check engine light BMW 3 SERIES 1991 E30 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1991, Model line: 3 SERIES, Model: BMW 3 SERIES 1991 E30Pages: 228, PDF Size: 7.04 MB

Page 120 of 228

the alternator complete, or take it to an

automotive electrician, who may be able to

overhaul it. Note:On models up to 1986, a

blown ignition/no-charge warning light bulb

will prevent the alternator from charging. After

1987, a resistor is wired in parallel with the

warning light, in order to allow current to

bypass the light in the event of a broken circuit

(blown warning light).

15 Alternator-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

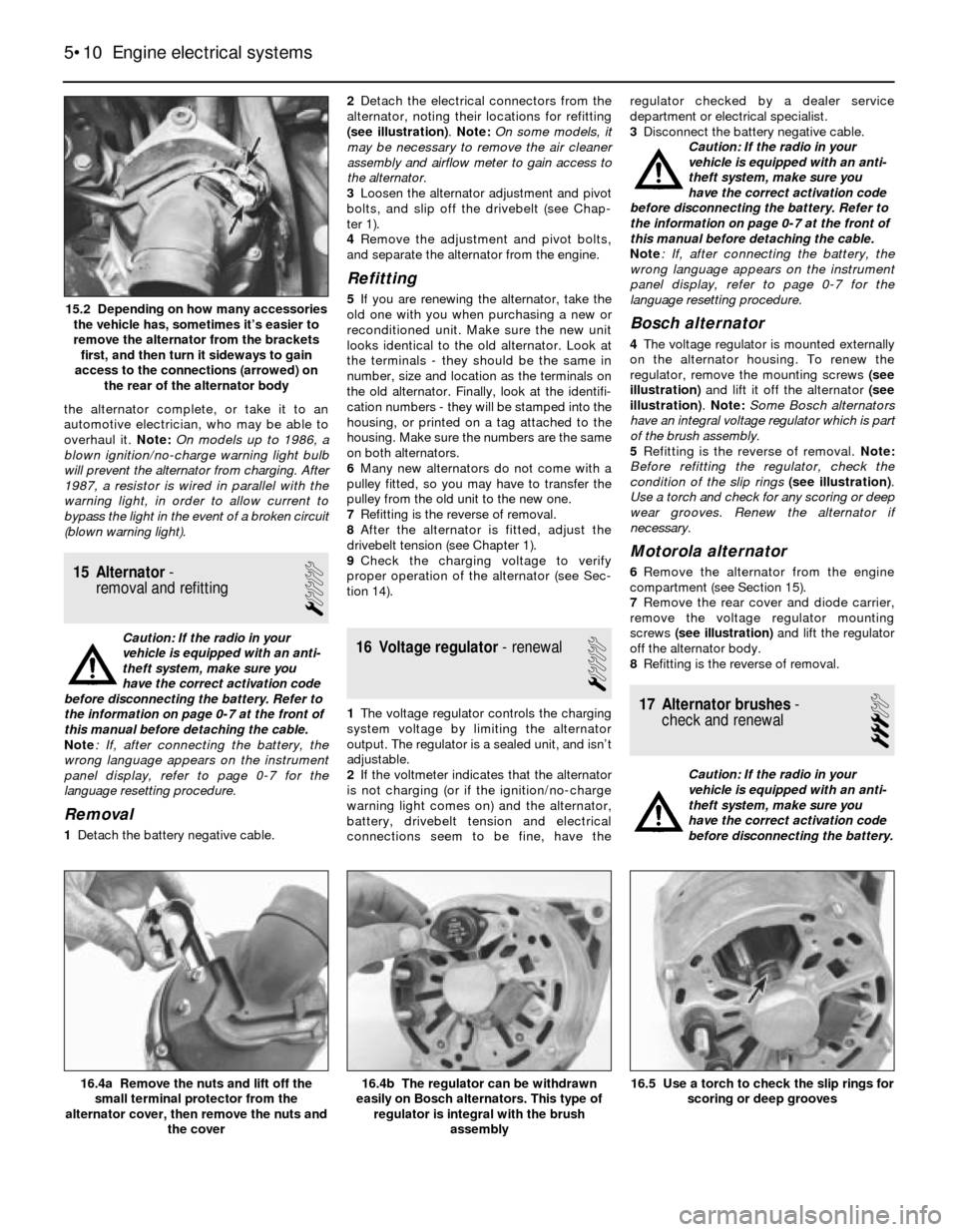

1Detach the battery negative cable.2Detach the electrical connectors from the

alternator, noting their locations for refitting

(see illustration). Note: On some models, it

may be necessary to remove the air cleaner

assembly and airflow meter to gain access to

the alternator.

3Loosen the alternator adjustment and pivot

bolts, and slip off the drivebelt (see Chap-

ter 1).

4Remove the adjustment and pivot bolts,

and separate the alternator from the engine.

Refitting

5If you are renewing the alternator, take the

old one with you when purchasing a new or

reconditioned unit. Make sure the new unit

looks identical to the old alternator. Look at

the terminals - they should be the same in

number, size and location as the terminals on

the old alternator. Finally, look at the identifi-

cation numbers - they will be stamped into the

housing, or printed on a tag attached to the

housing. Make sure the numbers are the same

on both alternators.

6Many new alternators do not come with a

pulley fitted, so you may have to transfer the

pulley from the old unit to the new one.

7Refitting is the reverse of removal.

8After the alternator is fitted, adjust the

drivebelt tension (see Chapter 1).

9Check the charging voltage to verify

proper operation of the alternator (see Sec-

tion 14).

16 Voltage regulator- renewal

1

1The voltage regulator controls the charging

system voltage by limiting the alternator

output. The regulator is a sealed unit, and isn’t

adjustable.

2If the voltmeter indicates that the alternator

is not charging (or if the ignition/no-charge

warning light comes on) and the alternator,

battery, drivebelt tension and electrical

connections seem to be fine, have theregulator checked by a dealer service

department or electrical specialist.

3Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery. Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Bosch alternator

4The voltage regulator is mounted externally

on the alternator housing. To renew the

regulator, remove the mounting screws (see

illustration)and lift it off the alternator (see

illustration). Note: Some Bosch alternators

have an integral voltage regulator which is part

of the brush assembly.

5Refitting is the reverse of removal. Note:

Before refitting the regulator, check the

condition of the slip rings(see illustration).

Use a torch and check for any scoring or deep

wear grooves. Renew the alternator if

necessary.

Motorola alternator

6Remove the alternator from the engine

compartment (see Section 15).

7Remove the rear cover and diode carrier,

remove the voltage regulator mounting

screws (see illustration)and lift the regulator

off the alternator body.

8Refitting is the reverse of removal.

17 Alternator brushes-

check and renewal

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

5•10 Engine electrical systems

16.5 Use a torch to check the slip rings for

scoring or deep grooves16.4b The regulator can be withdrawn

easily on Bosch alternators. This type of

regulator is integral with the brush

assembly16.4a Remove the nuts and lift off the

small terminal protector from the

alternator cover, then remove the nuts and

the cover

15.2 Depending on how many accessories

the vehicle has, sometimes it’s easier to

remove the alternator from the brackets

first, and then turn it sideways to gain

access to the connections (arrowed) on

the rear of the alternator body

Page 126 of 228

slightly by hand. Release the throttle slowly

until it reaches 0.2 to 0.6 mm from the throttle

stop. There should be continuity.

29Check the resistance between terminals 3

and 18 as the throttle is opened. There should

be continuity when the throttle switch is within

8 to 12 degrees of fully-open. If the readings

are incorrect, adjust the TPS.

30If all the resistance readings are correct

and the TPS is properly adjusted, check for

power (5 volts) at the sensor, and if necessary

trace any wiring circuit problems between the

sensor and ECU (see Chapter 12).

Adjustment

31If the adjustment is not as specified

(paragraphs 28 to 30), loosen the screws on

the TPS, and rotate the sensor into the correct

adjustment. Follow the procedure for

checking the TPS given above, and tighten

the screws when the setting is correct.

32Recheck the TPS once more; if the

readings are correct, reconnect the TPS

harness connector.

Early 535i models with automatic

transmission

Check

33First test the continuity of the TPS. Follow

paragraphs 28 to 30 and check for continuity.

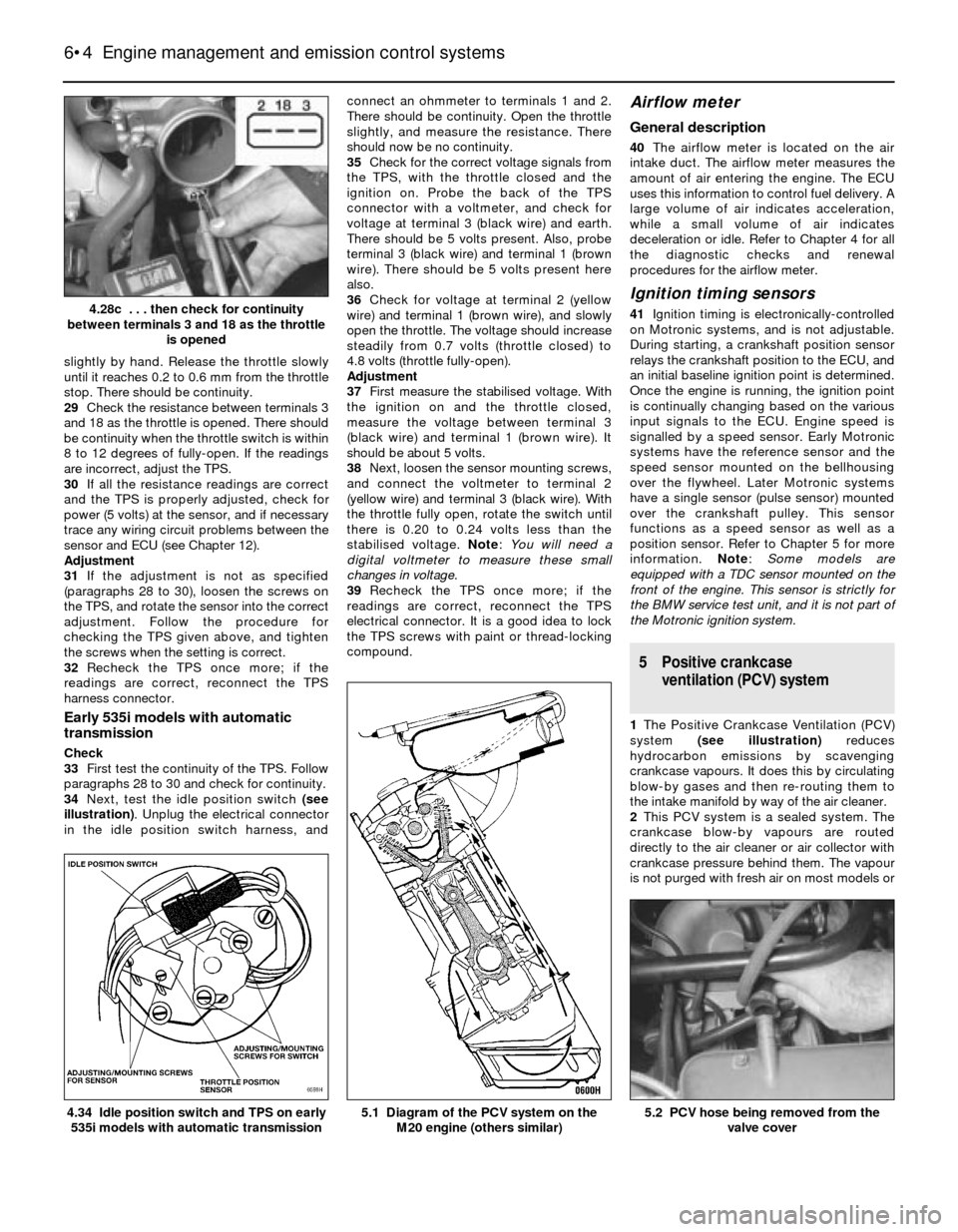

34Next, test the idle position switch (see

illustration). Unplug the electrical connector

in the idle position switch harness, andconnect an ohmmeter to terminals 1 and 2.

There should be continuity. Open the throttle

slightly, and measure the resistance. There

should now be no continuity.

35Check for the correct voltage signals from

the TPS, with the throttle closed and the

ignition on. Probe the back of the TPS

connector with a voltmeter, and check for

voltage at terminal 3 (black wire) and earth.

There should be 5 volts present. Also, probe

terminal 3 (black wire) and terminal 1 (brown

wire). There should be 5 volts present here

also.

36Check for voltage at terminal 2 (yellow

wire) and terminal 1 (brown wire), and slowly

open the throttle. The voltage should increase

steadily from 0.7 volts (throttle closed) to

4.8 volts (throttle fully-open).

Adjustment

37First measure the stabilised voltage. With

the ignition on and the throttle closed,

measure the voltage between terminal 3

(black wire) and terminal 1 (brown wire). It

should be about 5 volts.

38Next, loosen the sensor mounting screws,

and connect the voltmeter to terminal 2

(yellow wire) and terminal 3 (black wire). With

the throttle fully open, rotate the switch until

there is 0.20 to 0.24 volts less than the

stabilised voltage. Note: You will need a

digital voltmeter to measure these small

changes in voltage.

39Recheck the TPS once more; if the

readings are correct, reconnect the TPS

electrical connector. It is a good idea to lock

the TPS screws with paint or thread-locking

compound.

Airflow meter

General description

40The airflow meter is located on the air

intake duct. The airflow meter measures the

amount of air entering the engine. The ECU

uses this information to control fuel delivery. A

large volume of air indicates acceleration,

while a small volume of air indicates

deceleration or idle. Refer to Chapter 4 for all

the diagnostic checks and renewal

procedures for the airflow meter.

Ignition timing sensors

41Ignition timing is electronically-controlled

on Motronic systems, and is not adjustable.

During starting, a crankshaft position sensor

relays the crankshaft position to the ECU, and

an initial baseline ignition point is determined.

Once the engine is running, the ignition point

is continually changing based on the various

input signals to the ECU. Engine speed is

signalled by a speed sensor. Early Motronic

systems have the reference sensor and the

speed sensor mounted on the bellhousing

over the flywheel. Later Motronic systems

have a single sensor (pulse sensor) mounted

over the crankshaft pulley. This sensor

functions as a speed sensor as well as a

position sensor. Refer to Chapter 5 for more

information. Note: Some models are

equipped with a TDC sensor mounted on the

front of the engine. This sensor is strictly for

the BMW service test unit, and it is not part of

the Motronic ignition system.

5 Positive crankcase

ventilation (PCV) system

1The Positive Crankcase Ventilation (PCV)

system (see illustration)reduces

hydrocarbon emissions by scavenging

crankcase vapours. It does this by circulating

blow-by gases and then re-routing them to

the intake manifold by way of the air cleaner.

2This PCV system is a sealed system. The

crankcase blow-by vapours are routed

directly to the air cleaner or air collector with

crankcase pressure behind them. The vapour

is not purged with fresh air on most models or

6•4 Engine management and emission control systems

5.2 PCV hose being removed from the

valve cover5.1 Diagram of the PCV system on the

M20 engine (others similar)4.34 Idle position switch and TPS on early

535i models with automatic transmission

4.28c . . . then check for continuity

between terminals 3 and 18 as the throttle

is opened

Page 127 of 228

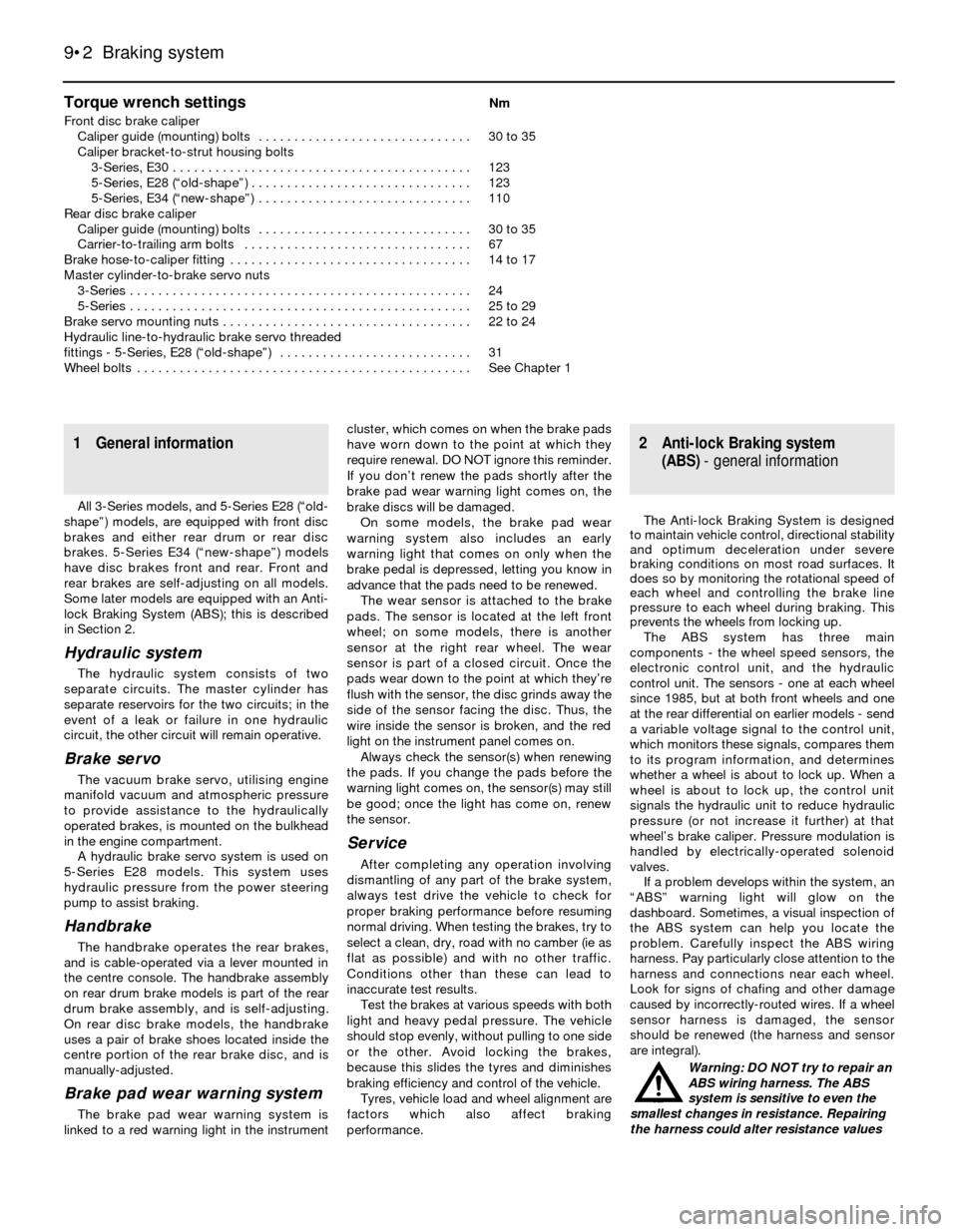

filtered with a flame trap like most

conventional systems. There are no

conventional PCV valves fitted on these

systems - just a hose (see illustration).

3The main components of the PCV system

are the hoses that connect the valve cover to

the throttle body or air cleaner. If abnormal

operating conditions (such as piston ring

problems) arise, the system is designed to

allow excessive amounts of blow-by gases to

flow back through the crankcase vent tube

into the intake system, to be consumed by

normal combustion. Note: Since these

models don’t use a filtering element, it’s a

good idea to check the PCV system

passageways for clogging from sludge and

combustion residue(see illustration).

6 Evaporative emissions

control (EVAP) system

2

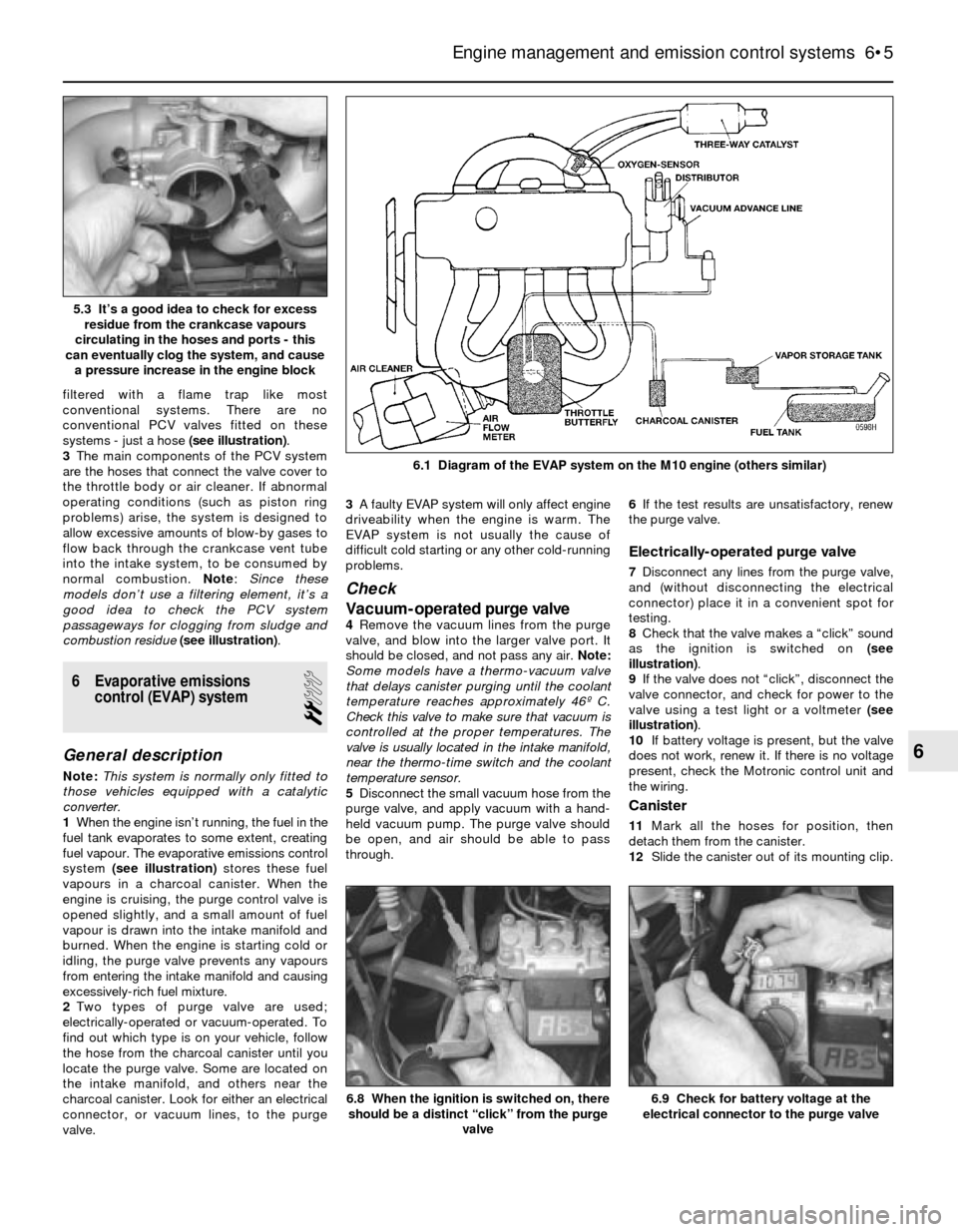

General description

Note:This system is normally only fitted to

those vehicles equipped with a catalytic

converter.

1When the engine isn’t running, the fuel in the

fuel tank evaporates to some extent, creating

fuel vapour. The evaporative emissions control

system (see illustration)stores these fuel

vapours in a charcoal canister. When the

engine is cruising, the purge control valve is

opened slightly, and a small amount of fuel

vapour is drawn into the intake manifold and

burned. When the engine is starting cold or

idling, the purge valve prevents any vapours

from entering the intake manifold and causing

excessively-rich fuel mixture.

2Two types of purge valve are used;

electrically-operated or vacuum-operated. To

find out which type is on your vehicle, follow

the hose from the charcoal canister until you

locate the purge valve. Some are located on

the intake manifold, and others near the

charcoal canister. Look for either an electrical

connector, or vacuum lines, to the purge

valve.3A faulty EVAP system will only affect engine

driveability when the engine is warm. The

EVAP system is not usually the cause of

difficult cold starting or any other cold-running

problems.

Check

Vacuum-operated purge valve

4Remove the vacuum lines from the purge

valve, and blow into the larger valve port. It

should be closed, and not pass any air. Note:

Some models have a thermo-vacuum valve

that delays canister purging until the coolant

temperature reaches approximately 46º C.

Check this valve to make sure that vacuum is

controlled at the proper temperatures. The

valve is usually located in the intake manifold,

near the thermo-time switch and the coolant

temperature sensor.

5Disconnect the small vacuum hose from the

purge valve, and apply vacuum with a hand-

held vacuum pump. The purge valve should

be open, and air should be able to pass

through.6If the test results are unsatisfactory, renew

the purge valve.

Electrically-operated purge valve

7Disconnect any lines from the purge valve,

and (without disconnecting the electrical

connector) place it in a convenient spot for

testing.

8Check that the valve makes a “click” sound

as the ignition is switched on (see

illustration).

9If the valve does not “click”, disconnect the

valve connector, and check for power to the

valve using a test light or a voltmeter (see

illustration).

10If battery voltage is present, but the valve

does not work, renew it. If there is no voltage

present, check the Motronic control unit and

the wiring.

Canister

11Mark all the hoses for position, then

detach them from the canister.

12Slide the canister out of its mounting clip.

Engine management and emission control systems 6•5

6.1 Diagram of the EVAP system on the M10 engine (others similar)

6.9 Check for battery voltage at the

electrical connector to the purge valve6.8 When the ignition is switched on, there

should be a distinct “click” from the purge

valve

6

5.3 It’s a good idea to check for excess

residue from the crankcase vapours

circulating in the hoses and ports - this

can eventually clog the system, and cause

a pressure increase in the engine block

Page 130 of 228

Torque wrench settingsNm

Front disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Caliper bracket-to-strut housing bolts

3-Series, E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Rear disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Carrier-to-trailing arm bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Brake hose-to-caliper fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 to 17

Master cylinder-to-brake servo nuts

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 29

Brake servo mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24

Hydraulic line-to-hydraulic brake servo threaded

fittings - 5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

9•2 Braking system

1 General information

All 3-Series models, and 5-Series E28 (“old-

shape”) models, are equipped with front disc

brakes and either rear drum or rear disc

brakes. 5-Series E34 (“new-shape”) models

have disc brakes front and rear. Front and

rear brakes are self-adjusting on all models.

Some later models are equipped with an Anti-

lock Braking System (ABS); this is described

in Section 2.

Hydraulic system

The hydraulic system consists of two

separate circuits. The master cylinder has

separate reservoirs for the two circuits; in the

event of a leak or failure in one hydraulic

circuit, the other circuit will remain operative.

Brake servo

The vacuum brake servo, utilising engine

manifold vacuum and atmospheric pressure

to provide assistance to the hydraulically

operated brakes, is mounted on the bulkhead

in the engine compartment.

A hydraulic brake servo system is used on

5-Series E28 models. This system uses

hydraulic pressure from the power steering

pump to assist braking.

Handbrake

The handbrake operates the rear brakes,

and is cable-operated via a lever mounted in

the centre console. The handbrake assembly

on rear drum brake models is part of the rear

drum brake assembly, and is self-adjusting.

On rear disc brake models, the handbrake

uses a pair of brake shoes located inside the

centre portion of the rear brake disc, and is

manually-adjusted.

Brake pad wear warning system

The brake pad wear warning system is

linked to a red warning light in the instrumentcluster, which comes on when the brake pads

have worn down to the point at which they

require renewal. DO NOT ignore this reminder.

If you don’t renew the pads shortly after the

brake pad wear warning light comes on, the

brake discs will be damaged.

On some models, the brake pad wear

warning system also includes an early

warning light that comes on only when the

brake pedal is depressed, letting you know in

advance that the pads need to be renewed.

The wear sensor is attached to the brake

pads. The sensor is located at the left front

wheel; on some models, there is another

sensor at the right rear wheel. The wear

sensor is part of a closed circuit. Once the

pads wear down to the point at which they’re

flush with the sensor, the disc grinds away the

side of the sensor facing the disc. Thus, the

wire inside the sensor is broken, and the red

light on the instrument panel comes on.

Always check the sensor(s) when renewing

the pads. If you change the pads before the

warning light comes on, the sensor(s) may still

be good; once the light has come on, renew

the sensor.

Service

After completing any operation involving

dismantling of any part of the brake system,

always test drive the vehicle to check for

proper braking performance before resuming

normal driving. When testing the brakes, try to

select a clean, dry, road with no camber (ie as

flat as possible) and with no other traffic.

Conditions other than these can lead to

inaccurate test results.

Test the brakes at various speeds with both

light and heavy pedal pressure. The vehicle

should stop evenly, without pulling to one side

or the other. Avoid locking the brakes,

because this slides the tyres and diminishes

braking efficiency and control of the vehicle.

Tyres, vehicle load and wheel alignment are

factors which also affect braking

performance.

2 Anti-lock Braking system

(ABS)- general information

The Anti-lock Braking System is designed

to maintain vehicle control, directional stability

and optimum deceleration under severe

braking conditions on most road surfaces. It

does so by monitoring the rotational speed of

each wheel and controlling the brake line

pressure to each wheel during braking. This

prevents the wheels from locking up.

The ABS system has three main

components - the wheel speed sensors, the

electronic control unit, and the hydraulic

control unit. The sensors - one at each wheel

since 1985, but at both front wheels and one

at the rear differential on earlier models - send

a variable voltage signal to the control unit,

which monitors these signals, compares them

to its program information, and determines

whether a wheel is about to lock up. When a

wheel is about to lock up, the control unit

signals the hydraulic unit to reduce hydraulic

pressure (or not increase it further) at that

wheel’s brake caliper. Pressure modulation is

handled by electrically-operated solenoid

valves.

If a problem develops within the system, an

“ABS” warning light will glow on the

dashboard. Sometimes, a visual inspection of

the ABS system can help you locate the

problem. Carefully inspect the ABS wiring

harness. Pay particularly close attention to the

harness and connections near each wheel.

Look for signs of chafing and other damage

caused by incorrectly-routed wires. If a wheel

sensor harness is damaged, the sensor

should be renewed (the harness and sensor

are integral).

Warning: DO NOT try to repair an

ABS wiring harness. The ABS

system is sensitive to even the

smallest changes in resistance. Repairing

the harness could alter resistance values

Page 137 of 228

friction surfaces of the brake shoes or

drums.

12Make sure the adjuster assembly is

properly engaged with its respective notch in

the handbrake lever.

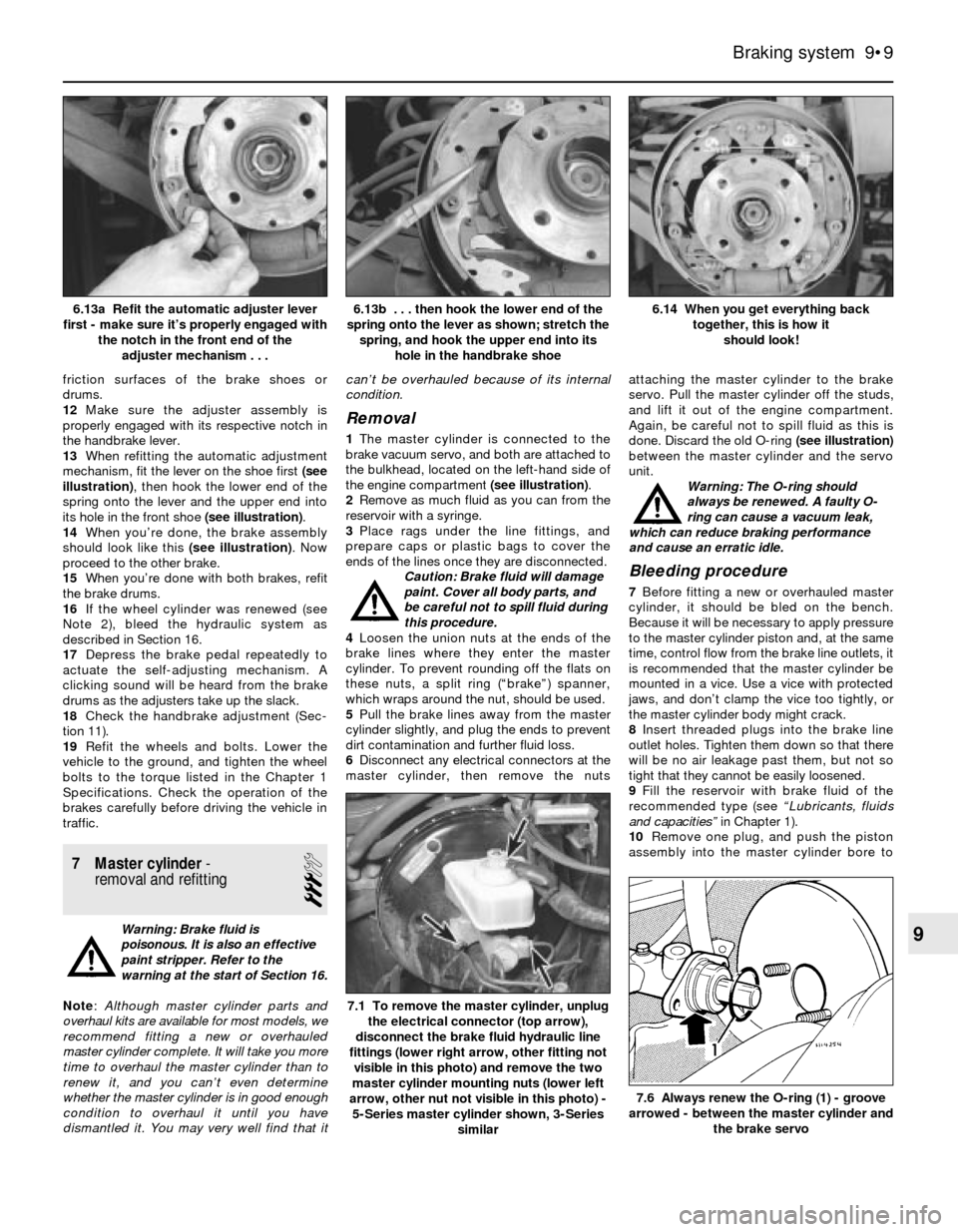

13When refitting the automatic adjustment

mechanism, fit the lever on the shoe first (see

illustration), then hook the lower end of the

spring onto the lever and the upper end into

its hole in the front shoe (see illustration).

14When you’re done, the brake assembly

should look like this (see illustration). Now

proceed to the other brake.

15When you’re done with both brakes, refit

the brake drums.

16If the wheel cylinder was renewed (see

Note 2), bleed the hydraulic system as

described in Section 16.

17Depress the brake pedal repeatedly to

actuate the self-adjusting mechanism. A

clicking sound will be heard from the brake

drums as the adjusters take up the slack.

18Check the handbrake adjustment (Sec-

tion 11).

19Refit the wheels and bolts. Lower the

vehicle to the ground, and tighten the wheel

bolts to the torque listed in the Chapter 1

Specifications. Check the operation of the

brakes carefully before driving the vehicle in

traffic.

7 Master cylinder-

removal and refitting

3

Warning: Brake fluid is

poisonous. It is also an effective

paint stripper. Refer to the

warning at the start of Section 16.

Note: Although master cylinder parts and

overhaul kits are available for most models, we

recommend fitting a new or overhauled

master cylinder complete. It will take you more

time to overhaul the master cylinder than to

renew it, and you can’t even determine

whether the master cylinder is in good enough

condition to overhaul it until you have

dismantled it. You may very well find that itcan’t be overhauled because of its internal

condition.

Removal

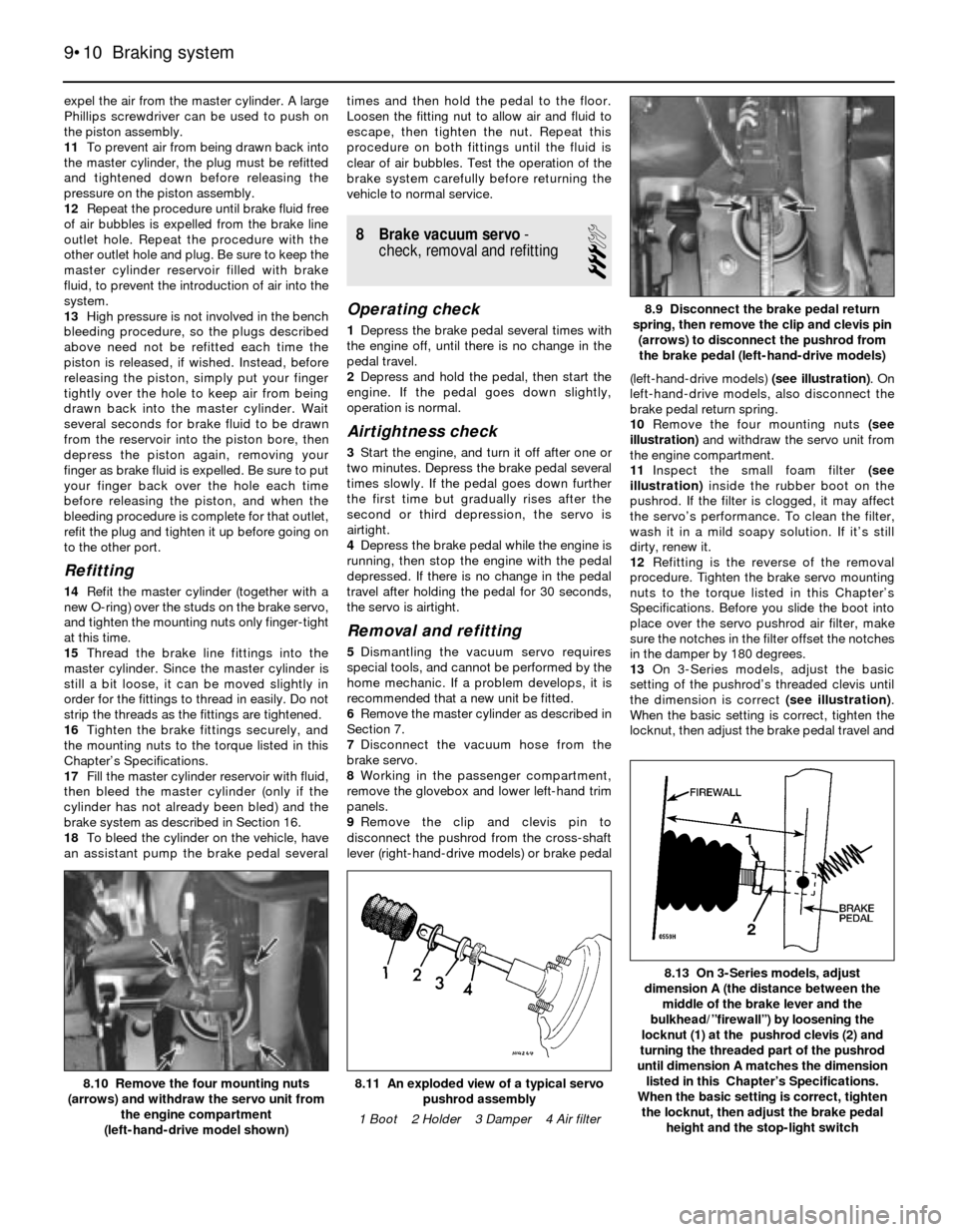

1The master cylinder is connected to the

brake vacuum servo, and both are attached to

the bulkhead, located on the left-hand side of

the engine compartment (see illustration).

2Remove as much fluid as you can from the

reservoir with a syringe.

3Place rags under the line fittings, and

prepare caps or plastic bags to cover the

ends of the lines once they are disconnected.

Caution: Brake fluid will damage

paint. Cover all body parts, and

be careful not to spill fluid during

this procedure.

4Loosen the union nuts at the ends of the

brake lines where they enter the master

cylinder. To prevent rounding off the flats on

these nuts, a split ring (“brake”) spanner,

which wraps around the nut, should be used.

5Pull the brake lines away from the master

cylinder slightly, and plug the ends to prevent

dirt contamination and further fluid loss.

6Disconnect any electrical connectors at the

master cylinder, then remove the nutsattaching the master cylinder to the brake

servo. Pull the master cylinder off the studs,

and lift it out of the engine compartment.

Again, be careful not to spill fluid as this is

done. Discard the old O-ring (see illustration)

between the master cylinder and the servo

unit.

Warning: The O-ring should

always be renewed. A faulty O-

ring can cause a vacuum leak,

which can reduce braking performance

and cause an erratic idle.

Bleeding procedure

7Before fitting a new or overhauled master

cylinder, it should be bled on the bench.

Because it will be necessary to apply pressure

to the master cylinder piston and, at the same

time, control flow from the brake line outlets, it

is recommended that the master cylinder be

mounted in a vice. Use a vice with protected

jaws, and don’t clamp the vice too tightly, or

the master cylinder body might crack.

8Insert threaded plugs into the brake line

outlet holes. Tighten them down so that there

will be no air leakage past them, but not so

tight that they cannot be easily loosened.

9Fill the reservoir with brake fluid of the

recommended type (see “Lubricants, fluids

and capacities” in Chapter 1).

10Remove one plug, and push the piston

assembly into the master cylinder bore to

Braking system 9•9

6.14 When you get everything back

together, this is how it

should look! 6.13b . . . then hook the lower end of the

spring onto the lever as shown; stretch the

spring, and hook the upper end into its

hole in the handbrake shoe6.13a Refit the automatic adjuster lever

first - make sure it’s properly engaged with

the notch in the front end of the

adjuster mechanism . . .

7.6 Always renew the O-ring (1) - groove

arrowed - between the master cylinder and

the brake servo

7.1 To remove the master cylinder, unplug

the electrical connector (top arrow),

disconnect the brake fluid hydraulic line

fittings (lower right arrow, other fitting not

visible in this photo) and remove the two

master cylinder mounting nuts (lower left

arrow, other nut not visible in this photo) -

5-Series master cylinder shown, 3-Series

similar

9

Page 138 of 228

expel the air from the master cylinder. A large

Phillips screwdriver can be used to push on

the piston assembly.

11To prevent air from being drawn back into

the master cylinder, the plug must be refitted

and tightened down before releasing the

pressure on the piston assembly.

12Repeat the procedure until brake fluid free

of air bubbles is expelled from the brake line

outlet hole. Repeat the procedure with the

other outlet hole and plug. Be sure to keep the

master cylinder reservoir filled with brake

fluid, to prevent the introduction of air into the

system.

13High pressure is not involved in the bench

bleeding procedure, so the plugs described

above need not be refitted each time the

piston is released, if wished. Instead, before

releasing the piston, simply put your finger

tightly over the hole to keep air from being

drawn back into the master cylinder. Wait

several seconds for brake fluid to be drawn

from the reservoir into the piston bore, then

depress the piston again, removing your

finger as brake fluid is expelled. Be sure to put

your finger back over the hole each time

before releasing the piston, and when the

bleeding procedure is complete for that outlet,

refit the plug and tighten it up before going on

to the other port.

Refitting

14Refit the master cylinder (together with a

new O-ring) over the studs on the brake servo,

and tighten the mounting nuts only finger-tight

at this time.

15Thread the brake line fittings into the

master cylinder. Since the master cylinder is

still a bit loose, it can be moved slightly in

order for the fittings to thread in easily. Do not

strip the threads as the fittings are tightened.

16Tighten the brake fittings securely, and

the mounting nuts to the torque listed in this

Chapter’s Specifications.

17Fill the master cylinder reservoir with fluid,

then bleed the master cylinder (only if the

cylinder has not already been bled) and the

brake system as described in Section 16.

18To bleed the cylinder on the vehicle, have

an assistant pump the brake pedal severaltimes and then hold the pedal to the floor.

Loosen the fitting nut to allow air and fluid to

escape, then tighten the nut. Repeat this

procedure on both fittings until the fluid is

clear of air bubbles. Test the operation of the

brake system carefully before returning the

vehicle to normal service.

8 Brake vacuum servo-

check, removal and refitting

3

Operating check

1Depress the brake pedal several times with

the engine off, until there is no change in the

pedal travel.

2Depress and hold the pedal, then start the

engine. If the pedal goes down slightly,

operation is normal.

Airtightness check

3Start the engine, and turn it off after one or

two minutes. Depress the brake pedal several

times slowly. If the pedal goes down further

the first time but gradually rises after the

second or third depression, the servo is

airtight.

4Depress the brake pedal while the engine is

running, then stop the engine with the pedal

depressed. If there is no change in the pedal

travel after holding the pedal for 30 seconds,

the servo is airtight.

Removal and refitting

5Dismantling the vacuum servo requires

special tools, and cannot be performed by the

home mechanic. If a problem develops, it is

recommended that a new unit be fitted.

6Remove the master cylinder as described in

Section 7.

7Disconnect the vacuum hose from the

brake servo.

8Working in the passenger compartment,

remove the glovebox and lower left-hand trim

panels.

9Remove the clip and clevis pin to

disconnect the pushrod from the cross-shaft

lever (right-hand-drive models) or brake pedal(left-hand-drive models) (see illustration). On

left-hand-drive models, also disconnect the

brake pedal return spring.

10Remove the four mounting nuts (see

illustration)and withdraw the servo unit from

the engine compartment.

11Inspect the small foam filter (see

illustration)inside the rubber boot on the

pushrod. If the filter is clogged, it may affect

the servo’s performance. To clean the filter,

wash it in a mild soapy solution. If it’s still

dirty, renew it.

12Refitting is the reverse of the removal

procedure. Tighten the brake servo mounting

nuts to the torque listed in this Chapter’s

Specifications. Before you slide the boot into

place over the servo pushrod air filter, make

sure the notches in the filter offset the notches

in the damper by 180 degrees.

13On 3-Series models, adjust the basic

setting of the pushrod’s threaded clevis until

the dimension is correct (see illustration).

When the basic setting is correct, tighten the

locknut, then adjust the brake pedal travel and

9•10 Braking system

8.13 On 3-Series models, adjust

dimension A (the distance between the

middle of the brake lever and the

bulkhead/”firewall”) by loosening the

locknut (1) at the pushrod clevis (2) and

turning the threaded part of the pushrod

until dimension A matches the dimension

listed in this Chapter’s Specifications.

When the basic setting is correct, tighten

the locknut, then adjust the brake pedal

height and the stop-light switch

8.11 An exploded view of a typical servo

pushrod assembly

1 Boot 2 Holder 3 Damper 4 Air filter8.10 Remove the four mounting nuts

(arrows) and withdraw the servo unit from

the engine compartment

(left-hand-drive model shown)

8.9 Disconnect the brake pedal return

spring, then remove the clip and clevis pin

(arrows) to disconnect the pushrod from

the brake pedal (left-hand-drive models)

Page 142 of 228

simply unscrew it. Plug the open fitting in the

caliper if the hose is removed for any length of

time, to prevent dirt ingress.

5Refitting is the reverse of the removal

procedure. Make sure the brackets are in

good condition and the locknuts are securely

tightened. Renew the spring clips if they don’t

fit tightly.

6Carefully check to make sure the

suspension and steering components do not

make contact with the hoses. Have an

assistant turn the steering wheel from lock-to-

lock during inspection.

7Bleed the brake system as described in

Section 16.

Metal brake line renewal

8When renewing brake lines, use genuine

parts only - preferably from a BMW dealer.

9Genuine BMW brake lines are supplied

straight. You’ll need a pipe-bending tool to

bend them to the proper shape.

10First, remove the line you intend to renew,

lay it on a clean workbench and measure it

carefully. Obtain a new line of the same

length, and bend it to match the pattern of the

old line.

Warning: Do not crimp or

damage the line. No bend should

have a smaller radius than

14 mm. Make sure the protective

coating on the new line is undamaged at

the bends.

11When fitting the new line, make sure it’s

well supported by the brackets, that the

routing matches the original, and that there’s

plenty of clearance between movable

components or those components which will

become hot.

12After refitting, check the master cylinder

fluid level, and add fluid as necessary. Bleed

the brake system as outlined in Section 16,

and test the brakes carefully before driving the

vehicle. Be sure there are no leaks.

16 Brake hydraulic system-

bleeding

3

Warning: Wear eye protection

when bleeding the brake system.

If the fluid comes in contact with

your eyes, immediately rinse

them with water, and seek medical

attention. Most types of brake fluid are

highly flammable, and may ignite if spilled

onto hot engine components, for example.

In this respect, brake fluid should be

treated with as much care as if it were

petrol. When topping-up or renewing the

fluid, always use the recommended type,

and ensure that it comes from a freshly-

opened sealed container. Never re-use old

brake fluid bled from the system, and don’t

top-up with fluid which has been standing

open for a long time, as it is potentially

dangerous to do so.

Note:Bleeding the hydraulic system is

necessary to remove any air which has

entered the system during removal and

refitting of a hose, line, caliper or master

cylinder.

1It will probably be necessary to bleed the

system at all four brakes if air has entered the

system due to low fluid level, or if the brake

lines have been disconnected at the master

cylinder.

2If a brake line was disconnected at only one

wheel, then only that caliper or wheel cylinder

need be bled.

3If a brake line is disconnected at a fitting

located between the master cylinder and any

of the brakes, that part of the system served

by the disconnected line must be bled.

4Bleed the right rear, the left rear, the right

front and the left front brake, in that order,

when the entire system is involved.

5Remove any residual vacuum from the

brake servo by applying the brakes about 30

times with the engine off. This will also relieve

any pressure in the anti-lock brake system

(where applicable).

6Remove the master cylinder reservoir

cover, and fill the reservoir with brake fluid.

Refit the cover. Note:Check the fluid level

often during the bleeding operation, and add

fluid as necessary to prevent the fluid level

from falling low enough to allow air into the

master cylinder.

7Have an assistant on hand, an empty clear

plastic container, and a length of clear plastic

or vinyl tubing to fit over the bleed screws.

Alternatively, a “one-man” bleeding kit can be

used. A “one-man” kit usually contains a tubeor bottle with a one-way valve incorporated -

in this way, the pedal can be pumped as

normal, but air is not drawn back into the

system when the pedal is released. If a one-

man kit is used, follow the instructions

provided with it; similarly with pressure

bleeding kits. In any case, you will also need a

supply of new brake fluid of the

recommended type, and a spanner for the

bleed screw.

8Beginning at the right rear wheel, loosen the

bleed screw slightly, then tighten it to a point

where it is tight but can still be loosened

quickly and easily.

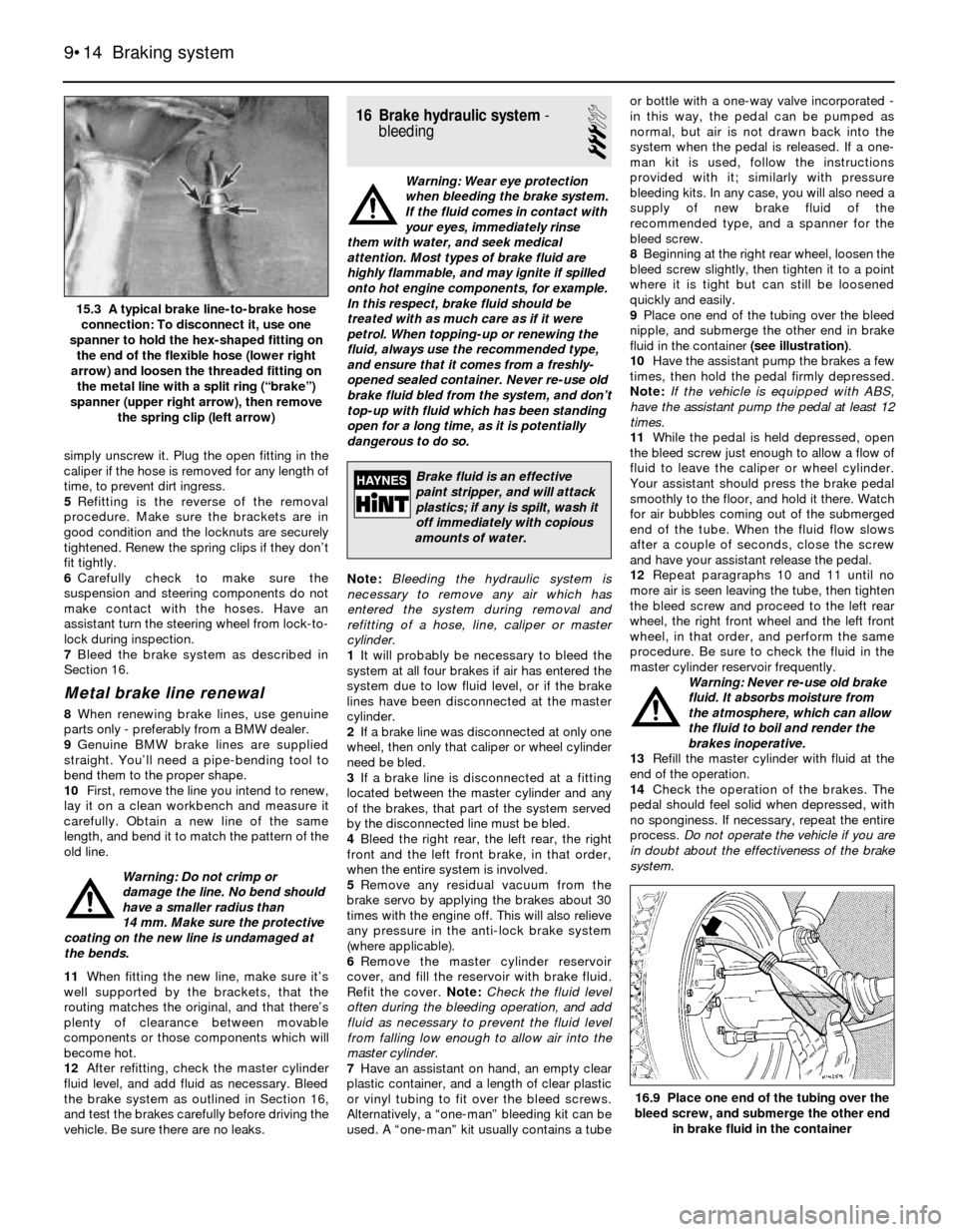

9Place one end of the tubing over the bleed

nipple, and submerge the other end in brake

fluid in the container (see illustration).

10Have the assistant pump the brakes a few

times, then hold the pedal firmly depressed.

Note:If the vehicle is equipped with ABS,

have the assistant pump the pedal at least 12

times.

11While the pedal is held depressed, open

the bleed screw just enough to allow a flow of

fluid to leave the caliper or wheel cylinder.

Your assistant should press the brake pedal

smoothly to the floor, and hold it there. Watch

for air bubbles coming out of the submerged

end of the tube. When the fluid flow slows

after a couple of seconds, close the screw

and have your assistant release the pedal.

12Repeat paragraphs 10 and 11 until no

more air is seen leaving the tube, then tighten

the bleed screw and proceed to the left rear

wheel, the right front wheel and the left front

wheel, in that order, and perform the same

procedure. Be sure to check the fluid in the

master cylinder reservoir frequently.

Warning: Never re-use old brake

fluid. It absorbs moisture from

the atmosphere, which can allow

the fluid to boil and render the

brakes inoperative.

13Refill the master cylinder with fluid at the

end of the operation.

14Check the operation of the brakes. The

pedal should feel solid when depressed, with

no sponginess. If necessary, repeat the entire

process. Do not operate the vehicle if you are

in doubt about the effectiveness of the brake

system.

9•14 Braking system

16.9 Place one end of the tubing over the

bleed screw, and submerge the other end

in brake fluid in the container

15.3 A typical brake line-to-brake hose

connection: To disconnect it, use one

spanner to hold the hex-shaped fitting on

the end of the flexible hose (lower right

arrow) and loosen the threaded fitting on

the metal line with a split ring (“brake”)

spanner (upper right arrow), then remove

the spring clip (left arrow)

Brake fluid is an effective

paint stripper, and will attack

plastics; if any is spilt, wash it

off immediately with copious

amounts of water.

Page 155 of 228

Where power-assistance is fitted, hydraulic

pressure (provided by an engine-driven pump)

delivers power steering fluid to the rack-and-

pinion steering gear or the recirculating-ball

steering box - this enhances steering

response and reduces steering effort.

Aside from maintaining the proper level of

power steering fluid in the system and

checking the tension of the drivebelt (see

Chapter 1, where applicable), the steering

system requires no maintenance. However,

on high-mileage vehicles, the track rod end

balljoints, the universal joints on either end of

the universal joint shaft, and the rubber

coupling between the steering column and the

universal joint shaft will wear, develop

excessive play, and cause the steering to feel

somewhat loose. At this point, you’ll have to

renew these items; they can’t be serviced.

Before you conclude that the steering

system needs work, however, always check

the tyres (see Section 25) and tyre pressures

(see Chapter 1). Also inspect the bearings in

the strut upper mounts (see Section 5), the

front hub bearings (see Section 8) and other

suspension parts, which may also be

contributing to an imprecise steering feel.

17 Track rod ends-

removal and refitting

4

1Loosen but do not remove the wheel bolts,

then raise the front of the vehicle and secure it

on axle stands. Remove the front wheel.

3-Series models

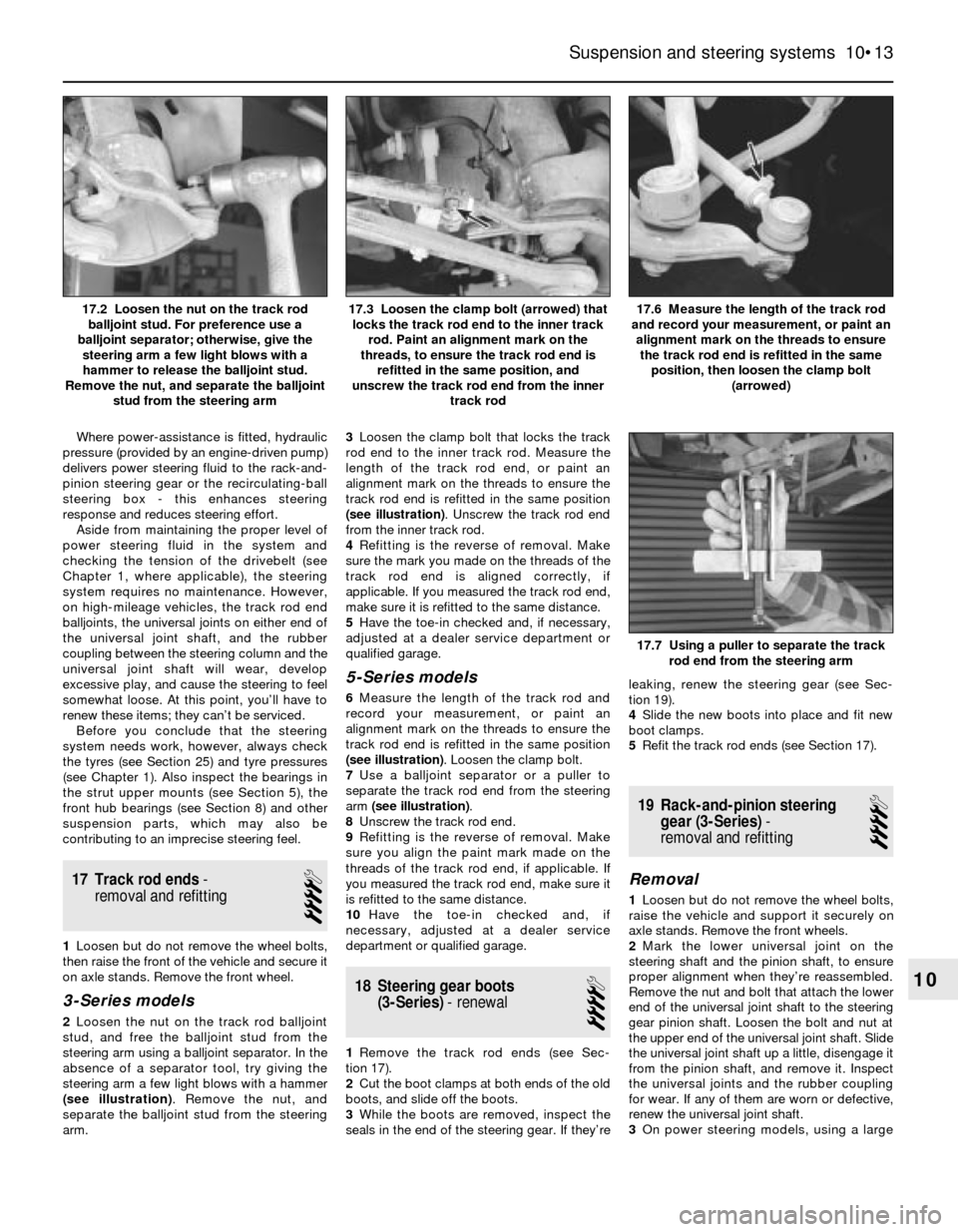

2Loosen the nut on the track rod balljoint

stud, and free the balljoint stud from the

steering arm using a balljoint separator. In the

absence of a separator tool, try giving the

steering arm a few light blows with a hammer

(see illustration). Remove the nut, and

separate the balljoint stud from the steering

arm.3Loosen the clamp bolt that locks the track

rod end to the inner track rod. Measure the

length of the track rod end, or paint an

alignment mark on the threads to ensure the

track rod end is refitted in the same position

(see illustration). Unscrew the track rod end

from the inner track rod.

4Refitting is the reverse of removal. Make

sure the mark you made on the threads of the

track rod end is aligned correctly, if

applicable. If you measured the track rod end,

make sure it is refitted to the same distance.

5Have the toe-in checked and, if necessary,

adjusted at a dealer service department or

qualified garage.

5-Series models

6Measure the length of the track rod and

record your measurement, or paint an

alignment mark on the threads to ensure the

track rod end is refitted in the same position

(see illustration). Loosen the clamp bolt.

7Use a balljoint separator or a puller to

separate the track rod end from the steering

arm (see illustration).

8Unscrew the track rod end.

9Refitting is the reverse of removal. Make

sure you align the paint mark made on the

threads of the track rod end, if applicable. If

you measured the track rod end, make sure it

is refitted to the same distance.

10Have the toe-in checked and, if

necessary, adjusted at a dealer service

department or qualified garage.

18 Steering gear boots

(3-Series)- renewal

4

1Remove the track rod ends (see Sec-

tion 17).

2Cut the boot clamps at both ends of the old

boots, and slide off the boots.

3While the boots are removed, inspect the

seals in the end of the steering gear. If they’releaking, renew the steering gear (see Sec-

tion 19).

4Slide the new boots into place and fit new

boot clamps.

5Refit the track rod ends (see Section 17).

19 Rack-and-pinion steering

gear (3-Series)-

removal and refitting

4

Removal

1Loosen but do not remove the wheel bolts,

raise the vehicle and support it securely on

axle stands. Remove the front wheels.

2Mark the lower universal joint on the

steering shaft and the pinion shaft, to ensure

proper alignment when they’re reassembled.

Remove the nut and bolt that attach the lower

end of the universal joint shaft to the steering

gear pinion shaft. Loosen the bolt and nut at

the upper end of the universal joint shaft. Slide

the universal joint shaft up a little, disengage it

from the pinion shaft, and remove it. Inspect

the universal joints and the rubber coupling

for wear. If any of them are worn or defective,

renew the universal joint shaft.

3On power steering models, using a large

Suspension and steering systems 10•13

17.6 Measure the length of the track rod

and record your measurement, or paint an

alignment mark on the threads to ensure

the track rod end is refitted in the same

position, then loosen the clamp bolt

(arrowed)17.3 Loosen the clamp bolt (arrowed) that

locks the track rod end to the inner track

rod. Paint an alignment mark on the

threads, to ensure the track rod end is

refitted in the same position, and

unscrew the track rod end from the inner

track rod17.2 Loosen the nut on the track rod

balljoint stud. For preference use a

balljoint separator; otherwise, give the

steering arm a few light blows with a

hammer to release the balljoint stud.

Remove the nut, and separate the balljoint

stud from the steering arm

17.7 Using a puller to separate the track

rod end from the steering arm

10

Page 169 of 228

12

Chapter 12 Body electrical systems

Bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Central locking system - description and check . . . . . . . . . . . . . . . . 20

Cruise control system - description and check . . . . . . . . . . . . . . . . 19

Direction indicator/hazard warning flasher - check and renewal . . . 5

Electric windows - description and check . . . . . . . . . . . . . . . . . . . . 21

Electrical system fault finding - general information . . . . . . . . . . . . . 2

Fuses - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight housing - removal and refitting . . . . . . . . . . . . . . . . . . . . . 14

Headlights - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Headlights - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Heated rear window - check and repair . . . . . . . . . . . . . . . . . . . . . . 17

Ignition switch - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Instrument cluster - removal and refitting . . . . . . . . . . . . . . . . . . . . . 10

Radio - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Radio aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Relays - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service Indicator (SI) board - general information . . . . . . . . . . . . . . 11

Steering column switches - removal and refitting . . . . . . . . . . . . . . . 6

Supplemental Restraint System (SRS) - general information . . . . . . 18

Windscreen/tailgate wiper motor - removal and refitting . . . . . . . . . 16

Wiring diagrams - general information . . . . . . . . . . . . . . . . . . . . . . . 22

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty Contents

1 General information

The chassis electrical system of this vehicle

is of 12-volt, negative earth type. Power for

the lights and all electrical accessories is

supplied by a lead/acid-type battery, which is

charged by the alternator.

This Chapter covers repair and service

procedures for various chassis (non-engine

related) electrical components. For

information regarding the engine electrical

system components (battery, alternator,

distributor and starter motor), see Chapter 5.

Warning: To prevent electrical

short-circuits, fires and injury,

always disconnect the battery

negative terminal before

checking, repairing or renewing electrical

components.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

2 Electrical system fault

finding- general information

2

A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links or circuit breakers,

etc related to that component, and the wiring

and connectors that link the components to

both the battery and the chassis. To help you

pinpoint an electrical circuit problem, wiring

diagrams are included at the end of this book.

Before tackling any troublesome electrical

circuit, first study the appropriate wiring

diagrams to get a complete understanding of

what makes up that individual circuit.

Troublespots, for instance, can often be

isolated by noting if other components related

to that circuit are routed through the same

fuse and earth connections.

Electrical problems usually stem from

simple causes such as loose or corroded

connectors, a blown fuse, a melted fusible

link, or a bad relay. Inspect all fuses, wires

and connectors in a problem circuit first.

The basic tools needed include a circuit

tester, a high-impedance digital voltmeter, a

continuity tester and a jumper wire with an in-

line circuit breaker for bypassing electrical

components. Before attempting to locate or

define a problem with electrical testinstruments, use the wiring diagrams to

decide where to make the necessary

connections.

Voltage checks

Perform a voltage check first when a circuit

is not functioning properly. Connect one lead

of a circuit tester to either the negative battery

terminal or a known good earth.

Connect the other lead to a connector in

the circuit being tested, preferably nearest to

the battery or fuse. If the bulb of the tester

lights up, voltage is present, which means that

the part of the circuit between the connector

and the battery is problem-free. Continue

checking the rest of the circuit in the same

fashion.

When you reach a point at which no voltage

is present, the problem lies between that point

and the last test point with voltage. Most of

the time, problems can be traced to a loose

connection.Note:Keep in mind that some

circuits receive voltage only when the ignition

key is turned to a certain position.

Electrical fault diagnosis is simple if you

keep in mind that all electrical circuits are

basically electricity running from the battery,

through the wires, switches, relays, fuses and

fusible links to each electrical component

(light bulb, motor, etc) and then to earth, from

where it is passed back to the battery. Any

electrical problem is an interruption in the flow

of electricity to and from the battery.

Page 170 of 228

Finding a short-circuit

One method of finding a short-circuit is to

remove the fuse and connect a test light or

voltmeter in its place. There should be no

voltage present in the circuit. Move the

electrical connectors from side-to-side while

watching the test light. If the bulb goes on,

there is a short to earth somewhere in that

area, probably where the insulation has been

rubbed through. The same test can be

performed on each component in a circuit,

even a switch.

Earth check

Perform a earth check to see whether a

component is properly earthed (passing

current back via the vehicle body). Disconnect

the battery, and connect one lead of a self-

powered test light (often known as a

continuity tester) to a known good earth.

Connect the other lead to the wire or earth

connection being tested. The bulb should

light, indicating a good earth connection. If

not, dismantle the connection, and clean all

relevant parts thoroughly. When re-making

the connection, use serrated (shakeproof)

washers if possible, and tighten all bolts, etc,

securely.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you have

the correct activation code

before disconnecting the battery, Refer to

the information on page 0-7 at the front of

this manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Continuity check

A continuity check determines if there are

any breaks in a circuit - if it is conducting

electricity properly. With the circuit off (no

power in the circuit), a self-powered continuity

tester can be used to check the circuit.

Connect the test leads to both ends of the

circuit, and if the test light comes on, the

circuit is passing current properly. If the light

doesn’t come on, there is a break somewhere

in the circuit. The same procedure can be

used to test a switch, by connecting the

continuity tester to the power-in and power-

out sides of the switch. With the switch turned

on, the test light should come on.

Finding an open-circuit

When diagnosing for possible open-

circuits, it is often difficult to locate them by

sight, because oxidation or terminal

misalignment are hidden by the connectors.

Intermittent problems are often caused by

oxidised or loose connections. Merely

wiggling an electrical connector may correct

the open-circuit condition, albeit temporarily.

Dismantle the connector, and spray with a

water-dispersant aerosol. On simpler

connectors, it may be possible to carefullybend the connector pins inside, to improve

the metal-to-metal contact - don’t damage

the connector in the process, however.

3 Fuses- general information

1

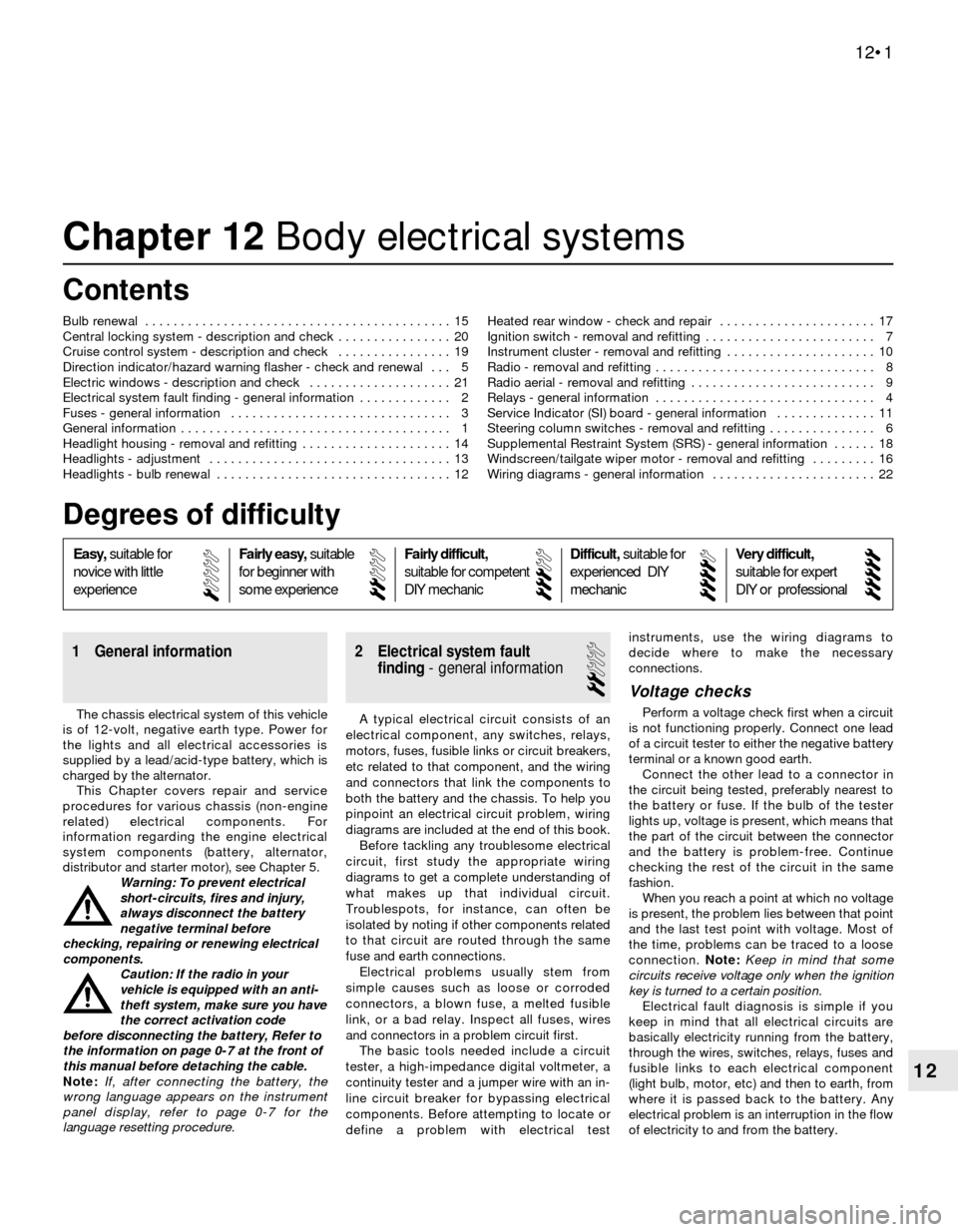

The electrical circuits of the vehicle are

protected by a combination of fuses and

circuit breakers. The fusebox is located in the

left corner of the engine compartment (see

illustration). On some later models, it is

located under the rear seat cushion.

Each of the fuses is designed to protect a

specific circuit, and on some models, the

various circuits are identified on the fuse

panel itself.

Miniaturised fuses are employed in the

fuseboxes. These compact fuses, with blade

terminal design, allow fingertip removal and

renewal. If an electrical component fails,

always check the fuse first. A blown fuse is

easily identified through the clear plastic

body. Visually inspect the element for

evidence of damage. If a continuity check is

called for, the blade terminal tips are exposed

in the fuse body.

Be sure to renew blown fuses with the

correct type. Fuses of different ratings are

physically interchangeable, but only fuses of

the proper rating should be used. Replacing a

fuse with one of a higher or lower value than

specified is not recommended. Each electrical

circuit needs a specific amount of protection.

The amperage value of each fuse is moulded

into the fuse body.

If the new fuse immediately fails, don’t

renew it again until the cause of the problem

is isolated and corrected. In most cases, the

cause will be a short-circuit in the wiring

caused by a broken or deteriorated wire.

4 Relays- general information

1

Several electrical accessories in the vehicle

use relays to transmit the electrical signal to

the component. If the relay is defective, thatcomponent will not operate properly. Relays

are electrically-operated switches, which are

often used in circuits drawing high levels of

current, or where more complex switching

arrangements are required.

The various relays are grouped together for

convenience in several locations under the

dash and in the engine compartment (see

accompanying illustration and illus-

tration 3.1).

If a faulty relay is suspected, it can be

removed and tested by a dealer or qualified

automotive electrician. No overhaul is

possible. Like fuses, defective relays must be

replaced with the correct type; some relays

look identical, but perform very different

functions.

5 Direction indicator/hazard

warning flasher unit- check

and renewal

2

Warning: Some later models are

equipped with an airbag or

Supplemental Restraint System

(SRS). To avoid possible damage

to this system, the manufacturer

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department, or

other specialist, because of the special

tools and techniques required. There is a

risk of injury if the airbag is accidentally

triggered.

1The direction indicator/hazard flasher unit is

a small canister- or box-shaped unit located

in the wiring harness on or near the steering

column. Access is gained by removing the

steering column shrouds (see illustration).

2When the flasher unit is functioning

properly, a regular clicking noise can be heard

from it when the indicators or hazard flashers

are switched on. If the direction indicators fail

on one side or the other, and the flasher unit

does not make its characteristic clicking

sound, a faulty direction indicator bulb is

indicated.

3If both direction indicators fail to blink, the

problem may be due to a blown fuse, a faulty

flasher unit, a broken switch or a loose or open

connection. If a quick check of the fusebox

12•2 Body electrical systems

4.2 Engine compartment relays3.1 The fusebox is located in the engine

compartment under a cover - the box also

includes several relays