Driver BMW 318i 1992 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 224 of 759

230-

4

MANUAL

TRANSMISSION

Output

shaft

sea¡,

replacing

(transmission

installed)

1

.

Raise

and

safely

support

vehicle

.

Support

transmission

with

transmission

jack

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-vent

damaging

the

car

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightly

and

the

jack

may

shift

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

transmission

crossmember

and

lower

trans-

mission

at

rear

.

CAUTION-

Tilting

the

engine

to

lower

thetransmissíon

can

lead

to

damage

to

various

componente

due

to

lackof

clearance

.

-On

cars

with

AST

(traction

control)

remove

throt-

tle

body

before

tilting

engine

.

-Remove

brake

fluid

reservoir

if

necessary

.

4

.

Bend

back

and

remove

collar

nut

lockplate

.

5

.

Hold

flange

steady

andremove

collar

lock

nut

(use

30mm

thin-walled

deep

socket

.)

See

Fig

.

5

.

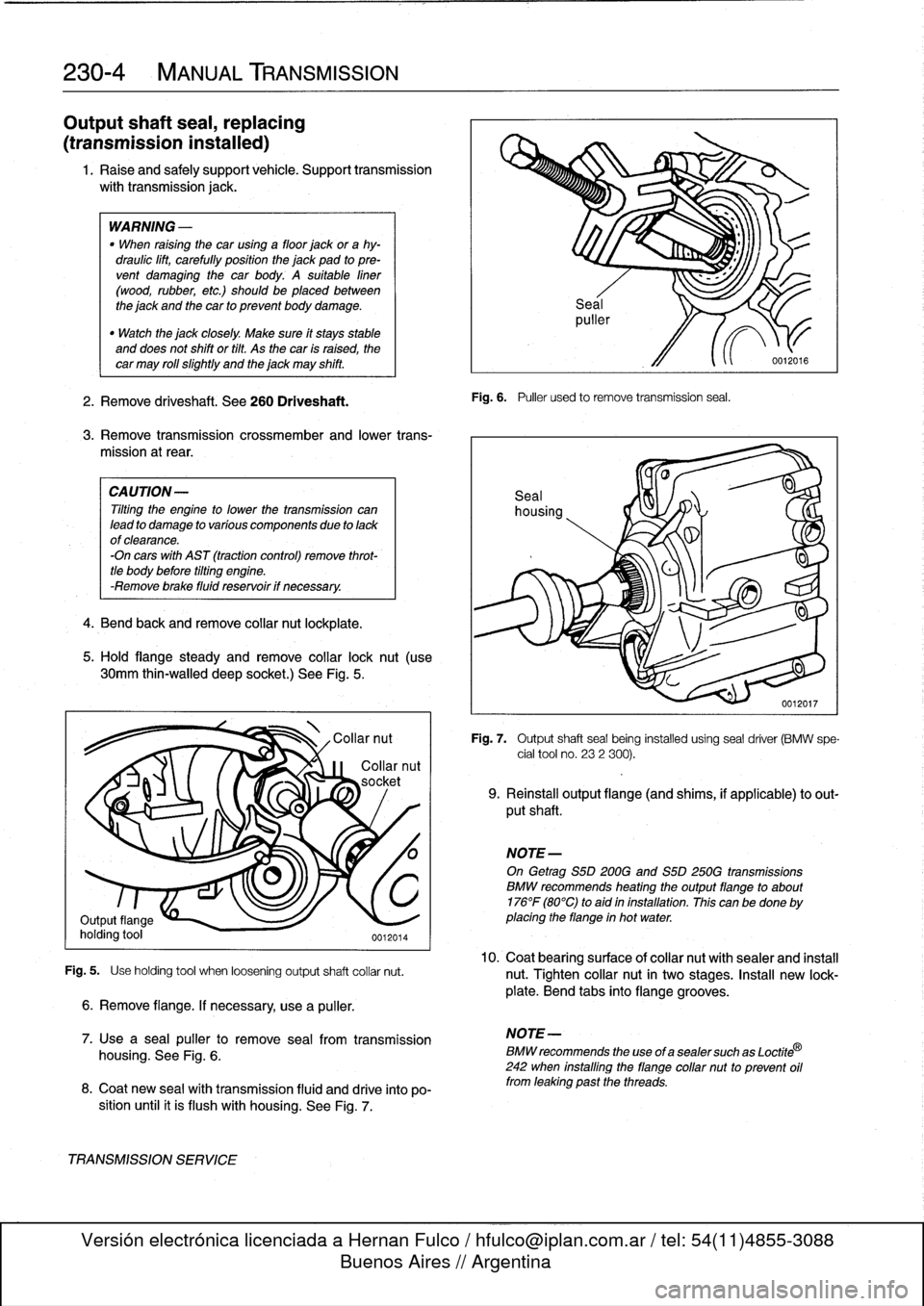

Fig

.

5

.

Use

holding

tool

when

loosening

output

shaft

collar

nut

.

6

.

Remove

flange

.

If

necessary,

use

a

puller

.

7

.

Use

a

sea¡

puller

to

remove

seal

from

transmission

housing

.

See

Fig

.

6

.

8

.

Coat

new

sea¡

wíth

transmission

fluid

and

drive

into

po-

sition

until

it

is

flush

with

housing

.

See

Fig

.

7

.

TRANSMISSIONSERVICE

Fig

.

6

.

Puller

used

to

remove

transmission

seal

.

Fig

.

7

.

Output

shaftseal

being

installed

using

seal

driver

(BMW

spe-

cial

tool

no

.

232

300)

.

9

.

Reinstall

output

flange

(and

shims,

if

applicable)

to

out-

put

shaft

.

NOTE-

On

Getrag

S5D200G

and

S5D

250G

transmissions

BMW

recommends

heating

theoutputflange

to

about

176°F

(80°C)

to

aid

in

installation

.

This

canbe

done

by

placing

the

flange

in

hot

water

.

10

.

Coat

bearingsurface

ofcollar

nut

withsealer

and

install

nut

.

Tighten

collar

nut

in

two

stages

.

Insta¡¡

new

lock-

plate

.

Bend

tabs

into

flange

grooves

.

NOTE-

BMW

recommends

the

use

of

a

sealer

such

as

Loctite

®

242

when

installing

the

flange

collar

nut

to

prevent

oil

from

leaking

past

the

threads

.

Page 229 of 759

AUTOMATIC

TRANSMISSION

240-1

240

Automatic

Transmission

GENERAL

.....

.

.

.

.

.

.

.

.

.

.

.

.

.

.........

.

240-1

TRANSMISSION

REMOVAL

AND

INSTALLATION

..................

.

.

.

.

.240-4

TRANSMISSION

SERVICE

.

.

.

.

.

.......

.

240-1

Transmission,

removing

and

installing

....

.

.

.240-4

ATF

leve¡,

checking

..

.

.

.

.

.

.

.

.

.

..........

240-1

ATF,

draining

and

filling

.

.

.

.

.

.

.

..........

240-2

TABLE

a

.

Automatic

Transmission

Gear

Ratios

.......

..

.

.

240-1

GENERAL

TRANSMISSION

SERVICE

lo

Automatic

transmissions

are

identified

by

code

letters

ATF

leve¡,

checking

foundon

a

data

plate

located

on

the

sideof

thetransmission

case,

behind

the

manual

valve

lever

.

See

200Transmis-

The

automatic

transmissions

installed

in

the

E36

models

sion-General

for

application

information

.

Forgear

ratio

spec-

are

normally

filled

with

Dexron

III

automatic

transmission

fluid

ifications,

see

Table

a

.

(ATF),

although

alternative

fluids

have

been

installed

from

the

factory,

depending

on

transmission

type

and

model

year

.

CAUTION-

Some

transmíssions

are

filled

with

a

special

BMW

"lifetime"

ATF

does

not

circulate

unless

the

engine

is

run-

automatic

transmission

fluid,

which

does

not

require

periodic

ning

.

When

towing

an

automafic

transmission

ve-

fluid

changes

.

hicle,

usea

flat-bed

truck

or

ralse

the

rear

wheels

off

the

ground

.

CAUTION-

Mixing

different

types

of

transmission

fluids

will

The

electronic

transmission

control

module

(TCM)

monitors

lead

to

transmission

failure

.

transmissionoperation

for

faults

and

alerts

the

driver

by

illumi-

nating

the

transmission

fault

indicator

on

the

instrument

pan-

el

.

On-board

diagnostic

codes

stored

in

the

TCM

mustbe

NOTE-

downloaded

and

interpreted

by

trained

technicians

using

spe-

The

transmission

lubricant

instafed

can

be

foundona

cial

BMW

diagnostic

equipment

.

type

plate

on

the

side

of

the

transmission

.

In

addition,

a

sticker

may

be

located

on

the

fluid

sump

indicatingthe

typeof

transmission

lubricant

used

.

Ifin

doubt,

con

NOTE-

sult

an

authorized

BMW

dealer

for

altemate

fluid

use

Internal

repairs

to

the

automatic

transmission

require

and

current

information

regardingtransmission

operat-

special

service

equipment

and

knowledge

.

If

it

is

deter-

ing

fluids

.

mined

thatinterna¡

service

is

required,

consult

en

au-

thorízedBMWdealerabouta

factoryreconditioned

unit

The

transmission

is

not

equipped

with

a

dipstick

.

Checking

or

a

transmission

rebuild

.

the

ATF

leve¡

requires

measuring

and

maintaining

a

specified

ATF

temperature

during

the

checking

procedure

.

The

check-

ing

temperature

is

not

fully

warm

orcold

(the

ATF

sump

should

be

approximately

warm

to

the

touch)

.

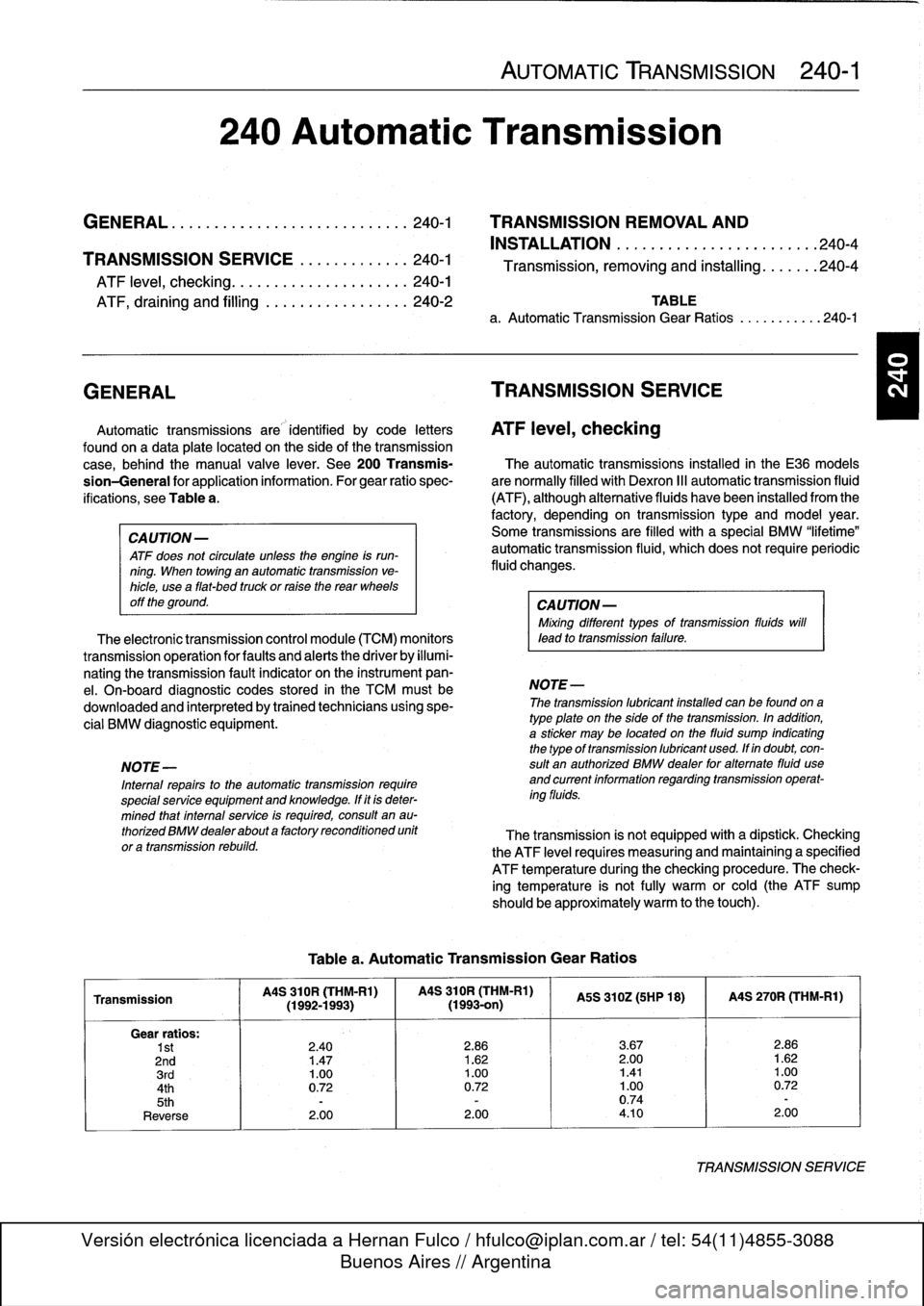

Table

a

.

Automatic

Transmission

Gear

Ratios

Transmission

MS

310R

(THM-R1)

MS

310R

(THM-Rl)

MS

310Z(5HP

18)

I

MS

270R

(THM-R1)

(1992-1993)(1993-on)

Gear

ratios

:

1st

2

.40

2

.86

3

.67

2

.86

2nd

1

.47

1

.62

2

.00

1

.62

3rd

1

.00

1

.00

1.41

1

.00

4th

0

.72

0

.72

1

.00

0

.72

5th

-

-

0

.74

-

Reverse

2

.00

2

.00

4

.10

2

.00

TRANSMISSIONSERVICE

Page 253 of 759

NOTE-

The

traction

control

system

referred

to

as

AST

(all

sea-

son

traction)

may

also

be

referred

to

as

ASC

(Automat-

ic

Stability

Control)

and

ASC+T

(Automatic

Stability

Control+Traction)

.

The

AST

system

improves

traction

by

electronically

apply-

ing

the

rear

brakes

when

therear

drive

wheels

are

spinning

at

a

faster

rate

than

the

front

wheels

.

The

combined

ABS/AST

control

module,

operating

through

the

ABS

hydraulic

control

unit,

modulates

braking

force

at

therear

wheels

.

In

addition,

AST

uses

retarded

ignition

timing

and

an

auxil-iary

engine

throttle

plate

to

reduceengine

torque

and

maintain

vehicle

stability

.

The

auxiliary

throttle

plate

is

held

open

by

spring

pressure

.

The

AST

system

actívates

the

auxiliary

throttie

position

motor

(ADS)

to

cose

the

AST

throttle

as

needed

.

This

reduces

the

volume

of

engine

intake

air

.

Due

to

the

throttle

closing

very

rapidly

during

AST

operationthe

driver

cannot

increase

theengine

power

output

regardless

of

how

far

theaccelerator

pedal

is

pushed

to

the

floor

.

The

auxiliary

throttle

plate

is

placed

ahead

of

the

conven-

tional

throttle

plate

in

the

throttle

body

.

Traction

control

also

comes

into

operationduringdecelera-

tion

.

Decelerating

on

snowy

or

icy

road

surfaces

can

lead

to

rear

wheel

slip

.

If

a

rear

wheel

startsto

drag

or

lock

up

when

the

throttle

is

closed

rapidly

orduringdownshifting,the

AST

system

can

limit

the

problem

by

advancing

the

ignition

timing

.

A

switch

on

the

center

console

is

used

to

togglethe

AST

on

or

off

.

The

AST

system

is

designed

to

be

maintenance

free

.

There

are

no

adjustments

that

can

be

made

.

Repair

and

trouble-

shooting

of

the

AST

system

requires

special

test

equipment

andknowledgeand

should

be

performed

only

by

an

autho-

rized

BMW

dealer

.

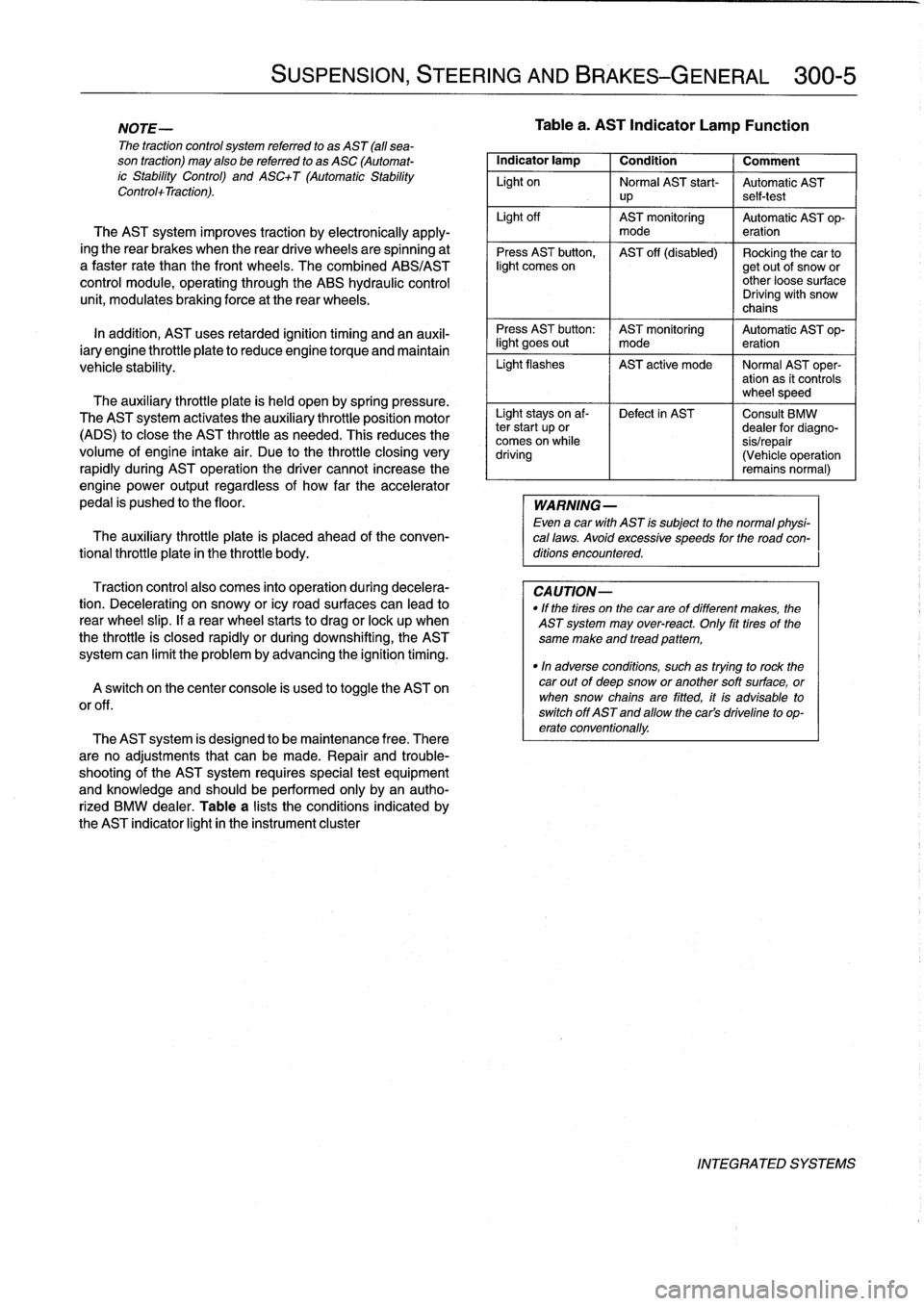

Table

a

lists

theconditions

indicated

by

the

AST

indicator

light

in

the

instrument

cluster

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-5

Tablea

.

AST

Indicator

Lamp

Function

Indicator

lamp

1

Condition

1

Comment

Light

on

Normal

AST

start-

Automatic

AST

up

self-test

Light

off

AST

monitoring

Automatic

AST

op-

mode

eration

Press

AST

button,

AST

off

(disabled)

Rocking

the

car

tolight

comes

on

getout

of

snow

or

other

loose

surface

Driving

with

snow

chains

Press

AST

button

:

AST

monitoring

Automatic

AST

op-

light

goes

out

I

mode

eration

Light

flashes

AST

active

mode

I

Normal

AST

oper-

ation

as

it

controls

wheel

speed

Light

stays

on

af-

Defect

in

AST

Consult

BMW

ter

start

up

or

dealer

for

diagno-

comes

on

while

sis/repair

driving

(Vehicle

operation

remains

normal)

WARNING

-

Even

a

car

with

AST

is

subject

to

the

normal

physi-

cal

laws

.

Avoid

excessive

speeds

for

the

road

con-

ditions

encountered

.

CAUTION-

"

If

the

tires

on

the

carare

of

different

makes,

the

AST

system

may

over-react

.

Only

fit

tires

of

the

same

make

and

tread

pattem,

"In

adverse

conditions,

such

as

trying

to

rock

the

car

outof

deep

snow

or

another

soft

surface,

or

when

snow

chainsare

fitted,

it

is

advisable

to

switch

off

AST

and

allow

the

cars

driveline

to

op-

erate

conventionally

.

INTEGRATED

SYSTEMS

Page 281 of 759

9

.

Packeach

CV

joint

and

rubber

boot

with

specified

REAR

SUSPENSION

ARMS

amount

of

lubricant

supplied

.

Apply

adhesive

to

large

end

of

boot

and

mount

it

on

joint

.

Secure

boot

with

clamps

.

The

trailing

arms,

control

arms

and

their

mountingbushings

Apply

sealer

to

inner

CV

joint

dust

cover

and

instan

.

control

the

position

of

the

rear

wheels

.

A

damaged

suspen-

sion

arm

or

worn

bushings

will

change

the

rear

wheel

align

NOTE-

ment

and

may

adversely

affect

handling

and

stability

.

"

Before

installing

each

small

boot

clamp

be

sure

to

"burp"

the

boot

by

flexing

the

CV

joint

as

far

overas

it

WARNING

will

go

.

A

small

screw-driver

inserted

between

the

Do

notattempt

to

straighten

a

damaged

suspension

boot

and

the

axle-shaft

will

help

the

process

.

arm

.

Bending

or

heating

may

weaken

the

original

"

BMW

recommends

Bostil101513

or

EppleC4851

ad-

part

.

If

the

suspension

arm

shows

any

signs

of

hesive,

and

Epple®39

or

Curil©T

sealer

damage

or

excessive

corrosion,

it

must

be

re-

placed

.

CV

Joint

Lubricant

Capacity

"

Wheel

hub

end

ex

.

M3

..

..

.

....

.

.............

80

gram

(2.8

oz

.)

M3

..

...

.

..

.................

100

gram

(3

.5

oz

.)

"

Finaldrive

end

.................

85

gram

(3

.0

oz

.)

10

.

Install

drive

axle

as

described

earlier

.

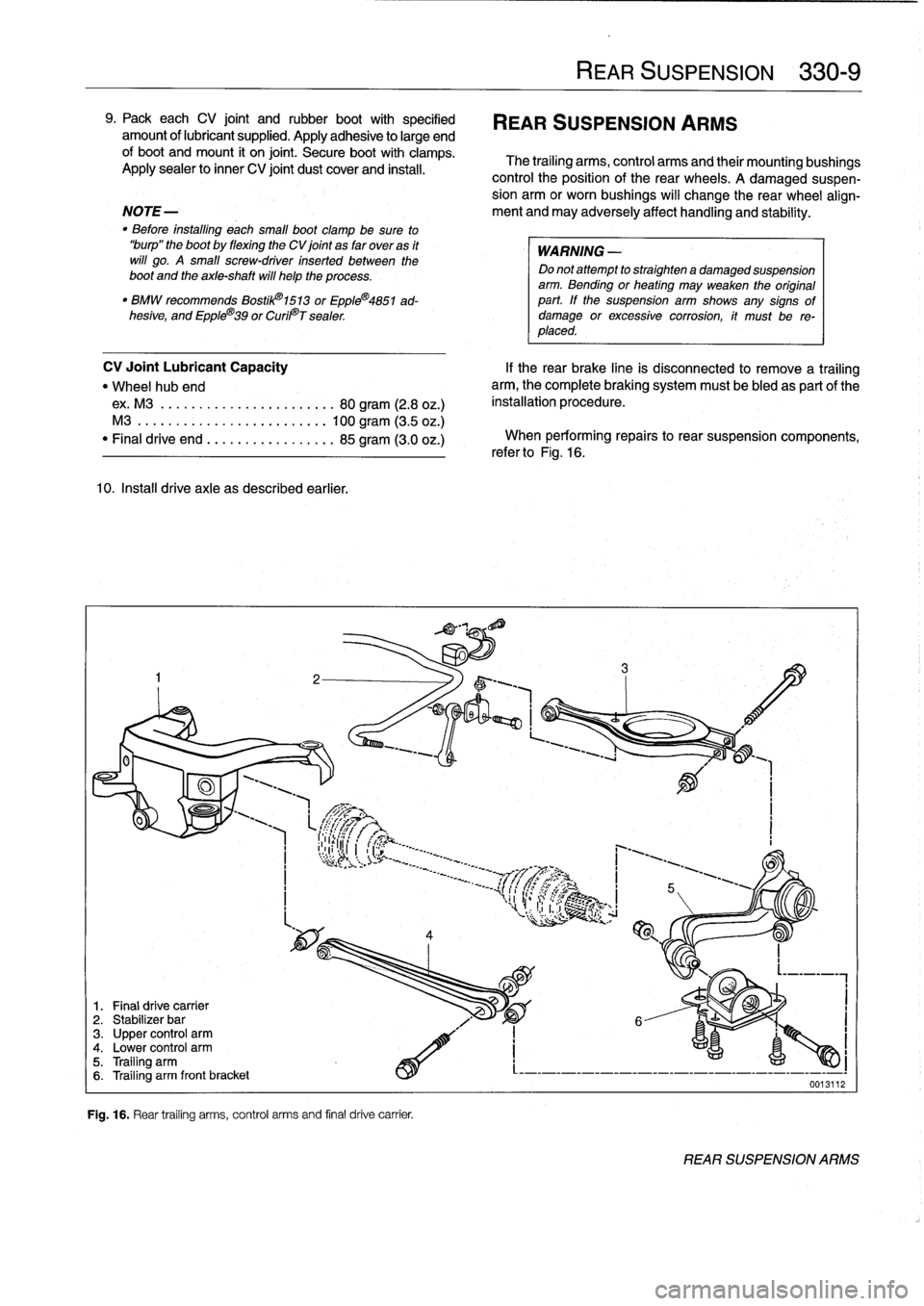

1

.

Final

drive

carrier

2

.

Stabilizer

bar

3

.

Upper

control

arm4

.

Lower

control

arm5

.

Trailing

arm6

.

Trailing

arm

front

bracket

Fig

.

16

.

Rear

trailing

arms,

control

arms

and

final

drive

carrier

.

If

the

rear

brake

cine

is

disconnected

to

remove

a

trailing

arm,

the

complete

braking

system

must

be

bled

as

partof

the

installation

procedure

.

When

performing

repairs

to

rear

suspension

components,

refer

to

Fig

.

16

.

REAR

SUSPENSION

330-

9

0013112

REAR

SUSPENSION

ARMS

Page 288 of 759

331-2

FINAL

DRIVE

Make

sure

that

the

car

is

firm1y

supportedon

Tjack

.

.-

"

:

.-

:

.

n

-

2

.

Detach

drive

axle(s)

from

final

drive

.

See330

Rear

Suspension

.

CA

UTION-

Suspend

the

detached

drive

axlefrom

the

car

body

with

a

stiff

wire

hook

to

prevent

damage

to

the

outer

CV

joint

.

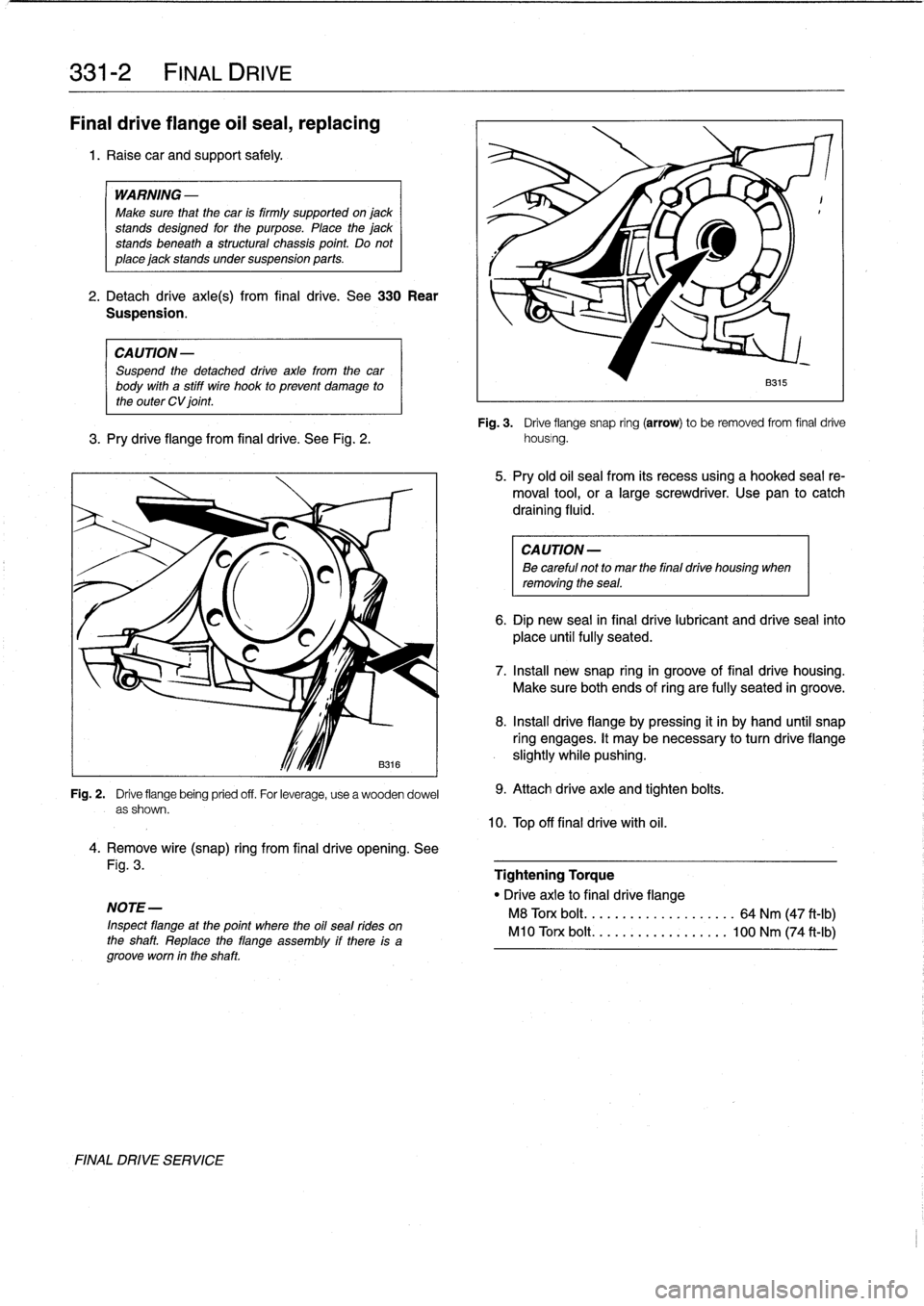

Fig

.

3

.

Drive

flange

snap

ring

(arrow)

to

be

removed

from

final

drive

3

.

Pry

drive

flange

from

final

drive

.

See

Fig

.

2

.

housing

.

Fig

.

2

.

Drive

flange

being

pried

off

.

For

leverage,

use

a

wooden

dowel

as

shown

.

4

.

Remove

wire(snap)

ring

from

final

drive

opening

.

See

Fig

.

3

.

NOTE-

Inspect

flangeat

the

point

where

the

oil

seal

rides

on

the

shaft

.

Replace

the

flange

assembly

if

there

is

agrooveworn

in

the

shaft

FINAL

DRIVE

SERVICE

9

.

Attach

drive

axle

and

tighten

bolts

.

10

.

Top

off

final

drive

with

ofl

.

B315

5

.

Pry

old

oil

sea¡

from

its

recess

using

a

hooked

seal

re-

moval

tool,

or

a

large

screwdriver

.

Use

pan

to

catch

draining

fluid

.

CA

UTION-

Be

careful

not

to

mar

the

final

drive

housing

when

removing

the

sea¡

.

6

.

Dip

new

seal

in

final

drive

lubricant

and

drive

seal

into

place

untilfully

seated

.

7

.

Insta¡¡

new

snap

ringin

groove

of

final

drive

housing

.

Make

sureboth

ends

ofring

are

fully

seated

in

groove

.

8

.

Insta¡¡

drive

flangeby

pressing

it

in

by

hand

until

snap

ring

engages

.

It

may

benecessary

to

turn

drive

flange

slightly

while

pushing

.

Tightening

Torque

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

..................

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.................

100

Nm

(74

ft-Ib)

Page 289 of 759

Final

driveinputshaft

oil

sea¡,

replacing

1

.

Raise

car

and

support

safely

.

2

.

Drain

final

drive

oil

as

described

earlier

.

3

.

Remove

driveshaft

from

final

drive

inputshaft

flange

.

See

260

Driveshaft

.

4

.

Make

matching

marks

on

input

shaft

and

inputshaft

collar

nut

.

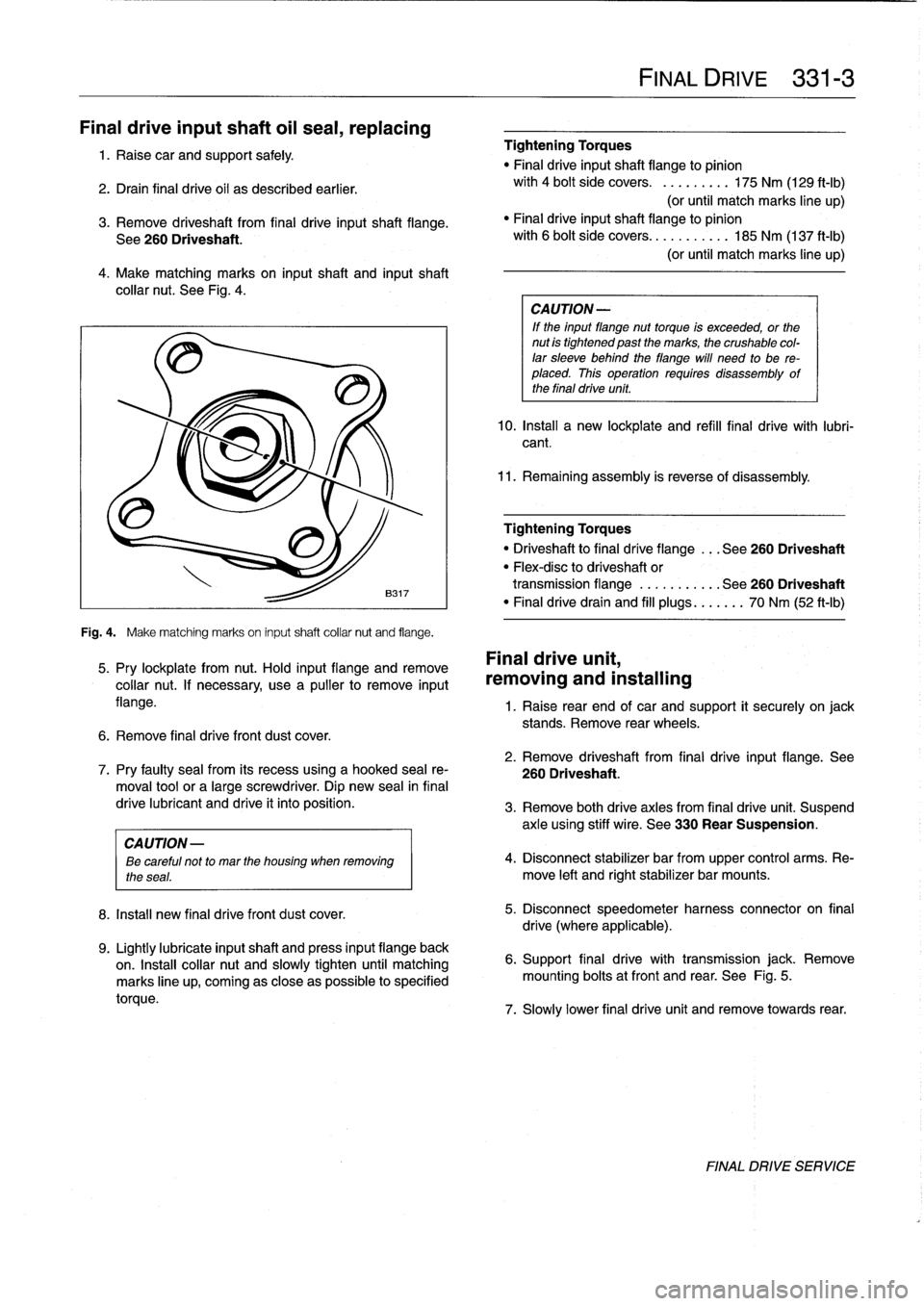

See

Fig

.

4

.

Fig

.

4

.

Make

matching

marks

on

input

shaft

collar

nut

and

flange

.

5

.

Pry

lockplate

from

nut

.

Hold

input

flange

andremove

collar

nut

.

If

necessary,

usea

pullerto

remove

input

flange

.

6

.

Remove

final

drive

front

dust

cover

.

8

.

Install

new

final

drivefront

dust

cover

.

9

.

Lightly

lubricate

inputshaft

and

press

input

flange

back

on

.

Insta¡¡

collar

nut

and

slowly

tighten

until

matching

marks

line

up,

coming

as

close

aspossible

to

specified

torque

.

Tightening

Torques

"

Final

driveinputshaft

flange

to

pinion

with

4

bolt

side

covers

.

.........

175

Nm

(129

ft-Ib)

(or

until

match

marks

line

up)

"

Finaldriveinputshaft

flange

to

pinion

with

6

bolt

side

covers

...........

185

Nm

(137

ft-Ib)

(or

until

match

marks

line

up)

CA

UTION-

If

the

input

flange

nuttorque

is

exceeded,

or

the

nut

is

tightened

past

the

marks,

the

crushable

col-

lar

sleeve

behind

theflange

will

need

to

be

re-

placed

.

This

operation

requires

disassembly

of

the

final

drive

unit

.

10

.

Install

a

new

lockplate

and

refill

final

drive

with

lubri-

cant

.

11

.

Remaining

assembly

is

reverse

of

disassembly

.

Tightening

Torques

"

Driveshaftto

final

dríve

flange

...

See260

Driveshaft

"

Flex-disc

to

driveshaft

or

transmission

flange

...........

See260

Driveshaft

"

Finaldrivedrain

and

fill

plugs

...

.

..

.

70

Nm

(52

ft-Ib)

Final

drive

unit,

removing

and

installing

FINAL

DRIVE

331-

3

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

from

final

drive

input

flange

.

See

7

.

Pry

faulty

sea¡

from

its

recess

using

a

hooked

sea¡

re-

260

Driveshaft

.

moval

toolor

a

large

screwdriver

.

Dip

new

sea¡

in

final

drive

lubricant

and

drive

it

into

position

.

3

.

Remove

both

drive

axles

from

final

drive

unit

.

Suspend

axle

using

stiff

wire

.

See

330

Rear

Suspension

.

CAUTION

-

ee

careful

not

to

mar

the

housing

when

removing

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

the

seas

.

move

left

and

rightstabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Support

final

drive

with

transmission

jack

.

Remove

mounting

bolts

atfront

and

rear

.

See

Fig

.

5

.

7

.

Slowly

lower

final

drive

unit

and

remove

towards

rear

.

FINAL

DRIVE

SERVICE

Page 294 of 759

340-

4

BRAKES

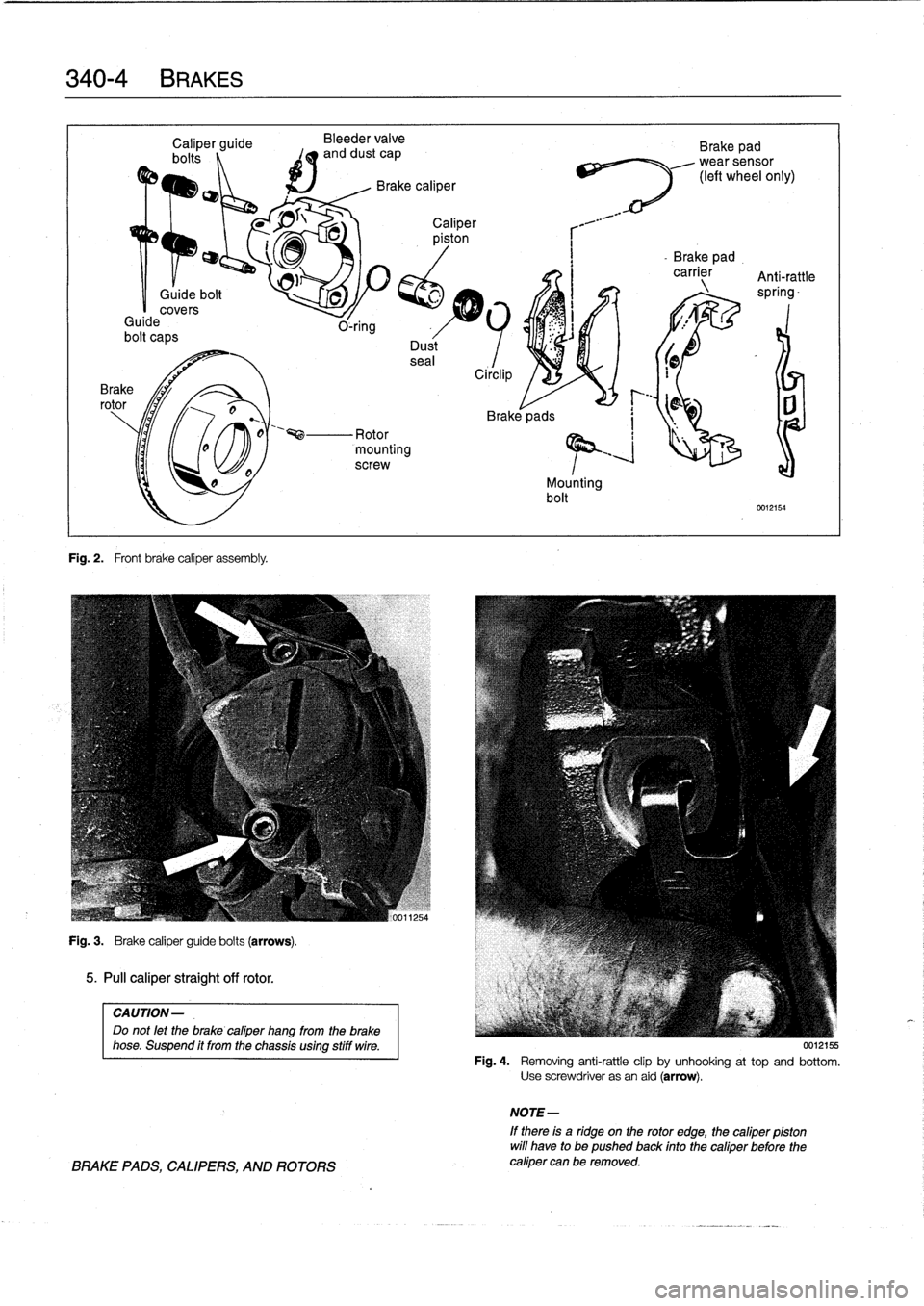

Fig

.

2

.

Front

brake

caliper

assembly

.

Bleeder

valve

and

dust

cap

Mounting

bolt

Brake

pad

wearsensor

(left

wheel

only)

-

Brake

pad

.

carrier

Anti-rattle

^_

spring-

0012154

Fig

.

3

.

Brake

caliper

guide

bolts

(arrows)

.

5

.

Pull

caliper

straight

off

rotor

.

CAUTION-

Do

not

let

the

brake

cafiper

hang

from

the

brake

hose

.

Suspend

ft

from

the

chassis

using

stiff

wire

.

BRAKE

PADS,

CALIPERS,

AND

ROTORS

0012155

Fig

.

4

.

Removing

anti-rattle

clip

by

unhooking

at

top

and

bottom

.

Use

screwdriver

asan

aid

(arrow)

.

NOTE-

If

there

is

a

ridge

on

the

rotor

edge,

the

cafiper

pfston

will

have

to

be

pushed

back

finto

the

cafiper

before

the

cafiper

can

be

removed

.

Page 297 of 759

Brake

rotor,

removing

and

installing

Brake

rotors

shouldalways

be

replaced

in

pairs

.

Fig

.

9

.

Brake

rotor

mounting

screw

(arrow)

.

3

.

Inspect

rotor

for

excessive

grooving,

cracks,

and

warp-

ing

.

Check

rotor

thickness

.

See

Table

b

.

4

.

Installation

is

reverse

of

removal

.

"

Clean

rotor

with

brakecleaner

before

installing

.

"

If

brake

fluid

hose

veas

removed

or

loosened,

brake

systemmustbe

bled

as

described

aboveunder

Bleeding

Brakes

.

BRAKES

340-

7

5

.

Once

brake

assembly

is

instalind,

depress

brakepedal

several

times

to

adjust

caliper

and

pads

.

"

Pedal

should

feel

firm

and

be

at

proper

height

.

"

Check

fluid

leve¡

.

Top

up

if

necessary

.

NOTE-

M3

models

use

directional

brake

rotors

and

mustbe

in-

NOTE-

stalled

on

the

proper

side

.

Part

numbes

are

cast

finto

When

installing

new

rear

brake

rotors,

the

parking

therotors

.

A

part

that

ends

in

an

odd

number

is

a

left

brakeshouldbe

adjusted

.

See

Parking

Brake

.

rotor

.

One

that

ends

in

an

even

number

is

a

right

rotor

.

1.

Remove

caliper

as

described-above

and

hang

from

Tightening

Torques

chassis

using

stiff

wire

.

"

Brake

rotor

to

wheel

hub

..........

16

Nm

(12

ft-Ib)

"

Front

brake

caliper

to

steering

arm

...

110

Nm

(81

ft-Ib)

NOTE-

"

Rear

brake

caliper

to

traíling

arm

....

67

Nm

(50

ft-Ib)

Do

notloosen

caliper

brake

hose

.

"

Road

wheel

to

hub

...

..

.

100

±

10

Nm

(74

t

7

ft-Ib)

2

.

Remove

mountingscrew

holding

rotor

to

wheel

hub

.

,

See

Fig

.

9

.

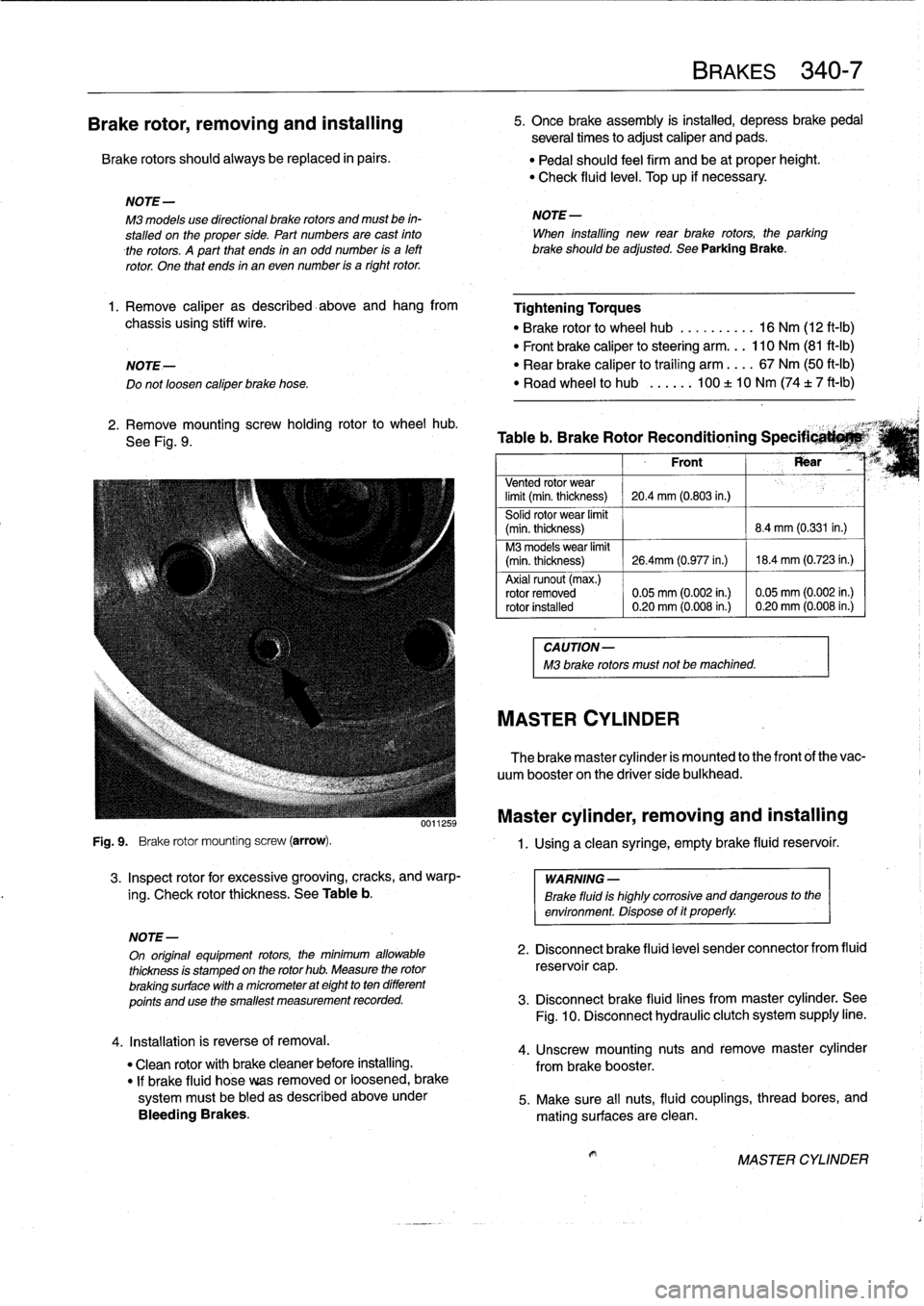

Table

b

.

Brake

Rotor

Reconditioning

Specificati*M`

Front

Rear

Vented

rotor

wear

limit

(min

.

thickness)

20

.4

mm

(0

.803

in.)

Solid

rotor

wear

limit

(min

.

thickness)

8

.4

mm

(0.331

in

.)

M3

models

wear

limit

(min

.

thickness)

26

.4mm

(0

.977

in

.)

18

.4

mm

(0

.723

in

.)

Axial

runout

(max

.)

rotor

removed

0

.05

mm

(0

.002

in

.)

0

.05

mm

(0

.002

in

.)

rotor

installed

0

.20

mm

(0

.008

in

.)

0

.20

mm

(0

.008

in

.)

CAUTION-

M3

brake

rotors

must

not

be

machined

.

MASTER

CYLINDER

The

brake

master

cylinder

is

mounted

to

the

front

of

the

vac-

uum

booster

on

the

driver

side

bulkhead

.

Master

cylinder,

removing

and

installing

1

.

Using

a

clean

syringe,

empty

brake

fluid

reservoir

.

WARNING

-

Brake

fluid

is

highly

corrosive

and

dangerous

to

the

environment

.

Dispose

of

it

properly

.

NOTE-

On

original

equipment

rotors,

the

mínimum

allowable

2

.

Disconnect

brake

fluid

leve¡

sender

connector

from

fluid

thickness

is

stamped

on

the

rotor

hub

.

Measure

the

rotor

reservoi

r

cap

.

brakingsurface

with

a

micrometer

at

eight

to

ten

different

points

and

use

the

smallest

measurement

recorded

.

3

.

Disconnect

brake

fluid

lines

frommaster

cylinder

.

See

Fig

.

10

.

Disconnect

hydraulic

clutch

system

supply

line

.

4

.

Unscrew

mounting

nuts

and

remove

master

cylinder

from

brake

booster

.

5

.

Make

sure

all

nuts,

fluid

couplings,

thread

bores,

and

mating

surfaces

are

clean

.

MASTER

CYLINDER

Page 298 of 759

340-

8

BRAKES

Fig

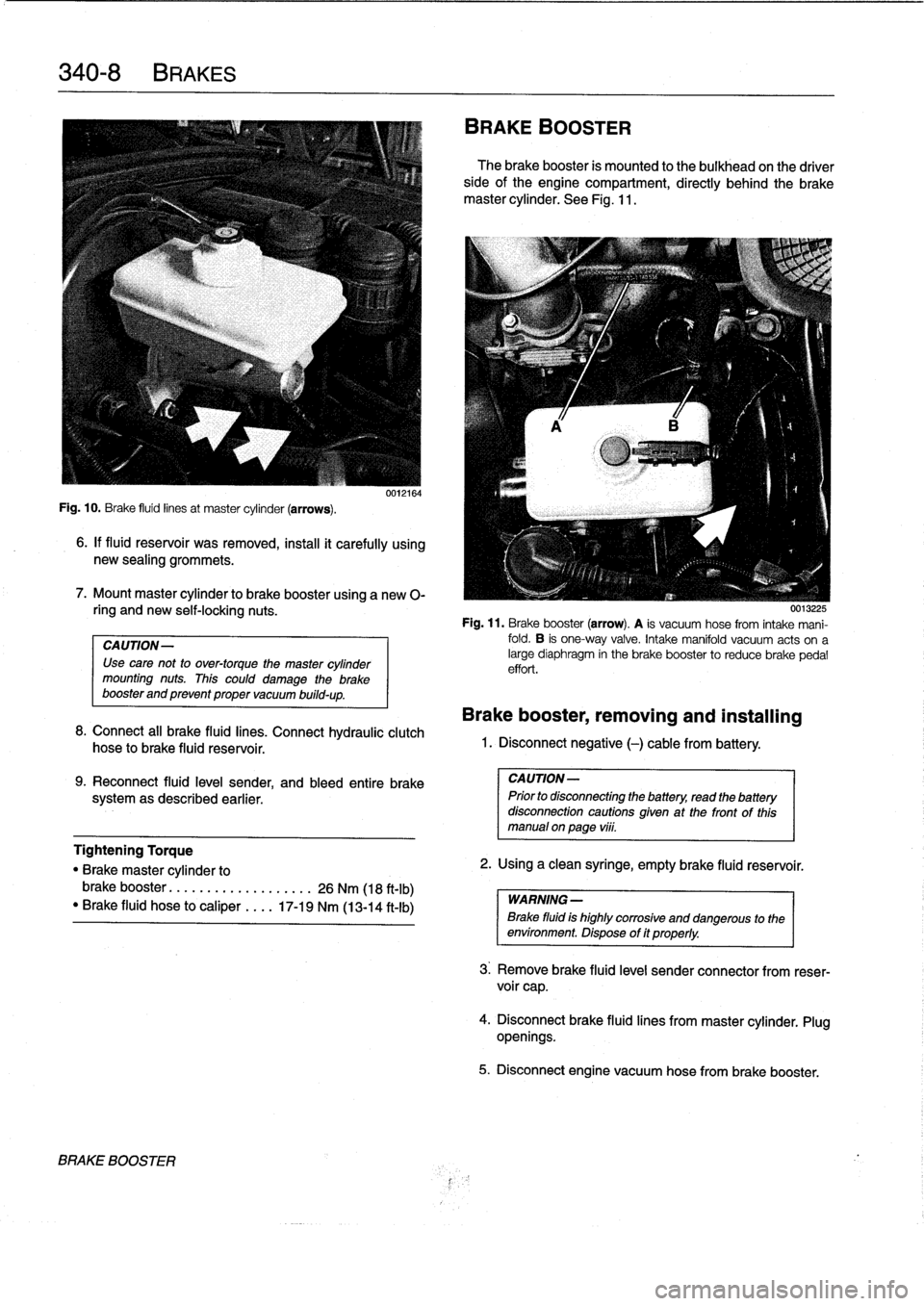

.

10

.

Brake

fluid

linesat

master

cylinder

(arrows)

.

6

.

If

fluid

reservoir

was

removed,

install

it

carefully

using

new

sealing

grommets

.

7

.

Mount

master

cylinder

to

brake

booster

using

a

new

0-

ring

and

new

self-locking

nuts

.

CAUTION-

Use

cave

not

to

over-torque

the

master

cylinder

mounting

nuts

.

This

could

damage

the

brake

booster

and

prevent

proper

vacuum

build-up

.

0012164

8

.

Connect

all

brake

fluid

lines

.

Connect

hydraulic

clutch

hose

to

brake

fluid

reservoir

.

9

.

Reconnect

fluid

leve¡

sender,

and

bleed

entire

brake

systemas

described

earlier

.

BRAKE

BOOSTER

BRAKE

BOOSTER

The

brake

booster

is

mounted

to

the

bulkhead

on

the

driver

sideofthe

engine

compartment,

directly

behind

the

brake

master

cylinder

.

See

Fig

.

11

.

0015225

Fig

.

11

.

Brake

booster

(arrow)

.

A

is

vacuum

hose

from

intake

mani-

fold

.

B

is

one-way

valve

.

Intake

manifold

vacuum

acts

ona

large

diaphragm

in

the

brake

booster

to

reducebrake

pedal

effort

.

Brake

booster,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

vi¡¡

.

Tightening

Torque

"

Brake

master

cylinder

to

2

.

Using

a

clean

syringe,

empty

brake

(luid

reservoir

.

brake

booster

.....

..

.

..

.........

26

Nm

(18

ft-Ib)

WARNING-

"

Brake

fluid

hose

to

caliper

....

17-19

Nm

(13-14

ft-Ib)

Brake

fluid

is

highly

corroslve

and

dangerous

to

the

environment

.

Dispose

of

it

properly

.

3

.

Remove

brake

fluid

level

sender

connector

from

reser-

voir

cap

.

4

.

Disconnectbrake

fluid

lines

from

master

cylinder

.

Plug

openings

.

5

.

Disconnect

engine

vacuum

hose

from

brake

booster

.

Page 300 of 759

340-

1

0

BRAKES

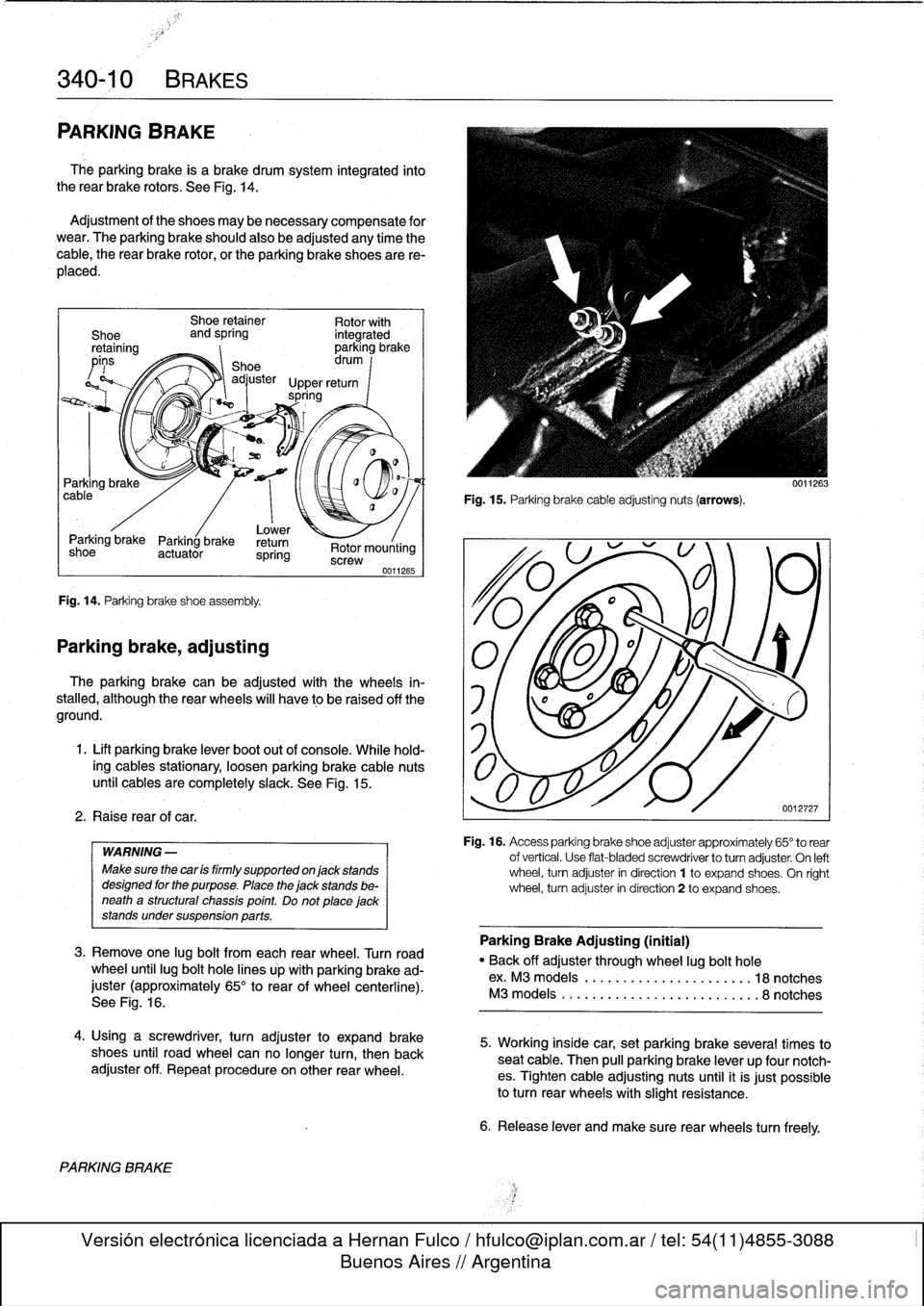

PARKING

BRAKE

The

parking

brake

is

a

brake

drum

system

integrated

into

the

rear

brake

rotors

.

See

Fig

.

14

.

Adjustment

of

the

shoes

may

benecessary

compensate

for

wear

.

The

parking

brake

should

also

be

adjusted

any

time

the

cable,

the

rear

brake

rotor,

or

the

parking

brake

shoes

are

re-

placed

.

Lower

Parking

brake

Parking

brake

retum

shoe

actuator

spring

Fig

.

14

.

Parking

brake

shoeassembly

.

Parking

brake,

adjusting

2

.

Raise

rearof

car

.

PARKING

BRAKE

Shoe

retainer

Rotor

with

and

spring

integrated

parking

brake

Shoe

drum

I

adjuster

Upper

return

spring

-í

<~

:

:

Rotor

mounting

screw

WARNING

-

Make

sure

the

car

is

firmly

supported

on

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

placejack

stands

undersuspension

parts

.

0011265

3

.

Remove

one

lug

bolt

from

each

rear

wheel

.

Turnroad

wheel

until

lug

bolt

hole

lines

úp

with

parking

brake

ad-

juster

(approximately

65°

to

rear

of

wheel

centerline)

.

See

Fig

.

16

.

4

.

Usinga

screwdriver,

turn

adjusterto

expand

brake

shoes

until

road

wheel

canno

longer

turn,

then

back

adjuster

off

.

Repeatprocedureon

other

rear

wheel

.

Fig

.

15

.

Parking

brake

cable

adjustingnuts

(arrows)

.

The

parking

brake

can

be

adjusted

with

the

wheels

in-

stalled,

although

the

rear

wheels

will

have

to

be

raised

off

the

1

f

l

i\

aground

.

1

.

Lift

parking

brake

lever

boot

out

of

console

.

While

hold-

ing

cables

stationary,

loosen

parking

brake

cable

nuts

until

cablesare

completely

slack

.

See

Fig

.

15

.

0011263

0012727

Fig

.

16

.

Access

parking

brake

shoe

adjuster

approxímately

65°

to

rear

of

vertical

.

Use

flat-bladed

screwdriver

to

turnadjuster

.

On

left

wheel,

turn

adjuster

in

direction

1

to

expand

shoes

.

On

ríght

wheel,

turn

adjuster

in

direction

2

to

expand

shoes

.

Parking

Brake

Adjusting

(initial)

"

Back

off

adjuster

through

wheel

lug

bolt

hole

ex

.

M3

models

.........

..

...

...

.

...

.

18notches

M3

models

............

.

.....

..

..

..

.

.

8notches

5

.

Working

inside

car,

set

parking

brake

several

times

to

seat

cable

.

Then

pull

parking

brake

lever

up

four

notch-

es

.

Tighten

cable

adjusting

nuts

until

it

is

just

possible

to

turnrear

wheels

with

slight

resistance

.

6

.

Release

lever

and

make

sure

rear

wheels

turn

freely

.