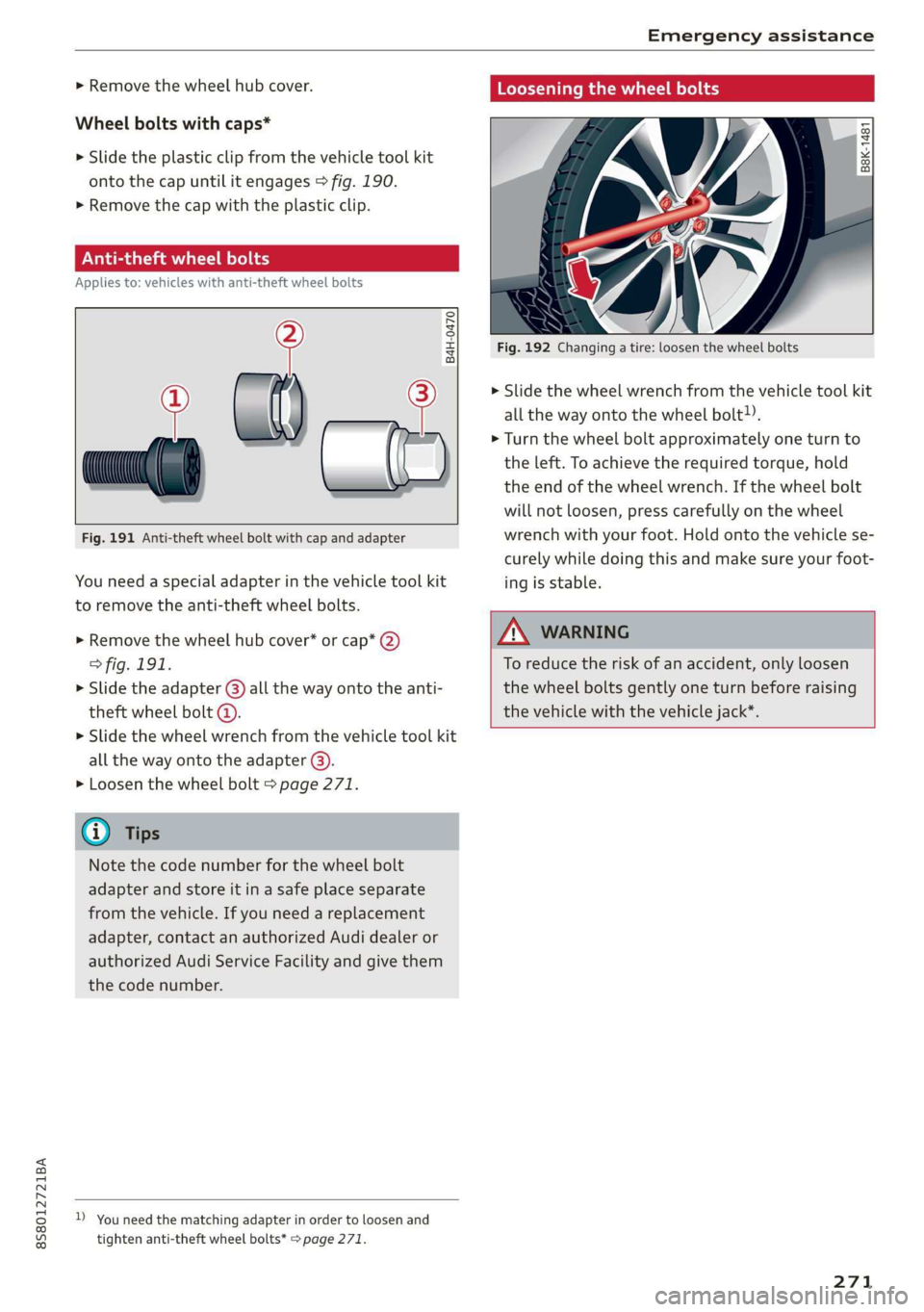

Oe ULE At ee)

Applies to: vehicles with anti-theft wheel bolts

7

i ue

Fig. 191 Anti-theft wheel bolt with cap and adapter

B4H-0470

You need a special adapter in the vehicle tool kit

to remove the anti-theft wheel bolts.

>» Remove the wheel hub cover* or cap* 2)

> fig. 191.

> Slide the adapter () all the way onto the anti-

theft wheel bolt @.

» Slide the wheel wrench from the vehicle tool kit

all the way onto the adapter @).

> Loosen the wheel bolt > page 271.

@) Tips

Note the code number for the wheel bolt

adapter and store it in a safe place separate

from the vehicle. If you need a replacement

adapter, contact an authorized Audi dealer or

authorized Audi Service Facility and give them

the code number.

D_ You need the matching adapter in order to loosen and

tighten anti-theft wheel bolts* > page 271.

Loosening the wheel bolts

| B8K-1481

Fig. 192 Changing a tire: loosen the wheel bolts

> Slide the wheel wrench from the vehicle tool kit

all the way onto the wheel bolt).

> Turn the wheel bolt approximately one turn to

the left. To achieve the required torque, hold

the end of the wheel wrench. If the wheel bolt

will not loosen, press carefully on the wheel

wrench with your foot. Hold onto the vehicle se-

curely while doing this and make sure your foot-

ing is stable.

ZA WARNING

To reduce the risk of an accident, only loosen

the wheel bolts gently one turn before raising

the vehicle with the vehicle jack*.

271

Page 274 of 304

Emergency assistance

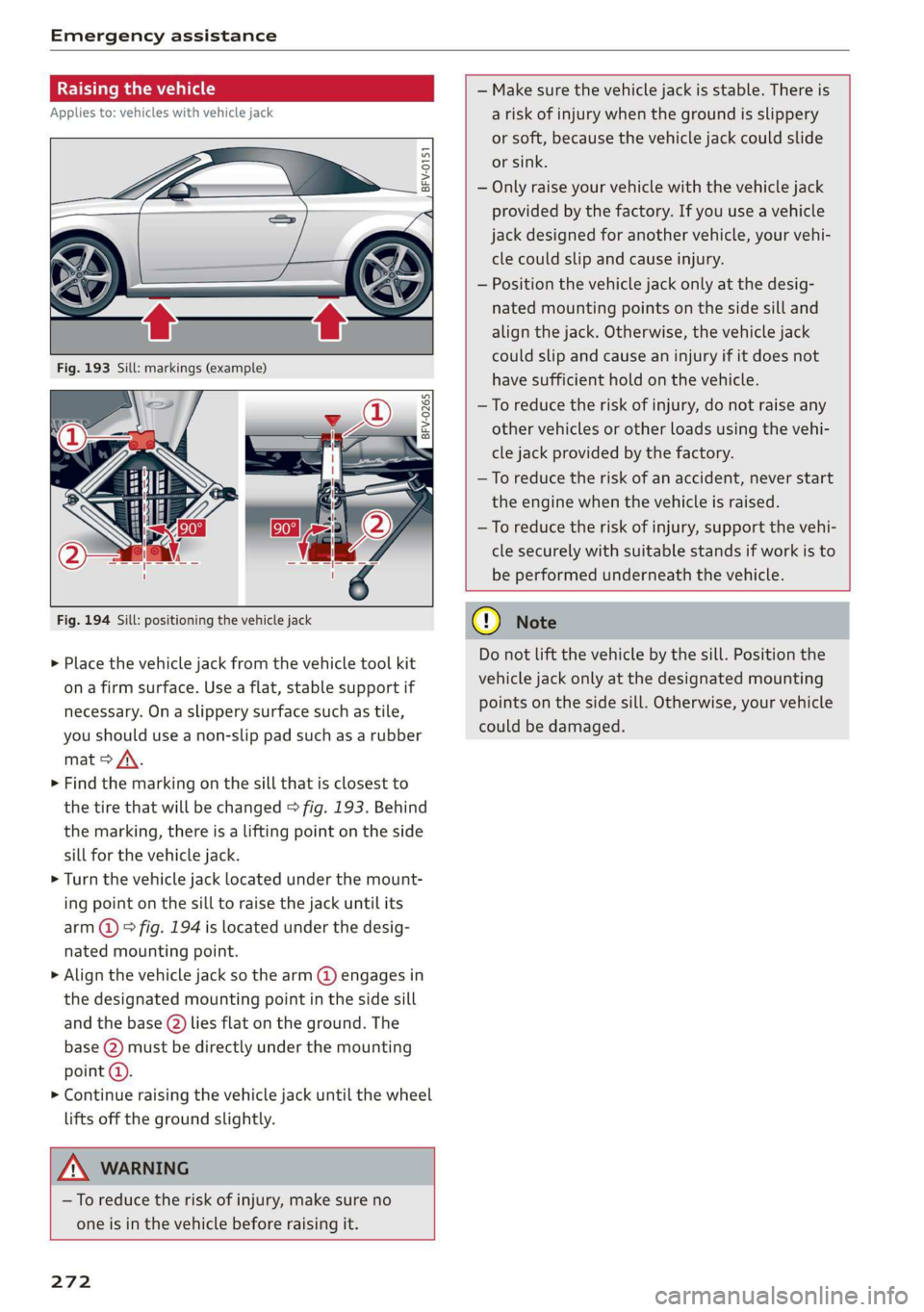

Raising the vehicle

Applies to: vehicles with vehicle jack

A,

BFV-0151

ry oS

a

S| > in oO

Fig. 194 Sill: positioning the vehicle jack

> Place the vehicle jack from the vehicle tool kit

ona firm surface. Use a flat, stable support if

necessary. On a slippery surface such as tile,

you should use a non-slip pad such as a rubber

mat > /\.

> Find the marking on the sill that is closest to

the tire that will be changed > fig. 193. Behind

the marking, there is a lifting point on the side

sill for the vehicle jack.

> Turn the vehicle jack located under the mount-

ing point on the sill to raise the jack until its

arm @) ° fig. 194 is located under the desig-

nated mounting point.

> Align the vehicle jack so the arm (@) engages in

the designated mounting point in the side sill

and the base (2) lies flat on the ground. The

base (2) must be directly under the mounting

point @).

> Continue raising the vehicle jack until the wheel

lifts off the ground slightly.

— Make sure the vehicle jack is stable. There is

a risk of injury when the ground is slippery

or soft, because the vehicle jack could slide

or sink.

— Only raise your vehicle with the vehicle jack

provided by the factory. If you use a vehicle

jack designed for another vehicle, your vehi-

cle could slip and cause injury.

— Position the vehicle jack only at the desig-

nated mounting points on the side sill and

align the jack. Otherwise, the vehicle jack

could slip and cause an injury if it does not

have sufficient hold on the vehicle.

—To reduce the risk of injury, do not raise any

other vehicles or other loads using the vehi-

cle jack provided by the factory.

—To reduce the risk of an accident, never start

the engine when the vehicle is raised.

—To reduce the risk of injury, support the vehi-

cle securely with suitable stands if work is to

be performed underneath the vehicle.

Z\ WARNING

—To reduce the risk of injury, make sure no

one is in the vehicle before raising it.

272

@) Note

Do not lift the vehicle by the sill. Position the

vehicle jack only at the designated mounting

points on the side sill. Otherwise, your vehicle

could be damaged.

Page 275 of 304

8S58012721BA

Emergency assistance

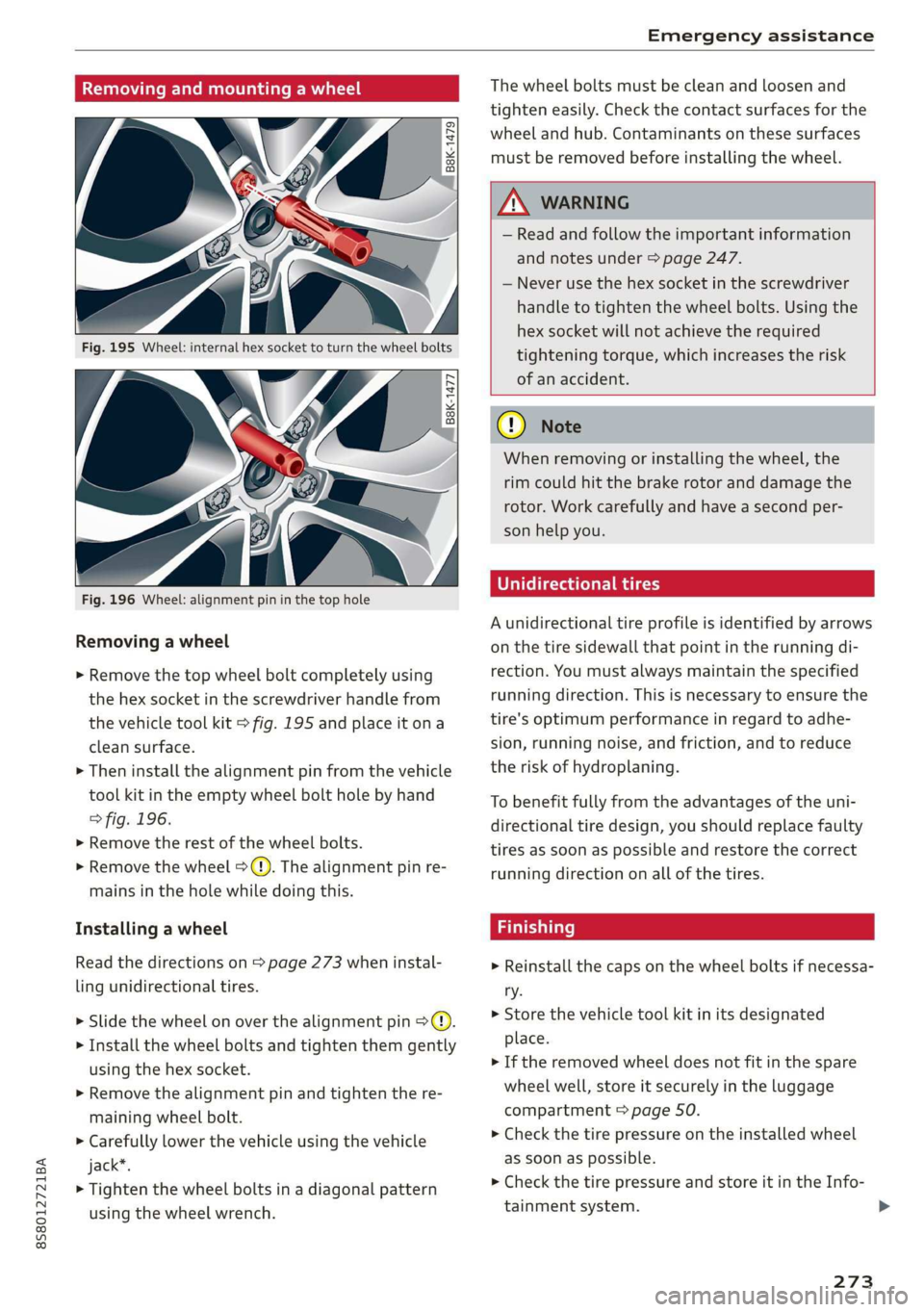

Removing and mounting a wheel

@ Rg Tt

“ 0 oO

B8K-1477

Fig. 196 Wheel: alignment pin in the top hole

Removing a wheel

> Remove the top wheel bolt completely using

the hex socket in the screwdriver handle from

the vehicle tool kit > fig. 195 and place it ona

clean surface.

> Then install the alignment pin from the vehicle

tool kit in the empty wheel bolt hole by hand

> fig. 196.

> Remove the rest of the wheel bolts.

>» Remove the wheel >). The alignment pin re-

mains in the hole while doing this.

Installing a wheel

Read the directions on > page 273 when instal-

ling unidirectional tires.

> Slide the wheel on over the alignment pin >@.

> Install the wheel bolts and tighten them gently

using the hex socket.

> Remove the alignment pin and tighten the re-

maining wheel bolt.

> Carefully lower the vehicle using the vehicle

jack*.

> Tighten the wheel bolts in a diagonal pattern

using the wheel wrench.

The wheel bolts must be clean and loosen and

tighten easily. Check the contact surfaces for the

wheel and hub. Contaminants on these surfaces

must be removed before installing the wheel.

ZA\ WARNING

— Read and follow the important information

and notes under > page 247.

— Never use the hex socket in the screwdriver

handle to tighten the wheel bolts. Using the

hex socket will not achieve the required

tightening torque, which increases the risk

of an accident.

() Note

When removing or installing the wheel, the

rim could hit the brake rotor and damage the

rotor. Work carefully and have a second per-

son help you.

Unidirectional tires

A unidirectional tire profile is identified by arrows

on the tire sidewall that point in the running di-

rection. You must always maintain the specified

running direction. This is necessary to ensure the

tire's optimum performance in regard to adhe-

sion, running noise, and friction, and to reduce

the risk of hydroplaning.

To benefit fully from the advantages of the uni-

directional tire design, you should replace faulty

tires as soon as possible and restore the correct

running direction on all of the tires.

> Reinstall the caps on the wheel bolts if necessa-

ry.

> Store the vehicle tool kit in its designated

place.

> If the removed wheel does not fit in the spare

wheel well, store it securely in the luggage

compartment > page 50.

> Check the tire pressure on the installed wheel

as soon as possible.

> Check the tire pressure and store it in the Info-

tainment system. >

273

Page 276 of 304

Emergency assistance

> The wheel bolt tightening specification must be

90 ft lbs (120 Nm). Have it checked as soon as

possible with a torque wrench. Drive carefully

until then.

> Have the faulty wheel replaced as quickly as

possible.

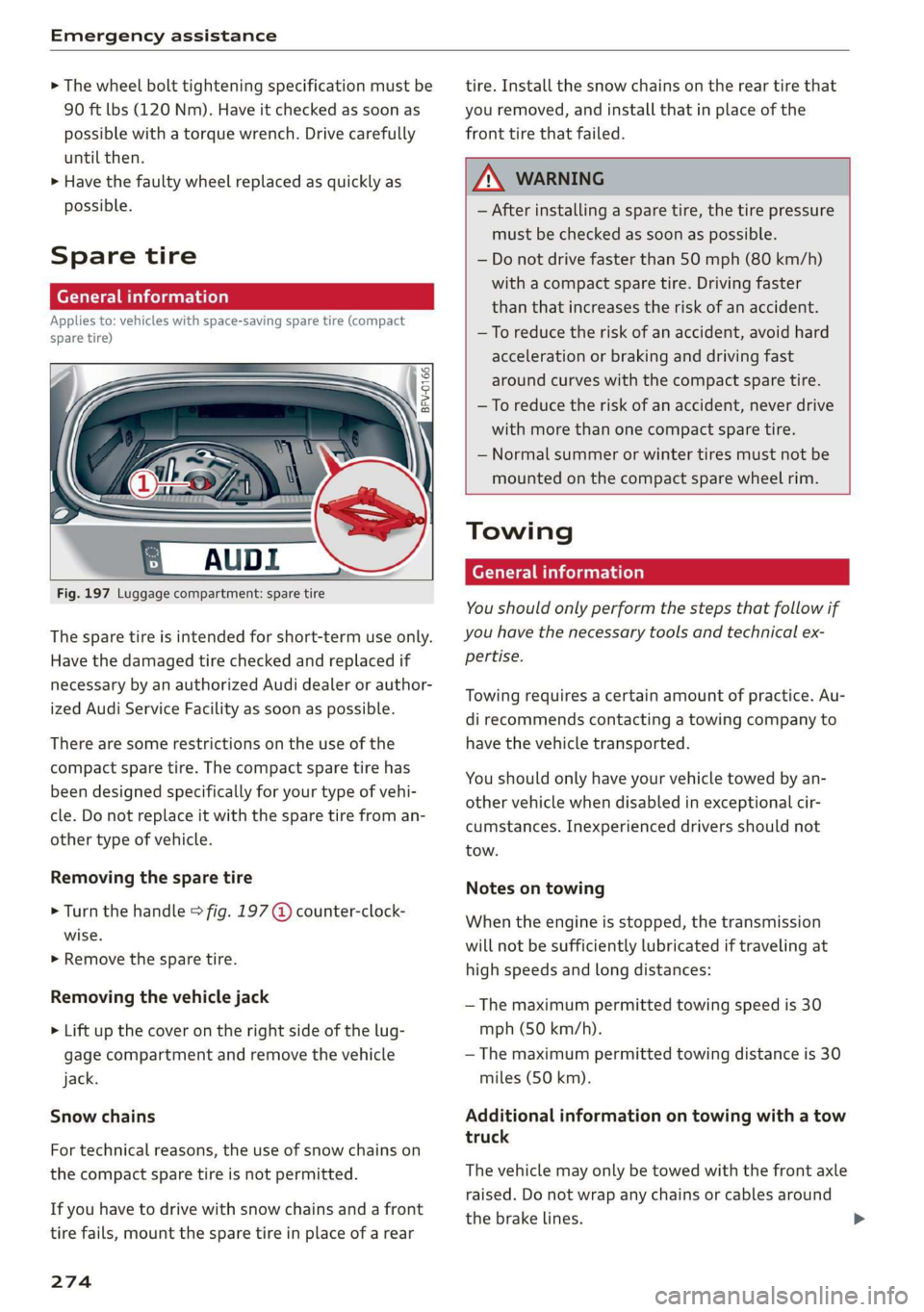

Spare tire

General information

Applies to: vehicles with space-saving spare tire (compact

spare tire)

—maa

BFV-0166

The spare tire is intended for short-term use only.

Have the damaged tire checked and replaced if

necessary by an authorized Audi dealer or author-

ized Audi Service Facility as soon as possible.

There are some restrictions on the use of the

compact spare tire. The compact spare tire has

been designed specifically for your type of vehi-

cle. Do not replace it with the spare tire from an-

other type of vehicle.

Removing the spare tire

> Turn the handle > fig. 197 @ counter-clock-

wise.

>» Remove the spare tire.

Removing the vehicle jack

> Lift up the cover on the right side of the lug-

gage compartment and remove the vehicle

jack.

Snow chains

For technical reasons, the use of snow chains on

the

compact spare tire is not permitted.

If you have to drive with snow chains and a front

tire fails, mount the spare tire in place of a rear

274

tire. Install the snow chains on the rear tire that

you removed, and install that in place of the

front tire that failed.

Z\ WARNING

— After installing a spare tire, the tire pressure

must be checked as soon as possible.

— Do not drive faster than SO mph (80 km/h)

with a compact spare tire. Driving faster

than that increases the risk of an accident.

— To reduce the risk of an accident, avoid hard

acceleration or braking and driving fast

around curves with the compact spare tire.

— To reduce the risk of an accident, never drive

with more than one compact spare tire.

— Normal summer or winter tires must not be

mounted on the compact spare wheel rim.

Towing

General information

You should only perform the steps that follow if

you have the necessary tools and technical ex-

pertise.

Towing requires a certain amount of practice. Au-

di recommends contacting a towing company to

have the vehicle transported.

You should only have your vehicle towed by an-

other vehicle when disabled in exceptional cir-

cumstances. Inexperienced drivers should not

tow.

Notes on towing

When the engine is stopped, the transmission

will not be sufficiently lubricated if traveling at

high speeds and long distances:

— The maximum permitted towing speed is 30

mph (50 km/h).

— The maximum permitted towing distance is 30

miles (50 km).

Additional information on towing with a tow

truck

The vehicle may only be towed with the front axle

raised. Do not wrap any chains or cables around

the brake lines.

Page 277 of 304

8S8012721BA

Emergency assistance

If the vehicle should be towed with the axle

raised, then the ignition must be switched off to

reduce the risk of damage to the drivetrain.

Tow bar and towing cable

The vehicle can be towed with a tow bar or tow-

ing cable. Both drivers should be familiar with

the special considerations when towing, especial-

ly when using a towing cable.

Always make sure the traction force does not ex-

ceed the permitted level and there are no shock

loading conditions. There is always the risk of the

coupling becoming overloaded when driving off-

road.

For the most safety and security, drive with a tow

bar. You should use a towing cable only if a tow

bar is not available. Use a towing cable made of

synthetic elastic cable similar elastic material.

ZA\ WARNING

— Towing highly increases the risk of an acci-

dent, for example from colliding with the

towing vehicle.

— To reduce the risk of an accident, do not al-

low anyone to remain inside the vehicle

when it is being transported by a tow truck

or a special transporter.

@) Note

— If normal towing is not possible, for exam-

ple if the transmission is faulty or if the

towing distance is greater than 30 miles

(50 km), then transport the vehicle on a

special carrier.

— If the vehicle is towed by a tow truck at the

axle that is not permitted, this can cause se-

vere damage to the transmission.

— The vehicle must not be tow started for

technical reasons.

@) Tips

—If there is a power failure, the selector lever

will not move out of the "P" position. The

parking lock must be released using the

D_ Requirement: the vehicle battery must have a sufficient

charge level.

emergency release before towing the vehi-

cle > page 68.

— Follow the local legal regulations for tow-

ing.

Read and follow the important information under

=> page 274.

Preparations

> Only secure the towing cable or tow bar at the

designated towing loops > page 276,

=> page 276.

> Make sure the towing cable is not twisted. Oth-

erwise it could disconnect from the towing loop

while towing.

» Switch the emergency flashers on in both vehi-

cles > page 40. However, do not do this if it

prohibited by law.

Towing vehicle (front)

> Only start to drive when the towing cable is

taut.

> Be especially careful when accelerating.

> Avoid sudden braking or driving maneuvers.

Vehicle being towed (rear)

» Make sure the ignition is switched on so that

the steering wheel is not locked and so that you

can use the turn signals, the horn, and the

windshield wipers if needed > A\.

> The brake booster only works when the engine

is running. Power steering only works when the

ignition is switched on and the vehicle is roll-

ing )). If the brake booster and power steering

are not functioning, you must press the brake

pedal much harder and use more force to steer.

> Release the parking brake > page 59.

> Select the "N" selector lever position.

> Make sure the towing cable is always taut.

275

>

Page 278 of 304

Emergency assistance

Z\ WARNING

Never tow a vehicle using a tow bar or towing

cable if the vehicle does not have electrical

power.

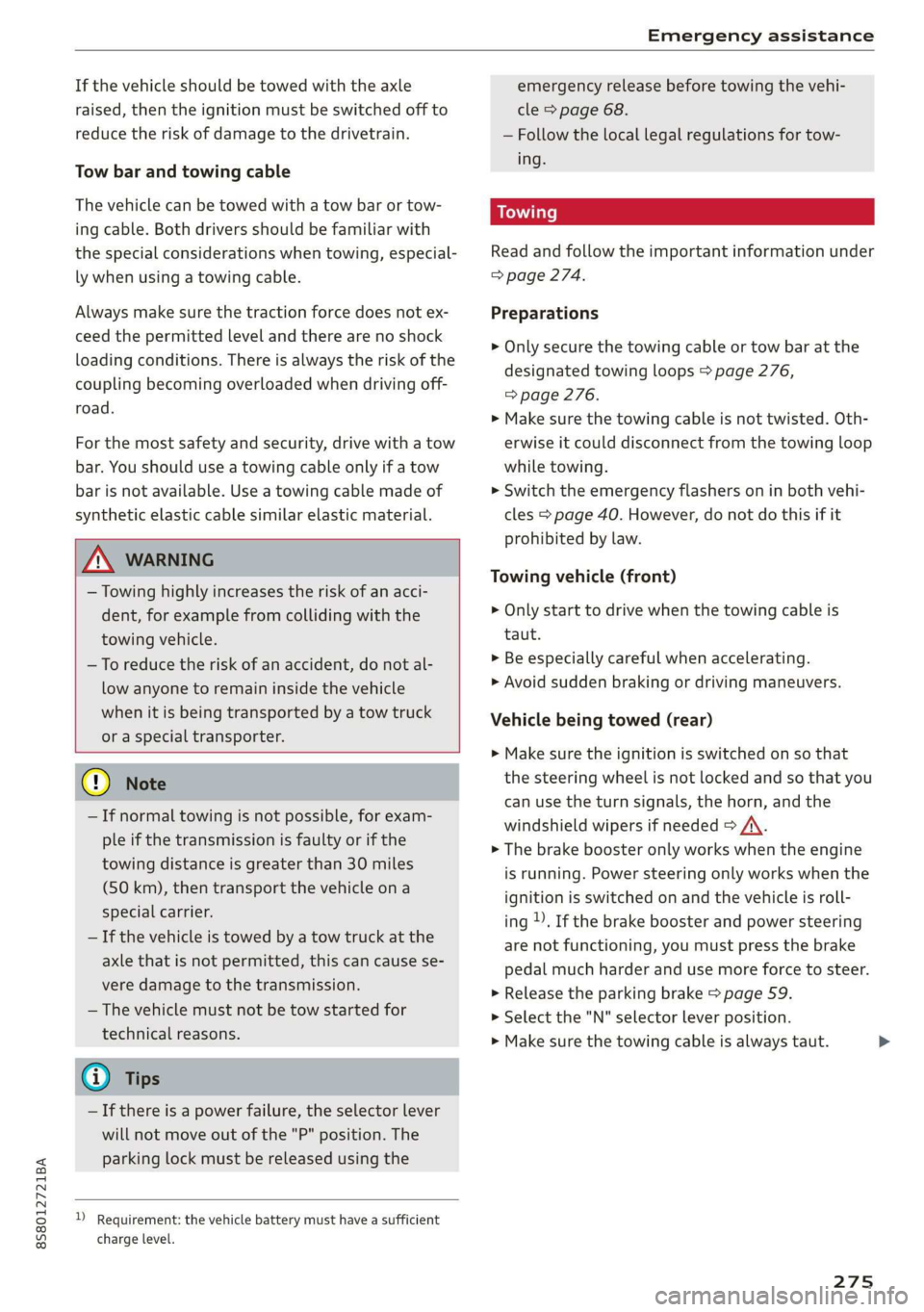

Front towing loop

———

Fig. 198 Front bumper: installing the towing loop

The threaded opening for the towing loop is lo-

cated on the right side of the front bumper.

> Remove the towing loop from the vehicle tool

kit > page 268.

> Press the cap inward with brief, strong pressure

> fig. 198. The cap will loosen from the bump-

er.

> Tighten the towing loop in the threaded open-

ing until it stops and then tighten it with a

wheel wrench.

> After using, place the towing loop back in the

vehicle tool kit.

ZX WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and result

in an accident.

276

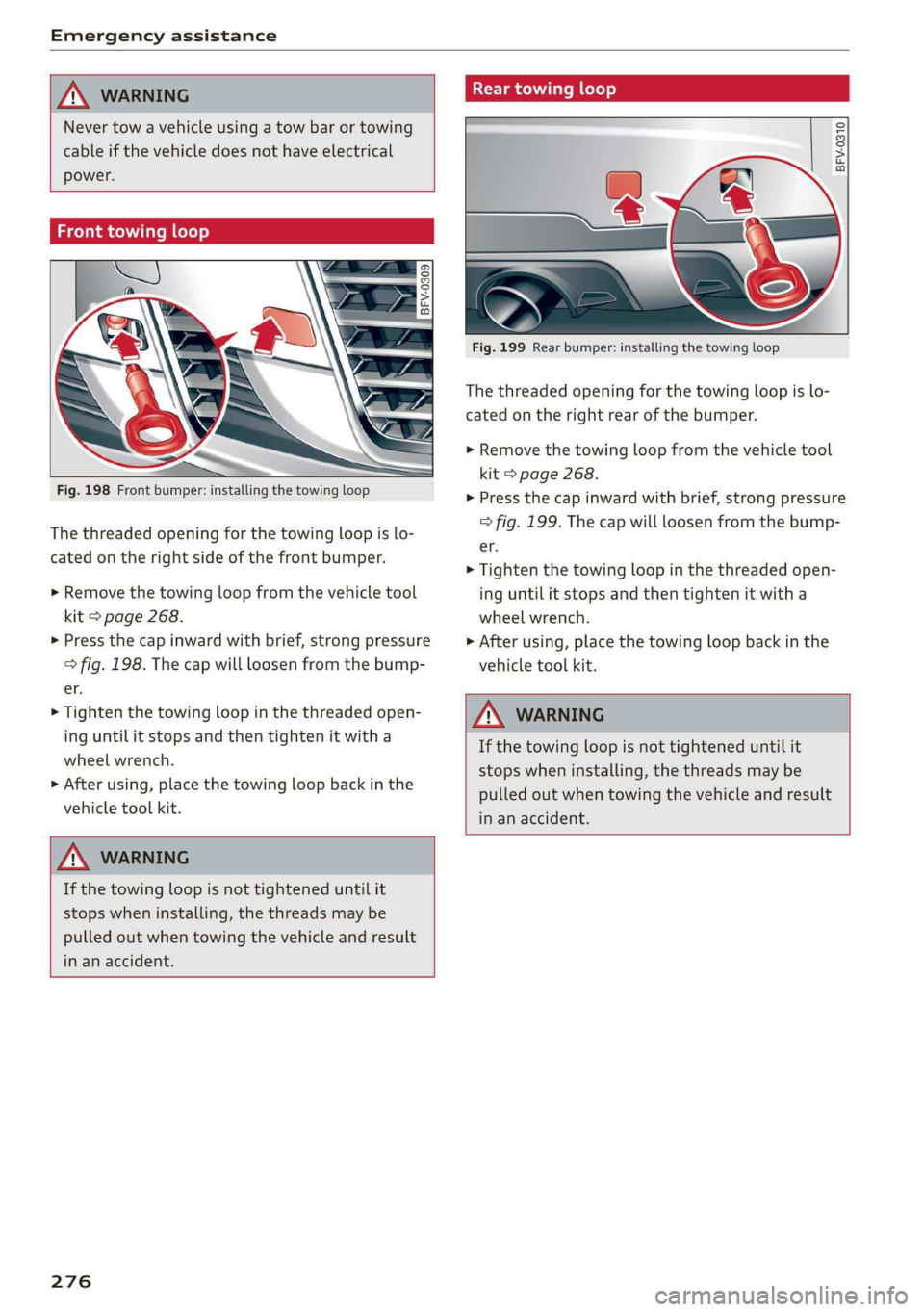

Rear towing loop

BFV-0310

Fig. 199 Rear bumper: installing the towing loop

The threaded opening for the towing loop is lo-

cated on the right rear of the bumper.

> Remove the towing loop from the vehicle tool

kit > page 268.

> Press the cap inward with brief, strong pressure

> fig. 199. The cap will loosen from the bump-

er.

> Tighten the towing loop in the threaded open-

ing until it stops and then tighten it with a

wheel wrench.

» After using, place the towing loop back in the

vehicle tool kit.

Z\ WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the vehicle and result

in an accident.

Page 279 of 304

8S58012721BA

Fuses and bulbs

Fuses and bulbs

Fuses

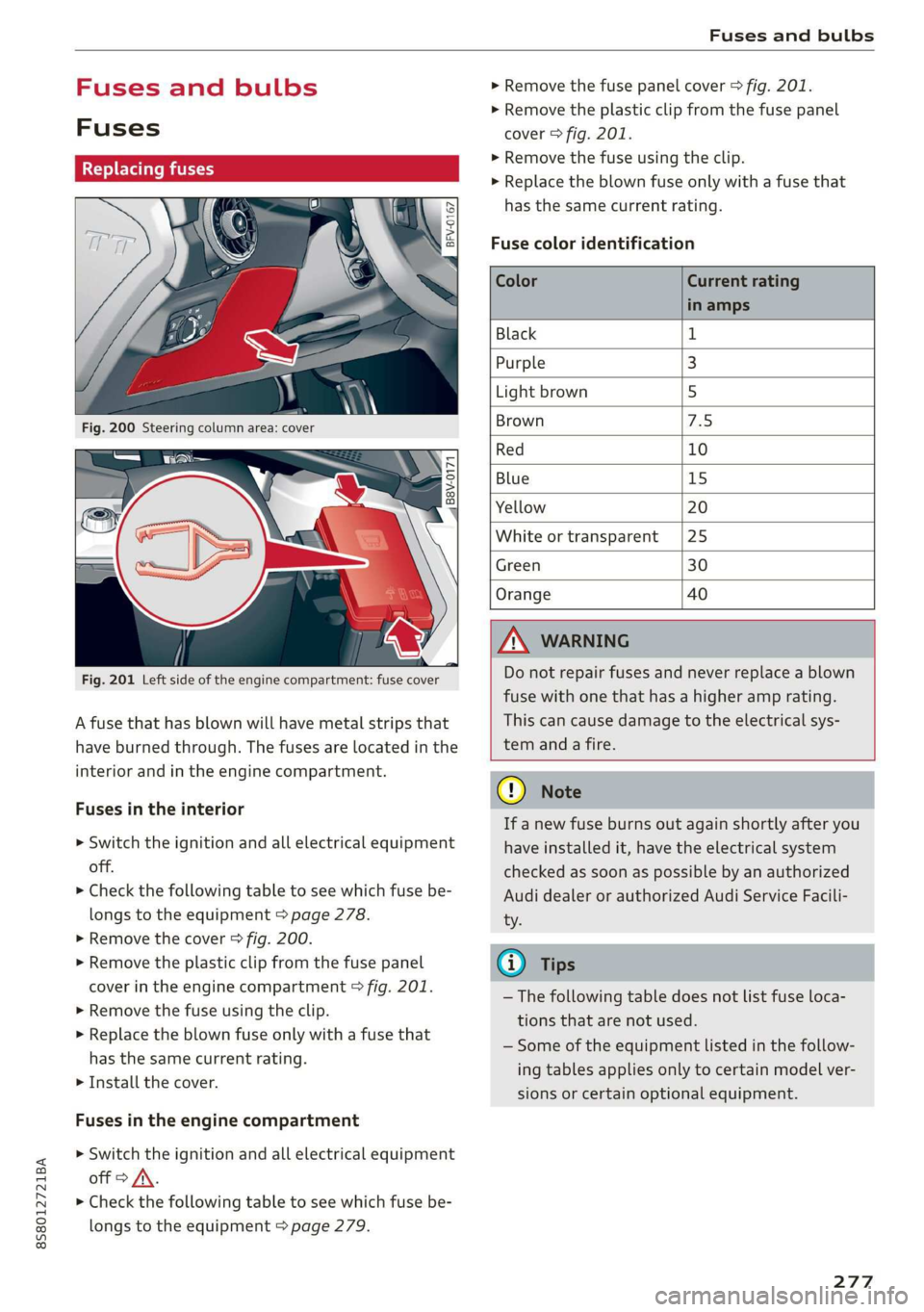

Replacing fuses

S 6

= o

q

= 2 % a.

Fig. 201 Left side of the engine compartment: fuse cover

A fuse that has blown will have metal strips that

have burned through. The fuses are located in the

interior and in the engine compartment.

Fuses in the interior

> Switch the ignition and all electrical equipment

off.

> Check the following table to see which fuse be-

longs to the equipment > page 278.

» Remove the cover > fig. 200.

> Remove the plastic clip from the fuse panel

cover in the engine compartment © fig. 201.

> Remove the fuse using the clip.

> Replace the blown fuse only with a fuse that

has the same current rating.

> Install the cover.

Fuses in the engine compartment

> Switch the ignition and all electrical equipment

off > A\.

> Check the following table to see which fuse be-

longs to the equipment > page 279.

> Remove the fuse panel cover > fig. 201.

> Remove the plastic clip from the fuse panel

cover > fig. 201.

> Remove the fuse using the clip.

> Replace the blown fuse only with a fuse that

has the same current rating.

Fuse color identification

Color Current rating

in amps

Black 1

Purple 3

Light brown 5

Brown 1d

Red 10

Blue 15

Yellow 20

White or transparent [25

Green 30

Orange 40

Z\ WARNING

Do not repair fuses and never replace a blown

fuse with one that has a higher amp rating.

This can cause damage to the electrical sys-

tem and a fire.

CG) Note

If a new fuse burns out again shortly after you

have installed it, have the electrical system

checked as soon as possible by an authorized

Audi dealer or authorized Audi Service Facili-

ty.

@) Tips

— The following table does not list fuse loca-

tions that are not used.

— Some of the equipment listed in the follow-

ing tables applies only to certain model ver-

sions or certain optional equipment.

277

Page 280 of 304

![AUDI TT ROADSTER 2019 Owners Manual Fuses and bulbs

Interior fuse assignment

ft

pl Bel Fe

» BEBE ERED

Poo

ns

[24] 25) rao) 27) Fe Ra

23 |

Fsacsomeemr STE 42)

eases eres] b

ro Wa a i ee

1F52) FOL

Re

B8V-0217

AUDI TT ROADSTER 2019 Owners Manual Fuses and bulbs

Interior fuse assignment

ft

pl Bel Fe

» BEBE ERED

Poo

ns

[24] 25) rao) 27) Fe Ra

23 |

Fsacsomeemr STE 42)

eases eres] b

ro Wa a i ee

1F52) FOL

Re

B8V-0217](/img/6/57667/w960_57667-279.png)

Fuses and bulbs

Interior fuse assignment

ft

pl Bel Fe

» BEBE ERED

Poo

ns

[24] 25) rao) 27) Fe Ra

23 |

Fsacsomeemr STE 42)

eases eres] b

ro Wa a i ee

1F52) FOL

Re

B8V-0217

No. | Equipment

F20 | Power lumbar support adjustment

Front passenger's side neck heating (Road-

F22

ster)

Right vehicle electrical system control

F24

module

F25 | Driver side door

F26 | Seat heating

Vehicle electrical system control module

Fae (terminal 30)

F28 | AMI High media port

F29 | Vehicle electrical system control module

F32 | Driver assistance systems

F33 | Airbag

Sockets, interior sound, tail light switch,

F34 | temperature sensor, oil level sensor, neck

heating, garage door opener

Fig. 202 Vehicle interior: fuse assignment

No. Equipment

Diagnosis, headlight range control, air

quality sensor, automatic dimming rear-

view mirror, center instrument panel

switch module

F35

F4 Central computer processor (MIB-2) F36 | Right cornering light / right LED headlight

FS Gateway (diagnostics) F37 | Left cornering light / left LED headlight

Fo Selector lever (automatic transmission)

F7

Climate control system controls, rear win-

dow defogger, tire pressure monitoring

Engine control module, ESC control mod-

F38

ule

F39 | Front passenger side door

F8

Switch for the electromechanical parking

brake, light switch, rain/light sensor, inte-

rior lighting, diagnostic connector, roof

electronics F40

| Cigarette lighter, sockets

F41 | Fuel tank diagnosis

F42 | Central locking area

FQ Steering column switch module

F44 | All wheel drive clutch control module

F10 Vehicle positioning

F45 | Power adjustable driver's side seat

Fll

All wheel drive clutch, left vehicle electri-

cal system control module

F46 | Driver's side neck heating (Roadster)

F49 | Engine start, clutch sensor

F12 Infotainment components

F52 | Control module for suspension control

F1l4 Climate control system blower fan

F53 | Rear window defogger

Fis Electronic steering column lock

F16

Infotainment system components, safety

belt microphone

F17 Instrument cluster

F18 Rearview camera

F19

Convenience access control module

278

The power seats* are protected via circuit break-

ers that automatically switch on after a few sec-

onds after the overload has been reduced.