compression ratio BMW 3 SERIES 1991 E30 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1991, Model line: 3 SERIES, Model: BMW 3 SERIES 1991 E30Pages: 228, PDF Size: 7.04 MB

Page 17 of 228

1 Introduction

This Chapter is designed to help the home

mechanic maintain his or her vehicle with the

goals of maximum performance, economy,

safety and reliability in mind. Included is a

master maintenance schedule, followed by

procedures dealing specifically with each item

on the schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of various components. Servicing the vehicle,

in accordance with the mileage/time

maintenance schedule and the step-by-step

procedures, will result in a planned

maintenance programme that should produce

a long and reliable service life. Keep in mind

that it is a comprehensive plan, so maintaining

some items but not others at specified

intervals, will not produce the same results.

2 Routine maintenance

As you service the vehicle, you will discover

that many of the procedures can - and should

- be grouped together, because of the nature

of the particular procedure you’re performing,

or because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for chassis lubrication, you should inspect the

exhaust, suspension, steering and fuelsystems while you’re under the vehicle. When

the wheels are removed for other work, it

makes good sense to check the brakes, since

the wheels are already removed. Finally, let’s

suppose you have to borrow a torque wrench.

Even if you only need it to tighten the spark

plugs, you might as well check the torque of

as many critical nuts and bolts as time allows.

The first step in this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the

procedures you’re planning to do, then gather

up all the parts and tools needed. If it looks

like you might run into problems during a

particular job, seek advice from a mechanic or

an experienced do-it-yourselfer.

3 Engine “tune-up”-

general information

The term “tune-up” is used in this manual to

represent a combination of individual

operations rather than one specific procedure.

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

More likely than not, however, there will be

times when the engine is running poorly due

to a lack of regular maintenance. This is even

more likely if a used vehicle, which has not

received regular and frequent maintenance

checks, is purchased. In such cases, an

engine tune-up will be needed outside of the

regular maintenance intervals. The first step in any tune-up or diagnostic

procedure to help correct a poor-running

engine is a cylinder compression check. A

compression check (see Chapter 2B) will help

determine the condition of internal engine

components, and should be used as a guide

for tune-up and repair procedures. If, for

instance, a compression check indicates

serious internal engine wear, a conventional

tune-up will not improve the performance of

the engine, and would be a waste of time and

money. Because of its importance, the

compression check should be done by

someone with the right equipment, and the

knowledge to use it properly.

The following procedures are those most

often needed to bring a generally poor-

running engine back into a proper state of

tune.

Minor tune-up

Check all engine-related fluids (Section 4)

Check all underbonnet hoses (Section 10)

Check and adjust the drivebelts (Sec-

tion 11)

Clean, inspect and test the battery (Sec-

tion 13)

Renew the spark plugs (Section 14)

Inspect the spark plug HT leads, distributor

cap and rotor (Section 15)

Check the air filter (Section 20)

Check the cooling system (Section 22)

Major tune-up

All items listed under minor tune-up, plus . . .

Check the ignition system (see Chapter 5)

Check the charging system (see Chapter 5)

Check the fuel system (see Chapter 4)

Renew the spark plug HT leads, distributor

cap and rotor (Section 15)

1•7

1

Routine Maintenance

Weekly checks

4 Fluid level checks

1

Note:The following are fluid level checks to

be done on a 250-mile or weekly basis.

Additional fluid level checks can be found in

specific maintenance procedures which

follow. Regardless of intervals, be alert to fluid

leaks under the vehicle, which would indicate

a fault to be corrected immediately.

1Fluids are an essential part of the

lubrication, cooling, brake and windscreen

washer systems. Because the fluids gradually

become depleted and/or contaminated during

normal operation of the vehicle, they must be

periodically replenished. See “Lubricants and

fluids”at the beginning of this Chapter before

adding fluid to any of the following

components. Note:The vehicle must be on

level ground when any fluid levels are

checked.

Engine oil

2Engine oil is checked with a dipstick, which

is located on the side of the engine (refer to

the underbonnet illustrations in this Chapter

for dipstick location). The dipstick extends

through a metal tube down into the sump.

3The engine oil should be checked before

the vehicle has been driven, or at least

15 minutes after the engine has been shut off.

4Pull the dipstick out of the tube, and wipe

all of the oil away from the end with a clean

rag or paper towel. Insert the clean dipstick all

the way back into the tube, and pull it out

again. Note the oil at the end of the dipstick.

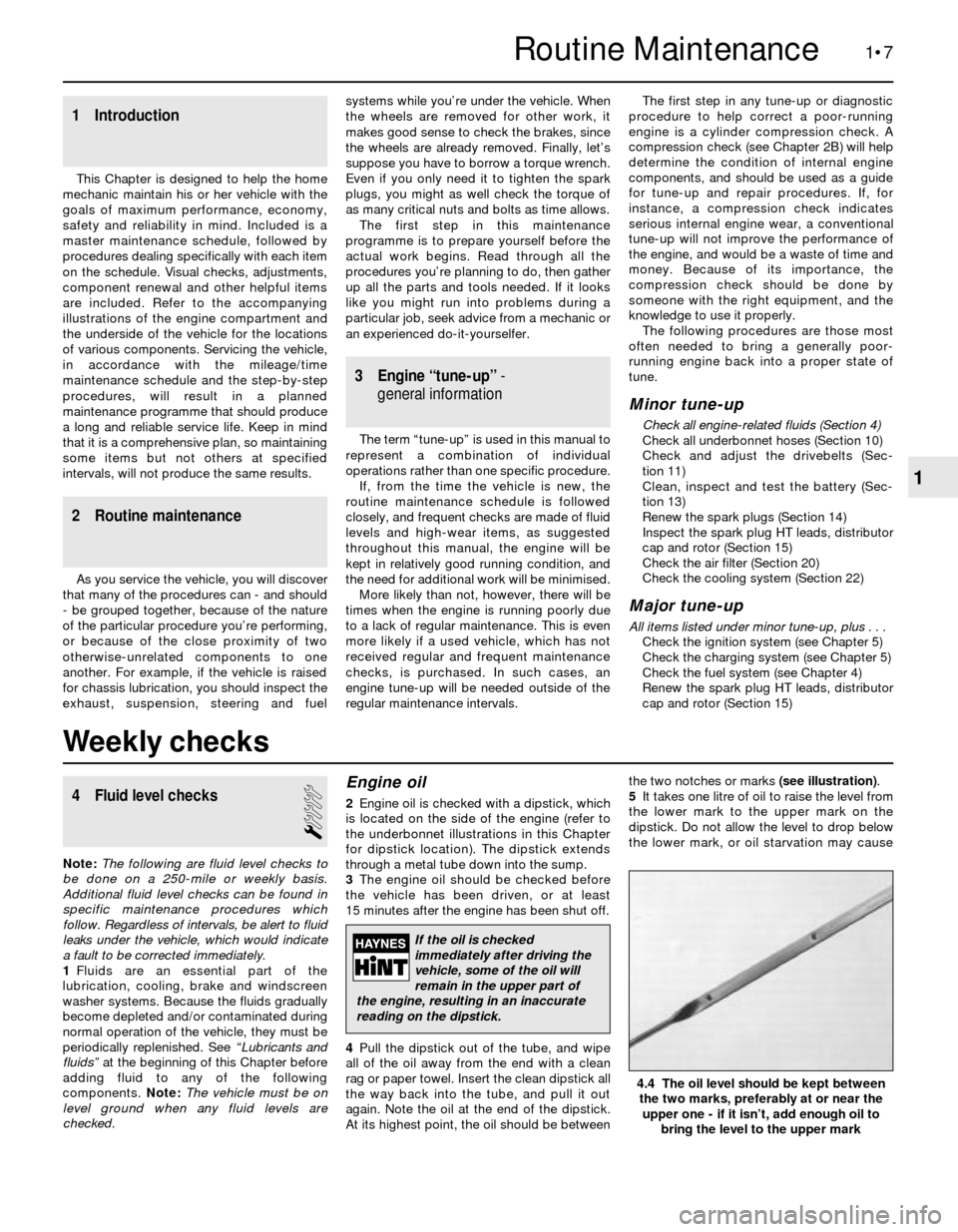

At its highest point, the oil should be betweenthe two notches or marks (see illustration).

5It takes one litre of oil to raise the level from

the lower mark to the upper mark on the

dipstick. Do not allow the level to drop below

the lower mark, or oil starvation may cause

4.4 The oil level should be kept between

the two marks, preferably at or near the

upper one - if it isn’t, add enough oil to

bring the level to the upper mark

If the oil is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper part of

the engine, resulting in an inaccurate

reading on the dipstick.

Page 29 of 228

them to the new cap in the exact same

location - do not simultaneously remove all

the HT leads, or firing order mix-ups may

occur.

16 Manual transmission

lubricant level check

1

1The transmission has a filler/level plug

which must be removed to check the lubricant

level. If the vehicle is raised to gain access to

the plug, be sure to support it safely - do not

crawl under a vehicle which is supported only

by a jack!Note:The vehicle should be level to

give an accurate lubricant check.

2Remove the plug from the side of thetransmission (see illustration)and use your

little finger to reach inside the plug from the

housing and feel the lubricant level. It should

be at or very near the bottom of the plug hole.

3If it isn’t, add the recommended lubricant

through the plug hole with a syringe or

squeeze-bottle, until it just starts to run out of

the hole. Refer to “Lubricants and fluids” at

the beginning of this Chapter for the correct

lubricant type. The manual transmissions on

some later or high-performance models are

filled with automatic transmission fluid (ATF).

Such transmissions normally carry a sticker to

this effect near the filler/level plug. Refer to a

BMW dealer if still in doubt.

4Refit the plug and tighten securely. Check

for leaks after the first few miles of driving.

5If regular topping-up is required, this can

only be due to a leak which should be found

and repaired before it becomes serious.17 Differential lubricant level

check

1

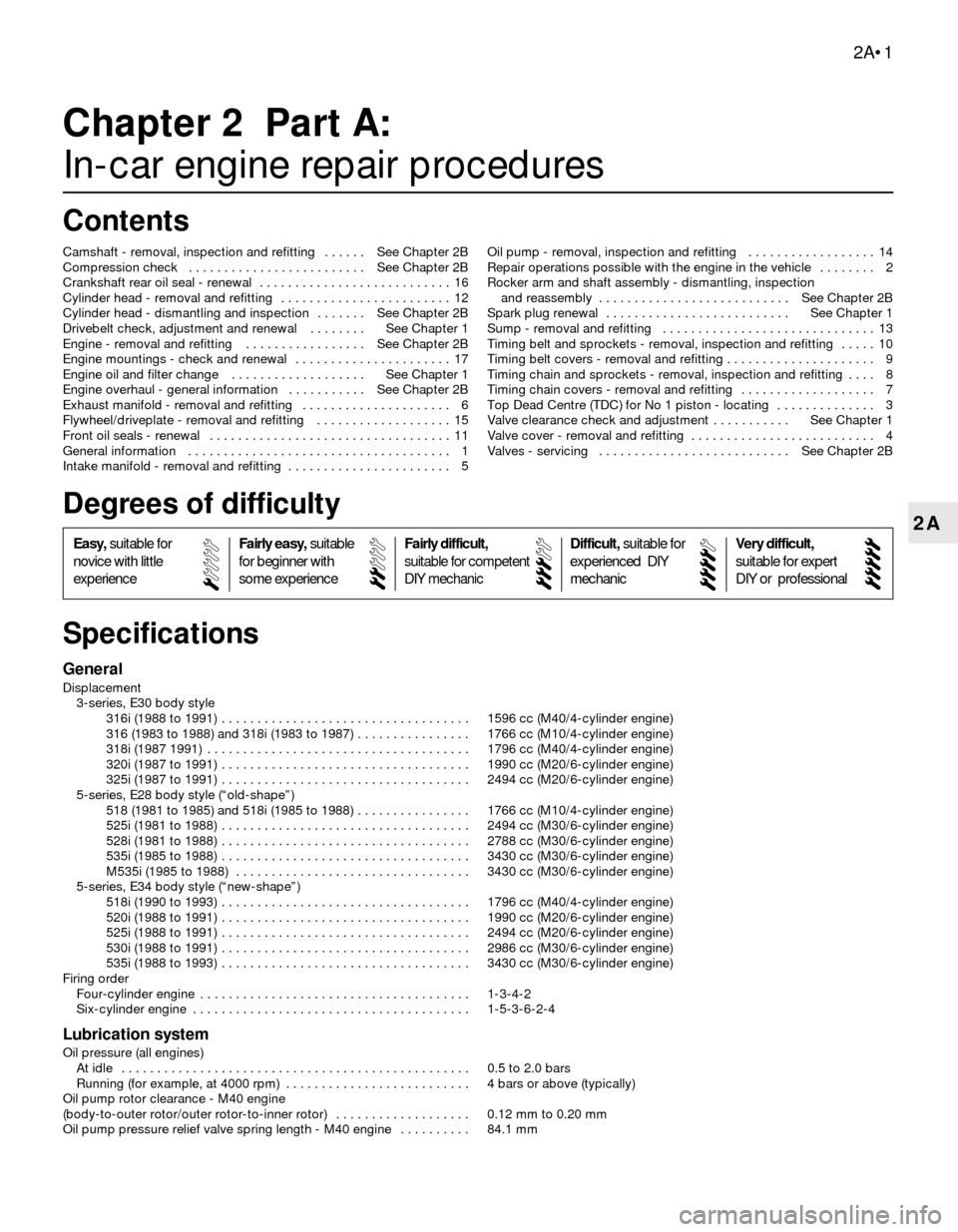

1The differential has a filler/level plug which

must be removed to check the lubricant level.

If the vehicle is raised to gain access to the

plug, be sure to support it safely - do notcrawl under the vehicle when it’s supported

only by the jack! Note:The vehicle should be

level to give an accurate lubricant check.

2Remove the filler/level plug from the

differential (see illustration). Use an Allen key

to unscrew the plug.

3Use your little finger as a dipstick to make

sure the lubricant level is up to the bottom of

the plug hole. If not, use a syringe or squeeze-

bottle to add the recommended lubricant until

it just starts to run out of the hole.

4Refit the plug and tighten it securely.

5If regular topping-up is required, this can

only be due to a leak which should be found

and repaired before it becomes serious.

18 Valve clearances -

check and adjustment

3

Note:This procedure does not apply to the

M40 engine, which has automatic adjusters.

1The valve clearances can be checked with

the engine hot or cold, but note that different

values are specified, depending on engine

temperature. If it is wished to check/adjust the

valve clearances with the engine hot, if

necessary start and run the engine until it

reaches normal operating temperature, then

shut it off.

Caution: If the clearances are checked

with the engine hot, extra care

must be taken to avoid burns.

2Remove the valve cover

from the engine (see Chapter 2A).

3Turn the engine as necessary until No 1

piston (front) is at Top Dead Centre (TDC) on

the compression stroke (see Chapter 2A).

4Check the valve clearances for No 1

cylinder. The valve clearances can be found in

the Specifications Section at the beginning of

this Chapter.

5The clearance is measured by inserting the

specified size feeler gauge between the end

of the valve stem and the rocker arm adjusting

eccentric. You should feel a slight amount of

1•19

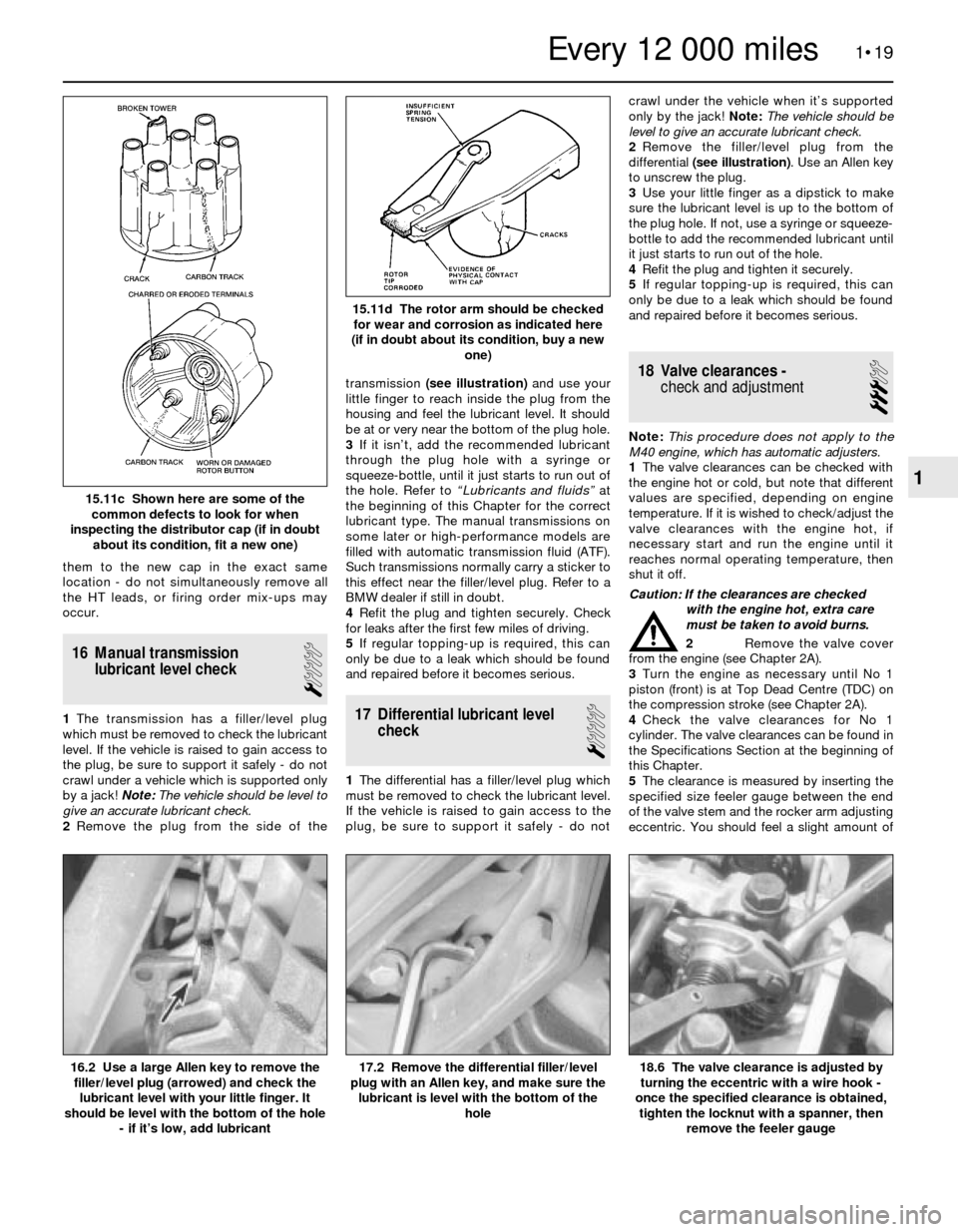

15.11d The rotor arm should be checked

for wear and corrosion as indicated here

(if in doubt about its condition, buy a new

one)

15.11c Shown here are some of the

common defects to look for when

inspecting the distributor cap (if in doubt

about its condition, fit a new one)

18.6 The valve clearance is adjusted by

turning the eccentric with a wire hook -

once the specified clearance is obtained,

tighten the locknut with a spanner, then

remove the feeler gauge17.2 Remove the differential filler/level

plug with an Allen key, and make sure the

lubricant is level with the bottom of the

hole16.2 Use a large Allen key to remove the

filler/level plug (arrowed) and check the

lubricant level with your little finger. It

should be level with the bottom of the hole

- if it’s low, add lubricant

1

Every 12 000 miles

Page 37 of 228

2A

General

Displacement

3-series, E30 body style

316i (1988 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1596 cc (M40/4-cylinder engine)

316 (1983 to 1988) and 318i (1983 to 1987) . . . . . . . . . . . . . . . . 1766 cc (M10/4-cylinder engine)

318i (1987 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1796 cc (M40/4-cylinder engine)

320i (1987 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1990 cc (M20/6-cylinder engine)

325i (1987 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2494 cc (M20/6-cylinder engine)

5-series, E28 body style (“old-shape”)

518 (1981 to 1985) and 518i (1985 to 1988) . . . . . . . . . . . . . . . . 1766 cc (M10/4-cylinder engine)

525i (1981 to 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2494 cc (M30/6-cylinder engine)

528i (1981 to 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2788 cc (M30/6-cylinder engine)

535i (1985 to 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3430 cc (M30/6-cylinder engine)

M535i (1985 to 1988) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3430 cc (M30/6-cylinder engine)

5-series, E34 body style (“new-shape”)

518i (1990 to 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1796 cc (M40/4-cylinder engine)

520i (1988 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1990 cc (M20/6-cylinder engine)

525i (1988 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2494 cc (M20/6-cylinder engine)

530i (1988 to 1991) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2986 cc (M30/6-cylinder engine)

535i (1988 to 1993) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3430 cc (M30/6-cylinder engine)

Firing order

Four-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2

Six-cylinder engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-3-6-2-4

Lubrication system

Oil pressure (all engines)

At idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 to 2.0 bars

Running (for example, at 4000 rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . 4 bars or above (typically)

Oil pump rotor clearance - M40 engine

(body-to-outer rotor/outer rotor-to-inner rotor) . . . . . . . . . . . . . . . . . . . 0.12 mm to 0.20 mm

Oil pump pressure relief valve spring length - M40 engine . . . . . . . . . . 84.1 mm

Chapter 2 Part A:

In-car engine repair procedures

Camshaft - removal, inspection and refitting . . . . . . See Chapter 2B

Compression check . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 2B

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder head - dismantling and inspection . . . . . . . See Chapter 2B

Drivebelt check, adjustment and renewal . . . . . . . . See Chapter 1

Engine - removal and refitting . . . . . . . . . . . . . . . . . See Chapter 2B

Engine mountings - check and renewal . . . . . . . . . . . . . . . . . . . . . . 17

Engine oil and filter change . . . . . . . . . . . . . . . . . . . See Chapter 1

Engine overhaul - general information . . . . . . . . . . . See Chapter 2B

Exhaust manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Flywheel/driveplate - removal and refitting . . . . . . . . . . . . . . . . . . . 15

Front oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intake manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 5Oil pump - removal, inspection and refitting . . . . . . . . . . . . . . . . . . 14

Repair operations possible with the engine in the vehicle . . . . . . . . 2

Rocker arm and shaft assembly - dismantling, inspection

and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 2B

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Timing belt and sprockets - removal, inspection and refitting . . . . . 10

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 9

Timing chain and sprockets - removal, inspection and refitting . . . . 8

Timing chain covers - removal and refitting . . . . . . . . . . . . . . . . . . . 7

Top Dead Centre (TDC) for No 1 piston - locating . . . . . . . . . . . . . . 3

Valve clearance check and adjustment . . . . . . . . . . . See Chapter 1

Valve cover - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Valves - servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 2B

2A•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 39 of 228

1 General information

This Part of Chapter 2 is devoted to in-

vehicle engine repair procedures. All

information concerning engine removal and

refitting and engine block and cylinder head

overhaul can be found in Chapter 2B.

The following repair procedures are based

on the assumption that the engine is still fitted

in the vehicle. If the engine has been removed

from the vehicle and mounted on a stand,

many of the steps outlined in this Part of

Chapter 2 will not apply.

The Specifications included in this Part of

Chapter 2 apply only to the procedures

contained in this Part. Chapter 2B contains

the Specifications necessary for cylinder head

and engine block rebuilding.

The single overhead camshaft four- and

six-cylinder engines covered in this manual

are very similar in design. Where there are

differences, they will be pointed out.

The means by which the overhead

camshaft is driven varies according to engine

type; M10 and M30 engines use a timing

chain, while M20 and M40 engines have a

timing belt.

2 Repair operations possible

with the engine in the vehicle

Many major repair operations can be

accomplished without removing the engine

from the vehicle.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and help keep dirt out of

the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet to

improve access to the engine as repairs are

performed (see Chapter 11 if necessary).

Cover the wings to prevent damage to the

paint. Special pads are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for gasket or seal

renewal, the repairs can generally be made

with the engine in the vehicle. The intake and

exhaust manifold gaskets, sump gasket,

crankshaft oil seals and cylinder head gasket

are all accessible with the engine in place.

Exterior components, such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator, the distributor and the fuel system

components, can be removed for repair with

the engine in place.

The cylinder head can be removed without

removing the engine, so this procedure is

covered in this Part of Chapter 2. Camshaft,

rocker arm and valve component servicing ismost easily accomplished with the cylinder

head removed; these procedures are covered

in Part B of this Chapter. Note, however, that

the camshaft on the M40 engine may be

removed with the engine in the vehicle since it

is retained by bearing caps.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine in

the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved.

3 Top Dead Centre (TDC) for

No 1 piston- locating

2

Note 1:The following procedure is based on

the assumption that the distributor (if

applicable) is correctly fitted. If you are trying

to locate TDC to refit the distributor correctly,

piston position must be determined by feeling

for compression at the No 1 spark plug hole,

then aligning the ignition timing marks or

inserting the timing tool in the flywheel, as

applicable.

Note 2:The No 1 cylinder is the one closest to

the radiator.

1Top Dead Centre (TDC) is the highest point

in the cylinder that each piston reaches as it

travels up and down when the crankshaft

turns. Each piston reaches TDC on the

compression stroke and again on the exhaust

stroke, but TDC generally refers to piston

position on the compression stroke.

2Positioning the piston at TDC is an essential

part of many procedures, such as timing belt

or chain removal and distributor removal.

3Before beginning this procedure, be sure to

place the transmission in Neutral, and apply

the handbrake or chock the rear wheels. Also,

disable the ignition system by detaching the

coil wire from the centre terminal of the

distributor cap, and earthing it on the engine

block with a jumper wire. Remove the spark

plugs (see Chapter 1).

4In order to bring any piston to TDC, the

crankshaft must be turned using one of the

methods outlined below. When looking at the

front of the engine, normal crankshaft rotation

is clockwise.

(a) The preferred method is to turn the

crankshaft with a socket and ratchet

attached to the bolt threaded into the

front of the crankshaft.

(b) A remote starter switch, which may save

some time, can also be used. Follow the

instructions included with the switch.

Once the piston is close to TDC, use a

socket and ratchet as described in the

previous paragraph.

(c) If an assistant is available to turn the

ignition switch to the Start position in

short bursts, you can get the piston close

to TDC without a remote starter switch.Make sure your assistant is out of the

vehicle, away from the ignition switch,

then use a socket and ratchet as

described in (a) to complete the

procedure.

5Note the position of the terminal for the

No 1 spark plug lead on the distributor cap. If

the terminal isn’t marked, follow the plug lead

from the No 1 cylinder spark plug to the cap

(No 1 cylinder is nearest the radiator).

6Use a felt-tip pen or chalk to make a mark

directly below the No 1 terminal on the

distributor body or timing cover.

7Detach the distributor cap, and set it aside

(see Chapter 1 if necessary).

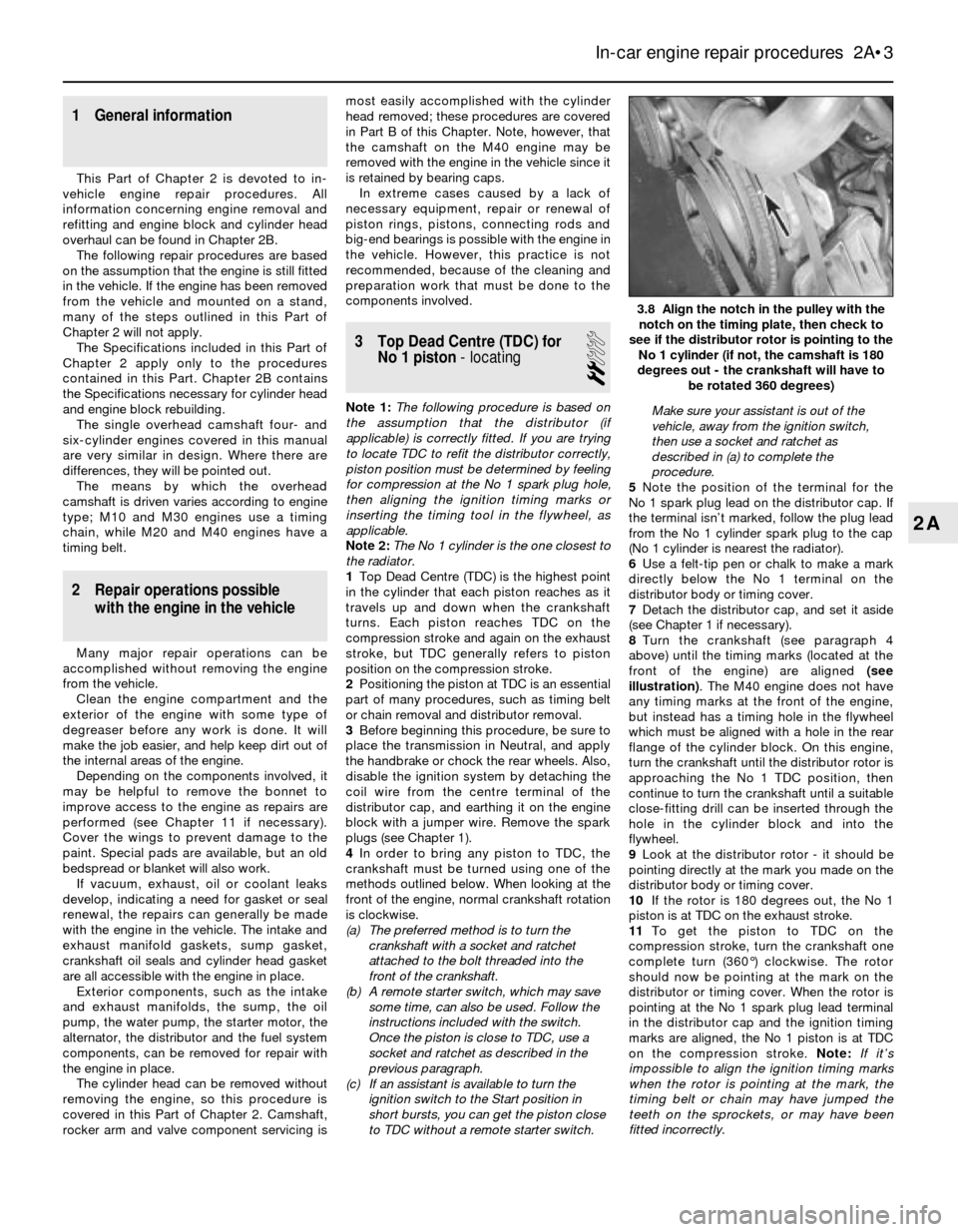

8Turn the crankshaft (see paragraph 4

above) until the timing marks (located at the

front of the engine) are aligned (see

illustration). The M40 engine does not have

any timing marks at the front of the engine,

but instead has a timing hole in the flywheel

which must be aligned with a hole in the rear

flange of the cylinder block. On this engine,

turn the crankshaft until the distributor rotor is

approaching the No 1 TDC position, then

continue to turn the crankshaft until a suitable

close-fitting drill can be inserted through the

hole in the cylinder block and into the

flywheel.

9Look at the distributor rotor - it should be

pointing directly at the mark you made on the

distributor body or timing cover.

10If the rotor is 180 degrees out, the No 1

piston is at TDC on the exhaust stroke.

11To get the piston to TDC on the

compression stroke, turn the crankshaft one

complete turn (360°) clockwise. The rotor

should now be pointing at the mark on the

distributor or timing cover. When the rotor is

pointing at the No 1 spark plug lead terminal

in the distributor cap and the ignition timing

marks are aligned, the No 1 piston is at TDC

on the compression stroke. Note:If it’s

impossible to align the ignition timing marks

when the rotor is pointing at the mark, the

timing belt or chain may have jumped the

teeth on the sprockets, or may have been

fitted incorrectly.

In-car engine repair procedures 2A•3

3.8 Align the notch in the pulley with the

notch on the timing plate, then check to

see if the distributor rotor is pointing to the

No 1 cylinder (if not, the camshaft is 180

degrees out - the crankshaft will have to

be rotated 360 degrees)

2A

Page 40 of 228

12After the No 1 piston has been positioned

at TDC on the compression stroke, TDC for

any of the remaining pistons can be located

by turning the crankshaft and following the

firing order. Mark the remaining spark plug

lead terminal locations just like you did for the

No 1 terminal, then number the marks to

correspond with the cylinder numbers. As you

turn the crankshaft, the rotor will also turn.

When it’s pointing directly at one of the marks

on the distributor, the piston for that particular

cylinder is at TDC on the compression stroke.

4 Valve cover-

removal and refitting

1

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal

1Disconnect the battery negative cable.

2Detach the breather hose from the valve

cover.

3On M20 engines, unbolt and remove the

intake manifold support bracket and, if

applicable, the bracket for the engine sensors

or idle air stabiliser (it will probably be

necessary to disconnect the electrical

connectors from the sensors and stabiliser).

4On M30 engines, disconnect the electrical

connector for the airflow sensor. Unclip the

electrical harness, moving it out of the way.

5Where necessary on M30 engines, remove

the hoses and fittings from the intake air hose,

then loosen the clamp and separate the hose

from the throttle body. Unscrew the mounting

nuts for the air cleaner housing, and remove

the housing together with the air hose and

airflow sensor.

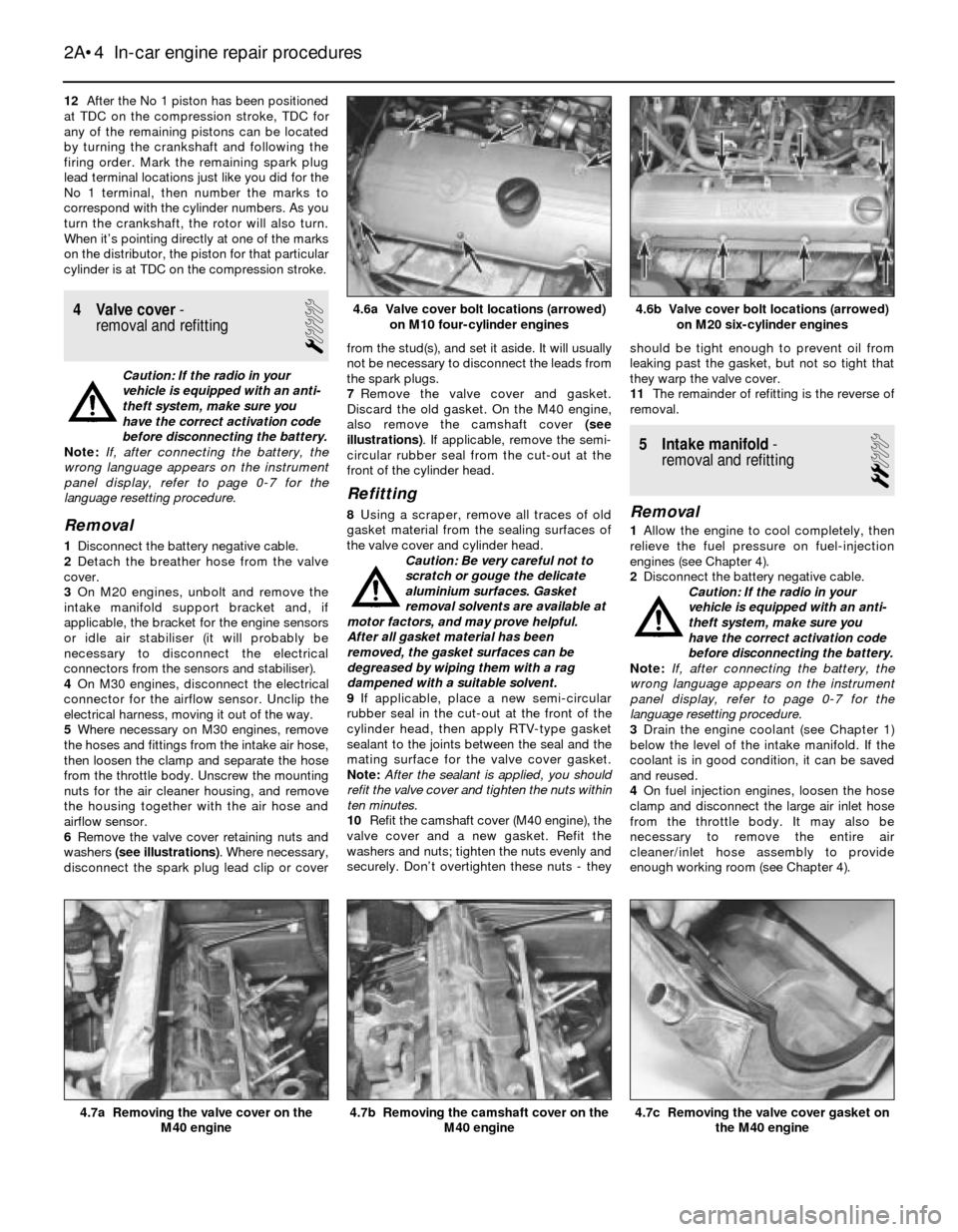

6Remove the valve cover retaining nuts and

washers (see illustrations). Where necessary,

disconnect the spark plug lead clip or coverfrom the stud(s), and set it aside. It will usually

not be necessary to disconnect the leads from

the spark plugs.

7Remove the valve cover and gasket.

Discard the old gasket. On the M40 engine,

also remove the camshaft cover (see

illustrations). If applicable, remove the semi-

circular rubber seal from the cut-out at the

front of the cylinder head.

Refitting

8Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the valve cover and cylinder head.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Gasket

removal solvents are available at

motor factors, and may prove helpful.

After all gasket material has been

removed, the gasket surfaces can be

degreased by wiping them with a rag

dampened with a suitable solvent.

9If applicable, place a new semi-circular

rubber seal in the cut-out at the front of the

cylinder head, then apply RTV-type gasket

sealant to the joints between the seal and the

mating surface for the valve cover gasket.

Note:After the sealant is applied, you should

refit the valve cover and tighten the nuts within

ten minutes.

10Refit the camshaft cover (M40 engine), the

valve cover and a new gasket. Refit the

washers and nuts; tighten the nuts evenly and

securely. Don’t overtighten these nuts - theyshould be tight enough to prevent oil from

leaking past the gasket, but not so tight that

they warp the valve cover.

11The remainder of refitting is the reverse of

removal.

5 Intake manifold-

removal and refitting

2

Removal

1Allow the engine to cool completely, then

relieve the fuel pressure on fuel-injection

engines (see Chapter 4).

2Disconnect the battery negative cable.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Drain the engine coolant (see Chapter 1)

below the level of the intake manifold. If the

coolant is in good condition, it can be saved

and reused.

4On fuel injection engines, loosen the hose

clamp and disconnect the large air inlet hose

from the throttle body. It may also be

necessary to remove the entire air

cleaner/inlet hose assembly to provide

enough working room (see Chapter 4).

2A•4 In-car engine repair procedures

4.7b Removing the camshaft cover on the

M40 engine4.7a Removing the valve cover on the

M40 engine4.7c Removing the valve cover gasket on

the M40 engine

4.6b Valve cover bolt locations (arrowed)

on M20 six-cylinder engines4.6a Valve cover bolt locations (arrowed)

on M10 four-cylinder engines

Page 44 of 228

8 Timing chain and

sprockets- removal,

inspection and refitting

5

Note:This procedure applies to M10 and M30

engines.

Caution: Once the engine is set

at TDC, do not rotate the

camshaft or crankshaft until the

timing chain is reinstalled. If the

crankshaft or camshaft is rotated with the

timing chain removed, the valves could hit

the pistons, causing expensive internal

engine damage.

Removal

1Position the No 1 cylinder at Top Dead

Centre (TDC) on the compression stroke (see

Section 3).

2Remove the valve cover (see Section 4).

Double-check that the No 1 cylinder is at TDC

on the compression stroke by making sure the

No 1 cylinder rocker arms are loose (not

compressing their valve springs).

3Remove the upper timing chain cover (see

Section 7). Note the location of the camshaft

timing marks, which should now be aligned.

On four-cylinder (M10) engines, there’s

usually a stamped line on the camshaft flange

that aligns with a cast mark on the top of the

cylinder head; also, the camshaft sprocket

dowel pin hole will be at its lowest point. On

six-cylinder (M30) engines, a line drawn

through two of the camshaft sprocket bolts

opposite each other would be exactly vertical,

while a line drawn through the other two bolts

would be horizontal. Additionally, the locating

pin should be in the lower left corner (between

the 7 and 8 o’clock positions). Be sure you’ve

identified the correct camshaft TDC position

before dismantling, because correct valve

timing depends on you aligning them exactly

on reassembly. Note:As the engine is

mounted in the engine compartment at anangle, all references to horizontal and vertical

whilst timing the camshafts are in relation to

the crankshaft, and not the ground.

4Hold the crankshaft stationary with a socket

and ratchet on the vibration damper centre bolt,

then loosen (but don’t unscrew completely) the

four bolts attaching the camshaft sprocket to

the camshaft. Be very careful not to rotate the

camshaft or crankshaft. Note:Some earlier

models may have locking tabs for the camshaft

sprocket bolts. Bend the tabs down before

loosening the bolts. The tabs are no longer

available from the manufacturer, and do not

have to be used on refitting.

5Remove the lower timing chain cover (see

Section 7).

6Unscrew and remove the four camshaft

sprocket bolts, then disengage the chain from

the crankshaft sprocket and carefully remove

the chain and camshaft sprocket from the

engine. It may be necessary to gently prise

the camshaft sprocket loose from the

camshaft with a screwdriver.

Inspection

Timing sprockets

7Examine the teeth on both the crankshaft

sprocket and the camshaft sprocket for wear.

Each tooth forms an inverted V. If worn, the

side of each tooth under tension will be

slightly concave in shape when compared

with the other side of the tooth (i.e. one side of

the inverted V will be concave when

compared with the other, giving the teeth a

hooked appearance). If the teeth appear to be

worn, the sprockets must be renewed. Note:

The crankshaft sprocket is a press fit on the

crankshaft, and can be removed with a jaw-

type puller after the Woodruff key and oil

pump are removed (see Section 14). However,

BMW recommends the new sprocket be

pressed onto the crankshaft after being

heated to 80°C (175°F) on the M10 engine, or

to 200°C(390°F) on the M30 engine. For this

reason, if the crankshaft sprocket requires

renewal, we recommend removing the

crankshaft (see Part B of this Chapter) and

taking it to an engineering works to have the

old sprocket pressed off and a new one

pressed on.

Timing chain

8The chain should be renewed if the

sprockets are worn or if the chain is loose

(indicated by excessive noise in operation).

It’s a good idea to renew the chain anyway if

the engine is stripped down for overhaul. The

rollers on a very badly worn chain may be

slightly grooved. To avoid future problems, if

there’s any doubt at all about the chain’s

condition, renew it.

Chain rail and tensioner

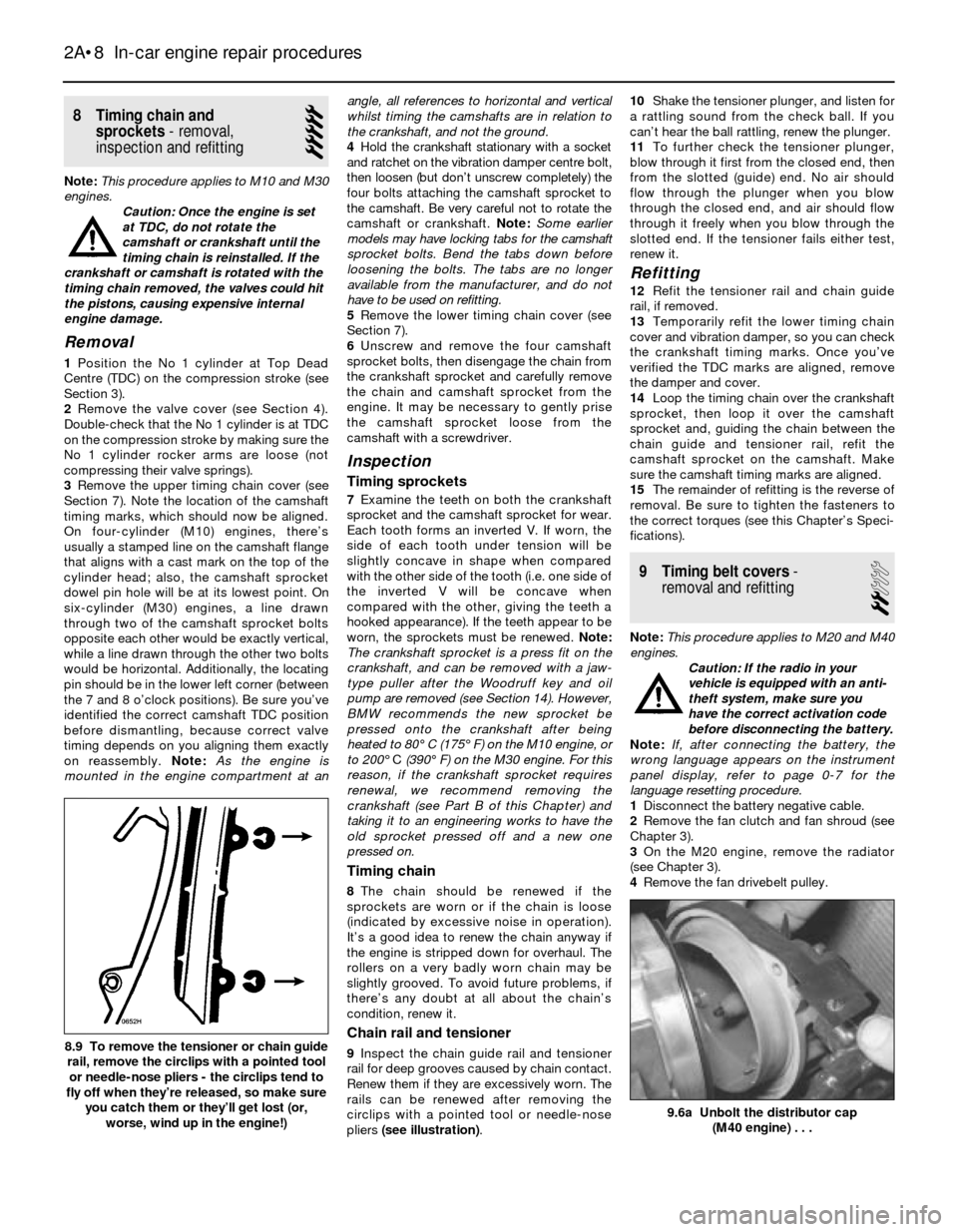

9Inspect the chain guide rail and tensioner

rail for deep grooves caused by chain contact.

Renew them if they are excessively worn. The

rails can be renewed after removing the

circlips with a pointed tool or needle-nose

pliers (see illustration).10Shake the tensioner plunger, and listen for

a rattling sound from the check ball. If you

can’t hear the ball rattling, renew the plunger.

11To further check the tensioner plunger,

blow through it first from the closed end, then

from the slotted (guide) end. No air should

flow through the plunger when you blow

through the closed end, and air should flow

through it freely when you blow through the

slotted end. If the tensioner fails either test,

renew it.

Refitting

12Refit the tensioner rail and chain guide

rail, if removed.

13Temporarily refit the lower timing chain

cover and vibration damper, so you can check

the crankshaft timing marks. Once you’ve

verified the TDC marks are aligned, remove

the damper and cover.

14Loop the timing chain over the crankshaft

sprocket, then loop it over the camshaft

sprocket and, guiding the chain between the

chain guide and tensioner rail, refit the

camshaft sprocket on the camshaft. Make

sure the camshaft timing marks are aligned.

15The remainder of refitting is the reverse of

removal. Be sure to tighten the fasteners to

the correct torques (see this Chapter’s Speci-

fications).

9 Timing belt covers-

removal and refitting

2

Note:This procedure applies to M20 and M40

engines.

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

1Disconnect the battery negative cable.

2Remove the fan clutch and fan shroud (see

Chapter 3).

3On the M20 engine, remove the radiator

(see Chapter 3).

4Remove the fan drivebelt pulley.

2A•8 In-car engine repair procedures

9.6a Unbolt the distributor cap

(M40 engine) . . .

8.9 To remove the tensioner or chain guide

rail, remove the circlips with a pointed tool

or needle-nose pliers - the circlips tend to

fly off when they’re released, so make sure

you catch them or they’ll get lost (or,

worse, wind up in the engine!)

Page 49 of 228

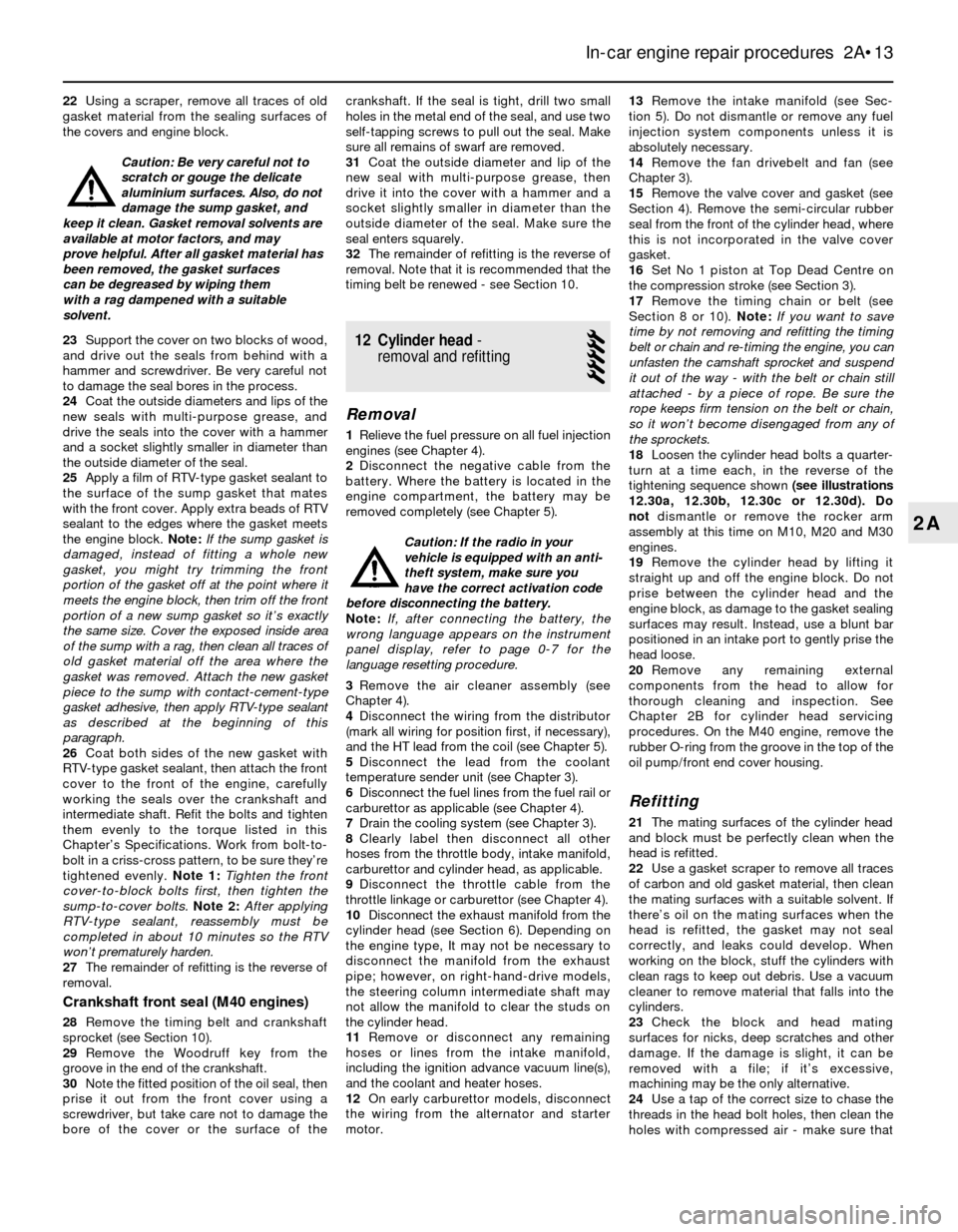

22Using a scraper, remove all traces of old

gasket material from the sealing surfaces of

the covers and engine block.

Caution: Be very careful not to

scratch or gouge the delicate

aluminium surfaces. Also, do not

damage the sump gasket, and

keep it clean. Gasket removal solvents are

available at motor factors, and may

prove helpful. After all gasket material has

been removed, the gasket surfaces

can be degreased by wiping them

with a rag dampened with a suitable

solvent.

23Support the cover on two blocks of wood,

and drive out the seals from behind with a

hammer and screwdriver. Be very careful not

to damage the seal bores in the process.

24Coat the outside diameters and lips of the

new seals with multi-purpose grease, and

drive the seals into the cover with a hammer

and a socket slightly smaller in diameter than

the outside diameter of the seal.

25Apply a film of RTV-type gasket sealant to

the surface of the sump gasket that mates

with the front cover. Apply extra beads of RTV

sealant to the edges where the gasket meets

the engine block. Note:If the sump gasket is

damaged, instead of fitting a whole new

gasket, you might try trimming the front

portion of the gasket off at the point where it

meets the engine block, then trim off the front

portion of a new sump gasket so it’s exactly

the same size. Cover the exposed inside area

of the sump with a rag, then clean all traces of

old gasket material off the area where the

gasket was removed. Attach the new gasket

piece to the sump with contact-cement-type

gasket adhesive, then apply RTV-type sealant

as described at the beginning of this

paragraph.

26Coat both sides of the new gasket with

RTV-type gasket sealant, then attach the front

cover to the front of the engine, carefully

working the seals over the crankshaft and

intermediate shaft. Refit the bolts and tighten

them evenly to the torque listed in this

Chapter’s Specifications. Work from bolt-to-

bolt in a criss-cross pattern, to be sure they’re

tightened evenly.Note 1:Tighten the front

cover-to-block bolts first, then tighten the

sump-to-cover bolts. Note 2:After applying

RTV-type sealant, reassembly must be

completed in about 10 minutes so the RTV

won’t prematurely harden.

27The remainder of refitting is the reverse of

removal.

Crankshaft front seal (M40 engines)

28Remove the timing belt and crankshaft

sprocket (see Section 10).

29Remove the Woodruff key from the

groove in the end of the crankshaft.

30Note the fitted position of the oil seal, then

prise it out from the front cover using a

screwdriver, but take care not to damage the

bore of the cover or the surface of thecrankshaft. If the seal is tight, drill two small

holes in the metal end of the seal, and use two

self-tapping screws to pull out the seal. Make

sure all remains of swarf are removed.

31Coat the outside diameter and lip of the

new seal with multi-purpose grease, then

drive it into the cover with a hammer and a

socket slightly smaller in diameter than the

outside diameter of the seal. Make sure the

seal enters squarely.

32The remainder of refitting is the reverse of

removal. Note that it is recommended that the

timing belt be renewed - see Section 10.

12 Cylinder head-

removal and refitting

5

Removal

1Relieve the fuel pressure on all fuel injection

engines (see Chapter 4).

2Disconnect the negative cable from the

battery. Where the battery is located in the

engine compartment, the battery may be

removed completely (see Chapter 5).

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code

before disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

3Remove the air cleaner assembly (see

Chapter 4).

4Disconnect the wiring from the distributor

(mark all wiring for position first, if necessary),

and the HT lead from the coil (see Chapter 5).

5Disconnect the lead from the coolant

temperature sender unit (see Chapter 3).

6Disconnect the fuel lines from the fuel rail or

carburettor as applicable (see Chapter 4).

7Drain the cooling system (see Chapter 3).

8Clearly label then disconnect all other

hoses from the throttle body, intake manifold,

carburettor and cylinder head, as applicable.

9Disconnect the throttle cable from the

throttle linkage or carburettor (see Chapter 4).

10Disconnect the exhaust manifold from the

cylinder head (see Section 6). Depending on

the engine type, It may not be necessary to

disconnect the manifold from the exhaust

pipe; however, on right-hand-drive models,

the steering column intermediate shaft may

not allow the manifold to clear the studs on

the cylinder head.

11Remove or disconnect any remaining

hoses or lines from the intake manifold,

including the ignition advance vacuum line(s),

and the coolant and heater hoses.

12On early carburettor models, disconnect

the wiring from the alternator and starter

motor.13Remove the intake manifold (see Sec-

tion 5). Do not dismantle or remove any fuel

injection system components unless it is

absolutely necessary.

14Remove the fan drivebelt and fan (see

Chapter 3).

15Remove the valve cover and gasket (see

Section 4). Remove the semi-circular rubber

seal from the front of the cylinder head, where

this is not incorporated in the valve cover

gasket.

16Set No 1 piston at Top Dead Centre on

the compression stroke (see Section 3).

17Remove the timing chain or belt (see

Section 8 or 10). Note:If you want to save

time by not removing and refitting the timing

belt or chain and re-timing the engine, you can

unfasten the camshaft sprocket and suspend

it out of the way - with the belt or chain still

attached - by a piece of rope. Be sure the

rope keeps firm tension on the belt or chain,

so it won’t become disengaged from any of

the sprockets.

18Loosen the cylinder head bolts a quarter-

turn at a time each, in the reverse of the

tightening sequence shown (see illustrations

12.30a, 12.30b, 12.30c or 12.30d). Do

notdismantle or remove the rocker arm

assembly at this time on M10, M20 and M30

engines.

19Remove the cylinder head by lifting it

straight up and off the engine block. Do not

prise between the cylinder head and the

engine block, as damage to the gasket sealing

surfaces may result. Instead, use a blunt bar

positioned in an intake port to gently prise the

head loose.

20Remove any remaining external

components from the head to allow for

thorough cleaning and inspection. See

Chapter 2B for cylinder head servicing

procedures. On the M40 engine, remove the

rubber O-ring from the groove in the top of the

oil pump/front end cover housing.

Refitting

21The mating surfaces of the cylinder head

and block must be perfectly clean when the

head is refitted.

22Use a gasket scraper to remove all traces

of carbon and old gasket material, then clean

the mating surfaces with a suitable solvent. If

there’s oil on the mating surfaces when the

head is refitted, the gasket may not seal

correctly, and leaks could develop. When

working on the block, stuff the cylinders with

clean rags to keep out debris. Use a vacuum

cleaner to remove material that falls into the

cylinders.

23Check the block and head mating

surfaces for nicks, deep scratches and other

damage. If the damage is slight, it can be

removed with a file; if it’s excessive,

machining may be the only alternative.

24Use a tap of the correct size to chase the

threads in the head bolt holes, then clean the

holes with compressed air - make sure that

In-car engine repair procedures 2A•13

2A

Page 60 of 228

Torque wrench settings (continued)Nm

Connecting rod cap bolts/nuts

M10 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

M20 and M40 engines

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 70°

Camshaft bearing caps (M40 engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Intermediate shaft sprocket-to-shaft bolt (M20 engine) . . . . . . . . . . . . . 60

Oil supply tube bolt(s)

M6 (normal) and M8 (banjo) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

* BMW recommend that the main bearing bolts are renewed as a matter of course.

2B•4 General engine overhaul procedures

1 General information

Included in this Part of Chapter 2 are the

general overhaul procedures for the cylinder

head and engine internal components.

The information ranges from advice

concerning preparation for an overhaul and

the purchase of new parts to detailed,

paragraph-by-paragraph procedures covering

removal and refitting of internal components

and the inspection of parts.

The following Sections have been written

based on the assumption that the engine has

been removed from the vehicle. For

information concerning in-vehicle engine

repair, as well as removal and refitting of the

external components necessary for the

overhaul, see Chapter 2A, and Section 7 of

this Part.

The Specifications included in this Part are

only those necessary for the inspection and

overhaul procedures which follow. Refer to

Part A for additional Specifications.

2 Engine overhaul-

general information

It’s not always easy to determine when, or

if, an engine should be completely

overhauled, as a number of factors must be

considered.

High mileage is not necessarily an

indication that an overhaul is needed, while

low mileage doesn’t preclude the need for an

overhaul. Frequency of servicing is probably

the most important consideration. An engine

that’s had regular and frequent oil and filter

changes, as well as other required

maintenance, will most likely give many

thousands of miles of reliable service.

Conversely, a neglected engine may require

an overhaul very early in its life.

Excessive oil consumption is an indication

that piston rings, valve seals and/or valve

guides are in need of attention. Make sure

that oil leaks aren’t responsible before

deciding that the rings and/or guides are

worn. Perform a cylinder compression check

to determine the extent of the work required

(see Section 3).Check the oil pressure: Unscrew the oil

pressure sender unit, and connect an oil

pressure gauge in its place. Measure the oil

pressure with the engine at its normal

operating temperature. Compare your

readings to the oil pressures listed in this

Chapter’s Specifications. If the readings are

significantly below these (and if the oil and oil

filter are in good condition), the crankshaft

bearings and/or the oil pump are probably

worn out. On M10 and M30 engines, the oil

pressure sender unit is located high on the left

rear of the cylinder head. On M20 engines, the

sender unit is threaded into the side of the

engine block, below the oil filter. On M40

engines, the sender unit is threaded into the

rear of the oil filter housing.

Loss of power, rough running, knocking or

metallic engine noises, excessive valve train

noise and high fuel consumption may also

point to the need for an overhaul, especially if

they’re all present at the same time. If a

complete tune-up doesn’t remedy the

situation, major mechanical work is the only

solution.

An engine overhaul involves restoring the

internal parts to the specifications of a new

engine. During an overhaul, new piston rings

are fitted and the cylinder walls are

reconditioned (rebored and/or honed). If a

rebore is done by an engineering works, new

oversize pistons will also be fitted. The main

bearings and connecting big-end bearings are

generally renewed and, if necessary, the

crankshaft may be reground to restore the

journals. Generally, the valves are serviced as

well, since they’re usually in less-than-perfect

condition at this point. While the engine is

being overhauled, other components, such as

the distributor, starter and alternator, can be

rebuilt as well. The end result should be a like-

new engine that will give many thousands of

trouble-free miles. Note: Critical cooling

system components such as the hoses,

drivebelts, thermostat and water pump MUST

be renewed when an engine is overhauled.

The radiator should be checked carefully, to

ensure that it isn’t clogged or leaking (see

Chapters 1 or 3). Also, we don’t recommend

overhauling the oil pump - always fit a new

one when an engine is rebuilt.

Before beginning the engine overhaul, read

through the entire procedure to familiarise

yourself with the scope and requirements ofthe job. Overhauling an engine isn’t difficult if

you follow all of the instructions carefully,

have the necessary tools and equipment and

pay close attention to all specifications;

however, it is time consuming. Plan on the

vehicle being tied up for a minimum of two

weeks, especially if parts must be taken to an

automotive machine shop for repair or recon-

ditioning. Check on availability of parts and

make sure that any necessary special tools

and equipment are obtained in advance. Most

work can be done with typical hand tools,

although a number of precision measuring

tools are required for inspecting parts to

determine if they must be replaced. Often an

automotive machine shop will handle the

inspection of parts and offer advice

concerning reconditioning and renewal. Note:

Always wait until the engine has been

completely disassembled and all components,

especially the engine block, have been

inspected before deciding what service and

repair operations must be performed by an

automotive machine shop. Since the block’s

condition will be the major factor to consider

when determining whether to overhaul the

original engine or buy a rebuilt one, never

purchase parts or have machine work done on

other components until the block has been

thoroughly inspected. As a general rule, time

is the primary cost of an overhaul, so it doesn’t

pay to refit worn or substandard parts.

As a final note, to ensure maximum life and

minimum trouble from a rebuilt engine,

everything must be assembled with care, in a

spotlessly-clean environment.

3 Compression check

2

1A compression check will tell you what

mechanical condition the upper end (pistons,

rings, valves, head gaskets) of your engine is

in. Specifically, it can tell you if the

compression is down due to leakage caused

by worn piston rings, defective valves and

seats, or a blown head gasket. Note:The

engine must be at normal operating

temperature, and the battery must be fully-

charged, for this check.

2Begin by cleaning the area around the

spark plugs before you remove them

(compressed air should be used, if available,

Page 61 of 228

otherwise a small brush or even a bicycle tyre

pump will work). The idea is to prevent dirt

from getting into the cylinders as the

compression check is being done.

3Remove all the spark plugs from the engine

(see Chapter 1).

4Block the throttle wide open, or have an

assistant hold the throttle pedal down.

5On carburettor models, disconnect the LT

lead from the coil. On fuel injection models,

disable the fuel pump and ignition circuit by

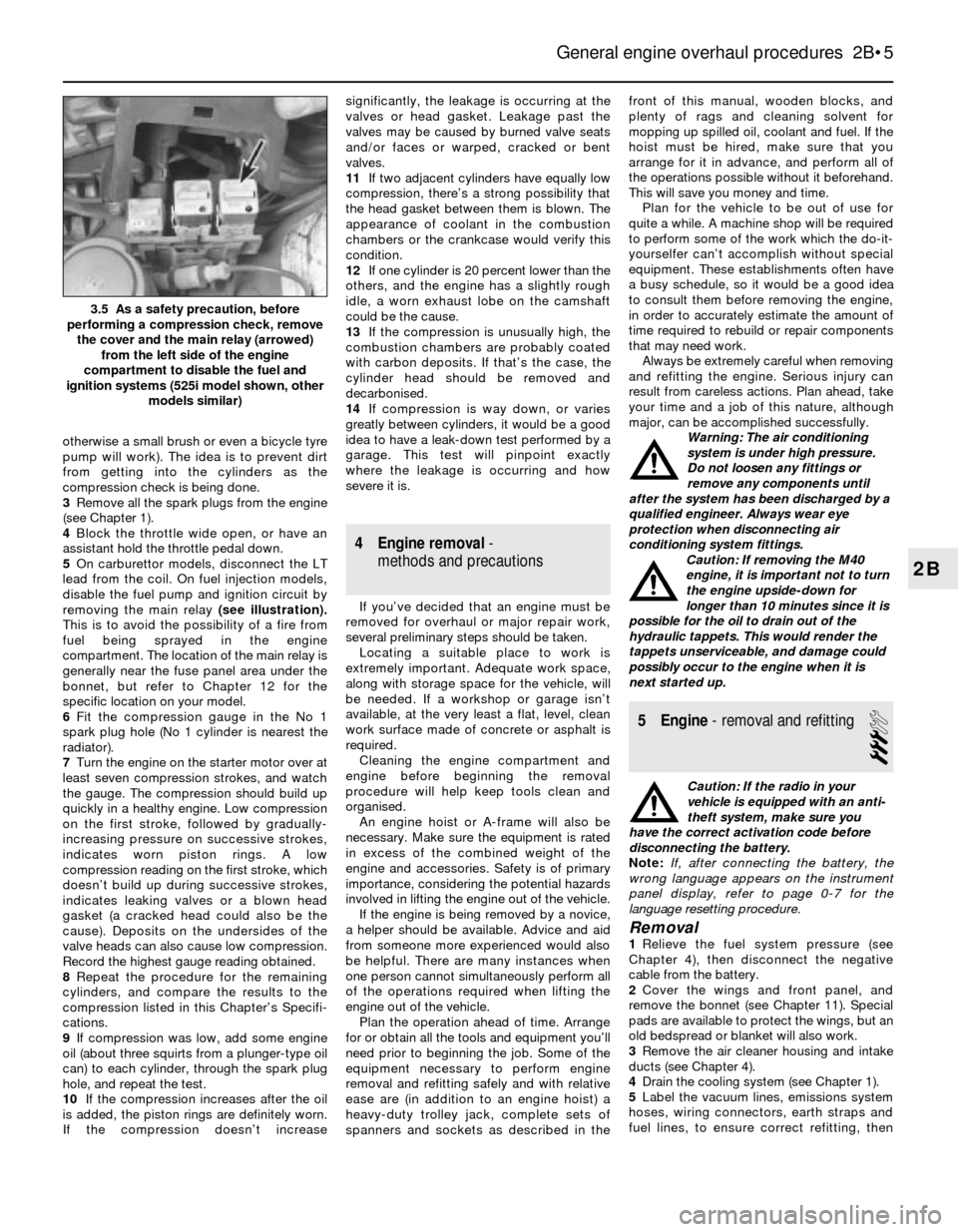

removing the main relay(see illustration).

This is to avoid the possibility of a fire from

fuel being sprayed in the engine

compartment. The location of the main relay is

generally near the fuse panel area under the

bonnet, but refer to Chapter 12 for the

specific location on your model.

6Fit the compression gauge in the No 1

spark plug hole (No 1 cylinder is nearest the

radiator).

7Turn the engine on the starter motor over at

least seven compression strokes, and watch

the gauge. The compression should build up

quickly in a healthy engine. Low compression

on the first stroke, followed by gradually-

increasing pressure on successive strokes,

indicates worn piston rings. A low

compression reading on the first stroke, which

doesn’t build up during successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause). Deposits on the undersides of the

valve heads can also cause low compression.

Record the highest gauge reading obtained.

8Repeat the procedure for the remaining

cylinders, and compare the results to the

compression listed in this Chapter’s Specifi-

cations.

9If compression was low, add some engine

oil (about three squirts from a plunger-type oil

can) to each cylinder, through the spark plug

hole, and repeat the test.

10If the compression increases after the oil

is added, the piston rings are definitely worn.

If the compression doesn’t increasesignificantly, the leakage is occurring at the

valves or head gasket. Leakage past the

valves may be caused by burned valve seats

and/or faces or warped, cracked or bent

valves.

11If two adjacent cylinders have equally low

compression, there’s a strong possibility that

the head gasket between them is blown. The

appearance of coolant in the combustion

chambers or the crankcase would verify this

condition.

12If one cylinder is 20 percent lower than the

others, and the engine has a slightly rough

idle, a worn exhaust lobe on the camshaft

could be the cause.

13If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If that’s the case, the

cylinder head should be removed and

decarbonised.

14If compression is way down, or varies

greatly between cylinders, it would be a good

idea to have a leak-down test performed by a

garage. This test will pinpoint exactly

where the leakage is occurring and how

severe it is.

4 Engine removal-

methods and precautions

If you’ve decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the vehicle, will

be needed. If a workshop or garage isn’t

available, at the very least a flat, level, clean

work surface made of concrete or asphalt is

required.

Cleaning the engine compartment and

engine before beginning the removal

procedure will help keep tools clean and

organised.

An engine hoist or A-frame will also be

necessary. Make sure the equipment is rated

in excess of the combined weight of the

engine and accessories. Safety is of primary

importance, considering the potential hazards

involved in lifting the engine out of the vehicle.

If the engine is being removed by a novice,

a helper should be available. Advice and aid

from someone more experienced would also

be helpful. There are many instances when

one person cannot simultaneously perform all

of the operations required when lifting the

engine out of the vehicle.

Plan the operation ahead of time. Arrange

for or obtain all the tools and equipment you’ll

need prior to beginning the job. Some of the

equipment necessary to perform engine

removal and refitting safely and with relative

ease are (in addition to an engine hoist) a

heavy-duty trolley jack, complete sets of

spanners and sockets as described in thefront of this manual, wooden blocks, and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and fuel. If the

hoist must be hired, make sure that you

arrange for it in advance, and perform all of

the operations possible without it beforehand.

This will save you money and time.

Plan for the vehicle to be out of use for

quite a while. A machine shop will be required

to perform some of the work which the do-it-

yourselfer can’t accomplish without special

equipment. These establishments often have

a busy schedule, so it would be a good idea

to consult them before removing the engine,

in order to accurately estimate the amount of

time required to rebuild or repair components

that may need work.

Always be extremely careful when removing

and refitting the engine. Serious injury can

result from careless actions. Plan ahead, take

your time and a job of this nature, although

major, can be accomplished successfully.

Warning: The air conditioning

system is under high pressure.

Do not loosen any fittings or

remove any components until

after the system has been discharged by a

qualified engineer. Always wear eye

protection when disconnecting air

conditioning system fittings.

Caution: If removing the M40

engine, it is important not to turn

the engine upside-down for

longer than 10 minutes since it is

possible for the oil to drain out of the

hydraulic tappets. This would render the

tappets unserviceable, and damage could

possibly occur to the engine when it is

next started up.

5 Engine- removal and refitting

3

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

Removal1Relieve the fuel system pressure (see

Chapter 4), then disconnect the negative

cable from the battery.

2Cover the wings and front panel, and

remove the bonnet (see Chapter 11). Special

pads are available to protect the wings, but an

old bedspread or blanket will also work.

3Remove the air cleaner housing and intake

ducts (see Chapter 4).

4Drain the cooling system (see Chapter 1).

5Label the vacuum lines, emissions system

hoses, wiring connectors, earth straps and

fuel lines, to ensure correct refitting, then

General engine overhaul procedures 2B•5

3.5 As a safety precaution, before

performing a compression check, remove

the cover and the main relay (arrowed)

from the left side of the engine

compartment to disable the fuel and

ignition systems (525i model shown, other

models similar)

2B

Page 72 of 228

7Wipe the oil out of the cylinder, and repeat

the procedure for the remaining cylinders.

8After the honing job is complete, chamfer

the top edges of the cylinder bores with a

small file, so the rings won’t catch when the

pistons are refitted. Be very careful not to nick

the cylinder walls with the end of the file.

9The entire engine block must be washed

again very thoroughly with warm, soapy

water, to remove all traces of the abrasive grit

produced during the honing operation. Note:

The bores can be considered clean when a

lint-free white cloth - dampened with clean

engine oil - used to wipe them out doesn’t

pick up any more honing residue, which will

show up as grey areas on the cloth.Be sure to

run a brush through all oil holes and galleries,

and flush them with running water.

10After rinsing, dry the block, and apply a

coat of light rust-preventive oil to all machined

surfaces. Wrap the block in a plastic bag to

keep it clean, and set it aside until

reassembly.

18 Pistons/connecting rods-

inspection

3

1Before the inspection process can be

carried out, the piston/connecting rod

assemblies must be cleaned and the original

piston rings removed from the pistons.Note:

Always use new piston rings when the engine

is reassembled.

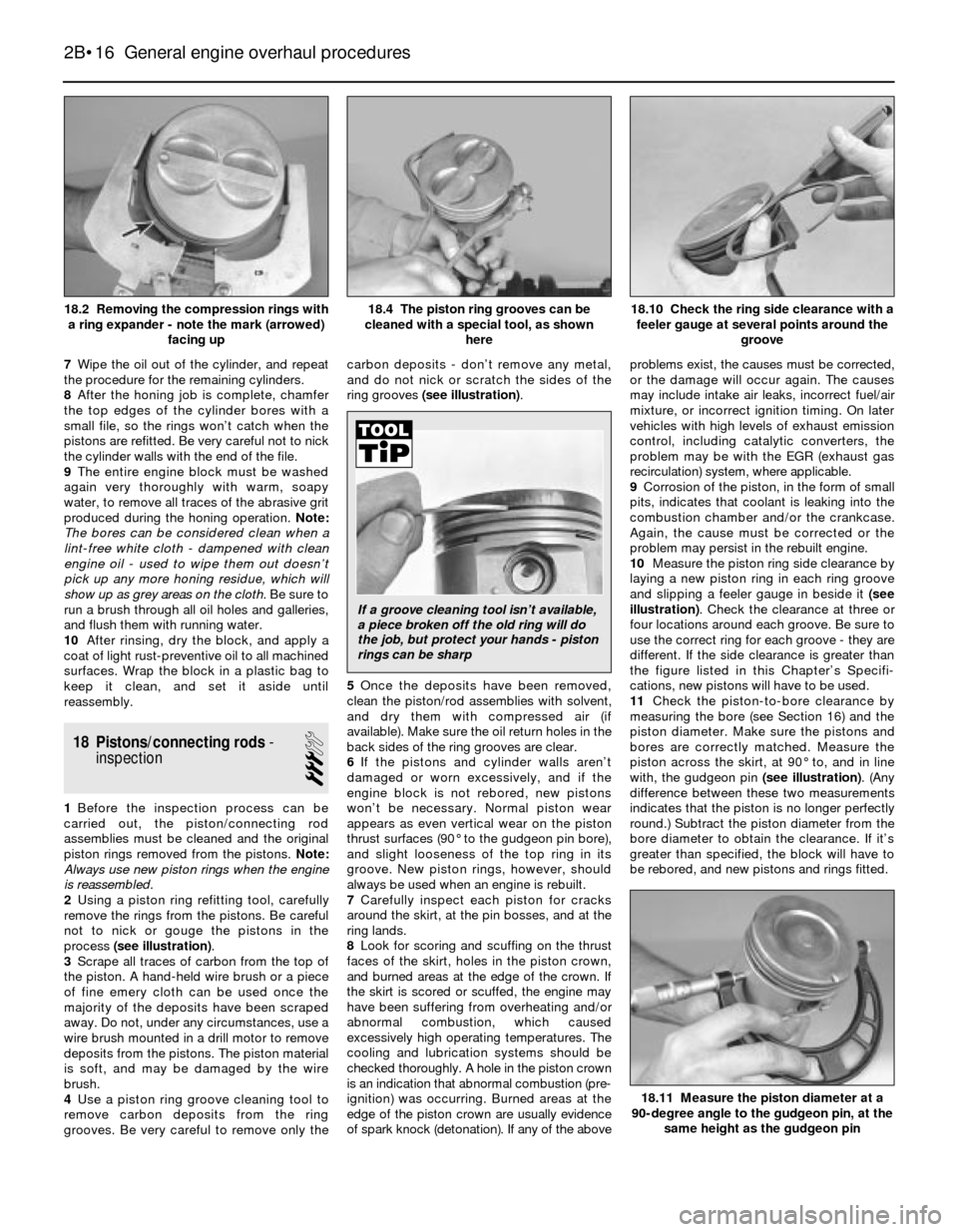

2Using a piston ring refitting tool, carefully

remove the rings from the pistons. Be careful

not to nick or gouge the pistons in the

process (see illustration).

3Scrape all traces of carbon from the top of

the piston. A hand-held wire brush or a piece

of fine emery cloth can be used once the

majority of the deposits have been scraped

away. Do not, under any circumstances, use a

wire brush mounted in a drill motor to remove

deposits from the pistons. The piston material

is soft, and may be damaged by the wire

brush.

4Use a piston ring groove cleaning tool to

remove carbon deposits from the ring

grooves. Be very careful to remove only thecarbon deposits - don’t remove any metal,

and do not nick or scratch the sides of the

ring grooves (see illustration).

5Once the deposits have been removed,

clean the piston/rod assemblies with solvent,

and dry them with compressed air (if

available). Make sure the oil return holes in the

back sides of the ring grooves are clear.

6If the pistons and cylinder walls aren’t

damaged or worn excessively, and if the

engine block is not rebored, new pistons

won’t be necessary. Normal piston wear

appears as even vertical wear on the piston

thrust surfaces (90° to the gudgeon pin bore),

and slight looseness of the top ring in its

groove. New piston rings, however, should

always be used when an engine is rebuilt.

7Carefully inspect each piston for cracks

around the skirt, at the pin bosses, and at the

ring lands.

8Look for scoring and scuffing on the thrust

faces of the skirt, holes in the piston crown,

and burned areas at the edge of the crown. If

the skirt is scored or scuffed, the engine may

have been suffering from overheating and/or

abnormal combustion, which caused

excessively high operating temperatures. The

cooling and lubrication systems should be

checked thoroughly. A hole in the piston crown

is an indication that abnormal combustion (pre-

ignition) was occurring. Burned areas at the

edge of the piston crown are usually evidence

of spark knock (detonation). If any of the aboveproblems exist, the causes must be corrected,

or the damage will occur again. The causes

may include intake air leaks, incorrect fuel/air

mixture, or incorrect ignition timing. On later

vehicles with high levels of exhaust emission

control, including catalytic converters, the

problem may be with the EGR (exhaust gas

recirculation) system, where applicable.

9Corrosion of the piston, in the form of small

pits, indicates that coolant is leaking into the

combustion chamber and/or the crankcase.

Again, the cause must be corrected or the

problem may persist in the rebuilt engine.

10Measure the piston ring side clearance by

laying a new piston ring in each ring groove

and slipping a feeler gauge in beside it(see

illustration). Check the clearance at three or

four locations around each groove. Be sure to

use the correct ring for each groove - they are

different. If the side clearance is greater than

the figure listed in this Chapter’s Specifi-

cations, new pistons will have to be used.

11Check the piston-to-bore clearance by

measuring the bore (see Section 16) and the

piston diameter. Make sure the pistons and

bores are correctly matched. Measure the

piston across the skirt, at 90° to, and in line

with, the gudgeon pin (see illustration). (Any

difference between these two measurements

indicates that the piston is no longer perfectly

round.) Subtract the piston diameter from the

bore diameter to obtain the clearance. If it’s

greater than specified, the block will have to

be rebored, and new pistons and rings fitted.

2B•16 General engine overhaul procedures

18.11 Measure the piston diameter at a

90-degree angle to the gudgeon pin, at the

same height as the gudgeon pin

18.10 Check the ring side clearance with a

feeler gauge at several points around the

groove18.4 The piston ring grooves can be

cleaned with a special tool, as shown

here18.2 Removing the compression rings with

a ring expander - note the mark (arrowed)

facing up

If a groove cleaning tool isn’t available,

a piece broken off the old ring will do

the job, but protect your hands - piston

rings can be sharp