check transmission fluid BMW 3 SERIES 1987 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1987, Model line: 3 SERIES, Model: BMW 3 SERIES 1987 E30Pages: 228, PDF Size: 7.04 MB

Page 6 of 228

0•6Safety First!

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

Page 11 of 228

1

Engine

Oil filter

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C121

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C160

M30 engines

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C160

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X115

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X120

Valve clearances (intake and exhaust)

M10 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm

M20 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm

M30 engines

Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm

Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.35 mm

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic adjusters

Cooling system

Antifreeze mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40% antifreeze/60% water

Chapter 1

Routine maintenance and servicing

Air filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic transmission fluid and filter change . . . . . . . . . . . . . . . . . 28

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . 8

Battery check, maintenance and charging . . . . . . . . . . . . . . . . . . . . 13

Brake system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cooling system - draining, flushing and refilling . . . . . . . . . . . . . . . . 29

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Differential lubricant change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Differential lubricant level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Driveshaft gaiter check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Drivebelt check, adjustment and renewal . . . . . . . . . . . . . . . . . . . . . 11

Engine idle speed and CO level check and adjustment . . . . . . . . . . 12

Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Evaporative Emissions Control (EVAP) system check . . . . . . . . . . . 33

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual transmission lubricant change . . . . . . . . . . . . . . . . . . . . . . . 31

Manual transmission lubricant level check . . . . . . . . . . . . . . . . . . . . 16

Power steering fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service light resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Spark plug check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spark plug HT leads, distributor cap and rotor - check

and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Steering and suspension check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Throttle linkage - check and lubrication . . . . . . . . . . . . . . . . . . . . . . 19

Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tune-up general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Underbonnet hoses - check and renewal . . . . . . . . . . . . . . . . . . . . . 10

Valve clearances - check and adjustment . . . . . . . . . . . . . . . . . . . . 18

Wiper blades - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 14 of 228

Maintenance schedule

The following maintenance intervals are based on the assumption

that the vehicle owner will be doing the maintenance or service work,

as opposed to having a dealer service department do the work.

Although the time/mileage intervals are loosely based on factory rec-

ommendations, most have been shortened to ensure, for example, that

such items as lubricants and fluids are checked/changed at intervals

that promote maximum engine/driveline service life. Also, subject to

the preference of the individual owner interested in keeping his or her

vehicle in peak condition at all times, and with the vehicle’s ultimate

resale in mind, many of the maintenance procedures may be

performed more often than recommended in the following schedule.

We encourage such owner initiative.

When the vehicle is new, it should be serviced initially by a factory-

authorised dealer service department, to protect the factory warranty.

In many cases, the initial maintenance check is done at no cost to the

owner (check with your dealer service department for more

information).

1•4Maintenance and servicing

Every 250 miles or weekly, whichever

comes first

m mCheck the engine oil level (Section 4)

m mCheck the engine coolant level (Section 4)

m mCheck the brake fluid level (Section 4)

m mCheck the clutch fluid level (Section 4)

m mCheck the washer fluid level (Section 4)

m mCheck the tyres and tyre pressures (Section 5)

Every 6000 miles or 6 months,

whichever comes first

All items listed above, plus:

m mChange the engine oil and oil filter (Section 6)

m mCheck the power steering fluid level (Section 7)

m mCheck the tyres, and rotate if necessary (Section 9)

m mCheck the automatic transmission fluid level

(Section 8)

m mCheck the underbonnet hoses (Section 10)

m mCheck/adjust the drivebelts (Section 11)

m mCheck engine idle speed and CO (Section 12)

Every 12 000 miles or 12 months,

whichever comes first

All items listed above, plus:

m mCheck/service the battery (Section 13)

m mCheck the spark plugs (Section 14)

m mCheck/renew the HT leads, distributor cap and

rotor (Section 15)

m mCheck/top-up the manual transmission lubricant

(Section 16)

m mCheck the differential oil level (Section 17)

m mCheck the valve clearances, and adjust if

necessary - does not apply to M40 engines

(Section 18)

m mCheck and lubricate the throttle linkage (Section 19)

m mRenew the air filter (Section 20)

m mCheck the fuel system (Section 21)

m mInspect the cooling system (Section 22)

m mInspect the exhaust system (Section 23)

m mInspect the steering and suspension components

(Section 24)

m mCheck the driveshaft gaiter(s) (Section 25)

m mInspect the brakes (Section 26)

m mInspect/renew the windscreen wiper blades

(Section 27)

Every 24 000 miles or 2 years,

whichever comes first

All items listed above plus:

m mChange the automatic transmission fluid and filter

(Section 28)

m mDrain, flush and refill the cooling system (Section 29)

m mRenew the spark plugs (Section 14)

m mCheck/renew the spark plug HT leads (Section 15)

m mRenew the fuel filter (Section 30)

m mChange the manual transmission lubricant (Section 31)

m mChange the differential oil (Section 32)

m mCheck the evaporative emissions system, where

applicable (Section 33)

m mReset the service indicator lights (Section 34)

m mRenew brake fluid by bleeding (see Chapter 9)

m mCheck the handbrake operation (see Chapter 9)

Every 60 000 miles

m

mRenew the timing belt (Section 35)

Page 19 of 228

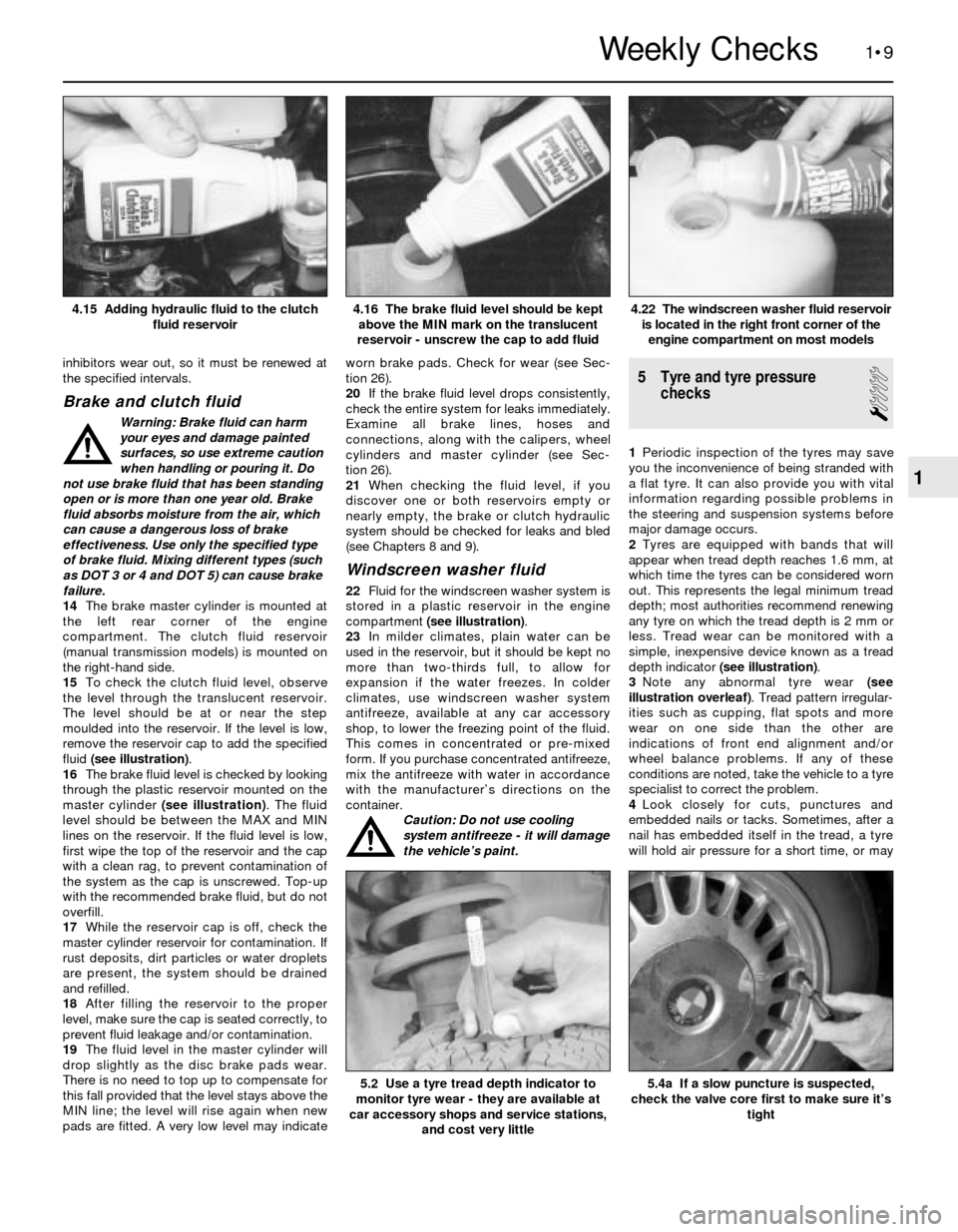

inhibitors wear out, so it must be renewed at

the specified intervals.

Brake and clutch fluid

Warning: Brake fluid can harm

your eyes and damage painted

surfaces, so use extreme caution

when handling or pouring it. Do

not use brake fluid that has been standing

open or is more than one year old. Brake

fluid absorbs moisture from the air, which

can cause a dangerous loss of brake

effectiveness. Use only the specified type

of brake fluid. Mixing different types (such

as DOT 3 or 4 and DOT 5) can cause brake

failure.

14The brake master cylinder is mounted at

the left rear corner of the engine

compartment. The clutch fluid reservoir

(manual transmission models) is mounted on

the right-hand side.

15To check the clutch fluid level, observe

the level through the translucent reservoir.

The level should be at or near the step

moulded into the reservoir. If the level is low,

remove the reservoir cap to add the specified

fluid (see illustration).

16The brake fluid level is checked by looking

through the plastic reservoir mounted on the

master cylinder (see illustration). The fluid

level should be between the MAX and MIN

lines on the reservoir. If the fluid level is low,

first wipe the top of the reservoir and the cap

with a clean rag, to prevent contamination of

the system as the cap is unscrewed. Top-up

with the recommended brake fluid, but do not

overfill.

17While the reservoir cap is off, check the

master cylinder reservoir for contamination. If

rust deposits, dirt particles or water droplets

are present, the system should be drained

and refilled.

18After filling the reservoir to the proper

level, make sure the cap is seated correctly, to

prevent fluid leakage and/or contamination.

19The fluid level in the master cylinder will

drop slightly as the disc brake pads wear.

There is no need to top up to compensate for

this fall provided that the level stays above the

MIN line; the level will rise again when new

pads are fitted. A very low level may indicateworn brake pads. Check for wear (see Sec-

tion 26).

20If the brake fluid level drops consistently,

check the entire system for leaks immediately.

Examine all brake lines, hoses and

connections, along with the calipers, wheel

cylinders and master cylinder (see Sec-

tion 26).

21When checking the fluid level, if you

discover one or both reservoirs empty or

nearly empty, the brake or clutch hydraulic

system should be checked for leaks and bled

(see Chapters 8 and 9).

Windscreen washer fluid

22Fluid for the windscreen washer system is

stored in a plastic reservoir in the engine

compartment (see illustration).

23In milder climates, plain water can be

used in the reservoir, but it should be kept no

more than two-thirds full, to allow for

expansion if the water freezes. In colder

climates, use windscreen washer system

antifreeze, available at any car accessory

shop, to lower the freezing point of the fluid.

This comes in concentrated or pre-mixed

form. If you purchase concentrated antifreeze,

mix the antifreeze with water in accordance

with the manufacturer’s directions on the

container.

Caution: Do not use cooling

system antifreeze - it will damage

the vehicle’s paint.

5 Tyre and tyre pressure

checks

1

1Periodic inspection of the tyres may save

you the inconvenience of being stranded with

a flat tyre. It can also provide you with vital

information regarding possible problems in

the steering and suspension systems before

major damage occurs.

2Tyres are equipped with bands that will

appear when tread depth reaches 1.6 mm, at

which time the tyres can be considered worn

out. This represents the legal minimum tread

depth; most authorities recommend renewing

any tyre on which the tread depth is 2 mm or

less. Tread wear can be monitored with a

simple, inexpensive device known as a tread

depth indicator (see illustration).

3Note any abnormal tyre wear (see

illustration overleaf). Tread pattern irregular-

ities such as cupping, flat spots and more

wear on one side than the other are

indications of front end alignment and/or

wheel balance problems. If any of these

conditions are noted, take the vehicle to a tyre

specialist to correct the problem.

4Look closely for cuts, punctures and

embedded nails or tacks. Sometimes, after a

nail has embedded itself in the tread, a tyre

will hold air pressure for a short time, or may

1•9

4.22 The windscreen washer fluid reservoir

is located in the right front corner of the

engine compartment on most models4.16 The brake fluid level should be kept

above the MIN mark on the translucent

reservoir - unscrew the cap to add fluid4.15 Adding hydraulic fluid to the clutch

fluid reservoir

5.4a If a slow puncture is suspected,

check the valve core first to make sure it’s

tight5.2 Use a tyre tread depth indicator to

monitor tyre wear - they are available at

car accessory shops and service stations,

and cost very little

1

Weekly Checks

Page 23 of 228

Caution: Do not overfill the

reservoir. If too much fluid is

added, remove the excess with a

clean syringe. Refit the cap.

7If frequent topping-up is needed, check the

power steering hoses and connections for

leaks and wear (see Section 10).

8Check the condition and tension of the

drivebelt (see Section 11).

8 Automatic transmission fluid

level check

1

Caution: The use of transmission

fluid other than the type listed in

this Chapter’s Specifications

could result in transmission

malfunctions or failure.

1The automatic transmission fluid should be

carefully maintained. Low fluid level can lead

to slipping or loss of drive, while overfilling

can cause foaming and loss of fluid. Either

condition can cause transmission damage.

2Since transmission fluid expands as it heats

up, the fluid level should only be checked

when the transmission is warm (at normal

operating temperature). If the vehicle has just

been driven over 20 miles (32 km), the

transmission can be considered warm. You

can also check the fluid level when the

transmission is cold. If the vehicle has not

been driven for over five hours and the fluid is

about room temperature (20°C), the

transmission is cold. However, the fluid level

is normally checked with the transmission

warm, to ensure accurate results.

Caution: If the vehicle has just

been driven for a long time at

high speed or in city traffic, in hot

weather, or if it has been pulling

a trailer, an accurate fluid level reading

cannot be obtained. Allow the trans-

mission to cool down for about 30 minutes.

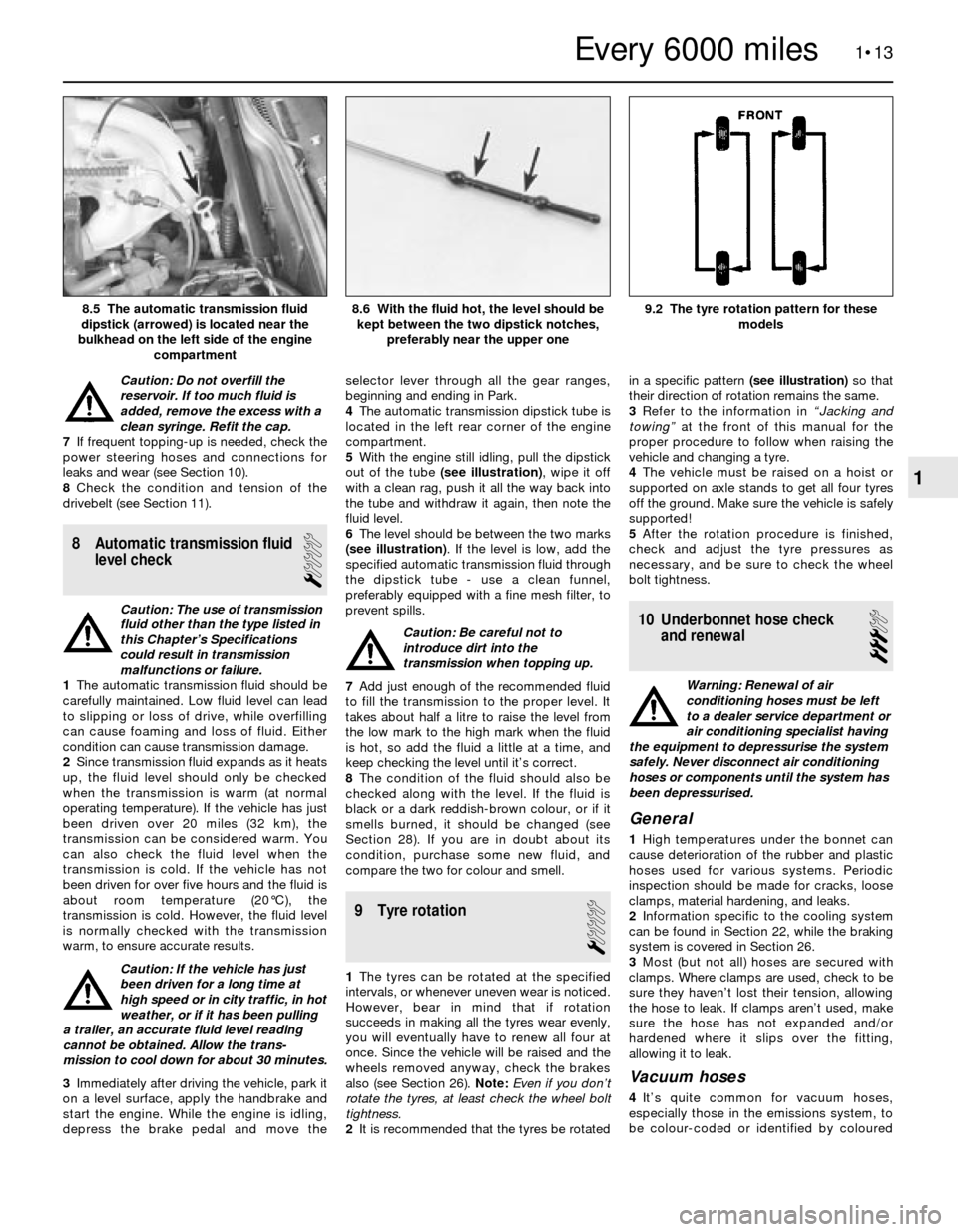

3Immediately after driving the vehicle, park it

on a level surface, apply the handbrake and

start the engine. While the engine is idling,

depress the brake pedal and move theselector lever through all the gear ranges,

beginning and ending in Park.

4The automatic transmission dipstick tube is

located in the left rear corner of the engine

compartment.

5With the engine still idling, pull the dipstick

out of the tube (see illustration), wipe it off

with a clean rag, push it all the way back into

the tube and withdraw it again, then note the

fluid level.

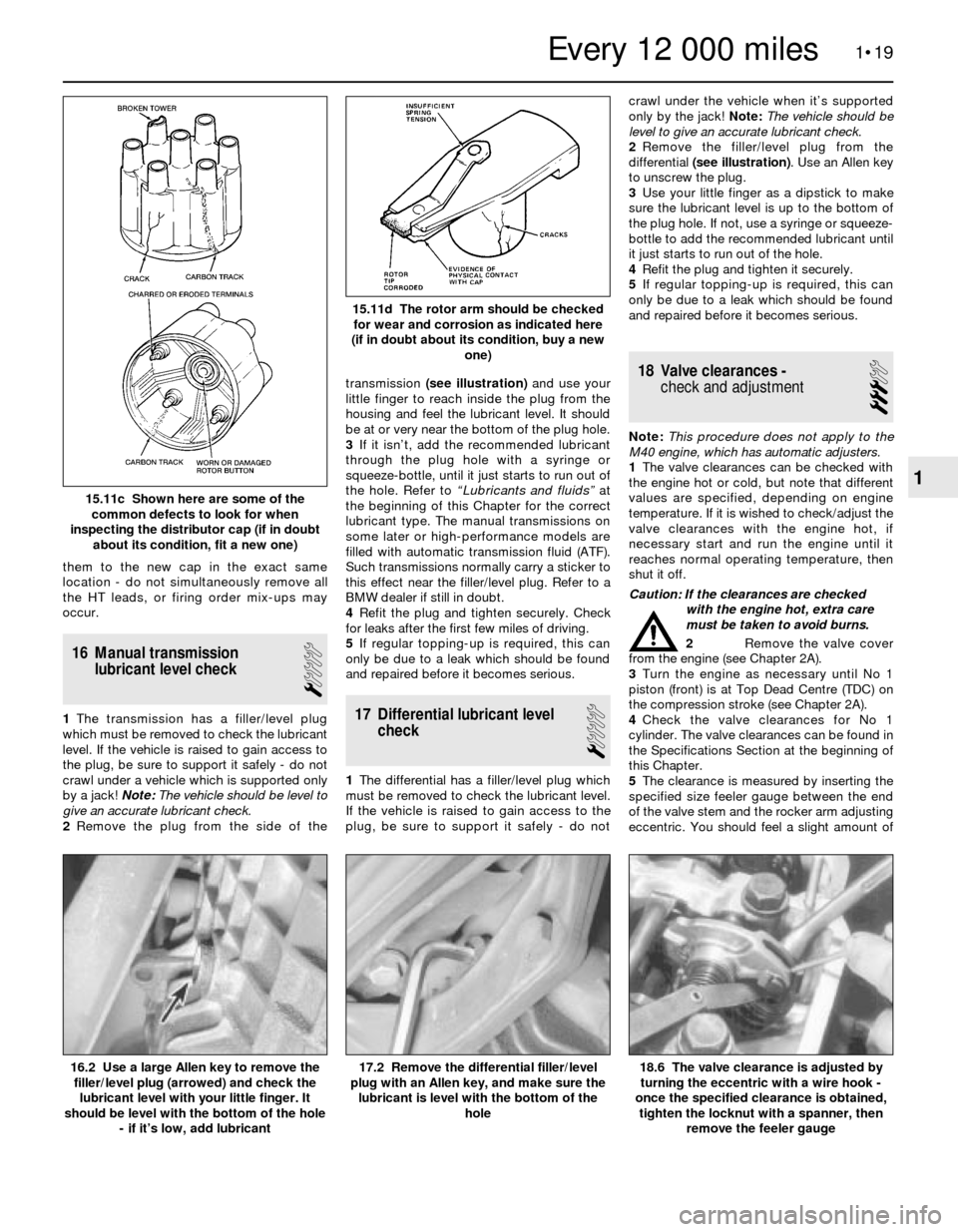

6The level should be between the two marks

(see illustration). If the level is low, add the

specified automatic transmission fluid through

the dipstick tube - use a clean funnel,

preferably equipped with a fine mesh filter, to

prevent spills.

Caution: Be careful not to

introduce dirt into the

transmission when topping up.

7Add just enough of the recommended fluid

to fill the transmission to the proper level. It

takes about half a litre to raise the level from

the low mark to the high mark when the fluid

is hot, so add the fluid a little at a time, and

keep checking the level until it’s correct.

8The condition of the fluid should also be

checked along with the level. If the fluid is

black or a dark reddish-brown colour, or if it

smells burned, it should be changed (see

Section 28). If you are in doubt about its

condition, purchase some new fluid, and

compare the two for colour and smell.

9 Tyre rotation

1

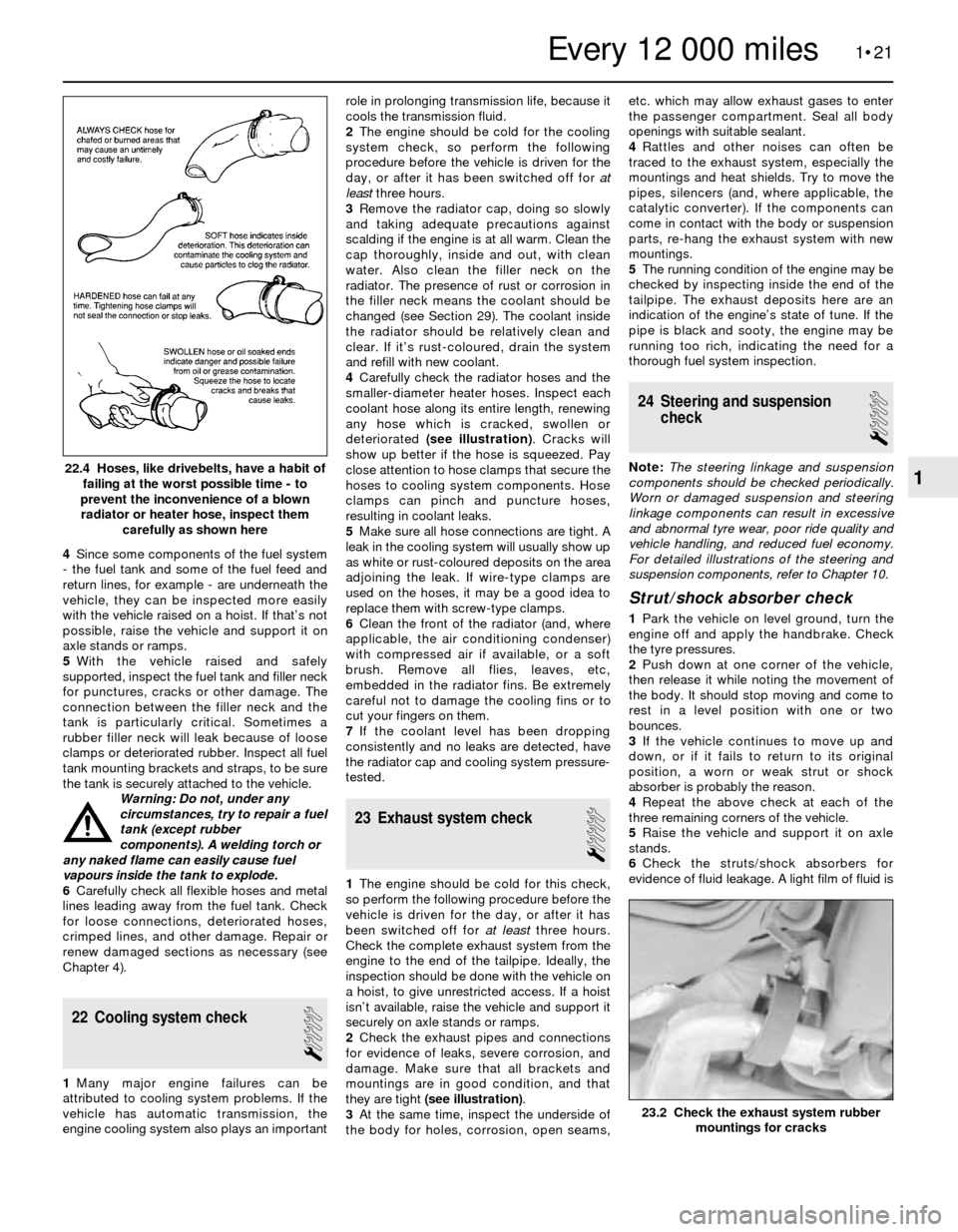

1The tyres can be rotated at the specified

intervals, or whenever uneven wear is noticed.

However, bear in mind that if rotation

succeeds in making all the tyres wear evenly,

you will eventually have to renew all four at

once. Since the vehicle will be raised and the

wheels removed anyway, check the brakes

also (see Section 26). Note: Even if you don’t

rotate the tyres, at least check the wheel bolt

tightness.

2It is recommended that the tyres be rotatedin a specific pattern (see illustration)so that

their direction of rotation remains the same.

3Refer to the information in “Jacking and

towing”at the front of this manual for the

proper procedure to follow when raising the

vehicle and changing a tyre.

4The vehicle must be raised on a hoist or

supported on axle stands to get all four tyres

off the ground. Make sure the vehicle is safely

supported!

5After the rotation procedure is finished,

check and adjust the tyre pressures as

necessary, and be sure to check the wheel

bolt tightness.

10 Underbonnet hose check

and renewal

3

Warning: Renewal of air

conditioning hoses must be left

to a dealer service department or

air conditioning specialist having

the equipment to depressurise the system

safely. Never disconnect air conditioning

hoses or components until the system has

been depressurised.

General

1High temperatures under the bonnet can

cause deterioration of the rubber and plastic

hoses used for various systems. Periodic

inspection should be made for cracks, loose

clamps, material hardening, and leaks.

2Information specific to the cooling system

can be found in Section 22, while the braking

system is covered in Section 26.

3Most (but not all) hoses are secured with

clamps. Where clamps are used, check to be

sure they haven’t lost their tension, allowing

the hose to leak. If clamps aren’t used, make

sure the hose has not expanded and/or

hardened where it slips over the fitting,

allowing it to leak.

Vacuum hoses

4It’s quite common for vacuum hoses,

especially those in the emissions system, to

be colour-coded or identified by coloured

1•13

9.2 The tyre rotation pattern for these

models8.6 With the fluid hot, the level should be

kept between the two dipstick notches,

preferably near the upper one8.5 The automatic transmission fluid

dipstick (arrowed) is located near the

bulkhead on the left side of the engine

compartment

1

Every 6000 miles

Page 29 of 228

them to the new cap in the exact same

location - do not simultaneously remove all

the HT leads, or firing order mix-ups may

occur.

16 Manual transmission

lubricant level check

1

1The transmission has a filler/level plug

which must be removed to check the lubricant

level. If the vehicle is raised to gain access to

the plug, be sure to support it safely - do not

crawl under a vehicle which is supported only

by a jack!Note:The vehicle should be level to

give an accurate lubricant check.

2Remove the plug from the side of thetransmission (see illustration)and use your

little finger to reach inside the plug from the

housing and feel the lubricant level. It should

be at or very near the bottom of the plug hole.

3If it isn’t, add the recommended lubricant

through the plug hole with a syringe or

squeeze-bottle, until it just starts to run out of

the hole. Refer to “Lubricants and fluids” at

the beginning of this Chapter for the correct

lubricant type. The manual transmissions on

some later or high-performance models are

filled with automatic transmission fluid (ATF).

Such transmissions normally carry a sticker to

this effect near the filler/level plug. Refer to a

BMW dealer if still in doubt.

4Refit the plug and tighten securely. Check

for leaks after the first few miles of driving.

5If regular topping-up is required, this can

only be due to a leak which should be found

and repaired before it becomes serious.17 Differential lubricant level

check

1

1The differential has a filler/level plug which

must be removed to check the lubricant level.

If the vehicle is raised to gain access to the

plug, be sure to support it safely - do notcrawl under the vehicle when it’s supported

only by the jack! Note:The vehicle should be

level to give an accurate lubricant check.

2Remove the filler/level plug from the

differential (see illustration). Use an Allen key

to unscrew the plug.

3Use your little finger as a dipstick to make

sure the lubricant level is up to the bottom of

the plug hole. If not, use a syringe or squeeze-

bottle to add the recommended lubricant until

it just starts to run out of the hole.

4Refit the plug and tighten it securely.

5If regular topping-up is required, this can

only be due to a leak which should be found

and repaired before it becomes serious.

18 Valve clearances -

check and adjustment

3

Note:This procedure does not apply to the

M40 engine, which has automatic adjusters.

1The valve clearances can be checked with

the engine hot or cold, but note that different

values are specified, depending on engine

temperature. If it is wished to check/adjust the

valve clearances with the engine hot, if

necessary start and run the engine until it

reaches normal operating temperature, then

shut it off.

Caution: If the clearances are checked

with the engine hot, extra care

must be taken to avoid burns.

2Remove the valve cover

from the engine (see Chapter 2A).

3Turn the engine as necessary until No 1

piston (front) is at Top Dead Centre (TDC) on

the compression stroke (see Chapter 2A).

4Check the valve clearances for No 1

cylinder. The valve clearances can be found in

the Specifications Section at the beginning of

this Chapter.

5The clearance is measured by inserting the

specified size feeler gauge between the end

of the valve stem and the rocker arm adjusting

eccentric. You should feel a slight amount of

1•19

15.11d The rotor arm should be checked

for wear and corrosion as indicated here

(if in doubt about its condition, buy a new

one)

15.11c Shown here are some of the

common defects to look for when

inspecting the distributor cap (if in doubt

about its condition, fit a new one)

18.6 The valve clearance is adjusted by

turning the eccentric with a wire hook -

once the specified clearance is obtained,

tighten the locknut with a spanner, then

remove the feeler gauge17.2 Remove the differential filler/level

plug with an Allen key, and make sure the

lubricant is level with the bottom of the

hole16.2 Use a large Allen key to remove the

filler/level plug (arrowed) and check the

lubricant level with your little finger. It

should be level with the bottom of the hole

- if it’s low, add lubricant

1

Every 12 000 miles

Page 31 of 228

4Since some components of the fuel system

- the fuel tank and some of the fuel feed and

return lines, for example - are underneath the

vehicle, they can be inspected more easily

with the vehicle raised on a hoist. If that’s not

possible, raise the vehicle and support it on

axle stands or ramps.

5With the vehicle raised and safely

supported, inspect the fuel tank and filler neck

for punctures, cracks or other damage. The

connection between the filler neck and the

tank is particularly critical. Sometimes a

rubber filler neck will leak because of loose

clamps or deteriorated rubber. Inspect all fuel

tank mounting brackets and straps, to be sure

the tank is securely attached to the vehicle.

Warning: Do not, under any

circumstances, try to repair a fuel

tank (except rubber

components). A welding torch or

any naked flame can easily cause fuel

vapours inside the tank to explode.

6Carefully check all flexible hoses and metal

lines leading away from the fuel tank. Check

for loose connections, deteriorated hoses,

crimped lines, and other damage. Repair or

renew damaged sections as necessary (see

Chapter 4).

22 Cooling system check

1

1Many major engine failures can be

attributed to cooling system problems. If the

vehicle has automatic transmission, the

engine cooling system also plays an importantrole in prolonging transmission life, because it

cools the transmission fluid.

2The engine should be cold for the cooling

system check, so perform the following

procedure before the vehicle is driven for the

day, or after it has been switched off for at

leastthree hours.

3Remove the radiator cap, doing so slowly

and taking adequate precautions against

scalding if the engine is at all warm. Clean the

cap thoroughly, inside and out, with clean

water. Also clean the filler neck on the

radiator. The presence of rust or corrosion in

the filler neck means the coolant should be

changed (see Section 29). The coolant inside

the radiator should be relatively clean and

clear. If it’s rust-coloured, drain the system

and refill with new coolant.

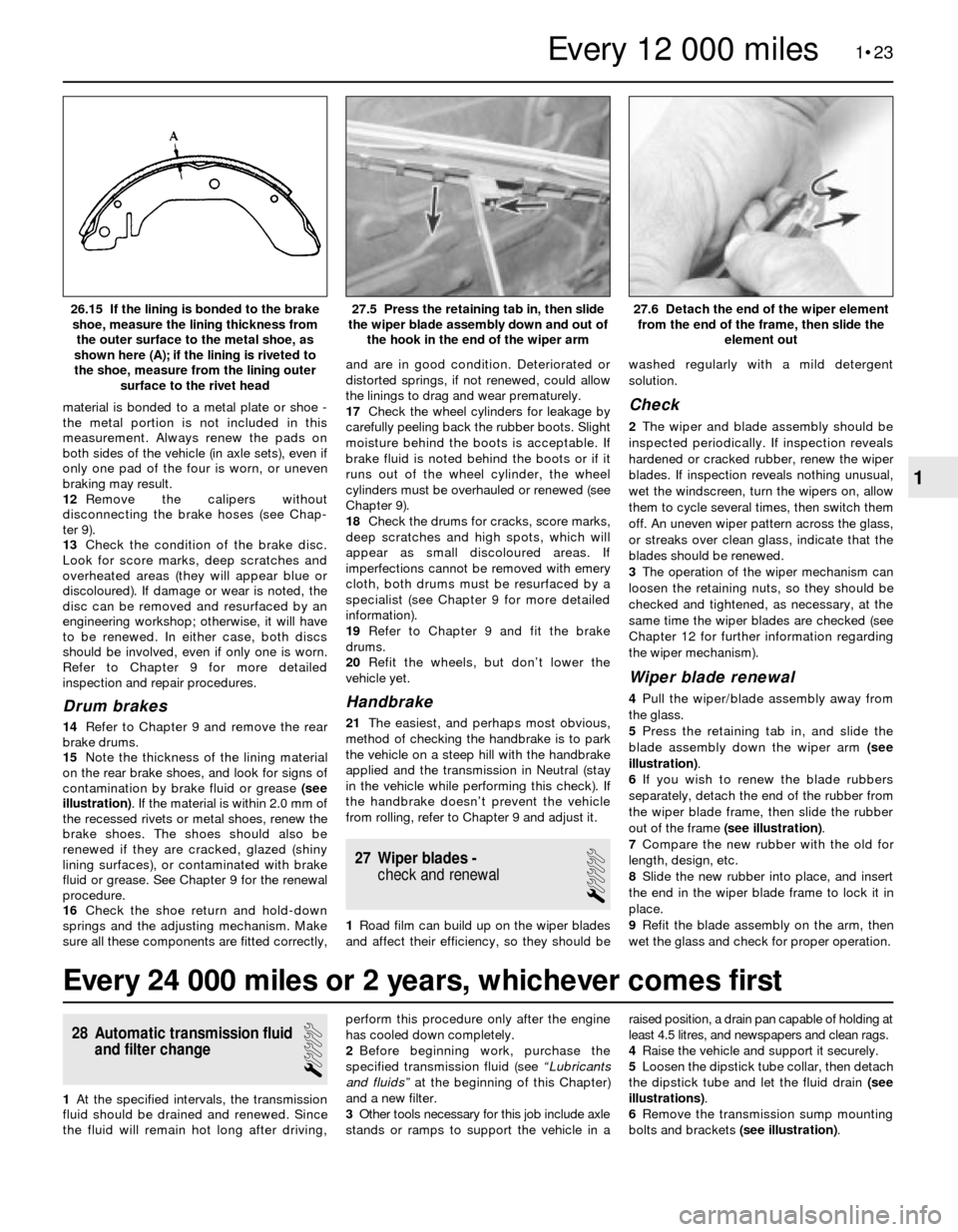

4Carefully check the radiator hoses and the

smaller-diameter heater hoses. Inspect each

coolant hose along its entire length, renewing

any hose which is cracked, swollen or

deteriorated (see illustration). Cracks will

show up better if the hose is squeezed. Pay

close attention to hose clamps that secure the

hoses to cooling system components. Hose

clamps can pinch and puncture hoses,

resulting in coolant leaks.

5Make sure all hose connections are tight. A

leak in the cooling system will usually show up

as white or rust-coloured deposits on the area

adjoining the leak. If wire-type clamps are

used on the hoses, it may be a good idea to

replace them with screw-type clamps.

6Clean the front of the radiator (and, where

applicable, the air conditioning condenser)

with compressed air if available, or a soft

brush. Remove all flies, leaves, etc,

embedded in the radiator fins. Be extremely

careful not to damage the cooling fins or to

cut your fingers on them.

7If the coolant level has been dropping

consistently and no leaks are detected, have

the radiator cap and cooling system pressure-

tested.

23 Exhaust system check

1

1The engine should be cold for this check,

so perform the following procedure before the

vehicle is driven for the day, or after it has

been switched off for at leastthree hours.

Check the complete exhaust system from the

engine to the end of the tailpipe. Ideally, the

inspection should be done with the vehicle on

a hoist, to give unrestricted access. If a hoist

isn’t available, raise the vehicle and support it

securely on axle stands or ramps.

2Check the exhaust pipes and connections

for evidence of leaks, severe corrosion, and

damage. Make sure that all brackets and

mountings are in good condition, and that

they are tight (see illustration).

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with suitable sealant.

4Rattles and other noises can often be

traced to the exhaust system, especially the

mountings and heat shields. Try to move the

pipes, silencers (and, where applicable, the

catalytic converter). If the components can

come in contact with the body or suspension

parts, re-hang the exhaust system with new

mountings.

5The running condition of the engine may be

checked by inspecting inside the end of the

tailpipe. The exhaust deposits here are an

indication of the engine’s state of tune. If the

pipe is black and sooty, the engine may be

running too rich, indicating the need for a

thorough fuel system inspection.

24 Steering and suspension

check

1

Note: The steering linkage and suspension

components should be checked periodically.

Worn or damaged suspension and steering

linkage components can result in excessive

and abnormal tyre wear, poor ride quality and

vehicle handling, and reduced fuel economy.

For detailed illustrations of the steering and

suspension components, refer to Chapter 10.

Strut/shock absorber check

1Park the vehicle on level ground, turn the

engine off and apply the handbrake. Check

the tyre pressures.

2Push down at one corner of the vehicle,

then release it while noting the movement of

the body. It should stop moving and come to

rest in a level position with one or two

bounces.

3If the vehicle continues to move up and

down, or if it fails to return to its original

position, a worn or weak strut or shock

absorber is probably the reason.

4Repeat the above check at each of the

three remaining corners of the vehicle.

5Raise the vehicle and support it on axle

stands.

6Check the struts/shock absorbers for

evidence of fluid leakage. A light film of fluid is

1•21

22.4 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown

radiator or heater hose, inspect them

carefully as shown here

23.2 Check the exhaust system rubber

mountings for cracks

1

Every 12 000 miles

Page 33 of 228

material is bonded to a metal plate or shoe -

the metal portion is not included in this

measurement. Always renew the pads on

both sides of the vehicle (in axle sets), even if

only one pad of the four is worn, or uneven

braking may result.

12Remove the calipers without

disconnecting the brake hoses (see Chap-

ter 9).

13Check the condition of the brake disc.

Look for score marks, deep scratches and

overheated areas (they will appear blue or

discoloured). If damage or wear is noted, the

disc can be removed and resurfaced by an

engineering workshop; otherwise, it will have

to be renewed. In either case, both discs

should be involved, even if only one is worn.

Refer to Chapter 9 for more detailed

inspection and repair procedures.

Drum brakes

14Refer to Chapter 9 and remove the rear

brake drums.

15Note the thickness of the lining material

on the rear brake shoes, and look for signs of

contamination by brake fluid or grease (see

illustration). If the material is within 2.0 mm of

the recessed rivets or metal shoes, renew the

brake shoes. The shoes should also be

renewed if they are cracked, glazed (shiny

lining surfaces), or contaminated with brake

fluid or grease. See Chapter 9 for the renewal

procedure.

16Check the shoe return and hold-down

springs and the adjusting mechanism. Make

sure all these components are fitted correctly,and are in good condition. Deteriorated or

distorted springs, if not renewed, could allow

the linings to drag and wear prematurely.

17Check the wheel cylinders for leakage by

carefully peeling back the rubber boots. Slight

moisture behind the boots is acceptable. If

brake fluid is noted behind the boots or if it

runs out of the wheel cylinder, the wheel

cylinders must be overhauled or renewed (see

Chapter 9).

18Check the drums for cracks, score marks,

deep scratches and high spots, which will

appear as small discoloured areas. If

imperfections cannot be removed with emery

cloth, both drums must be resurfaced by a

specialist (see Chapter 9 for more detailed

information).

19Refer to Chapter 9 and fit the brake

drums.

20Refit the wheels, but don’t lower the

vehicle yet.

Handbrake

21The easiest, and perhaps most obvious,

method of checking the handbrake is to park

the vehicle on a steep hill with the handbrake

applied and the transmission in Neutral (stay

in the vehicle while performing this check). If

the handbrake doesn’t prevent the vehicle

from rolling, refer to Chapter 9 and adjust it.

27 Wiper blades -

check and renewal

1

1Road film can build up on the wiper blades

and affect their efficiency, so they should bewashed regularly with a mild detergent

solution.

Check

2The wiper and blade assembly should be

inspected periodically. If inspection reveals

hardened or cracked rubber, renew the wiper

blades. If inspection reveals nothing unusual,

wet the windscreen, turn the wipers on, allow

them to cycle several times, then switch them

off. An uneven wiper pattern across the glass,

or streaks over clean glass, indicate that the

blades should be renewed.

3The operation of the wiper mechanism can

loosen the retaining nuts, so they should be

checked and tightened, as necessary, at the

same time the wiper blades are checked (see

Chapter 12 for further information regarding

the wiper mechanism).

Wiper blade renewal

4Pull the wiper/blade assembly away from

the glass.

5Press the retaining tab in, and slide the

blade assembly down the wiper arm (see

illustration).

6If you wish to renew the blade rubbers

separately, detach the end of the rubber from

the wiper blade frame, then slide the rubber

out of the frame (see illustration).

7Compare the new rubber with the old for

length, design, etc.

8Slide the new rubber into place, and insert

the end in the wiper blade frame to lock it in

place.

9Refit the blade assembly on the arm, then

wet the glass and check for proper operation.

1•23

27.6 Detach the end of the wiper element

from the end of the frame, then slide the

element out27.5 Press the retaining tab in, then slide

the wiper blade assembly down and out of

the hook in the end of the wiper arm26.15 If the lining is bonded to the brake

shoe, measure the lining thickness from

the outer surface to the metal shoe, as

shown here (A); if the lining is riveted to

the shoe, measure from the lining outer

surface to the rivet head

1

Every 12 000 miles

Every 24 000 miles or 2 years, whichever comes first

28 Automatic transmission fluid

and filter change

1

1At the specified intervals, the transmission

fluid should be drained and renewed. Since

the fluid will remain hot long after driving,perform this procedure only after the engine

has cooled down completely.

2Before beginning work, purchase the

specified transmission fluid (see “Lubricants

and fluids”at the beginning of this Chapter)

and a new filter.

3Other tools necessary for this job include axle

stands or ramps to support the vehicle in araised position, a drain pan capable of holding at

least 4.5 litres, and newspapers and clean rags.

4Raise the vehicle and support it securely.

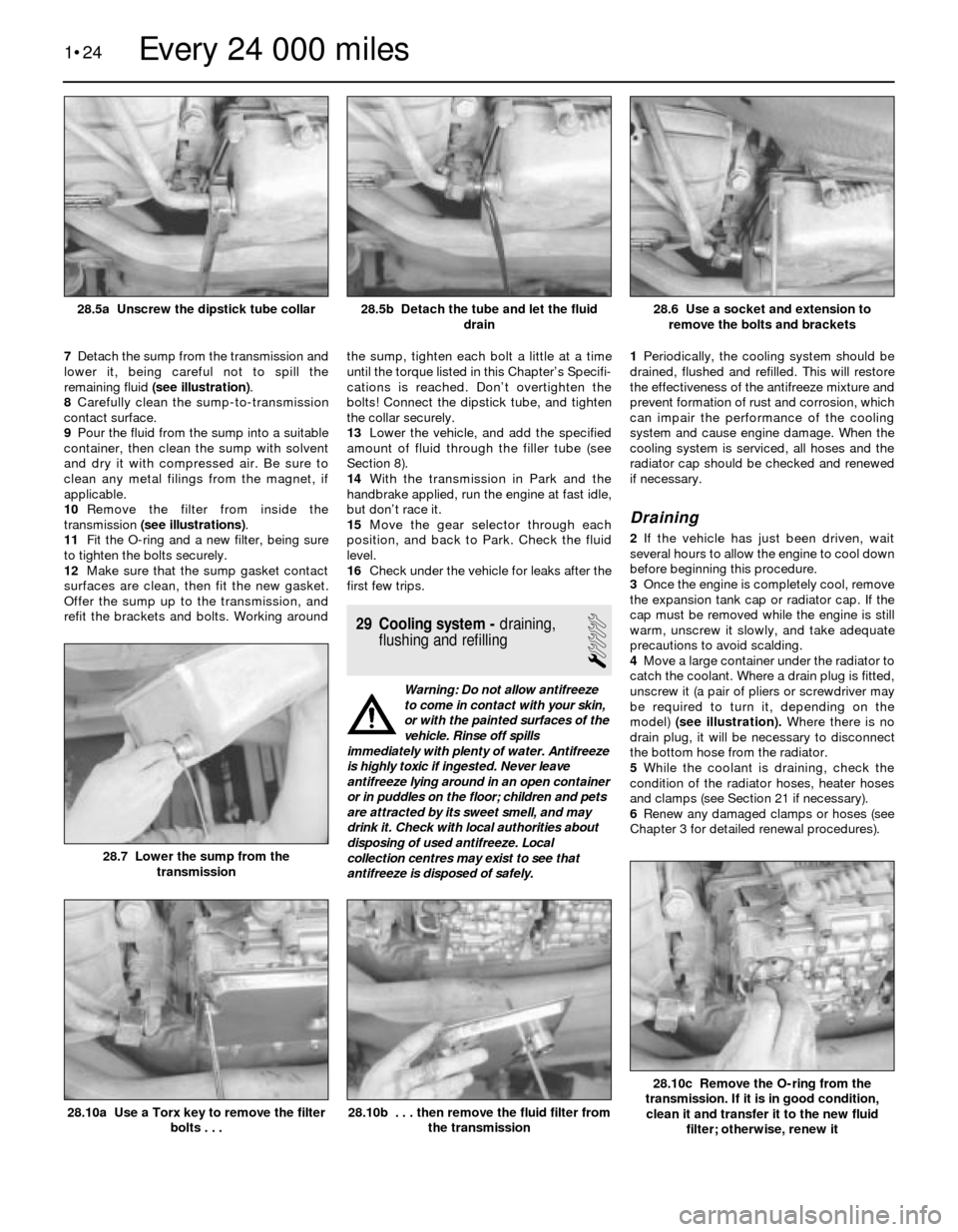

5Loosen the dipstick tube collar, then detach

the dipstick tube and let the fluid drain (see

illustrations).

6Remove the transmission sump mounting

bolts and brackets (see illustration).

Page 34 of 228

7Detach the sump from the transmission and

lower it, being careful not to spill the

remaining fluid (see illustration).

8Carefully clean the sump-to-transmission

contact surface.

9Pour the fluid from the sump into a suitable

container, then clean the sump with solvent

and dry it with compressed air. Be sure to

clean any metal filings from the magnet, if

applicable.

10Remove the filter from inside the

transmission (see illustrations).

11Fit the O-ring and a new filter, being sure

to tighten the bolts securely.

12Make sure that the sump gasket contact

surfaces are clean, then fit the new gasket.

Offer the sump up to the transmission, and

refit the brackets and bolts. Working aroundthe sump, tighten each bolt a little at a time

until the torque listed in this Chapter’s Specifi-

cations is reached. Don’t overtighten the

bolts! Connect the dipstick tube, and tighten

the collar securely.

13Lower the vehicle, and add the specified

amount of fluid through the filler tube (see

Section 8).

14With the transmission in Park and the

handbrake applied, run the engine at fast idle,

but don’t race it.

15Move the gear selector through each

position, and back to Park. Check the fluid

level.

16Check under the vehicle for leaks after the

first few trips.

29 Cooling system -draining,

flushing and refilling

1

Warning: Do not allow antifreeze

to come in contact with your skin,

or with the painted surfaces of the

vehicle. Rinse off spills

immediately with plenty of water. Antifreeze

is highly toxic if ingested. Never leave

antifreeze lying around in an open container

or in puddles on the floor; children and pets

are attracted by its sweet smell, and may

drink it. Check with local authorities about

disposing of used antifreeze. Local

collection centres may exist to see that

antifreeze is disposed of safely.1Periodically, the cooling system should be

drained, flushed and refilled. This will restore

the effectiveness of the antifreeze mixture and

prevent formation of rust and corrosion, which

can impair the performance of the cooling

system and cause engine damage. When the

cooling system is serviced, all hoses and the

radiator cap should be checked and renewed

if necessary.

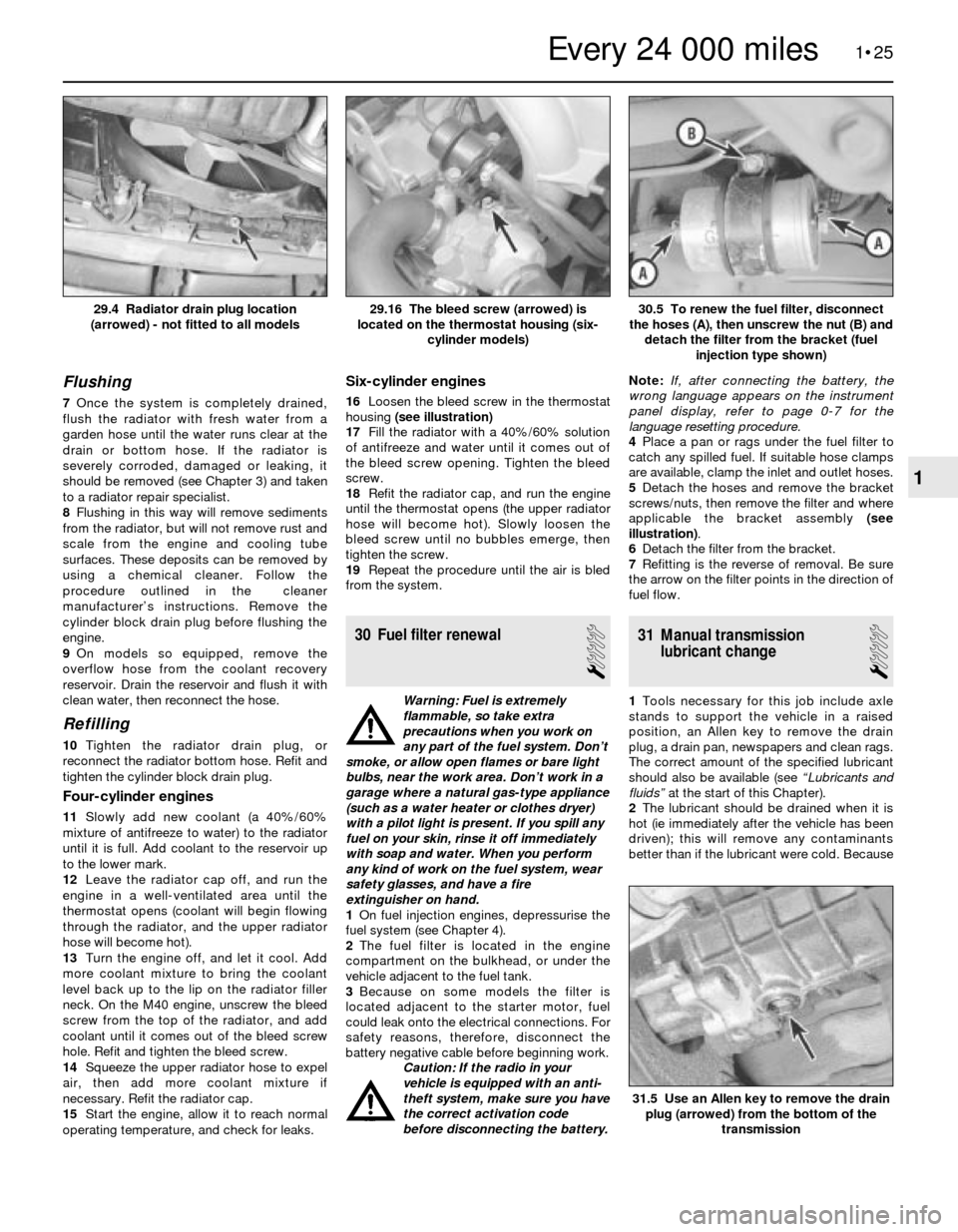

Draining

2If the vehicle has just been driven, wait

several hours to allow the engine to cool down

before beginning this procedure.

3Once the engine is completely cool, remove

the expansion tank cap or radiator cap. If the

cap must be removed while the engine is still

warm, unscrew it slowly, and take adequate

precautions to avoid scalding.

4Move a large container under the radiator to

catch the coolant. Where a drain plug is fitted,

unscrew it (a pair of pliers or screwdriver may

be required to turn it, depending on the

model) (see illustration). Where there is no

drain plug, it will be necessary to disconnect

the bottom hose from the radiator.

5While the coolant is draining, check the

condition of the radiator hoses, heater hoses

and clamps (see Section 21 if necessary).

6Renew any damaged clamps or hoses (see

Chapter 3 for detailed renewal procedures).

1•24

28.10c Remove the O-ring from the

transmission. If it is in good condition,

clean it and transfer it to the new fluid

filter; otherwise, renew it

28.10b . . . then remove the fluid filter from

the transmission28.10a Use a Torx key to remove the filter

bolts . . .

28.7 Lower the sump from the

transmission

28.6 Use a socket and extension to

remove the bolts and brackets28.5b Detach the tube and let the fluid

drain28.5a Unscrew the dipstick tube collar

Every 24 000 miles

Page 35 of 228

Flushing

7Once the system is completely drained,

flush the radiator with fresh water from a

garden hose until the water runs clear at the

drain or bottom hose. If the radiator is

severely corroded, damaged or leaking, it

should be removed (see Chapter 3) and taken

to a radiator repair specialist.

8Flushing in this way will remove sediments

from the radiator, but will not remove rust and

scale from the engine and cooling tube

surfaces. These deposits can be removed by

using a chemical cleaner. Follow the

procedure outlined in the cleaner

manufacturer’s instructions. Remove the

cylinder block drain plug before flushing the

engine.

9On models so equipped, remove the

overflow hose from the coolant recovery

reservoir. Drain the reservoir and flush it with

clean water, then reconnect the hose.

Refilling

10Tighten the radiator drain plug, or

reconnect the radiator bottom hose. Refit and

tighten the cylinder block drain plug.

Four-cylinder engines

11Slowly add new coolant (a 40%/60%

mixture of antifreeze to water) to the radiator

until it is full. Add coolant to the reservoir up

to the lower mark.

12Leave the radiator cap off, and run the

engine in a well-ventilated area until the

thermostat opens (coolant will begin flowing

through the radiator, and the upper radiator

hose will become hot).

13Turn the engine off, and let it cool. Add

more coolant mixture to bring the coolant

level back up to the lip on the radiator filler

neck. On the M40 engine, unscrew the bleed

screw from the top of the radiator, and add

coolant until it comes out of the bleed screw

hole. Refit and tighten the bleed screw.

14Squeeze the upper radiator hose to expel

air, then add more coolant mixture if

necessary. Refit the radiator cap.

15Start the engine, allow it to reach normal

operating temperature, and check for leaks.

Six-cylinder engines

16Loosen the bleed screw in the thermostat

housing (see illustration)

17Fill the radiator with a 40%/60% solution

of antifreeze and water until it comes out of

the bleed screw opening. Tighten the bleed

screw.

18Refit the radiator cap, and run the engine

until the thermostat opens (the upper radiator

hose will become hot). Slowly loosen the

bleed screw until no bubbles emerge, then

tighten the screw.

19Repeat the procedure until the air is bled

from the system.

30 Fuel filter renewal

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

1On fuel injection engines, depressurise the

fuel system (see Chapter 4).

2The fuel filter is located in the engine

compartment on the bulkhead, or under the

vehicle adjacent to the fuel tank.

3Because on some models the filter is

located adjacent to the starter motor, fuel

could leak onto the electrical connections. For

safety reasons, therefore, disconnect the

battery negative cable before beginning work.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery.Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

4Place a pan or rags under the fuel filter to

catch any spilled fuel. If suitable hose clamps

are available, clamp the inlet and outlet hoses.

5 Detach the hoses and remove the bracket

screws/nuts, then remove the filter and where

applicable the bracket assembly (see

illustration).

6Detach the filter from the bracket.

7Refitting is the reverse of removal. Be sure

the arrow on the filter points in the direction of

fuel flow.

31 Manual transmission

lubricant change

1

1Tools necessary for this job include axle

stands to support the vehicle in a raised

position, an Allen key to remove the drain

plug, a drain pan, newspapers and clean rags.

The correct amount of the specified lubricant

should also be available (see “Lubricants and

fluids”at the start of this Chapter).

2The lubricant should be drained when it is

hot (ie immediately after the vehicle has been

driven); this will remove any contaminants

better than if the lubricant were cold. Because

1•25

30.5 To renew the fuel filter, disconnect

the hoses (A), then unscrew the nut (B) and

detach the filter from the bracket (fuel

injection type shown)29.16 The bleed screw (arrowed) is

located on the thermostat housing (six-

cylinder models)29.4 Radiator drain plug location

(arrowed) - not fitted to all models

31.5 Use an Allen key to remove the drain

plug (arrowed) from the bottom of the

transmission

1

Every 24 000 miles