ECO mode BMW 3 SERIES 1983 E30 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1983, Model line: 3 SERIES, Model: BMW 3 SERIES 1983 E30Pages: 228, PDF Size: 7.04 MB

Page 64 of 228

M10, M20 and M30 engines

3Adjust all valves to their maximum clearance

by rotating the eccentric on the valve end of

the rocker arm towards the centre of the head

(see Chapter 1, if necessary).

4Before removing the thrustplate, measure

the camshaft endfloat by mounting a dial

indicator to the front end of the cylinder head,

with the probe resting on the camshaft (see

illustration). Prise the camshaft back-and-

forth in the cylinder head. The reading is the

camshaft endfloat. Compare the reading to

this Chapter’s Specifications.

5Unbolt and remove the camshaft

thrustplate. Note:There are two different

locations for the thrustplate. On M10 and M30

engines, it is attached on the front of the

cylinder head, behind the timing gear flange.

On M20 and M40 engines, the thrustplate is

located inside the head, by the rocker shafts,

at the forward end of the cylinder head.

6Remove the rear cover plate from the back

of the cylinder head (see illustration).

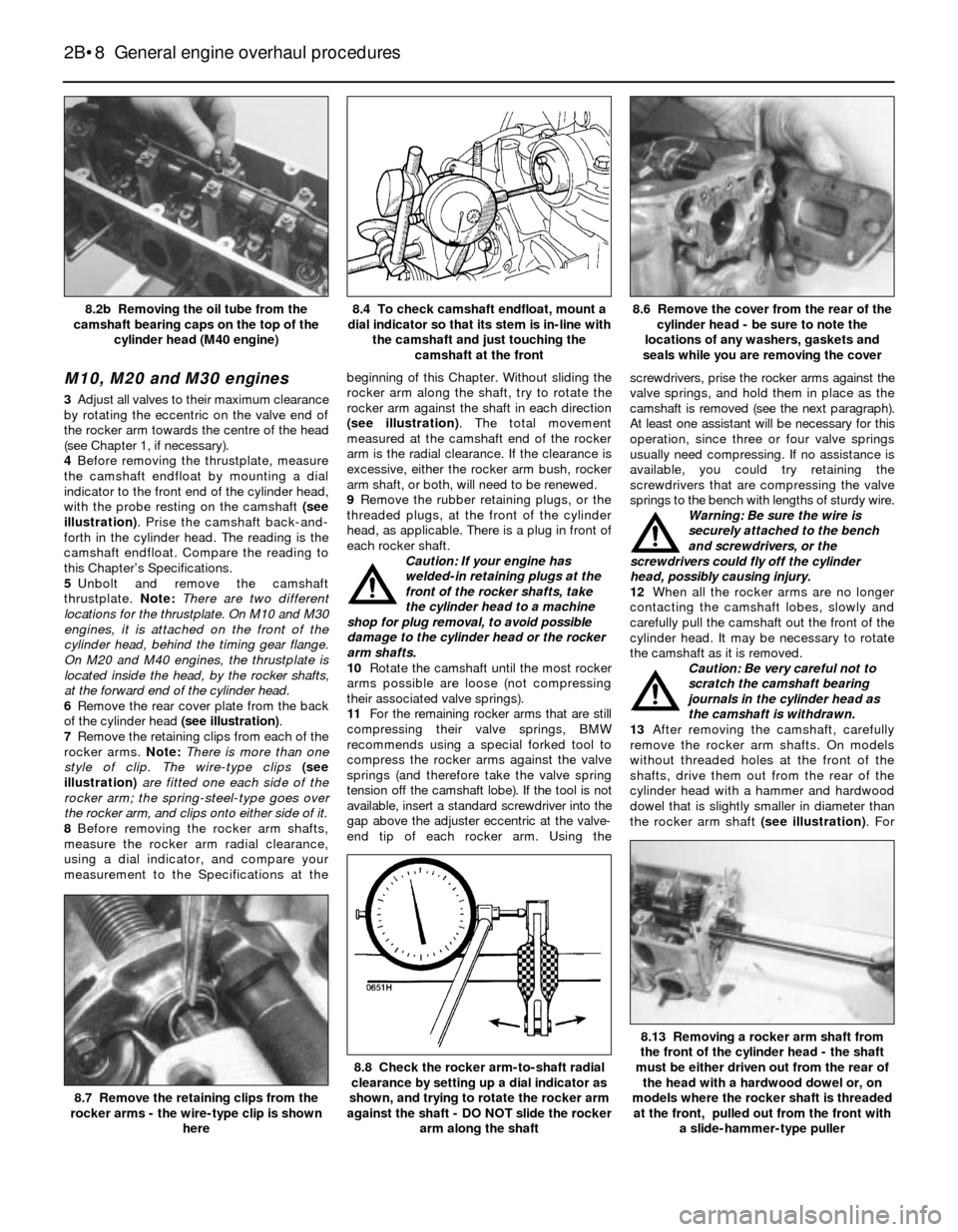

7Remove the retaining clips from each of the

rocker arms. Note:There is more than one

style of clip. The wire-type clips (see

illustration)are fitted one each side of the

rocker arm; the spring-steel-type goes over

the rocker arm, and clips onto either side of it.

8Before removing the rocker arm shafts,

measure the rocker arm radial clearance,

using a dial indicator, and compare your

measurement to the Specifications at thebeginning of this Chapter. Without sliding the

rocker arm along the shaft, try to rotate the

rocker arm against the shaft in each direction

(see illustration). The total movement

measured at the camshaft end of the rocker

arm is the radial clearance. If the clearance is

excessive, either the rocker arm bush, rocker

arm shaft, or both, will need to be renewed.

9Remove the rubber retaining plugs, or the

threaded plugs, at the front of the cylinder

head, as applicable. There is a plug in front of

each rocker shaft.

Caution: If your engine has

welded-in retaining plugs at the

front of the rocker shafts, take

the cylinder head to a machine

shop for plug removal, to avoid possible

damage to the cylinder head or the rocker

arm shafts.

10Rotate the camshaft until the most rocker

arms possible are loose (not compressing

their associated valve springs).

11For the remaining rocker arms that are still

compressing their valve springs, BMW

recommends using a special forked tool to

compress the rocker arms against the valve

springs (and therefore take the valve spring

tension off the camshaft lobe). If the tool is not

available, insert a standard screwdriver into the

gap above the adjuster eccentric at the valve-

end tip of each rocker arm. Using thescrewdrivers, prise the rocker arms against the

valve springs, and hold them in place as the

camshaft is removed (see the next paragraph).

At least one assistant will be necessary for this

operation, since three or four valve springs

usually need compressing. If no assistance is

available, you could try retaining the

screwdrivers that are compressing the valve

springs to the bench with lengths of sturdy wire.

Warning: Be sure the wire is

securely attached to the bench

and screwdrivers, or the

screwdrivers could fly off the cylinder

head, possibly causing injury.

12When all the rocker arms are no longer

contacting the camshaft lobes, slowly and

carefully pull the camshaft out the front of the

cylinder head. It may be necessary to rotate

the camshaft as it is removed.

Caution: Be very careful not to

scratch the camshaft bearing

journals in the cylinder head as

the camshaft is withdrawn.

13After removing the camshaft, carefully

remove the rocker arm shafts. On models

without threaded holes at the front of the

shafts, drive them out from the rear of the

cylinder head with a hammer and hardwood

dowel that is slightly smaller in diameter than

the rocker arm shaft (see illustration). For

2B•8 General engine overhaul procedures

8.13 Removing a rocker arm shaft from

the front of the cylinder head - the shaft

must be either driven out from the rear of

the head with a hardwood dowel or, on

models where the rocker shaft is threaded

at the front, pulled out from the front with

a slide-hammer-type puller

8.8 Check the rocker arm-to-shaft radial

clearance by setting up a dial indicator as

shown, and trying to rotate the rocker arm

against the shaft - DO NOT slide the rocker

arm along the shaft

8.7 Remove the retaining clips from the

rocker arms - the wire-type clip is shown

here

8.6 Remove the cover from the rear of the

cylinder head - be sure to note the

locations of any washers, gaskets and

seals while you are removing the cover8.4 To check camshaft endfloat, mount a

dial indicator so that its stem is in-line with

the camshaft and just touching the

camshaft at the front8.2b Removing the oil tube from the

camshaft bearing caps on the top of the

cylinder head (M40 engine)

Page 76 of 228

positions (don’t mix them up) with the arrows

pointing towards the front of the engine. Don’t

disturb the Plastigage.

13Starting with the centre main bearing and

working out toward the ends, progressively

tighten the main bearing cap bolts to the

torque listed in this Chapter’s Specifications.

On M10, M20 and M30 engines, tighten the

bolts in three stages. On the M40 engine,

tighten all the bolts initially to the Stage 1

torque, then angle-tighten them by the angle

given in the Specifications. Carry out the

angle-tightening on each bolt in one

controlled movement. Don’t rotate the

crankshaft at any time during the tightening

operation.

14Remove the bolts and carefully lift off the

main bearing caps. Keep them in order. Don’t

disturb the Plastigage or rotate the

crankshaft. If any of the main bearing caps are

difficult to remove, tap them gently from side-

to-side with a soft-face hammer to loosen

them.

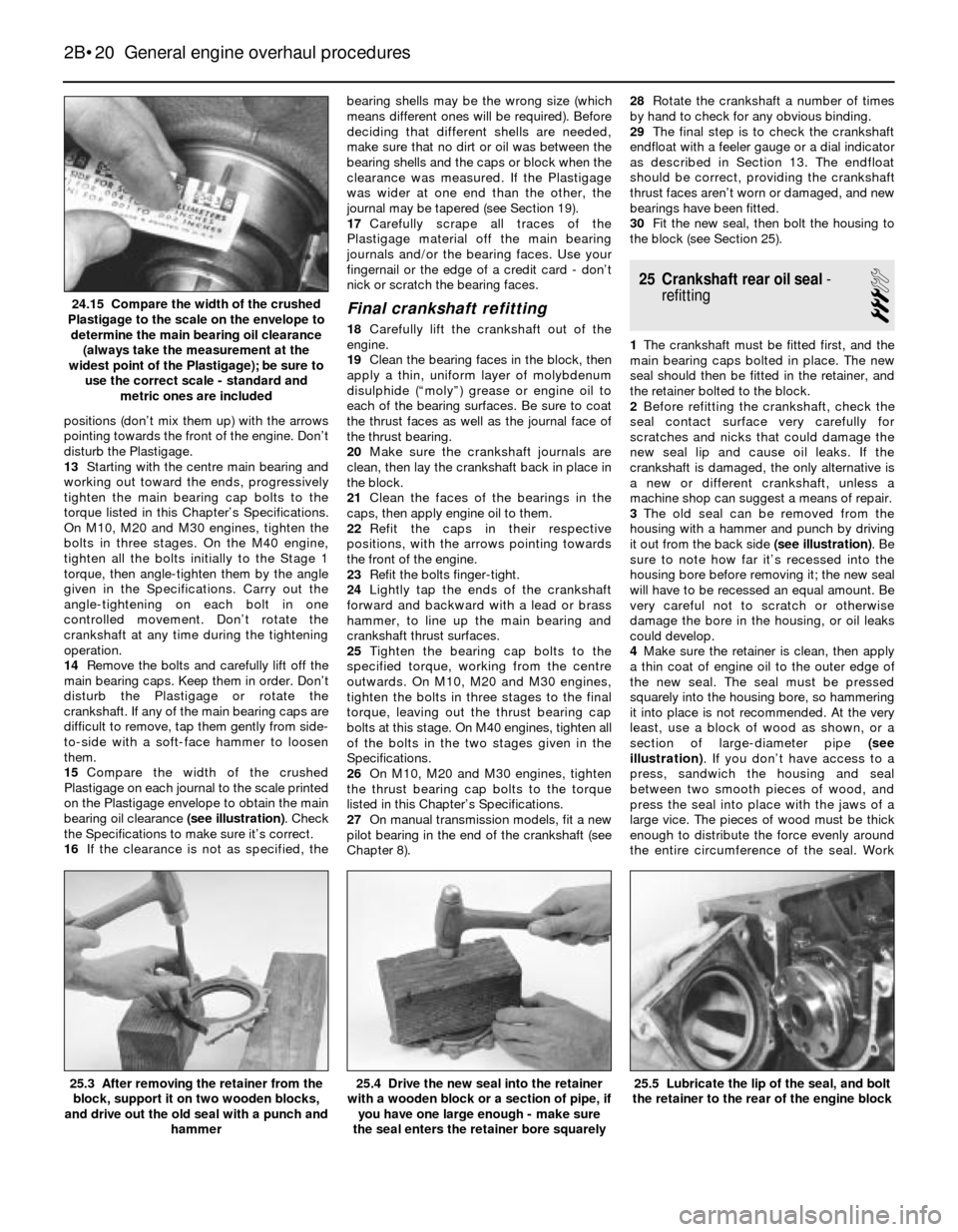

15Compare the width of the crushed

Plastigage on each journal to the scale printed

on the Plastigage envelope to obtain the main

bearing oil clearance (see illustration). Check

the Specifications to make sure it’s correct.

16If the clearance is not as specified, thebearing shells may be the wrong size (which

means different ones will be required). Before

deciding that different shells are needed,

make sure that no dirt or oil was between the

bearing shells and the caps or block when the

clearance was measured. If the Plastigage

was wider at one end than the other, the

journal may be tapered (see Section 19).

17Carefully scrape all traces of the

Plastigage material off the main bearing

journals and/or the bearing faces. Use your

fingernail or the edge of a credit card - don’t

nick or scratch the bearing faces.

Final crankshaft refitting

18Carefully lift the crankshaft out of the

engine.

19Clean the bearing faces in the block, then

apply a thin, uniform layer of molybdenum

disulphide (“moly”) grease or engine oil to

each of the bearing surfaces. Be sure to coat

the thrust faces as well as the journal face of

the thrust bearing.

20Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the block.

21Clean the faces of the bearings in the

caps, then apply engine oil to them.

22Refit the caps in their respective

positions, with the arrows pointing towards

the front of the engine.

23Refit the bolts finger-tight.

24Lightly tap the ends of the crankshaft

forward and backward with a lead or brass

hammer, to line up the main bearing and

crankshaft thrust surfaces.

25Tighten the bearing cap bolts to the

specified torque, working from the centre

outwards. On M10, M20 and M30 engines,

tighten the bolts in three stages to the final

torque, leaving out the thrust bearing cap

bolts at this stage. On M40 engines, tighten all

of the bolts in the two stages given in the

Specifications.

26On M10, M20 and M30 engines, tighten

the thrust bearing cap bolts to the torque

listed in this Chapter’s Specifications.

27On manual transmission models, fit a new

pilot bearing in the end of the crankshaft (see

Chapter 8).28Rotate the crankshaft a number of times

by hand to check for any obvious binding.

29The final step is to check the crankshaft

endfloat with a feeler gauge or a dial indicator

as described in Section 13. The endfloat

should be correct, providing the crankshaft

thrust faces aren’t worn or damaged, and new

bearings have been fitted.

30Fit the new seal, then bolt the housing to

the block (see Section 25).

25 Crankshaft rear oil seal-

refitting

3

1The crankshaft must be fitted first, and the

main bearing caps bolted in place. The new

seal should then be fitted in the retainer, and

the retainer bolted to the block.

2Before refitting the crankshaft, check the

seal contact surface very carefully for

scratches and nicks that could damage the

new seal lip and cause oil leaks. If the

crankshaft is damaged, the only alternative is

a new or different crankshaft, unless a

machine shop can suggest a means of repair.

3The old seal can be removed from the

housing with a hammer and punch by driving

it out from the back side (see illustration). Be

sure to note how far it’s recessed into the

housing bore before removing it; the new seal

will have to be recessed an equal amount. Be

very careful not to scratch or otherwise

damage the bore in the housing, or oil leaks

could develop.

4Make sure the retainer is clean, then apply

a thin coat of engine oil to the outer edge of

the new seal. The seal must be pressed

squarely into the housing bore, so hammering

it into place is not recommended. At the very

least, use a block of wood as shown, or a

section of large-diameter pipe (see

illustration). If you don’t have access to a

press, sandwich the housing and seal

between two smooth pieces of wood, and

press the seal into place with the jaws of a

large vice. The pieces of wood must be thick

enough to distribute the force evenly around

the entire circumference of the seal. Work

2B•20 General engine overhaul procedures

25.5 Lubricate the lip of the seal, and bolt

the retainer to the rear of the engine block25.4 Drive the new seal into the retainer

with a wooden block or a section of pipe, if

you have one large enough - make sure

the seal enters the retainer bore squarely25.3 After removing the retainer from the

block, support it on two wooden blocks,

and drive out the old seal with a punch and

hammer

24.15 Compare the width of the crushed

Plastigage to the scale on the envelope to

determine the main bearing oil clearance

(always take the measurement at the

widest point of the Plastigage); be sure to

use the correct scale - standard and

metric ones are included

Page 80 of 228

Warning: Do not remove the

pressure cap from the radiator or

expansion tank until the engine

has cooled completely and

there’s no pressure remaining in the

cooling system. Removing the cap from a

hot engine risks personal injury by

scalding.

Heating system

The heating system consists of a blower fan

and heater matrix located in the heater box,

with hoses connecting the heater matrix to the

engine cooling system, and the heater/air

conditioning control head on the dashboard.

Hot engine coolant is circulated through the

heater matrix passages all the time the engine

is running. Switching the heater on opens a

flap door to direct air through the heater

matrix, and the warmed air enters the

passenger compartment. A fan switch on the

control head activates the blower motor,

which forces more air through the heater

matrix, giving additional heater output for

demisting, etc.

Air conditioning system

The air conditioning system consists of a

condenser mounted in front of the radiator, an

evaporator mounted adjacent to the heater

matrix, a compressor mounted on the engine,

a filter-drier (receiver-drier) which contains a

high-pressure relief valve, and the plumbing

connecting all of the above components.

A blower fan forces the warmer air of the

passenger compartment through the

evaporator matrix (a radiator-in-reverse),

transferring the heat from the air to the

refrigerant. The liquid refrigerant boils off into

low-pressure vapour, taking the heat with it

when it leaves the evaporator.

Note: Refer to the precautions at the start

of Section 12 concerning the potential

dangers associated with the air conditioning

system.

2 Antifreeze-

general information

Warning: Do not allow antifreeze

to come in contact with your skin

or painted surfaces of the

vehicle. Rinse off spills

immediately with plenty of water. If

consumed, antifreeze can be fatal;

children and pets are attracted by its

sweet taste, so wipe up garage floor and

drip pan coolant spills immediately. Keep

antifreeze containers covered, and repair

leaks in your cooling system as soon as

they are noticed.

The cooling system should be filled with a

60/40% water/ethylene-glycol-based anti-

freeze solution, which will prevent freezing

down to approximately -27°C (-17°F). The

antifreeze also raises the boiling point of thecoolant, and (if of good quality) provides

protection against corrosion.

The cooling system should be drained,

flushed and refilled at the specified intervals

(see Chapter 1). Old or contaminated

antifreeze solutions are likely to cause

damage, and encourage the formation of rust

and scale in the system. Use distilled water

with the antifreeze, if available, or clean

rainwater. Tap water will do, but not if the

water in your area is at all “hard”.

Before adding antifreeze, check all hose

connections, because antifreeze tends to

search out and leak through very minute

openings. Engines don’t normally consume

coolant, so if the level goes down, find the

cause and correct it.

The antifreeze mixture should be

maintained at its correct proportions; adding

too much antifreeze reduces the efficiency of

the cooling system. If necessary, consult the

mixture ratio chart on the antifreeze container

before adding coolant. Hydrometers are

available at most car accessory shops to test

the coolant. Use antifreeze which meets the

vehicle manufacturer’s specifications.

3 Thermostat-

check and renewal

1

Warning: Do not remove the

radiator cap, drain the coolant, or

renew the thermostat until the

engine has cooled completely.

Check

1Before assuming the thermostat is to blame

for a cooling system problem, check the

coolant level, drivebelt tension (see Chapter 1)

and temperature gauge (or warning light)

operation.

2If the engine seems to be taking a long time

to warm up (based on heater output or

temperature gauge operation), the thermostat

is probably stuck open. Renew the

thermostat.

3If the engine runs hot, use your hand to

check the temperature of the upper radiator

hose. If the hose isn’t hot, but the engine is,

the thermostat is probably stuck closed,preventing the coolant inside the engine from

circulating to the radiator. Renew the

thermostat.

Caution: Don’t drive the vehicle

without a thermostat. The engine

will be very slow to warm-up in

cold conditions, resulting in poor

fuel economy and driveability. A new

thermostat is normally an inexpensive

component anyway.

4If the upper radiator hose is hot, it means

that the coolant is flowing and the thermostat

is at least partly open. Consult the “Fault

finding” Section at the rear of this manual for

cooling system diagnosis.

Renewal

All models

5Disconnect the negative cable from the

battery.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

6Drain the cooling system (see Chapter 1). If

the coolant is relatively new or in good

condition, save it and re-use it.

M10 engines

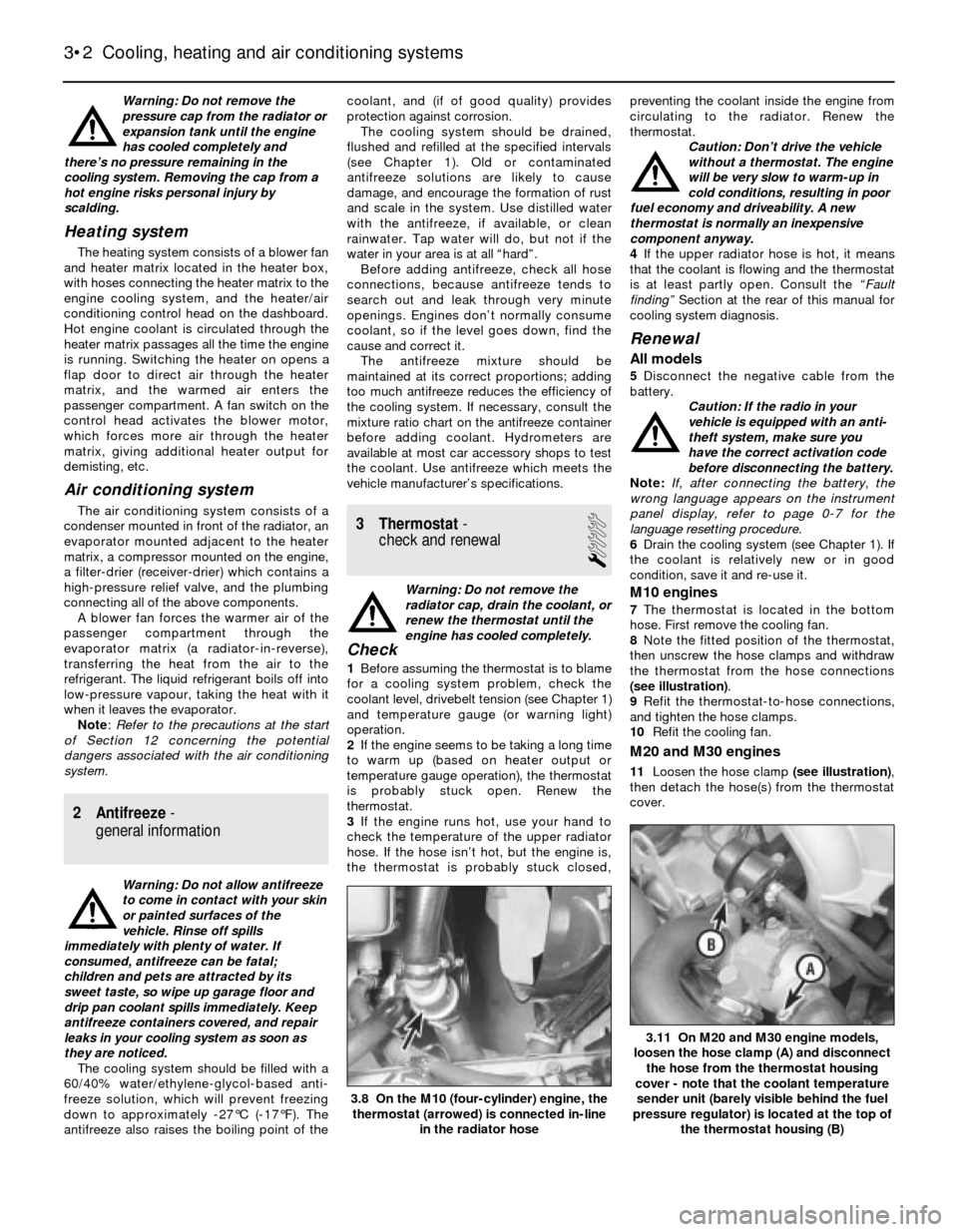

7The thermostat is located in the bottom

hose. First remove the cooling fan.

8Note the fitted position of the thermostat,

then unscrew the hose clamps and withdraw

the thermostat from the hose connections

(see illustration).

9Refit the thermostat-to-hose connections,

and tighten the hose clamps.

10Refit the cooling fan.

M20 and M30 engines

11Loosen the hose clamp (see illustration),

then detach the hose(s) from the thermostat

cover.

3•2 Cooling, heating and air conditioning systems

3.11 On M20 and M30 engine models,

loosen the hose clamp (A) and disconnect

the hose from the thermostat housing

cover - note that the coolant temperature

sender unit (barely visible behind the fuel

pressure regulator) is located at the top of

the thermostat housing (B)

3.8 On the M10 (four-cylinder) engine, the

thermostat (arrowed) is connected in-line

in the radiator hose

Page 82 of 228

disconnect the fluid cooler lines from the

radiator. Use a drip tray to catch spilled fluid.

Plug the fluid cooler lines and fittings.

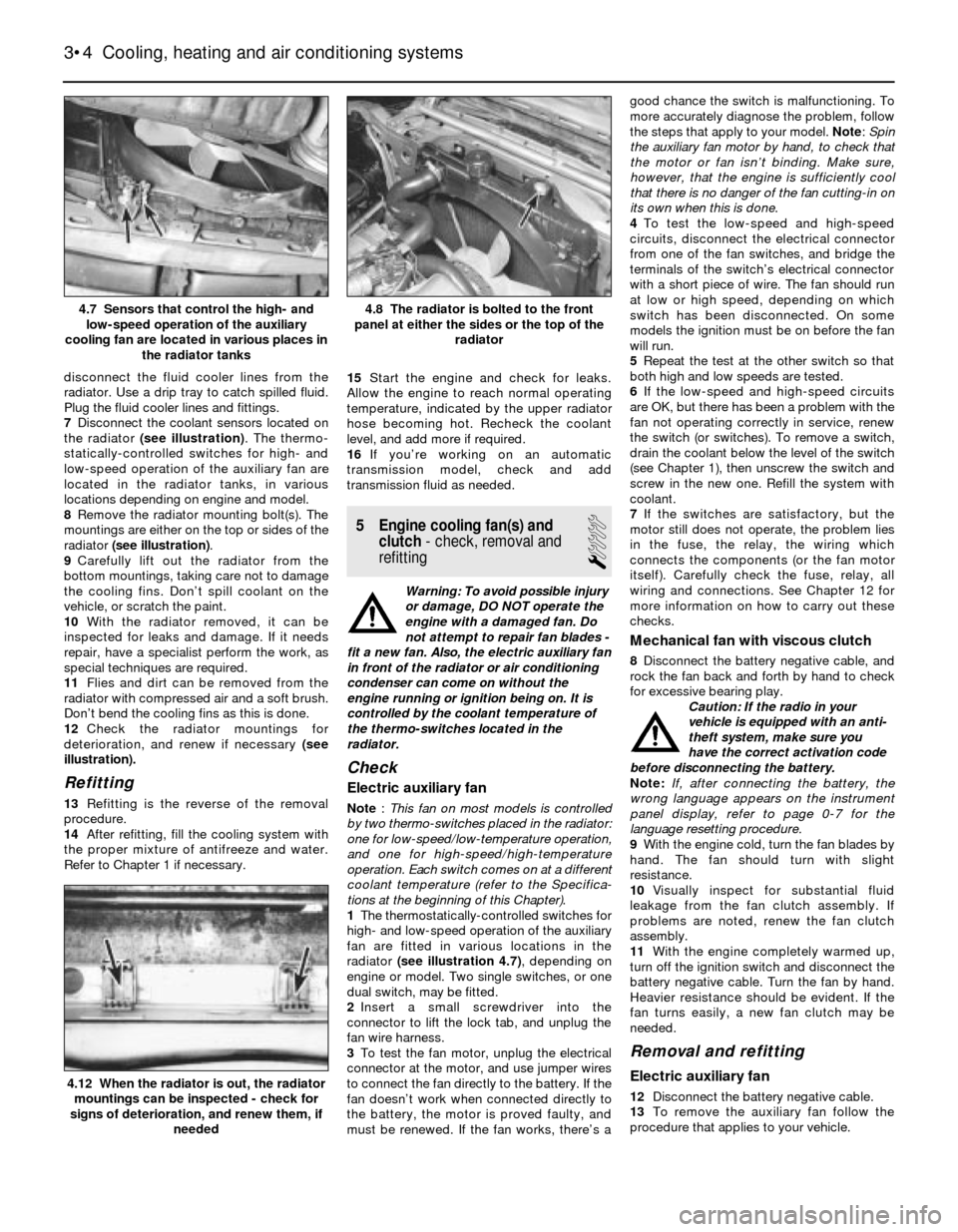

7Disconnect the coolant sensors located on

the radiator (see illustration). The thermo-

statically-controlled switches for high- and

low-speed operation of the auxiliary fan are

located in the radiator tanks, in various

locations depending on engine and model.

8Remove the radiator mounting bolt(s). The

mountings are either on the top or sides of the

radiator (see illustration).

9Carefully lift out the radiator from the

bottom mountings, taking care not to damage

the cooling fins. Don’t spill coolant on the

vehicle, or scratch the paint.

10With the radiator removed, it can be

inspected for leaks and damage. If it needs

repair, have a specialist perform the work, as

special techniques are required.

11Flies and dirt can be removed from the

radiator with compressed air and a soft brush.

Don’t bend the cooling fins as this is done.

12Check the radiator mountings for

deterioration, and renew if necessary (see

illustration).

Refitting

13Refitting is the reverse of the removal

procedure.

14After refitting, fill the cooling system with

the proper mixture of antifreeze and water.

Refer to Chapter 1 if necessary.15Start the engine and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by the upper radiator

hose becoming hot. Recheck the coolant

level, and add more if required.

16If you’re working on an automatic

transmission model, check and add

transmission fluid as needed.

5 Engine cooling fan(s) and

clutch- check, removal and

refitting

1

Warning: To avoid possible injury

or damage, DO NOT operate the

engine with a damaged fan. Do

not attempt to repair fan blades -

fit a new fan. Also, the electric auxiliary fan

in front of the radiator or air conditioning

condenser can come on without the

engine running or ignition being on. It is

controlled by the coolant temperature of

the thermo-switches located in the

radiator.

Check

Electric auxiliary fan

Note: This fan on most models is controlled

by two thermo-switches placed in the radiator:

one for low-speed/low-temperature operation,

and one for high-speed/high-temperature

operation. Each switch comes on at a different

coolant temperature (refer to the Specifica-

tions at the beginning of this Chapter).

1The thermostatically-controlled switches for

high- and low-speed operation of the auxiliary

fan are fitted in various locations in the

radiator (see illustration 4.7), depending on

engine or model. Two single switches, or one

dual switch, may be fitted.

2Insert a small screwdriver into the

connector to lift the lock tab, and unplug the

fan wire harness.

3To test the fan motor, unplug the electrical

connector at the motor, and use jumper wires

to connect the fan directly to the battery. If the

fan doesn’t work when connected directly to

the battery, the motor is proved faulty, and

must be renewed. If the fan works, there’s agood chance the switch is malfunctioning. To

more accurately diagnose the problem, follow

the steps that apply to your model. Note: Spin

the auxiliary fan motor by hand, to check that

the motor or fan isn’t binding. Make sure,

however, that the engine is sufficiently cool

that there is no danger of the fan cutting-in on

its own when this is done.

4To test the low-speed and high-speed

circuits, disconnect the electrical connector

from one of the fan switches, and bridge the

terminals of the switch’s electrical connector

with a short piece of wire. The fan should run

at low or high speed, depending on which

switch has been disconnected. On some

models the ignition must be on before the fan

will run.

5Repeat the test at the other switch so that

both high and low speeds are tested.

6If the low-speed and high-speed circuits

are OK, but there has been a problem with the

fan not operating correctly in service, renew

the switch (or switches). To remove a switch,

drain the coolant below the level of the switch

(see Chapter 1), then unscrew the switch and

screw in the new one. Refill the system with

coolant.

7If the switches are satisfactory, but the

motor still does not operate, the problem lies

in the fuse, the relay, the wiring which

connects the components (or the fan motor

itself). Carefully check the fuse, relay, all

wiring and connections. See Chapter 12 for

more information on how to carry out these

checks.

Mechanical fan with viscous clutch

8Disconnect the battery negative cable, and

rock the fan back and forth by hand to check

for excessive bearing play.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

9With the engine cold, turn the fan blades by

hand. The fan should turn with slight

resistance.

10Visually inspect for substantial fluid

leakage from the fan clutch assembly. If

problems are noted, renew the fan clutch

assembly.

11With the engine completely warmed up,

turn off the ignition switch and disconnect the

battery negative cable. Turn the fan by hand.

Heavier resistance should be evident. If the

fan turns easily, a new fan clutch may be

needed.

Removal and refitting

Electric auxiliary fan

12Disconnect the battery negative cable.

13To remove the auxiliary fan follow the

procedure that applies to your vehicle.

3•4 Cooling, heating and air conditioning systems

4.12 When the radiator is out, the radiator

mountings can be inspected - check for

signs of deterioration, and renew them, if

needed

4.8 The radiator is bolted to the front

panel at either the sides or the top of the

radiator4.7 Sensors that control the high- and

low-speed operation of the auxiliary

cooling fan are located in various places in

the radiator tanks

Page 85 of 228

4If a new sender unit is to be fitted, make

sure the engine is completely cool. There will

be some coolant loss when the unit is

unscrewed, so be prepared to catch it, or

have the new unit ready to fit immediately the

old one is removed. Disconnect the wiring,

then unscrew the old unit from the engine,

and fit the new one. Use sealant on the

threads. Reconnect the wiring, and check the

coolant level on completion.

9 Heater and air conditioning

blower motor- removal,

testing and refitting

1

Removal

Note: The 3-Series models covered by this

manual have always used a single blower

motor for ventilation, heating and air

conditioning. “Old-shape” (E28) 5-Series

models use two separate blower motors: one

for ventilation and heating, and another for air

conditioning. “New-shape” (E34) 5-Series

models have a single blower motor, like the 3-

Series. The removal and refitting of the single

blower motor, and the old-shape 5-Series

vent/heat motor, is described below. The

removal and refitting of the old-shape 5-Series

air conditioning blower motor is described in

Section 14 of this Chapter.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2The blower motor is located behind the

bulkhead, under an access panel. Remove the

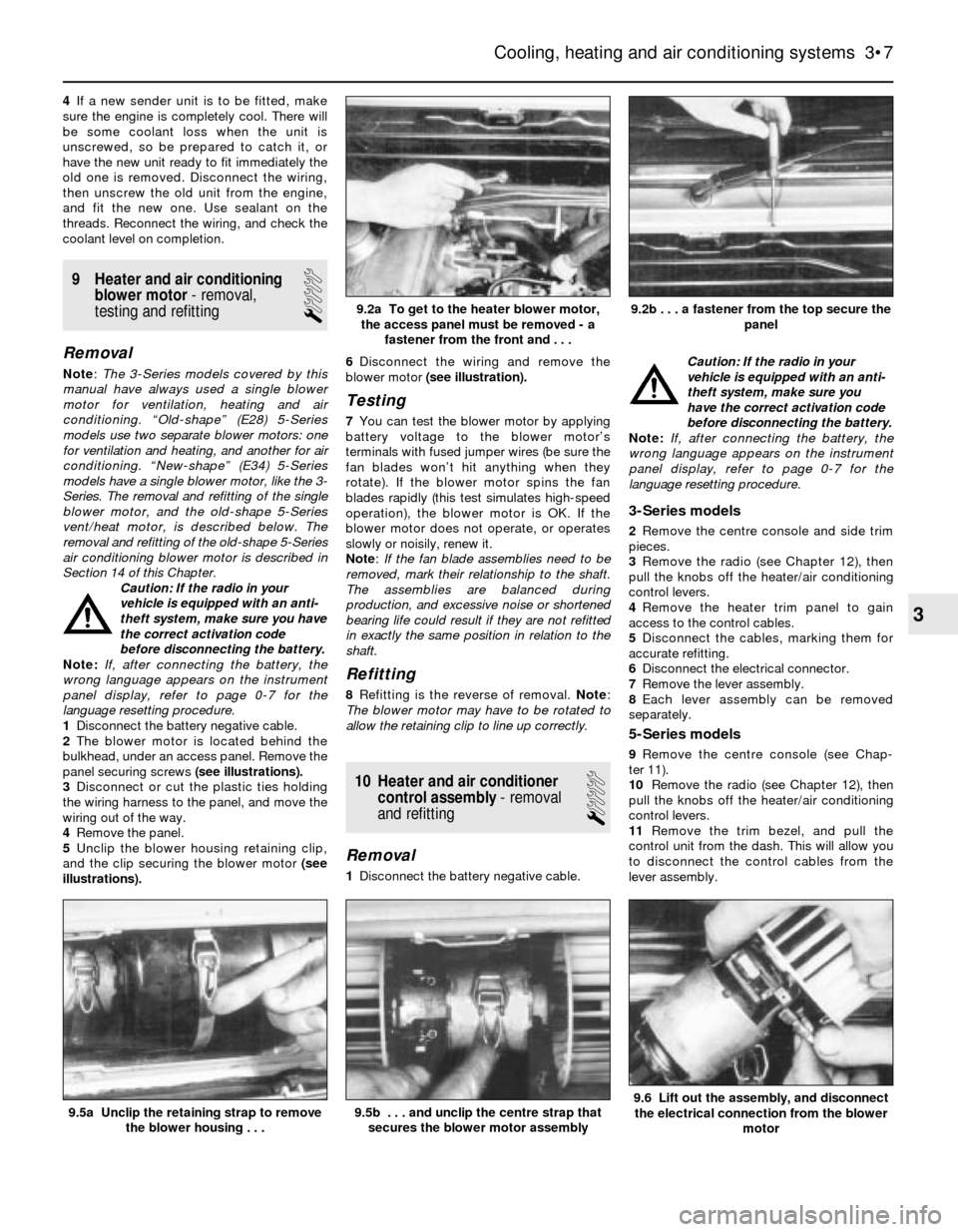

panel securing screws (see illustrations).

3Disconnect or cut the plastic ties holding

the wiring harness to the panel, and move the

wiring out of the way.

4Remove the panel.

5Unclip the blower housing retaining clip,

and the clip securing the blower motor (see

illustrations).6Disconnect the wiring and remove the

blower motor (see illustration).

Testing

7You can test the blower motor by applying

battery voltage to the blower motor’s

terminals with fused jumper wires (be sure the

fan blades won’t hit anything when they

rotate). If the blower motor spins the fan

blades rapidly (this test simulates high-speed

operation), the blower motor is OK. If the

blower motor does not operate, or operates

slowly or noisily, renew it.

Note: If the fan blade assemblies need to be

removed, mark their relationship to the shaft.

The assemblies are balanced during

production, and excessive noise or shortened

bearing life could result if they are not refitted

in exactly the same position in relation to the

shaft.

Refitting

8Refitting is the reverse of removal. Note:

The blower motor may have to be rotated to

allow the retaining clip to line up correctly.

10 Heater and air conditioner

control assembly- removal

and refitting

1

Removal

1Disconnect the battery negative cable. Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3-Series models

2Remove the centre console and side trim

pieces.

3Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

4Remove the heater trim panel to gain

access to the control cables.

5Disconnect the cables, marking them for

accurate refitting.

6Disconnect the electrical connector.

7Remove the lever assembly.

8Each lever assembly can be removed

separately.

5-Series models

9Remove the centre console (see Chap-

ter 11).

10Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

11Remove the trim bezel, and pull the

control unit from the dash. This will allow you

to disconnect the control cables from the

lever assembly.

Cooling, heating and air conditioning systems 3•7

9.5a Unclip the retaining strap to remove

the blower housing . . .

9.2b . . . a fastener from the top secure the

panel9.2a To get to the heater blower motor,

the access panel must be removed - a

fastener from the front and . . .

9.6 Lift out the assembly, and disconnect

the electrical connection from the blower

motor9.5b . . . and unclip the centre strap that

secures the blower motor assembly

3

Page 90 of 228

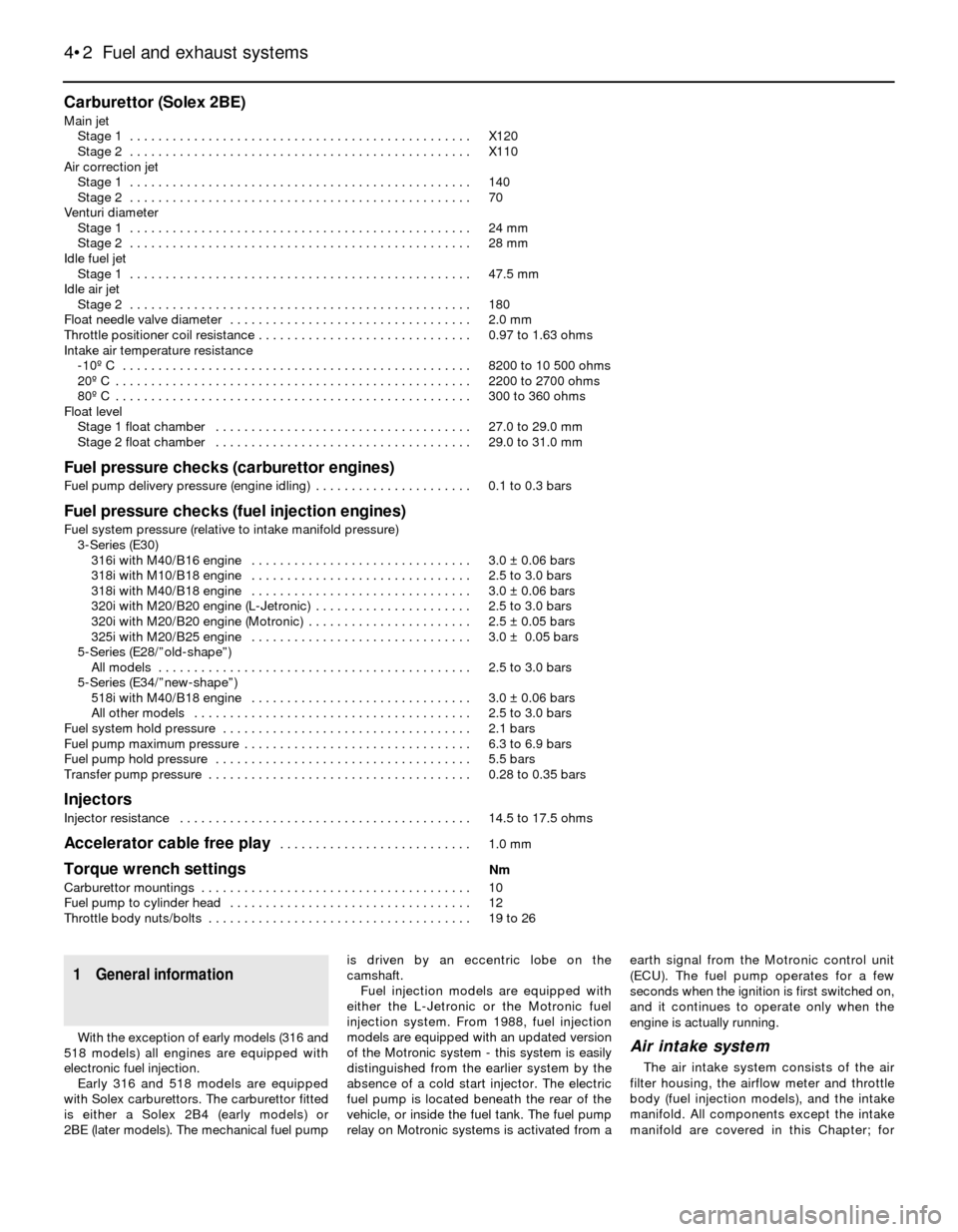

Carburettor (Solex 2BE)

Main jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X110

Air correction jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Venturi diameter

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 mm

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 mm

Idle fuel jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.5 mm

Idle air jet

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Float needle valve diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Throttle positioner coil resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.97 to 1.63 ohms

Intake air temperature resistance

-10º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8200 to 10 500 ohms

20º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200 to 2700 ohms

80º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 to 360 ohms

Float level

Stage 1 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.0 to 29.0 mm

Stage 2 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.0 to 31.0 mm

Fuel pressure checks (carburettor engines)

Fuel pump delivery pressure (engine idling) . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.3 bars

Fuel pressure checks (fuel injection engines)

Fuel system pressure (relative to intake manifold pressure)

3-Series (E30)

316i with M40/B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

318i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

320i with M20/B20 engine (L-Jetronic) . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

320i with M20/B20 engine (Motronic) . . . . . . . . . . . . . . . . . . . . . . . 2.5 ± 0.05 bars

325i with M20/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.05 bars

5-Series (E28/”old-shape”)

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

5-Series (E34/”new-shape”)

518i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

All other models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

Fuel system hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bars

Fuel pump maximum pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 to 6.9 bars

Fuel pump hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5 bars

Transfer pump pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.28 to 0.35 bars

Injectors

Injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.5 to 17.5 ohms

Accelerator cable free play . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Torque wrench settingsNm

Carburettor mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel pump to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Throttle body nuts/bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 to 26

4•2 Fuel and exhaust systems

1 General information

With the exception of early models (316 and

518 models) all engines are equipped with

electronic fuel injection.

Early 316 and 518 models are equipped

with Solex carburettors. The carburettor fitted

is either a Solex 2B4 (early models) or

2BE (later models). The mechanical fuel pumpis driven by an eccentric lobe on the

camshaft.

Fuel injection models are equipped with

either the L-Jetronic or the Motronic fuel

injection system. From 1988, fuel injection

models are equipped with an updated version

of the Motronic system - this system is easily

distinguished from the earlier system by the

absence of a cold start injector. The electric

fuel pump is located beneath the rear of the

vehicle, or inside the fuel tank. The fuel pump

relay on Motronic systems is activated from aearth signal from the Motronic control unit

(ECU). The fuel pump operates for a few

seconds when the ignition is first switched on,

and it continues to operate only when the

engine is actually running.Air intake system

The air intake system consists of the air

filter housing, the airflow meter and throttle

body (fuel injection models), and the intake

manifold. All components except the intake

manifold are covered in this Chapter; for

Page 91 of 228

information on removing and refitting the

intake manifold, refer to Chapter 2A.

The throttle valve inside the throttle body or

carburettor is actuated by the accelerator

cable. When you depress the accelerator

pedal, the throttle plate opens and airflow

through the intake system increases.

On fuel injection systems, a flap inside the

airflow meter opens wider as the airflow

increases. A throttle position switch attached

to the pivot shaft of the flap detects the angle

of the flap (how much it’s open) and converts

this to a voltage signal, which it sends to the

computer.

Fuel system

On carburettor models, the fuel pump

supplies fuel under pressure to the

carburettor. A needle valve in the float

chamber maintains the fuel at a constant

level. A fuel return system channels excess

fuel back to the fuel tank.

On fuel injection models, an electric fuel

pump supplies fuel under constant pressure

to the fuel rail, which distributes fuel to the

injectors. The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models

also have a transfer pump located in the fuel

tank. The transfer pump acts as an aid to the

larger main pump for delivering the necessary

pressure. A fuel pressure regulator controls

the pressure in the fuel system. The fuel

system also has a fuel pulsation damper

located near the fuel filter. The damper

reduces the pressure pulsations caused by

fuel pump operation, and the opening and

closing of the injectors. The amount of fuel

injected into the intake ports is precisely

controlled by an Electronic Control Unit (ECU

or computer). Some later 5-Series models

have a fuel cooler in the return line.

Electronic control system (fuel

injection system)

Besides altering the injector opening

duration as described above, the electronic

control unit performs a number of other tasks

related to fuel and emissions control. It

accomplishes these tasks by using data

relayed to it by a wide array of information

sensors located throughout the enginecompartment, comparing this information to

its stored map, and altering engine operation

by controlling a number of different actuators.

Since special equipment is required, most

fault diagnosis and repair of the electronic

control system is beyond the scope of the

home mechanic. Additional information and

testing procedures for the emissions system

components (oxygen sensor, coolant

temperature sensor, EVAP system, etc.) is

contained in Chapter 6.

2 Fuel injection system-

depressurising

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke or allow open flames or bare light

bulbs near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

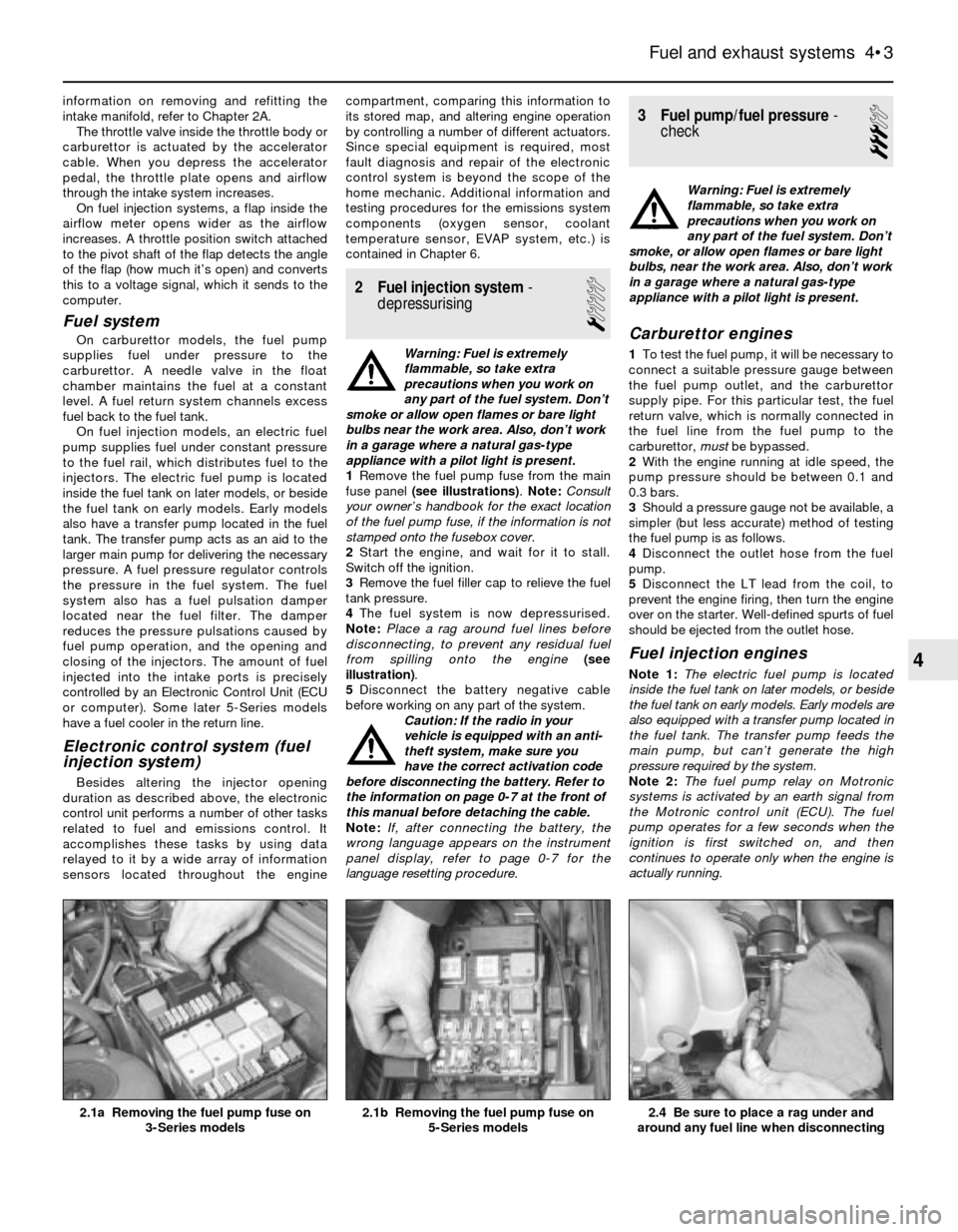

1Remove the fuel pump fuse from the main

fuse panel (see illustrations). Note:Consult

your owner’s handbook for the exact location

of the fuel pump fuse, if the information is not

stamped onto the fusebox cover.

2Start the engine, and wait for it to stall.

Switch off the ignition.

3Remove the fuel filler cap to relieve the fuel

tank pressure.

4The fuel system is now depressurised.

Note:Place a rag around fuel lines before

disconnecting, to prevent any residual fuel

from spilling onto the engine(see

illustration).

5Disconnect the battery negative cable

before working on any part of the system.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3 Fuel pump/fuel pressure-

check

3

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

Carburettor engines

1To test the fuel pump, it will be necessary to

connect a suitable pressure gauge between

the fuel pump outlet, and the carburettor

supply pipe. For this particular test, the fuel

return valve, which is normally connected in

the fuel line from the fuel pump to the

carburettor, mustbe bypassed.

2With the engine running at idle speed, the

pump pressure should be between 0.1 and

0.3 bars.

3Should a pressure gauge not be available, a

simpler (but less accurate) method of testing

the fuel pump is as follows.

4Disconnect the outlet hose from the fuel

pump.

5Disconnect the LT lead from the coil, to

prevent the engine firing, then turn the engine

over on the starter. Well-defined spurts of fuel

should be ejected from the outlet hose.

Fuel injection engines

Note 1:The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models are

also equipped with a transfer pump located in

the fuel tank. The transfer pump feeds the

main pump, but can’t generate the high

pressure required by the system.

Note 2:The fuel pump relay on Motronic

systems is activated by an earth signal from

the Motronic control unit (ECU). The fuel

pump operates for a few seconds when the

ignition is first switched on, and then

continues to operate only when the engine is

actually running.

Fuel and exhaust systems 4•3

2.4 Be sure to place a rag under and

around any fuel line when disconnecting2.1b Removing the fuel pump fuse on

5-Series models2.1a Removing the fuel pump fuse on

3-Series models

4

Page 92 of 228

Note 3:The following checks assume the fuel

filter is in good condition. If you doubt the

condition of your fuel filter, renew it (see

Chapter 1).

Note 4:In order to get accurate test results, it

is recommended that the fuel pressure be

checked from both the main fuel pump and

transfer pump where applicable.

Fuel pump/transfer pump operational

check

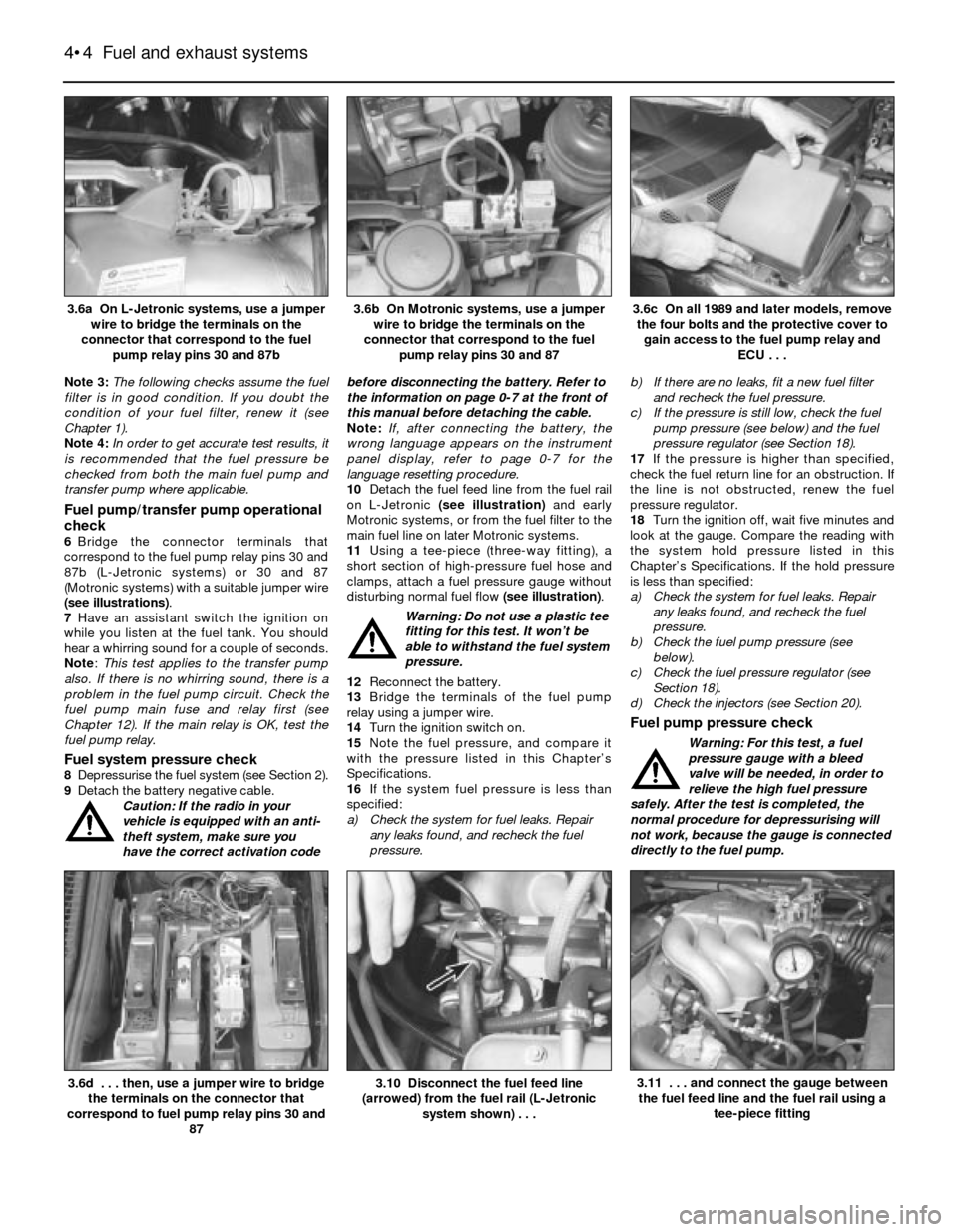

6Bridge the connector terminals that

correspond to the fuel pump relay pins 30 and

87b (L-Jetronic systems) or 30 and 87

(Motronic systems) with a suitable jumper wire

(see illustrations).

7Have an assistant switch the ignition on

while you listen at the fuel tank. You should

hear a whirring sound for a couple of seconds.

Note:This test applies to the transfer pump

also. If there is no whirring sound, there is a

problem in the fuel pump circuit. Check the

fuel pump main fuse and relay first (see

Chapter 12). If the main relay is OK, test the

fuel pump relay.

Fuel system pressure check8Depressurise the fuel system (see Section 2).

9Detach the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation codebefore disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

10Detach the fuel feed line from the fuel rail

on L-Jetronic (see illustration)and early

Motronic systems, or from the fuel filter to the

main fuel line on later Motronic systems.

11Using a tee-piece (three-way fitting), a

short section of high-pressure fuel hose and

clamps, attach a fuel pressure gauge without

disturbing normal fuel flow (see illustration).

Warning: Do not use a plastic tee

fitting for this test. It won’t be

able to withstand the fuel system

pressure.

12Reconnect the battery.

13Bridge the terminals of the fuel pump

relay using a jumper wire.

14Turn the ignition switch on.

15Note the fuel pressure, and compare it

with the pressure listed in this Chapter’s

Specifications.

16If the system fuel pressure is less than

specified:

a) Check the system for fuel leaks. Repair

any leaks found, and recheck the fuel

pressure.b) If there are no leaks, fit a new fuel filter

and recheck the fuel pressure.

c) If the pressure is still low, check the fuel

pump pressure (see below) and the fuel

pressure regulator (see Section 18).

17If the pressure is higher than specified,

check the fuel return line for an obstruction. If

the line is not obstructed, renew the fuel

pressure regulator.

18Turn the ignition off, wait five minutes and

look at the gauge. Compare the reading with

the system hold pressure listed in this

Chapter’s Specifications. If the hold pressure

is less than specified:

a) Check the system for fuel leaks. Repair

any leaks found, and recheck the fuel

pressure.

b) Check the fuel pump pressure (see

below).

c) Check the fuel pressure regulator (see

Section 18).

d) Check the injectors (see Section 20).

Fuel pump pressure check

Warning: For this test, a fuel

pressure gauge with a bleed

valve will be needed, in order to

relieve the high fuel pressure

safely. After the test is completed, the

normal procedure for depressurising will

not work, because the gauge is connected

directly to the fuel pump.

4•4 Fuel and exhaust systems

3.10 Disconnect the fuel feed line

(arrowed) from the fuel rail (L-Jetronic

system shown) . . .3.6d . . . then, use a jumper wire to bridge

the terminals on the connector that

correspond to fuel pump relay pins 30 and

87

3.6c On all 1989 and later models, remove

the four bolts and the protective cover to

gain access to the fuel pump relay and

ECU . . .3.6b On Motronic systems, use a jumper

wire to bridge the terminals on the

connector that correspond to the fuel

pump relay pins 30 and 873.6a On L-Jetronic systems, use a jumper

wire to bridge the terminals on the

connector that correspond to the fuel

pump relay pins 30 and 87b

3.11 . . . and connect the gauge between

the fuel feed line and the fuel rail using a

tee-piece fitting

Page 93 of 228

19Depressurise the fuel system (see Sec-

tion 2).

20Detach the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

21Detach the fuel feed hose from the fuel

rail, and attach a fuel pressure gauge directly

to the hose. Note:If the tee fitting is still

connected to the gauge, be sure to plug the

open end.

22Reconnect the battery.

23Using a jumper wire, bridge the terminals

of the fuel pump relay.

24Turn the ignition switch on to operate the

fuel pump.

25Note the pressure reading on the gauge,

and compare the reading to the fuel pump

pressure listed in this Chapter’s Specifica-

tions.

26If the indicated pressure is less than

specified, inspect the fuel line for leaks

between the pump and gauge. If no leaks are

found, renew the fuel pump.

27Turn the ignition off and wait five minutes.

Note the reading on the gauge, and compare

it to the fuel pump hold pressure listed in this

Chapter’s Specifications. If the hold pressure

is less than specified, check the fuel lines

between the pump and gauge for leaks. If no

leaks are found, renew the fuel pump.

28Remove the jumper wire. Relieve the fuel

pressure by opening the bleed valve on the

gauge and directing the fuel into a suitable

container. Remove the gauge and reconnect

the fuel line.

Transfer pump pressure check

29Depressurise the fuel system (see Sec-

tion 2).

30Detach the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

31Remove the transfer pump access plate

(on some models, it’s located under the rear

seat cushion - on others, it’s located under

the carpet in the luggage compartment).

Disconnect the output hose from the transfer

pump, and connect a fuel pressure gauge to

the outlet pipe.

32Reconnect the battery.33Using a jumper wire, bridge the terminals

of the fuel pump relay.

34Turn the ignition switch on to operate the

fuel pump.

35Note the pressure reading on the gauge,

and compare to the value listed in this

Chapter’s Specifications.

36If the indicated pressure is less than

specified, renew the transfer pump.

Fuel pump relay check

37Switch on the ignition.

38Using a voltmeter, probe the following

terminals from the back of the relay electrical

connector. Check for battery voltage at

terminal 30 (M20 and M30 engines) or

terminal 15 (M10 and M40 engines). Note:If

there is no voltage on models with luggage

compartment-mounted batteries, check for a

faulty fusible link. The 50-amp link is about

6 inches from the battery, in a black wire.

39Turn the ignition off, and disconnect the

relay from the electrical connector. Using a

voltmeter, probe the connector terminals that

correspond to fuel pump relay pins 85 (-) and

86(+) on M20 and M30 engines, or terminal 50

and earth on M10 and M40 engines. Have an

assistant turn the engine over on the starter,

and observe the voltage reading. Battery

voltage should be indicated.

40If there is no voltage, check the fuse(s)

and the wiring circuit for the fuel pump relay. If

the voltage readings are correct, and the fuel

pump only runs with the jumper wire in place,

then renew the relay.

41If the fuel pump still does not run, check

for the proper voltage at the fuel pump

terminals (see Section 4). If necessary, renew

the fuel pump.

4 Fuel pump, transfer pump

and fuel level sender unit-

removal and refitting

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

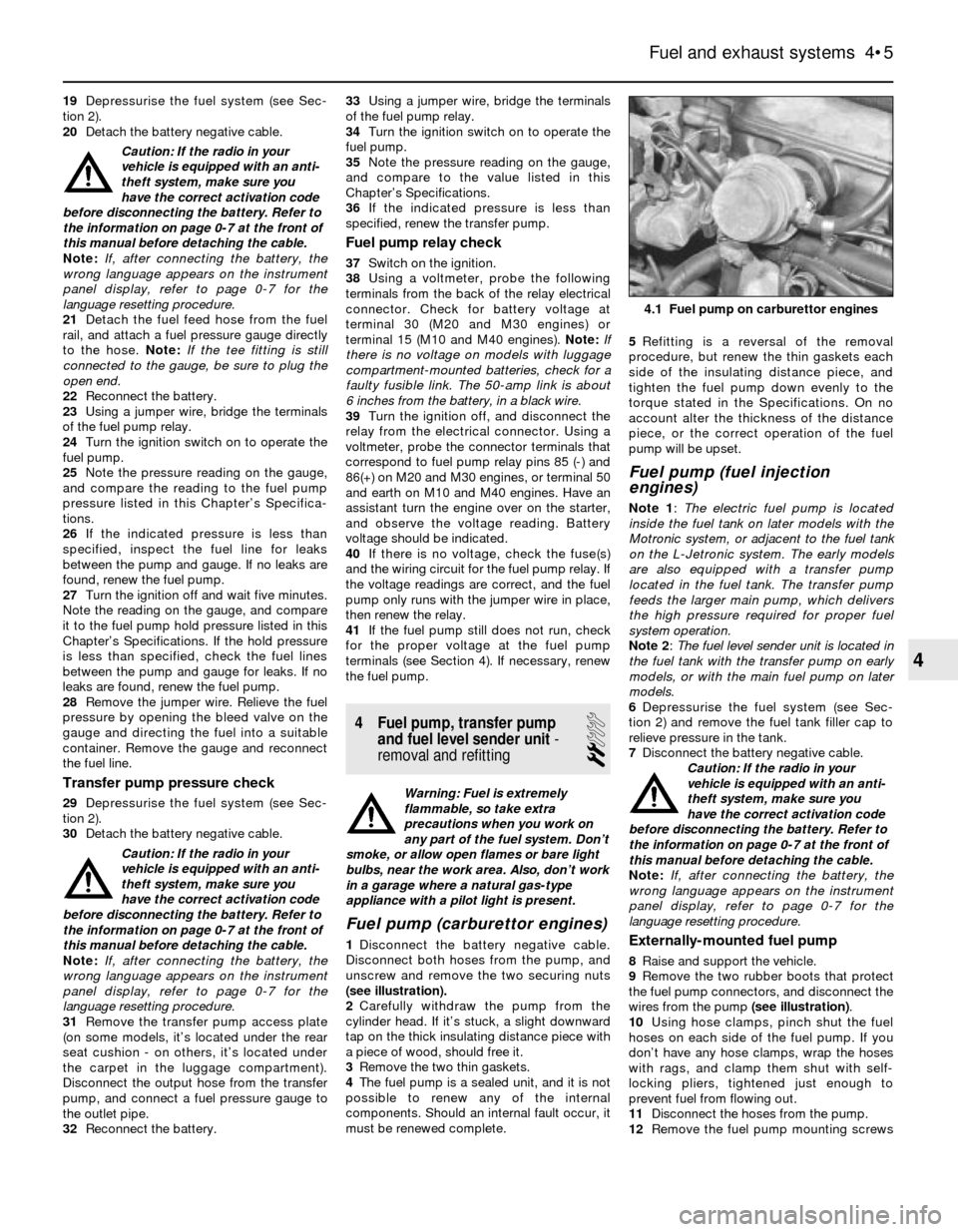

Fuel pump (carburettor engines)

1Disconnect the battery negative cable.

Disconnect both hoses from the pump, and

unscrew and remove the two securing nuts

(see illustration).

2Carefully withdraw the pump from the

cylinder head. If it’s stuck, a slight downward

tap on the thick insulating distance piece with

a piece of wood, should free it.

3Remove the two thin gaskets.

4The fuel pump is a sealed unit, and it is not

possible to renew any of the internal

components. Should an internal fault occur, it

must be renewed complete.5Refitting is a reversal of the removal

procedure, but renew the thin gaskets each

side of the insulating distance piece, and

tighten the fuel pump down evenly to the

torque stated in the Specifications. On no

account alter the thickness of the distance

piece, or the correct operation of the fuel

pump will be upset.

Fuel pump (fuel injection

engines)

Note 1: The electric fuel pump is located

inside the fuel tank on later models with the

Motronic system, or adjacent to the fuel tank

on the L-Jetronic system. The early models

are also equipped with a transfer pump

located in the fuel tank. The transfer pump

feeds the larger main pump, which delivers

the high pressure required for proper fuel

system operation.

Note 2: The fuel level sender unit is located in

the fuel tank with the transfer pump on early

models, or with the main fuel pump on later

models.

6Depressurise the fuel system (see Sec-

tion 2) and remove the fuel tank filler cap to

relieve pressure in the tank.

7Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Externally-mounted fuel pump

8Raise and support the vehicle.

9Remove the two rubber boots that protect

the fuel pump connectors, and disconnect the

wires from the pump (see illustration).

10Using hose clamps, pinch shut the fuel

hoses on each side of the fuel pump. If you

don’t have any hose clamps, wrap the hoses

with rags, and clamp them shut with self-

locking pliers, tightened just enough to

prevent fuel from flowing out.

11Disconnect the hoses from the pump.

12Remove the fuel pump mounting screws

Fuel and exhaust systems 4•5

4.1 Fuel pump on carburettor engines

4

Page 98 of 228

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery. Refer to the

information on page 0-7 at the front of this

manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

8Loosen the cable adjuster locknuts, and

detach the cable from its support bracket

located on the intake manifold (see

illustration).

9Pinch the plastic retainer with a pair of

needle-nose pliers, and push it out of the

bracket (see illustration).10Pull the cable down through the slot and

away from the bracket (see illustrations).

11Working from underneath the driver’s side

of the facia, reach up and detach the

accelerator cable from the top of the pedal.

12Pull the cable through the bulkhead, from

the engine compartment side.

13Refitting is the reverse of removal. Adjust

the cable as described earlier.

10 Carburettor-

general information

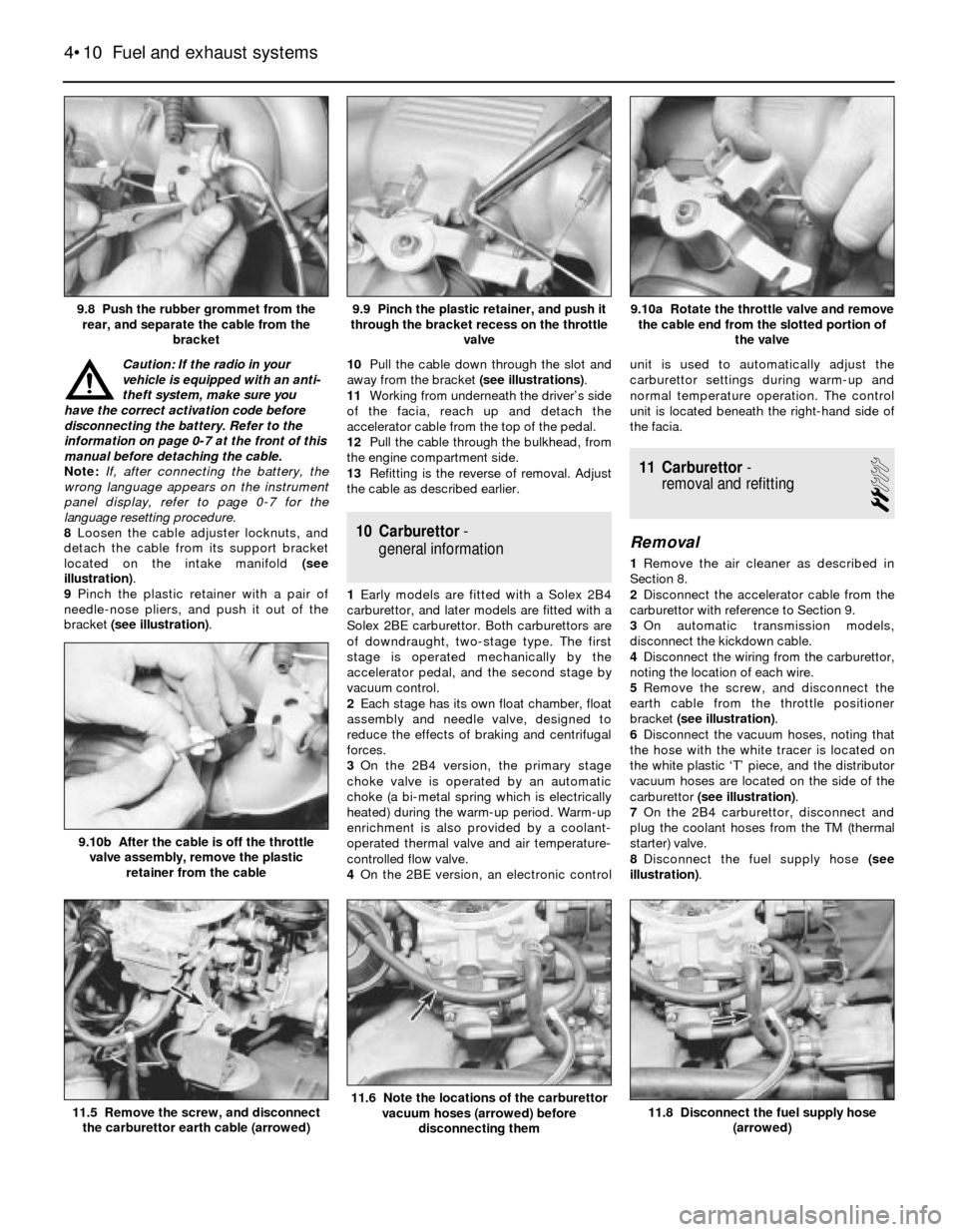

1Early models are fitted with a Solex 2B4

carburettor, and later models are fitted with a

Solex 2BE carburettor. Both carburettors are

of downdraught, two-stage type. The first

stage is operated mechanically by the

accelerator pedal, and the second stage by

vacuum control.

2Each stage has its own float chamber, float

assembly and needle valve, designed to

reduce the effects of braking and centrifugal

forces.

3On the 2B4 version, the primary stage

choke valve is operated by an automatic

choke (a bi-metal spring which is electrically

heated) during the warm-up period. Warm-up

enrichment is also provided by a coolant-

operated thermal valve and air temperature-

controlled flow valve.

4On the 2BE version, an electronic controlunit is used to automatically adjust the

carburettor settings during warm-up and

normal temperature operation. The control

unit is located beneath the right-hand side of

the facia.

11 Carburettor-

removal and refitting

2

Removal

1Remove the air cleaner as described in

Section 8.

2Disconnect the accelerator cable from the

carburettor with reference to Section 9.

3On automatic transmission models,

disconnect the kickdown cable.

4Disconnect the wiring from the carburettor,

noting the location of each wire.

5Remove the screw, and disconnect the

earth cable from the throttle positioner

bracket (see illustration).

6Disconnect the vacuum hoses, noting that

the hose with the white tracer is located on

the white plastic ‘T’ piece, and the distributor

vacuum hoses are located on the side of the

carburettor (see illustration).

7On the 2B4 carburettor, disconnect and

plug the coolant hoses from the TM (thermal

starter) valve.

8Disconnect the fuel supply hose (see

illustration).

4•10 Fuel and exhaust systems

11.8 Disconnect the fuel supply hose

(arrowed)11.6 Note the locations of the carburettor

vacuum hoses (arrowed) before

disconnecting them11.5 Remove the screw, and disconnect

the carburettor earth cable (arrowed)

9.10b After the cable is off the throttle

valve assembly, remove the plastic

retainer from the cable

9.10a Rotate the throttle valve and remove

the cable end from the slotted portion of

the valve9.9 Pinch the plastic retainer, and push it

through the bracket recess on the throttle

valve9.8 Push the rubber grommet from the

rear, and separate the cable from the

bracket