drain bolt BMW 3 SERIES 1983 E30 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1983, Model line: 3 SERIES, Model: BMW 3 SERIES 1983 E30Pages: 228, PDF Size: 7.04 MB

Page 157 of 228

21 Steering box (5-Series)-

removal and refitting

4

Removal

Note:If you find that the steering box is

defective, it is not recommended that you

overhaul it. Because of the special tools

needed to do the job, it is best to let your

dealer service department overhaul it for you

(otherwise, fit a new unit). Removal and

refitting the steering box is outlined here.

1On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times.

2Using a large syringe or hand pump, empty

the power steering fluid reservoir (see Chap-

ter 1).

3Raise the front of the vehicle and support it

securely on axle stands.

4Support the front of the engine with a trolley

jack. Place a block of wood between the jack

head and the sump to protect the sump from

damage.

5Remove the pivot bolts from the inner ends

of the front control arms (see Section 4).

6Remove the nuts from the left and right

engine mountings (see Chapter 2).

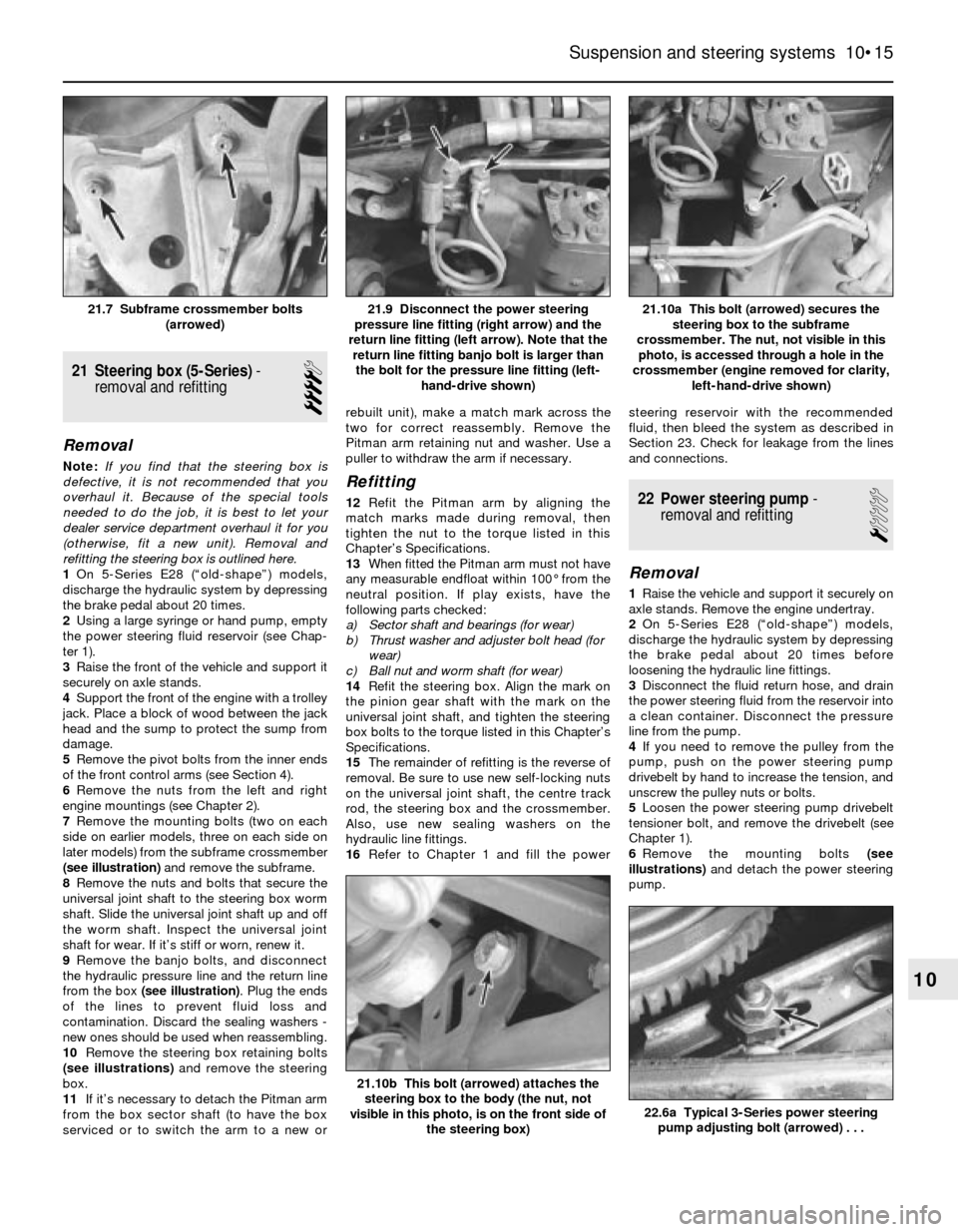

7Remove the mounting bolts (two on each

side on earlier models, three on each side on

later models) from the subframe crossmember

(see illustration)and remove the subframe.

8Remove the nuts and bolts that secure the

universal joint shaft to the steering box worm

shaft. Slide the universal joint shaft up and off

the worm shaft. Inspect the universal joint

shaft for wear. If it’s stiff or worn, renew it.

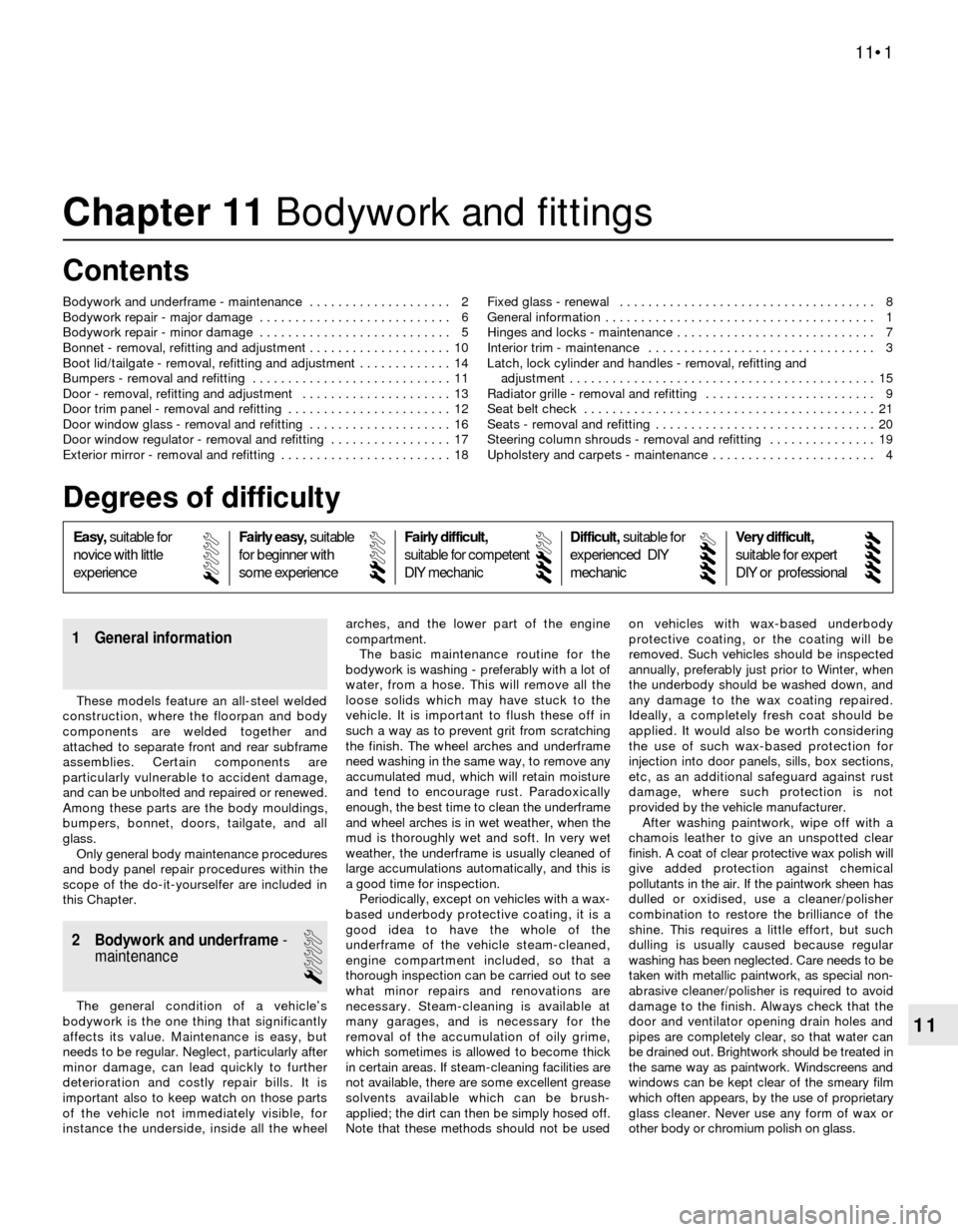

9Remove the banjo bolts, and disconnect

the hydraulic pressure line and the return line

from the box (see illustration). Plug the ends

of the lines to prevent fluid loss and

contamination. Discard the sealing washers -

new ones should be used when reassembling.

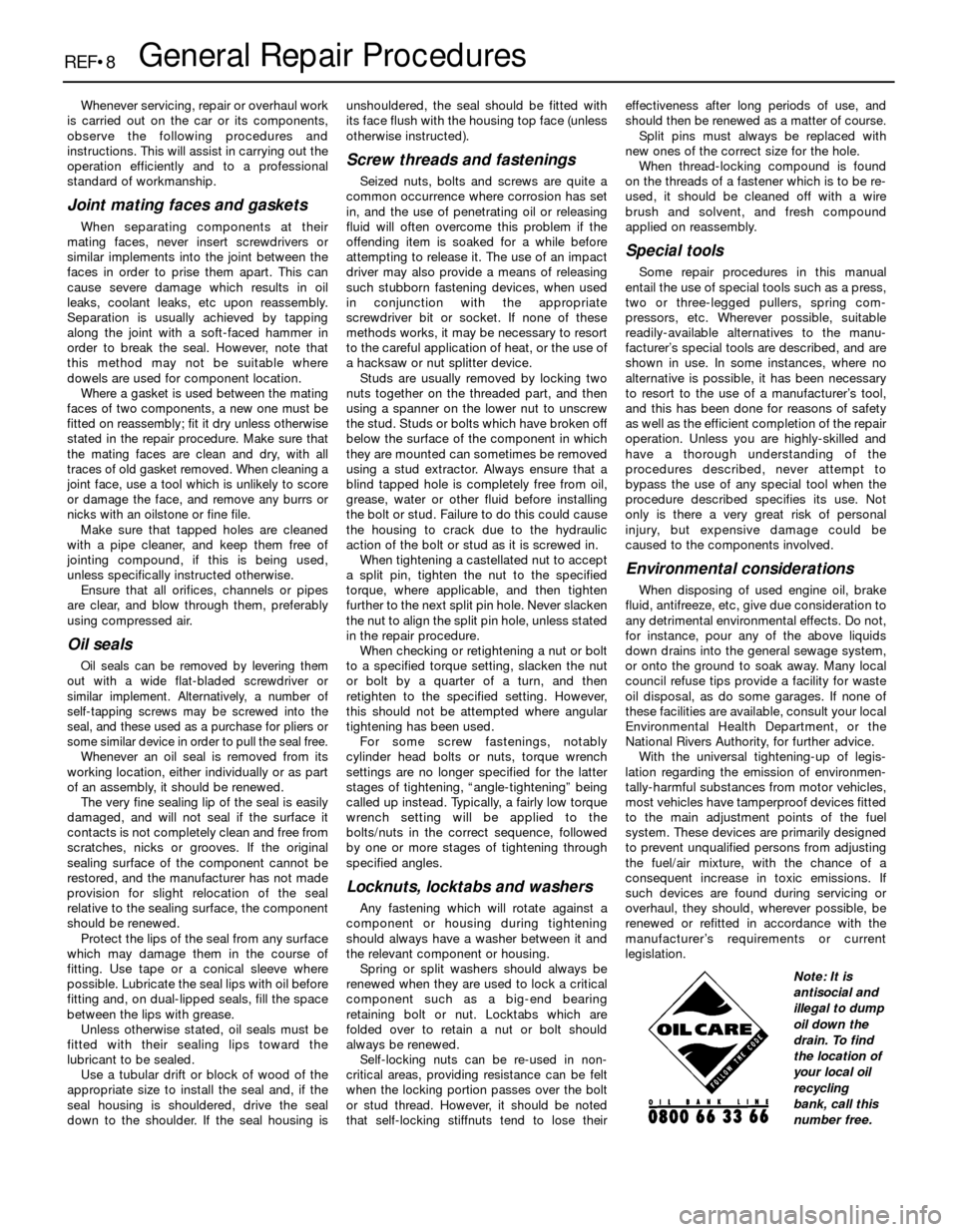

10Remove the steering box retaining bolts

(see illustrations)and remove the steering

box.

11If it’s necessary to detach the Pitman arm

from the box sector shaft (to have the box

serviced or to switch the arm to a new orrebuilt unit), make a match mark across the

two for correct reassembly. Remove the

Pitman arm retaining nut and washer. Use a

puller to withdraw the arm if necessary.

Refitting

12Refit the Pitman arm by aligning the

match marks made during removal, then

tighten the nut to the torque listed in this

Chapter’s Specifications.

13When fitted the Pitman arm must not have

any measurable endfloat within 100° from the

neutral position. If play exists, have the

following parts checked:

a) Sector shaft and bearings (for wear)

b) Thrust washer and adjuster bolt head (for

wear)

c) Ball nut and worm shaft (for wear)

14Refit the steering box. Align the mark on

the pinion gear shaft with the mark on the

universal joint shaft, and tighten the steering

box bolts to the torque listed in this Chapter’s

Specifications.

15The remainder of refitting is the reverse of

removal. Be sure to use new self-locking nuts

on the universal joint shaft, the centre track

rod, the steering box and the crossmember.

Also, use new sealing washers on the

hydraulic line fittings.

16Refer to Chapter 1 and fill the powersteering reservoir with the recommended

fluid, then bleed the system as described in

Section 23. Check for leakage from the lines

and connections.22 Power steering pump-

removal and refitting

1

Removal

1Raise the vehicle and support it securely on

axle stands. Remove the engine undertray.

2On 5-Series E28 (“old-shape”) models,

discharge the hydraulic system by depressing

the brake pedal about 20 times before

loosening the hydraulic line fittings.

3Disconnect the fluid return hose, and drain

the power steering fluid from the reservoir into

a clean container. Disconnect the pressure

line from the pump.

4If you need to remove the pulley from the

pump, push on the power steering pump

drivebelt by hand to increase the tension, and

unscrew the pulley nuts or bolts.

5Loosen the power steering pump drivebelt

tensioner bolt, and remove the drivebelt (see

Chapter 1).

6Remove the mounting bolts (see

illustrations)and detach the power steering

pump.

Suspension and steering systems 10•15

21.10a This bolt (arrowed) secures the

steering box to the subframe

crossmember. The nut, not visible in this

photo, is accessed through a hole in the

crossmember (engine removed for clarity,

left-hand-drive shown)21.9 Disconnect the power steering

pressure line fitting (right arrow) and the

return line fitting (left arrow). Note that the

return line fitting banjo bolt is larger than

the bolt for the pressure line fitting (left-

hand-drive shown)21.7 Subframe crossmember bolts

(arrowed)

22.6a Typical 3-Series power steering

pump adjusting bolt (arrowed) . . .

21.10b This bolt (arrowed) attaches the

steering box to the body (the nut, not

visible in this photo, is on the front side of

the steering box)

10

Page 160 of 228

11

1 General information

These models feature an all-steel welded

construction, where the floorpan and body

components are welded together and

attached to separate front and rear subframe

assemblies. Certain components are

particularly vulnerable to accident damage,

and can be unbolted and repaired or renewed.

Among these parts are the body mouldings,

bumpers, bonnet, doors, tailgate, and all

glass.

Only general body maintenance procedures

and body panel repair procedures within the

scope of the do-it-yourselfer are included in

this Chapter.

2 Bodywork and underframe-

maintenance

1

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheelarches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be usedon vehicles with wax-based underbody

protective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to be

taken with metallic paintwork, as special non-

abrasive cleaner/polisher is required to avoid

damage to the finish. Always check that the

door and ventilator opening drain holes and

pipes are completely clear, so that water can

be drained out. Brightwork should be treated in

the same way as paintwork. Windscreens and

windows can be kept clear of the smeary film

which often appears, by the use of proprietary

glass cleaner. Never use any form of wax or

other body or chromium polish on glass.

Chapter 11 Bodywork and fittings

Bodywork and underframe - maintenance . . . . . . . . . . . . . . . . . . . . 2

Bodywork repair - major damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bodywork repair - minor damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 10

Boot lid/tailgate - removal, refitting and adjustment . . . . . . . . . . . . . 14

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Door - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . 13

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 12

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 16

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 17

Exterior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 18Fixed glass - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hinges and locks - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interior trim - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Latch, lock cylinder and handles - removal, refitting and

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 9

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steering column shrouds - removal and refitting . . . . . . . . . . . . . . . 19

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . 4

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty Contents

Page 209 of 228

REF•8General Repair Procedures

Whenever servicing, repair or overhaul work

is carried out on the car or its components,

observe the following procedures and

instructions. This will assist in carrying out the

operation efficiently and to a professional

standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that

this method may not be suitable where

dowels are used for component location.

Where a gasket is used between the mating

faces of two components, a new one must be

fitted on reassembly; fit it dry unless otherwise

stated in the repair procedure. Make sure that

the mating faces are clean and dry, with all

traces of old gasket removed. When cleaning a

joint face, use a tool which is unlikely to score

or damage the face, and remove any burrs or

nicks with an oilstone or fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used,

unless specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar implement. Alternatively, a number of

self-tapping screws may be screwed into the

seal, and these used as a purchase for pliers or

some similar device in order to pull the seal free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves. If the original

sealing surface of the component cannot be

restored, and the manufacturer has not made

provision for slight relocation of the seal

relative to the sealing surface, the component

should be renewed.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing isunshouldered, the seal should be fitted with

its face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew

the stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a stud extractor. Always ensure that a

blind tapped hole is completely free from oil,

grease, water or other fluid before installing

the bolt or stud. Failure to do this could cause

the housing to crack due to the hydraulic

action of the bolt or stud as it is screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never slacken

the nut to align the split pin hole, unless stated

in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably

cylinder head bolts or nuts, torque wrench

settings are no longer specified for the latter

stages of tightening, “angle-tightening” being

called up instead. Typically, a fairly low torque

wrench setting will be applied to the

bolts/nuts in the correct sequence, followed

by one or more stages of tightening through

specified angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing during tightening

should always have a washer between it and

the relevant component or housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt

or stud thread. However, it should be noted

that self-locking stiffnuts tend to lose theireffectiveness after long periods of use, and

should then be renewed as a matter of course.

Split pins must always be replaced with

new ones of the correct size for the hole.

When thread-locking compound is found

on the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring com-

pressors, etc. Wherever possible, suitable

readily-available alternatives to the manu-

facturer’s special tools are described, and are

shown in use. In some instances, where no

alternative is possible, it has been necessary

to resort to the use of a manufacturer’s tool,

and this has been done for reasons of safety

as well as the efficient completion of the repair

operation. Unless you are highly-skilled and

have a thorough understanding of the

procedures described, never attempt to

bypass the use of any special tool when the

procedure described specifies its use. Not

only is there a very great risk of personal

injury, but expensive damage could be

caused to the components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department, or the

National Rivers Authority, for further advice.

With the universal tightening-up of legis-

lation regarding the emission of environmen-

tally-harmful substances from motor vehicles,

most vehicles have tamperproof devices fitted

to the main adjustment points of the fuel

system. These devices are primarily designed

to prevent unqualified persons from adjusting

the fuel/air mixture, with the chance of a

consequent increase in toxic emissions. If

such devices are found during servicing or

overhaul, they should, wherever possible, be

renewed or refitted in accordance with the

manufacturer’s requirements or current

legislation.

Note: It is

antisocial and

illegal to dump

oil down the

drain. To find

the location of

your local oil

recycling

bank, call this

number free.

Page 211 of 228

REF•10Fault Finding

Engine will not rotate when attempting to start

m mBattery terminal connections loose or corroded (Chapter 1).

m mBattery discharged or faulty (Chapter 1).

m mAutomatic transmission not completely engaged in Park (Chap-

ter 7B) or (on models with a clutch switch) clutch not completely

depressed (Chapter 8).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapters 5 and 12).

m mStarter motor pinion jammed in flywheel ring gear (Chapter 5).

m mStarter solenoid faulty (Chapter 5).

m mStarter motor faulty (Chapter 5).

m mIgnition switch faulty (Chapter 12).

m mStarter pinion or flywheel teeth worn or broken (Chapter 5).

m mEngine internal problem (Chapter 2B).

Engine rotates, but will not start

m

mFuel tank empty.

m mBattery discharged (engine rotates slowly) (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mLeaking fuel injector(s), faulty fuel pump, pressure regulator, etc

(Chapter 4).

m mFuel not reaching fuel injection system or carburettor (Chapter 4).

m mIgnition components damp or damaged (Chapter 5).

m mFuel injector stuck open (Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

m mLoose distributor mounting bolts causing ignition timing to wander

(Chapters 1 and 5).

m mBroken, loose or disconnected wires at the ignition coil, or faulty

coil (Chapter 5).

Engine hard to start when cold

m mBattery discharged (Chapter 1).

m mFuel system malfunctioning (Chapter 4).

m mInjector(s) leaking or carburettor automatic choke faulty (Chap-

ter 4).

m mDistributor rotor carbon-tracked (Chapter 5).

Engine hard to start when hot

m

mAir filter element clogged (Chapter 1).

m mFuel not reaching the fuel injection system or carburettor (Chap-

ter 4).

m mCorroded battery connections, especially earth (negative)

connection (Chapter 1).

Starter motor noisy or excessively-rough in

engagement

m mPinion or flywheel gear teeth worn or broken (Chapter 5).

m mStarter motor mounting bolts loose or missing (Chapter 5).

Engine starts, but stops immediately

m

mLoose or faulty electrical connections at distributor, coil or

alternator (Chapter 5).

m mInsufficient fuel reaching the fuel injector(s) or carburettor

(Chapters 1 and 4).

m mDamaged fuel injection system speed sensors (Chapter 5).

m mFaulty fuel injection relays (Chapter 5).

Oil puddle under engine

m

mOil sump gasket and/or sump drain plug seal leaking (Chapter 2).

m mOil pressure sender unit leaking (Chapter 2).

m mValve cover gaskets leaking (Chapter 2).

m mEngine oil seals leaking (Chapter 2).

Engine idles erratically

m

mVacuum leakage (Chapter 4).

m mAir filter element clogged (Chapter 1).

m mFuel pump not delivering sufficient fuel to the fuel injection system

or carburettor (Chapter 4).

m mLeaking head gasket (Chapter 2).

m mTiming belt/chain and/or sprockets worn (Chapter 2).

m mCamshaft lobes worn (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6). This Section provides an easy-reference guide to the more

common problems which may occur during the operation of your

vehicle. These problems and their possible causes are grouped under

headings denoting various components or systems, such as Engine,

Cooling system, etc. They also refer you to the Chapter and/or

Section which deals with the problem.

Remember that successful fault diagnosis is not a mysterious

black art practised only by professional mechanics. It is simply the

result of the right knowledge combined with an intelligent, systematic

approach to the problem. Always work by a process of elimination,

starting with the simplest solution and working through to the mostcomplex - and never overlook the obvious. Anyone can run the fuel

tank dry or leave the lights on overnight, so don’t assume that you are

exempt from such oversights.

Finally, always establish a clear idea of why a problem has

occurred, and take steps to ensure that it doesn’t happen again. If the

electrical system fails because of a poor connection, check all other

connections in the system to make sure that they don’t fail as well. If a

particular fuse continues to blow, find out why - don’t just renew one

fuse after another. Remember, failure of a small component can often

be indicative of potential failure or incorrect functioning of a more

important component or system.

Engine

Page 213 of 228

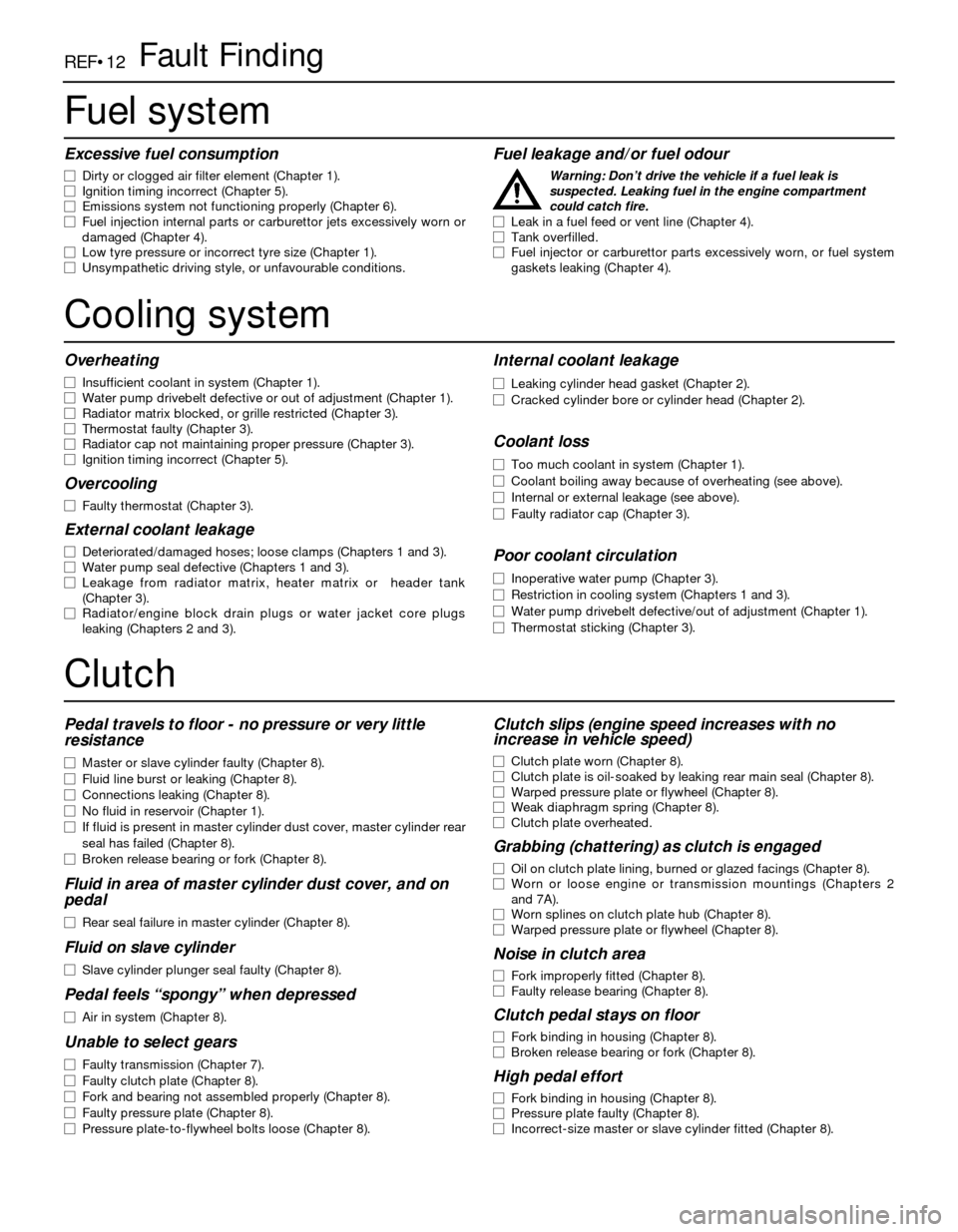

REF•12Fault Finding

Fuel system

Excessive fuel consumption

m mDirty or clogged air filter element (Chapter 1).

m mIgnition timing incorrect (Chapter 5).

m mEmissions system not functioning properly (Chapter 6).

m mFuel injection internal parts or carburettor jets excessively worn or

damaged (Chapter 4).

m mLow tyre pressure or incorrect tyre size (Chapter 1).

m mUnsympathetic driving style, or unfavourable conditions.

Fuel leakage and/or fuel odour

Warning: Don’t drive the vehicle if a fuel leak is

suspected. Leaking fuel in the engine compartment

could catch fire.

m mLeak in a fuel feed or vent line (Chapter 4).

m mTank overfilled.

m mFuel injector or carburettor parts excessively worn, or fuel system

gaskets leaking (Chapter 4).

Cooling system

Overheating

m mInsufficient coolant in system (Chapter 1).

m mWater pump drivebelt defective or out of adjustment (Chapter 1).

m mRadiator matrix blocked, or grille restricted (Chapter 3).

m mThermostat faulty (Chapter 3).

m mRadiator cap not maintaining proper pressure (Chapter 3).

m mIgnition timing incorrect (Chapter 5).

Overcooling

m

mFaulty thermostat (Chapter 3).

External coolant leakage

m

mDeteriorated/damaged hoses; loose clamps (Chapters 1 and 3).

m mWater pump seal defective (Chapters 1 and 3).

m mLeakage from radiator matrix, heater matrix or header tank

(Chapter 3).

m mRadiator/engine block drain plugs or water jacket core plugs

leaking (Chapters 2 and 3).

Internal coolant leakage

m mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder bore or cylinder head (Chapter 2).

Coolant loss

m

mToo much coolant in system (Chapter 1).

m mCoolant boiling away because of overheating (see above).

m mInternal or external leakage (see above).

m mFaulty radiator cap (Chapter 3).

Poor coolant circulation

m

mInoperative water pump (Chapter 3).

m mRestriction in cooling system (Chapters 1 and 3).

m mWater pump drivebelt defective/out of adjustment (Chapter 1).

m mThermostat sticking (Chapter 3).

Clutch

Pedal travels to floor - no pressure or very little

resistance

m mMaster or slave cylinder faulty (Chapter 8).

m mFluid line burst or leaking (Chapter 8).

m mConnections leaking (Chapter 8).

m mNo fluid in reservoir (Chapter 1).

m mIf fluid is present in master cylinder dust cover, master cylinder rear

seal has failed (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

Fluid in area of master cylinder dust cover, and on

pedal

m mRear seal failure in master cylinder (Chapter 8).

Fluid on slave cylinder

m

mSlave cylinder plunger seal faulty (Chapter 8).

Pedal feels “spongy” when depressed

m

mAir in system (Chapter 8).

Unable to select gears

m

mFaulty transmission (Chapter 7).

m mFaulty clutch plate (Chapter 8).

m mFork and bearing not assembled properly (Chapter 8).

m mFaulty pressure plate (Chapter 8).

m mPressure plate-to-flywheel bolts loose (Chapter 8).

Clutch slips (engine speed increases with no

increase in vehicle speed)

m mClutch plate worn (Chapter 8).

m mClutch plate is oil-soaked by leaking rear main seal (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

m mWeak diaphragm spring (Chapter 8).

m mClutch plate overheated.

Grabbing (chattering) as clutch is engaged

m

mOil on clutch plate lining, burned or glazed facings (Chapter 8).

m mWorn or loose engine or transmission mountings (Chapters 2

and 7A).

m mWorn splines on clutch plate hub (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

Noise in clutch area

m

mFork improperly fitted (Chapter 8).

m mFaulty release bearing (Chapter 8).

Clutch pedal stays on floor

m

mFork binding in housing (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

High pedal effort

m

mFork binding in housing (Chapter 8).

m mPressure plate faulty (Chapter 8).

m mIncorrect-size master or slave cylinder fitted (Chapter 8).