119 BMW 318i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 68 of 759

113-2

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

0011s6i

-

0Fig

.

1

.

Front

exhaust

pipe

to

exhaust

manifold

mountíng

nuts

(arrows)

.

-1

~~

0013023

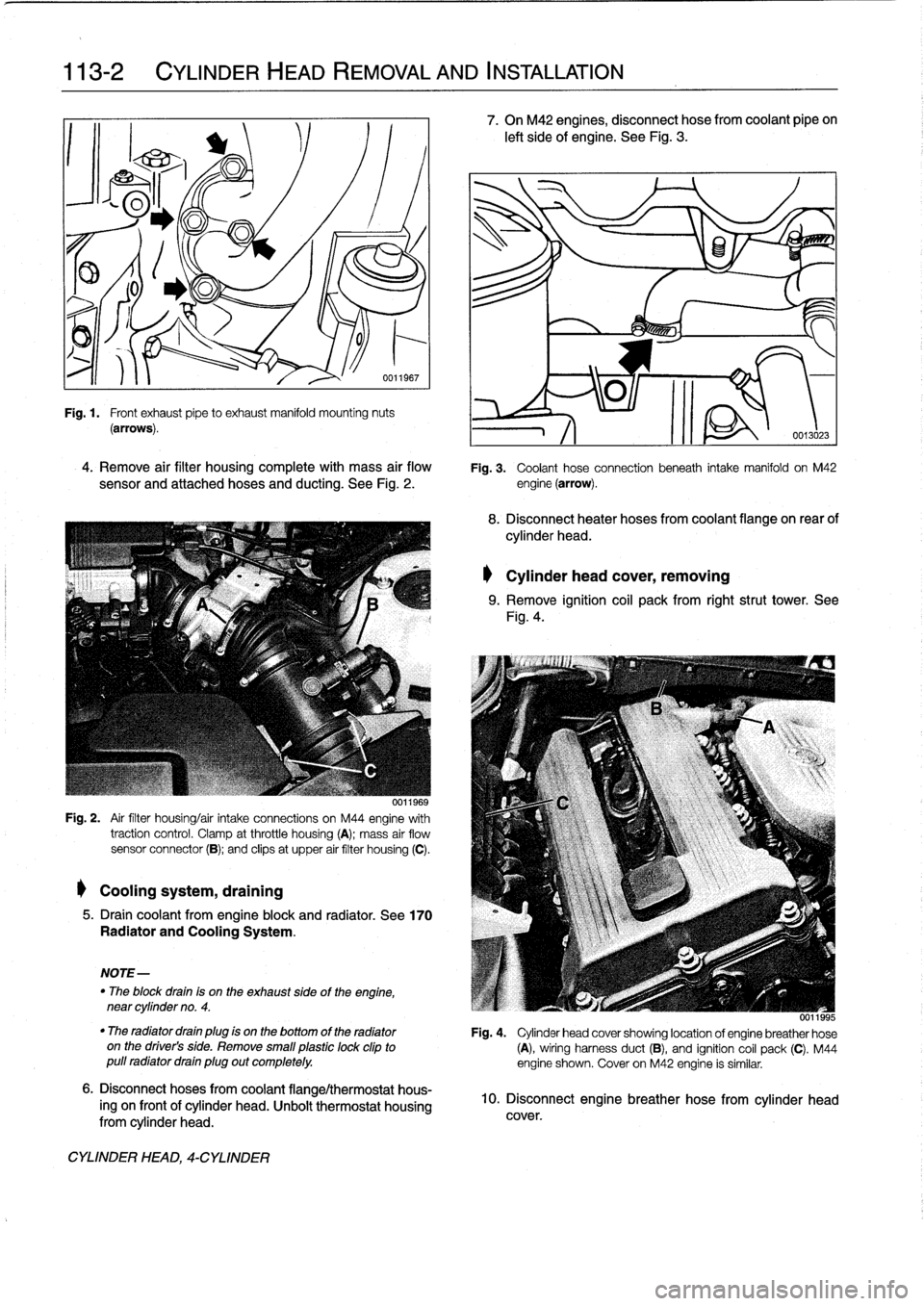

4

.

Remove

air

filter

housing

complete

with

mass

air

flow

Fig

.

3

.

Coolant

hose

connection

beneath

intake

manifold

on

M42

sensor

and

attached

hoses

and

ducting

.

See

Fig

.

2

.

engine

(arrow)

.

0011969

Fig

.

2

.

Air

filter

housing/air

intake

connections

on

M44

engine

with

traction

control

.

Clamp

atthrottle

housing

(A)

;

mass

air

flow

sensor

connector

(B)

;

and

clips

at

upper

air

filter

housing

(C)

.

Coolingsystem,

draining

5

.

Draincoolant

from

engine

block

and

radiator

.

See

170

Radiator

and

Cooling

System

.

NOTE-

"

The

block

drain

is

on

the

exhaust

sideof

the

engine,

near

cylinder

no

.

4

.

6

.

Disconnect

hoses

from

coolant

flange/thermostat

hous-

ing

on

frontof

cylinder

head

.

Unbolt

thermostat

housing

from

cylinder

head

.

CYLINDER

HEAD,

4-CYLINDER

7

.

On

M42

engines,

disconnect

hose

from

coolant

pipe

on

left

side

of

engine

.

See

Fig

.

3

.

8

.

Disconnect

heater

hoses

from

coolant

flange

on

rear

of

cylinder

head

.

Cylinder

head

cover,

removing

9

.

Remove

ignition

coil

pack

from

rightstrut

tower

.

See

Fig

.

4

.

0011995

"

The

radiator

drain

plug

is

on

the

bottomof

the

radiator

Fig

.

4

.

Cylinder

head

cover

showing

location

of

engine

breather

hose

on

the

driver's

side

.

Remove

small

plastic

lock

clipto

(A),

wiring

harness

duct

(B),

and

ignition

coil

pack

(C)

.

M44

pull

radiator

drain

plug

out

completely

.

engine

shown

.

Cover

on

M42

engine

is

similar

.

10

.

Disconnect

engine

breather

hose

from

cylinder

head

cover

.

Page 70 of 759

113-4

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

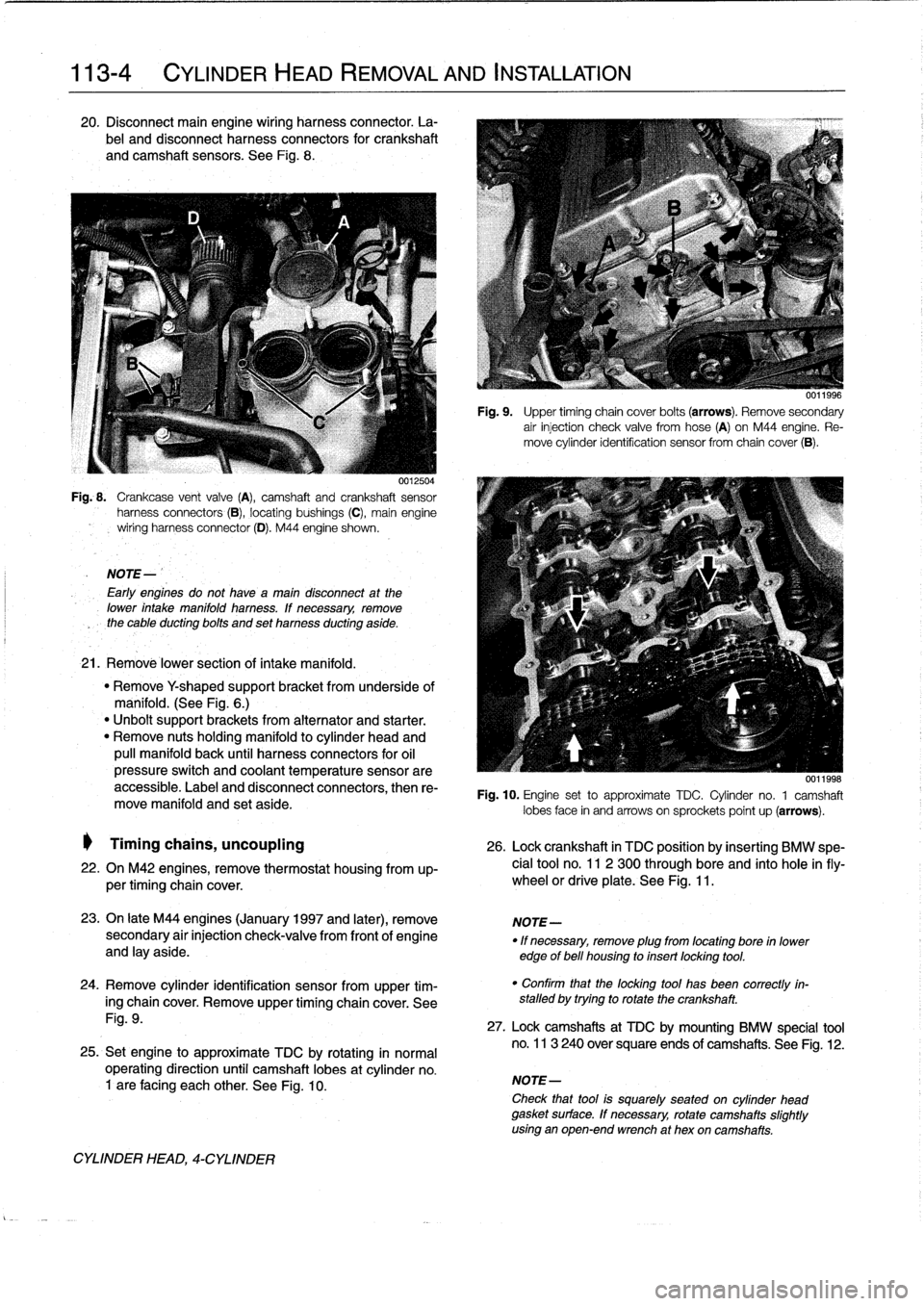

20

.

Disconnect

main

engine

wiring

harness

connector

.

La-

bel

and

disconnect

harness

connectors

for

crankshaft

and

camshaft

sensors

.

See

Fig

.

8

.

0012504

Fig

..

Crankcase

vent

valve

(A),

camshaft

and

crankshaft

sensor

harness

connectors

(B),

locating

bushings

(C),

main

engine

wiring

harnessconnector

(D)

.

M44

engine

shown

.

NOTE-

Early

engines

do

not

havea

maín

disconnect

at

the

lower

intake

manifold

harness

.

lf

necessary,

remove

the

cable

ducting

bolts

and

set

harness

ducting

aside

.

21

.

Remové

lower

section

of

intake

manifold

.

"

Remove

Y

shaped

supportbracket

from

underside

of

manifold

.

(See

Fig

.

6

.)

"

Unbolt

support

brackets

from

alternator

and

starter

.

"

Remove

nuts

holding

manifold

to

cylinder

head

and

pull

manifold

back

until

harness

connectors

for

oil

pressure

switch

and

coolant

temperature

sensorare

accessible

.

Label

and

disconnect

connectors,

then

re-

move

manifold

and

set

aside

.

Timing

chains,

uncoupling

26

.

Lock

crankshaft

in

TDC

position

by

insertíng

BMW

spe-

22

.

On

M42

engines,

remove

thermostat

housing

from

up-

cial

tool

no

.

11

2

300

through

bore

and

into

hole

infly-

per

timing

chaincover

.

wheel

or

driveplate

.

See

Fig

.

11

.

23

.

On

late

M44

engines

(January

1997

and

later),

remove

NOTE-

secondary

air

injection

check-valve

from

front

of

engine

"

If

necessary,

remove

plug

from

locating

bore

in

lower

and

lay

aside

.

edge

of

bell

housing

to

insert

locking

tool

.

24

.

Remove

cylinder

identification

sensor

from

upper

tim-

ing

chaincover

.

Remove

upper

timing

chaincover

.

See

Fig

.

9

.

25

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

10

.

CYLINDER

HEAD,

4-CYLINDER

Fig

.

9

.

Upper

timing

chain

cover

bolts

(arrows)

.

Remove

secondary

air

injection

check

valve

fromhose

(A)

on

M44

engine

.

Re-

move

cylinder

identification

sensor

from

chaincover

(B)

.

0011998

Fig

.

10

.

Engine

set

to

approximate

TDC

.

Cylinder

no

.

1

camshaft

lobes

face

in

and

arrows

on

sprockets

poínt

up

(arrows)

.

"

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotate

the

crankshaft

.

27

.

Lock

camshafts

at

TDC

by

mounting

BMW

specíal

tool

no

.

113

240

over

square

ends

of

camshafts

.

See

Fig

.

12

.

NOTE-

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

camshafts

slightly

using

an

open-end

wrench

at

hex

oncamshafts

.

Page 71 of 759

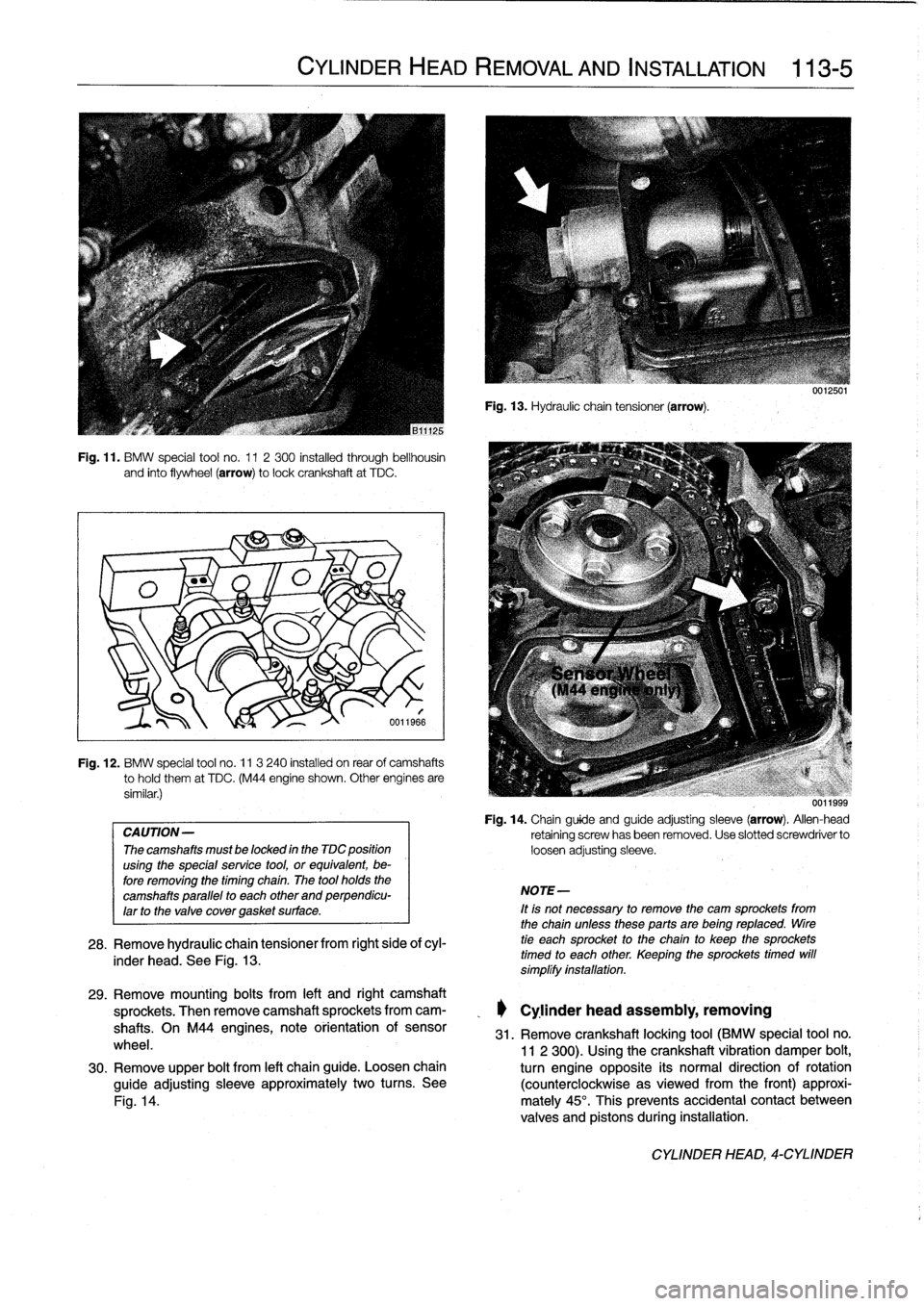

Fig

.

11

.

BMW

special

tool

no

.

11

2300

installed

through

bellhousin

and

finto

flywheel

(arrow)

tolockcrankshaft

at

TDC

.

Fig

.

12

.

BMW

special

tool

no

.

11

3

240

installed

on

rear

of

camshafts

tohold

them

at

TDC

.

(M44

engine

shown

.

Other

engínes

are

similar

.)

CAUTION-

The

camshafts

must

be

locked

in

the

TDC

position

using

the

special

service

tool,

or

equivalent,

be-

fore

removing

the

timing

chaín

.

The

tool

holds

the

camshafts

parallel

to

each

other

and

perpendicu-

larto

the

valve

covergasket

surface

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-5

6011966

28

.

Remove

hydraulic

chain

tensiones

from

right

side

ofcyl-

inder

head

.

See

Fig

.

13

.

Fig

.

13

.

Hydraulic

chain

tensioner

(arrow)

.

NOTE-

It

is

not

necessary

to

remove

the

cam

sprockets

from

the

chainuntessthese

parts

are

being

reptaced

.

tire

tie

each

sprocket

to

the

chain

to

keep

the

sprockets

timed

to

each

other

.

Keeping

the

sprockets

timed

will

símplífy

instaftation

.

uu

11999

Fig

.

14

.

Chainguide

and

guide

adjusting

sleeve

(arrow)

.

Allen-head

retaining

screwhasbeen

removed

.

Use

slotted

screwdriver

to

loosen

adjusting

sleeve

.

29

.

Remove

mounting

bolts

from

left

and

right

camshaft

sprockets

.

Then

remove

camshaft

sprockets

from

cam-

_

Cylinder

head

assembly,

removing

shafts

.

On

M44

engines,

note

orientation

of

sensor

31

.

Remove

crankshaft

locking

tool

(BMW

special

tool

no

.

wheel

.

11

2

300)

.

Usingthe

crankshaft

vibration

damper

bolt,

30

.

Remove

upper

bolt

from

left

chainguide

.

Loosen

chain

turn

engine

opposite

its

normal

direction

of

rotation

guide

adjusting

sleeve

approximately

two

turns

.

See

(counterclockwise

asviewed

from

the

front)

approxi

Fig

.

14

.

mately

45°

.

This

prevents

accidental

contact

between

valves

and

pistons

during

installation

.

CYLINDER

HEAD,

4-CYLINDER

Page 77 of 759

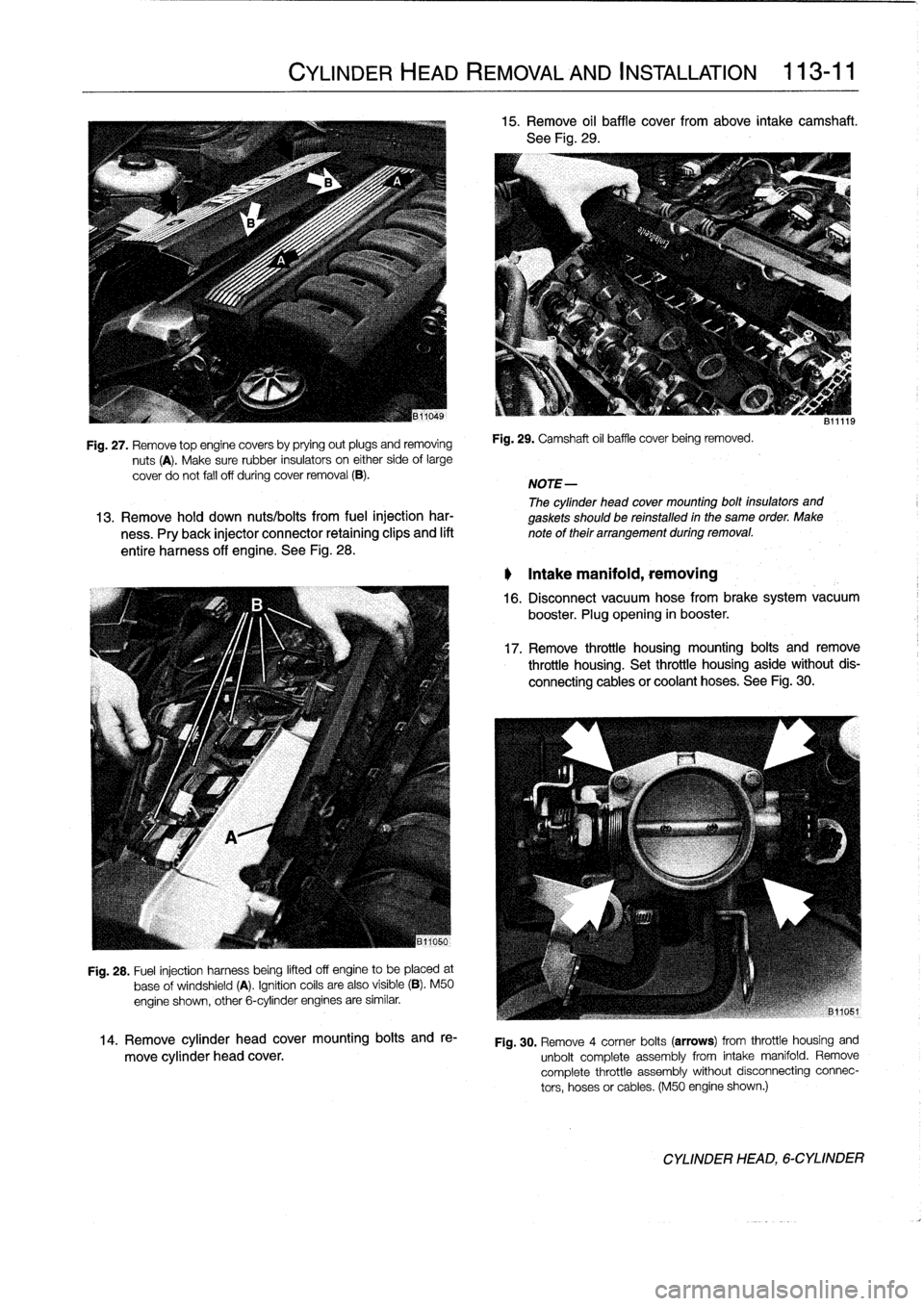

Fig

.

27

.

Remove

top

enginecovers

by

prying

out

plugs

and

removing

nuts

(A)

.

Make

sure

rubber

insulators

on

either

side

of

large

cover

do

not

fall

off

during

cover

removal

(B)

.

Fig

.

28

.

Fuel

injection

harness

beíng

lifted

off

engine

to

be

placed

at

base

of

windshield

(A)

.

Ignitioncoils

are

also

visible

(B)

.

M50

engine

shown,

other

6-cylinder

engines

are

similar

.

14

.

Remove

cylinder

head

cover

mounting

bolts

and

re-

move

cylinder

head

cover

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-

11

15

.

Remove

oil

baffle

cover

from

above

intake

camshaft

.

See

Fig

.

29

.

Fig

.

29

.

Camshaft

oil

baffle

coverbeing

removed

.

NOTE-

The

cylinder

head

cover

mounting

bolt

insulators

and

13

.

Remove

hold

down

nuts/bolts

from

fuel

injection

har-

gaskets

should

be

reinstalled

in

the

same

order

.

Make

ness

.

Pry

back

injector

connector

retaining

clips

and

lift

note

of

their

arrangement

during

removal

.

entire

harness

off

engine

.

See

Fig

.

28

.

Intake

manifold,

removing

811119

16

.

Disconnect

vacuum

hose

from

brake

system

vacuum

booster

.

Plug

opening

in

booster

.

17

.

Remove

throttle

housing

mounting

bolts

and

remove

throttle

housing

.

Set

throttle

housing

aside

without

dis-

connecting

cablesor

coolant

hoses

.

See

Fig

.

30

.

Fig

.

30

.

Remove

4

comer

bolts

(arrows)

from

throttle

housing

and

unbolt

complete

assembly

from

intake

manifold

.

Remove

complete

throttle

assembly

without

disconnecting

connec-

tors,

hoses

or

cables

.

(M50

engine

shown

.)

CYLINDER

HEAD,

6-CYLINDER

Page 98 of 759

117-2

CAMSHAFT

TIMING

CHAIN

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Special

BMW

service

tools

are

needed

for

timing

chain

re-

moval

and

installation

procedures

.

The

special

tools

assure

proper

timing

of

the

valvetrain

.

Precíse

marks

to

setthe

timing

on

the

camshafts

are

not

provided

for

reassembly

.

Read

the

procedures

through

before

beginning

the

job

.

CAUTION-

lf

the

camshaftsare

not

properly

timed,

the

pis-

tons

can

contact

thevalves

.

Camshaft

timing

chain,

removing

(4-cylinder

engines)

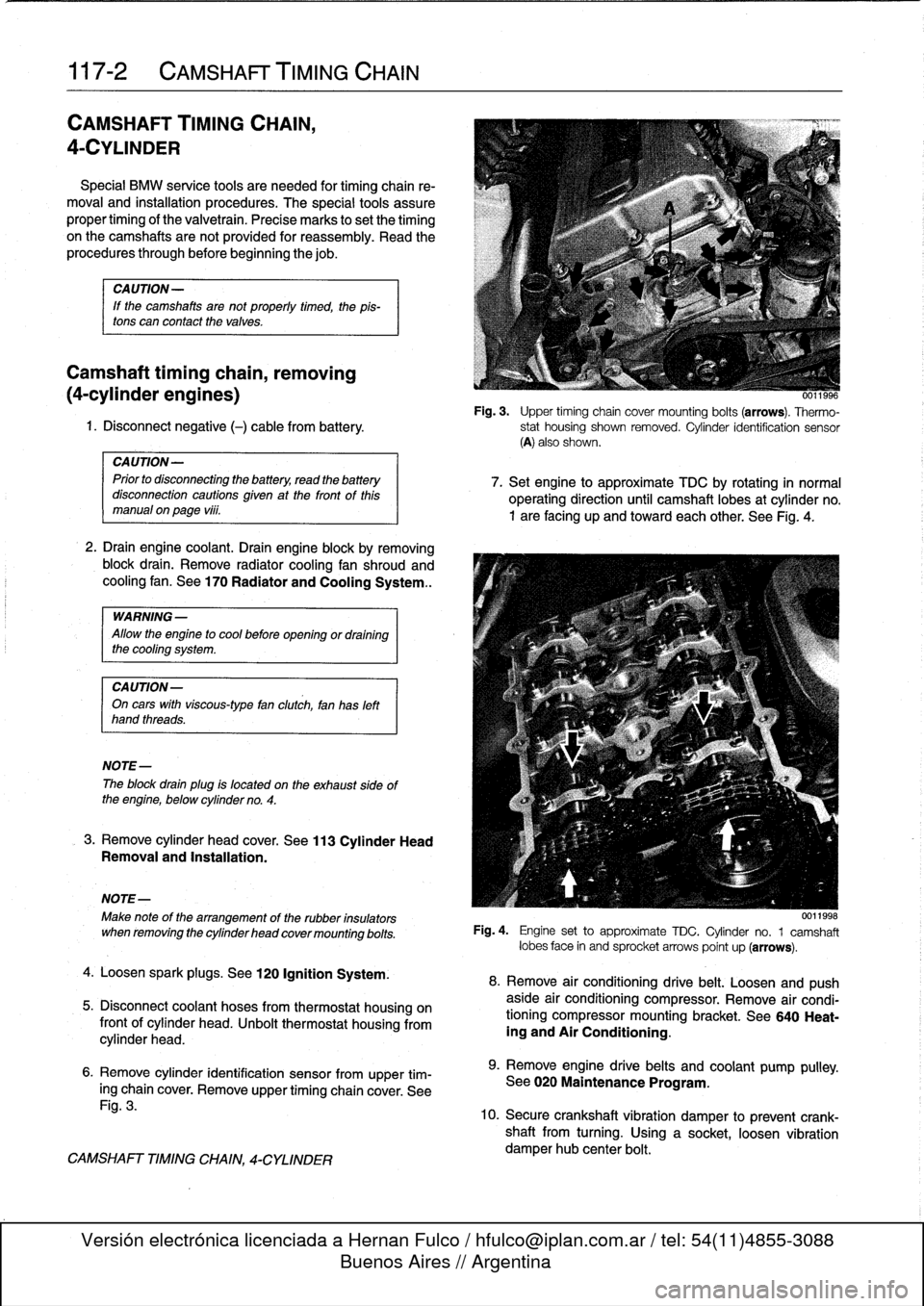

U0119-

Fig

.

3

.

Upper

timing

chain

covermounting

bolts(arrows)

.

Thermo-

1

.

Disconnect

negative

(-)cablefrom

battery

.

stat

housing

shown

removed

.

Cylinder

ídentification

sensor

(A)

also

shown

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Drain

engine

coolant

.

Drain

engine

block

byremoving

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See

170

Radiator

and

Cooling

System

..

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

cooling

system

.

CA

UTION-

On

cars

with

viscous-type

fan

clutch,

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

sideof

the

engine,

below

cylinder

no

.

4

.

3

.

Remove

cylinder

head

cover

.

See

113

Cylinder

HeadRemoval

and

Installation

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

belts

.

4

.

Loosen

sparkplugs

.

See

120

Ignition

System

.

5

.

Disconnect

coolant

hoses

from

thermostat

housingon

front

of

cylinder

head

.

Unbolt

thermostat

housing

from

cylinder

head

.

6

.

Remove

cylinder

identification

sensor

from

upper

tim-

ing

chain

cover

.

Remove

upper

timing

chain

cover

.

See

Fig

.

3

.

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

7

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

up

and

toward

each

other

.

See

Fig

.

4

.

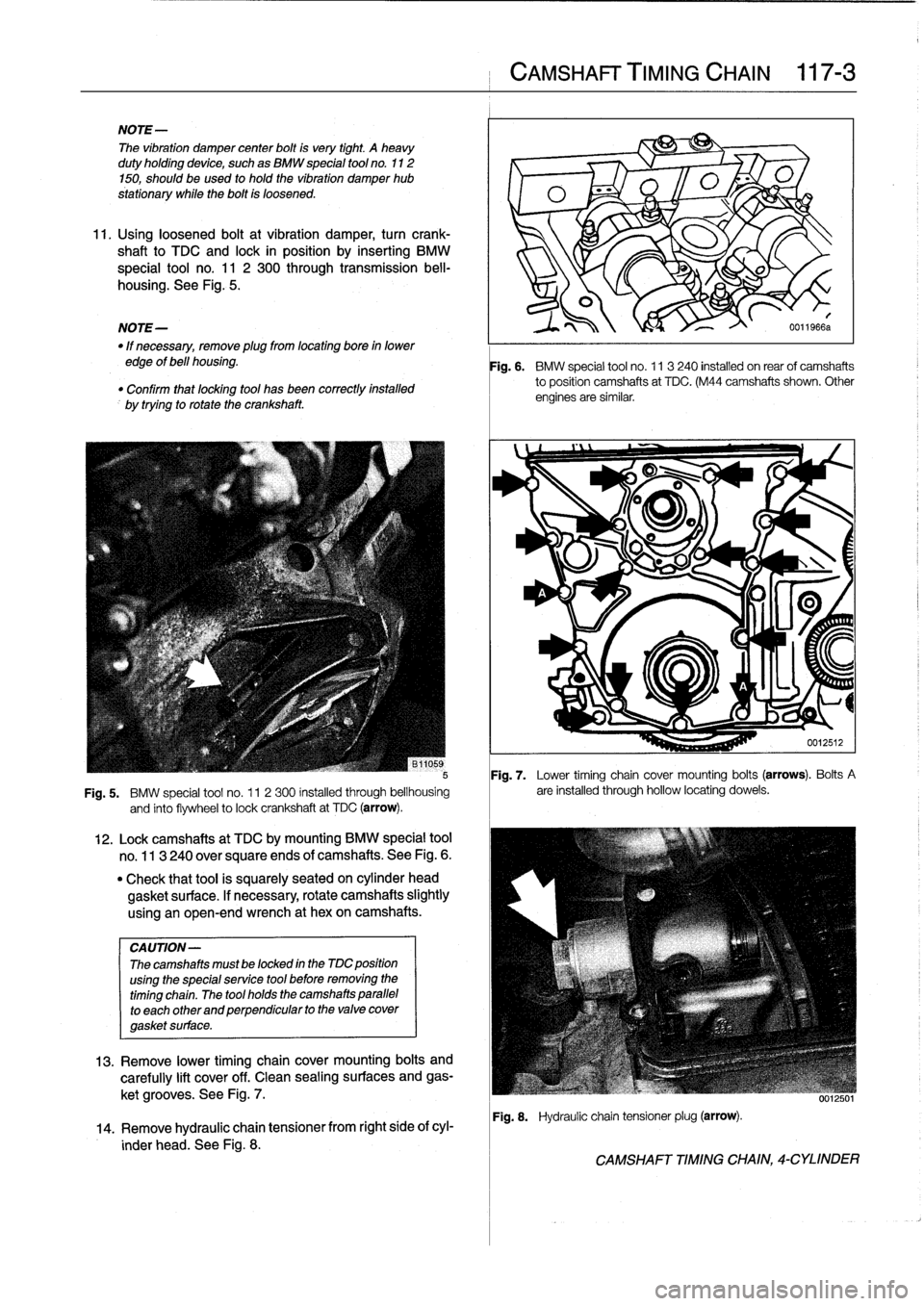

0011998

Fig

.

4

.

Engine

set

to

approximate

TDC

.

Cylinder

no

.

1

camshaft

lobes

face

in

and

sprocket

arrows

point

up

(arrows)

.

8

.

Remove

air

conditioning

drive

belt

.

Loosenand

push

aside

air

conditioning

compressor

.

Remove

air

condi-

tioning

compressor

mounting

bracket

.

See

640

Heat-

ing

and

Air

Conditioning

.

9

.

Remove

engine

drive

belts

and

coolant

pump

pulley

.

See

020

Maintenance

Program

.

10

.

Secure

crankshaft

vibration

damper

to

prevent

crank-

shaft

from

turning

.

Using

a

socket,

loosen

vibration

damper

hub

center

bolt

.

Page 99 of 759

NOTE-

The

vibration

damper

center

bolt

is

very

tight

.

A

heavy

duty

holding

device,

such

as

BMW

special

tool

no

.

112

150,

should

be

used

to

hold

the

vibration

damper

hub

V

stationary

while

the

bolt

is

loosened

.

v

11

.

Usingloosened

bolt

at

vibration

damper,

turn

crank-

shaft

to

TDC

and

lock

in

position

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bell-

-

p

housing

.

See

Fig

.

5

.

v

O

NOTE-

I\

0011966a

"

If

necessary,

remove

plugfrom

locating

boye

in

lower

edge

of

bell

housing

.

"

Confirm

that

locatng

tool

has

been

correctlyinstalled

by

trying

to

rotate

the

crankshaft

.

Fig

.

7

.

Lower

timing

chain

cover

mounting

bolts

(arrows)

.

Bolts

A

Fig

.

5

.

BMW

special

tool

no

.

11

2300

installed

through

bellhousing

are

installed

through

hollow

locating

dowels

.

and

finto

flywheel

to

lock

crankshaft

at

TDC

(arrow)

.

CA

UTION-

Thecamshafts

mustbe

locked

in

the

MC

position

using

the

specialservice

tool

before

removing

the

timing

chain

.

The

tool

holds

the

camshafts

parallel

to

each

other

and

perpendicular

to

the

valve

cover

gasket

surface

.

12

.

Lockcamshafts

at

TDC

bymounting

BMW

special

tool

no

.

113

240

over

square

ends

of

camshafts

.

See

Fig

.

6

.

"

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

camshafts

slightly

using

an

open-end

wrench

at

hexon

camshafts

.

13

.

Remove

lower

timing

chaincover

mounting

bolts

and

carefully

lift

cover

off

.

Clean

sealing

surfaces

and

gas-

ket

grooves

.

See

Fig

.

7

.

14

.

Remove

hydraulic

chaintensioner

from

right

side

of

cyl-

inder

head

.

See

Fig

.

8

.

CAMSHAFT

TIMING

CHAIN

117-

3

Fig

.

6

.

BMW

special

tool

no

.

11

3240

installed

on

rearof

camshafts

to

position

camshafts

at

TDC

.

(M44

camshafts

shown

.

Other

engines

are

similar

.

Fig

.

8

.

Hydraulic

chain

tensionerplug

(arrow)

.

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Page 103 of 759

Camshaft

timing

chains,

removing

(6-cylinder

engines)

1

.

Disconnect

negative

(-)

cable

from

battery

.

CA

UTION-

Disconnecting

the

battery

may

erase

fault

codes)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

.

2

.

Drain

engine

coolant

.

Drain

engine

block

by

removing

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See170

Radiator

and

Cooling

System

.

.

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

system

.

CAUTION-

Radiator

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

side

of

the

engine,

below

cylinder

no

.

4

.

3

.

Drain

engine

oíl

andremove

oil

pan

.

See

119

Lubrica-

tion

System

.

4

.

Remove

alternator

cooling

duct

.

5

.

Remove

two

large

coolant

hoses

from

thermostat

housing

.

Remove

engine

lifting

bracket

and

thermostat

housing

from

front

of

cylinder

head

.

6

.

Loosen

bolts

for

coolant

pump

pulley

.

Then

remove

drive

belts

for

alternator

andA/C

compressor

.

See

020

Maintenance

Program

.

Remove

coolant

pump

pulley

.

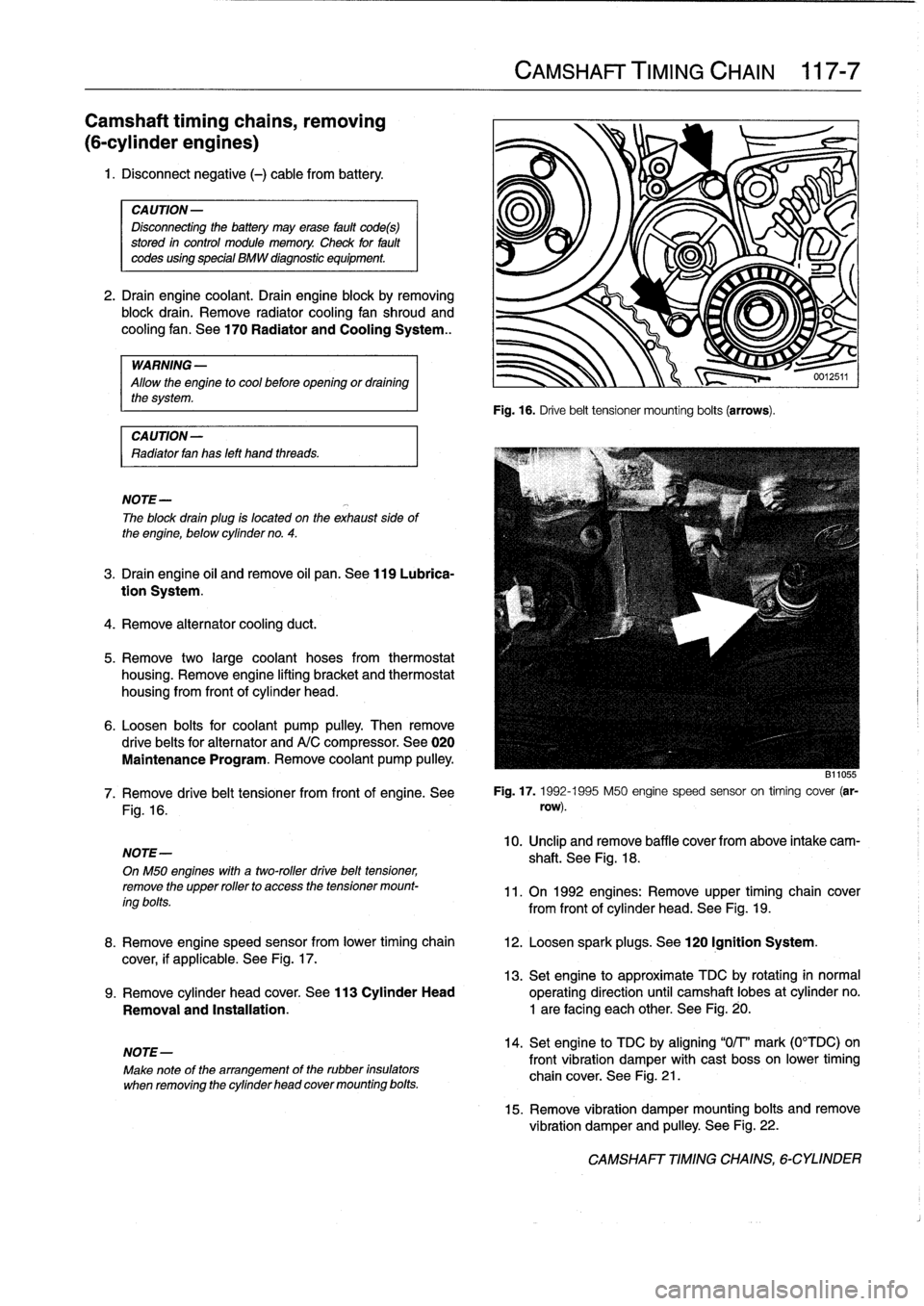

Fig

.

16

.

NOTE-

OnM50

engines

with

a

two-roller

drive

belt

tensioner,

remove

the

upper

rollerto

access

thetensioner

mount-

ing

bolts

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

bolts

.

CAMSHAFT

TIMING

CHAIN

117-

7

Fig

.

16

.

Drive

belt

tensioner

mounting

bolts

(arrows)

.

B11055

7

.

Remove

drive

belt

tensioner

from

front

of

engine

.

See

Fig

.

17

.

1992-1995

M50

engine

speed

sensor

on

timing

cover

(ar-

row)

.

10

.

Unclip

andremove

baffle

cover

from

above

intake

cam-

shaft

.

See

Fig

.

18

.

11

.

On

1992

engines

:

Remove

upper

timing

chain

cover

from

front

of

cylinder

head

.

See

Fig

.

19

.

8

.

Remove

engine

speed

sensor

from

lower

timing

chain

12

.

Loosen

spark

plugs

.

See

120

Ignition

System

.

cover,

if

applicable

.

See

Fig

.

17

.

13

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

9

.

Remove

cylinder

head

cover

.

See

113

Cylinder

Head

operating

direction

until

camshaft

lobes

at

cylinder

no

.

Removal

and

Installatíon

.

1

are

facing

each

other

.

See

Fig

.

20

.

14

.

Set

engine

to

TDC

by

aligning

"0/T'

mark

(0°TDC)on

front

vibration

damper

with

cast

bosson

lower

timing

chain

cover

.

See

Fig

.

21

.

15

.

Remove

vibration

damper

mounting

bolts

and

remove

vibration

damper

and

pulley

.

See

Fig

.

22

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

Page 107 of 759

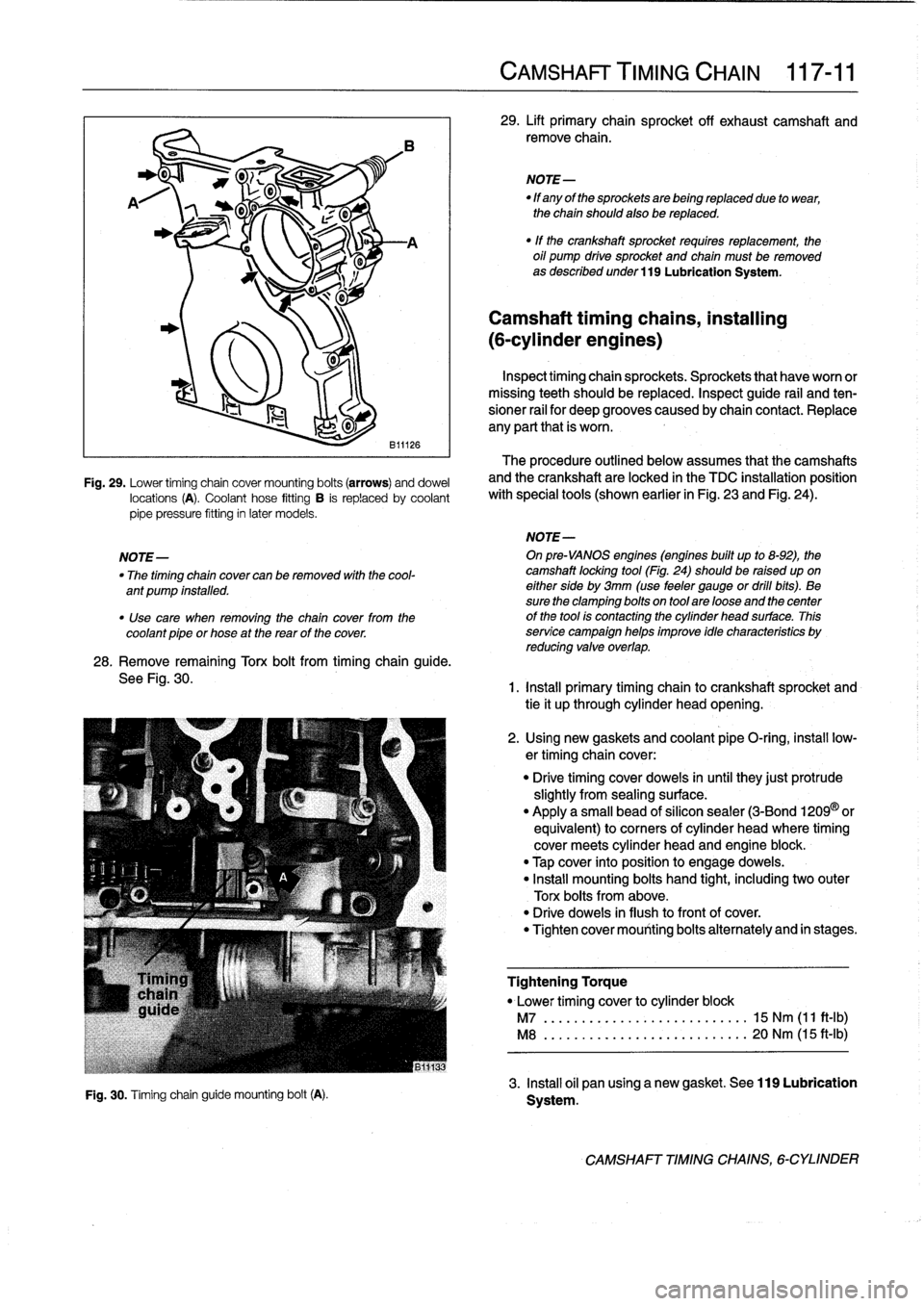

9)

B11126

Fig

.

29

.

Lower

timing

chain

cover

mounting

bolts

(arrows)

anddowel

locations

(A)

.

Coolant

hose

fitting

B

is

replaced

by

coolant

pipe

pressure

fitting

in

later

models

.

28

.

Remove

remaining

Torx

bolt

from

timing

chain

guide

.

See

Fig

.

30

.

Fig

.

30

.

Timing

chainguide

mounting

bolt(A)

.

CAMSHAFT

TIMING

CHAIN

117-

11

29

.

Lift

primary

chain

sprocket

off

exhaust

camshaft

and

remove

chain

.

NOTE-

"

If

any

of

the

sprockets

are

being

replaced

due

to

wear,

the

chain

should

also

be

replaced

.

"

If

the

crankshaft

sprocket

requires

replacement,

the

oil

pump

drive

sprocket

and

chain

must

be

removed

as

described

under

119

Lubrication

System

.

Camshaft

timing

chains,

installing

(6-cylinder

engines)

Inspecttiming

chainsprockets

.

Sprockets

that

haveworn

or

missing

teeth

should

be

replaced

.

Inspect

guide

rail

and

ten-

sioner

rail

for

deep

grooves

caused

by

chain

contact

.

Replace

any

parí

that

is

worn

.

The

procedure

outlined

below

assumes

that

the

camshafts

and

the

crankshaft

are

locked

in

the

TDC

installation

position

with

special

tools

(shown

earlier

in

Fig

.

23

and

Fig

.

24)

.

NOTE-

NOTE-

On

pre-VANOS

engines

(engines

built

up

to

8-92),

the

"

The

timing

chain

cover

can

be

removed

with

the

cool-

camshaft

locking

tool

(Fig

.

24)should

be

raised

upon

ant

pump

installed

.

eitherside

by

3mm

(use

feeler

gauge

or

dril¡

bits)

.

Be

sure

the

clamping

bolts

on

tool

are

loose

and

thecenter

"

Use

care

when

removing

the

chain

cover

from

the

of

the

tool

is

contacting

the

cylinder

head

surface

.

This

coolant

pipe

or

hose

at

the

rearof

the

cover

.

service

campaign

helps

improve

idle

characteristics

by

reducing

valve

overlap

.

1

.

Install

primary

timing

chain

to

crankshaft

sprocket

and

tie

it

up

through

cylinder

head

opening

.

2

.

Using

new

gaskets

and

coolant

pipe

O-ring

;

insta¡¡

low-

ertiming

chain

cover

:

"

Drive

timing

cover

doweis

inuntil

they

just

protrude

slightly

from

sealing

surface

.

"

Apply

a

small

bead

of

silicon

sealer

(3-Bond

1209

©

or

equivalent)

to

corners

of

cylinder

head

where

timing

cover

meets

cylinder

head

and

engine

block

.

"

Tap

cover

into

position

to

engage

doweis

.

"

Install

mounting

bolts

hand

tight,

including

two

outer

Torx

bolts

from

above

.

"

Drive

doweis

in

flush

to

front

of

cover

.

"

Tighten

cover

mounting

bolts

alternately

and

in

stages

.

Tightening

Torque

"

Lower

timing

cover

to

cylinder

block

M7

................

...

..

.

.....

15

Nm

(11

ft-Ib)

M8

.............

.

.

...

.........

20

Nm

(15

ft-Ib)

3

.

Insta¡¡

oil

pan

using

a

new

gasket

.

See

119

Lubrication

Systern

.

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

Page 110 of 759

117-

1

4

CAMSHAFT

TIMING

CHAIN

22

.

Installation

of

remaining

parts

is

reverse

of

removal,

When

theengine

is

running,

the

piston

housing

is

supplied

noting

the

following

:

with

pressurized

engine

oil

.

At

idie,

the

solenoid

isin

the

off

"

When

installing

thermostat,

make

sure

arrow

or

vent

position

(de-energized)

and

valve

timing

is

maintained

in

the

hole

faces

up,

if

applicable

.

normal

position

:

When

the

solenoid

is

energized,

the

gear

cup

"

Refill

cooling

systemas

described

in

170

Radiator

piston

moves

forward

to

advance

the

camshaftby

a

maximum

and

Coming

System

.

of

12

.5

.

"

Install

oil

pan

as

described

in

119

Lubrication

Sys-

tem

.

"

Fill

engine

with

oil

and

install

a

new

oil

filter

as

de-

scribed

in

020

Maintenance

Program

.

"

Insta¡¡

ground

wires

at

cylinder

head

cover

mounting

studs

and

at

front

of

cylinder

head

and

thermostat

housing,

where

applicable

.

VANOS

system

operation,

testing

Tightening

Torques

There

are3

special

tools

required

to

check

VANOS

opera-

"

Coolant

drain

plugto

cylinder

block

.

.

25

Nm

(18

ft-Ib)

tion

;

an

electricaltest

lead

(BMW

special

tool

no

.

12

6

410),

an

"

Radiator

cooling

fan

to

coolant

pump

.

40

Nm

(30

ft-Ib)

air

line

fitting

(BMW

special

tool

no

.

11

3

450),

and

a

crank-

"

Radiator

drain

screw

to

radiator

...

.

2

.5

Nm

(22

in-Ib)

shaft

TDC

locking

tool

(BMW

special

tool

no

.

112

300)

.

"

Upper

timing

chaincover

to

cylinder

head

The

test

leal

is

used

to

power

the

solenoid,

simulating

the

M6

nut

...

.....

.............

..

.

10

Nm

(89

in-lb)

ground

signal

from

the

DME

control

unit

.

The

air

line

fitting

M8

bolt

.....

....

.

.

.............

22

Nm

(17

ft-Ib)

takes

the

place

of

the

oil

supply

line

fitting

to

simulate

oil

Ares-

"

VANOS

control

unit

to

cylinder

head

sure

.

The

locking

tool

positions

and

locks

the

crankshaft

at

M6

nut

.........

..

..

.

..........

10

Nm

(89

in-lb)

TDC,

cylinder

no

.

l.

M8

bolt

........

...

.............

22

Nm

(17

ft-Ib)

"

VANOS

oil

supply

pipe

to

VANOS

control

unit

1

.

Remove

alternator

cooling

air

duct

.

banjo

bolt

.......

..

..

.

..........

32

Nm

(24

ft-Ib)

VANOS

(VARIABLE

VALVE

TIMING)

3

.

Remove

top

plastic

enginecovers

.

Disconnect

ignition

coil

harness

connectors

fromcofs

.

Remove

ignition

1993

and

later

6-cylinder

engines

are

equipped

with

a

vari-

coils

.

able

valve

timing

system

called

VANOS

.

This

system

is

con-

trolled

by

the

engine

management

system

and

dynamically

4

.

Remove

cylinder

head

cover

mounting

bolts

and

re-

adjusts

intake

camshaft

timing

based

on

engine

load,

engine

move

cylinder

head

cover

.

Unclip

andremove

oil

baffle

speed

and

engine

temperature

.

cover

from

above

intake

camshaft

.

See

113

Cylinder

Head

Removal

and

installation

.

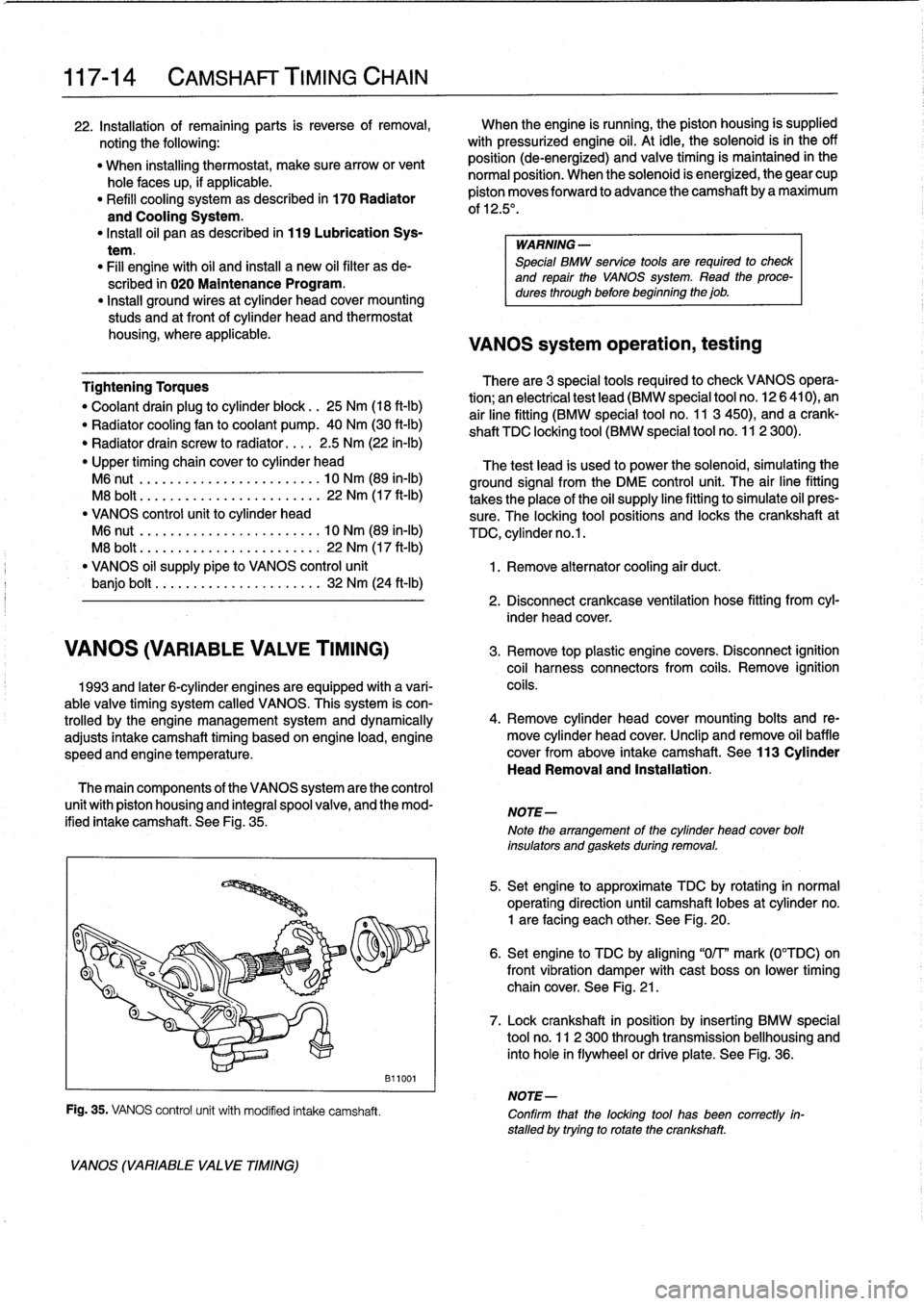

The

main

components

of

the

VANOS

system

are

the

control

unit

with

piston

housing

and

integral

spool

valve,

and

the

mod-

ified

intake

camshaft

.

See

Fig

.

35

.

VANOS

(VARIABLE

VA

LVE

TIMING)

Fig

.

35

.

VANOS

control

unit

with

modified

intake

camshaft

.

B11001

WARNING

-

Special

BMW

service

tools

are

required

to

check

and

repair

the

VANOS

System

.

Read

theproce-

dures

through

before

beginning

the

job

.

2

.

Disconnect

crankcase

ventilation

hose

fitting

from

cyl-

inder

head

cover

.

NOTE-

Note

the

arrangement

of

the

cylinder

head

cover

bolt

insulators

and

gaskets

during

removal

.

5

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

20

.

6

.

Set

engine

to

TDC

by

aligning

"0/T"

mark

(0°TDC)on

front

vibration

damper

withcast

boss

on

lower

timing

chain

cover

.

See

Fig

.

21

.

7

.

Lock

crankshaft

in

position

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

and

into

hole

in

flywheelor

driveplate

.

See

Fig

.

36

.

NOTE-

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotatethe

crankshaft

.

Page 115 of 759

119

Lubrication

System

LUBRICATION

SYSTEM

119-1

GENERAL

.

.

.

.

.

.

...

.

.

.

.

.

.

.

...,

,

...

.

.

.

.

119-1

OH

pan,

removing

and

installing

(6-cylinder

engine,

1992

models)

.

.

.

.

.

.

.

.

.

119-4

TROUBLESHOOTING

.

.

.

.

.

.

...

.

.

.

.....

.

119-1

Oil

pan,

removing

and

installing

Oil

pressure,

checking

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

119-1

(6-cylinder

engine,

1993

and

later

models)

.119-6

Oil

pressure

warning

system,

testing

.

.

.

.

.

.

.

119-2

OIL

PUMP

.

.......

.

.............

.119-8

OIL

PAN

.

.

.

.

.

.....

.

.

.

.

.

......

.

.

.

.

.

.

.

..

119-2

Oil

pump,

removing

and

installing

Oil

pan,

removing

and

installing

(4-cylinder

engine)

.

.

.

...

.

..........

.

.

.119-8

(4-cylinder

engines)

.

.

...

.

....

.

.

.

.

.

.

.

..

119-2

Oil

pump,

removing

and

installing

(6-cylinder

engine)

.

.

.....

.

.........

.

.119-10

GENERAL

Oil

pressure,

checking

The

oil

pan

and

the

oil

pump

can

be

removed

with

theen-

gine

installed,

although

engine

liftinglsupport

equipment

is

necessary

.

NOTE-

Oil

change

procedure

and

oil

filter

replacement

are

covered

in

020

Maintenance

Program

.

Al¡

engines

are

equipped

with

an

oil

pressure

warning

sys-

tem

to

help

prevent

engine

damage

.

Other

safety

features

in-

clude

:

"

A

filter

bypass

to

provide

lubrication

should

the

oil

filter

become

clogged

.

"

An

oil

pump

pressure

relief

valve

to

prevent

excessive

system

pressure

.

TROUBLESHOOTING

The

lubrication

warning

system

consists

of

an

oil

pressure

switch

mounted

in

the

oil

circuit

and

an

instrument

panel

warn-

ing

light

.

CAUTION-

If

the

red

oil

pressurewarning

light

comes

on

or

flashes

on

while

driving,

always

assume

that

the

oil

pressure

is

low

.

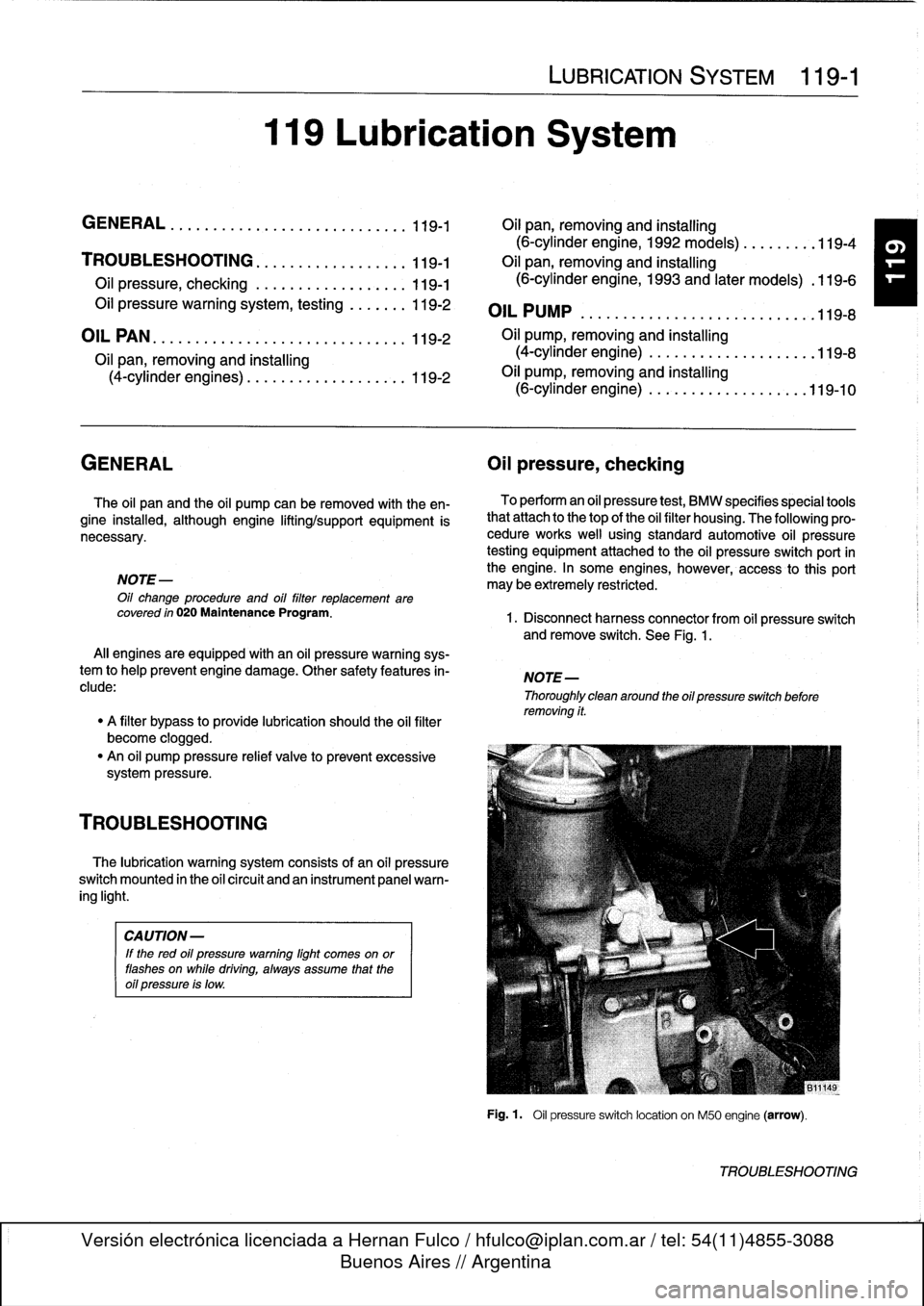

To

perform

an

oíl

pressure

test,

BMW

specifies

special

tools

that

attach

to

thetop

of

the

oíl

filter

housing

.

The

following

pro-

cedure

works

well

using

standard

automotive

oil

pressure

testing

equipment

attached

to

the

oil

pressure

switch

port

in

the

engine

.

In

some

engines,

however,

access

tothis

port

may

be

extremely

restricted

.

1

.

Disconnect

harness

connector

from

oil

pressure

switch

andremove

switch

.

See

Fig

.

1

.

NOTE-

Thoroughly

clean

around

the

oil

pressure

switchbefore

removing

it

.

Fig

.

1

.

Oil

pressure

switch

location

on

M50

engine

(arrow)

.

TROUBLESHOOTING