charging BMW 3 SERIES 1983 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1983, Model line: 3 SERIES, Model: BMW 3 SERIES 1983 E30Pages: 228, PDF Size: 7.04 MB

Page 120 of 228

the alternator complete, or take it to an

automotive electrician, who may be able to

overhaul it. Note:On models up to 1986, a

blown ignition/no-charge warning light bulb

will prevent the alternator from charging. After

1987, a resistor is wired in parallel with the

warning light, in order to allow current to

bypass the light in the event of a broken circuit

(blown warning light).

15 Alternator-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

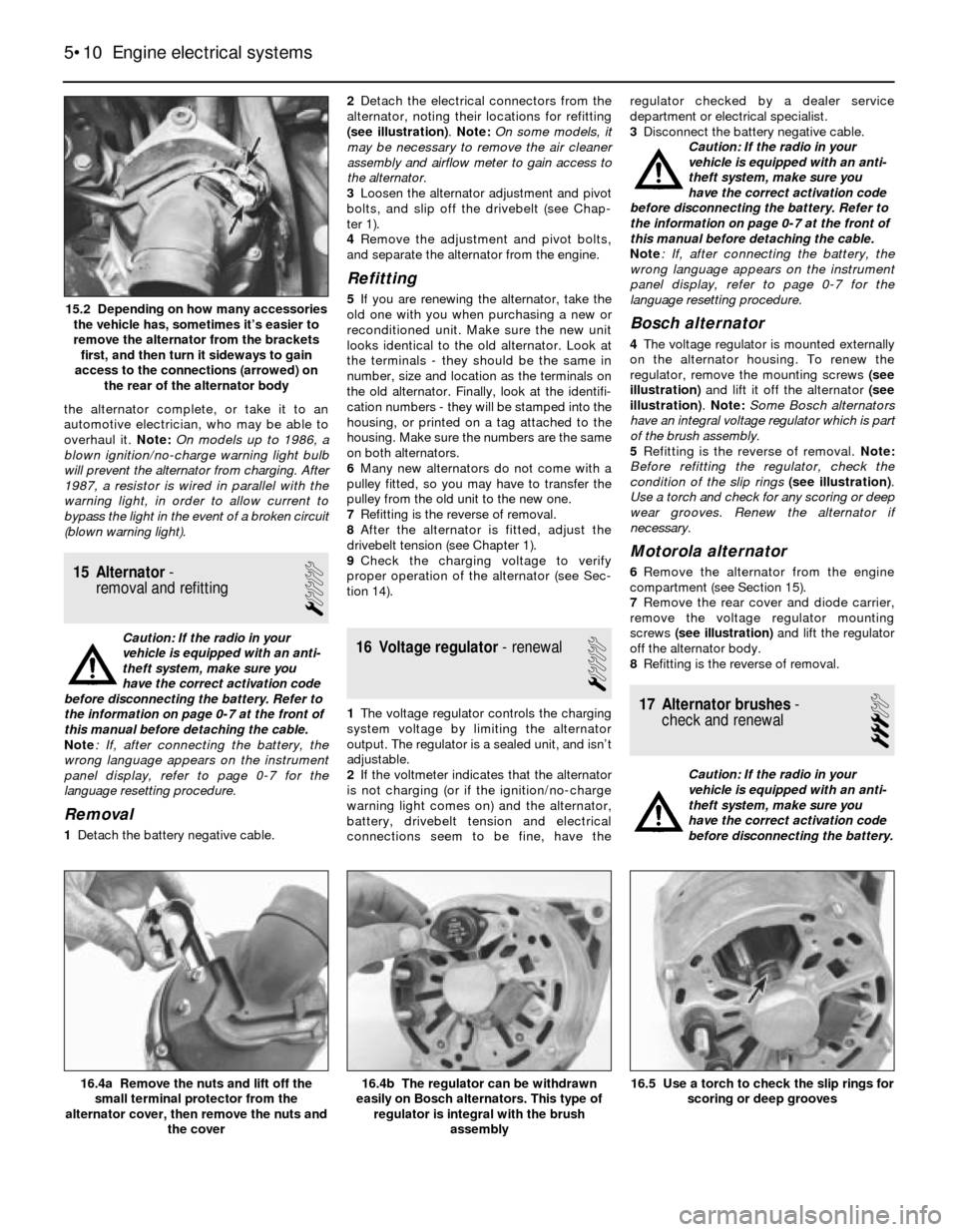

1Detach the battery negative cable.2Detach the electrical connectors from the

alternator, noting their locations for refitting

(see illustration). Note: On some models, it

may be necessary to remove the air cleaner

assembly and airflow meter to gain access to

the alternator.

3Loosen the alternator adjustment and pivot

bolts, and slip off the drivebelt (see Chap-

ter 1).

4Remove the adjustment and pivot bolts,

and separate the alternator from the engine.

Refitting

5If you are renewing the alternator, take the

old one with you when purchasing a new or

reconditioned unit. Make sure the new unit

looks identical to the old alternator. Look at

the terminals - they should be the same in

number, size and location as the terminals on

the old alternator. Finally, look at the identifi-

cation numbers - they will be stamped into the

housing, or printed on a tag attached to the

housing. Make sure the numbers are the same

on both alternators.

6Many new alternators do not come with a

pulley fitted, so you may have to transfer the

pulley from the old unit to the new one.

7Refitting is the reverse of removal.

8After the alternator is fitted, adjust the

drivebelt tension (see Chapter 1).

9Check the charging voltage to verify

proper operation of the alternator (see Sec-

tion 14).

16 Voltage regulator- renewal

1

1The voltage regulator controls the charging

system voltage by limiting the alternator

output. The regulator is a sealed unit, and isn’t

adjustable.

2If the voltmeter indicates that the alternator

is not charging (or if the ignition/no-charge

warning light comes on) and the alternator,

battery, drivebelt tension and electrical

connections seem to be fine, have theregulator checked by a dealer service

department or electrical specialist.

3Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Bosch alternator

4The voltage regulator is mounted externally

on the alternator housing. To renew the

regulator, remove the mounting screws (see

illustration)and lift it off the alternator (see

illustration). Note: Some Bosch alternators

have an integral voltage regulator which is part

of the brush assembly.

5Refitting is the reverse of removal. Note:

Before refitting the regulator, check the

condition of the slip rings(see illustration).

Use a torch and check for any scoring or deep

wear grooves. Renew the alternator if

necessary.

Motorola alternator

6Remove the alternator from the engine

compartment (see Section 15).

7Remove the rear cover and diode carrier,

remove the voltage regulator mounting

screws (see illustration)and lift the regulator

off the alternator body.

8Refitting is the reverse of removal.

17 Alternator brushes-

check and renewal

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

5•10 Engine electrical systems

16.5 Use a torch to check the slip rings for

scoring or deep grooves16.4b The regulator can be withdrawn

easily on Bosch alternators. This type of

regulator is integral with the brush

assembly16.4a Remove the nuts and lift off the

small terminal protector from the

alternator cover, then remove the nuts and

the cover

15.2 Depending on how many accessories

the vehicle has, sometimes it’s easier to

remove the alternator from the brackets

first, and then turn it sideways to gain

access to the connections (arrowed) on

the rear of the alternator body

Page 173 of 228

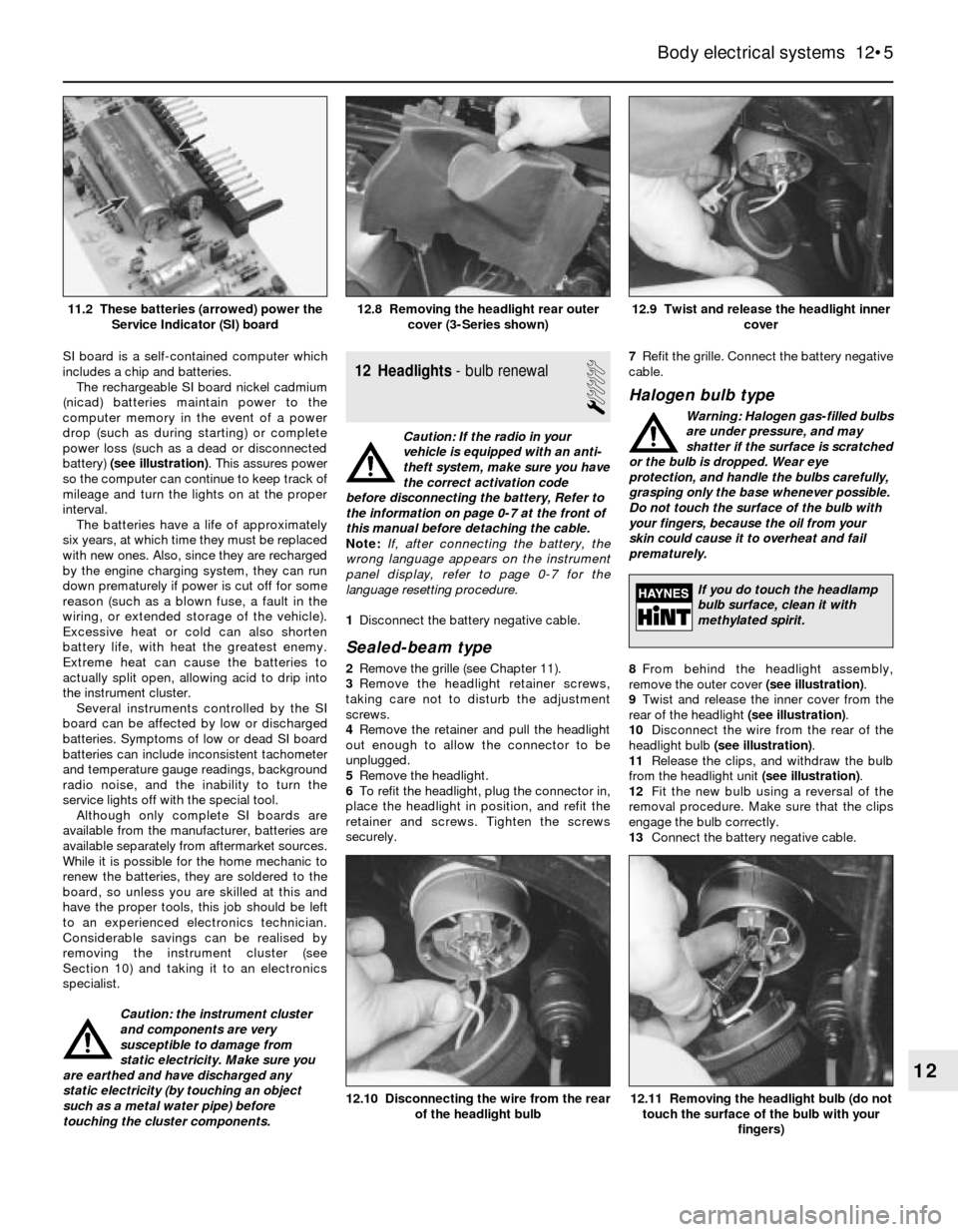

SI board is a self-contained computer which

includes a chip and batteries.

The rechargeable SI board nickel cadmium

(nicad) batteries maintain power to the

computer memory in the event of a power

drop (such as during starting) or complete

power loss (such as a dead or disconnected

battery) (see illustration). This assures power

so the computer can continue to keep track of

mileage and turn the lights on at the proper

interval.

The batteries have a life of approximately

six years, at which time they must be replaced

with new ones. Also, since they are recharged

by the engine charging system, they can run

down prematurely if power is cut off for some

reason (such as a blown fuse, a fault in the

wiring, or extended storage of the vehicle).

Excessive heat or cold can also shorten

battery life, with heat the greatest enemy.

Extreme heat can cause the batteries to

actually split open, allowing acid to drip into

the instrument cluster.

Several instruments controlled by the SI

board can be affected by low or discharged

batteries. Symptoms of low or dead SI board

batteries can include inconsistent tachometer

and temperature gauge readings, background

radio noise, and the inability to turn the

service lights off with the special tool.

Although only complete SI boards are

available from the manufacturer, batteries are

available separately from aftermarket sources.

While it is possible for the home mechanic to

renew the batteries, they are soldered to the

board, so unless you are skilled at this and

have the proper tools, this job should be left

to an experienced electronics technician.

Considerable savings can be realised by

removing the instrument cluster (see

Section 10) and taking it to an electronics

specialist.

Caution: the instrument cluster

and components are very

susceptible to damage from

static electricity. Make sure you

are earthed and have discharged any

static electricity (by touching an object

such as a metal water pipe) before

touching the cluster components.12 Headlights- bulb renewal

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

Sealed-beam type

2Remove the grille (see Chapter 11).

3Remove the headlight retainer screws,

taking care not to disturb the adjustment

screws.

4Remove the retainer and pull the headlight

out enough to allow the connector to be

unplugged.

5Remove the headlight.

6To refit the headlight, plug the connector in,

place the headlight in position, and refit the

retainer and screws. Tighten the screws

securely.7Refit the grille. Connect the battery negative

cable.

Halogen bulb type

Warning: Halogen gas-filled bulbs

are under pressure, and may

shatter if the surface is scratched

or the bulb is dropped. Wear eye

protection, and handle the bulbs carefully,

grasping only the base whenever possible.

Do not touch the surface of the bulb with

your fingers, because the oil from your

skin could cause it to overheat and fail

prematurely.

8From behind the headlight assembly,

remove the outer cover (see illustration).

9Twist and release the inner cover from the

rear of the headlight (see illustration).

10Disconnect the wire from the rear of the

headlight bulb (see illustration).

11Release the clips, and withdraw the bulb

from the headlight unit (see illustration).

12Fit the new bulb using a reversal of the

removal procedure. Make sure that the clips

engage the bulb correctly.

13Connect the battery negative cable.

Body electrical systems 12•5

12.9 Twist and release the headlight inner

cover12.8 Removing the headlight rear outer

cover (3-Series shown)11.2 These batteries (arrowed) power the

Service Indicator (SI) board

12.11 Removing the headlight bulb (do not

touch the surface of the bulb with your

fingers)12.10 Disconnecting the wire from the rear

of the headlight bulb

12

If you do touch the headlamp

bulb surface, clean it with

methylated spirit.

Page 178 of 228

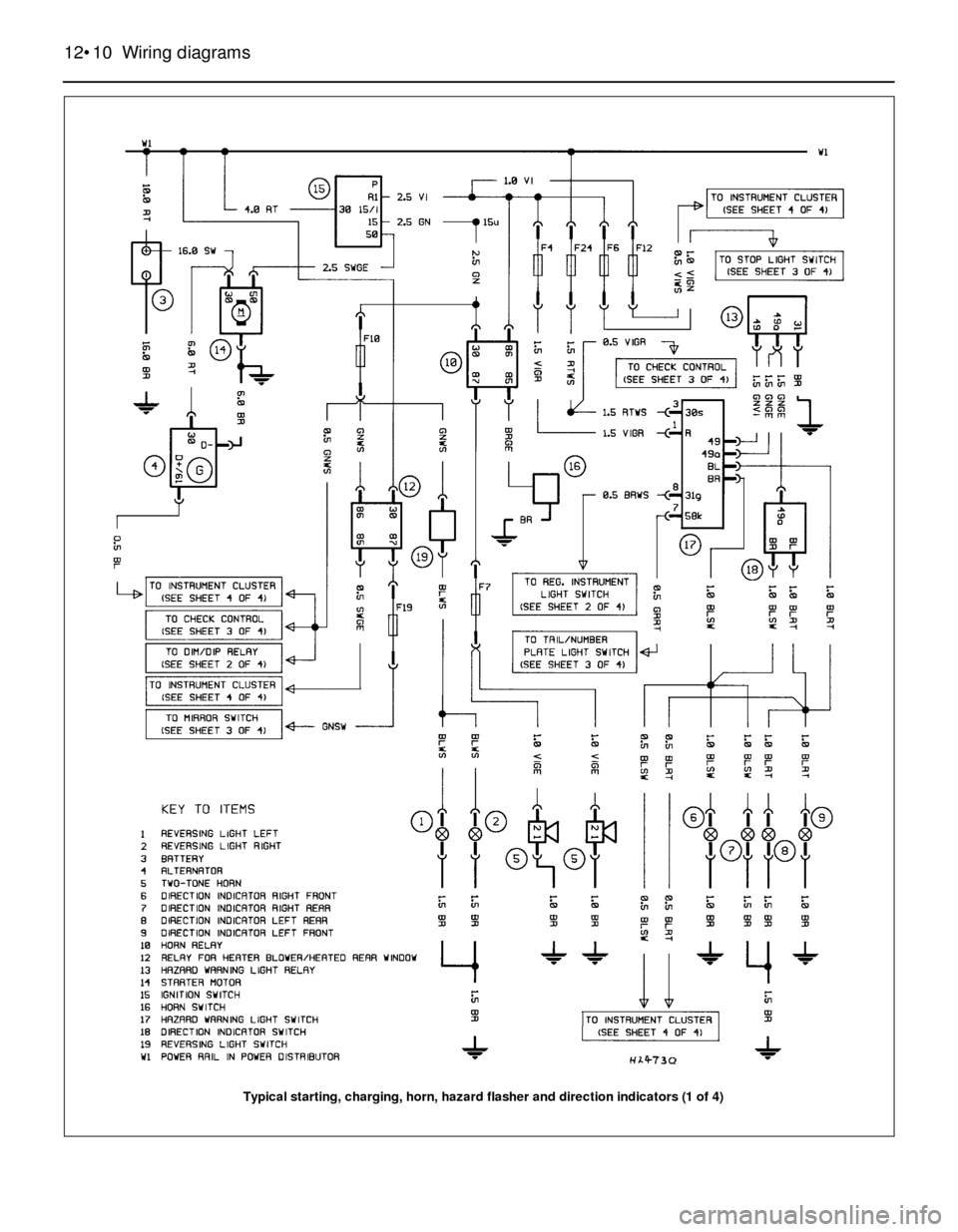

12•10 Wiring diagrams

Typical starting, charging, horn, hazard flasher and direction indicators (1 of 4)

Page 212 of 228

REF•11

REF

Fault Finding

Engine misses at idle speed

m mSpark plugs worn or incorrectly-gapped (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leaks (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mUneven or low compression (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6).

Engine misses throughout driving speed range

m

mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mLow fuel output at the injectors, or partially-blocked carburettor

jets (Chapter 4).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mCracked distributor cap, disconnected distributor HT leads, or

damaged distributor components (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mFaulty emission system components (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

m mWeak or faulty ignition system (Chapter 5).

m mVacuum leak in fuel injection system, intake manifold or vacuum

hoses (Chapter 4).

Engine misfires on acceleration

m mSpark plugs fouled (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFuel filter clogged (Chapters 1 and 4).

m mIncorrect ignition timing (Chapter 5).

m mIntake manifold air leak (Chapter 4).

Engine surges while holding accelerator steady

m

mIntake air leak (Chapter 4).

m mFuel pump faulty (Chapter 4).

m mLoose fuel injector harness connections (Chapters 4 and 6).

m mDefective ECU (Chapter 5).

Engine lacks power

m

mIncorrect ignition timing (Chapter 5).

m mExcessive play in distributor shaft (Chapter 5).

m mWorn rotor, distributor cap or HT leads (Chapters 1 and 5).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFaulty coil (Chapter 5).

m mBrakes binding (Chapter 1).

m mAutomatic transmission fluid level incorrect (Chapter 1).

m mClutch slipping (Chapter 8).

m mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mEmission control system not functioning properly (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

Engine stalls

m

mIdle speed incorrect (Chapter 1).

m mFuel filter clogged and/or water and impurities in the fuel system

(Chapter 1).

m mDistributor components damp or damaged (Chapter 5).

m mFaulty emissions system components (Chapter 6).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leak in the fuel injection system, intake manifold or

vacuum hoses (Chapter 4).

Engine backfires

m mEmissions system not functioning properly (Chapter 6).

m mIgnition timing incorrect (Chapter 5).

m mFaulty secondary ignition system (cracked spark plug insulator,

faulty plug HT leads, distributor cap and/or rotor) (Chapters 1 and 5).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mVacuum leak at fuel injector(s), intake manifold or vacuum hoses

(Chapter 4).

m mValve clearances incorrect (Chapter 1), or valve(s) sticking or

damaged (Chapter 2).

Pinking or knocking engine sounds when

accelerating or driving uphill

m mIncorrect grade of fuel.

m mIgnition timing incorrect (Chapter 5).

m mFuel injection system or carburettor in need of adjustment (Chap-

ter 4).

m mDamaged spark plugs or HT leads, or incorrect type fitted (Chapter 1).

m mWorn or damaged distributor components (Chapter 5).

m mFaulty emission system (Chapter 6).

m mVacuum leak (Chapter 4).

Engine runs with oil pressure light on

Caution: Stop the engine immediately if the oil

pressure light comes on and establish the cause.

Running the engine while the oil pressure is low can

cause severe damage.

m mLow oil level (Chapter 1).

m mIdle speed too low (Chapter 1).

m mShort-circuit in wiring (Chapter 12).

m mFaulty oil pressure sender unit (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

Engine runs-on after switching off

m

mIdle speed too high (Chapter 1).

m mExcessive engine operating temperature (Chapter 3).

m mIncorrect fuel octane grade.

m mSpark plugs defective or incorrect grade (Chapter 1).

Engine electrical system

Battery will not hold charge

m

mAlternator drivebelt defective or not adjusted properly (Chapter 1).

m mElectrolyte level low (Chapter 1).

m mBattery terminals loose or corroded (Chapter 1).

m mAlternator not charging properly (Chapter 5).

m mLoose, broken or faulty wiring in the charging circuit (Chapter 5).

m mShort in vehicle wiring (Chapters 5 and 12).

m mInternally-defective battery (Chapters 1 and 5).

m mIgnition (no-charge) warning light bulb blown - on some early

models (Chapter 5)

Ignition (no-charge) warning light fails to go out

m mFaulty alternator or charging circuit (Chapter 5).

m mAlternator drivebelt defective or out of adjustment (Chapter 1).

m mAlternator voltage regulator inoperative (Chapter 5).

Ignition (no-charge) warning light fails to come on

when key is turned

m mWarning light bulb defective (Chapter 12).

m mFault in the printed circuit, wiring or bulbholder (Chapter 12).

Page 225 of 228

REF•25

REF

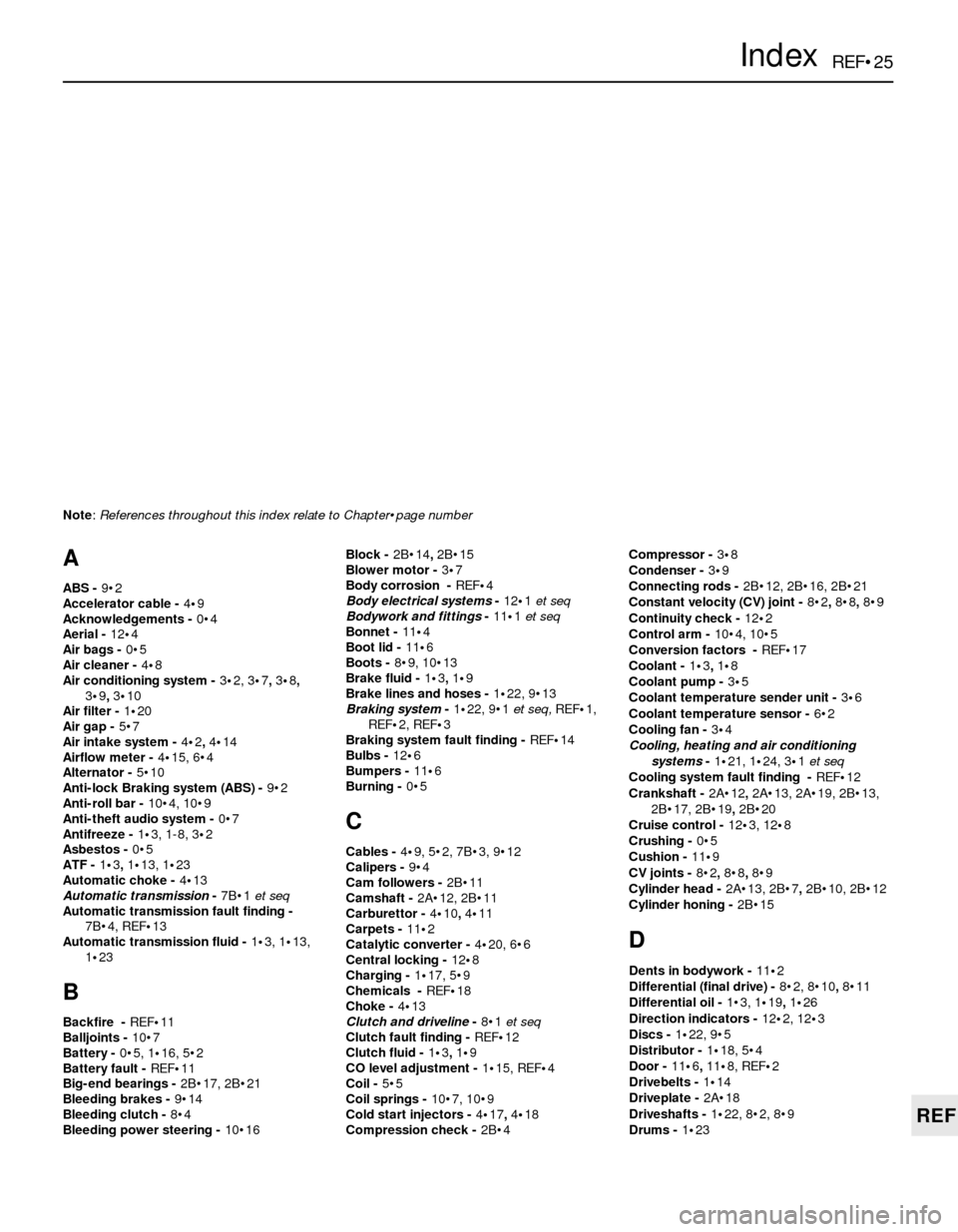

Index

Note: References throughout this index relate to Chapter•page number

A

ABS - 9•2

Accelerator cable - 4•9

Acknowledgements - 0•4

Aerial - 12•4

Air bags - 0•5

Air cleaner - 4•8

Air conditioning system - 3•2, 3•7, 3•8,

3•9, 3•10

Air filter - 1•20

Air gap - 5•7

Air intake system - 4•2, 4•14

Airflow meter - 4•15, 6•4

Alternator - 5•10

Anti-lock Braking system (ABS) - 9•2

Anti-roll bar - 10•4, 10•9

Anti-theft audio system - 0•7

Antifreeze - 1•3, 1-8, 3•2

Asbestos - 0•5

ATF - 1•3, 1•13, 1•23

Automatic choke - 4•13

Automatic transmission- 7B•1et seq

Automatic transmission fault finding -

7B•4, REF•13

Automatic transmission fluid - 1•3, 1•13,

1•23

B

Backfire - REF•11

Balljoints - 10•7

Battery - 0•5, 1•16, 5•2

Battery fault - REF•11

Big-end bearings - 2B•17, 2B•21

Bleeding brakes - 9•14

Bleeding clutch - 8•4

Bleeding power steering - 10•16Block - 2B•14, 2B•15

Blower motor - 3•7

Body corrosion - REF•4

Body electrical systems- 12•1et seq

Bodywork and fittings- 11•1et seq

Bonnet - 11•4

Boot lid - 11•6

Boots - 8•9, 10•13

Brake fluid - 1•3, 1•9

Brake lines and hoses - 1•22, 9•13

Braking system- 1•22, 9•1et seq,REF•1,

REF•2, REF•3

Braking system fault finding - REF•14

Bulbs - 12•6

Bumpers - 11•6

Burning - 0•5

C

Cables - 4•9, 5•2, 7B•3, 9•12

Calipers - 9•4

Cam followers - 2B•11

Camshaft - 2A•12, 2B•11

Carburettor - 4•10, 4•11

Carpets - 11•2

Catalytic converter - 4•20, 6•6

Central locking - 12•8

Charging - 1•17, 5•9

Chemicals - REF•18

Choke - 4•13

Clutch and driveline- 8•1et seq

Clutch fault finding - REF•12

Clutch fluid - 1•3, 1•9

CO level adjustment - 1•15, REF•4

Coil - 5•5

Coil springs - 10•7, 10•9

Cold start injectors - 4•17, 4•18

Compression check - 2B•4Compressor - 3•8

Condenser - 3•9

Connecting rods -2B•12, 2B•16, 2B•21

Constant velocity (CV) joint - 8•2, 8•8, 8•9

Continuity check - 12•2

Control arm - 10•4, 10•5

Conversion factors - REF•17

Coolant - 1•3, 1•8

Coolant pump - 3•5

Coolant temperature sender unit - 3•6

Coolant temperature sensor - 6•2

Cooling fan - 3•4

Cooling, heating and air conditioning

systems- 1•21, 1•24, 3•1et seq

Cooling system fault finding - REF•12

Crankshaft - 2A•12, 2A•13, 2A•19, 2B•13,

2B•17, 2B•19, 2B•20

Cruise control - 12•3, 12•8

Crushing - 0•5

Cushion - 11•9

CV joints - 8•2, 8•8, 8•9

Cylinder head - 2A•13, 2B•7, 2B•10, 2B•12

Cylinder honing - 2B•15

D

Dents in bodywork - 11•2

Differential (final drive) - 8•2, 8•10, 8•11

Differential oil -1•3, 1•19, 1•26

Direction indicators - 12•2, 12•3

Discs - 1•22, 9•5

Distributor - 1•18, 5•4

Door - 11•6, 11•8, REF•2

Drivebelts - 1•14

Driveplate - 2A•18

Driveshafts - 1•22, 8•2, 8•9

Drums - 1•23