Chapter 2 BMW 3 SERIES 1984 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1984, Model line: 3 SERIES, Model: BMW 3 SERIES 1984 E30Pages: 228, PDF Size: 7.04 MB

Page 171 of 228

indicates that the direction indicator and/or

hazard fuse has blown, check the wiring for a

short-circuit before fitting a new fuse.

4Make sure that the new unit is identical to

the original. Compare the old one to the new

one before fitting it.

5Refitting is the reverse of removal.

6 Steering column switches-

removal and refitting

1

Warning: Some later models are

equipped with an airbag or

Supplemental Restraint System

(SRS). To avoid possible damage

to this system, the manufacturer

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department, or

other specialist, because of the special

tools and techniques required. There is a

risk of injury if the airbag is accidentally

triggered.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable,

remove the steering wheel (see Chapter 10)

and steering column shrouds (see Chapter 11).

Direction indicator/headlight

switch

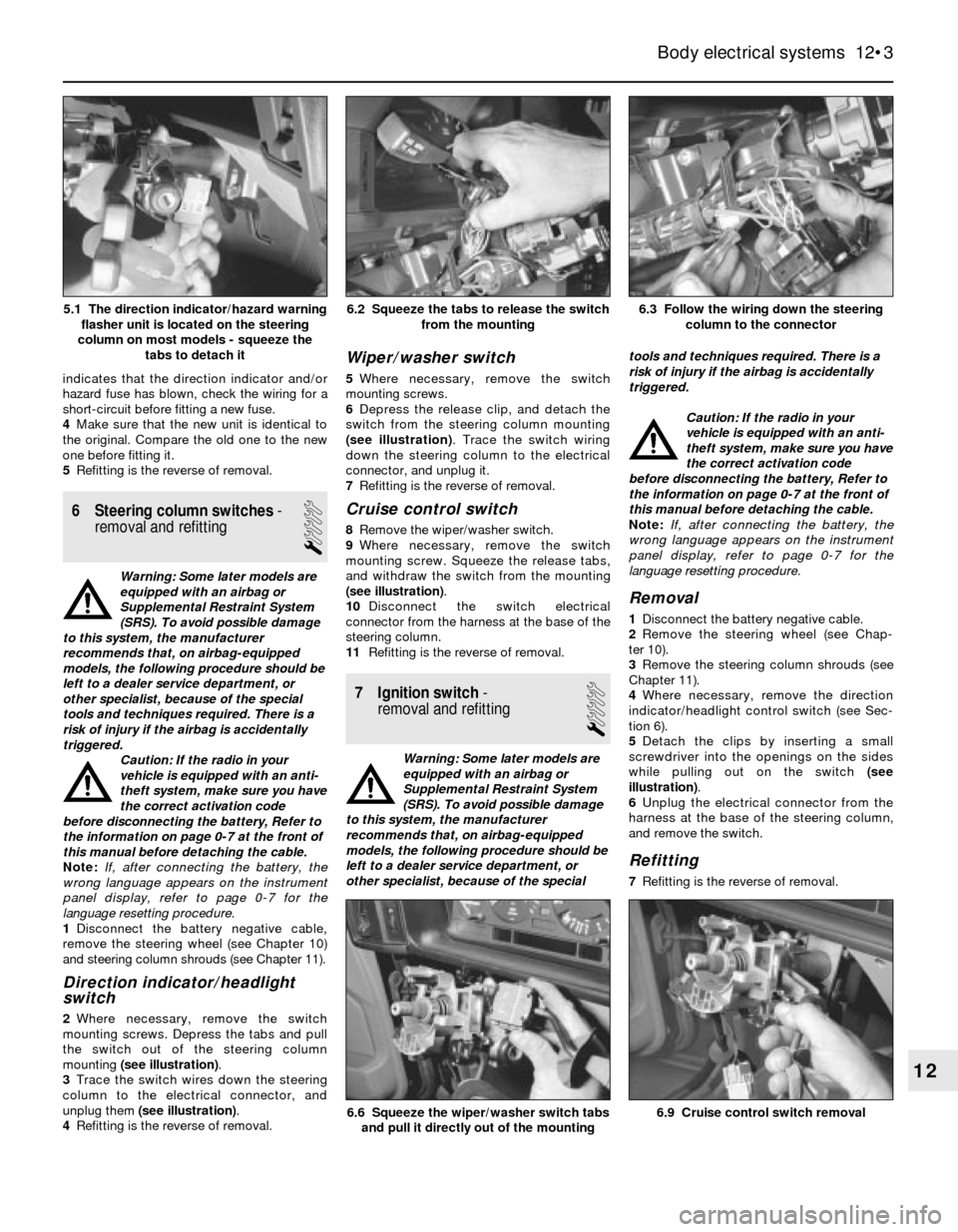

2Where necessary, remove the switch

mounting screws. Depress the tabs and pull

the switch out of the steering column

mounting (see illustration).

3Trace the switch wires down the steering

column to the electrical connector, and

unplug them (see illustration).

4Refitting is the reverse of removal.

Wiper/washer switch

5Where necessary, remove the switch

mounting screws.

6Depress the release clip, and detach the

switch from the steering column mounting

(see illustration). Trace the switch wiring

down the steering column to the electrical

connector, and unplug it.

7Refitting is the reverse of removal.

Cruise control switch

8Remove the wiper/washer switch.

9Where necessary, remove the switch

mounting screw. Squeeze the release tabs,

and withdraw the switch from the mounting

(see illustration).

10Disconnect the switch electrical

connector from the harness at the base of the

steering column.

11Refitting is the reverse of removal.

7 Ignition switch-

removal and refitting

1

Warning: Some later models are

equipped with an airbag or

Supplemental Restraint System

(SRS). To avoid possible damage

to this system, the manufacturer

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department, or

other specialist, because of the specialtools and techniques required. There is a

risk of injury if the airbag is accidentally

triggered.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Remove the steering wheel (see Chap-

ter 10).

3Remove the steering column shrouds (see

Chapter 11).

4Where necessary, remove the direction

indicator/headlight control switch (see Sec-

tion 6).

5Detach the clips by inserting a small

screwdriver into the openings on the sides

while pulling out on the switch (see

illustration).

6Unplug the electrical connector from the

harness at the base of the steering column,

and remove the switch.

Refitting

7Refitting is the reverse of removal.

Body electrical systems 12•3

6.3 Follow the wiring down the steering

column to the connector6.2 Squeeze the tabs to release the switch

from the mounting

6.9 Cruise control switch removal6.6 Squeeze the wiper/washer switch tabs

and pull it directly out of the mounting

12

5.1 The direction indicator/hazard warning

flasher unit is located on the steering

column on most models - squeeze the

tabs to detach it

Page 172 of 228

8 Radio- removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2The radios on most models are held in place

by internal clips which are usually located at

the sides or corners of the unit faceplate.

Removal requires a special tool which is

inserted into the holes to release the clips so

the radio can be pulled out. These tools can be

fabricated from heavy wire, or are available

from your dealer or a car audio specialist. On

anti-theft radios, the clips are moved in and

out by internal screws which require another

type of tool. Insert the tool into the holes until

the clips release, then withdraw the radio from

the dash panel. Disconnect the wiring from the

radio and remove it.3On some models, the radio is held in place

by screws located beneath the faceplate. The

control knobs must be pulled off before the

faceplate can be withdrawn.

Refitting

4Refitting is the reverse of removal.

9 Aerial- removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Use circlip pliers to unscrew the aerial

mounting nut.

3Open the boot lid/tailgate and remove the

left side trim panel. On some models, the jack

and tail light cluster cover will have to be

removed first.

4Unplug the aerial power and radio lead

connectors (as applicable), remove the

retaining bolts, and remove the aerial and

motor assembly.

Refitting

5Refitting is the reverse of removal.

10 Instrument cluster-

removal and refitting

2

Caution: The instrument cluster

and components are very

susceptible to damage from

static electricity. Make sure you

are earthed and have dischargedany static electricity (by touching an object

such as a metal water pipe) before

touching the cluster or components.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2As necessary, remove the steering column

shrouds and lower trim panel (see Chap-

ter 11).

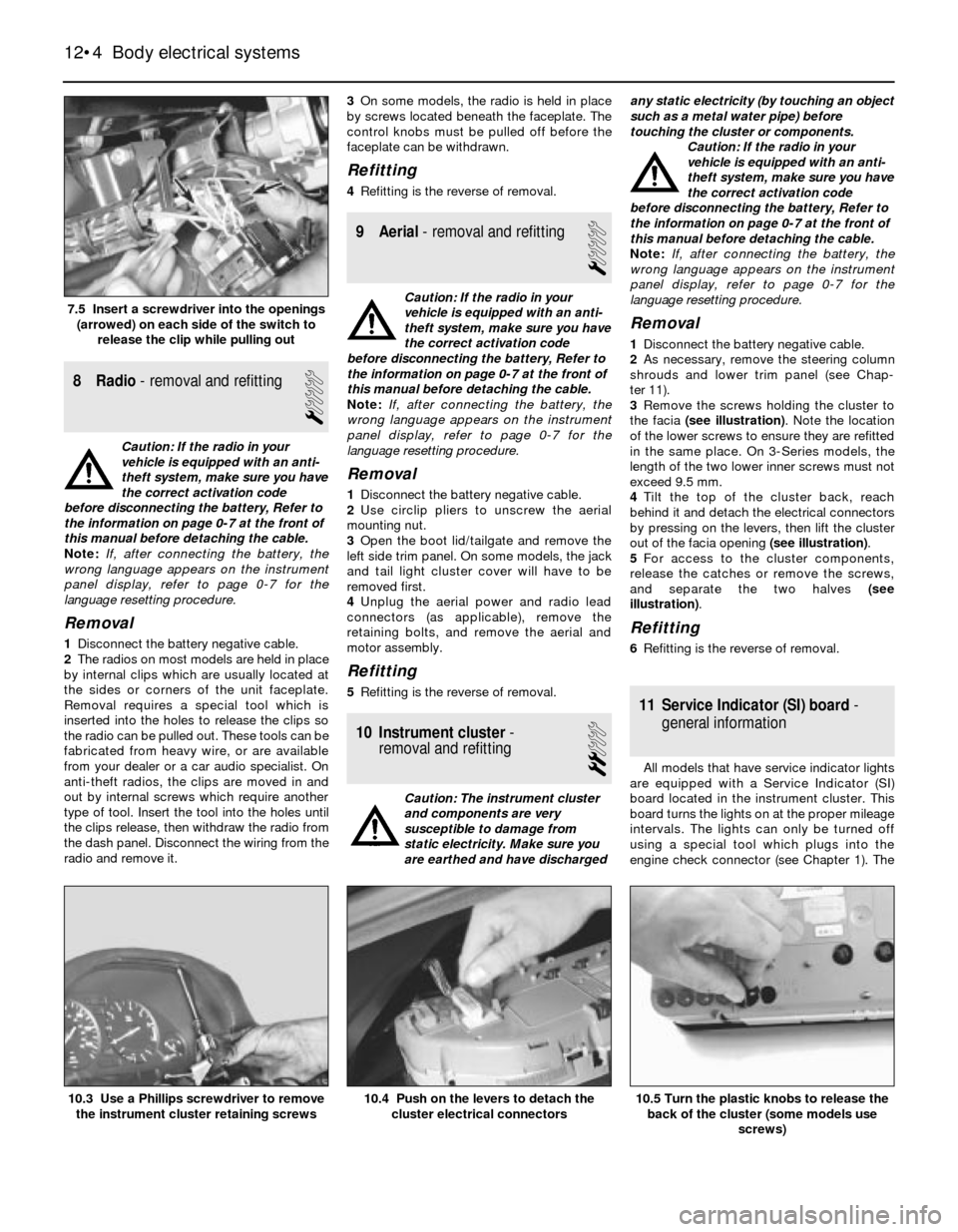

3Remove the screws holding the cluster to

the facia (see illustration). Note the location

of the lower screws to ensure they are refitted

in the same place. On 3-Series models, the

length of the two lower inner screws must not

exceed 9.5 mm.

4Tilt the top of the cluster back, reach

behind it and detach the electrical connectors

by pressing on the levers, then lift the cluster

out of the facia opening (see illustration).

5For access to the cluster components,

release the catches or remove the screws,

and separate the two halves (see

illustration).

Refitting

6Refitting is the reverse of removal.

11 Service Indicator (SI) board-

general information

All models that have service indicator lights

are equipped with a Service Indicator (SI)

board located in the instrument cluster. This

board turns the lights on at the proper mileage

intervals. The lights can only be turned off

using a special tool which plugs into the

engine check connector (see Chapter 1). The

12•4 Body electrical systems

10.5 Turn the plastic knobs to release the

back of the cluster (some models use

screws)10.4 Push on the levers to detach the

cluster electrical connectors10.3 Use a Phillips screwdriver to remove

the instrument cluster retaining screws

7.5 Insert a screwdriver into the openings

(arrowed) on each side of the switch to

release the clip while pulling out

Page 173 of 228

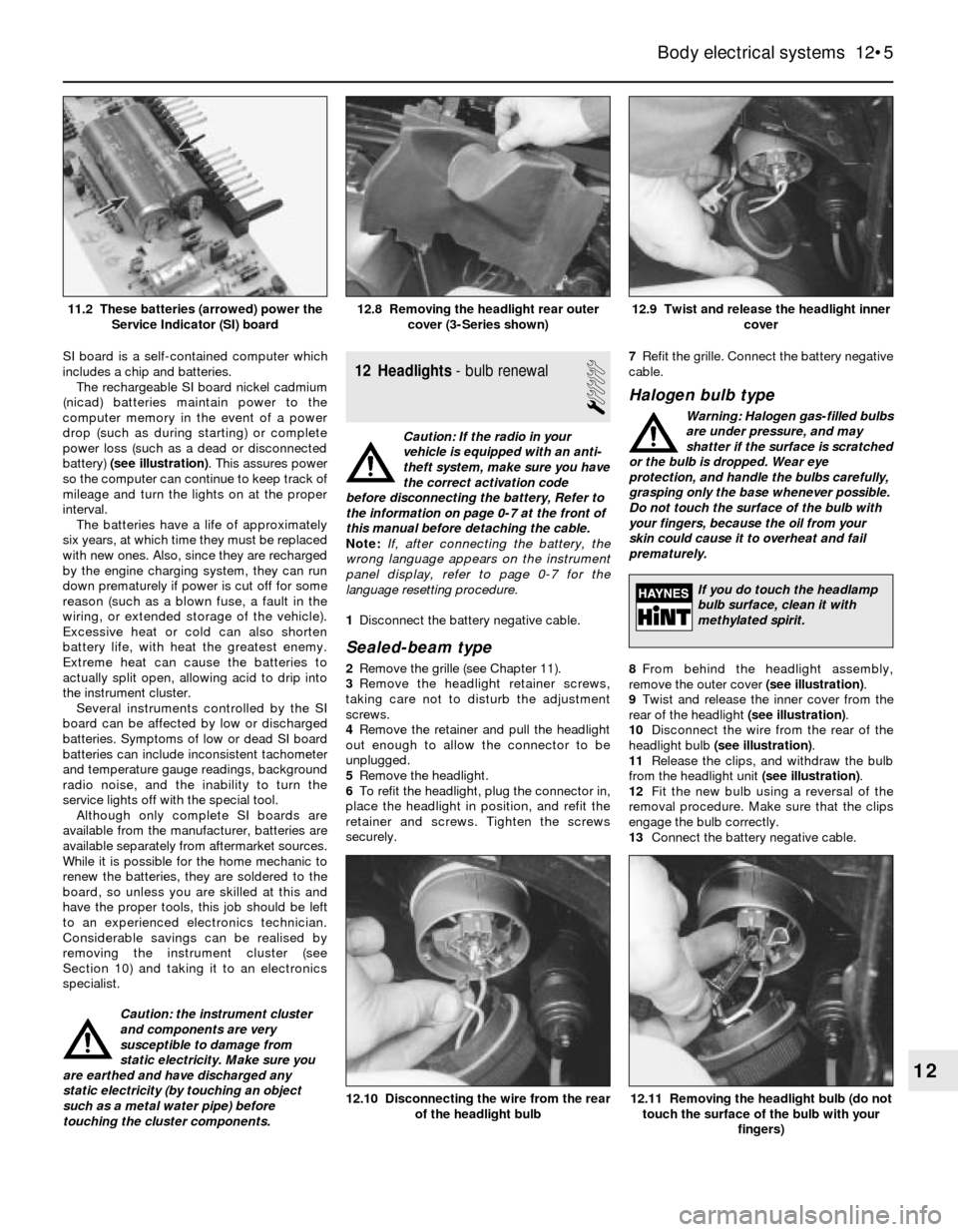

SI board is a self-contained computer which

includes a chip and batteries.

The rechargeable SI board nickel cadmium

(nicad) batteries maintain power to the

computer memory in the event of a power

drop (such as during starting) or complete

power loss (such as a dead or disconnected

battery) (see illustration). This assures power

so the computer can continue to keep track of

mileage and turn the lights on at the proper

interval.

The batteries have a life of approximately

six years, at which time they must be replaced

with new ones. Also, since they are recharged

by the engine charging system, they can run

down prematurely if power is cut off for some

reason (such as a blown fuse, a fault in the

wiring, or extended storage of the vehicle).

Excessive heat or cold can also shorten

battery life, with heat the greatest enemy.

Extreme heat can cause the batteries to

actually split open, allowing acid to drip into

the instrument cluster.

Several instruments controlled by the SI

board can be affected by low or discharged

batteries. Symptoms of low or dead SI board

batteries can include inconsistent tachometer

and temperature gauge readings, background

radio noise, and the inability to turn the

service lights off with the special tool.

Although only complete SI boards are

available from the manufacturer, batteries are

available separately from aftermarket sources.

While it is possible for the home mechanic to

renew the batteries, they are soldered to the

board, so unless you are skilled at this and

have the proper tools, this job should be left

to an experienced electronics technician.

Considerable savings can be realised by

removing the instrument cluster (see

Section 10) and taking it to an electronics

specialist.

Caution: the instrument cluster

and components are very

susceptible to damage from

static electricity. Make sure you

are earthed and have discharged any

static electricity (by touching an object

such as a metal water pipe) before

touching the cluster components.12 Headlights- bulb renewal

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

Sealed-beam type

2Remove the grille (see Chapter 11).

3Remove the headlight retainer screws,

taking care not to disturb the adjustment

screws.

4Remove the retainer and pull the headlight

out enough to allow the connector to be

unplugged.

5Remove the headlight.

6To refit the headlight, plug the connector in,

place the headlight in position, and refit the

retainer and screws. Tighten the screws

securely.7Refit the grille. Connect the battery negative

cable.

Halogen bulb type

Warning: Halogen gas-filled bulbs

are under pressure, and may

shatter if the surface is scratched

or the bulb is dropped. Wear eye

protection, and handle the bulbs carefully,

grasping only the base whenever possible.

Do not touch the surface of the bulb with

your fingers, because the oil from your

skin could cause it to overheat and fail

prematurely.

8From behind the headlight assembly,

remove the outer cover (see illustration).

9Twist and release the inner cover from the

rear of the headlight (see illustration).

10Disconnect the wire from the rear of the

headlight bulb (see illustration).

11Release the clips, and withdraw the bulb

from the headlight unit (see illustration).

12Fit the new bulb using a reversal of the

removal procedure. Make sure that the clips

engage the bulb correctly.

13Connect the battery negative cable.

Body electrical systems 12•5

12.9 Twist and release the headlight inner

cover12.8 Removing the headlight rear outer

cover (3-Series shown)11.2 These batteries (arrowed) power the

Service Indicator (SI) board

12.11 Removing the headlight bulb (do not

touch the surface of the bulb with your

fingers)12.10 Disconnecting the wire from the rear

of the headlight bulb

12

If you do touch the headlamp

bulb surface, clean it with

methylated spirit.

Page 174 of 228

13 Headlights- adjustment

2

Note:The headlights must be aimed correctly.

If adjusted incorrectly, they could momentarily

blind the driver of an oncoming vehicle and

cause a serious accident, or seriously reduce

your ability to see the road. The headlights

should be checked for proper aim every

12 months (as is done during the MOT test),

and any time a new headlight is fitted or front-

end body work is performed. It should be

emphasised that the following procedure will

only provide a temporary setting until the

headlights can be adjusted by a properly-

equipped garage.

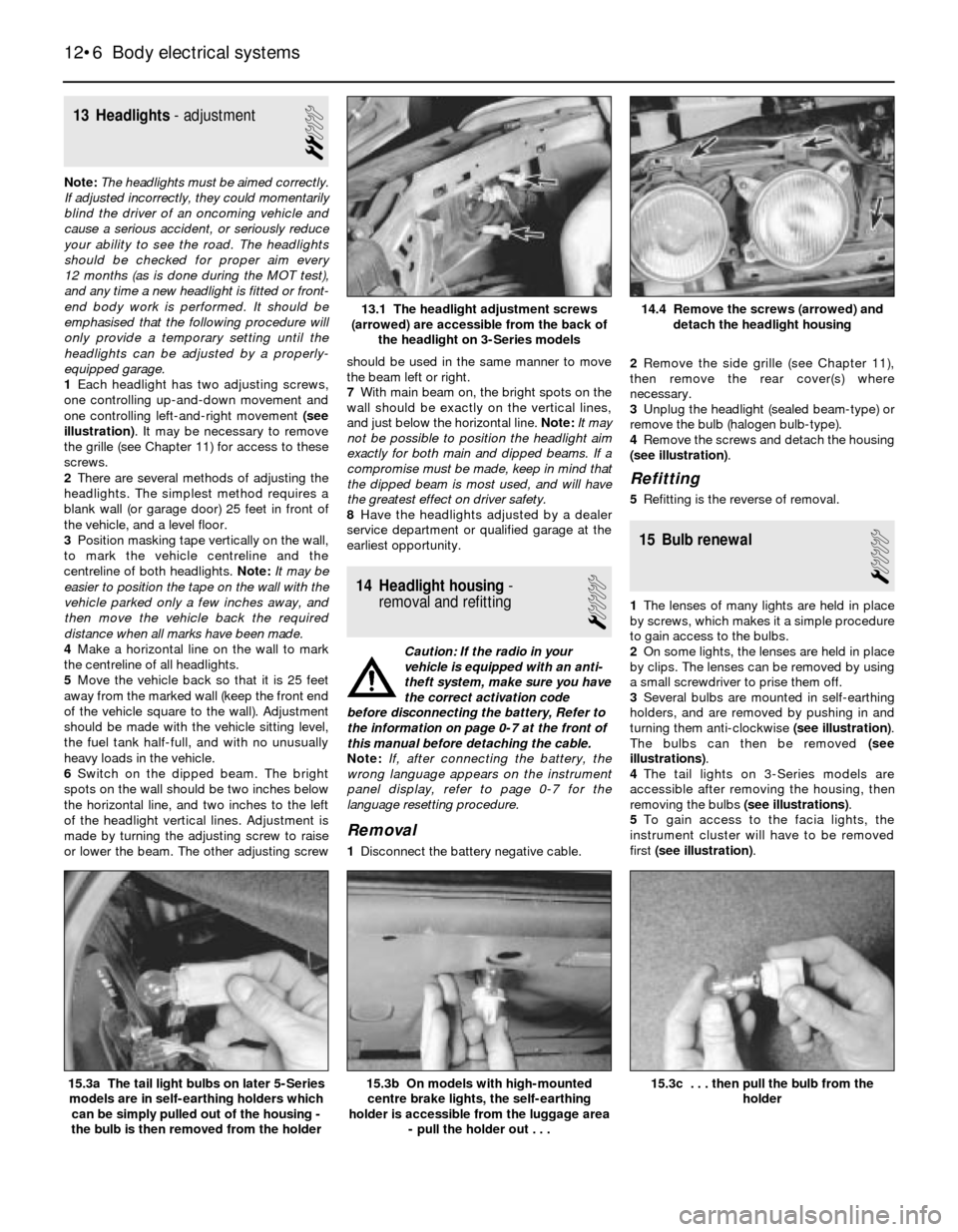

1Each headlight has two adjusting screws,

one controlling up-and-down movement and

one controlling left-and-right movement (see

illustration). It may be necessary to remove

the grille (see Chapter 11) for access to these

screws.

2There are several methods of adjusting the

headlights. The simplest method requires a

blank wall (or garage door) 25 feet in front of

the vehicle, and a level floor.

3Position masking tape vertically on the wall,

to mark the vehicle centreline and the

centreline of both headlights. Note:It may be

easier to position the tape on the wall with the

vehicle parked only a few inches away, and

then move the vehicle back the required

distance when all marks have been made.

4Make a horizontal line on the wall to mark

the centreline of all headlights.

5Move the vehicle back so that it is 25 feet

away from the marked wall (keep the front end

of the vehicle square to the wall). Adjustment

should be made with the vehicle sitting level,

the fuel tank half-full, and with no unusually

heavy loads in the vehicle.

6Switch on the dipped beam. The bright

spots on the wall should be two inches below

the horizontal line, and two inches to the left

of the headlight vertical lines. Adjustment is

made by turning the adjusting screw to raise

or lower the beam. The other adjusting screwshould be used in the same manner to move

the beam left or right.

7With main beam on, the bright spots on the

wall should be exactly on the vertical lines,

and just below the horizontal line. Note:It may

not be possible to position the headlight aim

exactly for both main and dipped beams. If a

compromise must be made, keep in mind that

the dipped beam is most used, and will have

the greatest effect on driver safety.

8Have the headlights adjusted by a dealer

service department or qualified garage at the

earliest opportunity.

14 Headlight housing-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.2Remove the side grille (see Chapter 11),

then remove the rear cover(s) where

necessary.

3Unplug the headlight (sealed beam-type) or

remove the bulb (halogen bulb-type).

4Remove the screws and detach the housing

(see illustration).

Refitting

5Refitting is the reverse of removal.

15 Bulb renewal

1

1The lenses of many lights are held in place

by screws, which makes it a simple procedure

to gain access to the bulbs.

2On some lights, the lenses are held in place

by clips. The lenses can be removed by using

a small screwdriver to prise them off.

3Several bulbs are mounted in self-earthing

holders, and are removed by pushing in and

turning them anti-clockwise (see illustration).

The bulbs can then be removed (see

illustrations).

4The tail lights on 3-Series models are

accessible after removing the housing, then

removing the bulbs (see illustrations).

5To gain access to the facia lights, the

instrument cluster will have to be removed

first (see illustration).

12•6 Body electrical systems

15.3c . . . then pull the bulb from the

holder15.3b On models with high-mounted

centre brake lights, the self-earthing

holder is accessible from the luggage area

- pull the holder out . . .15.3a The tail light bulbs on later 5-Series

models are in self-earthing holders which

can be simply pulled out of the housing -

the bulb is then removed from the holder

14.4 Remove the screws (arrowed) and

detach the headlight housing13.1 The headlight adjustment screws

(arrowed) are accessible from the back of

the headlight on 3-Series models

Page 177 of 228

BK Black

BL Blue

BR BrownGE Yellow

GN Green

GR Green or GreyGY Grey

OR Orange

PK PinkR Red

RS Pink

RT RedSW Black

TN Tan

V VioletVI Violet

W WhiteWS White

Y Yellow

Body electrical systems 12•9

12

Colour codes bent or damaged. The actuator can be

checked by applying battery power

momentarily. A discernible click indicates

that the solenoid is operating properly.

21 Electric window system-

description and check

2

The electric window system operates the

electric motors mounted in the doors which

lower and raise the windows. The system

consists of the control switches, the motors,

window mechanisms (regulators) andassociated wiring. Removal of the motors and

regulators is described in Chapter 11.

Diagnosis is usually limited to simple

checks of the wiring connections and motors

for minor faults which can be easily repaired.

These include:

a) Check the electric window switches for

broken wires and loose connections.

b) Check the electric window fuse/and or

circuit breaker (where applicable).

c) Remove the door trim panel(s) and check

the electric window motor wires to see if

they’re loose or damaged. Inspect the

window mechanisms for damage which

could cause binding.

22 Wiring diagrams-

general information

Since it isn’t possible to include all wiring

diagrams for every model year covered by this

manual, the following diagrams are those that

are typical and most commonly needed.

Prior to checking any circuit, check the

fuses and circuit breakers to make sure they’re

in good condition. Make sure the battery is

fully charged and check the cable connections

(see Chapter 1). Make sure all connectors are

clean, with no broken or loose terminals.

Page 211 of 228

REF•10Fault Finding

Engine will not rotate when attempting to start

m mBattery terminal connections loose or corroded (Chapter 1).

m mBattery discharged or faulty (Chapter 1).

m mAutomatic transmission not completely engaged in Park (Chap-

ter 7B) or (on models with a clutch switch) clutch not completely

depressed (Chapter 8).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapters 5 and 12).

m mStarter motor pinion jammed in flywheel ring gear (Chapter 5).

m mStarter solenoid faulty (Chapter 5).

m mStarter motor faulty (Chapter 5).

m mIgnition switch faulty (Chapter 12).

m mStarter pinion or flywheel teeth worn or broken (Chapter 5).

m mEngine internal problem (Chapter 2B).

Engine rotates, but will not start

m

mFuel tank empty.

m mBattery discharged (engine rotates slowly) (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mLeaking fuel injector(s), faulty fuel pump, pressure regulator, etc

(Chapter 4).

m mFuel not reaching fuel injection system or carburettor (Chapter 4).

m mIgnition components damp or damaged (Chapter 5).

m mFuel injector stuck open (Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

m mLoose distributor mounting bolts causing ignition timing to wander

(Chapters 1 and 5).

m mBroken, loose or disconnected wires at the ignition coil, or faulty

coil (Chapter 5).

Engine hard to start when cold

m mBattery discharged (Chapter 1).

m mFuel system malfunctioning (Chapter 4).

m mInjector(s) leaking or carburettor automatic choke faulty (Chap-

ter 4).

m mDistributor rotor carbon-tracked (Chapter 5).

Engine hard to start when hot

m

mAir filter element clogged (Chapter 1).

m mFuel not reaching the fuel injection system or carburettor (Chap-

ter 4).

m mCorroded battery connections, especially earth (negative)

connection (Chapter 1).

Starter motor noisy or excessively-rough in

engagement

m mPinion or flywheel gear teeth worn or broken (Chapter 5).

m mStarter motor mounting bolts loose or missing (Chapter 5).

Engine starts, but stops immediately

m

mLoose or faulty electrical connections at distributor, coil or

alternator (Chapter 5).

m mInsufficient fuel reaching the fuel injector(s) or carburettor

(Chapters 1 and 4).

m mDamaged fuel injection system speed sensors (Chapter 5).

m mFaulty fuel injection relays (Chapter 5).

Oil puddle under engine

m

mOil sump gasket and/or sump drain plug seal leaking (Chapter 2).

m mOil pressure sender unit leaking (Chapter 2).

m mValve cover gaskets leaking (Chapter 2).

m mEngine oil seals leaking (Chapter 2).

Engine idles erratically

m

mVacuum leakage (Chapter 4).

m mAir filter element clogged (Chapter 1).

m mFuel pump not delivering sufficient fuel to the fuel injection system

or carburettor (Chapter 4).

m mLeaking head gasket (Chapter 2).

m mTiming belt/chain and/or sprockets worn (Chapter 2).

m mCamshaft lobes worn (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6). This Section provides an easy-reference guide to the more

common problems which may occur during the operation of your

vehicle. These problems and their possible causes are grouped under

headings denoting various components or systems, such as Engine,

Cooling system, etc. They also refer you to the Chapter and/or

Section which deals with the problem.

Remember that successful fault diagnosis is not a mysterious

black art practised only by professional mechanics. It is simply the

result of the right knowledge combined with an intelligent, systematic

approach to the problem. Always work by a process of elimination,

starting with the simplest solution and working through to the mostcomplex - and never overlook the obvious. Anyone can run the fuel

tank dry or leave the lights on overnight, so don’t assume that you are

exempt from such oversights.

Finally, always establish a clear idea of why a problem has

occurred, and take steps to ensure that it doesn’t happen again. If the

electrical system fails because of a poor connection, check all other

connections in the system to make sure that they don’t fail as well. If a

particular fuse continues to blow, find out why - don’t just renew one

fuse after another. Remember, failure of a small component can often

be indicative of potential failure or incorrect functioning of a more

important component or system.

Engine

Page 212 of 228

REF•11

REF

Fault Finding

Engine misses at idle speed

m mSpark plugs worn or incorrectly-gapped (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leaks (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mUneven or low compression (Chapter 2).

m mFaulty charcoal canister, where fitted (Chapter 6).

Engine misses throughout driving speed range

m

mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mLow fuel output at the injectors, or partially-blocked carburettor

jets (Chapter 4).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mIncorrect ignition timing (Chapter 5).

m mCracked distributor cap, disconnected distributor HT leads, or

damaged distributor components (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mFaulty emission system components (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

m mWeak or faulty ignition system (Chapter 5).

m mVacuum leak in fuel injection system, intake manifold or vacuum

hoses (Chapter 4).

Engine misfires on acceleration

m mSpark plugs fouled (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFuel filter clogged (Chapters 1 and 4).

m mIncorrect ignition timing (Chapter 5).

m mIntake manifold air leak (Chapter 4).

Engine surges while holding accelerator steady

m

mIntake air leak (Chapter 4).

m mFuel pump faulty (Chapter 4).

m mLoose fuel injector harness connections (Chapters 4 and 6).

m mDefective ECU (Chapter 5).

Engine lacks power

m

mIncorrect ignition timing (Chapter 5).

m mExcessive play in distributor shaft (Chapter 5).

m mWorn rotor, distributor cap or HT leads (Chapters 1 and 5).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mFaulty coil (Chapter 5).

m mBrakes binding (Chapter 1).

m mAutomatic transmission fluid level incorrect (Chapter 1).

m mClutch slipping (Chapter 8).

m mFuel filter clogged and/or impurities in the fuel system (Chapter 1).

m mEmission control system not functioning properly (Chapter 6).

m mLow or uneven cylinder compression pressures (Chapter 2).

Engine stalls

m

mIdle speed incorrect (Chapter 1).

m mFuel filter clogged and/or water and impurities in the fuel system

(Chapter 1).

m mDistributor components damp or damaged (Chapter 5).

m mFaulty emissions system components (Chapter 6).

m mFaulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 1).

m mVacuum leak in the fuel injection system, intake manifold or

vacuum hoses (Chapter 4).

Engine backfires

m mEmissions system not functioning properly (Chapter 6).

m mIgnition timing incorrect (Chapter 5).

m mFaulty secondary ignition system (cracked spark plug insulator,

faulty plug HT leads, distributor cap and/or rotor) (Chapters 1 and 5).

m mFuel injection system or carburettor malfunctioning (Chapter 4).

m mVacuum leak at fuel injector(s), intake manifold or vacuum hoses

(Chapter 4).

m mValve clearances incorrect (Chapter 1), or valve(s) sticking or

damaged (Chapter 2).

Pinking or knocking engine sounds when

accelerating or driving uphill

m mIncorrect grade of fuel.

m mIgnition timing incorrect (Chapter 5).

m mFuel injection system or carburettor in need of adjustment (Chap-

ter 4).

m mDamaged spark plugs or HT leads, or incorrect type fitted (Chapter 1).

m mWorn or damaged distributor components (Chapter 5).

m mFaulty emission system (Chapter 6).

m mVacuum leak (Chapter 4).

Engine runs with oil pressure light on

Caution: Stop the engine immediately if the oil

pressure light comes on and establish the cause.

Running the engine while the oil pressure is low can

cause severe damage.

m mLow oil level (Chapter 1).

m mIdle speed too low (Chapter 1).

m mShort-circuit in wiring (Chapter 12).

m mFaulty oil pressure sender unit (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

Engine runs-on after switching off

m

mIdle speed too high (Chapter 1).

m mExcessive engine operating temperature (Chapter 3).

m mIncorrect fuel octane grade.

m mSpark plugs defective or incorrect grade (Chapter 1).

Engine electrical system

Battery will not hold charge

m

mAlternator drivebelt defective or not adjusted properly (Chapter 1).

m mElectrolyte level low (Chapter 1).

m mBattery terminals loose or corroded (Chapter 1).

m mAlternator not charging properly (Chapter 5).

m mLoose, broken or faulty wiring in the charging circuit (Chapter 5).

m mShort in vehicle wiring (Chapters 5 and 12).

m mInternally-defective battery (Chapters 1 and 5).

m mIgnition (no-charge) warning light bulb blown - on some early

models (Chapter 5)

Ignition (no-charge) warning light fails to go out

m mFaulty alternator or charging circuit (Chapter 5).

m mAlternator drivebelt defective or out of adjustment (Chapter 1).

m mAlternator voltage regulator inoperative (Chapter 5).

Ignition (no-charge) warning light fails to come on

when key is turned

m mWarning light bulb defective (Chapter 12).

m mFault in the printed circuit, wiring or bulbholder (Chapter 12).

Page 213 of 228

REF•12Fault Finding

Fuel system

Excessive fuel consumption

m mDirty or clogged air filter element (Chapter 1).

m mIgnition timing incorrect (Chapter 5).

m mEmissions system not functioning properly (Chapter 6).

m mFuel injection internal parts or carburettor jets excessively worn or

damaged (Chapter 4).

m mLow tyre pressure or incorrect tyre size (Chapter 1).

m mUnsympathetic driving style, or unfavourable conditions.

Fuel leakage and/or fuel odour

Warning: Don’t drive the vehicle if a fuel leak is

suspected. Leaking fuel in the engine compartment

could catch fire.

m mLeak in a fuel feed or vent line (Chapter 4).

m mTank overfilled.

m mFuel injector or carburettor parts excessively worn, or fuel system

gaskets leaking (Chapter 4).

Cooling system

Overheating

m mInsufficient coolant in system (Chapter 1).

m mWater pump drivebelt defective or out of adjustment (Chapter 1).

m mRadiator matrix blocked, or grille restricted (Chapter 3).

m mThermostat faulty (Chapter 3).

m mRadiator cap not maintaining proper pressure (Chapter 3).

m mIgnition timing incorrect (Chapter 5).

Overcooling

m

mFaulty thermostat (Chapter 3).

External coolant leakage

m

mDeteriorated/damaged hoses; loose clamps (Chapters 1 and 3).

m mWater pump seal defective (Chapters 1 and 3).

m mLeakage from radiator matrix, heater matrix or header tank

(Chapter 3).

m mRadiator/engine block drain plugs or water jacket core plugs

leaking (Chapters 2 and 3).

Internal coolant leakage

m mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder bore or cylinder head (Chapter 2).

Coolant loss

m

mToo much coolant in system (Chapter 1).

m mCoolant boiling away because of overheating (see above).

m mInternal or external leakage (see above).

m mFaulty radiator cap (Chapter 3).

Poor coolant circulation

m

mInoperative water pump (Chapter 3).

m mRestriction in cooling system (Chapters 1 and 3).

m mWater pump drivebelt defective/out of adjustment (Chapter 1).

m mThermostat sticking (Chapter 3).

Clutch

Pedal travels to floor - no pressure or very little

resistance

m mMaster or slave cylinder faulty (Chapter 8).

m mFluid line burst or leaking (Chapter 8).

m mConnections leaking (Chapter 8).

m mNo fluid in reservoir (Chapter 1).

m mIf fluid is present in master cylinder dust cover, master cylinder rear

seal has failed (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

Fluid in area of master cylinder dust cover, and on

pedal

m mRear seal failure in master cylinder (Chapter 8).

Fluid on slave cylinder

m

mSlave cylinder plunger seal faulty (Chapter 8).

Pedal feels “spongy” when depressed

m

mAir in system (Chapter 8).

Unable to select gears

m

mFaulty transmission (Chapter 7).

m mFaulty clutch plate (Chapter 8).

m mFork and bearing not assembled properly (Chapter 8).

m mFaulty pressure plate (Chapter 8).

m mPressure plate-to-flywheel bolts loose (Chapter 8).

Clutch slips (engine speed increases with no

increase in vehicle speed)

m mClutch plate worn (Chapter 8).

m mClutch plate is oil-soaked by leaking rear main seal (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

m mWeak diaphragm spring (Chapter 8).

m mClutch plate overheated.

Grabbing (chattering) as clutch is engaged

m

mOil on clutch plate lining, burned or glazed facings (Chapter 8).

m mWorn or loose engine or transmission mountings (Chapters 2

and 7A).

m mWorn splines on clutch plate hub (Chapter 8).

m mWarped pressure plate or flywheel (Chapter 8).

Noise in clutch area

m

mFork improperly fitted (Chapter 8).

m mFaulty release bearing (Chapter 8).

Clutch pedal stays on floor

m

mFork binding in housing (Chapter 8).

m mBroken release bearing or fork (Chapter 8).

High pedal effort

m

mFork binding in housing (Chapter 8).

m mPressure plate faulty (Chapter 8).

m mIncorrect-size master or slave cylinder fitted (Chapter 8).

Page 214 of 228

REF•13

REF

Fault Finding

Automatic transmission

Note:Due to the complexity of the automatic transmission, it is

difficult for the home mechanic to properly diagnose and service this

unit. For problems other than the following, the vehicle should be

taken to a dealer or transmission specialist.

Fluid leakage

m mAutomatic transmission fluid is a deep red colour. Fluid leaks

should not be confused with engine oil, which can easily be blown

by airflow onto the transmission.

m mTo pinpoint a leak, first remove all built-up dirt and grime from the

transmission housing with degreasing agents and/or by steam-

cleaning. Then drive the vehicle at low speed, so airflow will not

blow the leak far from its source. Raise the vehicle and determine

where the leak is coming from. Common areas of leakage are:

a) Transmission sump (Chapters 1 and 7B)

b) Filler pipe (Chapter 7B)

c) Transmission fluid cooler lines (Chapter 7B)

d) Speedometer sensor (Chapter 7B)

Transmission fluid brown, or has a burned smell

m mTransmission fluid burned; fluid should be changed. May indicate

transmission internal fault (Chapters 1 and 7B).

Transmission will not kickdown with accelerator

pedal pressed to the floor

m mKickdown cable out of adjustment (Chapter 7B).

General shift mechanism problems

m

mChapter 7B deals with checking and adjusting the shift linkage on

automatic transmissions. Common problems which may be

attributed to poorly-adjusted linkage are:

a) Engine starting in gears other than Park or Neutral.

b) Indicator on selector lever pointing to a gear other than the one

actually being used.

c) Vehicle moves when in Park.

m mRefer to Chapter 7B for the shift linkage adjustment procedure.

Engine will start in gears other than Park or Neutral

m

mInhibitor switch malfunctioning (Chapter 7B).

Transmission slips, shifts roughly, is noisy, or has

no drive in forward or reverse gears

m mThere are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility -

fluid level. Before taking the vehicle to an automatic transmission

specialist, check the level and condition of the fluid as described in

Chapter 1. Correct the fluid level as necessary, or change the fluid

if needed. If the problem persists, have a professional diagnose the

probable cause.

Manual transmission

Vibration

m mDamaged propeller shaft (Chapter 8).

m mOut-of-round tyres (Chapter 1).

m mTyre out-of-balance (Chapters 1 and 10).

m mWorn propeller shaft universal joint (Chapter 8).

Noisy in neutral with engine running

m

mWorn clutch release bearing (Chapter 8).

m mWorn transmission input shaft bearing (Chapter 7A).

Noisy in one particular gear

m

mDamaged or worn constant-mesh gears.

m mDamaged or worn synchronisers.

Noisy in all gears

m

mInsufficient lubricant (Chapter 1).

m mDamaged or worn bearings.

m mWorn or damaged input gear shaft and/or output gear shaft.

Slips out of gear

m

mWorn or incorrectly-adjusted linkage (Chapter 7A).

m mTransmission-to-engine mounting bolts loose (Chapter 7A).

m mShift linkage binding (Chapter 7A).

m mWorn shift fork (Chapter 7A).

Leaks lubricant

m

mExcessive amount of lubricant in transmission (Chapters 1 and 7A).

m mLoose or broken input shaft bearing retainer (Chapter 7A).

m mInput shaft bearing retainer O-ring and/or lip seal damaged

(Chapter 7A).

Page 215 of 228

REF•14Fault Finding

Brakes

Note:Before assuming that a brake problem exists, make sure that:

a) The tyres are in good condition and properly inflated (Chapter 1).

b) The wheel alignment (tracking) is correct (Chapter 10).

c) The vehicle is not loaded with weight in an unequal manner.

Vehicle pulls to one side during braking

m mIncorrect tyre pressures (Chapter 1).

m mWheel alignment (tracking) incorrect (Chapter 10)

m mUnmatched tyres on same axle.

m mRestricted brake lines or hoses (Chapter 9).

m mMalfunctioning caliper assembly (Chapter 9).

m mLoose suspension parts (Chapter 10).

m mLoose calipers (Chapter 9).

Noise (high-pitched squeal) when the brakes are

applied

m mFront and/or rear disc brake pads worn out. The noise comes from

the wear sensor rubbing against the disc. Renew the pads

immediately (Chapter 9).

Brake vibration (pedal pulsates)

Note:If the vehicle has ABS, it is normal for the brake pedal to pulsate

when the system is working.

m mExcessive lateral disc run-out (Chapter 9).

m mParallelism not within specifications (Chapter 9).

m mUneven pad wear - caused by caliper not sliding, due to improper

clearance or dirt (Chapter 9).

m mDefective disc (Chapter 9).

Excessive brake pedal travel

m

mPartial brake system failure (Chapter 9).

m mInsufficient fluid in master cylinder (Chapters 1 and 9).

m mAir trapped in system (Chapters 1 and 9).

Excessive pedal effort required to stop vehicle

m

mMalfunctioning brake servo unit (Chapter 9).

m mPartial system failure (Chapter 9).

m mExcessively-worn pads or shoes (Chapter 9).

m mCaliper piston stuck or sluggish (Chapter 9).

m mBrake pads contaminated with oil or grease (Chapter 9).

m mNew pads fitted and not yet seated. It will take a while for the new

material to seat against the disc.

Dragging brakes

m mMaster cylinder pistons not returning correctly (Chapter 9).

m mRestricted brakes lines or hoses (Chapters 1 and 9).

m mIncorrect handbrake adjustment (Chapter 9).

m mRear drum brake self-adjuster mechanism faulty (when applicable)

(Chapter 9).

Grabbing or uneven braking action

m mMalfunction of brake servo unit (Chapter 9).

m mBinding brake pedal mechanism (Chapter 9).

Brake pedal feels “spongy” when depressed

m

mAir in hydraulic lines (Chapter 9).

m mMaster cylinder mounting bolts loose (Chapter 9).

m mMaster cylinder defective (Chapter 9).

Brake pedal travels to the floor with little resistance

m

mLittle or no fluid in the master cylinder reservoir, caused by leaking

caliper piston(s), loose, damaged or disconnected brake lines

(Chapter 9).

Handbrake does not hold

m mHandbrake linkage incorrectly adjusted (Chapter 9).

m mHandbrake shoe linings worn out or contaminated (Chapter 9).