wiring BMW 3 SERIES 1987 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1987, Model line: 3 SERIES, Model: BMW 3 SERIES 1987 E30Pages: 228, PDF Size: 7.04 MB

Page 85 of 228

4If a new sender unit is to be fitted, make

sure the engine is completely cool. There will

be some coolant loss when the unit is

unscrewed, so be prepared to catch it, or

have the new unit ready to fit immediately the

old one is removed. Disconnect the wiring,

then unscrew the old unit from the engine,

and fit the new one. Use sealant on the

threads. Reconnect the wiring, and check the

coolant level on completion.

9 Heater and air conditioning

blower motor- removal,

testing and refitting

1

Removal

Note: The 3-Series models covered by this

manual have always used a single blower

motor for ventilation, heating and air

conditioning. “Old-shape” (E28) 5-Series

models use two separate blower motors: one

for ventilation and heating, and another for air

conditioning. “New-shape” (E34) 5-Series

models have a single blower motor, like the 3-

Series. The removal and refitting of the single

blower motor, and the old-shape 5-Series

vent/heat motor, is described below. The

removal and refitting of the old-shape 5-Series

air conditioning blower motor is described in

Section 14 of this Chapter.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2The blower motor is located behind the

bulkhead, under an access panel. Remove the

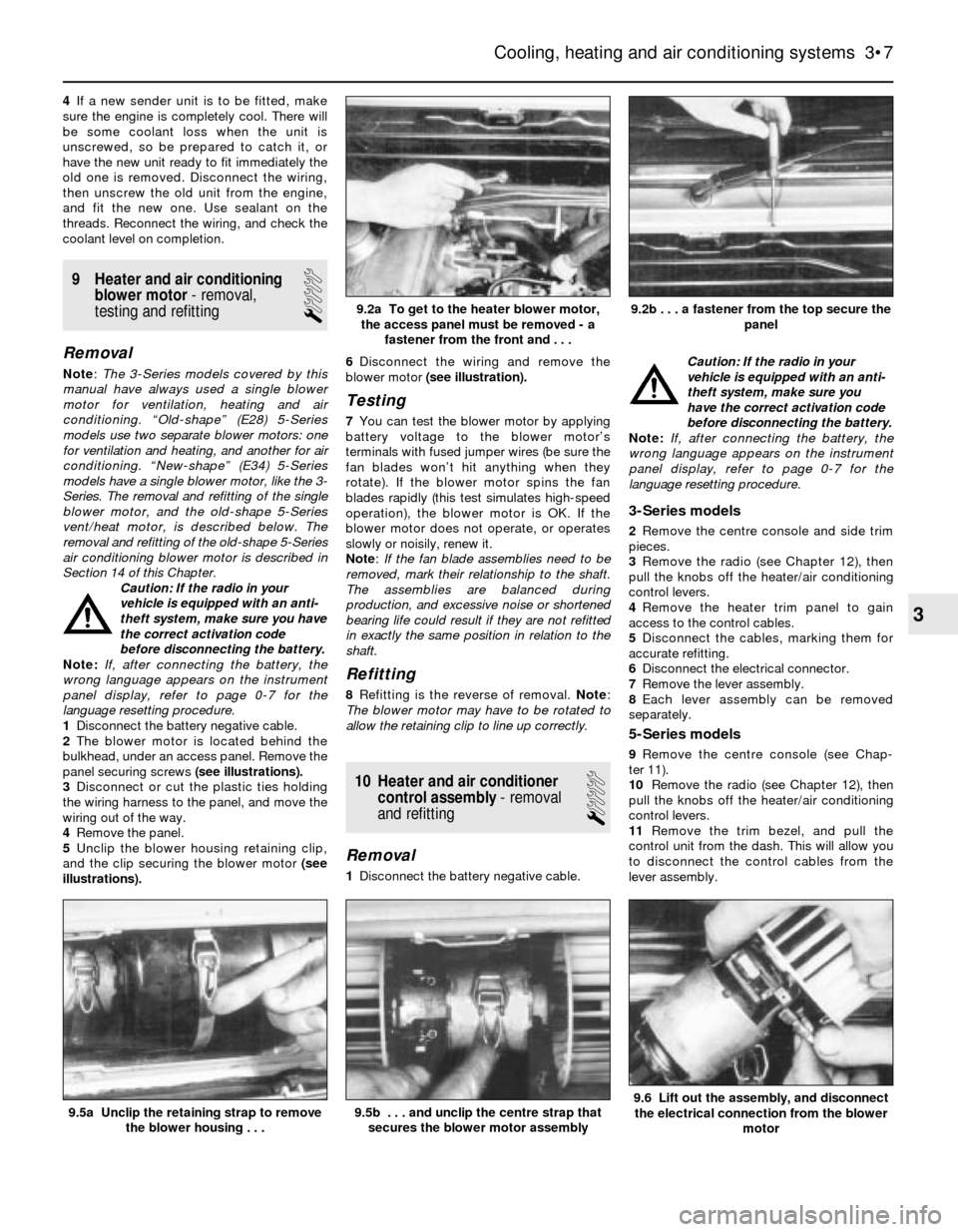

panel securing screws (see illustrations).

3Disconnect or cut the plastic ties holding

the wiring harness to the panel, and move the

wiring out of the way.

4Remove the panel.

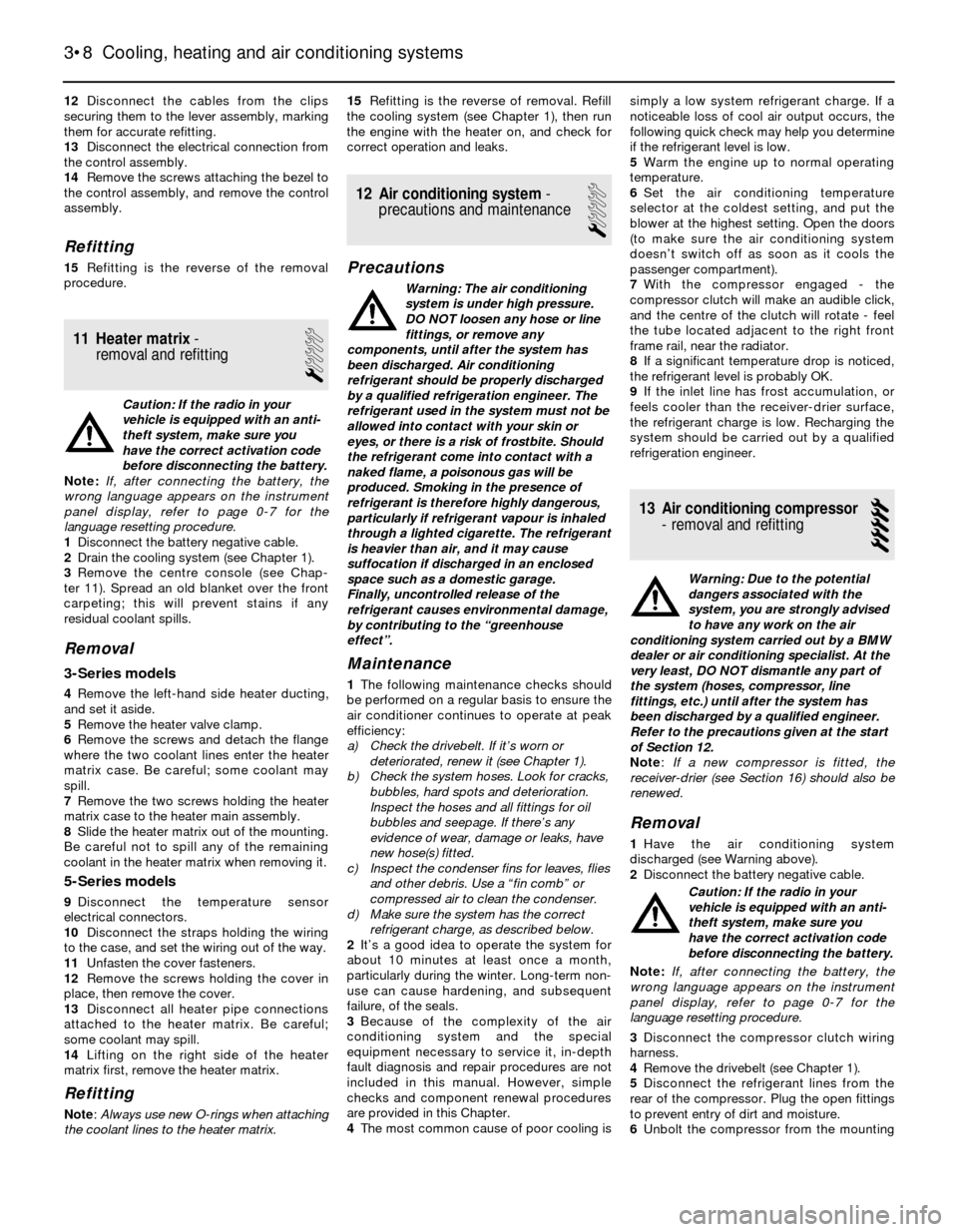

5Unclip the blower housing retaining clip,

and the clip securing the blower motor (see

illustrations).6Disconnect the wiring and remove the

blower motor (see illustration).

Testing

7You can test the blower motor by applying

battery voltage to the blower motor’s

terminals with fused jumper wires (be sure the

fan blades won’t hit anything when they

rotate). If the blower motor spins the fan

blades rapidly (this test simulates high-speed

operation), the blower motor is OK. If the

blower motor does not operate, or operates

slowly or noisily, renew it.

Note: If the fan blade assemblies need to be

removed, mark their relationship to the shaft.

The assemblies are balanced during

production, and excessive noise or shortened

bearing life could result if they are not refitted

in exactly the same position in relation to the

shaft.

Refitting

8Refitting is the reverse of removal. Note:

The blower motor may have to be rotated to

allow the retaining clip to line up correctly.

10 Heater and air conditioner

control assembly- removal

and refitting

1

Removal

1Disconnect the battery negative cable. Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3-Series models

2Remove the centre console and side trim

pieces.

3Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

4Remove the heater trim panel to gain

access to the control cables.

5Disconnect the cables, marking them for

accurate refitting.

6Disconnect the electrical connector.

7Remove the lever assembly.

8Each lever assembly can be removed

separately.

5-Series models

9Remove the centre console (see Chap-

ter 11).

10Remove the radio (see Chapter 12), then

pull the knobs off the heater/air conditioning

control levers.

11Remove the trim bezel, and pull the

control unit from the dash. This will allow you

to disconnect the control cables from the

lever assembly.

Cooling, heating and air conditioning systems 3•7

9.5a Unclip the retaining strap to remove

the blower housing . . .

9.2b . . . a fastener from the top secure the

panel9.2a To get to the heater blower motor,

the access panel must be removed - a

fastener from the front and . . .

9.6 Lift out the assembly, and disconnect

the electrical connection from the blower

motor9.5b . . . and unclip the centre strap that

secures the blower motor assembly

3

Page 86 of 228

12Disconnect the cables from the clips

securing them to the lever assembly, marking

them for accurate refitting.

13Disconnect the electrical connection from

the control assembly.

14Remove the screws attaching the bezel to

the control assembly, and remove the control

assembly.

Refitting

15Refitting is the reverse of the removal

procedure.

11 Heater matrix-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Drain the cooling system (see Chapter 1).

3Remove the centre console (see Chap-

ter 11). Spread an old blanket over the front

carpeting; this will prevent stains if any

residual coolant spills.

Removal

3-Series models

4Remove the left-hand side heater ducting,

and set it aside.

5Remove the heater valve clamp.

6Remove the screws and detach the flange

where the two coolant lines enter the heater

matrix case. Be careful; some coolant may

spill.

7Remove the two screws holding the heater

matrix case to the heater main assembly.

8Slide the heater matrix out of the mounting.

Be careful not to spill any of the remaining

coolant in the heater matrix when removing it.

5-Series models

9Disconnect the temperature sensor

electrical connectors.

10Disconnect the straps holding the wiring

to the case, and set the wiring out of the way.

11Unfasten the cover fasteners.

12Remove the screws holding the cover in

place, then remove the cover.

13Disconnect all heater pipe connections

attached to the heater matrix. Be careful;

some coolant may spill.

14Lifting on the right side of the heater

matrix first, remove the heater matrix.

Refitting

Note: Always use new O-rings when attaching

the coolant lines to the heater matrix.15Refitting is the reverse of removal. Refill

the cooling system (see Chapter 1), then run

the engine with the heater on, and check for

correct operation and leaks.

12 Air conditioning system-

precautions and maintenance

1

Precautions

Warning: The air conditioning

system is under high pressure.

DO NOT loosen any hose or line

fittings, or remove any

components, until after the system has

been discharged. Air conditioning

refrigerant should be properly discharged

by a qualified refrigeration engineer. The

refrigerant used in the system must not be

allowed into contact with your skin or

eyes, or there is a risk of frostbite. Should

the refrigerant come into contact with a

naked flame, a poisonous gas will be

produced. Smoking in the presence of

refrigerant is therefore highly dangerous,

particularly if refrigerant vapour is inhaled

through a lighted cigarette. The refrigerant

is heavier than air, and it may cause

suffocation if discharged in an enclosed

space such as a domestic garage.

Finally, uncontrolled release of the

refrigerant causes environmental damage,

by contributing to the “greenhouse

effect”.

Maintenance

1The following maintenance checks should

be performed on a regular basis to ensure the

air conditioner continues to operate at peak

efficiency:

a) Check the drivebelt. If it’s worn or

deteriorated, renew it (see Chapter 1).

b) Check the system hoses. Look for cracks,

bubbles, hard spots and deterioration.

Inspect the hoses and all fittings for oil

bubbles and seepage. If there’s any

evidence of wear, damage or leaks, have

new hose(s) fitted.

c) Inspect the condenser fins for leaves, flies

and other debris. Use a “fin comb” or

compressed air to clean the condenser.

d) Make sure the system has the correct

refrigerant charge, as described below.

2It’s a good idea to operate the system for

about 10 minutes at least once a month,

particularly during the winter. Long-term non-

use can cause hardening, and subsequent

failure, of the seals.

3Because of the complexity of the air

conditioning system and the special

equipment necessary to service it, in-depth

fault diagnosis and repair procedures are not

included in this manual. However, simple

checks and component renewal procedures

are provided in this Chapter.

4The most common cause of poor cooling issimply a low system refrigerant charge. If a

noticeable loss of cool air output occurs, the

following quick check may help you determine

if the refrigerant level is low.

5Warm the engine up to normal operating

temperature.

6Set the air conditioning temperature

selector at the coldest setting, and put the

blower at the highest setting. Open the doors

(to make sure the air conditioning system

doesn’t switch off as soon as it cools the

passenger compartment).

7With the compressor engaged - the

compressor clutch will make an audible click,

and the centre of the clutch will rotate - feel

the tube located adjacent to the right front

frame rail, near the radiator.

8If a significant temperature drop is noticed,

the refrigerant level is probably OK.

9If the inlet line has frost accumulation, or

feels cooler than the receiver-drier surface,

the refrigerant charge is low. Recharging the

system should be carried out by a qualified

refrigeration engineer.

13 Air conditioning compressor

- removal and refitting

5

Warning: Due to the potential

dangers associated with the

system, you are strongly advised

to have any work on the air

conditioning system carried out by a BMW

dealer or air conditioning specialist. At the

very least, DO NOT dismantle any part of

the system (hoses, compressor, line

fittings, etc.) until after the system has

been discharged by a qualified engineer.

Refer to the precautions given at the start

of Section 12.

Note: If a new compressor is fitted, the

receiver-drier (see Section 16) should also be

renewed.

Removal

1Have the air conditioning system

discharged (see Warning above).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Disconnect the compressor clutch wiring

harness.

4Remove the drivebelt (see Chapter 1).

5Disconnect the refrigerant lines from the

rear of the compressor. Plug the open fittings

to prevent entry of dirt and moisture.

6Unbolt the compressor from the mounting

3•8 Cooling, heating and air conditioning systems

Page 93 of 228

19Depressurise the fuel system (see Sec-

tion 2).

20Detach the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

21Detach the fuel feed hose from the fuel

rail, and attach a fuel pressure gauge directly

to the hose. Note:If the tee fitting is still

connected to the gauge, be sure to plug the

open end.

22Reconnect the battery.

23Using a jumper wire, bridge the terminals

of the fuel pump relay.

24Turn the ignition switch on to operate the

fuel pump.

25Note the pressure reading on the gauge,

and compare the reading to the fuel pump

pressure listed in this Chapter’s Specifica-

tions.

26If the indicated pressure is less than

specified, inspect the fuel line for leaks

between the pump and gauge. If no leaks are

found, renew the fuel pump.

27Turn the ignition off and wait five minutes.

Note the reading on the gauge, and compare

it to the fuel pump hold pressure listed in this

Chapter’s Specifications. If the hold pressure

is less than specified, check the fuel lines

between the pump and gauge for leaks. If no

leaks are found, renew the fuel pump.

28Remove the jumper wire. Relieve the fuel

pressure by opening the bleed valve on the

gauge and directing the fuel into a suitable

container. Remove the gauge and reconnect

the fuel line.

Transfer pump pressure check

29Depressurise the fuel system (see Sec-

tion 2).

30Detach the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

31Remove the transfer pump access plate

(on some models, it’s located under the rear

seat cushion - on others, it’s located under

the carpet in the luggage compartment).

Disconnect the output hose from the transfer

pump, and connect a fuel pressure gauge to

the outlet pipe.

32Reconnect the battery.33Using a jumper wire, bridge the terminals

of the fuel pump relay.

34Turn the ignition switch on to operate the

fuel pump.

35Note the pressure reading on the gauge,

and compare to the value listed in this

Chapter’s Specifications.

36If the indicated pressure is less than

specified, renew the transfer pump.

Fuel pump relay check

37Switch on the ignition.

38Using a voltmeter, probe the following

terminals from the back of the relay electrical

connector. Check for battery voltage at

terminal 30 (M20 and M30 engines) or

terminal 15 (M10 and M40 engines). Note:If

there is no voltage on models with luggage

compartment-mounted batteries, check for a

faulty fusible link. The 50-amp link is about

6 inches from the battery, in a black wire.

39Turn the ignition off, and disconnect the

relay from the electrical connector. Using a

voltmeter, probe the connector terminals that

correspond to fuel pump relay pins 85 (-) and

86(+) on M20 and M30 engines, or terminal 50

and earth on M10 and M40 engines. Have an

assistant turn the engine over on the starter,

and observe the voltage reading. Battery

voltage should be indicated.

40If there is no voltage, check the fuse(s)

and the wiring circuit for the fuel pump relay. If

the voltage readings are correct, and the fuel

pump only runs with the jumper wire in place,

then renew the relay.

41If the fuel pump still does not run, check

for the proper voltage at the fuel pump

terminals (see Section 4). If necessary, renew

the fuel pump.

4 Fuel pump, transfer pump

and fuel level sender unit-

removal and refitting

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

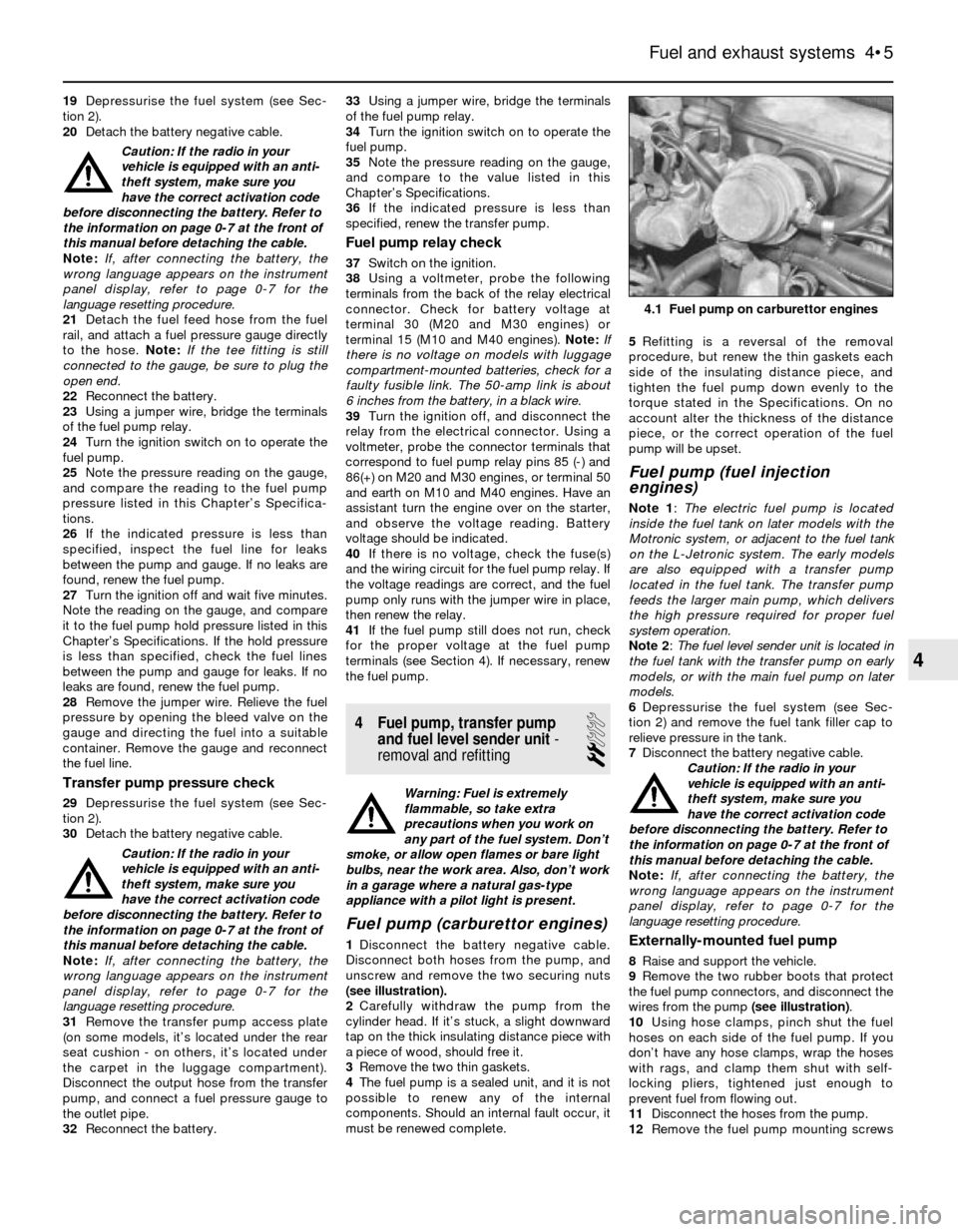

Fuel pump (carburettor engines)

1Disconnect the battery negative cable.

Disconnect both hoses from the pump, and

unscrew and remove the two securing nuts

(see illustration).

2Carefully withdraw the pump from the

cylinder head. If it’s stuck, a slight downward

tap on the thick insulating distance piece with

a piece of wood, should free it.

3Remove the two thin gaskets.

4The fuel pump is a sealed unit, and it is not

possible to renew any of the internal

components. Should an internal fault occur, it

must be renewed complete.5Refitting is a reversal of the removal

procedure, but renew the thin gaskets each

side of the insulating distance piece, and

tighten the fuel pump down evenly to the

torque stated in the Specifications. On no

account alter the thickness of the distance

piece, or the correct operation of the fuel

pump will be upset.

Fuel pump (fuel injection

engines)

Note 1: The electric fuel pump is located

inside the fuel tank on later models with the

Motronic system, or adjacent to the fuel tank

on the L-Jetronic system. The early models

are also equipped with a transfer pump

located in the fuel tank. The transfer pump

feeds the larger main pump, which delivers

the high pressure required for proper fuel

system operation.

Note 2: The fuel level sender unit is located in

the fuel tank with the transfer pump on early

models, or with the main fuel pump on later

models.

6Depressurise the fuel system (see Sec-

tion 2) and remove the fuel tank filler cap to

relieve pressure in the tank.

7Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Externally-mounted fuel pump

8Raise and support the vehicle.

9Remove the two rubber boots that protect

the fuel pump connectors, and disconnect the

wires from the pump (see illustration).

10Using hose clamps, pinch shut the fuel

hoses on each side of the fuel pump. If you

don’t have any hose clamps, wrap the hoses

with rags, and clamp them shut with self-

locking pliers, tightened just enough to

prevent fuel from flowing out.

11Disconnect the hoses from the pump.

12Remove the fuel pump mounting screws

Fuel and exhaust systems 4•5

4.1 Fuel pump on carburettor engines

4

Page 98 of 228

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery. Refer to the

information on page 0-7 at the front of this

manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

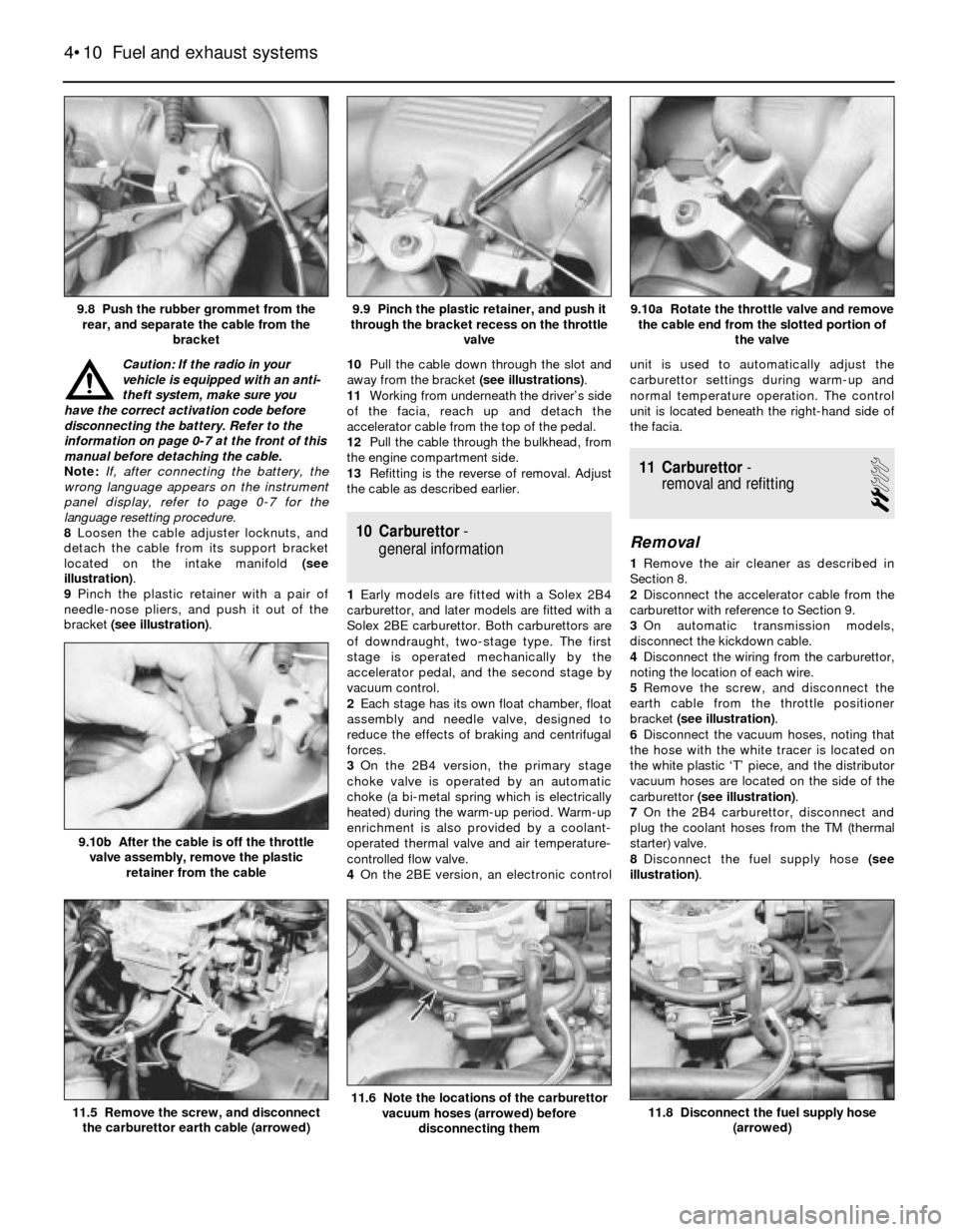

8Loosen the cable adjuster locknuts, and

detach the cable from its support bracket

located on the intake manifold (see

illustration).

9Pinch the plastic retainer with a pair of

needle-nose pliers, and push it out of the

bracket (see illustration).10Pull the cable down through the slot and

away from the bracket (see illustrations).

11Working from underneath the driver’s side

of the facia, reach up and detach the

accelerator cable from the top of the pedal.

12Pull the cable through the bulkhead, from

the engine compartment side.

13Refitting is the reverse of removal. Adjust

the cable as described earlier.

10 Carburettor-

general information

1Early models are fitted with a Solex 2B4

carburettor, and later models are fitted with a

Solex 2BE carburettor. Both carburettors are

of downdraught, two-stage type. The first

stage is operated mechanically by the

accelerator pedal, and the second stage by

vacuum control.

2Each stage has its own float chamber, float

assembly and needle valve, designed to

reduce the effects of braking and centrifugal

forces.

3On the 2B4 version, the primary stage

choke valve is operated by an automatic

choke (a bi-metal spring which is electrically

heated) during the warm-up period. Warm-up

enrichment is also provided by a coolant-

operated thermal valve and air temperature-

controlled flow valve.

4On the 2BE version, an electronic controlunit is used to automatically adjust the

carburettor settings during warm-up and

normal temperature operation. The control

unit is located beneath the right-hand side of

the facia.

11 Carburettor-

removal and refitting

2

Removal

1Remove the air cleaner as described in

Section 8.

2Disconnect the accelerator cable from the

carburettor with reference to Section 9.

3On automatic transmission models,

disconnect the kickdown cable.

4Disconnect the wiring from the carburettor,

noting the location of each wire.

5Remove the screw, and disconnect the

earth cable from the throttle positioner

bracket (see illustration).

6Disconnect the vacuum hoses, noting that

the hose with the white tracer is located on

the white plastic ‘T’ piece, and the distributor

vacuum hoses are located on the side of the

carburettor (see illustration).

7On the 2B4 carburettor, disconnect and

plug the coolant hoses from the TM (thermal

starter) valve.

8Disconnect the fuel supply hose (see

illustration).

4•10 Fuel and exhaust systems

11.8 Disconnect the fuel supply hose

(arrowed)11.6 Note the locations of the carburettor

vacuum hoses (arrowed) before

disconnecting them11.5 Remove the screw, and disconnect

the carburettor earth cable (arrowed)

9.10b After the cable is off the throttle

valve assembly, remove the plastic

retainer from the cable

9.10a Rotate the throttle valve and remove

the cable end from the slotted portion of

the valve9.9 Pinch the plastic retainer, and push it

through the bracket recess on the throttle

valve9.8 Push the rubber grommet from the

rear, and separate the cable from the

bracket

Page 102 of 228

Throttle positioner (2BE)

24Special tools are required to carry out a

comprehensive adjustment on the 2BE

carburettor. This work should therefore be left

to a BMW dealer.

13 Fuel injection -

general information

The fuel injection system is composed of

three basic sub-systems: fuel system, air

intake system and electronic control system.

Fuel system

An electric fuel pump, located inside the

fuel tank or beside the fuel tank, supplies fuel

under constant pressure to the fuel rail, which

distributes fuel evenly to all injectors. From

the fuel rail, fuel is injected into the intake

ports, just above the intake valves, by the fuel

injectors. The amount of fuel supplied by the

injectors is precisely controlled by an

Electronic Control Unit (ECU). An additional

injector, known as the cold start injector (L-

Jetronic and early Motronic systems only),

supplies extra fuel into the intake manifold for

starting. A pressure regulator controls system

pressure in relation to intake manifold

vacuum. A fuel filter between the fuel pump

and the fuel rail filters the fuel, to protect the

components of the system.

Air intake system

The air intake system consists of an air filter

housing, an airflow meter, a throttle body, the

intake manifold, and the associated ducting.

The airflow meter is an information-gathering

device for the ECU. These models are

equipped with the vane-type airflow meter. A

potentiometer measures intake airflow, and a

temperature sensor measures intake air

temperature. This information helps the ECU

determine the amount of fuel to be injected by

the injectors (injection duration). The throttle

plate inside the throttle body is controlled by

the driver. As the throttle plate opens, the

amount of air that can pass through the

system increases, so the potentiometer opens

further and the ECU signals the injectors to

increase the amount of fuel delivered to the

intake ports.

Electronic control system

The computer control system controls the

fuel system and other systems by means of

an Electronic Control Unit (ECU). The ECU

receives signals from a number of information

sensors which monitor such variables as

intake air volume, intake air temperature,

coolant temperature, engine rpm,

acceleration/deceleration, and exhaust

oxygen content. These signals help the ECU

determine the injection duration necessary for

the optimum air/fuel ratio. These sensors and

their corresponding ECU-controlled outputactuators are located throughout the engine

compartment. For further information

regarding the ECU and its relationship to the

engine electrical systems and ignition system,

refer to Chapters 5 and 6.

Either an L-Jetronic system or a Motronic

system is fitted. Later models have an

updated version of the original Motronic

system.

14 Fuel injection systems

L-Jetronic fuel injection system

The Bosch L-Jetronic fuel injection system

is used on most 3-Series models up to 1987,

and on most E28 (“old-shape”) 5-Series

models. It is an electronically-controlled fuel

injection system that utilises one solenoid-

operated fuel injector per cylinder. The system

is governed by an Electronic Control Unit

(ECU) which processes information sent by

various sensors, and in turn precisely

meters the fuel to the cylinders by

adjusting the amount of time that the injectors

are open.

An electric fuel pump delivers fuel under

high pressure to the injectors, through the fuel

feed line and an in-line filter. A pressure

regulator keeps fuel available at an optimum

pressure, allowing pressure to rise or fall

depending on engine speed and load. Any

excess fuel is returned to the fuel tank by a

separate line.

A sensor in the air intake duct constantly

measures the mass of the incoming air, and

the ECU adjusts the fuel mixture to provide an

optimum air/fuel ratio.

Other components incorporated in the

system are the throttle valve (which controls

airflow to the engine), the coolant temperature

sensor, the throttle position switch, idle

stabiliser valve (which bypasses air around

the throttle plate to control idle speed) and

associated relays and fuses.

Motronic fuel injection system

The Motronic system combines the fuel

control of the L-Jetronic fuel injection system

with the control of ignition timing, idle speed

and emissions into one control unit.

The fuel injection and idle speed control

functions are similar to those used on the L-

Jetronic system described above. For more

information on the Motronic system, see

Chapter 6.

An oxygen sensor is mounted in the

exhaust system on later models with a

catalytic converter. This sensor continually

reads the oxygen content of the exhaust gas.

The information is used by the ECU to adjust

the duration of injection, making it possible to

adjust the fuel mixture for optimum converter

efficiency and minimum emissions.

15 Fuel injection system-

check

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

1Check the earth wire connections. Check

all wiring harness connectors that are related

to the system. Loose connectors and poor

earths can cause many problems that

resemble more serious malfunctions.

2Make sure the battery is fully charged, as

the control unit and sensors depend on an

accurate supply voltage in order to properly

meter the fuel.

3Check the air filter element - a dirty or

partially-blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for an earthed

wire in the harness related to the system.

5Check the air intake duct from the airflow

meter to the intake manifold for leaks. Intake

air leaks can cause a variety of problems. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body, and check for dirt, carbon and other

residue build-up. If it’s dirty, clean it with

carburettor cleaner and a toothbrush.

7With the engine running, place a

screwdriver or a stethoscope against each

injector, one at a time, and listen for a clicking

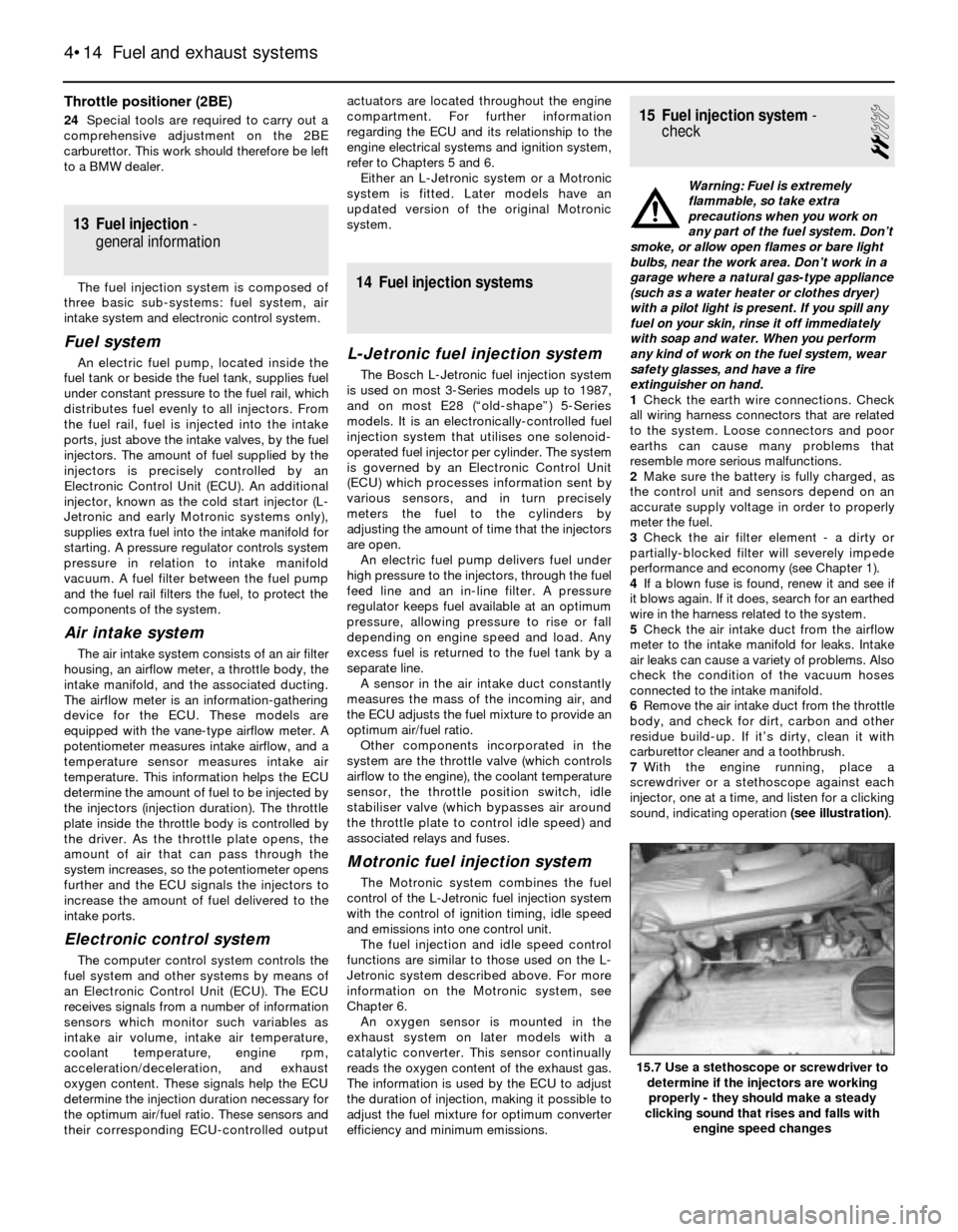

sound, indicating operation (see illustration).

4•14 Fuel and exhaust systems

15.7 Use a stethoscope or screwdriver to

determine if the injectors are working

properly - they should make a steady

clicking sound that rises and falls with

engine speed changes

Page 103 of 228

8Check the fuel system pressure (see

Section 3).

9If these checks do not locate the problem,

take the vehicle to a BMW dealer, who will be

able to read the fault codes stored in the ECU,

using special equipment.

16 Airflow meter- check,

removal and refitting

2

Check (L-Jetronic systems)

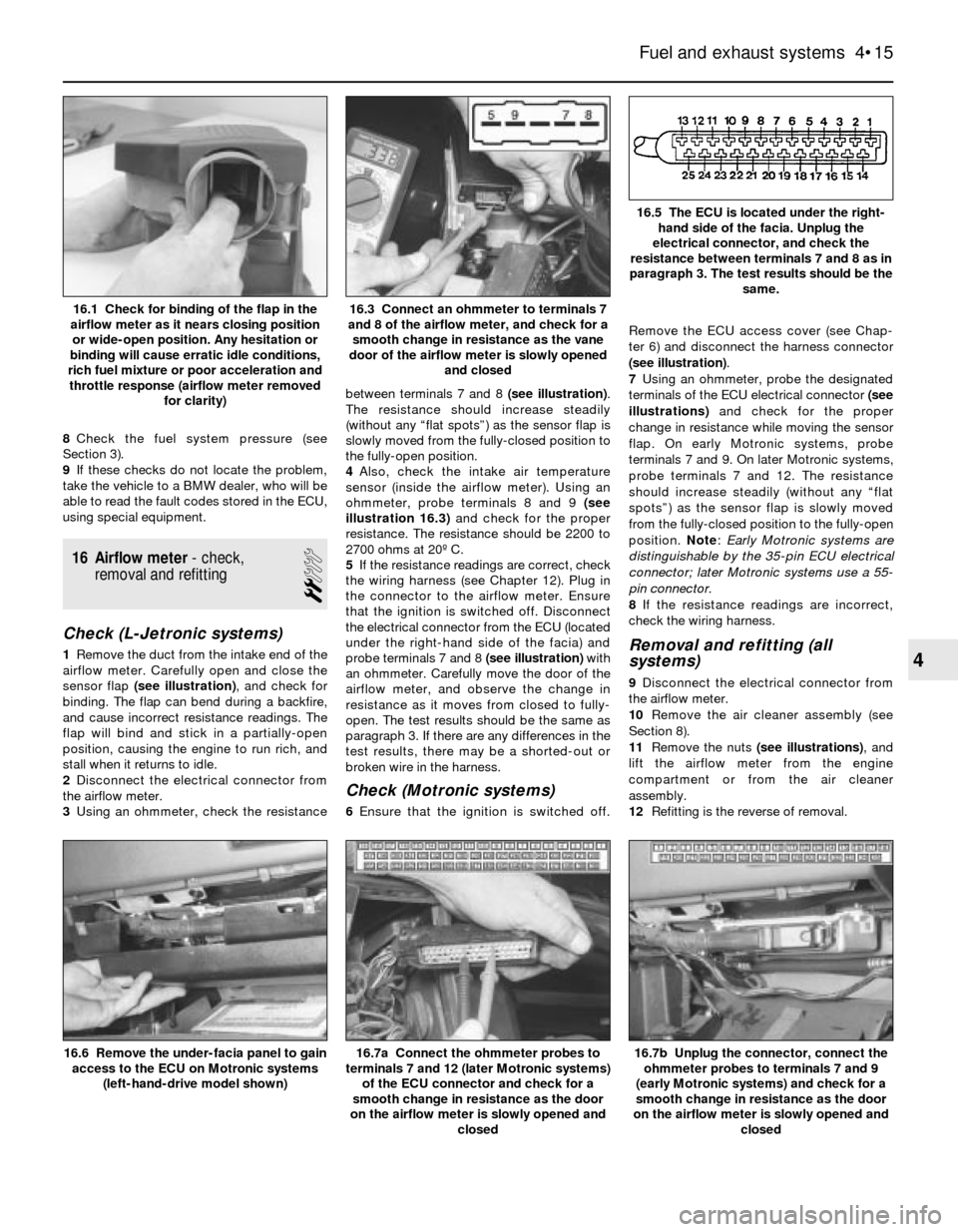

1Remove the duct from the intake end of the

airflow meter. Carefully open and close the

sensor flap (see illustration), and check for

binding. The flap can bend during a backfire,

and cause incorrect resistance readings. The

flap will bind and stick in a partially-open

position, causing the engine to run rich, and

stall when it returns to idle.

2Disconnect the electrical connector from

the airflow meter.

3Using an ohmmeter, check the resistancebetween terminals 7 and 8 (see illustration).

The resistance should increase steadily

(without any “flat spots”) as the sensor flap is

slowly moved from the fully-closed position to

the fully-open position.

4Also, check the intake air temperature

sensor (inside the airflow meter). Using an

ohmmeter, probe terminals 8 and 9 (see

illustration 16.3)and check for the proper

resistance. The resistance should be 2200 to

2700 ohms at 20º C.

5If the resistance readings are correct, check

the wiring harness (see Chapter 12). Plug in

the connector to the airflow meter. Ensure

that the ignition is switched off. Disconnect

the electrical connector from the ECU (located

under the right-hand side of the facia) and

probe terminals 7 and 8 (see illustration)with

an ohmmeter. Carefully move the door of the

airflow meter, and observe the change in

resistance as it moves from closed to fully-

open. The test results should be the same as

paragraph 3. If there are any differences in the

test results, there may be a shorted-out or

broken wire in the harness.

Check (Motronic systems)

6Ensure that the ignition is switched off.Remove the ECU access cover (see Chap-

ter 6) and disconnect the harness connector

(see illustration).

7Using an ohmmeter, probe the designated

terminals of the ECU electrical connector (see

illustrations)and check for the proper

change in resistance while moving the sensor

flap. On early Motronic systems, probe

terminals 7 and 9. On later Motronic systems,

probe terminals 7 and 12. The resistance

should increase steadily (without any “flat

spots”) as the sensor flap is slowly moved

from the fully-closed position to the fully-open

position. Note: Early Motronic systems are

distinguishable by the 35-pin ECU electrical

connector; later Motronic systems use a 55-

pin connector.

8If the resistance readings are incorrect,

check the wiring harness.

Removal and refitting (all

systems)

9Disconnect the electrical connector from

the airflow meter.

10Remove the air cleaner assembly (see

Section 8).

11Remove the nuts (see illustrations), and

lift the airflow meter from the engine

compartment or from the air cleaner

assembly.

12Refitting is the reverse of removal.

Fuel and exhaust systems 4•15

16.5 The ECU is located under the right-

hand side of the facia. Unplug the

electrical connector, and check the

resistance between terminals 7 and 8 as in

paragraph 3. The test results should be the

same.

16.3 Connect an ohmmeter to terminals 7

and 8 of the airflow meter, and check for a

smooth change in resistance as the vane

door of the airflow meter is slowly opened

and closed16.1 Check for binding of the flap in the

airflow meter as it nears closing position

or wide-open position. Any hesitation or

binding will cause erratic idle conditions,

rich fuel mixture or poor acceleration and

throttle response (airflow meter removed

for clarity)

16.7b Unplug the connector, connect the

ohmmeter probes to terminals 7 and 9

(early Motronic systems) and check for a

smooth change in resistance as the door

on the airflow meter is slowly opened and

closed16.7a Connect the ohmmeter probes to

terminals 7 and 12 (later Motronic systems)

of the ECU connector and check for a

smooth change in resistance as the door

on the airflow meter is slowly opened and

closed16.6 Remove the under-facia panel to gain

access to the ECU on Motronic systems

(left-hand-drive model shown)

4

Page 106 of 228

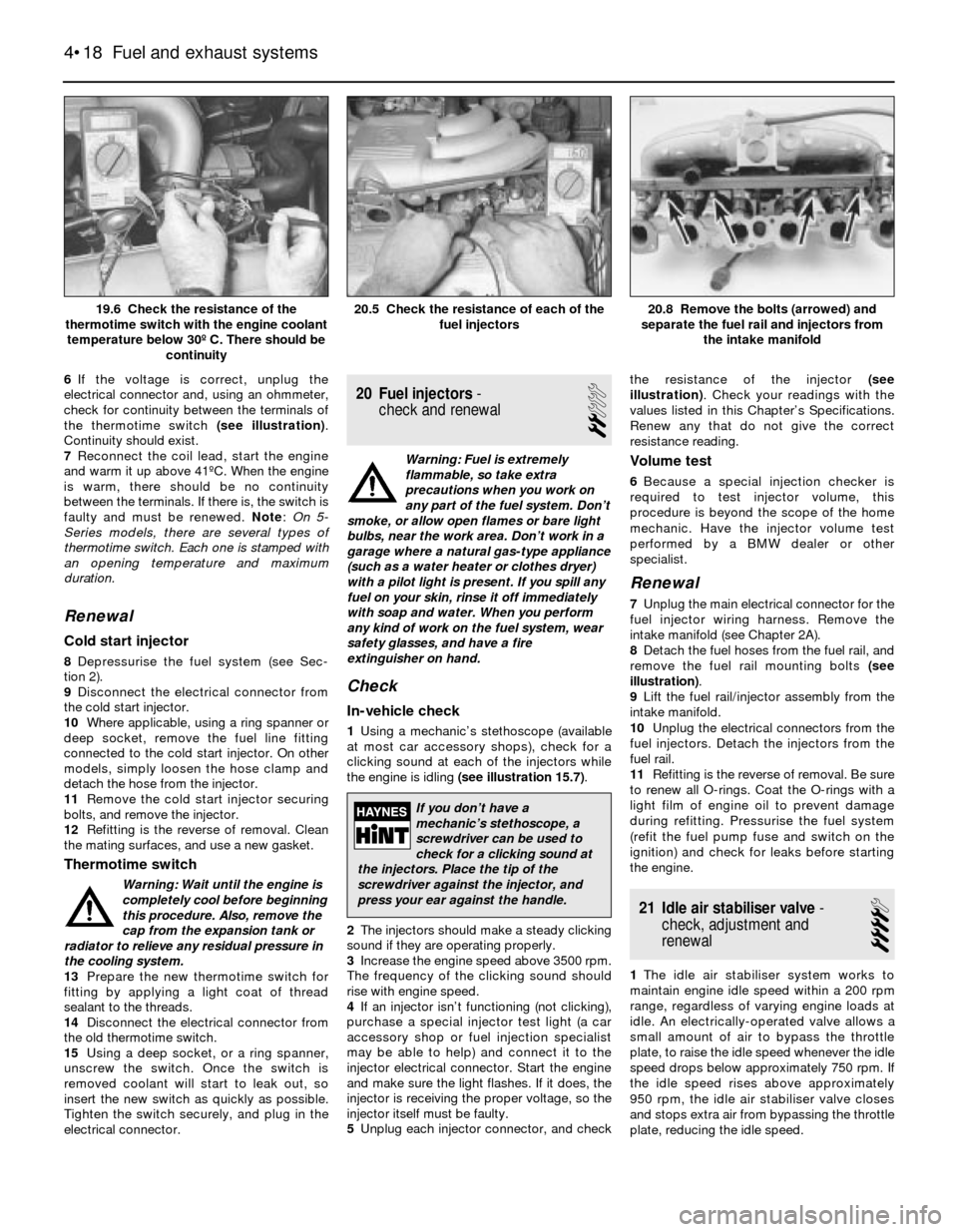

6If the voltage is correct, unplug the

electrical connector and, using an ohmmeter,

check for continuity between the terminals of

the thermotime switch (see illustration).

Continuity should exist.

7Reconnect the coil lead, start the engine

and warm it up above 41ºC. When the engine

is warm, there should be no continuity

between the terminals. If there is, the switch is

faulty and must be renewed. Note: On 5-

Series models, there are several types of

thermotime switch. Each one is stamped with

an opening temperature and maximum

duration.

Renewal

Cold start injector

8Depressurise the fuel system (see Sec-

tion 2).

9Disconnect the electrical connector from

the cold start injector.

10Where applicable, using a ring spanner or

deep socket, remove the fuel line fitting

connected to the cold start injector. On other

models, simply loosen the hose clamp and

detach the hose from the injector.

11Remove the cold start injector securing

bolts, and remove the injector.

12Refitting is the reverse of removal. Clean

the mating surfaces, and use a new gasket.

Thermotime switch

Warning: Wait until the engine is

completely cool before beginning

this procedure. Also, remove the

cap from the expansion tank or

radiator to relieve any residual pressure in

the cooling system.

13Prepare the new thermotime switch for

fitting by applying a light coat of thread

sealant to the threads.

14Disconnect the electrical connector from

the old thermotime switch.

15Using a deep socket, or a ring spanner,

unscrew the switch. Once the switch is

removed coolant will start to leak out, so

insert the new switch as quickly as possible.

Tighten the switch securely, and plug in the

electrical connector.

20 Fuel injectors-

check and renewal

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

Check

In-vehicle check

1Using a mechanic’s stethoscope (available

at most car accessory shops), check for a

clicking sound at each of the injectors while

the engine is idling (see illustration 15.7).

2The injectors should make a steady clicking

sound if they are operating properly.

3Increase the engine speed above 3500 rpm.

The frequency of the clicking sound should

rise with engine speed.

4If an injector isn’t functioning (not clicking),

purchase a special injector test light (a car

accessory shop or fuel injection specialist

may be able to help) and connect it to the

injector electrical connector. Start the engine

and make sure the light flashes. If it does, the

injector is receiving the proper voltage, so the

injector itself must be faulty.

5Unplug each injector connector, and checkthe resistance of the injector (see

illustration). Check your readings with the

values listed in this Chapter’s Specifications.

Renew any that do not give the correct

resistance reading.

Volume test

6Because a special injection checker is

required to test injector volume, this

procedure is beyond the scope of the home

mechanic. Have the injector volume test

performed by a BMW dealer or other

specialist.

Renewal

7Unplug the main electrical connector for the

fuel injector wiring harness. Remove the

intake manifold (see Chapter 2A).

8Detach the fuel hoses from the fuel rail, and

remove the fuel rail mounting bolts (see

illustration).

9Lift the fuel rail/injector assembly from the

intake manifold.

10Unplug the electrical connectors from the

fuel injectors. Detach the injectors from the

fuel rail.

11Refitting is the reverse of removal. Be sure

to renew all O-rings. Coat the O-rings with a

light film of engine oil to prevent damage

during refitting. Pressurise the fuel system

(refit the fuel pump fuse and switch on the

ignition) and check for leaks before starting

the engine.

21 Idle air stabiliser valve-

check, adjustment and

renewal

4

1The idle air stabiliser system works to

maintain engine idle speed within a 200 rpm

range, regardless of varying engine loads at

idle. An electrically-operated valve allows a

small amount of air to bypass the throttle

plate, to raise the idle speed whenever the idle

speed drops below approximately 750 rpm. If

the idle speed rises above approximately

950 rpm, the idle air stabiliser valve closes

and stops extra air from bypassing the throttle

plate, reducing the idle speed.

4•18 Fuel and exhaust systems

20.8 Remove the bolts (arrowed) and

separate the fuel rail and injectors from

the intake manifold20.5 Check the resistance of each of the

fuel injectors19.6 Check the resistance of the

thermotime switch with the engine coolant

temperature below 30º C. There should be

continuity

If you don’t have a

mechanic’s stethoscope, a

screwdriver can be used to

check for a clicking sound at

the injectors. Place the tip of the

screwdriver against the injector, and

press your ear against the handle.

Page 109 of 228

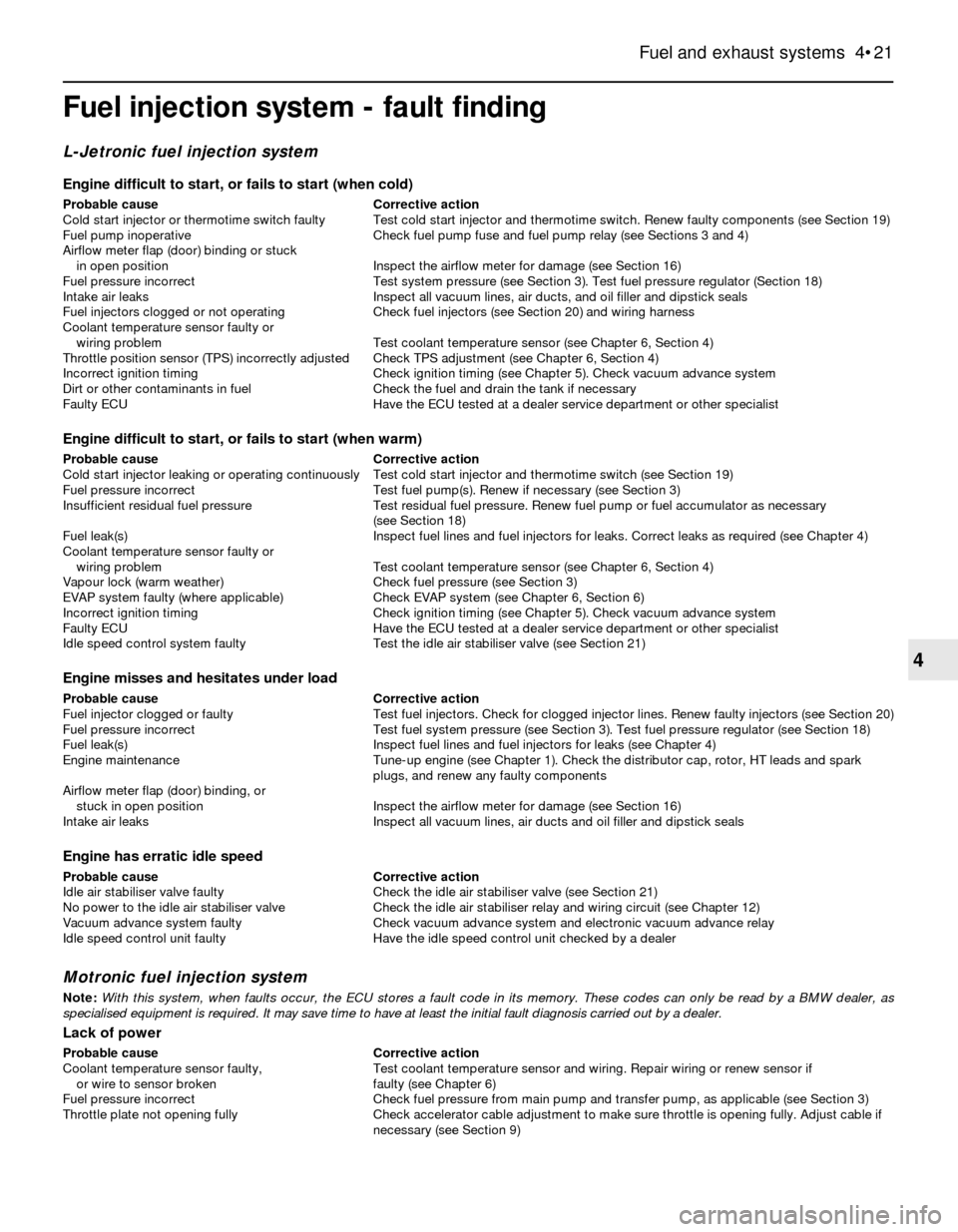

Fuel injection system - fault finding

L-Jetronic fuel injection system

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch faulty Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump inoperative Check fuel pump fuse and fuel pump relay (see Sections 3 and 4)

Airflow meter flap (door) binding or stuck

in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3). Test fuel pressure regulator (Section 18)

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating continuously Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pump(s). Renew if necessary (see Section 3)

Insufficient residual fuel pressure Test residual fuel pressure. Renew fuel pump or fuel accumulator as necessary

(see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as required (see Chapter 4)

Coolant temperature sensor faulty or

wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (warm weather) Check fuel pressure (see Section 3)

EVAP system faulty (where applicable) Check EVAP system (see Chapter 6, Section 6)

Incorrect ignition timing Check ignition timing (see Chapter 5). Check vacuum advance system

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged or faulty Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Vacuum advance system faulty Check vacuum advance system and electronic vacuum advance relay

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Motronic fuel injection system

Note:With this system, when faults occur, the ECU stores a fault code in its memory. These codes can only be read by a BMW dealer, as

specialised equipment is required. It may save time to have at least the initial fault diagnosis carried out by a dealer.

Lack of power

Probable cause Corrective action

Coolant temperature sensor faulty, Test coolant temperature sensor and wiring. Repair wiring or renew sensor if

or wire to sensor broken faulty (see Chapter 6)

Fuel pressure incorrect Check fuel pressure from main pump and transfer pump, as applicable (see Section 3)

Throttle plate not opening fully Check accelerator cable adjustment to make sure throttle is opening fully. Adjust cable if

necessary (see Section 9)

Fuel and exhaust systems 4•21

4

Page 110 of 228

Engine difficult to start, or fails to start (when cold)

Probable cause Corrective action

Cold start injector or thermotime switch

faulty (early Motronic system only) Test cold start injector and thermotime switch. Renew faulty components (see Section 19)

Fuel pump not running Check fuel pump fuse and fuel pump relay (see Sections 2 and 3)

Airflow meter flap (door) binding, or

stuck in open position Inspect the airflow meter for damage (see Section 16)

Fuel pressure incorrect Test system pressure (see Section 3)

Intake air leaks Inspect all vacuum lines, air ducts and oil filler and dipstick seals

Fuel injectors clogged or not operating Check fuel injectors (see Section 20) and wiring harness

Coolant temperature sensor faulty or Test coolant temperature sensor (see Chapter 6, Section 4)

wiring problem

TPS (throttle position sensor) incorrectly adjusted Check TPS adjustment (see Chapter 6, Section 4)

Dirt or other contaminants in fuel Check the fuel and drain the tank if necessary

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Crankshaft position signal missing Faulty position sensor or flywheel, or reference pin missing (see Chapter 5)

Engine difficult to start, or fails to start (when warm)

Probable cause Corrective action

Cold start injector leaking or operating

continuously (early Motronic system only) Test cold start injector and thermotime switch (see Section 19)

Fuel pressure incorrect Test fuel pressure (see Section 3)

Insufficient residual fuel pressure Test fuel system hold pressure (see Section 3)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks. Correct leaks as necessary

Coolant temperature sensor faulty

or wiring problem Test coolant temperature sensor (see Chapter 6, Section 4)

Vapour lock (in warm weather) Check fuel pressure (see Section 3)

EVAP system faulty Check EVAP system (see Chapter 6, Section 6)

Faulty ECU Have the ECU tested at a dealer service department or other specialist

Idle speed control system faulty Test the idle air stabiliser valve (see Section 21)

Oxygen sensor faulty (where applicable) Check the oxygen sensor (see Chapter 6, Section 4)

Engine misses and hesitates under load

Probable cause Corrective action

Fuel injector clogged Test fuel injectors. Check for clogged injector lines. Renew faulty injectors (see Section 20)

Fuel pressure incorrect Test fuel system pressure (see Section 3). Test fuel pressure regulator (see Section 18)

Fuel leak(s) Inspect fuel lines and fuel injectors for leaks (see Chapter 4)

Engine maintenance Tune-up engine (see Chapter 1). Check the distributor cap, rotor, HT leads and spark

plugs, and renew any faulty components

Airflow meter flap (door) binding, or Inspect the airflow meter for damage (see Section 16)

stuck in open position

Intake air leaks Inspect all vacuum lines, air ducts, and oil filler and dipstick seals

Throttle position sensor (TPS) incorrectly adjusted Check TPS adjustment (see Chapter 6)

Engine idles too fast

Probable cause Corrective action

Accelerator pedal, cable or throttle valve binding Check for worn or broken components, kinked cable, or other damage. Renew faulty

components

Air leaking past throttle valve Inspect throttle valve, and adjust or renew as required

Engine has erratic idle speed

Probable cause Corrective action

Idle air stabiliser valve faulty Check the idle air stabiliser valve (see Section 21)

No power to the idle air stabiliser valve Check the idle air stabiliser relay and wiring circuit (see Chapter 12)

Idle speed control unit faulty Have the idle speed control unit checked by a dealer

Poor fuel economy

Probable cause Corrective action

Cold start injector leaking

(early Motronic system only) Test and, if necessary, renew cold start injector (see Section 19)

Oxygen sensor faulty (where applicable) Test the oxygen sensor (see Chapter 6, Section 4))

Sticking handbrake/binding brakes Check the handbrake/braking system (see Chapter 9)

Tyre pressures low Check tyre pressures (Chapter 1)

4•22 Fuel and exhaust systems

Page 113 of 228

5 Ignition system- general

information and precautions

The ignition system includes the ignition

switch, the battery, the distributor, the primary

(low-voltage/low-tension or LT) and

secondary (high-voltage/high-tension or HT)

wiring circuits, the spark plugs and the spark

plug leads. Models fitted with a carburettor or

L-Jetronic fuel injection are equipped with a

Transistorised Coil Ignition (TCI) system.

Models fitted with the Motronic fuel injection

system have the ignition system incorporated

within the Motronic system (Digital Motor

Electronics or DME).

Transistorised Coil Ignition (TCI)

system

This system is has four major components;

the impulse generator, the ignition control

unit, the coil, and the spark plugs. The

impulse generator provides a timing signal for

the ignition system. Equivalent to cam-

actuated breaker points in a standard

distributor, the impulse generator creates an

A/C voltage signal every time the trigger

wheel tabs pass the impulse generator tabs.

When the ignition control unit (capacitive

discharge unit) receives the voltage signal, it

triggers a spark discharge from the coil by

interrupting the primary coil circuit. The

ignition dwell (coil charging time) is adjusted

by the ignition control unit for the most

intense spark. Note: The air gap (distance

between the impulse generator and trigger

wheel tabs) can be adjusted (see Section 11).

Ignition timing is mechanically adjusted

(see Section 7). A centrifugal advance unit

that consists of spring-loaded rotating

weights advances ignition timing as engine

speed increases. The vacuum advance

adjusts ignition timing to compensate for

changes in engine load.

Motronic ignition system

This system, also known as Digital Motor

Electronics (DME), incorporates all ignition

and fuel injection functions into one central

control unit or ECU (computer). The ignition

timing is based on inputs the ECU receives for

engine load, engine speed, coolant

temperature and intake air temperature. The

only function the distributor performs is the

distribution of the high voltage signal to the

individual spark plugs. The distributor is

attached directly to the cylinder head. There is

no mechanical spark advance system used on

these systems.

Ignition timing is electronically-controlled,

and is not adjustable on Motronic systems.

During starting, a crankshaft position sensor

(reference sensor) relays the crankshaft

position to the ECU, and an initial baseline

ignition point is determined. Once the engineis running, the ignition timing is continually

changing, based on the various input signals

to the ECU. Engine speed is signalled by a

speed sensor. Early Motronic systems have

the position reference sensor and the speed

sensor mounted on the bellhousing over the

flywheel on the left-hand side. Later Motronic

systems have a single sensor (pulse sensor)

mounted over the crankshaft pulley. This

sensor functions as a speed sensor as well as

a position reference sensor. Refer to Sec-

tion 12 for checking and renewing the ignition

sensors. Note: Some models are equipped

with a TDC sensor mounted on the front of the

engine. This sensor is strictly for the BMW

service test unit, and it is not part of the

Motronic ignition system.

Precautions

Certain precautions must be observed

when working on a transistorised ignition

system.

a) Do not disconnect the battery cables

when the engine is running

b) Make sure the ignition control unit (TCI

ignition system) is always well earthed

(see Section 10).

c) Keep water away from the distributor and

HT leads.

d) If a tachometer is to be connected to the

engine, always connect the tachometer

positive (+) lead to the ignition coil

negative terminal (-) and never to the

distributor.

e) Do not allow the coil terminals to be

earthed, as the impulse generator or coil

could be damaged.

f) Do not leave the ignition switch on for

more than ten minutes with the engine

off, or if the engine will not start.

6 Ignition system- check

2

Warning: Because of the high

voltage generated by the ignition

system, extreme care should be

taken whenever an operation is

performed involving ignition components.

This not only includes the impulse

generator (electronic ignition), coil,

distributor and spark plug HT leads, but

related components such as spark plug

connectors, tachometer and other test

equipment.

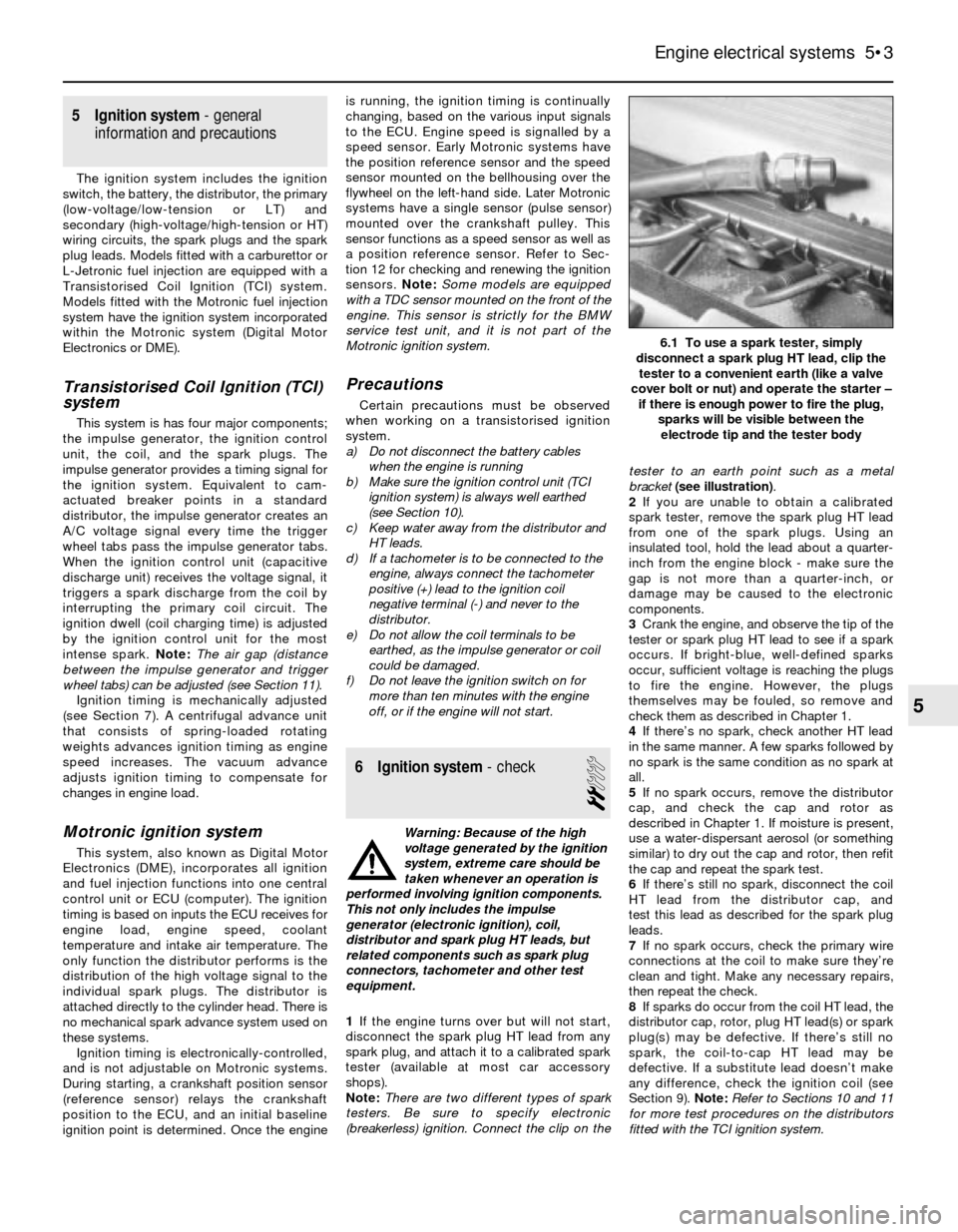

1If the engine turns over but will not start,

disconnect the spark plug HT lead from any

spark plug, and attach it to a calibrated spark

tester (available at most car accessory

shops).

Note:There are two different types of spark

testers. Be sure to specify electronic

(breakerless) ignition. Connect the clip on thetester to an earth point such as a metal

bracket (see illustration).

2If you are unable to obtain a calibrated

spark tester, remove the spark plug HT lead

from one of the spark plugs. Using an

insulated tool, hold the lead about a quarter-

inch from the engine block - make sure the

gap is not more than a quarter-inch, or

damage may be caused to the electronic

components.

3Crank the engine, and observe the tip of the

tester or spark plug HT lead to see if a spark

occurs. If bright-blue, well-defined sparks

occur, sufficient voltage is reaching the plugs

to fire the engine. However, the plugs

themselves may be fouled, so remove and

check them as described in Chapter 1.

4If there’s no spark, check another HT lead

in the same manner. A few sparks followed by

no spark is the same condition as no spark at

all.

5If no spark occurs, remove the distributor

cap, and check the cap and rotor as

described in Chapter 1. If moisture is present,

use a water-dispersant aerosol (or something

similar) to dry out the cap and rotor, then refit

the cap and repeat the spark test.

6If there’s still no spark, disconnect the coil

HT lead from the distributor cap, and

test this lead as described for the spark plug

leads.

7If no spark occurs, check the primary wire

connections at the coil to make sure they’re

clean and tight. Make any necessary repairs,

then repeat the check.

8If sparks do occur from the coil HT lead, the

distributor cap, rotor, plug HT lead(s) or spark

plug(s) may be defective. If there’s still no

spark, the coil-to-cap HT lead may be

defective. If a substitute lead doesn’t make

any difference, check the ignition coil (see

Section 9). Note:Refer to Sections 10 and 11

for more test procedures on the distributors

fitted with the TCI ignition system.

Engine electrical systems 5•3

6.1 To use a spark tester, simply

disconnect a spark plug HT lead, clip the

tester to a convenient earth (like a valve

cover bolt or nut) and operate the starter –

if there is enough power to fire the plug,

sparks will be visible between the

electrode tip and the tester body

5