throttle cable BMW 3 SERIES 1988 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1988, Model line: 3 SERIES, Model: BMW 3 SERIES 1988 E30Pages: 228, PDF Size: 7.04 MB

Page 14 of 228

Maintenance schedule

The following maintenance intervals are based on the assumption

that the vehicle owner will be doing the maintenance or service work,

as opposed to having a dealer service department do the work.

Although the time/mileage intervals are loosely based on factory rec-

ommendations, most have been shortened to ensure, for example, that

such items as lubricants and fluids are checked/changed at intervals

that promote maximum engine/driveline service life. Also, subject to

the preference of the individual owner interested in keeping his or her

vehicle in peak condition at all times, and with the vehicle’s ultimate

resale in mind, many of the maintenance procedures may be

performed more often than recommended in the following schedule.

We encourage such owner initiative.

When the vehicle is new, it should be serviced initially by a factory-

authorised dealer service department, to protect the factory warranty.

In many cases, the initial maintenance check is done at no cost to the

owner (check with your dealer service department for more

information).

1•4Maintenance and servicing

Every 250 miles or weekly, whichever

comes first

m mCheck the engine oil level (Section 4)

m mCheck the engine coolant level (Section 4)

m mCheck the brake fluid level (Section 4)

m mCheck the clutch fluid level (Section 4)

m mCheck the washer fluid level (Section 4)

m mCheck the tyres and tyre pressures (Section 5)

Every 6000 miles or 6 months,

whichever comes first

All items listed above, plus:

m mChange the engine oil and oil filter (Section 6)

m mCheck the power steering fluid level (Section 7)

m mCheck the tyres, and rotate if necessary (Section 9)

m mCheck the automatic transmission fluid level

(Section 8)

m mCheck the underbonnet hoses (Section 10)

m mCheck/adjust the drivebelts (Section 11)

m mCheck engine idle speed and CO (Section 12)

Every 12 000 miles or 12 months,

whichever comes first

All items listed above, plus:

m mCheck/service the battery (Section 13)

m mCheck the spark plugs (Section 14)

m mCheck/renew the HT leads, distributor cap and

rotor (Section 15)

m mCheck/top-up the manual transmission lubricant

(Section 16)

m mCheck the differential oil level (Section 17)

m mCheck the valve clearances, and adjust if

necessary - does not apply to M40 engines

(Section 18)

m mCheck and lubricate the throttle linkage (Section 19)

m mRenew the air filter (Section 20)

m mCheck the fuel system (Section 21)

m mInspect the cooling system (Section 22)

m mInspect the exhaust system (Section 23)

m mInspect the steering and suspension components

(Section 24)

m mCheck the driveshaft gaiter(s) (Section 25)

m mInspect the brakes (Section 26)

m mInspect/renew the windscreen wiper blades

(Section 27)

Every 24 000 miles or 2 years,

whichever comes first

All items listed above plus:

m mChange the automatic transmission fluid and filter

(Section 28)

m mDrain, flush and refill the cooling system (Section 29)

m mRenew the spark plugs (Section 14)

m mCheck/renew the spark plug HT leads (Section 15)

m mRenew the fuel filter (Section 30)

m mChange the manual transmission lubricant (Section 31)

m mChange the differential oil (Section 32)

m mCheck the evaporative emissions system, where

applicable (Section 33)

m mReset the service indicator lights (Section 34)

m mRenew brake fluid by bleeding (see Chapter 9)

m mCheck the handbrake operation (see Chapter 9)

Every 60 000 miles

m

mRenew the timing belt (Section 35)

Page 40 of 228

12After the No 1 piston has been positioned

at TDC on the compression stroke, TDC for

any of the remaining pistons can be located

by turning the crankshaft and following the

firing order. Mark the remaining spark plug

lead terminal locations just like you did for the

No 1 terminal, then number the marks to

correspond with the cylinder numbers. As you

turn the crankshaft, the rotor will also turn.

When it’s pointing directly at one of the marks

on the distributor, the piston for that particular

cylinder is at TDC on the compression stroke.

4 Valve cover-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Detach the breather hose from the valve

cover.

3On M20 engines, unbolt and remove the

intake manifold support bracket and, if

applicable, the bracket for the engine sensors

or idle air stabiliser (it will probably be

necessary to disconnect the electrical

connectors from the sensors and stabiliser).

4On M30 engines, disconnect the electrical

connector for the airflow sensor. Unclip the

electrical harness, moving it out of the way.

5Where necessary on M30 engines, remove

the hoses and fittings from the intake air hose,

then loosen the clamp and separate the hose

from the throttle body. Unscrew the mounting

nuts for the air cleaner housing, and remove

the housing together with the air hose and

airflow sensor.

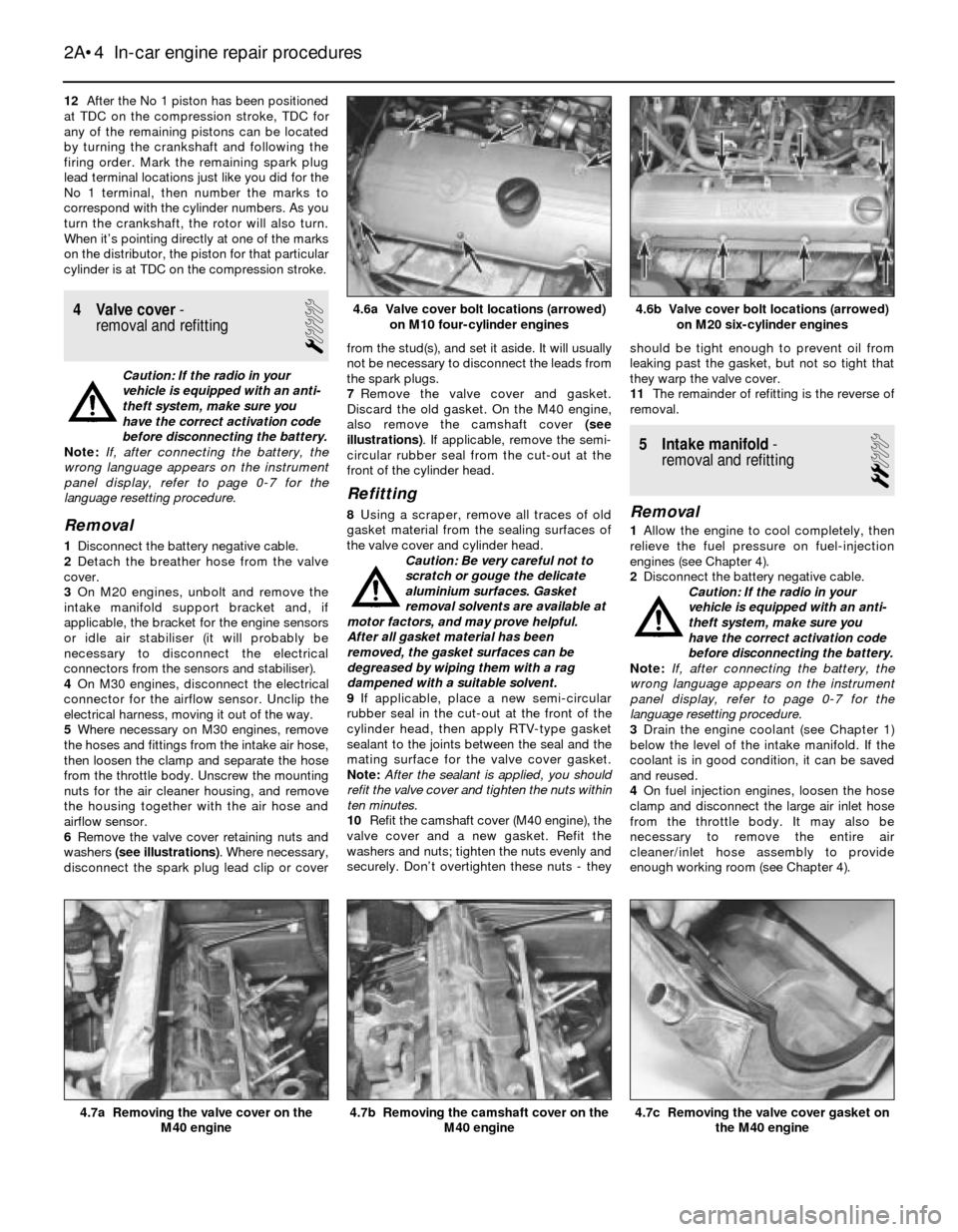

6Remove the valve cover retaining nuts and

washers (see illustrations). Where necessary,

disconnect the spark plug lead clip or coverfrom the stud(s), and set it aside. It will usually

not be necessary to disconnect the leads from

the spark plugs.

7Remove the valve cover and gasket.

Discard the old gasket. On the M40 engine,

also remove the camshaft cover (see

illustrations). If applicable, remove the semi-

circular rubber seal from the cut-out at the

front of the cylinder head.

Refitting

8Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the valve cover and cylinder head.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Gasket

removal solvents are available at

motor factors, and may prove helpful.

After all gasket material has been

removed, the gasket surfaces can be

degreased by wiping them with a rag

dampened with a suitable solvent.

9If applicable, place a new semi-circular

rubber seal in the cut-out at the front of the

cylinder head, then apply RTV-type gasket

sealant to the joints between the seal and the

mating surface for the valve cover gasket.

Note:After the sealant is applied, you should

refit the valve cover and tighten the nuts within

ten minutes.

10Refit the camshaft cover (M40 engine), the

valve cover and a new gasket. Refit the

washers and nuts; tighten the nuts evenly and

securely. Don’t overtighten these nuts - theyshould be tight enough to prevent oil from

leaking past the gasket, but not so tight that

they warp the valve cover.

11The remainder of refitting is the reverse of

removal.

5 Intake manifold-

removal and refitting

2

Removal

1Allow the engine to cool completely, then

relieve the fuel pressure on fuel-injection

engines (see Chapter 4).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Drain the engine coolant (see Chapter 1)

below the level of the intake manifold. If the

coolant is in good condition, it can be saved

and reused.

4On fuel injection engines, loosen the hose

clamp and disconnect the large air inlet hose

from the throttle body. It may also be

necessary to remove the entire air

cleaner/inlet hose assembly to provide

enough working room (see Chapter 4).

2A•4 In-car engine repair procedures

4.7b Removing the camshaft cover on the

M40 engine4.7a Removing the valve cover on the

M40 engine4.7c Removing the valve cover gasket on

the M40 engine

4.6b Valve cover bolt locations (arrowed)

on M20 six-cylinder engines4.6a Valve cover bolt locations (arrowed)

on M10 four-cylinder engines

Page 41 of 228

5On carburettor engines, remove the

complete air cleaner assembly (see Chap-

ter 4).

6Disconnect the coolant hoses from the

throttle body/intake manifold as applicable.

7Disconnect the throttle cable and, if

applicable, cruise control cable (see Chap-

ter 4).

8Remove the EGR valve and line where

applicable (see Chapter 6).

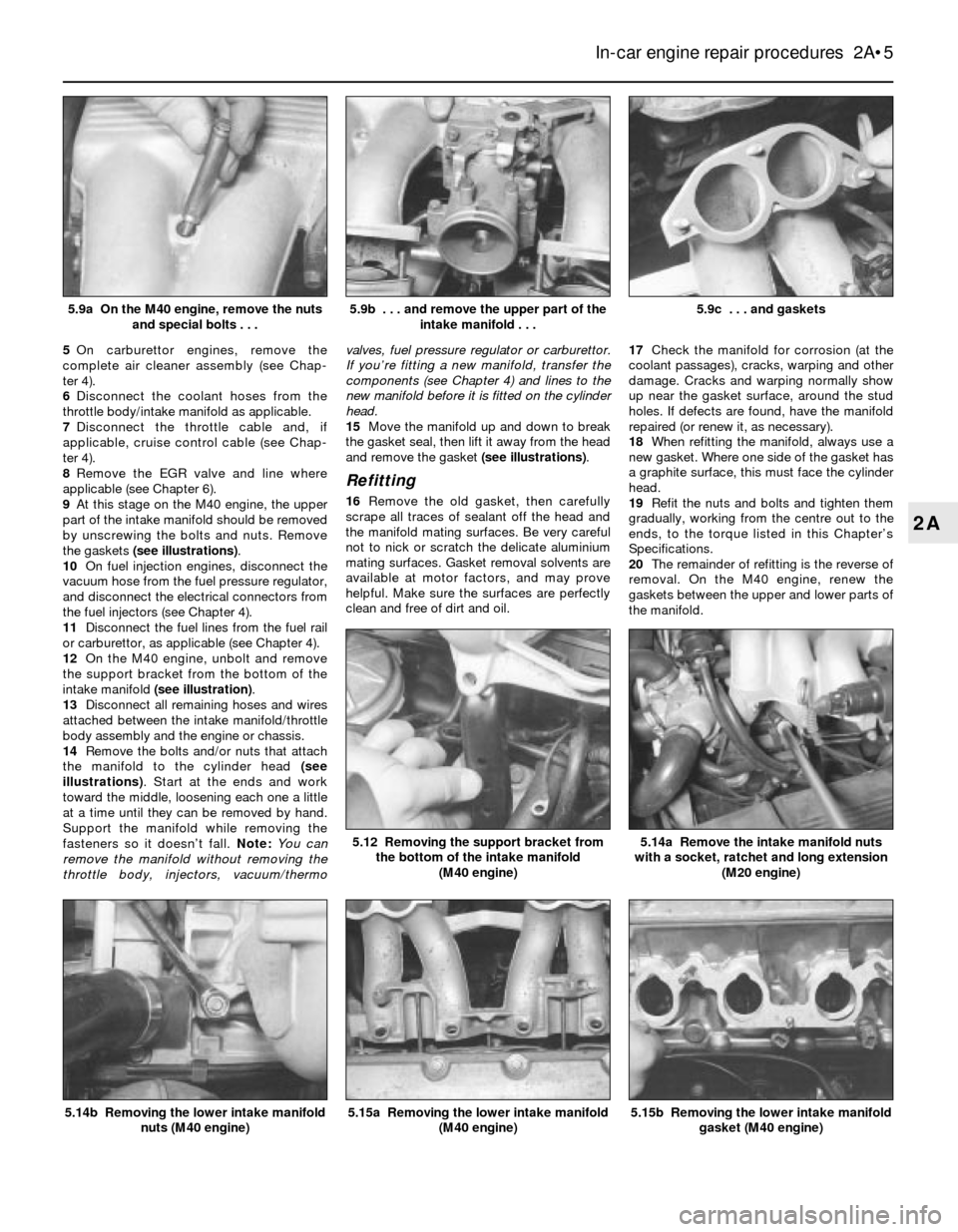

9At this stage on the M40 engine, the upper

part of the intake manifold should be removed

by unscrewing the bolts and nuts. Remove

the gaskets (see illustrations).

10On fuel injection engines, disconnect the

vacuum hose from the fuel pressure regulator,

and disconnect the electrical connectors from

the fuel injectors (see Chapter 4).

11Disconnect the fuel lines from the fuel rail

or carburettor, as applicable (see Chapter 4).

12On the M40 engine, unbolt and remove

the support bracket from the bottom of the

intake manifold (see illustration).

13Disconnect all remaining hoses and wires

attached between the intake manifold/throttle

body assembly and the engine or chassis.

14Remove the bolts and/or nuts that attach

the manifold to the cylinder head (see

illustrations). Start at the ends and work

toward the middle, loosening each one a little

at a time until they can be removed by hand.

Support the manifold while removing the

fasteners so it doesn’t fall. Note: You can

remove the manifold without removing the

throttle body, injectors, vacuum/thermovalves, fuel pressure regulator or carburettor.

If you’re fitting a new manifold, transfer the

components (see Chapter 4) and lines to the

new manifold before it is fitted on the cylinder

head.

15Move the manifold up and down to break

the gasket seal, then lift it away from the head

and remove the gasket (see illustrations).

Refitting

16Remove the old gasket, then carefully

scrape all traces of sealant off the head and

the manifold mating surfaces. Be very careful

not to nick or scratch the delicate aluminium

mating surfaces. Gasket removal solvents are

available at motor factors, and may prove

helpful. Make sure the surfaces are perfectly

clean and free of dirt and oil.17Check the manifold for corrosion (at the

coolant passages), cracks, warping and other

damage. Cracks and warping normally show

up near the gasket surface, around the stud

holes. If defects are found, have the manifold

repaired (or renew it, as necessary).

18When refitting the manifold, always use a

new gasket. Where one side of the gasket has

a graphite surface, this must face the cylinder

head.

19Refit the nuts and bolts and tighten them

gradually, working from the centre out to the

ends, to the torque listed in this Chapter’s

Specifications.

20The remainder of refitting is the reverse of

removal. On the M40 engine, renew the

gaskets between the upper and lower parts of

the manifold.

In-car engine repair procedures 2A•5

5.9c . . . and gaskets5.9b . . . and remove the upper part of the

intake manifold . . .5.9a On the M40 engine, remove the nuts

and special bolts . . .

5.15b Removing the lower intake manifold

gasket (M40 engine)5.15a Removing the lower intake manifold

(M40 engine)

5.14a Remove the intake manifold nuts

with a socket, ratchet and long extension

(M20 engine)5.12 Removing the support bracket from

the bottom of the intake manifold

(M40 engine)

5.14b Removing the lower intake manifold

nuts (M40 engine)

2A

Page 49 of 228

22Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the covers and engine block.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Also, do not

damage the sump gasket, and

keep it clean. Gasket removal solvents are

available at motor factors, and may

prove helpful. After all gasket material has

been removed, the gasket surfaces

can be degreased by wiping them

with a rag dampened with a suitable

solvent.

23Support the cover on two blocks of wood,

and drive out the seals from behind with a

hammer and screwdriver. Be very careful not

to damage the seal bores in the process.

24Coat the outside diameters and lips of the

new seals with multi-purpose grease, and

drive the seals into the cover with a hammer

and a socket slightly smaller in diameter than

the outside diameter of the seal.

25Apply a film of RTV-type gasket sealant to

the surface of the sump gasket that mates

with the front cover. Apply extra beads of RTV

sealant to the edges where the gasket meets

the engine block. Note:If the sump gasket is

damaged, instead of fitting a whole new

gasket, you might try trimming the front

portion of the gasket off at the point where it

meets the engine block, then trim off the front

portion of a new sump gasket so it’s exactly

the same size. Cover the exposed inside area

of the sump with a rag, then clean all traces of

old gasket material off the area where the

gasket was removed. Attach the new gasket

piece to the sump with contact-cement-type

gasket adhesive, then apply RTV-type sealant

as described at the beginning of this

paragraph.

26Coat both sides of the new gasket with

RTV-type gasket sealant, then attach the front

cover to the front of the engine, carefully

working the seals over the crankshaft and

intermediate shaft. Refit the bolts and tighten

them evenly to the torque listed in this

Chapter’s Specifications. Work from bolt-to-

bolt in a criss-cross pattern, to be sure they’re

tightened evenly.Note 1:Tighten the front

cover-to-block bolts first, then tighten the

sump-to-cover bolts. Note 2:After applying

RTV-type sealant, reassembly must be

completed in about 10 minutes so the RTV

won’t prematurely harden.

27The remainder of refitting is the reverse of

removal.

Crankshaft front seal (M40 engines)

28Remove the timing belt and crankshaft

sprocket (see Section 10).

29Remove the Woodruff key from the

groove in the end of the crankshaft.

30Note the fitted position of the oil seal, then

prise it out from the front cover using a

screwdriver, but take care not to damage the

bore of the cover or the surface of thecrankshaft. If the seal is tight, drill two small

holes in the metal end of the seal, and use two

self-tapping screws to pull out the seal. Make

sure all remains of swarf are removed.

31Coat the outside diameter and lip of the

new seal with multi-purpose grease, then

drive it into the cover with a hammer and a

socket slightly smaller in diameter than the

outside diameter of the seal. Make sure the

seal enters squarely.

32The remainder of refitting is the reverse of

removal. Note that it is recommended that the

timing belt be renewed - see Section 10.

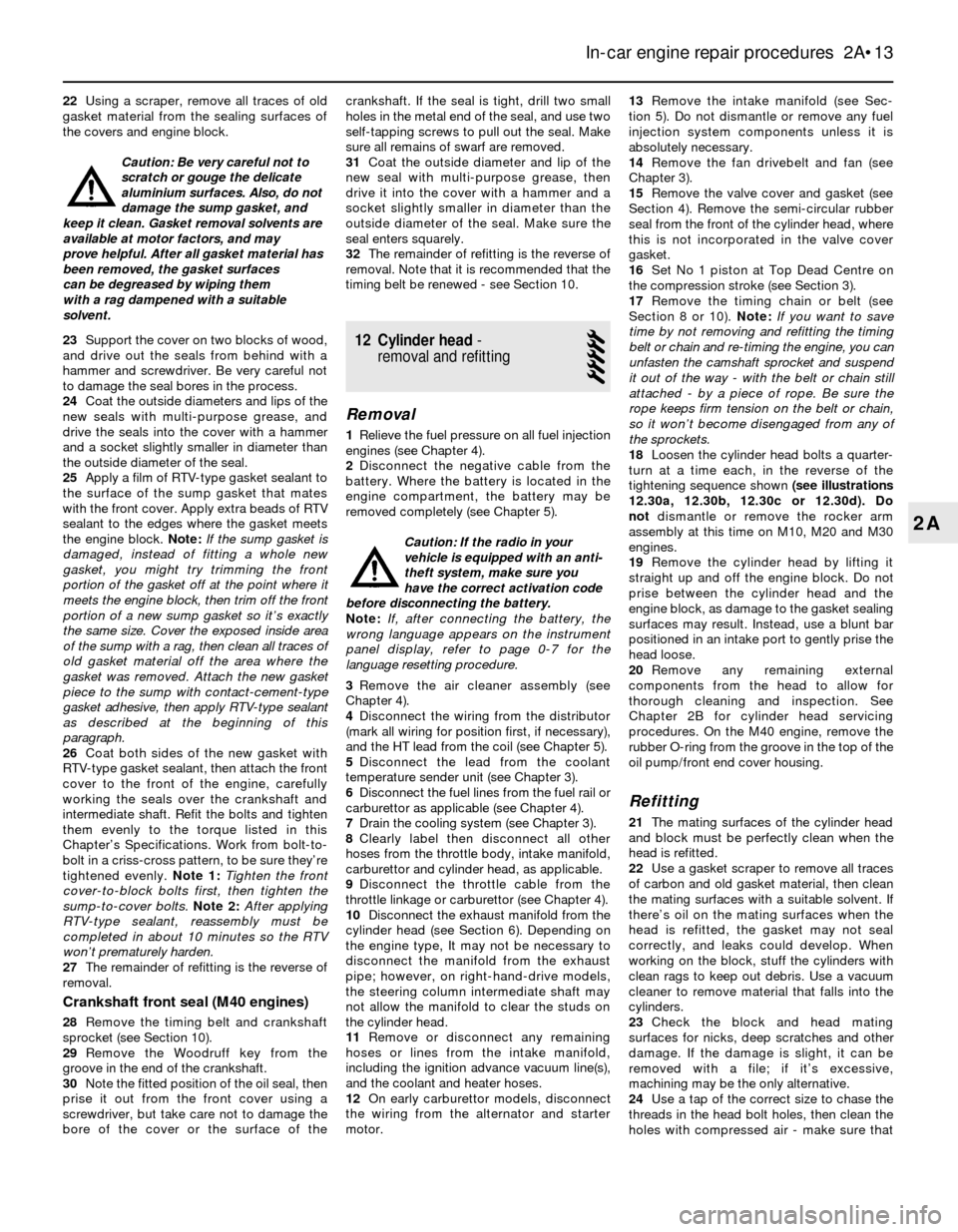

12 Cylinder head-

removal and refitting

5

Removal

1Relieve the fuel pressure on all fuel injection

engines (see Chapter 4).

2Disconnect the negative cable from the

battery. Where the battery is located in the

engine compartment, the battery may be

removed completely (see Chapter 5).

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Remove the air cleaner assembly (see

Chapter 4).

4Disconnect the wiring from the distributor

(mark all wiring for position first, if necessary),

and the HT lead from the coil (see Chapter 5).

5Disconnect the lead from the coolant

temperature sender unit (see Chapter 3).

6Disconnect the fuel lines from the fuel rail or

carburettor as applicable (see Chapter 4).

7Drain the cooling system (see Chapter 3).

8Clearly label then disconnect all other

hoses from the throttle body, intake manifold,

carburettor and cylinder head, as applicable.

9Disconnect the throttle cable from the

throttle linkage or carburettor (see Chapter 4).

10Disconnect the exhaust manifold from the

cylinder head (see Section 6). Depending on

the engine type, It may not be necessary to

disconnect the manifold from the exhaust

pipe; however, on right-hand-drive models,

the steering column intermediate shaft may

not allow the manifold to clear the studs on

the cylinder head.

11Remove or disconnect any remaining

hoses or lines from the intake manifold,

including the ignition advance vacuum line(s),

and the coolant and heater hoses.

12On early carburettor models, disconnect

the wiring from the alternator and starter

motor.13Remove the intake manifold (see Sec-

tion 5). Do not dismantle or remove any fuel

injection system components unless it is

absolutely necessary.

14Remove the fan drivebelt and fan (see

Chapter 3).

15Remove the valve cover and gasket (see

Section 4). Remove the semi-circular rubber

seal from the front of the cylinder head, where

this is not incorporated in the valve cover

gasket.

16Set No 1 piston at Top Dead Centre on

the compression stroke (see Section 3).

17Remove the timing chain or belt (see

Section 8 or 10). Note:If you want to save

time by not removing and refitting the timing

belt or chain and re-timing the engine, you can

unfasten the camshaft sprocket and suspend

it out of the way - with the belt or chain still

attached - by a piece of rope. Be sure the

rope keeps firm tension on the belt or chain,

so it won’t become disengaged from any of

the sprockets.

18Loosen the cylinder head bolts a quarter-

turn at a time each, in the reverse of the

tightening sequence shown (see illustrations

12.30a, 12.30b, 12.30c or 12.30d). Do

notdismantle or remove the rocker arm

assembly at this time on M10, M20 and M30

engines.

19Remove the cylinder head by lifting it

straight up and off the engine block. Do not

prise between the cylinder head and the

engine block, as damage to the gasket sealing

surfaces may result. Instead, use a blunt bar

positioned in an intake port to gently prise the

head loose.

20Remove any remaining external

components from the head to allow for

thorough cleaning and inspection. See

Chapter 2B for cylinder head servicing

procedures. On the M40 engine, remove the

rubber O-ring from the groove in the top of the

oil pump/front end cover housing.

Refitting

21The mating surfaces of the cylinder head

and block must be perfectly clean when the

head is refitted.

22Use a gasket scraper to remove all traces

of carbon and old gasket material, then clean

the mating surfaces with a suitable solvent. If

there’s oil on the mating surfaces when the

head is refitted, the gasket may not seal

correctly, and leaks could develop. When

working on the block, stuff the cylinders with

clean rags to keep out debris. Use a vacuum

cleaner to remove material that falls into the

cylinders.

23Check the block and head mating

surfaces for nicks, deep scratches and other

damage. If the damage is slight, it can be

removed with a file; if it’s excessive,

machining may be the only alternative.

24Use a tap of the correct size to chase the

threads in the head bolt holes, then clean the

holes with compressed air - make sure that

In-car engine repair procedures 2A•13

2A

Page 61 of 228

otherwise a small brush or even a bicycle tyre

pump will work). The idea is to prevent dirt

from getting into the cylinders as the

compression check is being done.

3Remove all the spark plugs from the engine

(see Chapter 1).

4Block the throttle wide open, or have an

assistant hold the throttle pedal down.

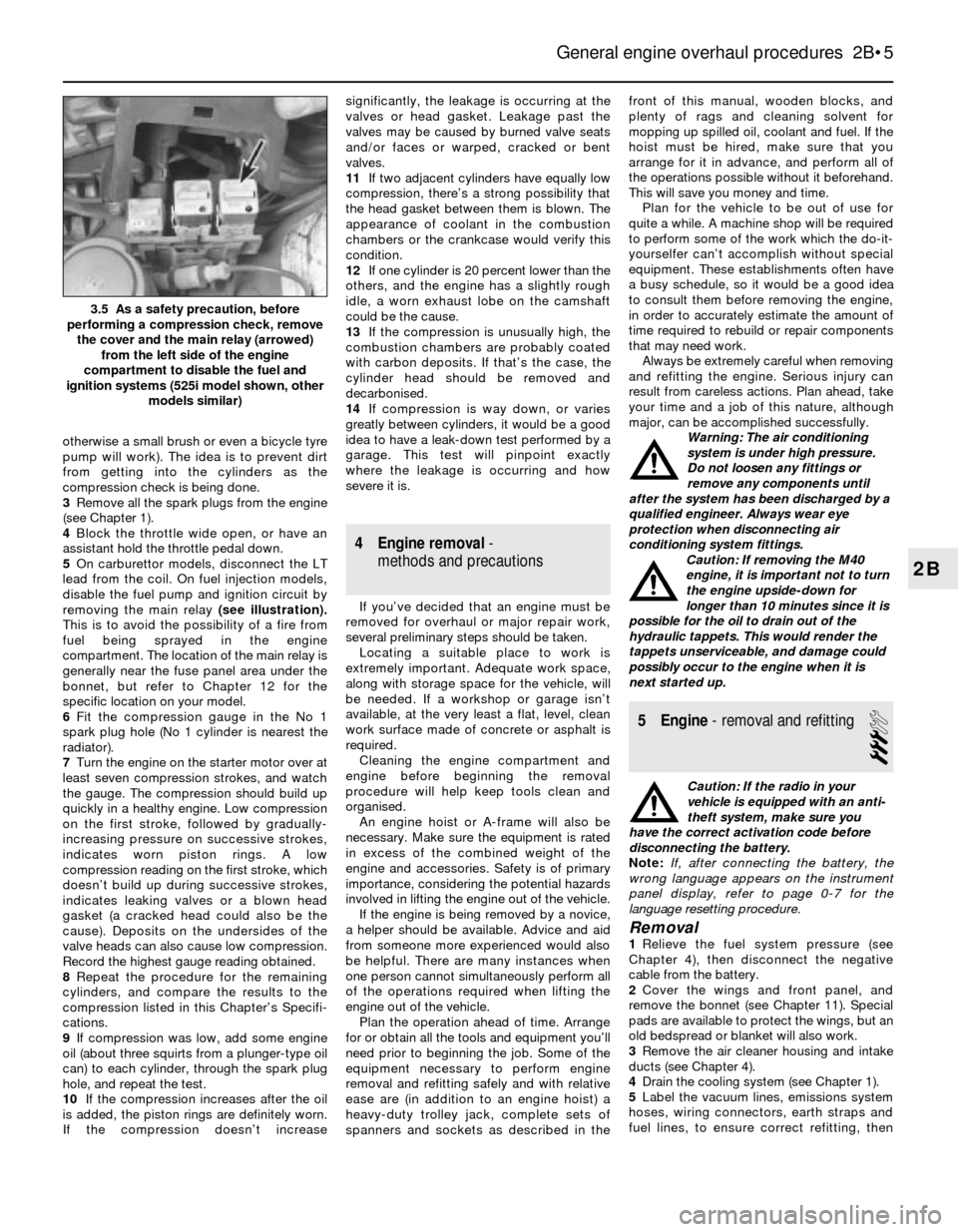

5On carburettor models, disconnect the LT

lead from the coil. On fuel injection models,

disable the fuel pump and ignition circuit by

removing the main relay(see illustration).

This is to avoid the possibility of a fire from

fuel being sprayed in the engine

compartment. The location of the main relay is

generally near the fuse panel area under the

bonnet, but refer to Chapter 12 for the

specific location on your model.

6Fit the compression gauge in the No 1

spark plug hole (No 1 cylinder is nearest the

radiator).

7Turn the engine on the starter motor over at

least seven compression strokes, and watch

the gauge. The compression should build up

quickly in a healthy engine. Low compression

on the first stroke, followed by gradually-

increasing pressure on successive strokes,

indicates worn piston rings. A low

compression reading on the first stroke, which

doesn’t build up during successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause). Deposits on the undersides of the

valve heads can also cause low compression.

Record the highest gauge reading obtained.

8Repeat the procedure for the remaining

cylinders, and compare the results to the

compression listed in this Chapter’s Specifi-

cations.

9If compression was low, add some engine

oil (about three squirts from a plunger-type oil

can) to each cylinder, through the spark plug

hole, and repeat the test.

10If the compression increases after the oil

is added, the piston rings are definitely worn.

If the compression doesn’t increasesignificantly, the leakage is occurring at the

valves or head gasket. Leakage past the

valves may be caused by burned valve seats

and/or faces or warped, cracked or bent

valves.

11If two adjacent cylinders have equally low

compression, there’s a strong possibility that

the head gasket between them is blown. The

appearance of coolant in the combustion

chambers or the crankcase would verify this

condition.

12If one cylinder is 20 percent lower than the

others, and the engine has a slightly rough

idle, a worn exhaust lobe on the camshaft

could be the cause.

13If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If that’s the case, the

cylinder head should be removed and

decarbonised.

14If compression is way down, or varies

greatly between cylinders, it would be a good

idea to have a leak-down test performed by a

garage. This test will pinpoint exactly

where the leakage is occurring and how

severe it is.

4 Engine removal-

methods and precautions

If you’ve decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the vehicle, will

be needed. If a workshop or garage isn’t

available, at the very least a flat, level, clean

work surface made of concrete or asphalt is

required.

Cleaning the engine compartment and

engine before beginning the removal

procedure will help keep tools clean and

organised.

An engine hoist or A-frame will also be

necessary. Make sure the equipment is rated

in excess of the combined weight of the

engine and accessories. Safety is of primary

importance, considering the potential hazards

involved in lifting the engine out of the vehicle.

If the engine is being removed by a novice,

a helper should be available. Advice and aid

from someone more experienced would also

be helpful. There are many instances when

one person cannot simultaneously perform all

of the operations required when lifting the

engine out of the vehicle.

Plan the operation ahead of time. Arrange

for or obtain all the tools and equipment you’ll

need prior to beginning the job. Some of the

equipment necessary to perform engine

removal and refitting safely and with relative

ease are (in addition to an engine hoist) a

heavy-duty trolley jack, complete sets of

spanners and sockets as described in thefront of this manual, wooden blocks, and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and fuel. If the

hoist must be hired, make sure that you

arrange for it in advance, and perform all of

the operations possible without it beforehand.

This will save you money and time.

Plan for the vehicle to be out of use for

quite a while. A machine shop will be required

to perform some of the work which the do-it-

yourselfer can’t accomplish without special

equipment. These establishments often have

a busy schedule, so it would be a good idea

to consult them before removing the engine,

in order to accurately estimate the amount of

time required to rebuild or repair components

that may need work.

Always be extremely careful when removing

and refitting the engine. Serious injury can

result from careless actions. Plan ahead, take

your time and a job of this nature, although

major, can be accomplished successfully.

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged by a

qualified engineer. Always wear eye

protection when disconnecting air

conditioning system fittings.

Caution: If removing the M40

engine, it is important not to turn

the engine upside-down for

longer than 10 minutes since it is

possible for the oil to drain out of the

hydraulic tappets. This would render the

tappets unserviceable, and damage could

possibly occur to the engine when it is

next started up.

5 Engine- removal and refitting

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal1Relieve the fuel system pressure (see

Chapter 4), then disconnect the negative

cable from the battery.

2Cover the wings and front panel, and

remove the bonnet (see Chapter 11). Special

pads are available to protect the wings, but an

old bedspread or blanket will also work.

3Remove the air cleaner housing and intake

ducts (see Chapter 4).

4Drain the cooling system (see Chapter 1).

5Label the vacuum lines, emissions system

hoses, wiring connectors, earth straps and

fuel lines, to ensure correct refitting, then

General engine overhaul procedures 2B•5

3.5 As a safety precaution, before

performing a compression check, remove

the cover and the main relay (arrowed)

from the left side of the engine

compartment to disable the fuel and

ignition systems (525i model shown, other

models similar)

2B

Page 74 of 228

3When examining the bearings, remove

them from the engine block, the main bearing

caps, the connecting rods and the rod caps,

and lay them out on a clean surface in the

same general position as their location in the

engine. This will enable you to match any

bearing problems with the corresponding

crankshaft journal.

4Dirt and other foreign particles get into the

engine in a variety of ways. It may be left in

the engine during assembly, or it may pass

through filters or the crankcase ventilation

(PCV) system. It may get into the oil, and from

there into the bearings. Metal chips from

machining operations and normal engine wear

are often present. Abrasives are sometimes

left in engine components after recondi-

tioning, especially when parts are not

thoroughly cleaned using the proper cleaning

methods. Whatever the source, these foreign

objects often end up embedded in the soft

bearing material, and are easily recognised.

Large particles will not embed in the bearing,

and will score or gouge the bearing and

journal. The best prevention for this cause of

bearing failure is to clean all parts thoroughly,

and to keep everything spotlessly-clean

during engine assembly. Frequent and regular

engine oil and filter changes are also

recommended.

5Lack of lubrication (or lubrication

breakdown) has a number of interrelated

causes. Excessive heat (which thins the oil),

overloading (which squeezes the oil from the

bearing face) and oil “leakage” or “throw off”

(from excessive bearing clearances, worn oil

pump, or high engine speeds) all contribute to

lubrication breakdown. Blocked oil passages,

which usually are the result of misaligned oil

holes in a bearing shell, will also oil-starve a

bearing and destroy it. When lack of

lubrication is the cause of bearing failure, the

bearing material is wiped or extruded from the

steel backing of the bearing. Temperatures

may increase to the point where the steel

backing turns blue from overheating.

6Driving habits can have a definite effect on

bearing life. Full-throttle, low-speed operation

(labouring the engine) puts very high loads onbearings, which tends to squeeze out the oil

film. These loads cause the bearings to flex,

which produces fine cracks in the bearing

face (fatigue failure). Eventually, the bearing

material will loosen in places, and tear away

from the steel backing. Short-trip driving

leads to corrosion of bearings, because

insufficient engine heat is produced to drive

off the condensation and corrosive gases.

These products collect in the engine oil,

forming acid and sludge. As the oil is carried

to the engine bearings, the acid attacks and

corrodes the bearing material.

7Incorrect bearing refitting during engine

assembly will lead to bearing failure as well.

Tight-fitting bearings leave insufficient bearing

oil clearance, and will result in oil starvation.

Dirt or foreign particles trapped behind a

bearing shell result in high spots on the

bearing, which will lead to failure.

21 Engine overhaul-

reassembly sequence

1Before beginning engine reassembly, make

sure you have all the necessary new parts,

gaskets and seals, as well as the following

items on hand:

Common hand tools

A torque wrench

Piston ring refitting tool

Piston ring compressor

Vibration damper refitting tool

Short lengths of rubber or plastic hose to fit

over connecting rod bolts (where

applicable)

Plastigage

Feeler gauges

A fine-tooth file

New engine oil

Engine assembly oil or molybdenum

disulphide (“moly”) grease

Gasket sealant

Thread-locking compound

2In order to save time and avoid problems,

engine reassembly should be done in the

following general order:Piston rings

Crankshaft and main bearings

Piston/connecting rod assemblies

Oil pump

Sump

Cylinder head assembly

Timing belt or chain and tensioner

assemblies

Water pump

Timing belt or chain covers

Intake and exhaust manifolds

Valve cover

Engine rear plate

Flywheel/driveplate

22 Piston rings- refitting

2

1Before fitting the new piston rings, the ring

end gaps must be checked. It’s assumed that

the piston ring side clearance has been

checked and verified (see Section 18).

2Lay out the piston/connecting rod

assemblies and the new ring sets, so that the

ring sets will be matched with the same piston

and cylinder during the end gap measurement

and engine assembly.

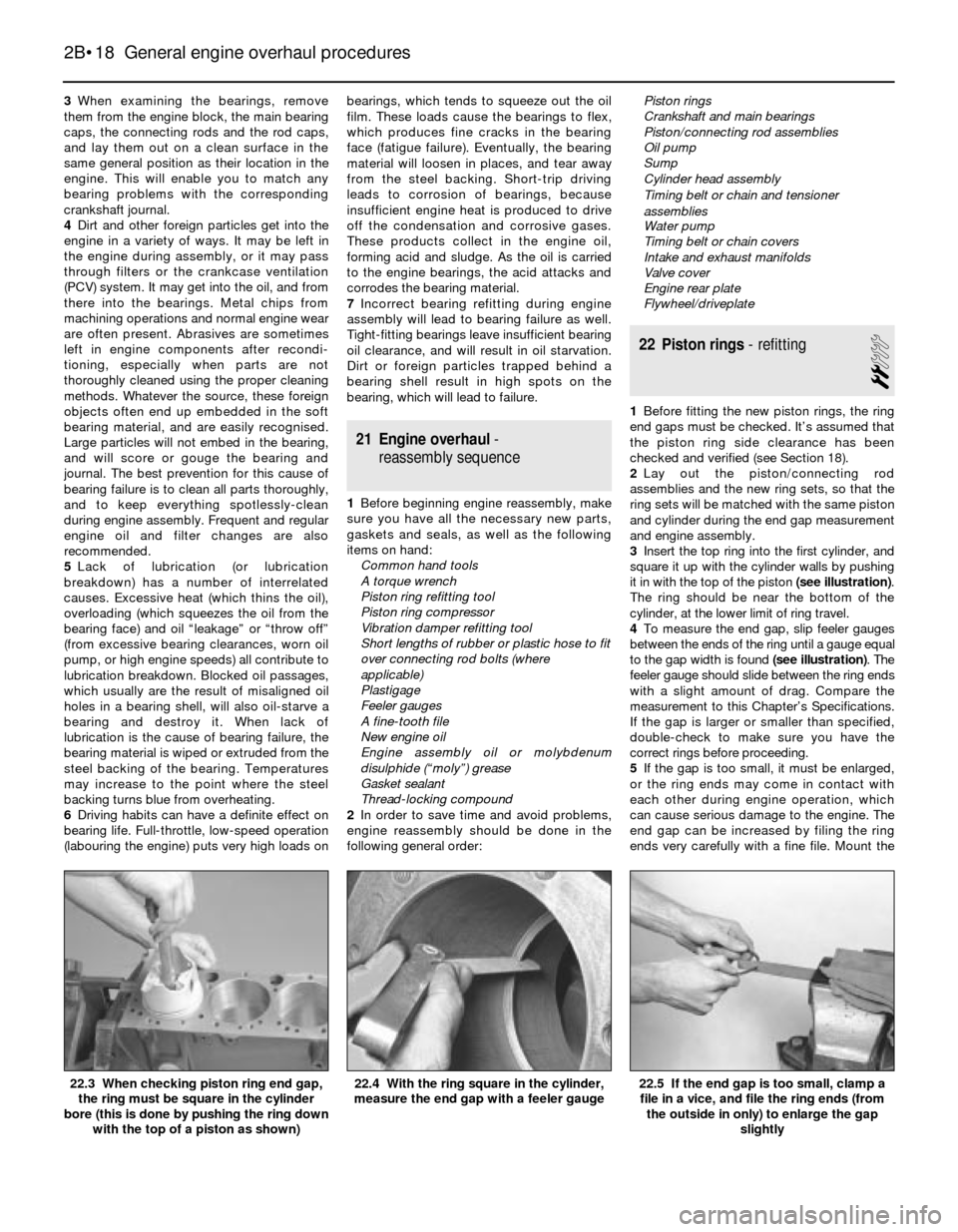

3Insert the top ring into the first cylinder, and

square it up with the cylinder walls by pushing

it in with the top of the piston (see illustration).

The ring should be near the bottom of the

cylinder, at the lower limit of ring travel.

4To measure the end gap, slip feeler gauges

between the ends of the ring until a gauge equal

to the gap width is found(see illustration). The

feeler gauge should slide between the ring ends

with a slight amount of drag. Compare the

measurement to this Chapter’s Specifications.

If the gap is larger or smaller than specified,

double-check to make sure you have the

correct rings before proceeding.

5If the gap is too small, it must be enlarged,

or the ring ends may come in contact with

each other during engine operation, which

can cause serious damage to the engine. The

end gap can be increased by filing the ring

ends very carefully with a fine file. Mount the

2B•18 General engine overhaul procedures

22.5 If the end gap is too small, clamp a

file in a vice, and file the ring ends (from

the outside in only) to enlarge the gap

slightly22.4 With the ring square in the cylinder,

measure the end gap with a feeler gauge22.3 When checking piston ring end gap,

the ring must be square in the cylinder

bore (this is done by pushing the ring down

with the top of a piston as shown)

Page 78 of 228

the bearing - use your fingernail or the edge of

a credit card.

20Make sure the bearing faces are perfectly

clean, then apply a uniform layer of

molybdenum disulphide (“moly”) grease or

engine assembly oil to both of them. You’ll

have to push the piston into the cylinder to

expose the face of the bearing shell in the

connecting rod - be sure to slip the protective

hoses over the rod bolts first, where

applicable.

21Slide the connecting rod back into place

on the journal, and remove the protective

hoses from the rod cap bolts. Refit the rod

cap, and tighten the nuts/bolts to the

specified torque.

22Repeat the entire procedure for the

remaining pistons/connecting rods.

23The important points to remember are:

a) Keep the back sides of the bearing shells

and the insides of the connecting rods

and caps perfectly clean when

assembling them.

b) Make sure you have the correct

piston/rod assembly for each cylinder.

c) The notch or mark on the piston must

face the front of the engine.

d) Lubricate the cylinder walls with clean oil.

e) Lubricate the bearing faces when refitting

the rod caps after the oil clearance has

been checked.

24After all the piston/connecting rod

assemblies have been properly fitted, rotate

the crankshaft a number of times by hand to

check for any obvious binding.25Check the connecting rod side play (see

Section 13).

26Compare the measured side play to the

Specifications to make sure it’s correct. If it

was correct before dismantling, and the

original crankshaft and rods were refitted, it

should still be right. If new rods or a new

crankshaft were fitted, the side play may be

incorrect. If so, the rods will have to be

removed and taken to a machine shop for

attention.

27 Initial start-up and running-

in after overhaul

1

Warning:Have a fire extinguisher

handy when starting the engine

for the first time.

1Once the engine has been refitted in the

vehicle, double-check the engine oil and

coolant levels.

2With the spark plugs removed and the

ignition system disabled (see Section 3), crank

the engine until oil pressure registers on the

gauge, or until the oil pressure warning light

goes out.

3Refit the spark plugs, connect the HT leads,

and restore the ignition system functions (see

Section 3).

4Start the engine. It may take a few

moments for the fuel system to build uppressure, but the engine should start without

a great deal of effort. Note: If backfiring

occurs through the throttle body or

carburettor, check the valve timing (check that

the timing chain/belt has been correctly fitted),

the firing order (check the fitted order of the

spark plug HT leads), and the ignition timing.

5After the engine starts, it should be allowed

to warm up to normal operating temperature.

While the engine is warming up, make a

thorough check for fuel, oil and coolant leaks.

6Shut the engine off and recheck the engine

oil and coolant levels.

7Drive the vehicle to an area with minimum

traffic, accelerate at full throttle from 30 to

50 mph, then lift off the throttle completely,

and allow the vehicle to slow to 30 mph with

the throttle closed. Repeat the procedure

10 or 12 times. This will load the piston rings,

and cause them to seat properly against the

cylinder walls. Check again for oil and coolant

leaks.

8Drive the vehicle gently for the first

500 miles (no sustained high speeds) and

keep a constant check on the oil level. It is not

unusual for an engine to use oil during the

running-in period.

9At approximately 500 to 600 miles, change

the oil and filter.

10For the next few hundred miles, drive the

vehicle normally - don’t nurse it, but don’t

abuse it, either.

11After 2000 miles, change the oil and filter

again. The engine may now be considered to

be fully run-in.

2B•22 General engine overhaul procedures

Page 89 of 228

4

Carburettor (Solex 2B4)

Main jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X90

Air correction jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Venturi diameter

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 mm

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 mm

Idle/air jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50/120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40/125

Float needle valve diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Choke gap (pulldown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 5.5 mm

Throttle positioner spring preload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.0 to 24.0 mm

Float level

Stage 1 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.0 to 29.0 mm

Stage 2 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.0 to 31.0 mm

Chapter 4 Fuel and exhaust systems

Accelerator cable - check, adjustment and renewal . . . . . . . . . . . . . 9

Air cleaner assembly - removal and refitting . . . . . . . . . . . . . . . . . . . 8

Air filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Airflow meter - check, removal and refitting . . . . . . . . . . . . . . . . . . . 16

Carburettor - cleaning and adjustment . . . . . . . . . . . . . . . . . . . . . . . 12

Carburettor - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Carburettor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cold start injector and thermotime switch -

checkand renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine idle speed check and adjustment . . . . . . . . . See Chapter 1

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exhaust system servicing - general information . . . . . . . . . . . . . . . . 22

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel injection system - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fuel injection system - depressurising . . . . . . . . . . . . . . . . . . . . . . . 2Fuel injection system - fault finding . . . . . . . . . . . . See end of Chapter

Fuel injection - general information . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel injection systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fuel injectors - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fuel lines and fittings - repair and renewal . . . . . . . . . . . . . . . . . . . . 5

Fuel pressure regulator - check and renewal . . . . . . . . . . . . . . . . . . 18

Fuel pump, transfer pump and fuel level sender unit -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel pump/fuel pressure - check . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fuel tank cleaning and repair - general information . . . . . . . . . . . . . 7

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Idle air stabiliser valve - check, adjustment and renewal . . . . . . . . . 21

Throttle body - check, removal and refitting . . . . . . . . . . . . . . . . . . . 17

4•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 90 of 228

Carburettor (Solex 2BE)

Main jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X110

Air correction jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Venturi diameter

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 mm

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 mm

Idle fuel jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.5 mm

Idle air jet

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Float needle valve diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Throttle positioner coil resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.97 to 1.63 ohms

Intake air temperature resistance

-10º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8200 to 10 500 ohms

20º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200 to 2700 ohms

80º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 to 360 ohms

Float level

Stage 1 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.0 to 29.0 mm

Stage 2 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.0 to 31.0 mm

Fuel pressure checks (carburettor engines)

Fuel pump delivery pressure (engine idling) . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.3 bars

Fuel pressure checks (fuel injection engines)

Fuel system pressure (relative to intake manifold pressure)

3-Series (E30)

316i with M40/B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

318i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

320i with M20/B20 engine (L-Jetronic) . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

320i with M20/B20 engine (Motronic) . . . . . . . . . . . . . . . . . . . . . . . 2.5 ± 0.05 bars

325i with M20/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.05 bars

5-Series (E28/”old-shape”)

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

5-Series (E34/”new-shape”)

518i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

All other models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

Fuel system hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bars

Fuel pump maximum pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 to 6.9 bars

Fuel pump hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5 bars

Transfer pump pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.28 to 0.35 bars

Injectors

Injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.5 to 17.5 ohms

Accelerator cable free play . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Torque wrench settingsNm

Carburettor mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel pump to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Throttle body nuts/bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 to 26

4•2 Fuel and exhaust systems

1 General information

With the exception of early models (316 and

518 models) all engines are equipped with

electronic fuel injection.

Early 316 and 518 models are equipped

with Solex carburettors. The carburettor fitted

is either a Solex 2B4 (early models) or

2BE (later models). The mechanical fuel pumpis driven by an eccentric lobe on the

camshaft.

Fuel injection models are equipped with

either the L-Jetronic or the Motronic fuel

injection system. From 1988, fuel injection

models are equipped with an updated version

of the Motronic system - this system is easily

distinguished from the earlier system by the

absence of a cold start injector. The electric

fuel pump is located beneath the rear of the

vehicle, or inside the fuel tank. The fuel pump

relay on Motronic systems is activated from aearth signal from the Motronic control unit

(ECU). The fuel pump operates for a few

seconds when the ignition is first switched on,

and it continues to operate only when the

engine is actually running.Air intake system

The air intake system consists of the air

filter housing, the airflow meter and throttle

body (fuel injection models), and the intake

manifold. All components except the intake

manifold are covered in this Chapter; for

Page 91 of 228

information on removing and refitting the

intake manifold, refer to Chapter 2A.

The throttle valve inside the throttle body or

carburettor is actuated by the accelerator

cable. When you depress the accelerator

pedal, the throttle plate opens and airflow

through the intake system increases.

On fuel injection systems, a flap inside the

airflow meter opens wider as the airflow

increases. A throttle position switch attached

to the pivot shaft of the flap detects the angle

of the flap (how much it’s open) and converts

this to a voltage signal, which it sends to the

computer.

Fuel system

On carburettor models, the fuel pump

supplies fuel under pressure to the

carburettor. A needle valve in the float

chamber maintains the fuel at a constant

level. A fuel return system channels excess

fuel back to the fuel tank.

On fuel injection models, an electric fuel

pump supplies fuel under constant pressure

to the fuel rail, which distributes fuel to the

injectors. The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models

also have a transfer pump located in the fuel

tank. The transfer pump acts as an aid to the

larger main pump for delivering the necessary

pressure. A fuel pressure regulator controls

the pressure in the fuel system. The fuel

system also has a fuel pulsation damper

located near the fuel filter. The damper

reduces the pressure pulsations caused by

fuel pump operation, and the opening and

closing of the injectors. The amount of fuel

injected into the intake ports is precisely

controlled by an Electronic Control Unit (ECU

or computer). Some later 5-Series models

have a fuel cooler in the return line.

Electronic control system (fuel

injection system)

Besides altering the injector opening

duration as described above, the electronic

control unit performs a number of other tasks

related to fuel and emissions control. It

accomplishes these tasks by using data

relayed to it by a wide array of information

sensors located throughout the enginecompartment, comparing this information to

its stored map, and altering engine operation

by controlling a number of different actuators.

Since special equipment is required, most

fault diagnosis and repair of the electronic

control system is beyond the scope of the

home mechanic. Additional information and

testing procedures for the emissions system

components (oxygen sensor, coolant

temperature sensor, EVAP system, etc.) is

contained in Chapter 6.

2 Fuel injection system-

depressurising

1

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke or allow open flames or bare light

bulbs near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

1Remove the fuel pump fuse from the main

fuse panel (see illustrations). Note:Consult

your owner’s handbook for the exact location

of the fuel pump fuse, if the information is not

stamped onto the fusebox cover.

2Start the engine, and wait for it to stall.

Switch off the ignition.

3Remove the fuel filler cap to relieve the fuel

tank pressure.

4The fuel system is now depressurised.

Note:Place a rag around fuel lines before

disconnecting, to prevent any residual fuel

from spilling onto the engine(see

illustration).

5Disconnect the battery negative cable

before working on any part of the system.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3 Fuel pump/fuel pressure-

check

3

Warning: Fuel is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. Don’t

smoke, or allow open flames or bare light

bulbs, near the work area. Also, don’t work

in a garage where a natural gas-type

appliance with a pilot light is present.

Carburettor engines

1To test the fuel pump, it will be necessary to

connect a suitable pressure gauge between

the fuel pump outlet, and the carburettor

supply pipe. For this particular test, the fuel

return valve, which is normally connected in

the fuel line from the fuel pump to the

carburettor, mustbe bypassed.

2With the engine running at idle speed, the

pump pressure should be between 0.1 and

0.3 bars.

3Should a pressure gauge not be available, a

simpler (but less accurate) method of testing

the fuel pump is as follows.

4Disconnect the outlet hose from the fuel

pump.

5Disconnect the LT lead from the coil, to

prevent the engine firing, then turn the engine

over on the starter. Well-defined spurts of fuel

should be ejected from the outlet hose.

Fuel injection engines

Note 1:The electric fuel pump is located

inside the fuel tank on later models, or beside

the fuel tank on early models. Early models are

also equipped with a transfer pump located in

the fuel tank. The transfer pump feeds the

main pump, but can’t generate the high

pressure required by the system.

Note 2:The fuel pump relay on Motronic

systems is activated by an earth signal from

the Motronic control unit (ECU). The fuel

pump operates for a few seconds when the

ignition is first switched on, and then

continues to operate only when the engine is

actually running.

Fuel and exhaust systems 4•3

2.4 Be sure to place a rag under and

around any fuel line when disconnecting2.1b Removing the fuel pump fuse on

5-Series models2.1a Removing the fuel pump fuse on

3-Series models

4