bar BMW 3 SERIES 1991 E30 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1991, Model line: 3 SERIES, Model: BMW 3 SERIES 1991 E30Pages: 228, PDF Size: 7.04 MB

Page 153 of 228

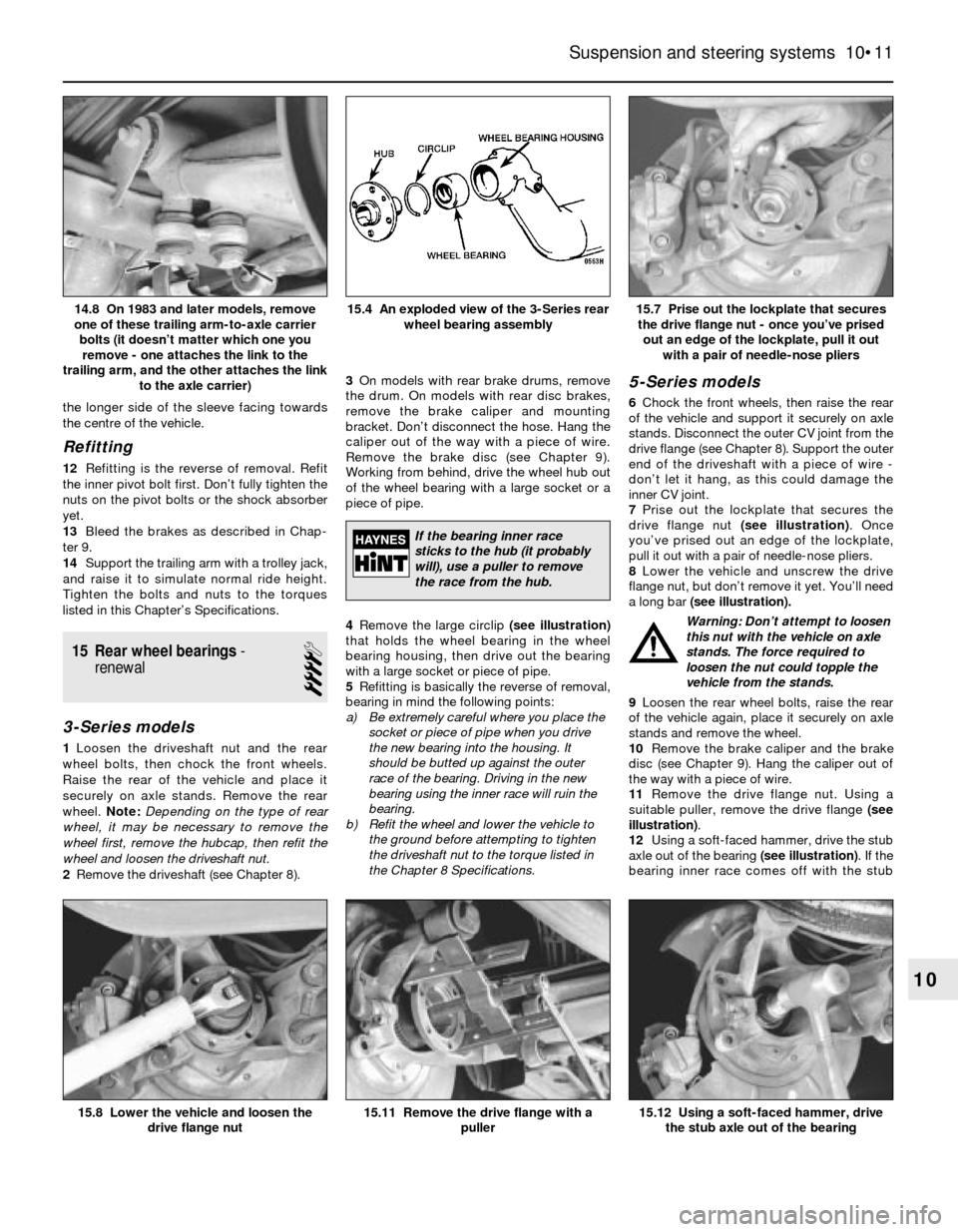

the longer side of the sleeve facing towards

the centre of the vehicle.

Refitting

12Refitting is the reverse of removal. Refit

the inner pivot bolt first. Don’t fully tighten the

nuts on the pivot bolts or the shock absorber

yet.

13Bleed the brakes as described in Chap-

ter 9.

14Support the trailing arm with a trolley jack,

and raise it to simulate normal ride height.

Tighten the bolts and nuts to the torques

listed in this Chapter’s Specifications.

15 Rear wheel bearings-

renewal

4

3-Series models

1Loosen the driveshaft nut and the rear

wheel bolts, then chock the front wheels.

Raise the rear of the vehicle and place it

securely on axle stands. Remove the rear

wheel. Note: Depending on the type of rear

wheel, it may be necessary to remove the

wheel first, remove the hubcap, then refit the

wheel and loosen the driveshaft nut.

2Remove the driveshaft (see Chapter 8).3On models with rear brake drums, remove

the drum. On models with rear disc brakes,

remove the brake caliper and mounting

bracket. Don’t disconnect the hose. Hang the

caliper out of the way with a piece of wire.

Remove the brake disc (see Chapter 9).

Working from behind, drive the wheel hub out

of the wheel bearing with a large socket or a

piece of pipe.

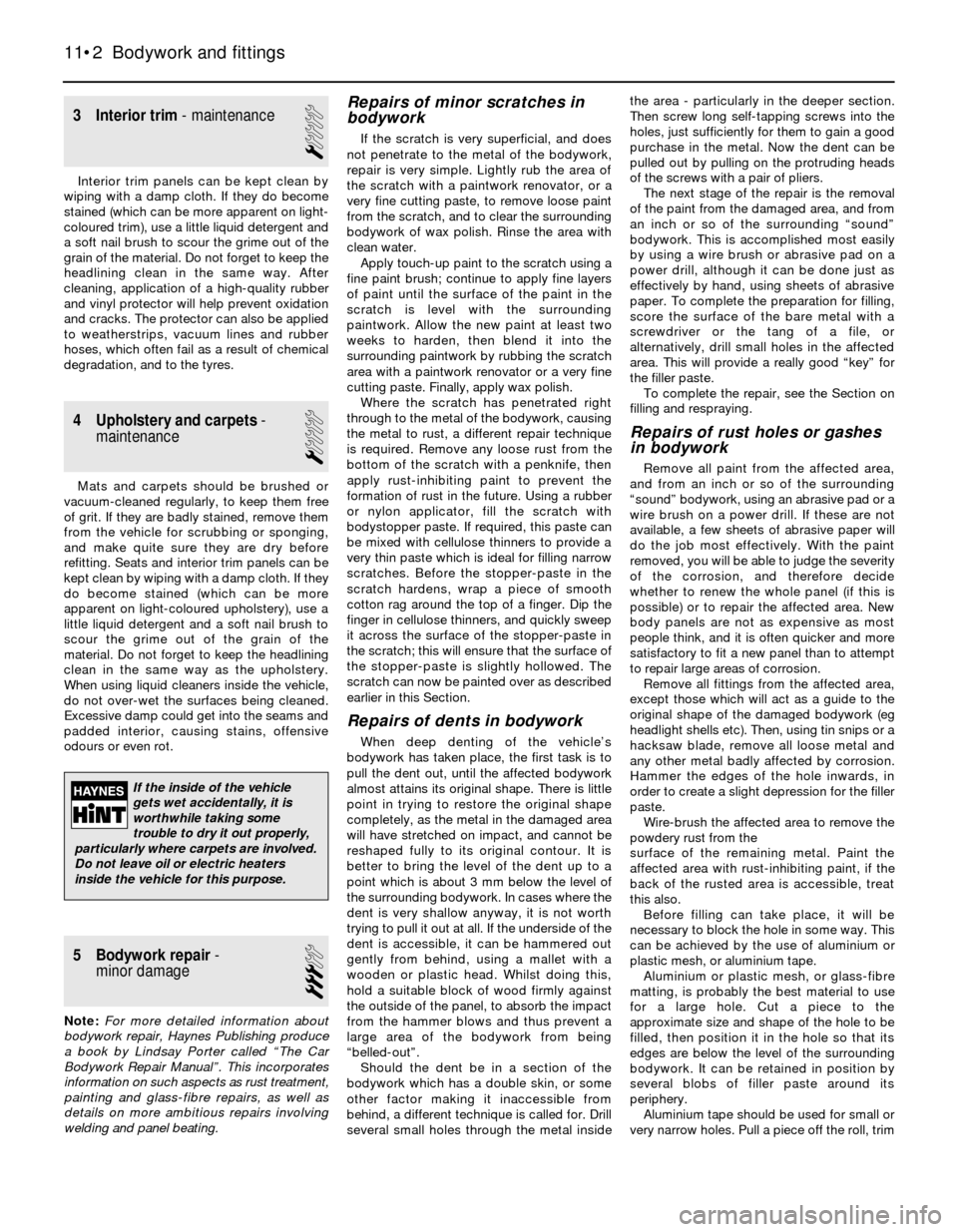

4Remove the large circlip (see illustration)

that holds the wheel bearing in the wheel

bearing housing, then drive out the bearing

with a large socket or piece of pipe.

5Refitting is basically the reverse of removal,

bearing in mind the following points:

a) Be extremely careful where you place the

socket or piece of pipe when you drive

the new bearing into the housing. It

should be butted up against the outer

race of the bearing. Driving in the new

bearing using the inner race will ruin the

bearing.

b) Refit the wheel and lower the vehicle to

the ground before attempting to tighten

the driveshaft nut to the torque listed in

the Chapter 8 Specifications.

5-Series models

6Chock the front wheels, then raise the rear

of the vehicle and support it securely on axle

stands. Disconnect the outer CV joint from the

drive flange (see Chapter 8). Support the outer

end of the driveshaft with a piece of wire -

don’t let it hang, as this could damage the

inner CV joint.

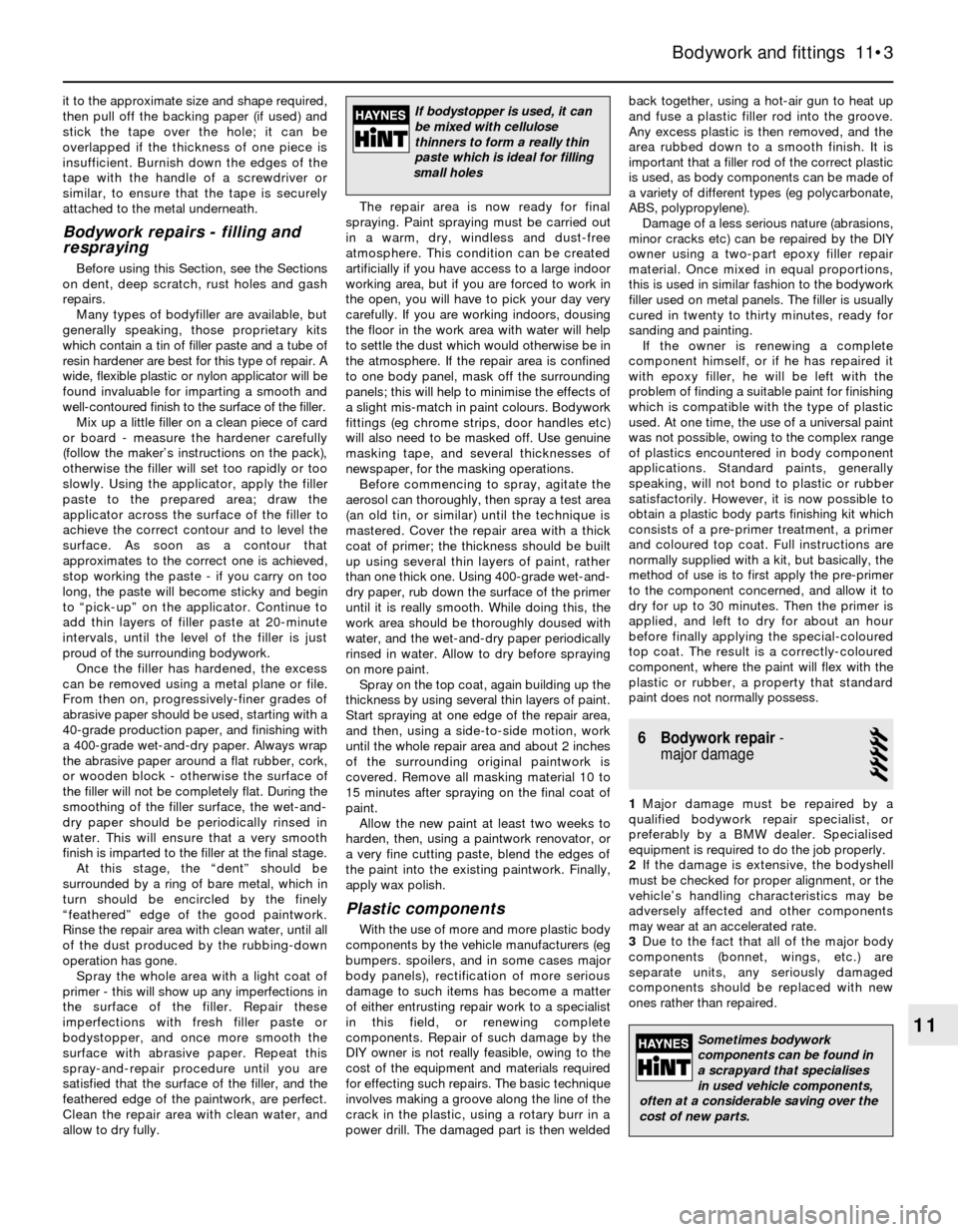

7Prise out the lockplate that secures the

drive flange nut (see illustration). Once

you’ve prised out an edge of the lockplate,

pull it out with a pair of needle-nose pliers.

8Lower the vehicle and unscrew the drive

flange nut, but don’t remove it yet. You’ll need

a long bar (see illustration).

Warning: Don’t attempt to loosen

this nut with the vehicle on axle

stands. The force required to

loosen the nut could topple the

vehicle from the stands.

9Loosen the rear wheel bolts, raise the rear

of the vehicle again, place it securely on axle

stands and remove the wheel.

10Remove the brake caliper and the brake

disc (see Chapter 9). Hang the caliper out of

the way with a piece of wire.

11Remove the drive flange nut. Using a

suitable puller, remove the drive flange (see

illustration).

12Using a soft-faced hammer, drive the stub

axle out of the bearing (see illustration). If the

bearing inner race comes off with the stub

Suspension and steering systems 10•11

15.7 Prise out the lockplate that secures

the drive flange nut - once you’ve prised

out an edge of the lockplate, pull it out

with a pair of needle-nose pliers15.4 An exploded view of the 3-Series rear

wheel bearing assembly14.8 On 1983 and later models, remove

one of these trailing arm-to-axle carrier

bolts (it doesn’t matter which one you

remove - one attaches the link to the

trailing arm, and the other attaches the link

to the axle carrier)

15.12 Using a soft-faced hammer, drive

the stub axle out of the bearing15.11 Remove the drive flange with a

puller15.8 Lower the vehicle and loosen the

drive flange nut

10

If the bearing inner race

sticks to the hub (it probably

will), use a puller to remove

the race from the hub.

Page 161 of 228

3 Interior trim- maintenance

1

Interior trim panels can be kept clean by

wiping with a damp cloth. If they do become

stained (which can be more apparent on light-

coloured trim), use a little liquid detergent and

a soft nail brush to scour the grime out of the

grain of the material. Do not forget to keep the

headlining clean in the same way. After

cleaning, application of a high-quality rubber

and vinyl protector will help prevent oxidation

and cracks. The protector can also be applied

to weatherstrips, vacuum lines and rubber

hoses, which often fail as a result of chemical

degradation, and to the tyres.

4 Upholstery and carpets-

maintenance

1

Mats and carpets should be brushed or

vacuum-cleaned regularly, to keep them free

of grit. If they are badly stained, remove them

from the vehicle for scrubbing or sponging,

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light-coloured upholstery), use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the

material. Do not forget to keep the headlining

clean in the same way as the upholstery.

When using liquid cleaners inside the vehicle,

do not over-wet the surfaces being cleaned.

Excessive damp could get into the seams and

padded interior, causing stains, offensive

odours or even rot.

5 Bodywork repair-

minor damage

3

Note:For more detailed information about

bodywork repair, Haynes Publishing produce

a book by Lindsay Porter called “The Car

Bodywork Repair Manual”. This incorporates

information on such aspects as rust treatment,

painting and glass-fibre repairs, as well as

details on more ambitious repairs involving

welding and panel beating.

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of

the scratch with a paintwork renovator, or a

very fine cutting paste, to remove loose paint

from the scratch, and to clear the surrounding

bodywork of wax polish. Rinse the area with

clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden, then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique

is required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust-inhibiting paint to prevent the

formation of rust in the future. Using a rubber

or nylon applicator, fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste which is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smooth

cotton rag around the top of a finger. Dip the

finger in cellulose thinners, and quickly sweep

it across the surface of the stopper-paste in

the scratch; this will ensure that the surface of

the stopper-paste is slightly hollowed. The

scratch can now be painted over as described

earlier in this Section.

Repairs of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact, and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point which is about 3 mm below the level of

the surrounding bodywork. In cases where the

dent is very shallow anyway, it is not worth

trying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a suitable block of wood firmly against

the outside of the panel, to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being

“belled-out”.

Should the dent be in a section of the

bodywork which has a double skin, or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal insidethe area - particularly in the deeper section.

Then screw long self-tapping screws into the

holes, just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand, using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a really good “key” for

the filler paste.

To complete the repair, see the Section on

filling and respraying.

Repairs of rust holes or gashes

in bodywork

Remove all paint from the affected area,

and from an inch or so of the surrounding

“sound” bodywork, using an abrasive pad or a

wire brush on a power drill. If these are not

available, a few sheets of abrasive paper will

do the job most effectively. With the paint

removed, you will be able to judge the severity

of the corrosion, and therefore decide

whether to renew the whole panel (if this is

possible) or to repair the affected area. New

body panels are not as expensive as most

people think, and it is often quicker and more

satisfactory to fit a new panel than to attempt

to repair large areas of corrosion.

Remove all fittings from the affected area,

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlight shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards, in

order to create a slight depression for the filler

paste.

Wire-brush the affected area to remove the

powdery rust from the

surface of the remaining metal. Paint the

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat

this also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

11•2 Bodywork and fittings

If the inside of the vehicle

gets wet accidentally, it is

worthwhile taking some

trouble to dry it out properly,

particularly where carpets are involved.

Do not leave oil or electric heaters

inside the vehicle for this purpose.

Page 162 of 228

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair. A

wide, flexible plastic or nylon applicator will be

found invaluable for imparting a smooth and

well-contoured finish to the surface of the filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minute

intervals, until the level of the filler is just

proud of the surrounding bodywork.

Once the filler has hardened, the excess

can be removed using a metal plane or file.

From then on, progressively-finer grades of

abrasive paper should be used, starting with a

40-grade production paper, and finishing with

a 400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of

the filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.

At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork.

Rinse the repair area with clean water, until all

of the dust produced by the rubbing-down

operation has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.The repair area is now ready for final

spraying. Paint spraying must be carried out

in a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused with

water, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up the

thickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to

15 minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or

a very fine cutting paste, blend the edges of

the paint into the existing paintwork. Finally,

apply wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers. spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter

of either entrusting repair work to a specialist

in this field, or renewing complete

components. Repair of such damage by the

DIY owner is not really feasible, owing to the

cost of the equipment and materials required

for effecting such repairs. The basic technique

involves making a groove along the line of the

crack in the plastic, using a rotary burr in a

power drill. The damaged part is then weldedback together, using a hot-air gun to heat up

and fuse a plastic filler rod into the groove.

Any excess plastic is then removed, and the

area rubbed down to a smooth finish. It is

important that a filler rod of the correct plastic

is used, as body components can be made of

a variety of different types (eg polycarbonate,

ABS, polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions,

this is used in similar fashion to the bodywork

filler used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will be left with the

problem of finding a suitable paint for finishing

which is compatible with the type of plastic

used. At one time, the use of a universal paint

was not possible, owing to the complex range

of plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily. However, it is now possible to

obtain a plastic body parts finishing kit which

consists of a pre-primer treatment, a primer

and coloured top coat. Full instructions are

normally supplied with a kit, but basically, the

method of use is to first apply the pre-primer

to the component concerned, and allow it to

dry for up to 30 minutes. Then the primer is

applied, and left to dry for about an hour

before finally applying the special-coloured

top coat. The result is a correctly-coloured

component, where the paint will flex with the

plastic or rubber, a property that standard

paint does not normally possess.

6 Bodywork repair-

major damage

5

1Major damage must be repaired by a

qualified bodywork repair specialist, or

preferably by a BMW dealer. Specialised

equipment is required to do the job properly.

2If the damage is extensive, the bodyshell

must be checked for proper alignment, or the

vehicle’s handling characteristics may be

adversely affected and other components

may wear at an accelerated rate.

3Due to the fact that all of the major body

components (bonnet, wings, etc.) are

separate units, any seriously damaged

components should be replaced with new

ones rather than repaired.

Bodywork and fittings 11•3

11

If bodystopper is used, it can

be mixed with cellulose

thinners to form a really thin

paste which is ideal for filling

small holes

Sometimes bodywork

components can be found in

a scrapyard that specialises

in used vehicle components,

often at a considerable saving over the

cost of new parts.

Page 204 of 228

REF•3

REF

MOT Test Checks

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entire system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from

lock to lock. Check that the steering turns

smoothly, and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

MExamine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stiffness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

MStarting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

free play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

MNow grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

roughness or tightness of the front wheel

bearing.

MIf excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

retaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

MCarry out all the above checks at the other

front wheel, and then at both rear wheels.

Springs and shock absorbers

MExamine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

MIf coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles.MThe same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensure that all mountings and attachments are

secure, that there are no signs of excessive

wear, corrosion or damage, and (on hydraulic

types) that there are no fluid leaks or damaged

pipes.

MInspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

MRotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

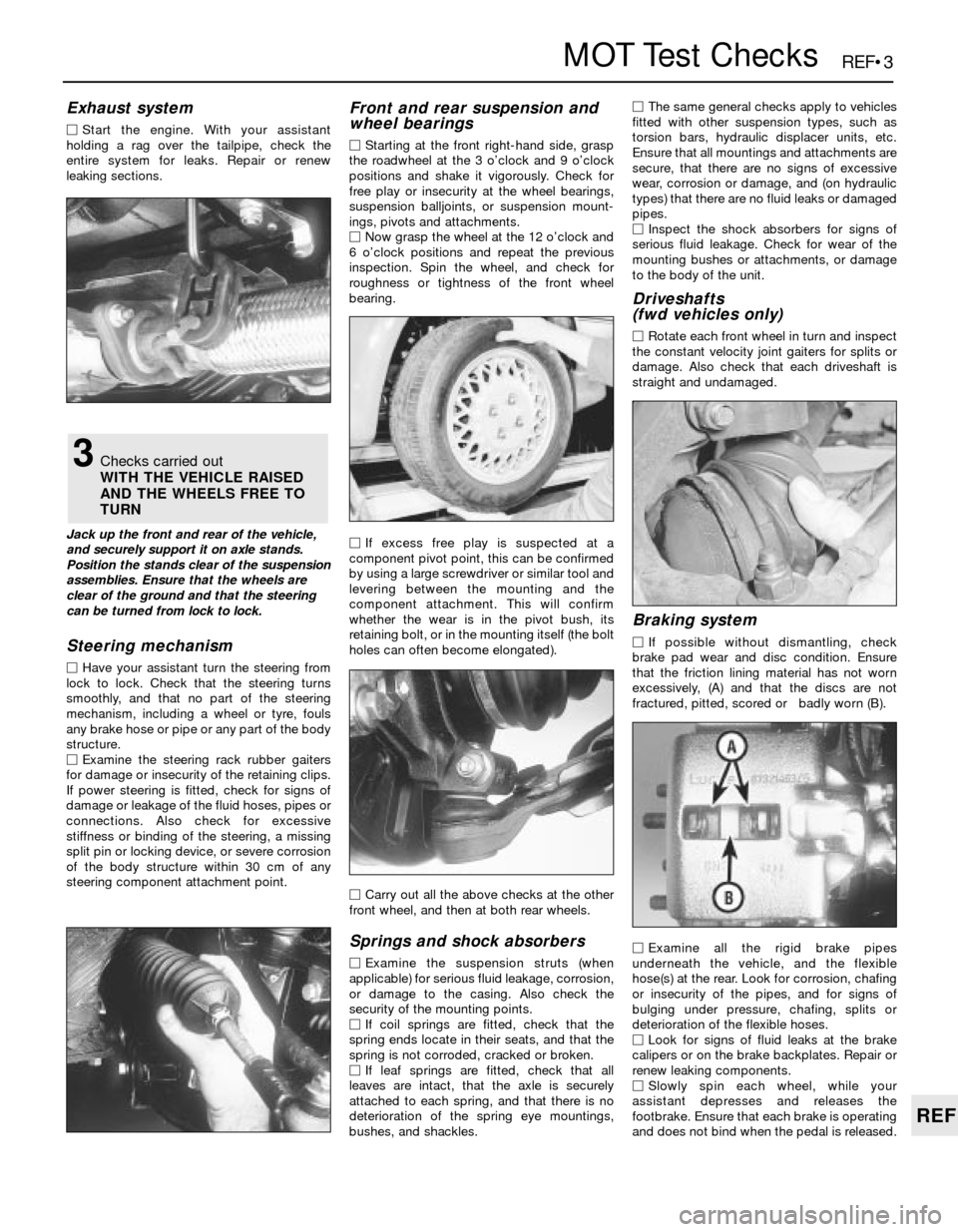

Braking system

MIf possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively, (A) and that the discs are not

fractured, pitted, scored or badly worn (B).

MExamine all the rigid brake pipes

underneath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

renew leaking components.

MSlowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

Page 216 of 228

REF•15

REF

Fault Finding

Suspension and steering

Note:Before assuming that a problem exists, check the following

items:

a) Tyre pressures and tyre condition (also check for out-of-round or

out-of-balance tyres, and bent wheel rims).

b) Steering universal joints from the column to the steering gear (for

play or wear).

c) Front and rear suspension, and the rack-and-pinion assembly (for

loose or damaged parts).

d) Wheel bearings (wheel wobble or roughness when spun).

Vehicle pulls to one side

m mMismatched or uneven tyres (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mFront wheel or rear wheel alignment incorrect (Chapter 10).

m mFront brake problem (Chapter 9).

Abnormal or excessive tyre wear

m

mFront wheel or rear wheel alignment incorrect (Chapter 10).

m mSagging or broken springs (Chapter 10).

m mTyre out of balance (Chapter 10).

m mWorn shock absorber (Chapter 10).

m mOverloaded vehicle or unsympathetic driving style.

m mTyres not rotated regularly.

Wheel makes a “thumping” noise

m

mBlister or bump on tyre (Chapter 10).

m mFaulty shock absorber action (Chapter 10).

m mWheel bolts loose.

Shimmy, shake or vibration

m

mTyre or wheel out of balance or out of round (Chapter 10).

m mLoose, worn or incorrectly-adjusted wheel bearings (Chapter 1).

m mWorn tie-rod ends (Chapter 10).

m mWorn balljoints (Chapter 10).

m mExcessive wheel run-out (Chapter 10).

m mBlister or bump on tyre (Chapter 10).

m mWheel bolts loose.

High steering effort

m

mLack of lubrication at balljoints, tie-rod ends and steering gear

(Chapter 1).

m mIncorrect front wheel alignment (Chapter 10).

m mLow tyre pressure(s) (Chapter 1).

m mPower steering fluid low, or steering pump drivebelt slipping,

where applicable (Chapter 10)

Poor steering self-centring

m mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mBinding in balljoints (Chapter 10).

m mBinding in steering column (Chapter 10).

m mLack of lubricant in steering gear (Chapter 10).

m mInaccurate front wheel alignment (Chapter 10).

Abnormal noise at the front end

m

mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mDamaged shock absorber mounting (Chapter 10).

m mWorn control arm bushings or tie-rod ends (Chapter 10).

m mLoose anti-roll bar (Chapter 10).

m mLoose wheel bolts.

m mLoose suspension mounting bolts (Chapter 10).

Wandering or poor steering stability

m

mMismatched or uneven tyres (Chapter 10).

m mLack of lubrication at balljoints and tie-rod ends (Chapter 1).

m mWorn shock absorbers (Chapter 10).

m mLoose anti-roll bar (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mFront or rear wheel alignment incorrect (Chapter 10).

Erratic steering when braking

m

mWheel bearings worn (Chapter 1).

m mBroken or sagging springs (Chapter 10).

m mLeaking wheel cylinder (rear drum brake models) or caliper

(Chapter 9).

m mWarped discs (Chapter 9).

Excessive pitching and/or rolling around corners or

during braking

m mLoose anti-roll bar (Chapter 10).

m mWorn shock absorbers or mountings (Chapter 10).

m mBroken or sagging springs (Chapter 10).

m mOverloaded vehicle.

Suspension bottoms

m

mOverloaded vehicle.

m mWorn shock absorbers (Chapter 10).

m mBroken or sagging springs, or incorrect springs fitted (Chapter 10).

Unevenly-worn tyres

m

mFront wheel or rear wheel alignment incorrect (Chapter 10).

m mWorn shock absorbers (Chapter 10).

m mWheel bearings worn (Chapter 10).

m mExcessive tyre or wheel run-out (Chapter 10).

m mWorn balljoints (Chapter 10).

Excessive tyre wear on outside edge

m

mTyre pressures incorrect (Chapter 1).

m mExcessive cornering speed.

m mWheel alignment incorrect (excessive toe-in) (Chapter 10).

m mSuspension components damaged (Chapter 10).

Excessive tyre wear on inside edge

m

mTyre pressures incorrect (Chapter 1).

m mWheel alignment incorrect (excessive toe-out) (Chapter 10).

m mLoose or damaged steering components (Chapter 10).

Tyre tread worn in one place

m

mTyres out of balance.

m mDamaged or buckled wheel. Inspect and renew if necessary.

m mDefective tyre (Chapter 1).

Excessive play or looseness in steering system

m

mWheel bearing(s) worn (Chapter 10.

m mTie-rod end loose or worn (Chapter 10).

m mSteering gear mountings loose (Chapter 10).

Rattling or clicking noise in steering gear

m

mInsufficient or incorrect lubricant in rack-and-pinion assembly

(Chapter 10).

m mSteering gear mountings loose (Chapter 10).

Page 217 of 228

REF•17

REF

Conversion Factors

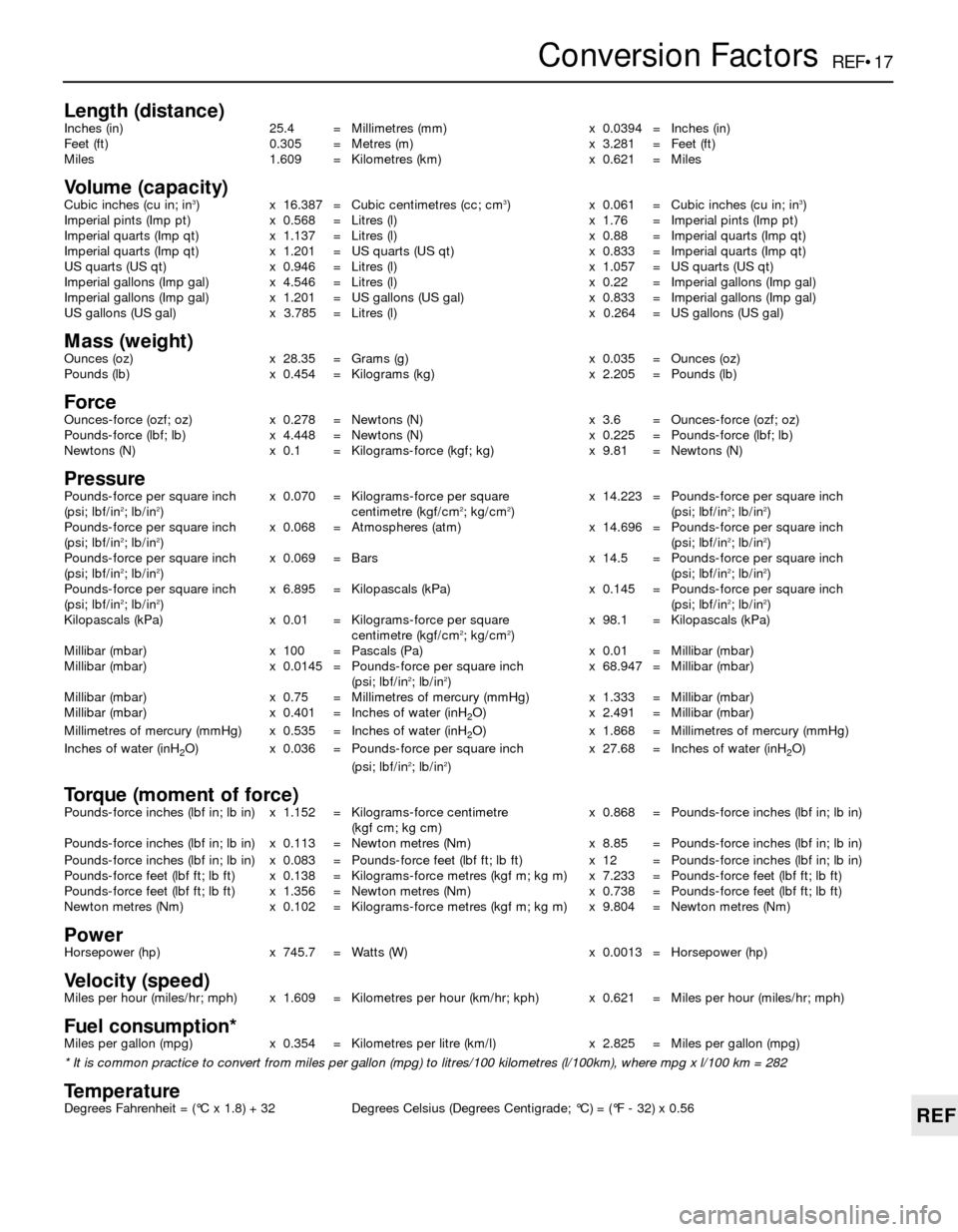

Length (distance)Inches (in) 25.4 = Millimetres (mm) x 0.0394 = Inches (in)

Feet (ft) 0.305 = Metres (m) x 3.281 = Feet (ft)

Miles 1.609 = Kilometres (km) x 0.621 = Miles

Volume (capacity)Cubic inches (cu in; in3) x 16.387 = Cubic centimetres (cc; cm3) x 0.061 = Cubic inches (cu in; in3)

Imperial pints (Imp pt) x 0.568 = Litres (l) x 1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Litres (l) x 0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 = US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Litres (l) x 1.057 = US quarts (US qt)

Imperial gallons (Imp gal) x 4.546 = Litres (l) x 0.22 = Imperial gallons (Imp gal)

Imperial gallons (Imp gal) x 1.201 = US gallons (US gal) x 0.833 = Imperial gallons (Imp gal)

US gallons (US gal) x 3.785 = Litres (l) x 0.264 = US gallons (US gal)

Mass (weight)Ounces (oz) x 28.35 = Grams (g) x 0.035 = Ounces (oz)

Pounds (lb) x 0.454 = Kilograms (kg) x 2.205 = Pounds (lb)

ForceOunces-force (ozf; oz) x 0.278 = Newtons (N) x 3.6 = Ounces-force (ozf; oz)

Pounds-force (lbf; lb) x 4.448 = Newtons (N) x 0.225 = Pounds-force (lbf; lb)

Newtons (N) x 0.1 = Kilograms-force (kgf; kg) x 9.81 = Newtons (N)

PressurePounds-force per square inch x 0.070 = Kilograms-force per square x 14.223 = Pounds-force per square inch

(psi; lbf/in2; lb/in2) centimetre (kgf/cm2; kg/cm2) (psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.068 = Atmospheres (atm) x 14.696 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.069 = Bars x 14.5 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 6.895 = Kilopascals (kPa) x 0.145 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Kilopascals (kPa) x 0.01 = Kilograms-force per square x 98.1 = Kilopascals (kPa)

centimetre (kgf/cm

2; kg/cm2)

Millibar (mbar) x 100 = Pascals (Pa) x 0.01 = Millibar (mbar)

Millibar (mbar) x 0.0145 = Pounds-force per square inch x 68.947 = Millibar (mbar)

(psi; lbf/in

2; lb/in2)

Millibar (mbar) x 0.75 = Millimetres of mercury (mmHg) x 1.333 = Millibar (mbar)

Millibar (mbar) x 0.401 = Inches of water (inH

2O) x 2.491 = Millibar (mbar)

Millimetres of mercury (mmHg) x 0.535 = Inches of water (inH

2O) x 1.868 = Millimetres of mercury (mmHg)

Inches of water (inH

2O) x 0.036 = Pounds-force per square inch x 27.68 = Inches of water (inH2O)

(psi; lbf/in2; lb/in2)

Torque (moment of force)Pounds-force inches (lbf in; lb in) x 1.152 = Kilograms-force centimetre x 0.868 = Pounds-force inches (lbf in; lb in)

(kgf cm; kg cm)

Pounds-force inches (lbf in; lb in) x 0.113 = Newton metres (Nm) x 8.85 = Pounds-force inches (lbf in; lb in)

Pounds-force inches (lbf in; lb in) x 0.083 = Pounds-force feet (lbf ft; lb ft) x 12 = Pounds-force inches (lbf in; lb in)

Pounds-force feet (lbf ft; lb ft) x 0.138 = Kilograms-force metres (kgf m; kg m) x 7.233 = Pounds-force feet (lbf ft; lb ft)

Pounds-force feet (lbf ft; lb ft) x 1.356 = Newton metres (Nm) x 0.738 = Pounds-force feet (lbf ft; lb ft)

Newton metres (Nm) x 0.102 = Kilograms-force metres (kgf m; kg m) x 9.804 = Newton metres (Nm)

PowerHorsepower (hp) x 745.7 = Watts (W) x 0.0013 = Horsepower (hp)

Velocity (speed)Miles per hour (miles/hr; mph) x 1.609 = Kilometres per hour (km/hr; kph) x 0.621 = Miles per hour (miles/hr; mph)

Fuel consumption*Miles per gallon (mpg) x 0.354 = Kilometres per litre (km/l) x 2.825 = Miles per gallon (mpg)

* It is common practice to convert from miles per gallon (mpg) to litres/100 kilometres (l/100km), where mpg x l/100 km = 282

TemperatureDegrees Fahrenheit = (°C x 1.8) + 32 Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

Page 220 of 228

REF•20Glossary of Technical Terms

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits thatwould tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.

Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.

Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

Brake bleeding

Bearing

Axle assembly

Anti-seize compound

Alternator (exploded view)

Air filter

Page 223 of 228

REF•23

REF

Glossary of Technical Terms

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).

Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful tothe ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.

SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

O-ring

Serpentine drivebelt

Plastigage

Page 225 of 228

REF•25

REF

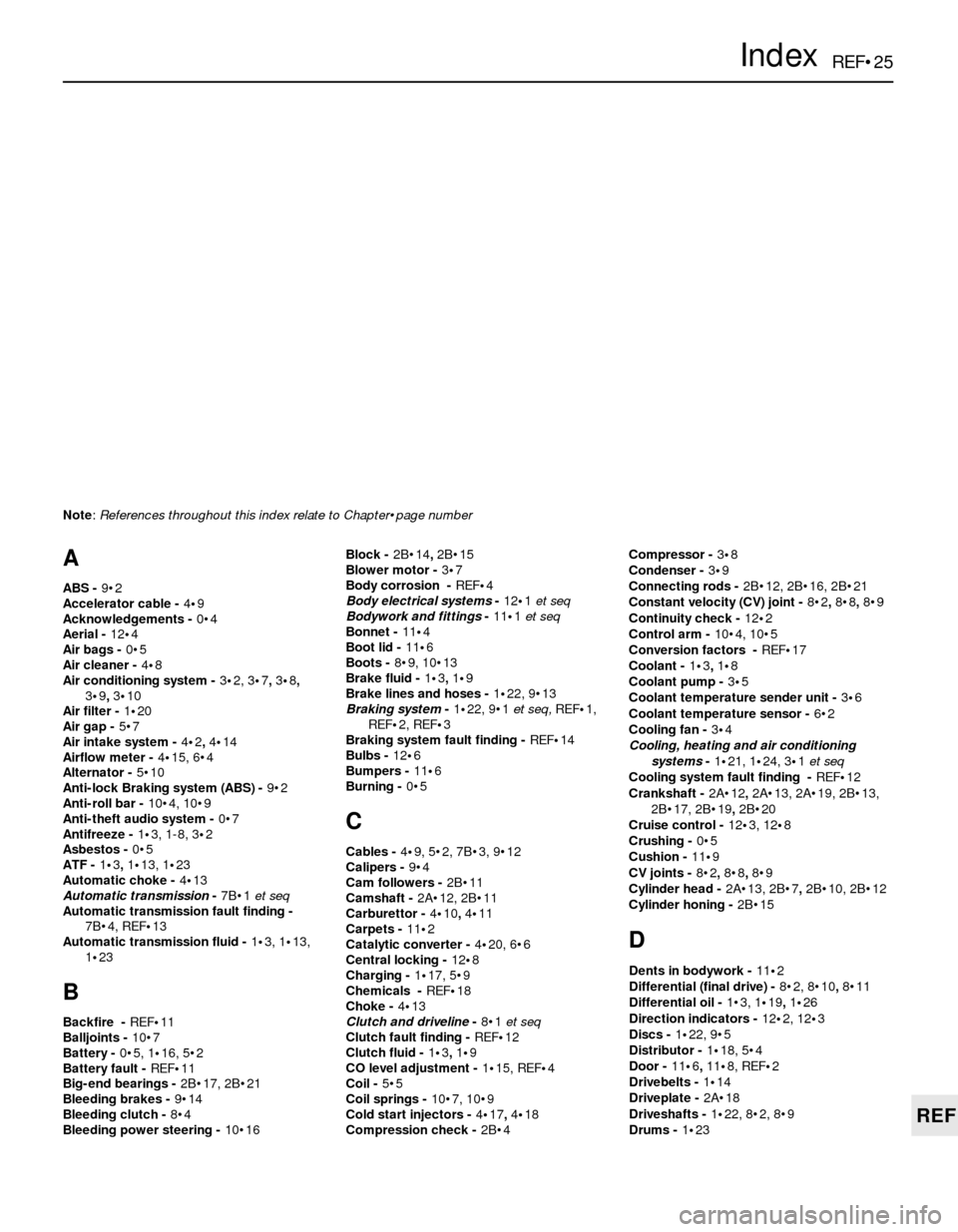

Index

Note: References throughout this index relate to Chapter•page number

A

ABS - 9•2

Accelerator cable - 4•9

Acknowledgements - 0•4

Aerial - 12•4

Air bags - 0•5

Air cleaner - 4•8

Air conditioning system - 3•2, 3•7, 3•8,

3•9, 3•10

Air filter - 1•20

Air gap - 5•7

Air intake system - 4•2, 4•14

Airflow meter - 4•15, 6•4

Alternator - 5•10

Anti-lock Braking system (ABS) - 9•2

Anti-roll bar - 10•4, 10•9

Anti-theft audio system - 0•7

Antifreeze - 1•3, 1-8, 3•2

Asbestos - 0•5

ATF - 1•3, 1•13, 1•23

Automatic choke - 4•13

Automatic transmission- 7B•1et seq

Automatic transmission fault finding -

7B•4, REF•13

Automatic transmission fluid - 1•3, 1•13,

1•23

B

Backfire - REF•11

Balljoints - 10•7

Battery - 0•5, 1•16, 5•2

Battery fault - REF•11

Big-end bearings - 2B•17, 2B•21

Bleeding brakes - 9•14

Bleeding clutch - 8•4

Bleeding power steering - 10•16Block - 2B•14, 2B•15

Blower motor - 3•7

Body corrosion - REF•4

Body electrical systems- 12•1et seq

Bodywork and fittings- 11•1et seq

Bonnet - 11•4

Boot lid - 11•6

Boots - 8•9, 10•13

Brake fluid - 1•3, 1•9

Brake lines and hoses - 1•22, 9•13

Braking system- 1•22, 9•1et seq,REF•1,

REF•2, REF•3

Braking system fault finding - REF•14

Bulbs - 12•6

Bumpers - 11•6

Burning - 0•5

C

Cables - 4•9, 5•2, 7B•3, 9•12

Calipers - 9•4

Cam followers - 2B•11

Camshaft - 2A•12, 2B•11

Carburettor - 4•10, 4•11

Carpets - 11•2

Catalytic converter - 4•20, 6•6

Central locking - 12•8

Charging - 1•17, 5•9

Chemicals - REF•18

Choke - 4•13

Clutch and driveline- 8•1et seq

Clutch fault finding - REF•12

Clutch fluid - 1•3, 1•9

CO level adjustment - 1•15, REF•4

Coil - 5•5

Coil springs - 10•7, 10•9

Cold start injectors - 4•17, 4•18

Compression check - 2B•4Compressor - 3•8

Condenser - 3•9

Connecting rods -2B•12, 2B•16, 2B•21

Constant velocity (CV) joint - 8•2, 8•8, 8•9

Continuity check - 12•2

Control arm - 10•4, 10•5

Conversion factors - REF•17

Coolant - 1•3, 1•8

Coolant pump - 3•5

Coolant temperature sender unit - 3•6

Coolant temperature sensor - 6•2

Cooling fan - 3•4

Cooling, heating and air conditioning

systems- 1•21, 1•24, 3•1et seq

Cooling system fault finding - REF•12

Crankshaft - 2A•12, 2A•13, 2A•19, 2B•13,

2B•17, 2B•19, 2B•20

Cruise control - 12•3, 12•8

Crushing - 0•5

Cushion - 11•9

CV joints - 8•2, 8•8, 8•9

Cylinder head - 2A•13, 2B•7, 2B•10, 2B•12

Cylinder honing - 2B•15

D

Dents in bodywork - 11•2

Differential (final drive) - 8•2, 8•10, 8•11

Differential oil -1•3, 1•19, 1•26

Direction indicators - 12•2, 12•3

Discs - 1•22, 9•5

Distributor - 1•18, 5•4

Door - 11•6, 11•8, REF•2

Drivebelts - 1•14

Driveplate - 2A•18

Driveshafts - 1•22, 8•2, 8•9

Drums - 1•23