light BMW 3 SERIES 1987 E30 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1987, Model line: 3 SERIES, Model: BMW 3 SERIES 1987 E30Pages: 228, PDF Size: 7.04 MB

Page 49 of 228

22Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the covers and engine block.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Also, do not

damage the sump gasket, and

keep it clean. Gasket removal solvents are

available at motor factors, and may

prove helpful. After all gasket material has

been removed, the gasket surfaces

can be degreased by wiping them

with a rag dampened with a suitable

solvent.

23Support the cover on two blocks of wood,

and drive out the seals from behind with a

hammer and screwdriver. Be very careful not

to damage the seal bores in the process.

24Coat the outside diameters and lips of the

new seals with multi-purpose grease, and

drive the seals into the cover with a hammer

and a socket slightly smaller in diameter than

the outside diameter of the seal.

25Apply a film of RTV-type gasket sealant to

the surface of the sump gasket that mates

with the front cover. Apply extra beads of RTV

sealant to the edges where the gasket meets

the engine block. Note:If the sump gasket is

damaged, instead of fitting a whole new

gasket, you might try trimming the front

portion of the gasket off at the point where it

meets the engine block, then trim off the front

portion of a new sump gasket so it’s exactly

the same size. Cover the exposed inside area

of the sump with a rag, then clean all traces of

old gasket material off the area where the

gasket was removed. Attach the new gasket

piece to the sump with contact-cement-type

gasket adhesive, then apply RTV-type sealant

as described at the beginning of this

paragraph.

26Coat both sides of the new gasket with

RTV-type gasket sealant, then attach the front

cover to the front of the engine, carefully

working the seals over the crankshaft and

intermediate shaft. Refit the bolts and tighten

them evenly to the torque listed in this

Chapter’s Specifications. Work from bolt-to-

bolt in a criss-cross pattern, to be sure they’re

tightened evenly.Note 1:Tighten the front

cover-to-block bolts first, then tighten the

sump-to-cover bolts. Note 2:After applying

RTV-type sealant, reassembly must be

completed in about 10 minutes so the RTV

won’t prematurely harden.

27The remainder of refitting is the reverse of

removal.

Crankshaft front seal (M40 engines)

28Remove the timing belt and crankshaft

sprocket (see Section 10).

29Remove the Woodruff key from the

groove in the end of the crankshaft.

30Note the fitted position of the oil seal, then

prise it out from the front cover using a

screwdriver, but take care not to damage the

bore of the cover or the surface of thecrankshaft. If the seal is tight, drill two small

holes in the metal end of the seal, and use two

self-tapping screws to pull out the seal. Make

sure all remains of swarf are removed.

31Coat the outside diameter and lip of the

new seal with multi-purpose grease, then

drive it into the cover with a hammer and a

socket slightly smaller in diameter than the

outside diameter of the seal. Make sure the

seal enters squarely.

32The remainder of refitting is the reverse of

removal. Note that it is recommended that the

timing belt be renewed - see Section 10.

12 Cylinder head-

removal and refitting

5

Removal

1Relieve the fuel pressure on all fuel injection

engines (see Chapter 4).

2Disconnect the negative cable from the

battery. Where the battery is located in the

engine compartment, the battery may be

removed completely (see Chapter 5).

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Remove the air cleaner assembly (see

Chapter 4).

4Disconnect the wiring from the distributor

(mark all wiring for position first, if necessary),

and the HT lead from the coil (see Chapter 5).

5Disconnect the lead from the coolant

temperature sender unit (see Chapter 3).

6Disconnect the fuel lines from the fuel rail or

carburettor as applicable (see Chapter 4).

7Drain the cooling system (see Chapter 3).

8Clearly label then disconnect all other

hoses from the throttle body, intake manifold,

carburettor and cylinder head, as applicable.

9Disconnect the throttle cable from the

throttle linkage or carburettor (see Chapter 4).

10Disconnect the exhaust manifold from the

cylinder head (see Section 6). Depending on

the engine type, It may not be necessary to

disconnect the manifold from the exhaust

pipe; however, on right-hand-drive models,

the steering column intermediate shaft may

not allow the manifold to clear the studs on

the cylinder head.

11Remove or disconnect any remaining

hoses or lines from the intake manifold,

including the ignition advance vacuum line(s),

and the coolant and heater hoses.

12On early carburettor models, disconnect

the wiring from the alternator and starter

motor.13Remove the intake manifold (see Sec-

tion 5). Do not dismantle or remove any fuel

injection system components unless it is

absolutely necessary.

14Remove the fan drivebelt and fan (see

Chapter 3).

15Remove the valve cover and gasket (see

Section 4). Remove the semi-circular rubber

seal from the front of the cylinder head, where

this is not incorporated in the valve cover

gasket.

16Set No 1 piston at Top Dead Centre on

the compression stroke (see Section 3).

17Remove the timing chain or belt (see

Section 8 or 10). Note:If you want to save

time by not removing and refitting the timing

belt or chain and re-timing the engine, you can

unfasten the camshaft sprocket and suspend

it out of the way - with the belt or chain still

attached - by a piece of rope. Be sure the

rope keeps firm tension on the belt or chain,

so it won’t become disengaged from any of

the sprockets.

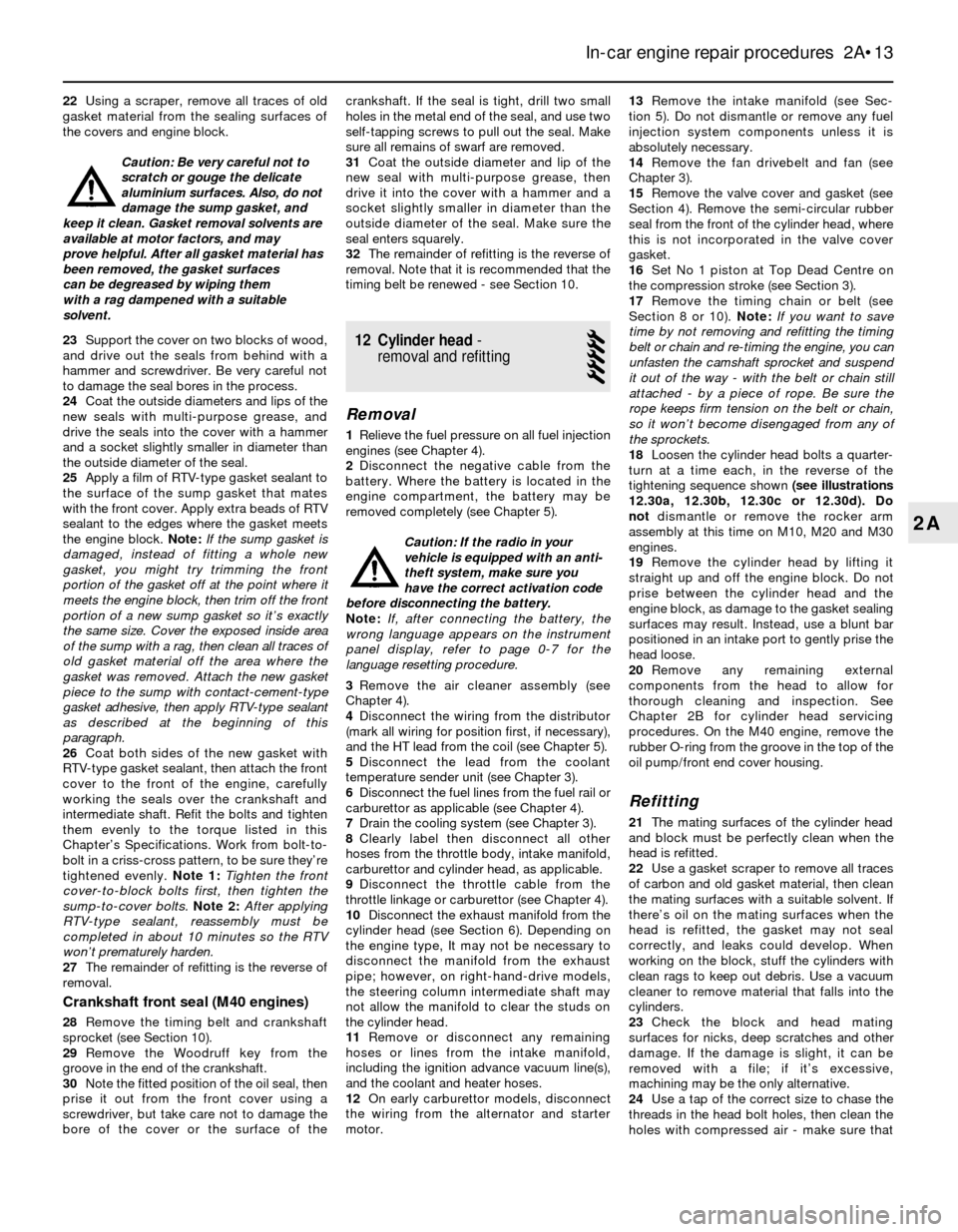

18Loosen the cylinder head bolts a quarter-

turn at a time each, in the reverse of the

tightening sequence shown (see illustrations

12.30a, 12.30b, 12.30c or 12.30d). Do

notdismantle or remove the rocker arm

assembly at this time on M10, M20 and M30

engines.

19Remove the cylinder head by lifting it

straight up and off the engine block. Do not

prise between the cylinder head and the

engine block, as damage to the gasket sealing

surfaces may result. Instead, use a blunt bar

positioned in an intake port to gently prise the

head loose.

20Remove any remaining external

components from the head to allow for

thorough cleaning and inspection. See

Chapter 2B for cylinder head servicing

procedures. On the M40 engine, remove the

rubber O-ring from the groove in the top of the

oil pump/front end cover housing.

Refitting

21The mating surfaces of the cylinder head

and block must be perfectly clean when the

head is refitted.

22Use a gasket scraper to remove all traces

of carbon and old gasket material, then clean

the mating surfaces with a suitable solvent. If

there’s oil on the mating surfaces when the

head is refitted, the gasket may not seal

correctly, and leaks could develop. When

working on the block, stuff the cylinders with

clean rags to keep out debris. Use a vacuum

cleaner to remove material that falls into the

cylinders.

23Check the block and head mating

surfaces for nicks, deep scratches and other

damage. If the damage is slight, it can be

removed with a file; if it’s excessive,

machining may be the only alternative.

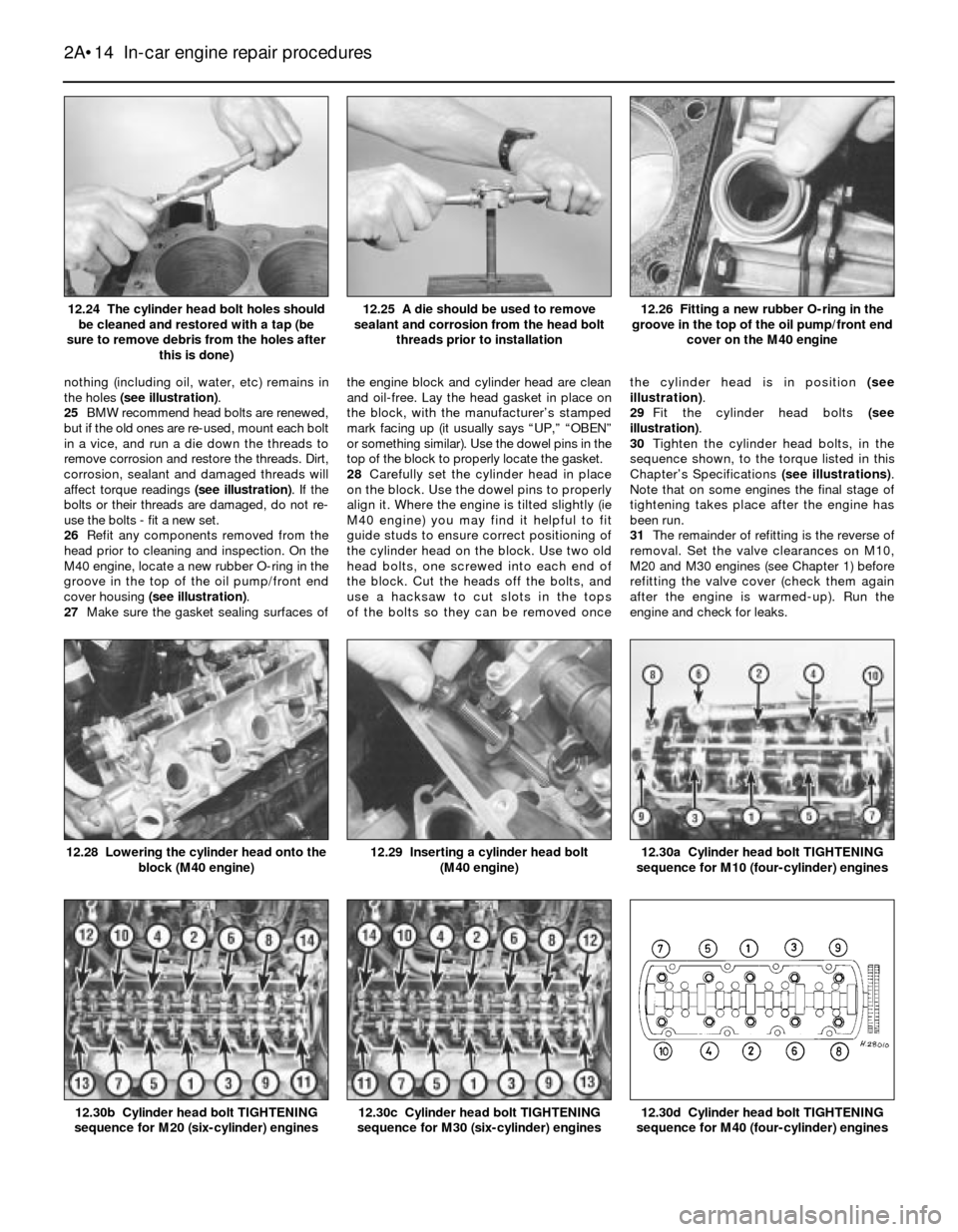

24Use a tap of the correct size to chase the

threads in the head bolt holes, then clean the

holes with compressed air - make sure that

In-car engine repair procedures 2A•13

2A

Page 50 of 228

nothing (including oil, water, etc) remains in

the holes (see illustration).

25BMW recommend head bolts are renewed,

but if the old ones are re-used, mount each bolt

in a vice, and run a die down the threads to

remove corrosion and restore the threads. Dirt,

corrosion, sealant and damaged threads will

affect torque readings (see illustration). If the

bolts or their threads are damaged, do not re-

use the bolts - fit a new set.

26Refit any components removed from the

head prior to cleaning and inspection. On the

M40 engine, locate a new rubber O-ring in the

groove in the top of the oil pump/front end

cover housing (see illustration).

27Make sure the gasket sealing surfaces ofthe engine block and cylinder head are clean

and oil-free. Lay the head gasket in place on

the block, with the manufacturer’s stamped

mark facing up (it usually says “UP,” “OBEN”

or something similar). Use the dowel pins in the

top of the block to properly locate the gasket.

28Carefully set the cylinder head in place

on the block. Use the dowel pins to properly

align it. Where the engine is tilted slightly (ie

M40 engine) you may find it helpful to fit

guide studs to ensure correct positioning of

the cylinder head on the block. Use two old

head bolts, one screwed into each end of

the block. Cut the heads off the bolts, and

use a hacksaw to cut slots in the tops

of the bolts so they can be removed oncethe cylinder head is in position (see

illustration).

29Fit the cylinder head bolts (see

illustration).

30Tighten the cylinder head bolts, in the

sequence shown, to the torque listed in this

Chapter’s Specifications (see illustrations).

Note that on some engines the final stage of

tightening takes place after the engine has

been run.

31The remainder of refitting is the reverse of

removal. Set the valve clearances on M10,

M20 and M30 engines (see Chapter 1) before

refitting the valve cover (check them again

after the engine is warmed-up). Run the

engine and check for leaks.

2A•14 In-car engine repair procedures

12.30d Cylinder head bolt TIGHTENING

sequence for M40 (four-cylinder) engines12.30c Cylinder head bolt TIGHTENING

sequence for M30 (six-cylinder) engines12.30b Cylinder head bolt TIGHTENING

sequence for M20 (six-cylinder) engines

12.30a Cylinder head bolt TIGHTENING

sequence for M10 (four-cylinder) engines12.29 Inserting a cylinder head bolt

(M40 engine)12.28 Lowering the cylinder head onto the

block (M40 engine)

12.26 Fitting a new rubber O-ring in the

groove in the top of the oil pump/front end

cover on the M40 engine12.25 A die should be used to remove

sealant and corrosion from the head bolt

threads prior to installation12.24 The cylinder head bolt holes should

be cleaned and restored with a tap (be

sure to remove debris from the holes after

this is done)

Page 55 of 228

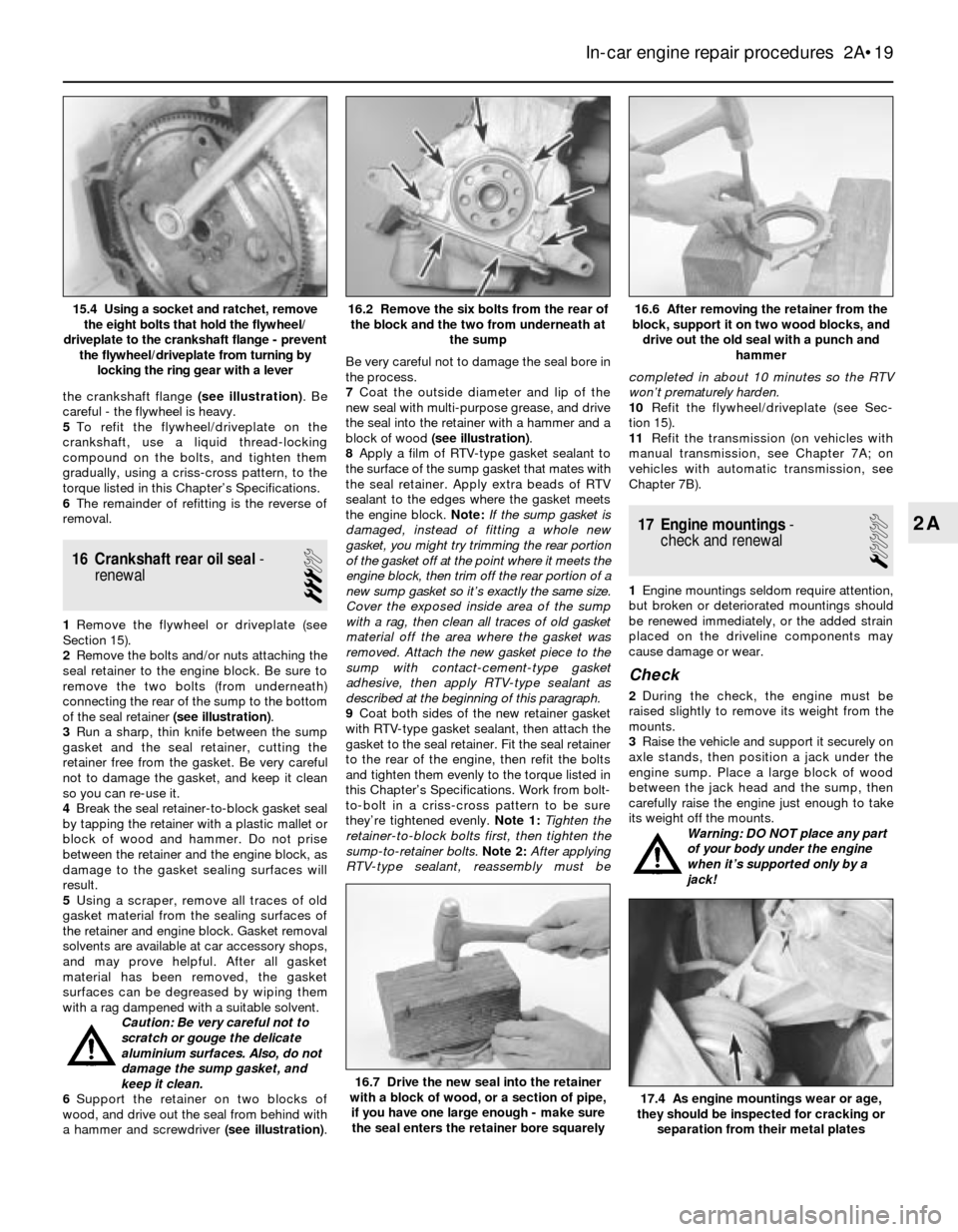

the crankshaft flange (see illustration). Be

careful - the flywheel is heavy.

5To refit the flywheel/driveplate on the

crankshaft, use a liquid thread-locking

compound on the bolts, and tighten them

gradually, using a criss-cross pattern, to the

torque listed in this Chapter’s Specifications.

6The remainder of refitting is the reverse of

removal.

16 Crankshaft rear oil seal-

renewal

3

1Remove the flywheel or driveplate (see

Section 15).

2Remove the bolts and/or nuts attaching the

seal retainer to the engine block. Be sure to

remove the two bolts (from underneath)

connecting the rear of the sump to the bottom

of the seal retainer (see illustration).

3Run a sharp, thin knife between the sump

gasket and the seal retainer, cutting the

retainer free from the gasket. Be very careful

not to damage the gasket, and keep it clean

so you can re-use it.

4Break the seal retainer-to-block gasket seal

by tapping the retainer with a plastic mallet or

block of wood and hammer. Do not prise

between the retainer and the engine block, as

damage to the gasket sealing surfaces will

result.

5Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the retainer and engine block. Gasket removal

solvents are available at car accessory shops,

and may prove helpful. After all gasket

material has been removed, the gasket

surfaces can be degreased by wiping them

with a rag dampened with a suitable solvent.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Also, do not

damage the sump gasket, and

keep it clean.

6Support the retainer on two blocks of

wood, and drive out the seal from behind with

a hammer and screwdriver (see illustration).Be very careful not to damage the seal bore in

the process.

7Coat the outside diameter and lip of the

new seal with multi-purpose grease, and drive

the seal into the retainer with a hammer and a

block of wood (see illustration).

8Apply a film of RTV-type gasket sealant to

the surface of the sump gasket that mates with

the seal retainer. Apply extra beads of RTV

sealant to the edges where the gasket meets

the engine block. Note:If the sump gasket is

damaged, instead of fitting a whole new

gasket, you might try trimming the rear portion

of the gasket off at the point where it meets the

engine block, then trim off the rear portion of a

new sump gasket so it’s exactly the same size.

Cover the exposed inside area of the sump

with a rag, then clean all traces of old gasket

material off the area where the gasket was

removed. Attach the new gasket piece to the

sump with contact-cement-type gasket

adhesive, then apply RTV-type sealant as

described at the beginning of this paragraph.

9Coat both sides of the new retainer gasket

with RTV-type gasket sealant, then attach the

gasket to the seal retainer. Fit the seal retainer

to the rear of the engine, then refit the bolts

and tighten them evenly to the torque listed in

this Chapter’s Specifications. Work from bolt-

to-bolt in a criss-cross pattern to be sure

they’re tightened evenly.Note 1:Tighten the

retainer-to-block bolts first, then tighten the

sump-to-retainer bolts.Note 2:After applying

RTV-type sealant, reassembly must becompleted in about 10 minutes so the RTV

won’t prematurely harden.

10Refit the flywheel/driveplate (see Sec-

tion 15).

11Refit the transmission (on vehicles with

manual transmission, see Chapter 7A; on

vehicles with automatic transmission, see

Chapter 7B).

17 Engine mountings-

check and renewal

1

1Engine mountings seldom require attention,

but broken or deteriorated mountings should

be renewed immediately, or the added strain

placed on the driveline components may

cause damage or wear.

Check

2During the check, the engine must be

raised slightly to remove its weight from the

mounts.

3Raise the vehicle and support it securely on

axle stands, then position a jack under the

engine sump. Place a large block of wood

between the jack head and the sump, then

carefully raise the engine just enough to take

its weight off the mounts.

Warning: DO NOT place any part

of your body under the engine

when it’s supported only by a

jack!

In-car engine repair procedures 2A•19

16.6 After removing the retainer from the

block, support it on two wood blocks, and

drive out the old seal with a punch and

hammer16.2 Remove the six bolts from the rear of

the block and the two from underneath at

the sump15.4 Using a socket and ratchet, remove

the eight bolts that hold the flywheel/

driveplate to the crankshaft flange - prevent

the flywheel/driveplate from turning by

locking the ring gear with a lever

17.4 As engine mountings wear or age,

they should be inspected for cracking or

separation from their metal plates

16.7 Drive the new seal into the retainer

with a block of wood, or a section of pipe,

if you have one large enough - make sure

the seal enters the retainer bore squarely

2A

Page 56 of 228

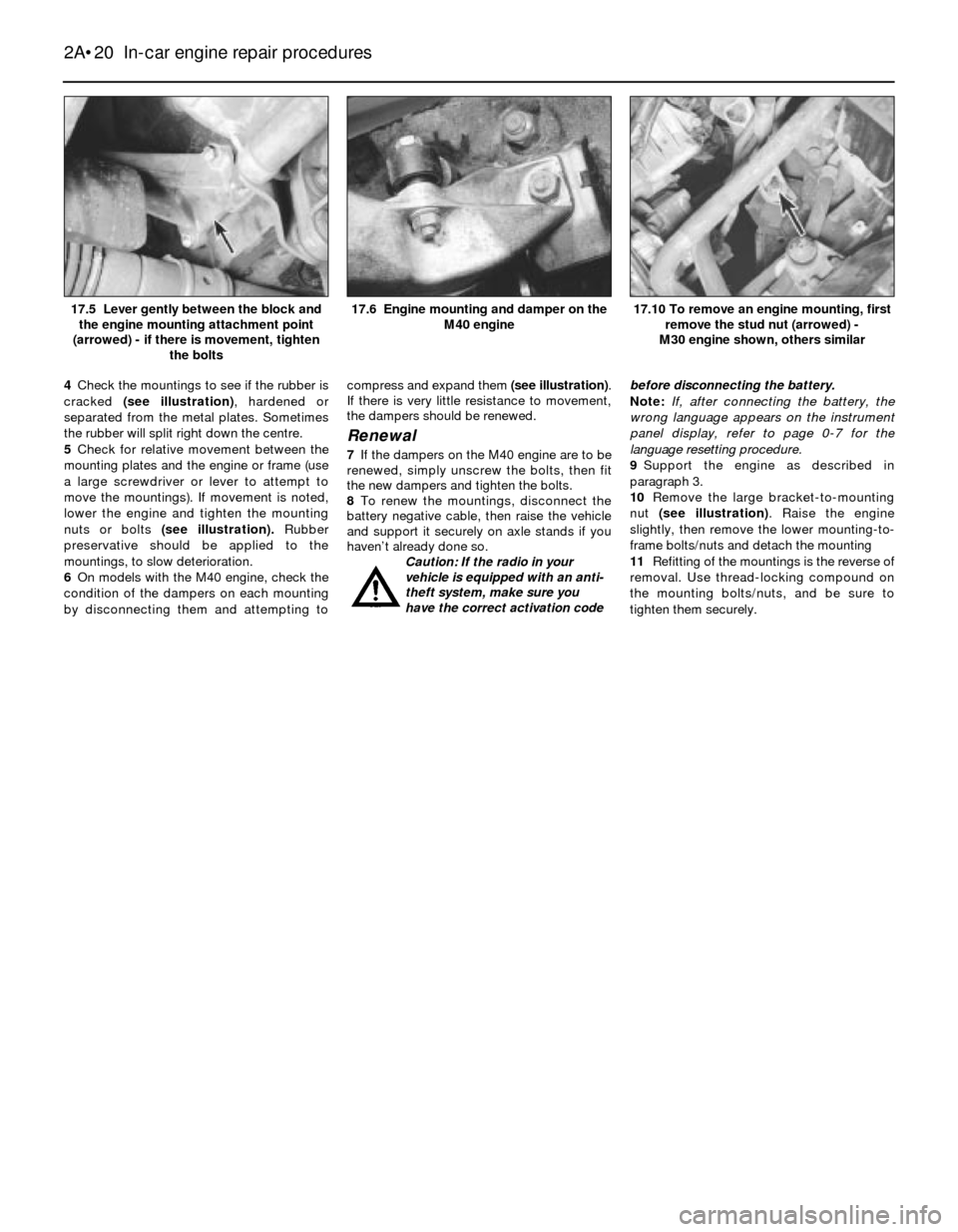

4Check the mountings to see if the rubber is

cracked (see illustration), hardened or

separated from the metal plates. Sometimes

the rubber will split right down the centre.

5Check for relative movement between the

mounting plates and the engine or frame (use

a large screwdriver or lever to attempt to

move the mountings). If movement is noted,

lower the engine and tighten the mounting

nuts or bolts (see illustration). Rubber

preservative should be applied to the

mountings, to slow deterioration.

6On models with the M40 engine, check the

condition of the dampers on each mounting

by disconnecting them and attempting tocompress and expand them (see illustration).

If there is very little resistance to movement,

the dampers should be renewed.

Renewal

7If the dampers on the M40 engine are to be

renewed, simply unscrew the bolts, then fit

the new dampers and tighten the bolts.

8To renew the mountings, disconnect the

battery negative cable, then raise the vehicle

and support it securely on axle stands if you

haven’t already done so.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation codebefore disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

9Support the engine as described in

paragraph 3.

10Remove the large bracket-to-mounting

nut (see illustration). Raise the engine

slightly, then remove the lower mounting-to-

frame bolts/nuts and detach the mounting

11Refitting of the mountings is the reverse of

removal. Use thread-locking compound on

the mounting bolts/nuts, and be sure to

tighten them securely.

2A•20 In-car engine repair procedures

17.10 To remove an engine mounting, first

remove the stud nut (arrowed) -

M30 engine shown, others similar17.6 Engine mounting and damper on the

M40 engine17.5 Lever gently between the block and

the engine mounting attachment point

(arrowed) - if there is movement, tighten

the bolts

Page 61 of 228

otherwise a small brush or even a bicycle tyre

pump will work). The idea is to prevent dirt

from getting into the cylinders as the

compression check is being done.

3Remove all the spark plugs from the engine

(see Chapter 1).

4Block the throttle wide open, or have an

assistant hold the throttle pedal down.

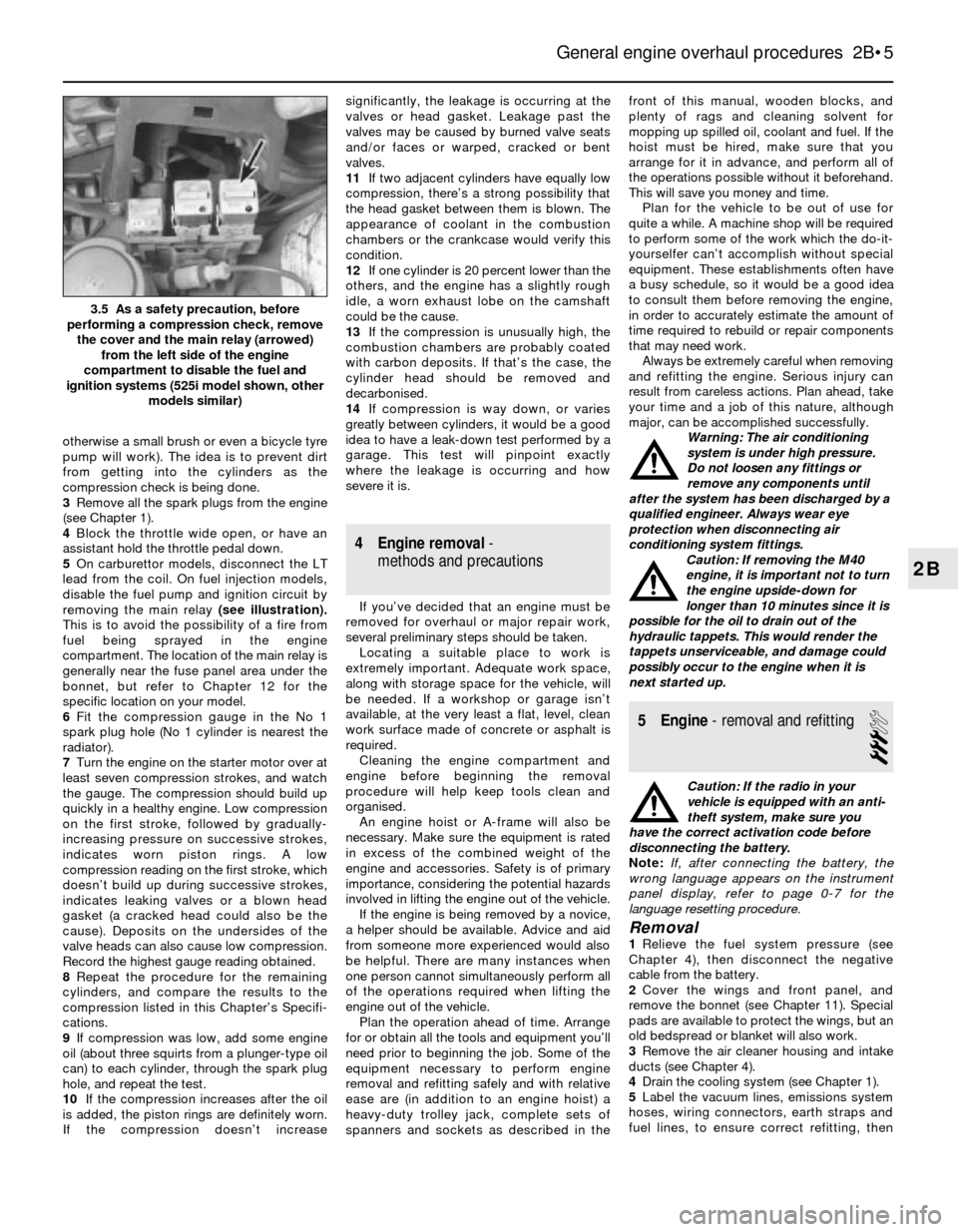

5On carburettor models, disconnect the LT

lead from the coil. On fuel injection models,

disable the fuel pump and ignition circuit by

removing the main relay(see illustration).

This is to avoid the possibility of a fire from

fuel being sprayed in the engine

compartment. The location of the main relay is

generally near the fuse panel area under the

bonnet, but refer to Chapter 12 for the

specific location on your model.

6Fit the compression gauge in the No 1

spark plug hole (No 1 cylinder is nearest the

radiator).

7Turn the engine on the starter motor over at

least seven compression strokes, and watch

the gauge. The compression should build up

quickly in a healthy engine. Low compression

on the first stroke, followed by gradually-

increasing pressure on successive strokes,

indicates worn piston rings. A low

compression reading on the first stroke, which

doesn’t build up during successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause). Deposits on the undersides of the

valve heads can also cause low compression.

Record the highest gauge reading obtained.

8Repeat the procedure for the remaining

cylinders, and compare the results to the

compression listed in this Chapter’s Specifi-

cations.

9If compression was low, add some engine

oil (about three squirts from a plunger-type oil

can) to each cylinder, through the spark plug

hole, and repeat the test.

10If the compression increases after the oil

is added, the piston rings are definitely worn.

If the compression doesn’t increasesignificantly, the leakage is occurring at the

valves or head gasket. Leakage past the

valves may be caused by burned valve seats

and/or faces or warped, cracked or bent

valves.

11If two adjacent cylinders have equally low

compression, there’s a strong possibility that

the head gasket between them is blown. The

appearance of coolant in the combustion

chambers or the crankcase would verify this

condition.

12If one cylinder is 20 percent lower than the

others, and the engine has a slightly rough

idle, a worn exhaust lobe on the camshaft

could be the cause.

13If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If that’s the case, the

cylinder head should be removed and

decarbonised.

14If compression is way down, or varies

greatly between cylinders, it would be a good

idea to have a leak-down test performed by a

garage. This test will pinpoint exactly

where the leakage is occurring and how

severe it is.

4 Engine removal-

methods and precautions

If you’ve decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the vehicle, will

be needed. If a workshop or garage isn’t

available, at the very least a flat, level, clean

work surface made of concrete or asphalt is

required.

Cleaning the engine compartment and

engine before beginning the removal

procedure will help keep tools clean and

organised.

An engine hoist or A-frame will also be

necessary. Make sure the equipment is rated

in excess of the combined weight of the

engine and accessories. Safety is of primary

importance, considering the potential hazards

involved in lifting the engine out of the vehicle.

If the engine is being removed by a novice,

a helper should be available. Advice and aid

from someone more experienced would also

be helpful. There are many instances when

one person cannot simultaneously perform all

of the operations required when lifting the

engine out of the vehicle.

Plan the operation ahead of time. Arrange

for or obtain all the tools and equipment you’ll

need prior to beginning the job. Some of the

equipment necessary to perform engine

removal and refitting safely and with relative

ease are (in addition to an engine hoist) a

heavy-duty trolley jack, complete sets of

spanners and sockets as described in thefront of this manual, wooden blocks, and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and fuel. If the

hoist must be hired, make sure that you

arrange for it in advance, and perform all of

the operations possible without it beforehand.

This will save you money and time.

Plan for the vehicle to be out of use for

quite a while. A machine shop will be required

to perform some of the work which the do-it-

yourselfer can’t accomplish without special

equipment. These establishments often have

a busy schedule, so it would be a good idea

to consult them before removing the engine,

in order to accurately estimate the amount of

time required to rebuild or repair components

that may need work.

Always be extremely careful when removing

and refitting the engine. Serious injury can

result from careless actions. Plan ahead, take

your time and a job of this nature, although

major, can be accomplished successfully.

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged by a

qualified engineer. Always wear eye

protection when disconnecting air

conditioning system fittings.

Caution: If removing the M40

engine, it is important not to turn

the engine upside-down for

longer than 10 minutes since it is

possible for the oil to drain out of the

hydraulic tappets. This would render the

tappets unserviceable, and damage could

possibly occur to the engine when it is

next started up.

5 Engine- removal and refitting

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal1Relieve the fuel system pressure (see

Chapter 4), then disconnect the negative

cable from the battery.

2Cover the wings and front panel, and

remove the bonnet (see Chapter 11). Special

pads are available to protect the wings, but an

old bedspread or blanket will also work.

3Remove the air cleaner housing and intake

ducts (see Chapter 4).

4Drain the cooling system (see Chapter 1).

5Label the vacuum lines, emissions system

hoses, wiring connectors, earth straps and

fuel lines, to ensure correct refitting, then

General engine overhaul procedures 2B•5

3.5 As a safety precaution, before

performing a compression check, remove

the cover and the main relay (arrowed)

from the left side of the engine

compartment to disable the fuel and

ignition systems (525i model shown, other

models similar)

2B

Page 62 of 228

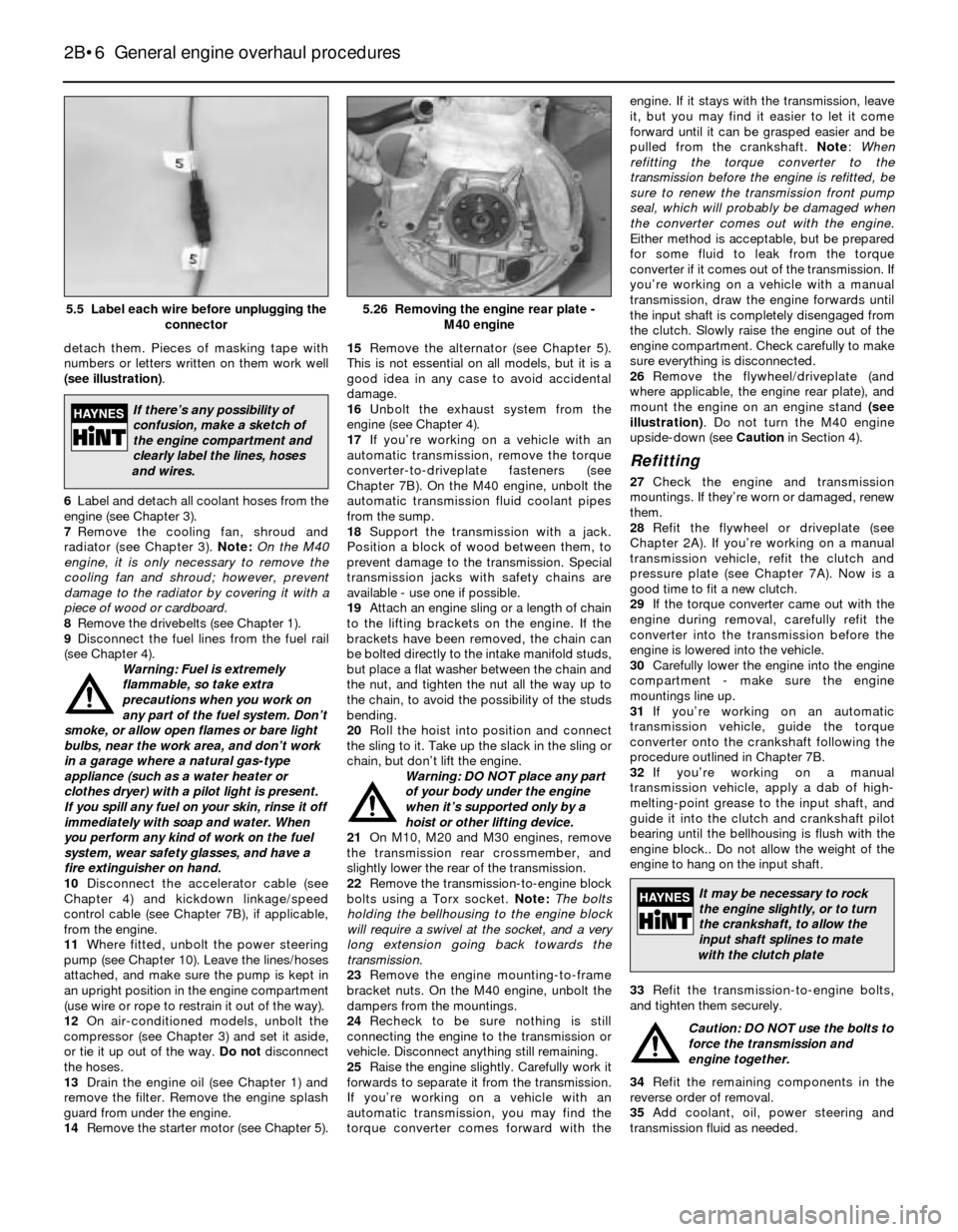

detach them. Pieces of masking tape with

numbers or letters written on them work well

(see illustration).

6Label and detach all coolant hoses from the

engine (see Chapter 3).

7Remove the cooling fan, shroud and

radiator (see Chapter 3). Note:On the M40

engine, it is only necessary to remove the

cooling fan and shroud; however, prevent

damage to the radiator by covering it with a

piece of wood or cardboard.

8Remove the drivebelts (see Chapter 1).

9Disconnect the fuel lines from the fuel rail

(see Chapter 4).

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area, and don’t work

in a garage where a natural gas-type

appliance (such as a water heater or

clothes dryer) with a pilot light is present.

If you spill any fuel on your skin, rinse it off

immediately with soap and water. When

you perform any kind of work on the fuel

system, wear safety glasses, and have a

fire extinguisher on hand.

10Disconnect the accelerator cable (see

Chapter 4) and kickdown linkage/speed

control cable (see Chapter 7B), if applicable,

from the engine.

11Where fitted, unbolt the power steering

pump (see Chapter 10). Leave the lines/hoses

attached, and make sure the pump is kept in

an upright position in the engine compartment

(use wire or rope to restrain it out of the way).

12On air-conditioned models, unbolt the

compressor (see Chapter 3) and set it aside,

or tie it up out of the way. Do not disconnect

the hoses.

13Drain the engine oil (see Chapter 1) and

remove the filter. Remove the engine splash

guard from under the engine.

14Remove the starter motor (see Chapter 5).15Remove the alternator (see Chapter 5).

This is not essential on all models, but it is a

good idea in any case to avoid accidental

damage.

16Unbolt the exhaust system from the

engine (see Chapter 4).

17If you’re working on a vehicle with an

automatic transmission, remove the torque

converter-to-driveplate fasteners (see

Chapter 7B). On the M40 engine, unbolt the

automatic transmission fluid coolant pipes

from the sump.

18Support the transmission with a jack.

Position a block of wood between them, to

prevent damage to the transmission. Special

transmission jacks with safety chains are

available - use one if possible.

19Attach an engine sling or a length of chain

to the lifting brackets on the engine. If the

brackets have been removed, the chain can

be bolted directly to the intake manifold studs,

but place a flat washer between the chain and

the nut, and tighten the nut all the way up to

the chain, to avoid the possibility of the studs

bending.

20Roll the hoist into position and connect

the sling to it. Take up the slack in the sling or

chain, but don’t lift the engine.

Warning: DO NOT place any part

of your body under the engine

when it’s supported only by a

hoist or other lifting device.

21On M10, M20 and M30 engines, remove

the transmission rear crossmember, and

slightly lower the rear of the transmission.

22Remove the transmission-to-engine block

bolts using a Torx socket. Note:The bolts

holding the bellhousing to the engine block

will require a swivel at the socket, and a very

long extension going back towards the

transmission.

23Remove the engine mounting-to-frame

bracket nuts. On the M40 engine, unbolt the

dampers from the mountings.

24Recheck to be sure nothing is still

connecting the engine to the transmission or

vehicle. Disconnect anything still remaining.

25Raise the engine slightly. Carefully work it

forwards to separate it from the transmission.

If you’re working on a vehicle with an

automatic transmission, you may find the

torque converter comes forward with theengine. If it stays with the transmission, leave

it, but you may find it easier to let it come

forward until it can be grasped easier and be

pulled from the crankshaft. Note:When

refitting the torque converter to the

transmission before the engine is refitted, be

sure to renew the transmission front pump

seal, which will probably be damaged when

the converter comes out with the engine.

Either method is acceptable, but be prepared

for some fluid to leak from the torque

converter if it comes out of the transmission. If

you’re working on a vehicle with a manual

transmission, draw the engine forwards until

the input shaft is completely disengaged from

the clutch. Slowly raise the engine out of the

engine compartment. Check carefully to make

sure everything is disconnected.

26Remove the flywheel/driveplate (and

where applicable, the engine rear plate), and

mount the engine on an engine stand (see

illustration). Do not turn the M40 engine

upside-down (see Cautionin Section 4).

Refitting

27Check the engine and transmission

mountings. If they’re worn or damaged, renew

them.

28Refit the flywheel or driveplate (see

Chapter 2A). If you’re working on a manual

transmission vehicle, refit the clutch and

pressure plate (see Chapter 7A). Now is a

good time to fit a new clutch.

29If the torque converter came out with the

engine during removal, carefully refit the

converter into the transmission before the

engine is lowered into the vehicle.

30Carefully lower the engine into the engine

compartment - make sure the engine

mountings line up.

31If you’re working on an automatic

transmission vehicle, guide the torque

converter onto the crankshaft following the

procedure outlined in Chapter 7B.

32If you’re working on a manual

transmission vehicle, apply a dab of high-

melting-point grease to the input shaft, and

guide it into the clutch and crankshaft pilot

bearing until the bellhousing is flush with the

engine block.. Do not allow the weight of the

engine to hang on the input shaft.

33Refit the transmission-to-engine bolts,

and tighten them securely.

Caution: DO NOT use the bolts to

force the transmission and

engine together.

34Refit the remaining components in the

reverse order of removal.

35Add coolant, oil, power steering and

transmission fluid as needed.

2B•6 General engine overhaul procedures

5.26 Removing the engine rear plate -

M40 engine5.5 Label each wire before unplugging the

connector

If there’s any possibility of

confusion, make a sketch of

the engine compartment and

clearly label the lines, hoses

and wires.

It may be necessary to rock

the engine slightly, or to turn

the crankshaft, to allow the

input shaft splines to mate

with the clutch plate

Page 64 of 228

M10, M20 and M30 engines

3Adjust all valves to their maximum clearance

by rotating the eccentric on the valve end of

the rocker arm towards the centre of the head

(see Chapter 1, if necessary).

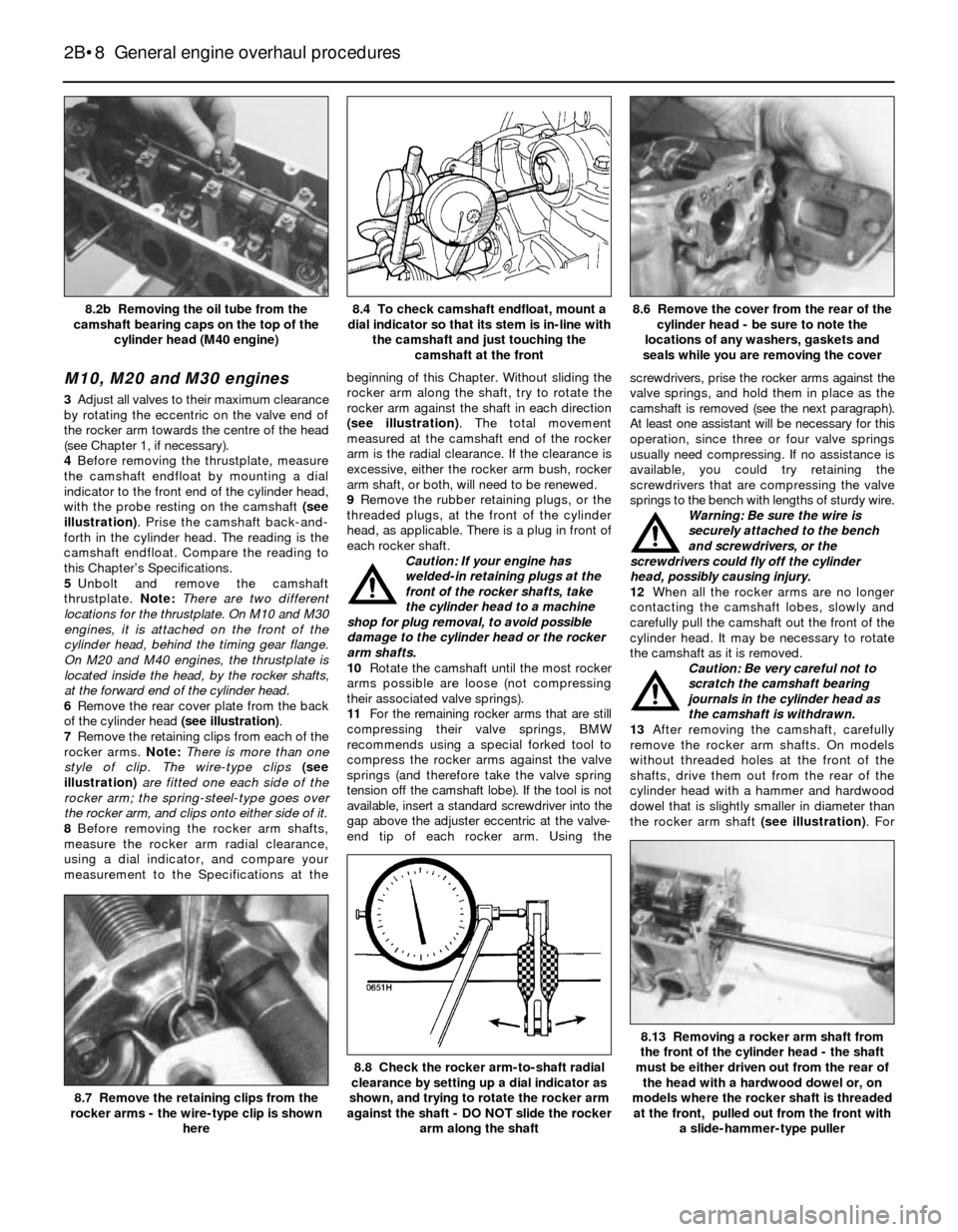

4Before removing the thrustplate, measure

the camshaft endfloat by mounting a dial

indicator to the front end of the cylinder head,

with the probe resting on the camshaft (see

illustration). Prise the camshaft back-and-

forth in the cylinder head. The reading is the

camshaft endfloat. Compare the reading to

this Chapter’s Specifications.

5Unbolt and remove the camshaft

thrustplate. Note:There are two different

locations for the thrustplate. On M10 and M30

engines, it is attached on the front of the

cylinder head, behind the timing gear flange.

On M20 and M40 engines, the thrustplate is

located inside the head, by the rocker shafts,

at the forward end of the cylinder head.

6Remove the rear cover plate from the back

of the cylinder head (see illustration).

7Remove the retaining clips from each of the

rocker arms. Note:There is more than one

style of clip. The wire-type clips (see

illustration)are fitted one each side of the

rocker arm; the spring-steel-type goes over

the rocker arm, and clips onto either side of it.

8Before removing the rocker arm shafts,

measure the rocker arm radial clearance,

using a dial indicator, and compare your

measurement to the Specifications at thebeginning of this Chapter. Without sliding the

rocker arm along the shaft, try to rotate the

rocker arm against the shaft in each direction

(see illustration). The total movement

measured at the camshaft end of the rocker

arm is the radial clearance. If the clearance is

excessive, either the rocker arm bush, rocker

arm shaft, or both, will need to be renewed.

9Remove the rubber retaining plugs, or the

threaded plugs, at the front of the cylinder

head, as applicable. There is a plug in front of

each rocker shaft.

Caution: If your engine has

welded-in retaining plugs at the

front of the rocker shafts, take

the cylinder head to a machine

shop for plug removal, to avoid possible

damage to the cylinder head or the rocker

arm shafts.

10Rotate the camshaft until the most rocker

arms possible are loose (not compressing

their associated valve springs).

11For the remaining rocker arms that are still

compressing their valve springs, BMW

recommends using a special forked tool to

compress the rocker arms against the valve

springs (and therefore take the valve spring

tension off the camshaft lobe). If the tool is not

available, insert a standard screwdriver into the

gap above the adjuster eccentric at the valve-

end tip of each rocker arm. Using thescrewdrivers, prise the rocker arms against the

valve springs, and hold them in place as the

camshaft is removed (see the next paragraph).

At least one assistant will be necessary for this

operation, since three or four valve springs

usually need compressing. If no assistance is

available, you could try retaining the

screwdrivers that are compressing the valve

springs to the bench with lengths of sturdy wire.

Warning: Be sure the wire is

securely attached to the bench

and screwdrivers, or the

screwdrivers could fly off the cylinder

head, possibly causing injury.

12When all the rocker arms are no longer

contacting the camshaft lobes, slowly and

carefully pull the camshaft out the front of the

cylinder head. It may be necessary to rotate

the camshaft as it is removed.

Caution: Be very careful not to

scratch the camshaft bearing

journals in the cylinder head as

the camshaft is withdrawn.

13After removing the camshaft, carefully

remove the rocker arm shafts. On models

without threaded holes at the front of the

shafts, drive them out from the rear of the

cylinder head with a hammer and hardwood

dowel that is slightly smaller in diameter than

the rocker arm shaft (see illustration). For

2B•8 General engine overhaul procedures

8.13 Removing a rocker arm shaft from

the front of the cylinder head - the shaft

must be either driven out from the rear of

the head with a hardwood dowel or, on

models where the rocker shaft is threaded

at the front, pulled out from the front with

a slide-hammer-type puller

8.8 Check the rocker arm-to-shaft radial

clearance by setting up a dial indicator as

shown, and trying to rotate the rocker arm

against the shaft - DO NOT slide the rocker

arm along the shaft

8.7 Remove the retaining clips from the

rocker arms - the wire-type clip is shown

here

8.6 Remove the cover from the rear of the

cylinder head - be sure to note the

locations of any washers, gaskets and

seals while you are removing the cover8.4 To check camshaft endfloat, mount a

dial indicator so that its stem is in-line with

the camshaft and just touching the

camshaft at the front8.2b Removing the oil tube from the

camshaft bearing caps on the top of the

cylinder head (M40 engine)

Page 67 of 228

that they’re suitable for use in a rebuilt engine

(take the springs to a machine shop for this

check).

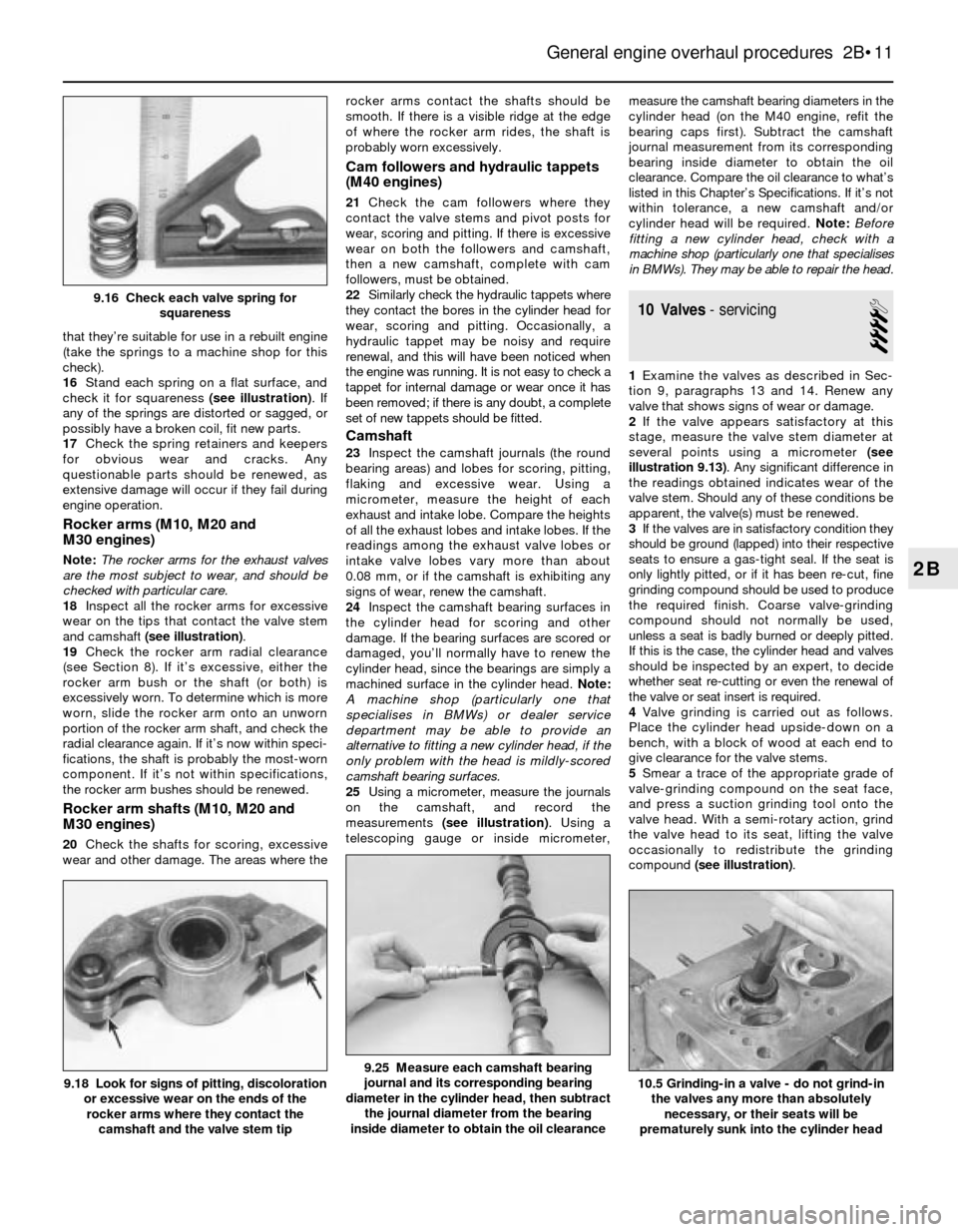

16Stand each spring on a flat surface, and

check it for squareness (see illustration). If

any of the springs are distorted or sagged, or

possibly have a broken coil, fit new parts.

17Check the spring retainers and keepers

for obvious wear and cracks. Any

questionable parts should be renewed, as

extensive damage will occur if they fail during

engine operation.

Rocker arms (M10, M20 and

M30 engines)

Note:The rocker arms for the exhaust valves

are the most subject to wear, and should be

checked with particular care.

18Inspect all the rocker arms for excessive

wear on the tips that contact the valve stem

and camshaft (see illustration).

19Check the rocker arm radial clearance

(see Section 8). If it’s excessive, either the

rocker arm bush or the shaft (or both) is

excessively worn. To determine which is more

worn, slide the rocker arm onto an unworn

portion of the rocker arm shaft, and check the

radial clearance again. If it’s now within speci-

fications, the shaft is probably the most-worn

component. If it’s not within specifications,

the rocker arm bushes should be renewed.

Rocker arm shafts (M10, M20 and

M30 engines)

20Check the shafts for scoring, excessive

wear and other damage. The areas where therocker arms contact the shafts should be

smooth. If there is a visible ridge at the edge

of where the rocker arm rides, the shaft is

probably worn excessively.

Cam followers and hydraulic tappets

(M40 engines)

21Check the cam followers where they

contact the valve stems and pivot posts for

wear, scoring and pitting. If there is excessive

wear on both the followers and camshaft,

then a new camshaft, complete with cam

followers, must be obtained.

22Similarly check the hydraulic tappets where

they contact the bores in the cylinder head for

wear, scoring and pitting. Occasionally, a

hydraulic tappet may be noisy and require

renewal, and this will have been noticed when

the engine was running. It is not easy to check a

tappet for internal damage or wear once it has

been removed; if there is any doubt, a complete

set of new tappets should be fitted.

Camshaft

23Inspect the camshaft journals (the round

bearing areas) and lobes for scoring, pitting,

flaking and excessive wear. Using a

micrometer, measure the height of each

exhaust and intake lobe. Compare the heights

of all the exhaust lobes and intake lobes. If the

readings among the exhaust valve lobes or

intake valve lobes vary more than about

0.08 mm, or if the camshaft is exhibiting any

signs of wear, renew the camshaft.

24Inspect the camshaft bearing surfaces in

the cylinder head for scoring and other

damage. If the bearing surfaces are scored or

damaged, you’ll normally have to renew the

cylinder head, since the bearings are simply a

machined surface in the cylinder head. Note:

A machine shop (particularly one that

specialises in BMWs) or dealer service

department may be able to provide an

alternative to fitting a new cylinder head, if the

only problem with the head is mildly-scored

camshaft bearing surfaces.

25Using a micrometer, measure the journals

on the camshaft, and record the

measurements (see illustration). Using a

telescoping gauge or inside micrometer,measure the camshaft bearing diameters in the

cylinder head (on the M40 engine, refit the

bearing caps first). Subtract the camshaft

journal measurement from its corresponding

bearing inside diameter to obtain the oil

clearance. Compare the oil clearance to what’s

listed in this Chapter’s Specifications. If it’s not

within tolerance, a new camshaft and/or

cylinder head will be required. Note:Before

fitting a new cylinder head, check with a

machine shop (particularly one that specialises

in BMWs). They may be able to repair the head.

10 Valves- servicing

4

1Examine the valves as described in Sec-

tion 9, paragraphs 13 and 14. Renew any

valve that shows signs of wear or damage.

2If the valve appears satisfactory at this

stage, measure the valve stem diameter at

several points using a micrometer (see

illustration 9.13). Any significant difference in

the readings obtained indicates wear of the

valve stem. Should any of these conditions be

apparent, the valve(s) must be renewed.

3If the valves are in satisfactory condition they

should be ground (lapped) into their respective

seats to ensure a gas-tight seal. If the seat is

only lightly pitted, or if it has been re-cut, fine

grinding compound should be used to produce

the required finish. Coarse valve-grinding

compound should not normally be used,

unless a seat is badly burned or deeply pitted.

If this is the case, the cylinder head and valves

should be inspected by an expert, to decide

whether seat re-cutting or even the renewal of

the valve or seat insert is required.

4Valve grinding is carried out as follows.

Place the cylinder head upside-down on a

bench, with a block of wood at each end to

give clearance for the valve stems.

5Smear a trace of the appropriate grade of

valve-grinding compound on the seat face,

and press a suction grinding tool onto the

valve head. With a semi-rotary action, grind

the valve head to its seat, lifting the valve

occasionally to redistribute the grinding

compound (see illustration).

General engine overhaul procedures 2B•11

9.25 Measure each camshaft bearing

journal and its corresponding bearing

diameter in the cylinder head, then subtract

the journal diameter from the bearing

inside diameter to obtain the oil clearance9.18 Look for signs of pitting, discoloration

or excessive wear on the ends of the

rocker arms where they contact the

camshaft and the valve stem tip10.5 Grinding-in a valve - do not grind-in

the valves any more than absolutely

necessary, or their seats will be

prematurely sunk into the cylinder head

2B

9.16 Check each valve spring for

squareness

Page 68 of 228

6If coarse grinding compound is being used,

work only until a dull, matt even surface is

produced on both the valve seat and the

valve, then wipe off the used compound and

repeat the process with fine compound. When

a smooth, unbroken ring of light grey matt

finish is produced on both the valve and seat,

the grinding operation is complete. Do not

grind in the valves any further than absolutely

necessary.

7When all the valves have been ground-in,

carefully wash off all traces of grinding

compound using paraffin or a suitable solvent

before reassembly of the cylinder head.

11 Cylinder head- reassembly

5

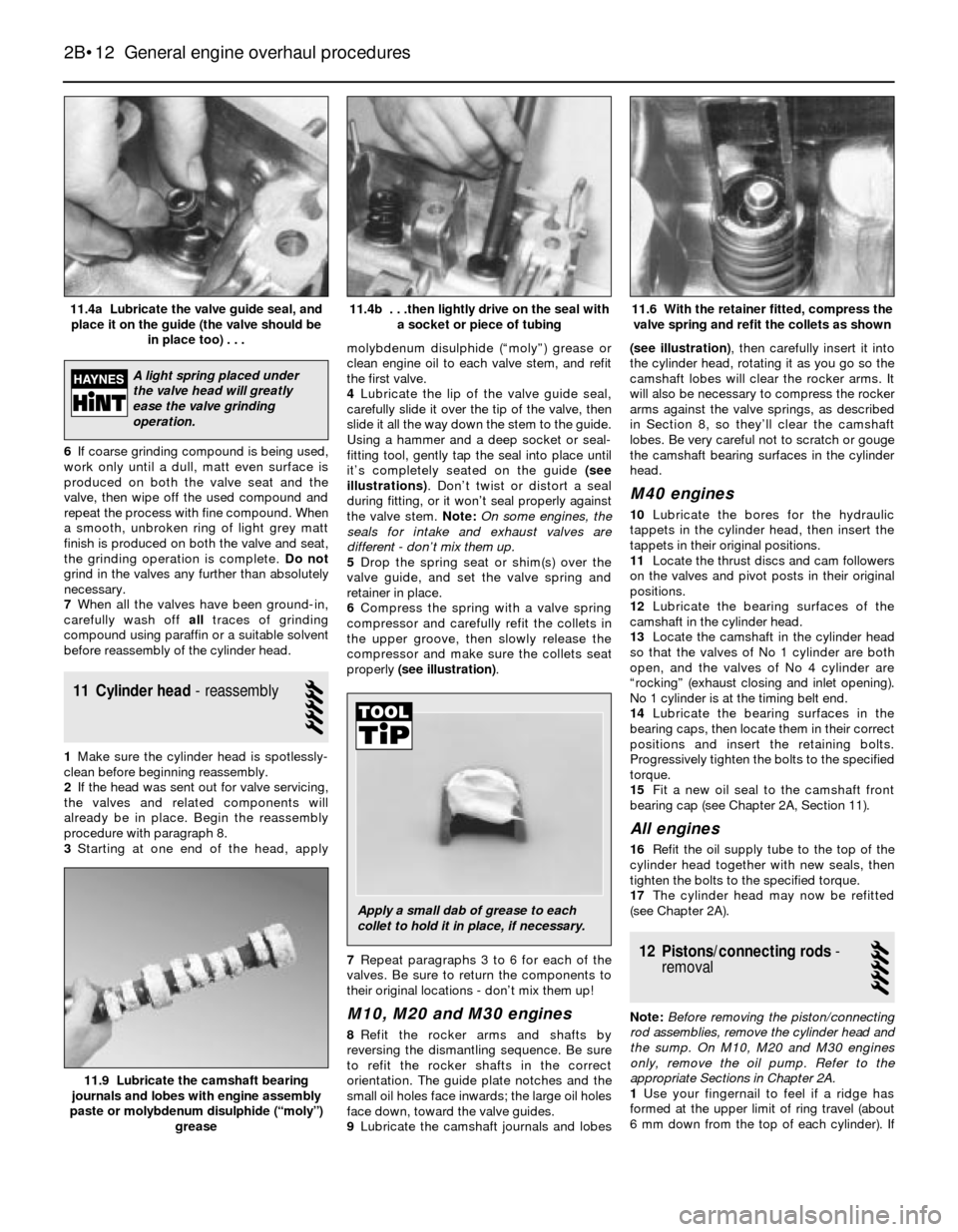

1Make sure the cylinder head is spotlessly-

clean before beginning reassembly.

2If the head was sent out for valve servicing,

the valves and related components will

already be in place. Begin the reassembly

procedure with paragraph 8.

3Starting at one end of the head, applymolybdenum disulphide (“moly”) grease or

clean engine oil to each valve stem, and refit

the first valve.

4Lubricate the lip of the valve guide seal,

carefully slide it over the tip of the valve, then

slide it all the way down the stem to the guide.

Using a hammer and a deep socket or seal-

fitting tool, gently tap the seal into place until

it’s completely seated on the guide (see

illustrations). Don’t twist or distort a seal

during fitting, or it won’t seal properly against

the valve stem. Note:On some engines, the

seals for intake and exhaust valves are

different - don’t mix them up.

5Drop the spring seat or shim(s) over the

valve guide, and set the valve spring and

retainer in place.

6Compress the spring with a valve spring

compressor and carefully refit the collets in

the upper groove, then slowly release the

compressor and make sure the collets seat

properly (see illustration).

7Repeat paragraphs 3 to 6 for each of the

valves. Be sure to return the components to

their original locations - don’t mix them up!

M10, M20 and M30 engines

8Refit the rocker arms and shafts by

reversing the dismantling sequence. Be sure

to refit the rocker shafts in the correct

orientation. The guide plate notches and the

small oil holes face inwards; the large oil holes

face down, toward the valve guides.

9Lubricate the camshaft journals and lobes(see illustration), then carefully insert it into

the cylinder head, rotating it as you go so the

camshaft lobes will clear the rocker arms. It

will also be necessary to compress the rocker

arms against the valve springs, as described

in Section 8, so they’ll clear the camshaft

lobes. Be very careful not to scratch or gouge

the camshaft bearing surfaces in the cylinder

head.

M40 engines

10Lubricate the bores for the hydraulic

tappets in the cylinder head, then insert the

tappets in their original positions.

11Locate the thrust discs and cam followers

on the valves and pivot posts in their original

positions.

12Lubricate the bearing surfaces of the

camshaft in the cylinder head.

13Locate the camshaft in the cylinder head

so that the valves of No 1 cylinder are both

open, and the valves of No 4 cylinder are

“rocking” (exhaust closing and inlet opening).

No 1 cylinder is at the timing belt end.

14Lubricate the bearing surfaces in the

bearing caps, then locate them in their correct

positions and insert the retaining bolts.

Progressively tighten the bolts to the specified

torque.

15Fit a new oil seal to the camshaft front

bearing cap (see Chapter 2A, Section 11).

All engines

16Refit the oil supply tube to the top of the

cylinder head together with new seals, then

tighten the bolts to the specified torque.

17The cylinder head may now be refitted

(see Chapter 2A).

12 Pistons/connecting rods-

removal

5

Note:Before removing the piston/connecting

rod assemblies, remove the cylinder head and

the sump. On M10, M20 and M30 engines

only, remove the oil pump. Refer to the

appropriate Sections in Chapter 2A.

1Use your fingernail to feel if a ridge has

formed at the upper limit of ring travel (about

6 mm down from the top of each cylinder). If

2B•12 General engine overhaul procedures

11.9 Lubricate the camshaft bearing

journals and lobes with engine assembly

paste or molybdenum disulphide (“moly”)

grease

11.6 With the retainer fitted, compress the

valve spring and refit the collets as shown 11.4b . . .then lightly drive on the seal with

a socket or piece of tubing11.4a Lubricate the valve guide seal, and

place it on the guide (the valve should be

in place too) . . .

A light spring placed under

the valve head will greatly

ease the valve grinding

operation.

Apply a small dab of grease to each

collet to hold it in place, if necessary.

Page 70 of 228

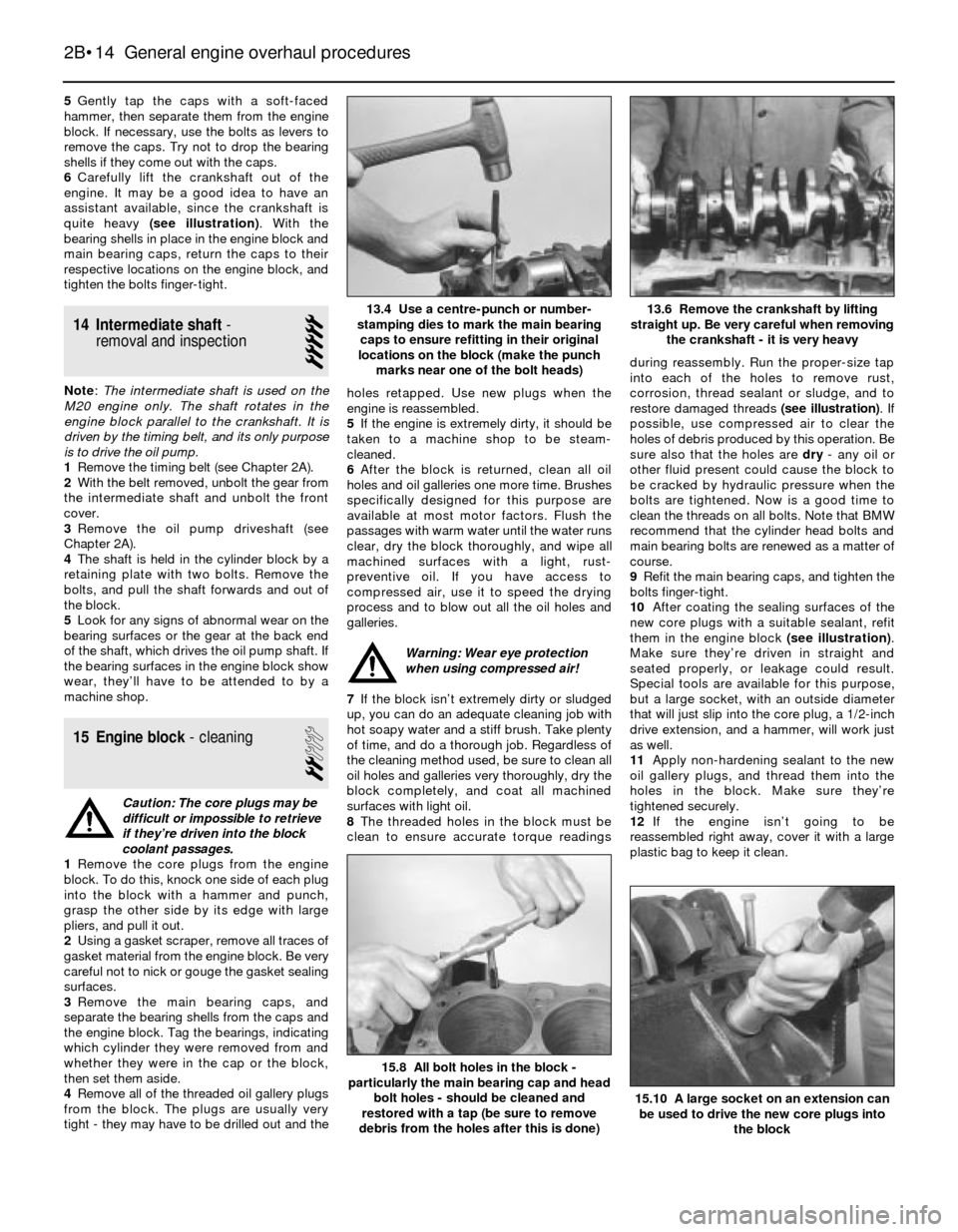

5Gently tap the caps with a soft-faced

hammer, then separate them from the engine

block. If necessary, use the bolts as levers to

remove the caps. Try not to drop the bearing

shells if they come out with the caps.

6Carefully lift the crankshaft out of the

engine. It may be a good idea to have an

assistant available, since the crankshaft is

quite heavy (see illustration). With the

bearing shells in place in the engine block and

main bearing caps, return the caps to their

respective locations on the engine block, and

tighten the bolts finger-tight.

14 Intermediate shaft-

removal and inspection

5

Note:The intermediate shaft is used on the

M20 engine only. The shaft rotates in the

engine block parallel to the crankshaft. It is

driven by the timing belt, and its only purpose

is to drive the oil pump.

1Remove the timing belt (see Chapter 2A).

2With the belt removed, unbolt the gear from

the intermediate shaft and unbolt the front

cover.

3Remove the oil pump driveshaft (see

Chapter 2A).

4The shaft is held in the cylinder block by a

retaining plate with two bolts. Remove the

bolts, and pull the shaft forwards and out of

the block.

5Look for any signs of abnormal wear on the

bearing surfaces or the gear at the back end

of the shaft, which drives the oil pump shaft. If

the bearing surfaces in the engine block show

wear, they’ll have to be attended to by a

machine shop.

15 Engine block- cleaning

2

Caution: The core plugs may be

difficult or impossible to retrieve

if they’re driven into the block

coolant passages.

1Remove the core plugs from the engine

block. To do this, knock one side of each plug

into the block with a hammer and punch,

grasp the other side by its edge with large

pliers, and pull it out.

2Using a gasket scraper, remove all traces of

gasket material from the engine block. Be very

careful not to nick or gouge the gasket sealing

surfaces.

3Remove the main bearing caps, and

separate the bearing shells from the caps and

the engine block. Tag the bearings, indicating

which cylinder they were removed from and

whether they were in the cap or the block,

then set them aside.

4Remove all of the threaded oil gallery plugs

from the block. The plugs are usually very

tight - they may have to be drilled out and theholes retapped. Use new plugs when the

engine is reassembled.

5If the engine is extremely dirty, it should be

taken to a machine shop to be steam-

cleaned.

6After the block is returned, clean all oil

holes and oil galleries one more time. Brushes

specifically designed for this purpose are

available at most motor factors. Flush the

passages with warm water until the water runs

clear, dry the block thoroughly, and wipe all

machined surfaces with a light, rust-

preventive oil. If you have access to

compressed air, use it to speed the drying

process and to blow out all the oil holes and

galleries.

Warning: Wear eye protection

when using compressed air!

7If the block isn’t extremely dirty or sludged

up, you can do an adequate cleaning job with

hot soapy water and a stiff brush. Take plenty

of time, and do a thorough job. Regardless of

the cleaning method used, be sure to clean all

oil holes and galleries very thoroughly, dry the

block completely, and coat all machined

surfaces with light oil.

8The threaded holes in the block must be

clean to ensure accurate torque readingsduring reassembly. Run the proper-size tap

into each of the holes to remove rust,

corrosion, thread sealant or sludge, and to

restore damaged threads (see illustration). If

possible, use compressed air to clear the

holes of debris produced by this operation. Be

sure also that the holes are dry- any oil or

other fluid present could cause the block to

be cracked by hydraulic pressure when the

bolts are tightened. Now is a good time to

clean the threads on all bolts. Note that BMW

recommend that the cylinder head bolts and

main bearing bolts are renewed as a matter of

course.

9Refit the main bearing caps, and tighten the

bolts finger-tight.

10After coating the sealing surfaces of the

new core plugs with a suitable sealant, refit

them in the engine block (see illustration).

Make sure they’re driven in straight and

seated properly, or leakage could result.

Special tools are available for this purpose,

but a large socket, with an outside diameter

that will just slip into the core plug, a 1/2-inch

drive extension, and a hammer, will work just

as well.

11Apply non-hardening sealant to the new

oil gallery plugs, and thread them into the

holes in the block. Make sure they’re

tightened securely.

12If the engine isn’t going to be

reassembled right away, cover it with a large

plastic bag to keep it clean.

2B•14 General engine overhaul procedures

15.10 A large socket on an extension can

be used to drive the new core plugs into

the block

15.8 All bolt holes in the block -

particularly the main bearing cap and head

bolt holes - should be cleaned and

restored with a tap (be sure to remove

debris from the holes after this is done)

13.6 Remove the crankshaft by lifting

straight up. Be very careful when removing

the crankshaft - it is very heavy13.4 Use a centre-punch or number-

stamping dies to mark the main bearing

caps to ensure refitting in their original

locations on the block (make the punch

marks near one of the bolt heads)