brush BMW 3 SERIES 1988 E30 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 82 of 228

disconnect the fluid cooler lines from the

radiator. Use a drip tray to catch spilled fluid.

Plug the fluid cooler lines and fittings.

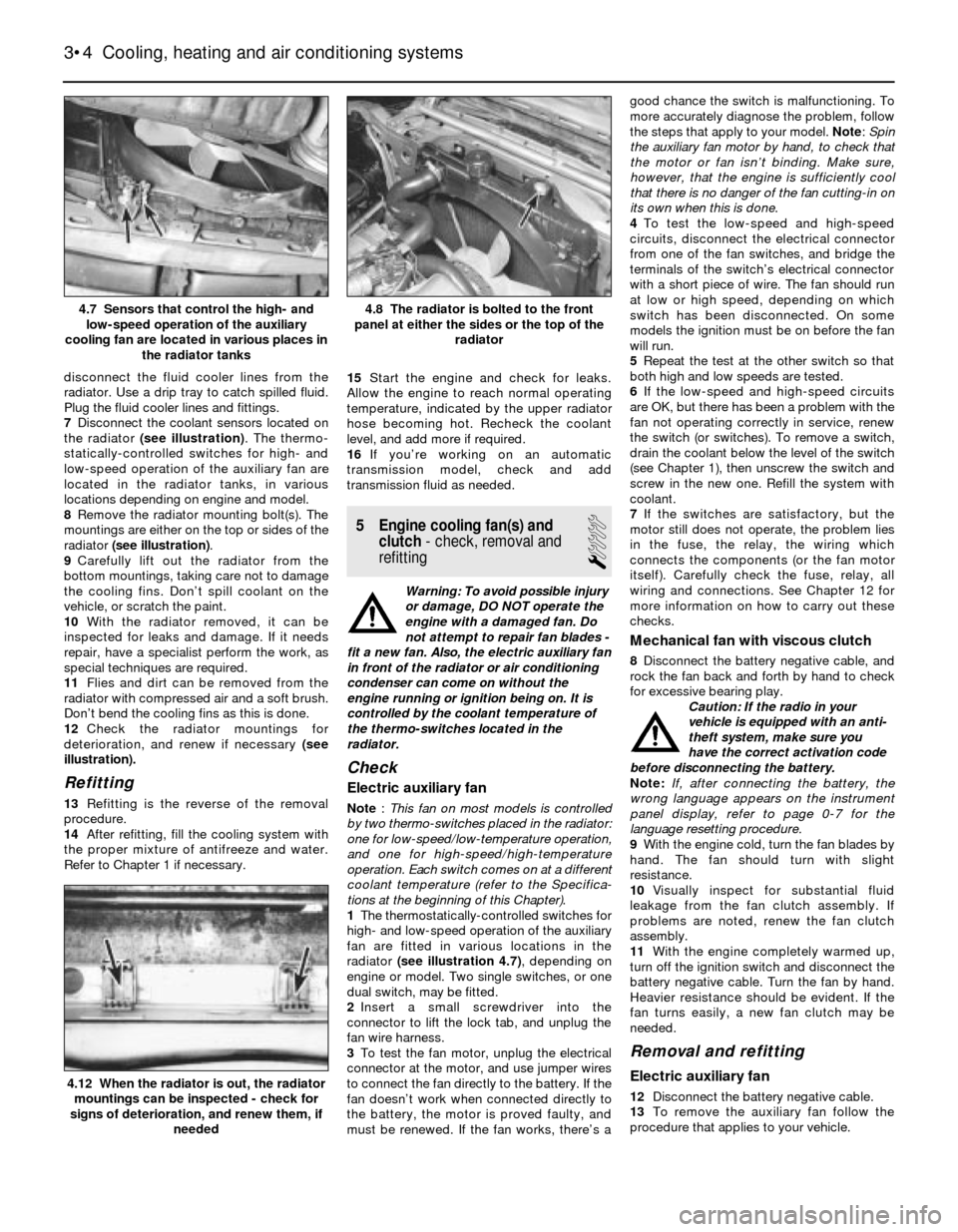

7Disconnect the coolant sensors located on

the radiator (see illustration). The thermo-

statically-controlled switches for high- and

low-speed operation of the auxiliary fan are

located in the radiator tanks, in various

locations depending on engine and model.

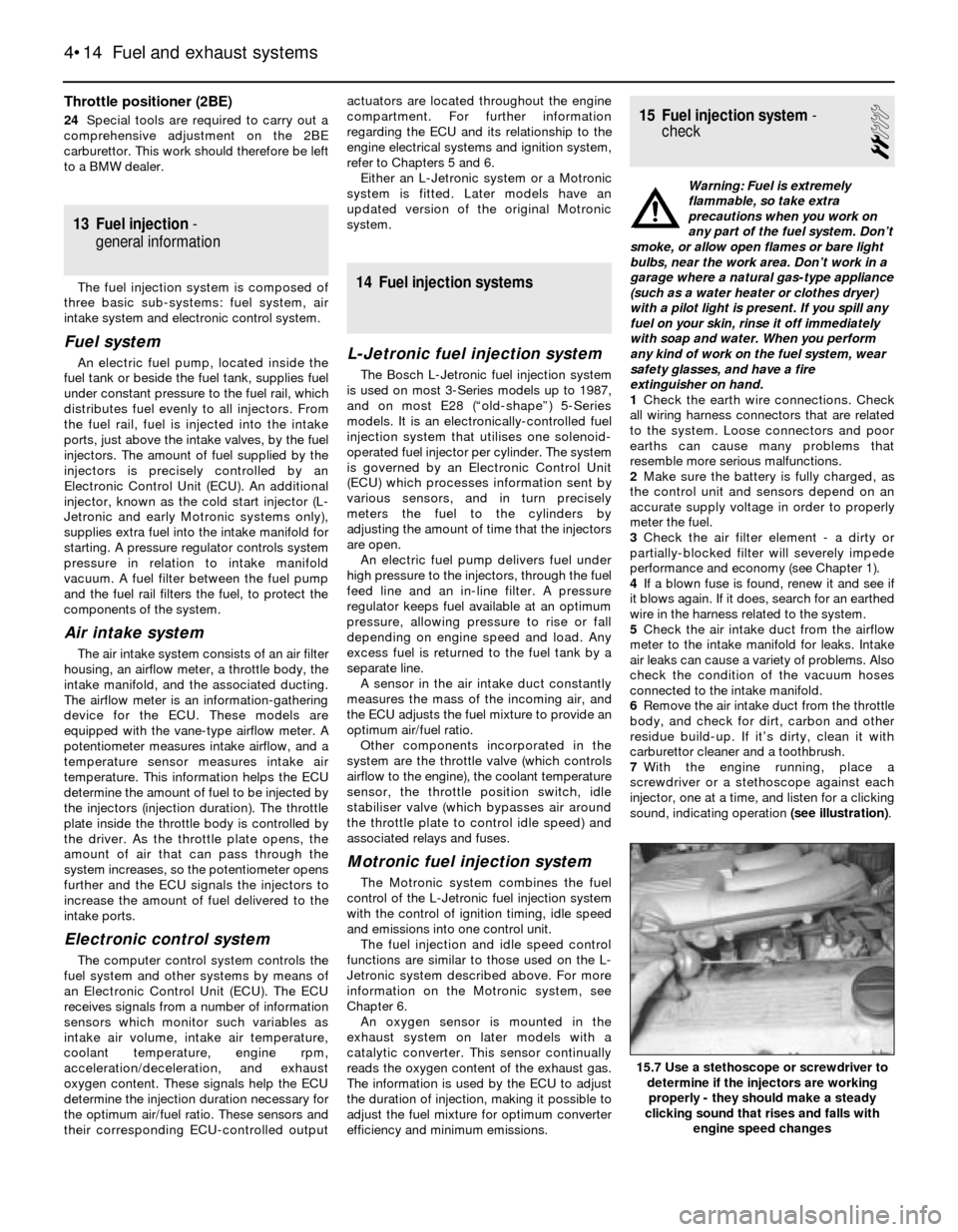

8Remove the radiator mounting bolt(s). The

mountings are either on the top or sides of the

radiator (see illustration).

9Carefully lift out the radiator from the

bottom mountings, taking care not to damage

the cooling fins. Don’t spill coolant on the

vehicle, or scratch the paint.

10With the radiator removed, it can be

inspected for leaks and damage. If it needs

repair, have a specialist perform the work, as

special techniques are required.

11Flies and dirt can be removed from the

radiator with compressed air and a soft brush.

Don’t bend the cooling fins as this is done.

12Check the radiator mountings for

deterioration, and renew if necessary (see

illustration).

Refitting

13Refitting is the reverse of the removal

procedure.

14After refitting, fill the cooling system with

the proper mixture of antifreeze and water.

Refer to Chapter 1 if necessary.15Start the engine and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by the upper radiator

hose becoming hot. Recheck the coolant

level, and add more if required.

16If you’re working on an automatic

transmission model, check and add

transmission fluid as needed.

5 Engine cooling fan(s) and

clutch- check, removal and

refitting

1

Warning: To avoid possible injury

or damage, DO NOT operate the

engine with a damaged fan. Do

not attempt to repair fan blades -

fit a new fan. Also, the electric auxiliary fan

in front of the radiator or air conditioning

condenser can come on without the

engine running or ignition being on. It is

controlled by the coolant temperature of

the thermo-switches located in the

radiator.

Check

Electric auxiliary fan

Note: This fan on most models is controlled

by two thermo-switches placed in the radiator:

one for low-speed/low-temperature operation,

and one for high-speed/high-temperature

operation. Each switch comes on at a different

coolant temperature (refer to the Specifica-

tions at the beginning of this Chapter).

1The thermostatically-controlled switches for

high- and low-speed operation of the auxiliary

fan are fitted in various locations in the

radiator (see illustration 4.7), depending on

engine or model. Two single switches, or one

dual switch, may be fitted.

2Insert a small screwdriver into the

connector to lift the lock tab, and unplug the

fan wire harness.

3To test the fan motor, unplug the electrical

connector at the motor, and use jumper wires

to connect the fan directly to the battery. If the

fan doesn’t work when connected directly to

the battery, the motor is proved faulty, and

must be renewed. If the fan works, there’s agood chance the switch is malfunctioning. To

more accurately diagnose the problem, follow

the steps that apply to your model. Note: Spin

the auxiliary fan motor by hand, to check that

the motor or fan isn’t binding. Make sure,

however, that the engine is sufficiently cool

that there is no danger of the fan cutting-in on

its own when this is done.

4To test the low-speed and high-speed

circuits, disconnect the electrical connector

from one of the fan switches, and bridge the

terminals of the switch’s electrical connector

with a short piece of wire. The fan should run

at low or high speed, depending on which

switch has been disconnected. On some

models the ignition must be on before the fan

will run.

5Repeat the test at the other switch so that

both high and low speeds are tested.

6If the low-speed and high-speed circuits

are OK, but there has been a problem with the

fan not operating correctly in service, renew

the switch (or switches). To remove a switch,

drain the coolant below the level of the switch

(see Chapter 1), then unscrew the switch and

screw in the new one. Refill the system with

coolant.

7If the switches are satisfactory, but the

motor still does not operate, the problem lies

in the fuse, the relay, the wiring which

connects the components (or the fan motor

itself). Carefully check the fuse, relay, all

wiring and connections. See Chapter 12 for

more information on how to carry out these

checks.

Mechanical fan with viscous clutch

8Disconnect the battery negative cable, and

rock the fan back and forth by hand to check

for excessive bearing play.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

9With the engine cold, turn the fan blades by

hand. The fan should turn with slight

resistance.

10Visually inspect for substantial fluid

leakage from the fan clutch assembly. If

problems are noted, renew the fan clutch

assembly.

11With the engine completely warmed up,

turn off the ignition switch and disconnect the

battery negative cable. Turn the fan by hand.

Heavier resistance should be evident. If the

fan turns easily, a new fan clutch may be

needed.

Removal and refitting

Electric auxiliary fan

12Disconnect the battery negative cable.

13To remove the auxiliary fan follow the

procedure that applies to your vehicle.

3•4 Cooling, heating and air conditioning systems

4.12 When the radiator is out, the radiator

mountings can be inspected - check for

signs of deterioration, and renew them, if

needed

4.8 The radiator is bolted to the front

panel at either the sides or the top of the

radiator4.7 Sensors that control the high- and

low-speed operation of the auxiliary

cooling fan are located in various places in

the radiator tanks

Page 102 of 228

Throttle positioner (2BE)

24Special tools are required to carry out a

comprehensive adjustment on the 2BE

carburettor. This work should therefore be left

to a BMW dealer.

13 Fuel injection -

general information

The fuel injection system is composed of

three basic sub-systems: fuel system, air

intake system and electronic control system.

Fuel system

An electric fuel pump, located inside the

fuel tank or beside the fuel tank, supplies fuel

under constant pressure to the fuel rail, which

distributes fuel evenly to all injectors. From

the fuel rail, fuel is injected into the intake

ports, just above the intake valves, by the fuel

injectors. The amount of fuel supplied by the

injectors is precisely controlled by an

Electronic Control Unit (ECU). An additional

injector, known as the cold start injector (L-

Jetronic and early Motronic systems only),

supplies extra fuel into the intake manifold for

starting. A pressure regulator controls system

pressure in relation to intake manifold

vacuum. A fuel filter between the fuel pump

and the fuel rail filters the fuel, to protect the

components of the system.

Air intake system

The air intake system consists of an air filter

housing, an airflow meter, a throttle body, the

intake manifold, and the associated ducting.

The airflow meter is an information-gathering

device for the ECU. These models are

equipped with the vane-type airflow meter. A

potentiometer measures intake airflow, and a

temperature sensor measures intake air

temperature. This information helps the ECU

determine the amount of fuel to be injected by

the injectors (injection duration). The throttle

plate inside the throttle body is controlled by

the driver. As the throttle plate opens, the

amount of air that can pass through the

system increases, so the potentiometer opens

further and the ECU signals the injectors to

increase the amount of fuel delivered to the

intake ports.

Electronic control system

The computer control system controls the

fuel system and other systems by means of

an Electronic Control Unit (ECU). The ECU

receives signals from a number of information

sensors which monitor such variables as

intake air volume, intake air temperature,

coolant temperature, engine rpm,

acceleration/deceleration, and exhaust

oxygen content. These signals help the ECU

determine the injection duration necessary for

the optimum air/fuel ratio. These sensors and

their corresponding ECU-controlled outputactuators are located throughout the engine

compartment. For further information

regarding the ECU and its relationship to the

engine electrical systems and ignition system,

refer to Chapters 5 and 6.

Either an L-Jetronic system or a Motronic

system is fitted. Later models have an

updated version of the original Motronic

system.

14 Fuel injection systems

L-Jetronic fuel injection system

The Bosch L-Jetronic fuel injection system

is used on most 3-Series models up to 1987,

and on most E28 (“old-shape”) 5-Series

models. It is an electronically-controlled fuel

injection system that utilises one solenoid-

operated fuel injector per cylinder. The system

is governed by an Electronic Control Unit

(ECU) which processes information sent by

various sensors, and in turn precisely

meters the fuel to the cylinders by

adjusting the amount of time that the injectors

are open.

An electric fuel pump delivers fuel under

high pressure to the injectors, through the fuel

feed line and an in-line filter. A pressure

regulator keeps fuel available at an optimum

pressure, allowing pressure to rise or fall

depending on engine speed and load. Any

excess fuel is returned to the fuel tank by a

separate line.

A sensor in the air intake duct constantly

measures the mass of the incoming air, and

the ECU adjusts the fuel mixture to provide an

optimum air/fuel ratio.

Other components incorporated in the

system are the throttle valve (which controls

airflow to the engine), the coolant temperature

sensor, the throttle position switch, idle

stabiliser valve (which bypasses air around

the throttle plate to control idle speed) and

associated relays and fuses.

Motronic fuel injection system

The Motronic system combines the fuel

control of the L-Jetronic fuel injection system

with the control of ignition timing, idle speed

and emissions into one control unit.

The fuel injection and idle speed control

functions are similar to those used on the L-

Jetronic system described above. For more

information on the Motronic system, see

Chapter 6.

An oxygen sensor is mounted in the

exhaust system on later models with a

catalytic converter. This sensor continually

reads the oxygen content of the exhaust gas.

The information is used by the ECU to adjust

the duration of injection, making it possible to

adjust the fuel mixture for optimum converter

efficiency and minimum emissions.

15 Fuel injection system-

check

2

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Don’t work in a

garage where a natural gas-type appliance

(such as a water heater or clothes dryer)

with a pilot light is present. If you spill any

fuel on your skin, rinse it off immediately

with soap and water. When you perform

any kind of work on the fuel system, wear

safety glasses, and have a fire

extinguisher on hand.

1Check the earth wire connections. Check

all wiring harness connectors that are related

to the system. Loose connectors and poor

earths can cause many problems that

resemble more serious malfunctions.

2Make sure the battery is fully charged, as

the control unit and sensors depend on an

accurate supply voltage in order to properly

meter the fuel.

3Check the air filter element - a dirty or

partially-blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for an earthed

wire in the harness related to the system.

5Check the air intake duct from the airflow

meter to the intake manifold for leaks. Intake

air leaks can cause a variety of problems. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body, and check for dirt, carbon and other

residue build-up. If it’s dirty, clean it with

carburettor cleaner and a toothbrush.

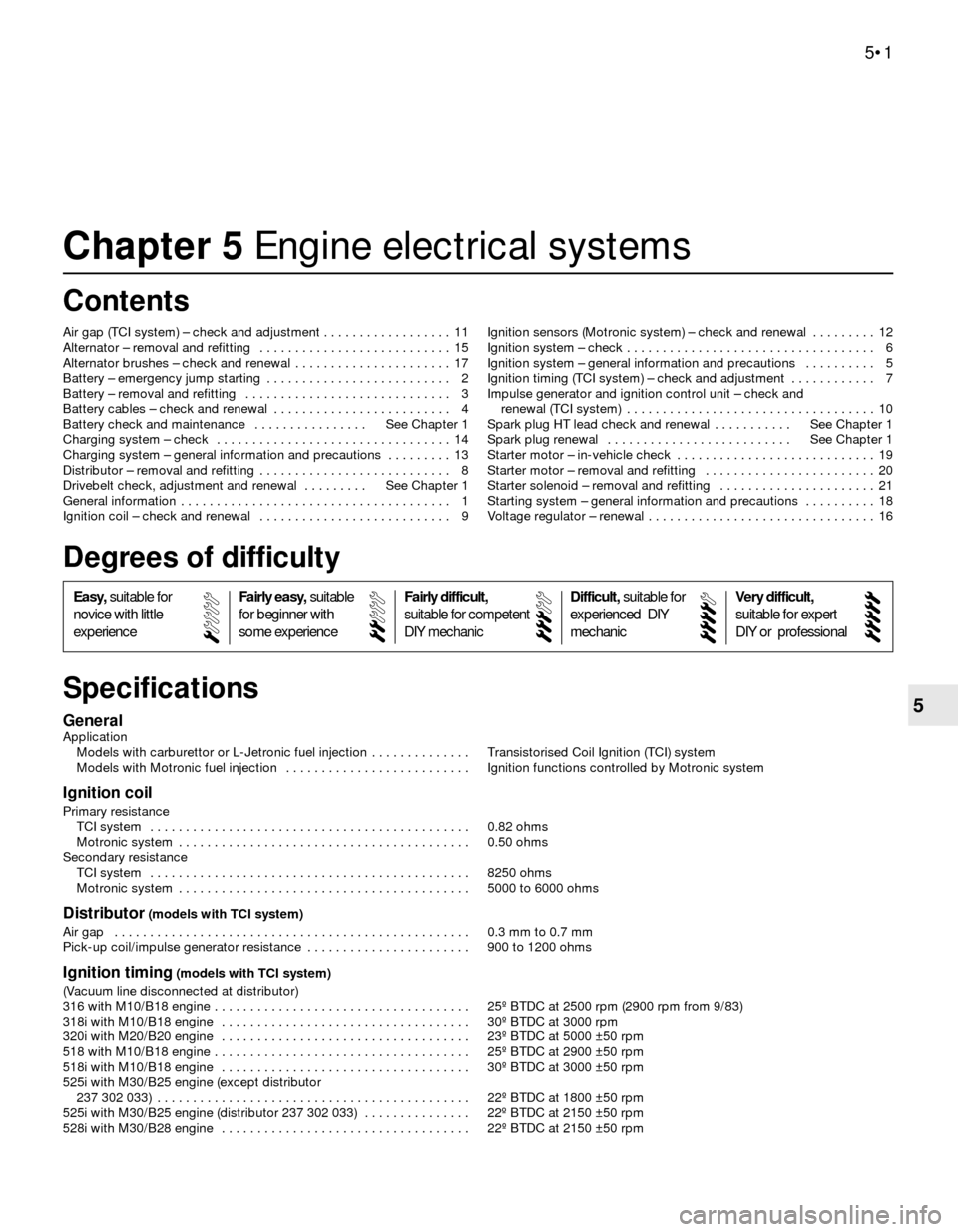

7With the engine running, place a

screwdriver or a stethoscope against each

injector, one at a time, and listen for a clicking

sound, indicating operation (see illustration).

4•14 Fuel and exhaust systems

15.7 Use a stethoscope or screwdriver to

determine if the injectors are working

properly - they should make a steady

clicking sound that rises and falls with

engine speed changes

Page 111 of 228

5GeneralApplication

Models with carburettor or L-Jetronic fuel injection . . . . . . . . . . . . . . Transistorised Coil Ignition (TCI) system

Models with Motronic fuel injection . . . . . . . . . . . . . . . . . . . . . . . . . . Ignition functions controlled by Motronic system

Ignition coil

Primary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.82 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 ohms

Secondary resistance

TCI system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8250 ohms

Motronic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5000 to 6000 ohms

Distributor(models with TCI system)

Air gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 mm to 0.7 mm

Pick-up coil/impulse generator resistance . . . . . . . . . . . . . . . . . . . . . . . 900 to 1200 ohms

Ignition timing(models with TCI system)

(Vacuum line disconnected at distributor)

316 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2500 rpm (2900 rpm from 9/83)

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 rpm

320i with M20/B20 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23º BTDC at 5000 ±50 rpm

518 with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25º BTDC at 2900 ±50 rpm

518i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30º BTDC at 3000 ±50 rpm

525i with M30/B25 engine (except distributor

237 302 033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 1800 ±50 rpm

525i with M30/B25 engine (distributor 237 302 033) . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

528i with M30/B28 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22º BTDC at 2150 ±50 rpm

Chapter 5 Engine electrical systems

Air gap (TCI system) – check and adjustment . . . . . . . . . . . . . . . . . . 11

Alternator – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alternator brushes – check and renewal . . . . . . . . . . . . . . . . . . . . . . 17

Battery – emergency jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery cables – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery check and maintenance . . . . . . . . . . . . . . . . See Chapter 1

Charging system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Charging system – general information and precautions . . . . . . . . . 13

Distributor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drivebelt check, adjustment and renewal . . . . . . . . . See Chapter 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Ignition coil – check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Ignition sensors (Motronic system) – check and renewal . . . . . . . . . 12

Ignition system – check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ignition system – general information and precautions . . . . . . . . . . 5

Ignition timing (TCI system) – check and adjustment . . . . . . . . . . . . 7

Impulse generator and ignition control unit – check and

renewal (TCI system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spark plug HT lead check and renewal . . . . . . . . . . . See Chapter 1

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Starter motor – in-vehicle check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starter motor – removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 20

Starter solenoid – removal and refitting . . . . . . . . . . . . . . . . . . . . . . 21

Starting system – general information and precautions . . . . . . . . . . 18

Voltage regulator – renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 112 of 228

1 General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine-related functions,

these components are discussed separately

from body-related electrical devices such as

the lights, the instruments, etc. (which are

included in Chapter 12).

Always observe the following precautions

when working on the electrical systems:

a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if improperly checked,

connected or handled.

b) Never leave the ignition switched on for

long periods of time with the engine off.

c) Don’t disconnect the battery cables while

the engine is running.

d) Observe the rules when jump-starting

your vehicle. Read the precautions at the

front of this manual.

e) Always disconnect the battery negative

cable first, and connect it last, to reduce

the risk of accidental short-circuits.

f) Don’t charge the battery with the cables

connected to the terminals.

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems in the “Safety first”section

near the front of this manual before beginning

any operation included in this Chapter.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2 Battery-

emergency jump starting

1

Refer to the “Jump starting”procedure at

the front of this manual.

3 Battery- removal and refitting

1

Note:Depending on the model, the battery

may be located in the engine compartment, in

the rear luggage compartment, or under the

rear seat. Consult your owners handbook for

the location of the battery, if not already

known to you.Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Detach the cable from the positive terminal.

3Remove the battery hold-down bracket

(see illustrations)and lift out the battery. Be

careful - it’s heavy. Do not tilt the battery to

any extent while it is being removed, and

store it upright.

4While the battery is out, inspect the carrier

(tray) for corrosion (see Chapter 1).

5If you are renewing the battery, make sure

that you get one that’s identical, with the

same dimensions, amperage rating, cold

cranking rating, etc.

6Refitting is the reverse of removal.

4 Battery cables-

check and renewal

1

Check

1Periodically inspect the entire length of

each battery cable for damage, cracked or

burned insulation, and corrosion.

Poor battery cable connections can cause

starting problems and decreased engine

performance.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.2Check the cable-to-terminal connections at

the ends of the cables for cracks, loose wire

strands, and corrosion. The presence of

white, fluffy deposits under the insulation at

the cable terminal connection is a sign that

the cable is corroded, and should be cleaned

or renewed. Check the terminals for

distortion, missing mounting bolts, and

corrosion.

Renewal

3When removing the cables, always

disconnect the negative cable first and

connect it up last. This reduces the risk of

accidental short-circuits. Even if only a new

positive cable is being fitted, be sure to

disconnect the negative cable from the

battery first (see Chapter 1 for further

information regarding battery cable removal).

4Disconnect the old cables from the battery,

then trace each of them to their opposite ends

and detach them from the starter solenoid

and earth terminals. Note the routing of each

cable to ensure correct refitting.

5If the old cables are to be renewed, take

them with you when buying new cables. It is

vitally important that you renew the cables

with identical parts. Cables have character-

istics that make them easy to identify: positive

cables are usually red, larger in cross-section,

and have a larger-diameter battery post

clamp; earth cables are usually black, smaller

in cross-section, and have a slightly smaller

diameter clamp for the negative post.

6Clean the threads of the solenoid or earth

connection with a wire brush to remove rust

and corrosion.

7Attach the cable to the solenoid or earth

connection, and tighten the mounting nut/bolt

securely.

8Before connecting a new cable to the

battery, make sure that it reaches the battery

post without having to be stretched.

9Connect the positive cable first, followed by

the negative cable.

5•2 Engine electrical systems

3.3b The battery is mounted under the

rear seat on some models

3.3a Always detach the cable from the

battery negative terminal first, then detach

the positive cable – to remove the hold-

down assembly, remove the nuts (arrowed)

or single bolt

Apply a light coat of battery

terminal corrosion inhibitor,

or petroleum jelly, to the

terminal threads, to prevent

future corrosion.

Page 115 of 228

8Remove the hold-down nut or bolt and

clamp.

9Remove the distributor. Note:Do not rotate

the engine with the distributor out.

Refitting

10Before refitting the distributor, make

certain No 1 piston is still at TDC on the

compression stroke.

11Insert the distributor into the engine, with

the adjusting clamp centred over the hold-

down hole. Make allowance for the gear to

turn as the distributor is inserted.

12Refit the hold-down nut or bolt. The marks

previously made on the distributor housing,

and on the rotor and engine, should line up

before the nut or bolt is tightened.

13Refit the distributor cap.

14Connect the wiring for the distributor.

15Reconnect the spark plug HT leads.

16Reconnect the vacuum hoses as

previously marked.

17Check the ignition timing (see Section 7).

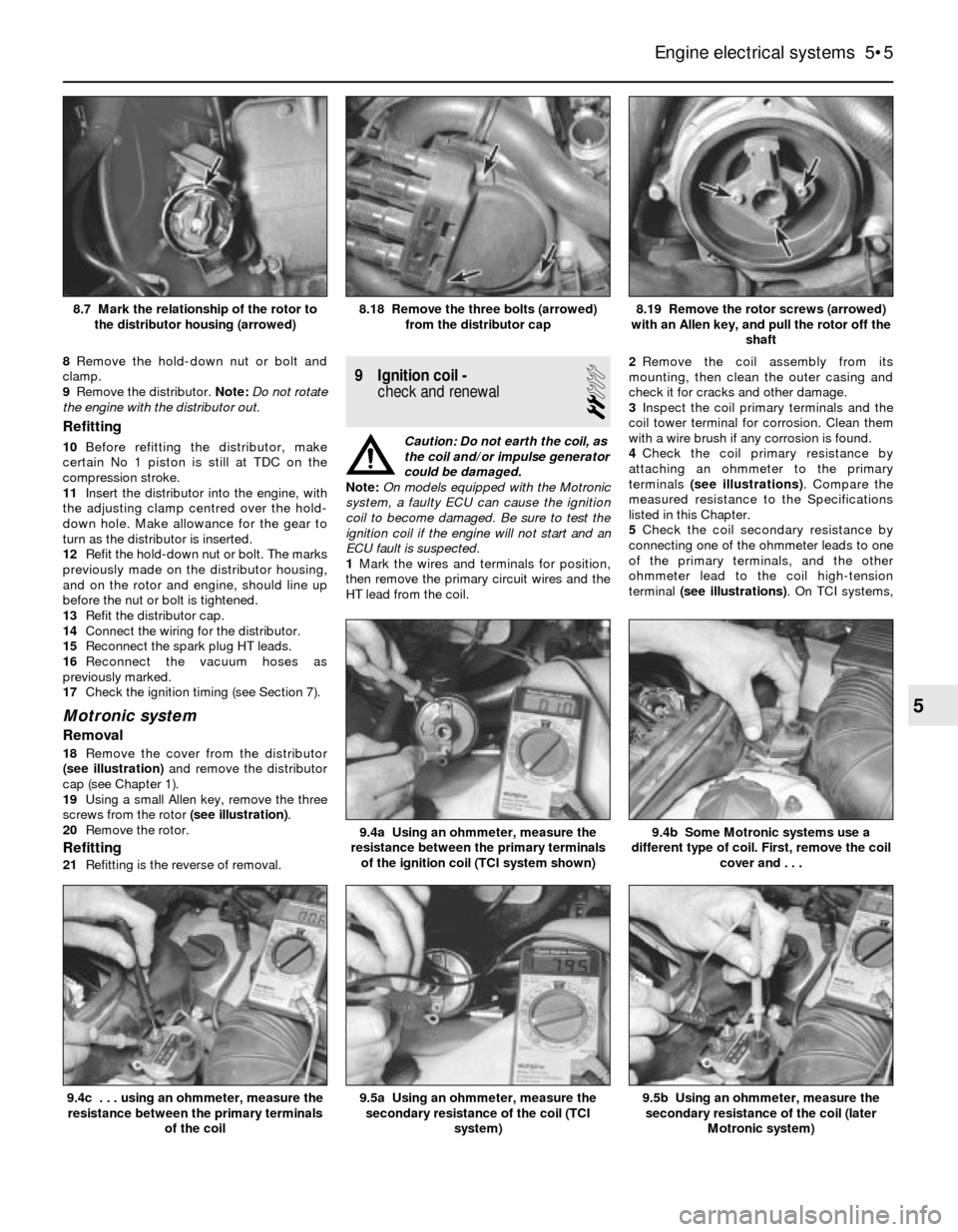

Motronic system

Removal

18Remove the cover from the distributor

(see illustration)and remove the distributor

cap (see Chapter 1).

19Using a small Allen key, remove the three

screws from the rotor (see illustration).

20Remove the rotor.

Refitting

21Refitting is the reverse of removal.

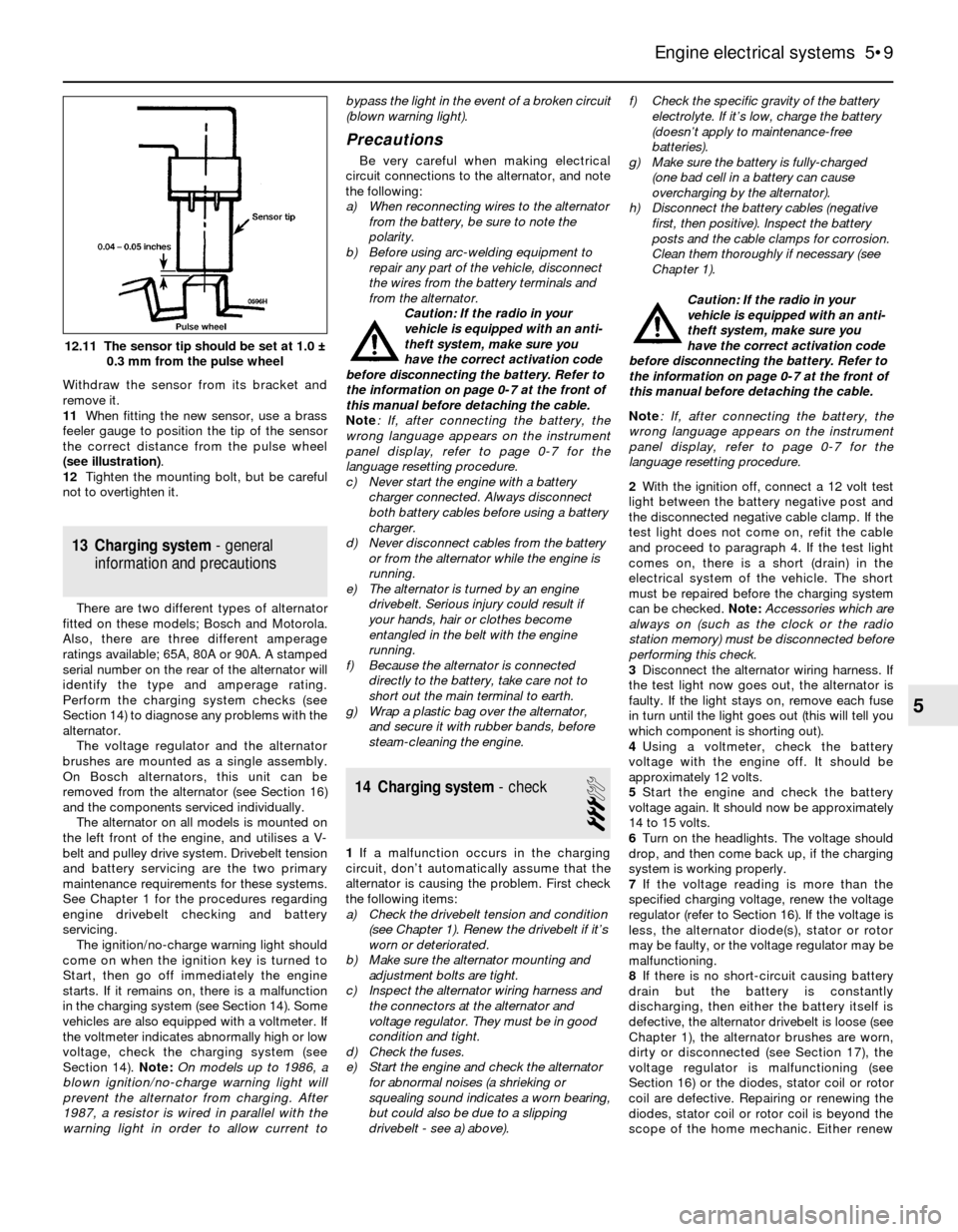

9 Ignition coil -

check and renewal

2

Caution: Do not earth the coil, as

the coil and/or impulse generator

could be damaged.

Note:On models equipped with the Motronic

system, a faulty ECU can cause the ignition

coil to become damaged. Be sure to test the

ignition coil if the engine will not start and an

ECU fault is suspected.

1Mark the wires and terminals for position,

then remove the primary circuit wires and the

HT lead from the coil.2Remove the coil assembly from its

mounting, then clean the outer casing and

check it for cracks and other damage.

3Inspect the coil primary terminals and the

coil tower terminal for corrosion. Clean them

with a wire brush if any corrosion is found.

4Check the coil primary resistance by

attaching an ohmmeter to the primary

terminals (see illustrations). Compare the

measured resistance to the Specifications

listed in this Chapter.

5Check the coil secondary resistance by

connecting one of the ohmmeter leads to one

of the primary terminals, and the other

ohmmeter lead to the coil high-tension

terminal (see illustrations). On TCI systems,

Engine electrical systems 5•5

8.19 Remove the rotor screws (arrowed)

with an Allen key, and pull the rotor off the

shaft8.18 Remove the three bolts (arrowed)

from the distributor cap8.7 Mark the relationship of the rotor to

the distributor housing (arrowed)

9.5b Using an ohmmeter, measure the

secondary resistance of the coil (later

Motronic system)9.5a Using an ohmmeter, measure the

secondary resistance of the coil (TCI

system)

9.4b Some Motronic systems use a

different type of coil. First, remove the coil

cover and . . .9.4a Using an ohmmeter, measure the

resistance between the primary terminals

of the ignition coil (TCI system shown)

9.4c . . . using an ohmmeter, measure the

resistance between the primary terminals

of the coil

5

Page 119 of 228

Withdraw the sensor from its bracket and

remove it.

11When fitting the new sensor, use a brass

feeler gauge to position the tip of the sensor

the correct distance from the pulse wheel

(see illustration).

12Tighten the mounting bolt, but be careful

not to overtighten it.

13 Charging system- general

information and precautions

There are two different types of alternator

fitted on these models; Bosch and Motorola.

Also, there are three different amperage

ratings available; 65A, 80A or 90A. A stamped

serial number on the rear of the alternator will

identify the type and amperage rating.

Perform the charging system checks (see

Section 14) to diagnose any problems with the

alternator.

The voltage regulator and the alternator

brushes are mounted as a single assembly.

On Bosch alternators, this unit can be

removed from the alternator (see Section 16)

and the components serviced individually.

The alternator on all models is mounted on

the left front of the engine, and utilises a V-

belt and pulley drive system. Drivebelt tension

and battery servicing are the two primary

maintenance requirements for these systems.

See Chapter 1 for the procedures regarding

engine drivebelt checking and battery

servicing.

The ignition/no-charge warning light should

come on when the ignition key is turned to

Start, then go off immediately the engine

starts. If it remains on, there is a malfunction

in the charging system (see Section 14). Some

vehicles are also equipped with a voltmeter. If

the voltmeter indicates abnormally high or low

voltage, check the charging system (see

Section 14). Note:On models up to 1986, a

blown ignition/no-charge warning light will

prevent the alternator from charging. After

1987, a resistor is wired in parallel with the

warning light in order to allow current tobypass the light in the event of a broken circuit

(blown warning light).

Precautions

Be very careful when making electrical

circuit connections to the alternator, and note

the following:

a) When reconnecting wires to the alternator

from the battery, be sure to note the

polarity.

b) Before using arc-welding equipment to

repair any part of the vehicle, disconnect

the wires from the battery terminals and

from the alternator.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

c) Never start the engine with a battery

charger connected. Always disconnect

both battery cables before using a battery

charger.

d) Never disconnect cables from the battery

or from the alternator while the engine is

running.

e) The alternator is turned by an engine

drivebelt. Serious injury could result if

your hands, hair or clothes become

entangled in the belt with the engine

running.

f) Because the alternator is connected

directly to the battery, take care not to

short out the main terminal to earth.

g) Wrap a plastic bag over the alternator,

and secure it with rubber bands, before

steam-cleaning the engine.

14 Charging system- check

3

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

a) Check the drivebelt tension and condition

(see Chapter 1). Renew the drivebelt if it’s

worn or deteriorated.

b) Make sure the alternator mounting and

adjustment bolts are tight.

c) Inspect the alternator wiring harness and

the connectors at the alternator and

voltage regulator. They must be in good

condition and tight.

d) Check the fuses.

e) Start the engine and check the alternator

for abnormal noises (a shrieking or

squealing sound indicates a worn bearing,

but could also be due to a slipping

drivebelt - see a) above).f) Check the specific gravity of the battery

electrolyte. If it’s low, charge the battery

(doesn’t apply to maintenance-free

batteries).

g) Make sure the battery is fully-charged

(one bad cell in a battery can cause

overcharging by the alternator).

h) Disconnect the battery cables (negative

first, then positive). Inspect the battery

posts and the cable clamps for corrosion.

Clean them thoroughly if necessary (see

Chapter 1).

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2With the ignition off, connect a 12 volt test

light between the battery negative post and

the disconnected negative cable clamp. If the

test light does not come on, refit the cable

and proceed to paragraph 4. If the test light

comes on, there is a short (drain) in the

electrical system of the vehicle. The short

must be repaired before the charging system

can be checked. Note: Accessories which are

always on (such as the clock or the radio

station memory) must be disconnected before

performing this check.

3Disconnect the alternator wiring harness. If

the test light now goes out, the alternator is

faulty. If the light stays on, remove each fuse

in turn until the light goes out (this will tell you

which component is shorting out).

4Using a voltmeter, check the battery

voltage with the engine off. It should be

approximately 12 volts.

5Start the engine and check the battery

voltage again. It should now be approximately

14 to 15 volts.

6Turn on the headlights. The voltage should

drop, and then come back up, if the charging

system is working properly.

7If the voltage reading is more than the

specified charging voltage, renew the voltage

regulator (refer to Section 16). If the voltage is

less, the alternator diode(s), stator or rotor

may be faulty, or the voltage regulator may be

malfunctioning.

8If there is no short-circuit causing battery

drain but the battery is constantly

discharging, then either the battery itself is

defective, the alternator drivebelt is loose (see

Chapter 1), the alternator brushes are worn,

dirty or disconnected (see Section 17), the

voltage regulator is malfunctioning (see

Section 16) or the diodes, stator coil or rotor

coil are defective. Repairing or renewing the

diodes, stator coil or rotor coil is beyond the

scope of the home mechanic. Either renew

Engine electrical systems 5•9

12.11 The sensor tip should be set at 1.0 ±

0.3 mm from the pulse wheel

5

Page 120 of 228

the alternator complete, or take it to an

automotive electrician, who may be able to

overhaul it. Note:On models up to 1986, a

blown ignition/no-charge warning light bulb

will prevent the alternator from charging. After

1987, a resistor is wired in parallel with the

warning light, in order to allow current to

bypass the light in the event of a broken circuit

(blown warning light).

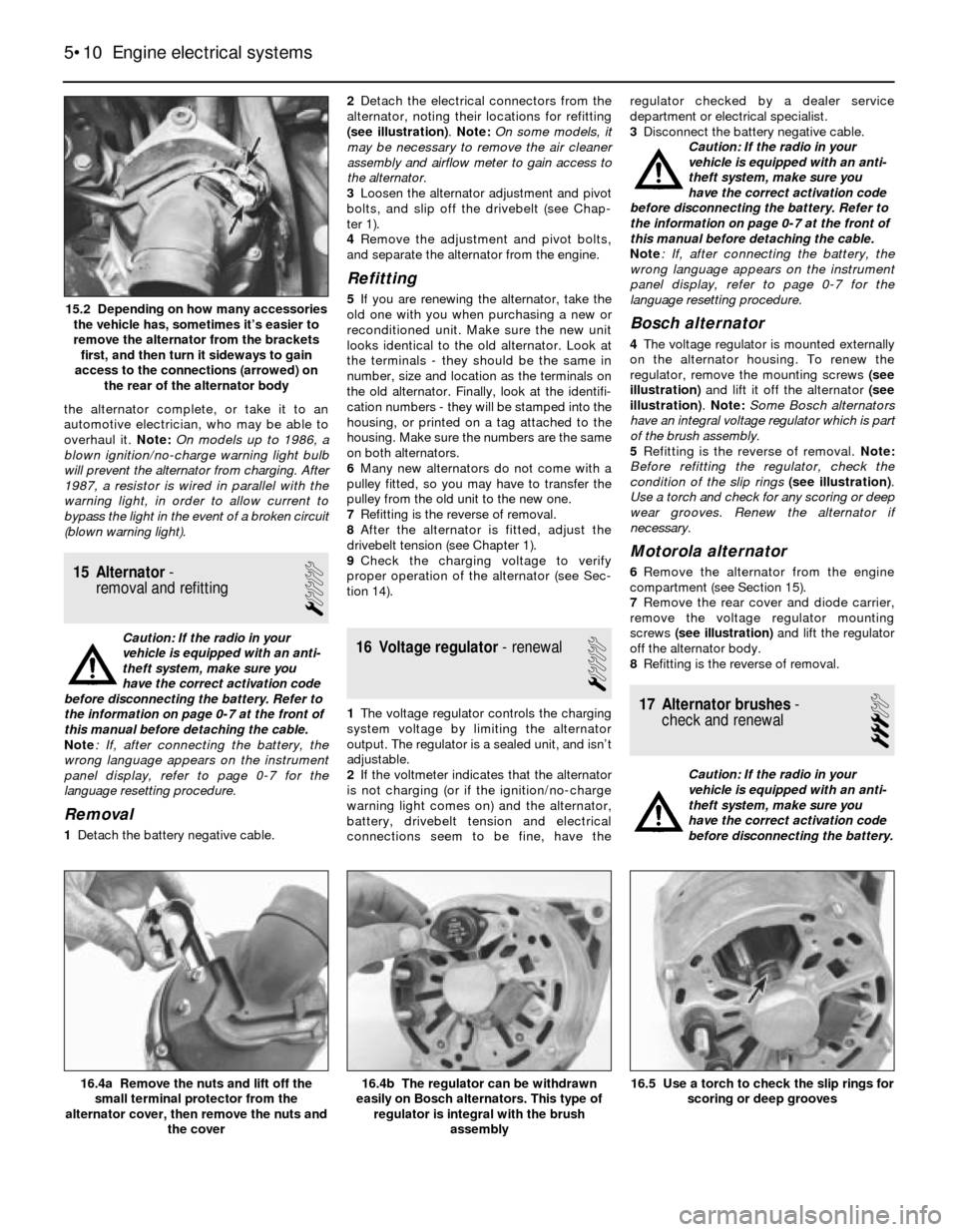

15 Alternator-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Detach the battery negative cable.2Detach the electrical connectors from the

alternator, noting their locations for refitting

(see illustration). Note: On some models, it

may be necessary to remove the air cleaner

assembly and airflow meter to gain access to

the alternator.

3Loosen the alternator adjustment and pivot

bolts, and slip off the drivebelt (see Chap-

ter 1).

4Remove the adjustment and pivot bolts,

and separate the alternator from the engine.

Refitting

5If you are renewing the alternator, take the

old one with you when purchasing a new or

reconditioned unit. Make sure the new unit

looks identical to the old alternator. Look at

the terminals - they should be the same in

number, size and location as the terminals on

the old alternator. Finally, look at the identifi-

cation numbers - they will be stamped into the

housing, or printed on a tag attached to the

housing. Make sure the numbers are the same

on both alternators.

6Many new alternators do not come with a

pulley fitted, so you may have to transfer the

pulley from the old unit to the new one.

7Refitting is the reverse of removal.

8After the alternator is fitted, adjust the

drivebelt tension (see Chapter 1).

9Check the charging voltage to verify

proper operation of the alternator (see Sec-

tion 14).

16 Voltage regulator- renewal

1

1The voltage regulator controls the charging

system voltage by limiting the alternator

output. The regulator is a sealed unit, and isn’t

adjustable.

2If the voltmeter indicates that the alternator

is not charging (or if the ignition/no-charge

warning light comes on) and the alternator,

battery, drivebelt tension and electrical

connections seem to be fine, have theregulator checked by a dealer service

department or electrical specialist.

3Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Bosch alternator

4The voltage regulator is mounted externally

on the alternator housing. To renew the

regulator, remove the mounting screws (see

illustration)and lift it off the alternator (see

illustration). Note: Some Bosch alternators

have an integral voltage regulator which is part

of the brush assembly.

5Refitting is the reverse of removal. Note:

Before refitting the regulator, check the

condition of the slip rings(see illustration).

Use a torch and check for any scoring or deep

wear grooves. Renew the alternator if

necessary.

Motorola alternator

6Remove the alternator from the engine

compartment (see Section 15).

7Remove the rear cover and diode carrier,

remove the voltage regulator mounting

screws (see illustration)and lift the regulator

off the alternator body.

8Refitting is the reverse of removal.

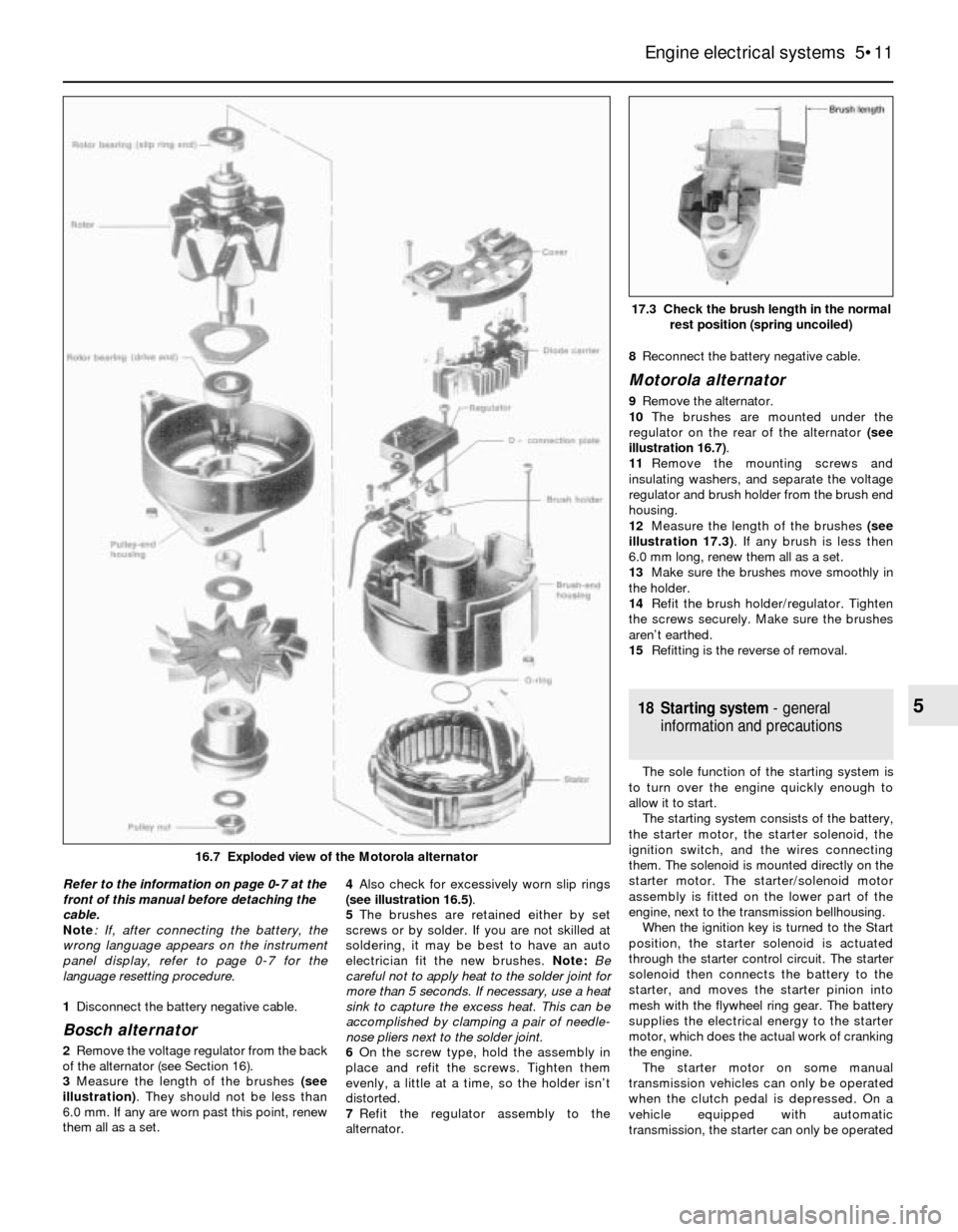

17 Alternator brushes-

check and renewal

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

5•10 Engine electrical systems

16.5 Use a torch to check the slip rings for

scoring or deep grooves16.4b The regulator can be withdrawn

easily on Bosch alternators. This type of

regulator is integral with the brush

assembly16.4a Remove the nuts and lift off the

small terminal protector from the

alternator cover, then remove the nuts and

the cover

15.2 Depending on how many accessories

the vehicle has, sometimes it’s easier to

remove the alternator from the brackets

first, and then turn it sideways to gain

access to the connections (arrowed) on

the rear of the alternator body

Page 121 of 228

Refer to the information on page 0-7 at the

front of this manual before detaching the

cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

Bosch alternator

2Remove the voltage regulator from the back

of the alternator (see Section 16).

3Measure the length of the brushes (see

illustration). They should not be less than

6.0 mm. If any are worn past this point, renew

them all as a set. 4Also check for excessively worn slip rings

(see illustration 16.5).

5The brushes are retained either by set

screws or by solder. If you are not skilled at

soldering, it may be best to have an auto

electrician fit the new brushes. Note: Be

careful not to apply heat to the solder joint for

more than 5 seconds. If necessary, use a heat

sink to capture the excess heat. This can be

accomplished by clamping a pair of needle-

nose pliers next to the solder joint.

6On the screw type, hold the assembly in

place and refit the screws. Tighten them

evenly, a little at a time, so the holder isn’t

distorted.

7Refit the regulator assembly to the

alternator.8Reconnect the battery negative cable.

Motorola alternator

9Remove the alternator.

10The brushes are mounted under the

regulator on the rear of the alternator (see

illustration 16.7).

11Remove the mounting screws and

insulating washers, and separate the voltage

regulator and brush holder from the brush end

housing.

12Measure the length of the brushes (see

illustration 17.3). If any brush is less then

6.0 mm long, renew them all as a set.

13Make sure the brushes move smoothly in

the holder.

14Refit the brush holder/regulator. Tighten

the screws securely. Make sure the brushes

aren’t earthed.

15Refitting is the reverse of removal.

18 Starting system- general

information and precautions

The sole function of the starting system is

to turn over the engine quickly enough to

allow it to start.

The starting system consists of the battery,

the starter motor, the starter solenoid, the

ignition switch, and the wires connecting

them. The solenoid is mounted directly on the

starter motor. The starter/solenoid motor

assembly is fitted on the lower part of the

engine, next to the transmission bellhousing.

When the ignition key is turned to the Start

position, the starter solenoid is actuated

through the starter control circuit. The starter

solenoid then connects the battery to the

starter, and moves the starter pinion into

mesh with the flywheel ring gear. The battery

supplies the electrical energy to the starter

motor, which does the actual work of cranking

the engine.

The starter motor on some manual

transmission vehicles can only be operated

when the clutch pedal is depressed. On a

vehicle equipped with automatic

transmission, the starter can only be operated

Engine electrical systems 5•11

17.3 Check the brush length in the normal

rest position (spring uncoiled)

5

16.7 Exploded view of the Motorola alternator

Page 128 of 228

On some models, it will be necessary to

release the retaining clip (see illustration).

13Visually examine the canister for leakage

or damage.

14Renew the canister if you find evidence of

damage or leakage.

7 Catalytic converter

1

General description

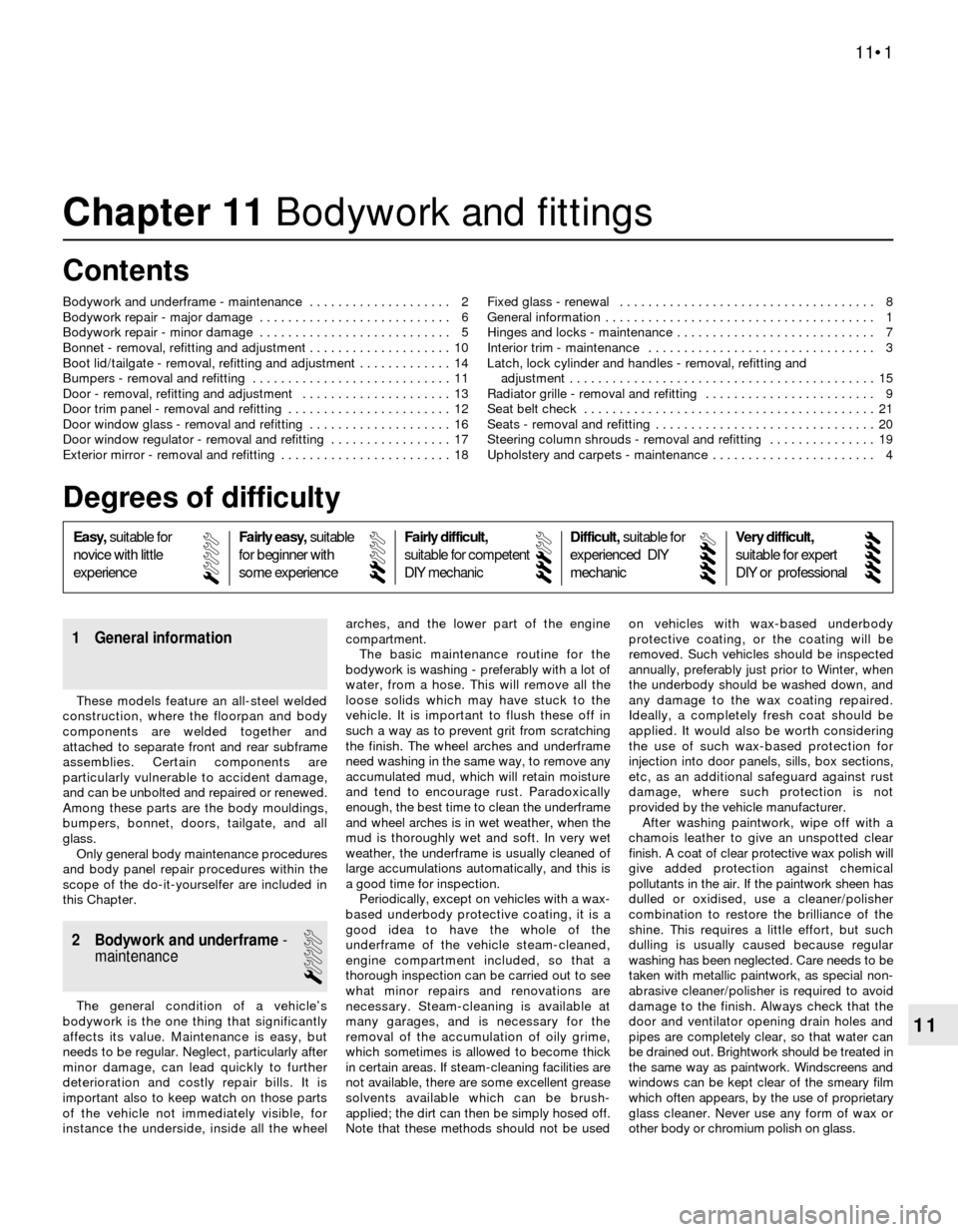

1To reduce emissions of unburnt

hydrocarbons (HC), carbon monoxide (CO)

and oxides of nitrogen (NOx), the later

vehicles covered by this manual are equipped

with a catalytic converter (see illustration).

The converter contains a ceramic honeycomb

coated with precious metals, which speed up

the reaction between the pollutants listed

previously and the oxygen in the exhaust gas.

The pollutants are oxidised to produce water

(H

2O), nitrogen and carbon dioxide (CO2).

Check

2Visually examine the converter(s) for cracks

or damage. Make sure all nuts and bolts are

tight.

3Inspect the insulation cover (if applicable)

welded onto the converter - it should not be

loose.

Caution: If an insulation cover is

dented so that it touches the

converter housing inside,

excessive heat may be

transferred to the floor.

4Start the engine and run it at idle speed.

5Check for exhaust gas leakage from the

converter flanges. Check the body of each

converter for holes.

Component renewal

6See Chapter 4 for removal and refitting

procedures.

Precautions

7The catalytic converter is a reliable and

simple device, which needs no maintenance

in itself, but there are some facts of which an

owner should be aware, if the converter is to

function properly for its full service life.

(a) DO NOT use leaded (eg UK “4-star”)

petrol in a car equipped with a catalytic

converter - the lead will coat the precious

metals, reducing their converting

efficiency, and will eventually destroy the

converter.

(b) Always keep the ignition and fuel systems

well-maintained in accordance with the

manufacturer’s schedule, as given in

Chapter 1. In particular, ensure that the air

cleaner filter element, the fuel filter (where

fitted) and the spark plugs are renewed at

the correct interval. If the intake air/fuel

mixture is allowed to become too rich due

to neglect, unburned fuel will enter the

catalytic converter, overheating the

element and eventually destroying the

converter.

(c) If the engine develops a misfire, do not

drive the car at all (or at least as little as

possible) until the fault is cured - the

misfire will allow unburned fuel to enter

the converter, which will result in its

overheating, as noted above.

(d) DO NOT push- or tow-start the car - this

will soak the catalytic converter in

unburned fuel, causing it to overheat

when the engine does start - see (b) or (c)

above.

(e) DO NOT switch off the ignition at high

engine speeds - ie do not “blip” the

throttle immediately before switching offthe engine. If the ignition is switched off

at anything above idle speed, unburned

fuel will enter the (very hot) catalytic

converter, with the possible risk of its

igniting on the element and damaging the

converter.

(f) DO NOT use fuel or engine oil additives -

these may contain substances harmful to

the catalytic converter.

(g) DO NOT continue to use the car if the

engine burns oil to the extent of leaving a

visible trail of blue smoke - the unburned

carbon deposits will clog the converter

passages, and reduce its efficiency; in

severe cases, the element will overheat.

(h) Remember that the catalytic converter

operates at very high temperatures -

hence the heat shields on the car’s

underbody - and the casing will become

hot enough to ignite combustible

materials which brush against it. DO NOT,

therefore, park the car in dry

undergrowth, or over long grass or piles

of dead leaves.

(i) Remember that the catalytic converter is

FRAGILE - do not strike it with tools

during servicing work, and take great care

when working on the exhaust system.

Ensure that the converter is well clear of

any jacks or other lifting gear used to raise

the car, and do not drive the car over

rough ground, road humps, etc, in such a

way as to “ground” the exhaust system.

(j) In some cases, particularly when the car

is new and/or is used for stop/start

driving, a sulphurous smell (like that of

rotten eggs) may be noticed from the

exhaust. This is common to many

catalytic converter-equipped cars, and

seems to be due to the small amount of

sulphur found in some petrols reacting

with hydrogen in the exhaust, to produce

hydrogen sulphide (H

2S) gas; while this

gas is toxic, it is not produced in sufficient

amounts to be a problem. Once the car

has covered a few thousand miles, the

problem should disappear - in the

meanwhile, a change of driving style, or of

the brand of petrol used, may effect a

solution.

(k) The catalytic converter, used on a well-

maintained and well-driven car, should

last for 50 000 to 100 000 miles - from

this point on, the CO level should be

carefully checked regularly, to ensure that

the converter is still operating efficiently. If

the converter is no longer effective, it

must be renewed.

6•6 Engine management and emission control systems

7.1 Typical catalytic converter (M10

engine type shown, others similar)6.12 EVAP system charcoal canister

viewed from under the vehicle (316i model)

Page 160 of 228

11

1 General information

These models feature an all-steel welded

construction, where the floorpan and body

components are welded together and

attached to separate front and rear subframe

assemblies. Certain components are

particularly vulnerable to accident damage,

and can be unbolted and repaired or renewed.

Among these parts are the body mouldings,

bumpers, bonnet, doors, tailgate, and all

glass.

Only general body maintenance procedures

and body panel repair procedures within the

scope of the do-it-yourselfer are included in

this Chapter.

2 Bodywork and underframe-

maintenance

1

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheelarches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

Note that these methods should not be usedon vehicles with wax-based underbody

protective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to be

taken with metallic paintwork, as special non-

abrasive cleaner/polisher is required to avoid

damage to the finish. Always check that the

door and ventilator opening drain holes and

pipes are completely clear, so that water can

be drained out. Brightwork should be treated in

the same way as paintwork. Windscreens and

windows can be kept clear of the smeary film

which often appears, by the use of proprietary

glass cleaner. Never use any form of wax or

other body or chromium polish on glass.

Chapter 11 Bodywork and fittings

Bodywork and underframe - maintenance . . . . . . . . . . . . . . . . . . . . 2

Bodywork repair - major damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bodywork repair - minor damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 10

Boot lid/tailgate - removal, refitting and adjustment . . . . . . . . . . . . . 14

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Door - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . 13

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 12

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 16

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 17

Exterior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 18Fixed glass - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hinges and locks - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Interior trim - maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Latch, lock cylinder and handles - removal, refitting and

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 9

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steering column shrouds - removal and refitting . . . . . . . . . . . . . . . 19

Upholstery and carpets - maintenance . . . . . . . . . . . . . . . . . . . . . . . 4

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty Contents