Driver BMW 318i 1992 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 448 of 759

640-2

HEATING

AND

AIR

CONDITIONING

3

.

Remove

wiring

harness

retaining

clip

at

bulkhead

.

Re-

move

screws

retaining

wiring

harness

cover

and

pull

cover

forward

.

See

Fig

.

2

.

0012529

Fig

.

2

.

Ming

harness

cover

screws

at

base

ofwindshield

(arrows)

.

4

.

On

passenger

side,

push

aside

wiring

harness

and

re-

move

two

screws

retaining

plenum

housing

.

See

Fig

.

3

.

Fig

.

3

.

Ríghtside

plenum

retaining

screws

(arrows)

.

VU1L535

5

.

On

driverside,

push

aside

wiring

harness

and

remove

screw

retaining

plenum

.

Pull

plenum

up

and

remove

from

engine

bay

.

See

Fig

.

4

.

6

.

Unclip

blower

motor

housing

cover,

disconnect

control

cable,

and

turn

center

retainer

1

/4

turn

to

remove

cover

.

See

Fig

.

5

.

7

.

Disconnect

electrical

connectors

from

blower

motor

.

8

.

Remove

left

upper

section

of

blower

housingby

detach-

ing

spring

clipsat

edge

of

housing

.

See

Fig

.

6

.

HEATER

AND

CONTROLS

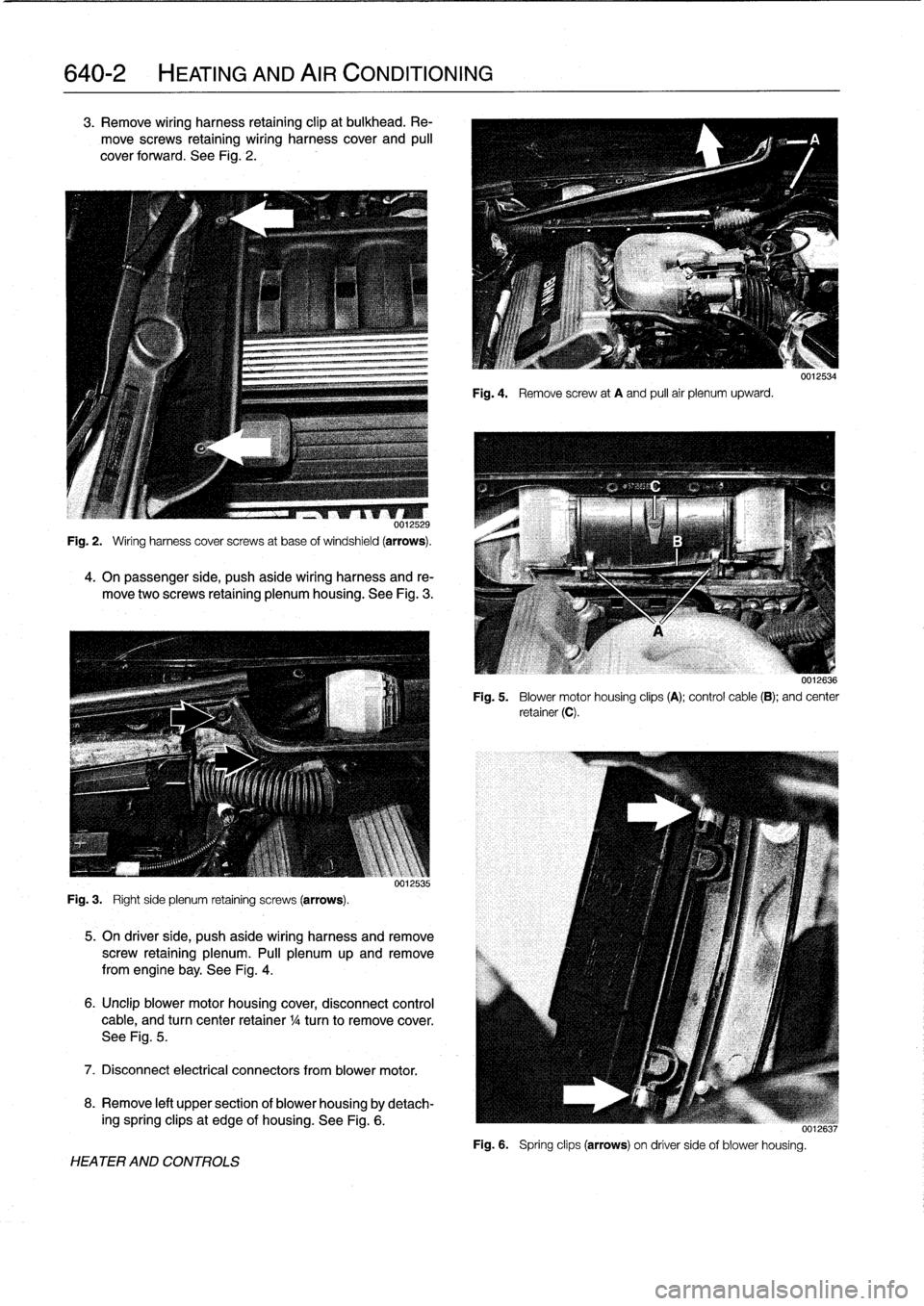

Fig

.

4

.

Remove

screw

at

A

and

pull

air

plenumupward

.

0012534

0012636

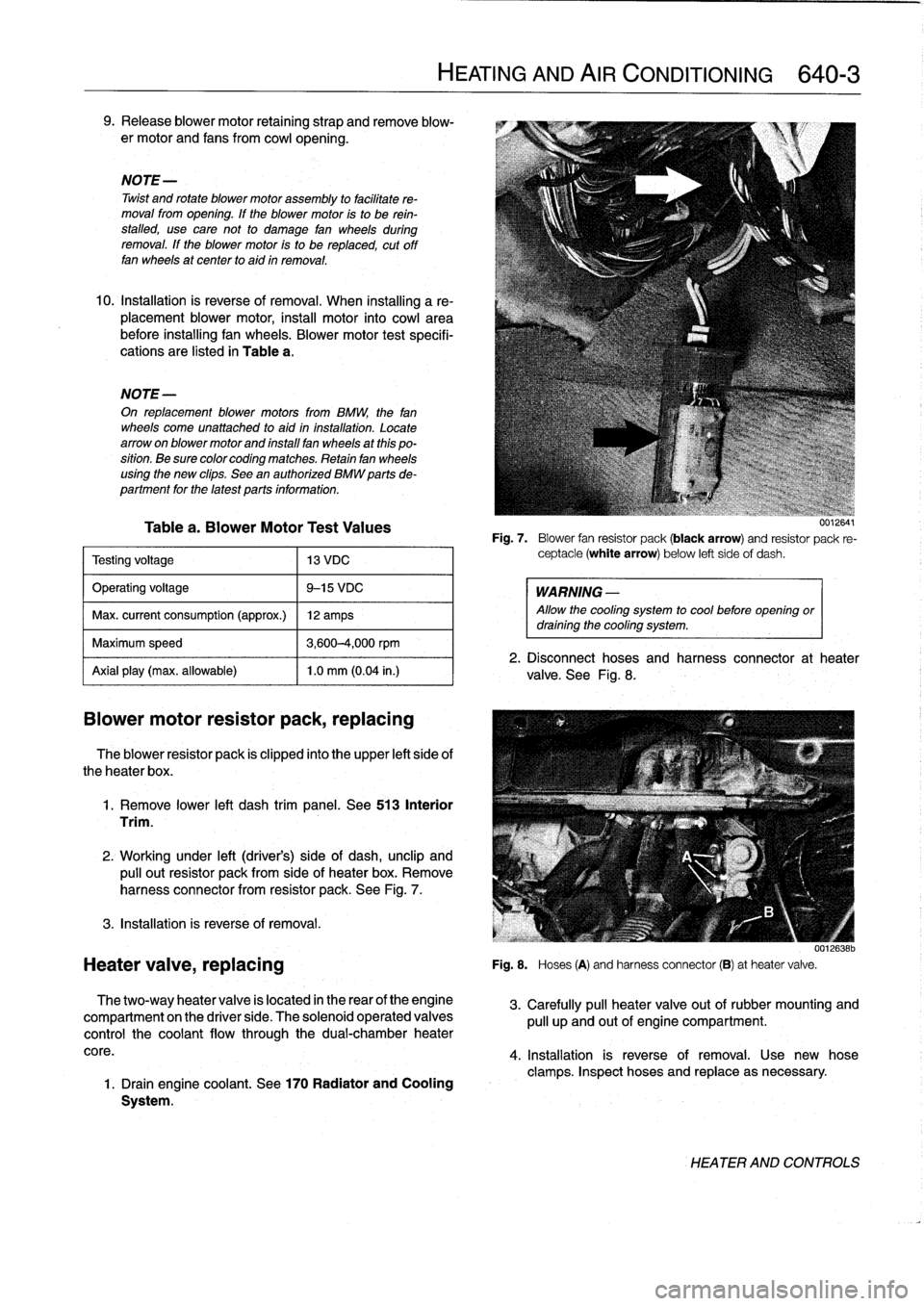

Fig

.

5

.

Blower

motor

housing

clips

(A)

;

control

cable

(B)

;

and

center

retainer(C)

.

i

[u6,

Fig

.

6

.

Spring

clips

(arrows)

on

driver

sideof

blower

housing

.

Page 449 of 759

9

.

Release

blower

motor

retaining

strap

andremove

blow-

er

motor

and

fans

fromcowl

opening

.

NOTE-

Twist

and

rotate

blowermotor

assembly

to

facilítate

re-

moval

from

opening

.

If

the

blower

motor

is

to

be

rein-stafled,

use

care

not

to

damage

fan

wheels

during

removal

.

ff

the

blower

motor

fs

to

be

replaced,

cut

offfan

wheels

at

center

to

aid

in

removal

.

10

.

Installation

is

reverse

of

removal

.

When

installing

a

re-

placement

blower

motor,

instan

motor

into

cowlarea

before

installing

fan

wheels

.

Blower

motor

test

specifi-

cations

are

listed

in

Table

a

.

NOTE

-

On

replacementblowermotors

from

BMW,

thefan

wheels

come

unattached

to

aid

in

installation

.

Locatearrow

on

blower

motor

and

instan

fan

wheels

atthis

po-

sition

.

Be

sure

color

coolng

matches

.

Retain

fan

wheels

using

the

new

clips

.

See

an

authorized

BMW

parts

de-

partment

for

the

latest

parts

information

.

Table

a

.

Blower

Motor

Test

Values

Testingvoltage

13

VDC

Operating

voltage

9-15

VDC

Max

.

current

consumption

(approx

.)

12

amps

Maximum

speed

3,600-4,000rpm

Axialplay

(max

.

allowable)

1

.0

mm

(0

.04

in

.)

Blower

motor

resistor

pack,

replacing

The

blower

resistor

pack

is

clipped

into

the

upper

left

side

of

theheater

box

.

1

.

Remove

lower

left

dash

trim

panel

.

See513

Interior

Trim

.

2

.

Working

under

left

(driver's)

side

of

dash,

unclip

and

pulí

out

resistor

pack

from

sideof

heater

box

.

Remove

harness

connector

from

resistor

pack

.

See

Fig

.

7

.

3

.

Installation

is

reverse

of

removal

.

Heater

valve,

replacing

The

two-way

heater

valve

is

located

in

the

rear

of

the

engine

compartment

on

the

driver

side

.

The

solenoid

operated

valves

control

the

coolant

flow

through

the

dual-chamber

heater

core

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

System

.

HEATING

AND

AIR

CONDITIONING

640-

3

uuiGO4I

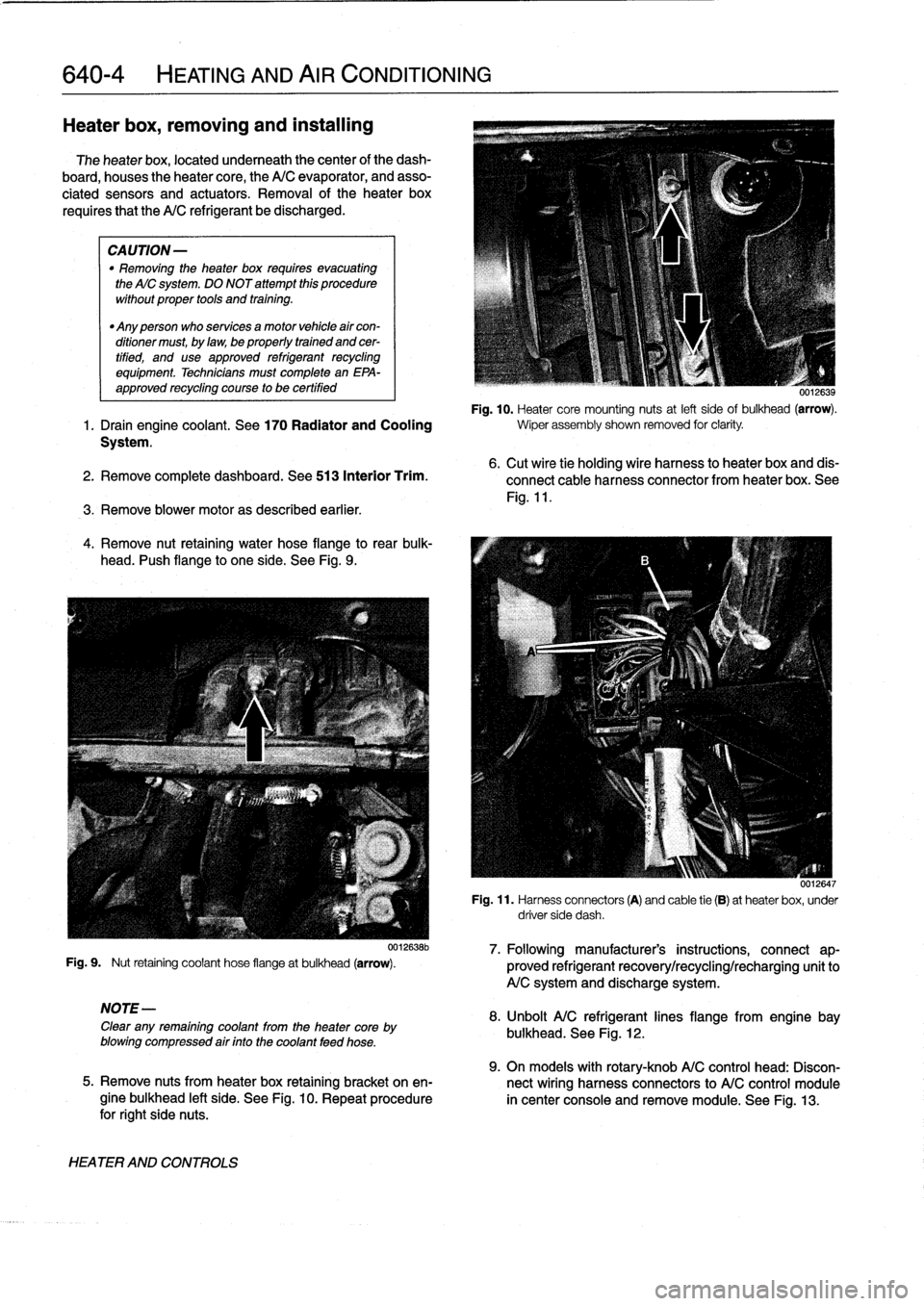

Fig

.

7

.

Blower

fan

resistor

pack

(black

arrow)

and

resistor

pack

re-

ceptacle

(white

arrow)

below

left

sideof

dash

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

ordraining

the

cooling

system

.

2

.

Disconnect

hoses

and

harness

connector

at

heater

valve

.

See

Fig

.

8

.

001[ó38b

Fig

.

S

.

Hoses

(A)

and

harnessconnector

(B)

at

heatervalve

.

3

.

Carefully

pull

heater

valve

out

of

rubber

mounting

and

pull

up

and

out

of

engine

compartment

.

4

.

Installation

is

reverse

of

removal

.

Use

new

hose

clamps

.

Inspect

hoses

and

replace

asnecessary

.

HEATER

AND

CONTROLS

Page 450 of 759

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

UU12639

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 452 of 759

640-6

HEATING

AND

AIRCONDITIONING

Heater

core,replacing

1.

Drain

engíne

coolant

.

See170

Radiator

and

Cooling

System

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

or

drainíng

the

cooling

system

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Remove

Multi-Information

Display

(MID)

module

.

See

620

Instruments

.

4

.

Remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

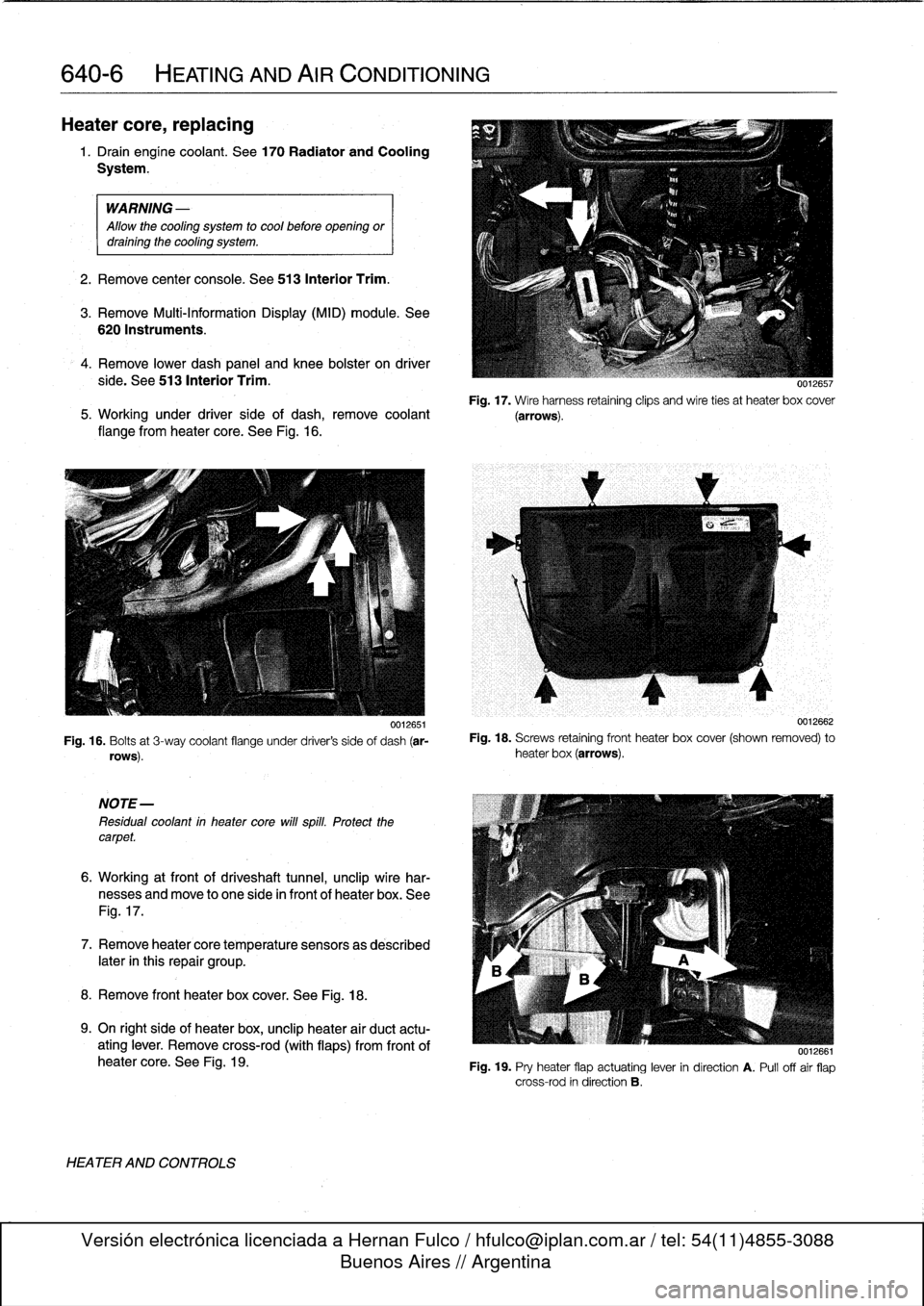

Fig

.

17

.

Wire

harness

retaining

clips

and

wire

ties

at

heater

box

cover

5

.

Working

under

driver

side

of

dash,

remove

coolant

(arrows)

.

flange

from

heater

core

.

See

Fig

.

16

.

0012651

Fig

.

16

.

Bolts

at

3-way

coolant

flange

under

driver's

side

of

dash

(ar-

rows)

.

NOTE-

Residual

coolant

in

heater

core

will

spill

.

Protect

thecarpet

.

6

.

Working

at

front

of

driveshaft

tunnel,

unclip

wire

har-

nesses

and

move

to

one

side

in

front

of

heater

box

.

See

Fig

.

17

.

7

.

Remove

heatercore

temperature

sensorsas

described

later

in

this

repair

group

.

8

.

Remove

front

heater

box

cover

.

See

Fig

.

18

.

9

.

On

right

side

of

heater

box,

unclip

heater

air

duct

actu-

ating

lever

.

Remove

cross-rod

(with

flaps)

from

frontof

heater

core

.

See

Fig

.

19

.

HEATER

AND

CONTROLS

0012662

Fig

.

18

.

Screws

retaining

front

heater

box

cover

(shown

removed)

to

heater

box

(arrows)

.

0012661

Fig

.

19

.

Pry

heater

flap

actuating

lever

in

direction

A

.

Pull

offair

flap

cross-rod

in

direction

B

.

Page 456 of 759

640-10

HEATING

AND

AIR

CONDITIONING

i

El

Radio

Antenna

Rear

.

,

si,-

Left

side

I

d

1

.

Rear

vents

2

.

Fresh

air

3

.

Face-level

vents

4

.

Recirculation

5

.

Footwell

vents

0013017

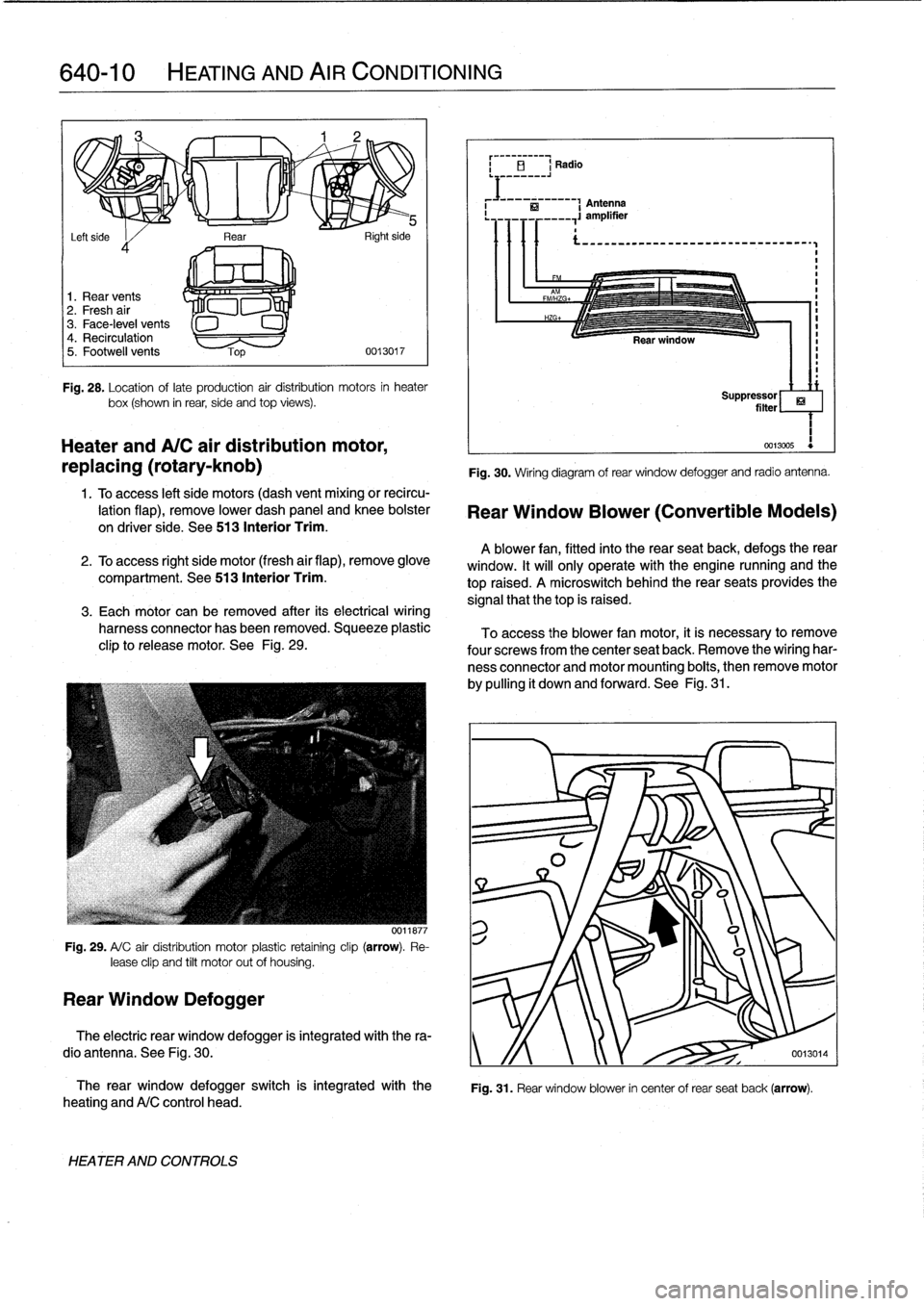

Fig

.

28

.

Location

oflate

production

air

distribution

motors

in

heater

box(shown

in

rear,

side

and

top

views)

.

Heater

andA/C

air

distribution

motor,

replacing

(rotary-knob)

1

.

Toaccess

left

side

motors

(dash

vent

mixing

or

recircu-

lation

flap),

remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

2

.

To

access

right

side

motor

(fresh

air

flap),

remove

glove

compartment

.

See513

Interior

Trim

.

3

.

Each

motor

can

be

removed

after

its

electrical

wiring

harness

connector

has

been

removed

.

Squeeze

plastic

clip

to

release

motor

.

See

Fig

.

29

.

Fig

.

29

.

A/

C

air

distribution

motor

plastic

retaíning

clip

(arrow)

.

Re-

lease

clip

and

tilt

motor

out

of

housing

.

Rear

Window

Defogger

0011877

The

rear

window

defogger

switch

is

integrated

with

the

heating

andA/C

control

head

.

HEATER

AND

CONTROLS

Fig

.

30

.

Wiring

diagram

of

rear

window

defogger

and

radio

antenna

.

Rear

Window

Blower

(Convertible

Models)

A

blower

fan,

fitted

into

the

rear

seatback,

defogs

therear

window

.

It

will

only

operate

with

the

engine

nunning

and

the

top

raised

.

A

microswitch

behindthe

rear

seats

provides

the

signal

that

thetop

is

raised

.

To

access

the

blower

fan

motor,

it

is

necessary

to

remove

four

screwsfrom

the

center

seat

back

.

Remove

the

wiring

har-

ness

connector

and

motor

mounting

boits,

then

remove

motor

by

pulling

it

down

and

forward

.

See

Fig

.

31

.

ri

Suppressor

filter

1

0013005

Fig

.

31

.

Rear

window

blower

in

center

of

rear

seat

back

(arrow)

.

The

electric

rear

window

defogger

is

integrated

with

the

ra-

dio

antenna

.

See

Fig

.

30

.

y

/f

0013014

Page 463 of 759

CAUTION

-

Always

replace

O-rings

when

reconnecting

refrig-

erant

fines

.

9

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

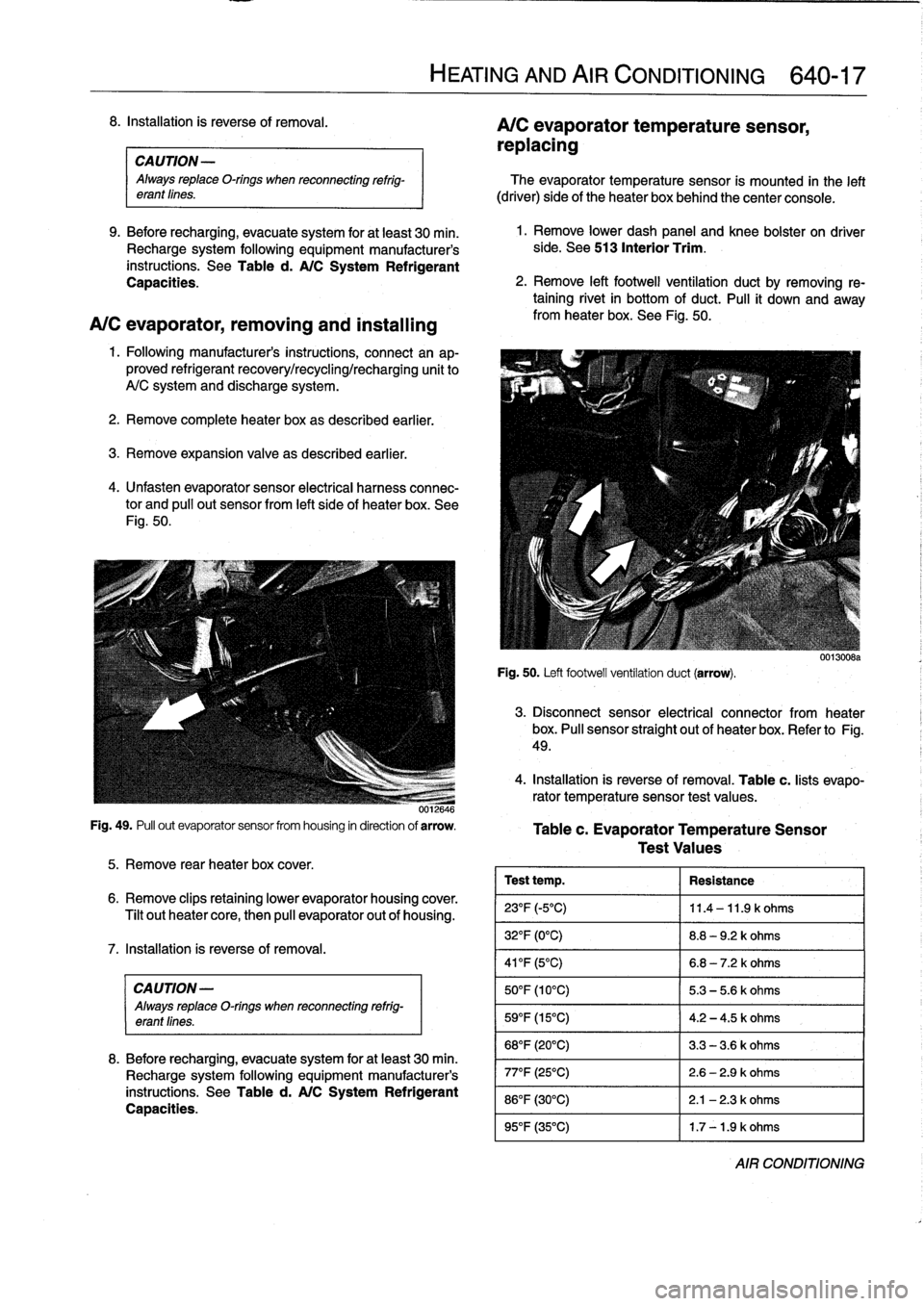

A/C

evaporator,

removing

and

installing

1

.

Followingmanufacturer's

instructions,

connectanap-proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

complete

heater

boxas

described

earlier

.

3

.

Remove

expansion

valve

as

described

earlier

.

4

.

Unfasten

evaporator

sensor

electrical

harness

connec-

tor

and

puli

out

sensor

from

ieft

side

of

heater

box

.

See

Fig

.

50

.

Fig

.

49

.

Pull

out

evaporator

sensor

from

housing

in

direction

of

arrow

.

5

.

Remove

rear

heater

box

cover

.

6

.

Remove

clips

retaining

lower

evaporator

housingcover

.

Tilt

outheater

core,

then

pull

evaporator

out

of

housing

.

7

.

Installation

is

reverse

of

removal

.

CAUTION

-

Always

reptace

O-rings

when

reconnecting

refrtg-

erant

fines

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

HEATING

AND

AIR

CONDITIONING

640-17

8

.

Installation

is

reverse

of

removal

.

A/C

evaporator

temperature

sensor,

replacing

ou12b46

The

evaporator

temperature

sensor

is

mounted

in

the

left

(driver)

side

of

theheater

box

behind

thecenter

console

.

1

.

Remove

lower

dash

panel

and

knee

boister

on

driver

side

.

See

513

Interior

Trim

.

2

.

Remove

left

footwell

ventilation

duct

byremoving

re-

taining

rivet

in

bottom

of

duct

.

Pull

it

down

and

away

from

heater

box

.

See

Fig

.

50

.

Fig

.

50

.

Left

footwellventilatíon

duct

(arrow)

.

0o1300ba

3

.

Disconnect

sensor

electrical

connector

from

heater

box

.

Pull

sensor

straight

out

of

heater

box

.

Refer

to

Fig

.

49

.

4

.

Installation

is

reverse

of

removal

.

Table

c

.

lists

evapo-

rator

temperature

sensor

test

values

.

Tablec

.

Evaporator

Temperature

Sensor

Test

Values

Test

temp

.

Resistance

23°F

(-5°C)

11

.4

-11

.9

k

ohms

32°F

(0°C)

8

.8

-

9

.2

k

ohms

41

°F

(5°C)

6

.8

-

7

.2

k

ohms

50°F

(10°C)

5

.3-5

.6

k

ohms

59

°

F

(15°C)

4

.2

-4

.5

k

ohms

68°F

(20°C)

3

.3

-

3

.6

k

ohms

77°F

(25°C)

2

.6-2

.9

k

ohms

86°F

(30°C)

2

.1

-

2

.3

k

ohms

95°F

(35°C)

1

.7

-1

.9

k

ohms

AIR

CONDITIONING

Page 467 of 759

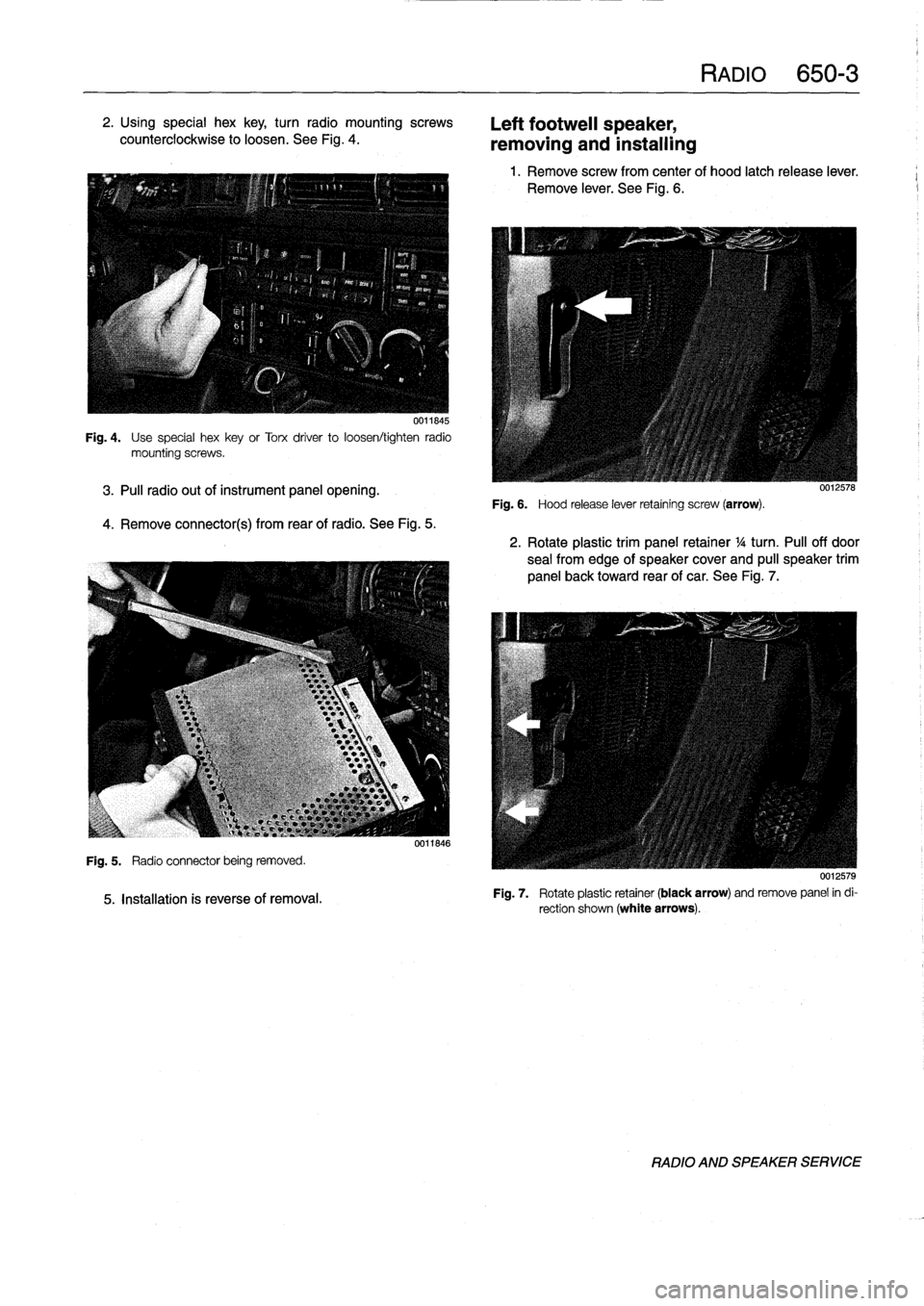

2

.

Using

special

hex

key,

turn

radio

mountingscrews

counterclockwise

to

loosen

.

See

Fig

.

4

.

0011845

Fig

.

4

.

Use

special

hexkey

or

Torx

driver

to

loosen/tighten

radio

mountingscrews

.

3

.

Pul¡

radio

out

of

instrument

panel

opening

.

4

.

Remove

connector(s)

from

rearof

radio

.

See

Fig

.

5

.

Fig

.

5

.

Radio

connector

being

removed

.

5

.

Installation

is

reverse

of

removal

.

0011846

Left

footweil

speaker,

removing

and

installing

Fig

.

6

.

Hood

release

lever

retaining

screw

(arrow)

.

RADIO

650-

3

1

.

Remove

screw

from

center

of

hood

latch

release

lever

.

Remove

lever

.

See

Fig

.

6

.

0012578

2

.

Rotate

plastic

trim

panel

retainer

1

/4

turn

.

Pul¡

off

door

sea¡

from

edge

of

speaker

cover

and

pull

speaker

trim

panel

back

toward

rear

of

car

.

See

Fig

.

7

.

0012579

Fig

.

7

.

Rotate

plastic

retainer

(black

arrow)

andremove

panel

in

di-

rection

shown

(white

arrows)

.

RADIO

AND

SPEAKER

SERVICE

Page 477 of 759

721

Airbag

System

(SRS)

Airbag

Systems

.......

.

...

.

.

.

.

.

....

.

.

.

.

721-1

AIRBAG

SENSORS

AND

ELECTRONICS

721-2

SRS

Warning

Light

and

Fault

Display

.

.

.

.

.

..

721-2

Airbagcontact

ring,

replacing

........

.

.

.

.

.

721-3

Airbag

crash

sensor,replacing

..

.

....

.

...

.

721-4

ZAE

control

module,

replacing

.

.

.

.........

721-5

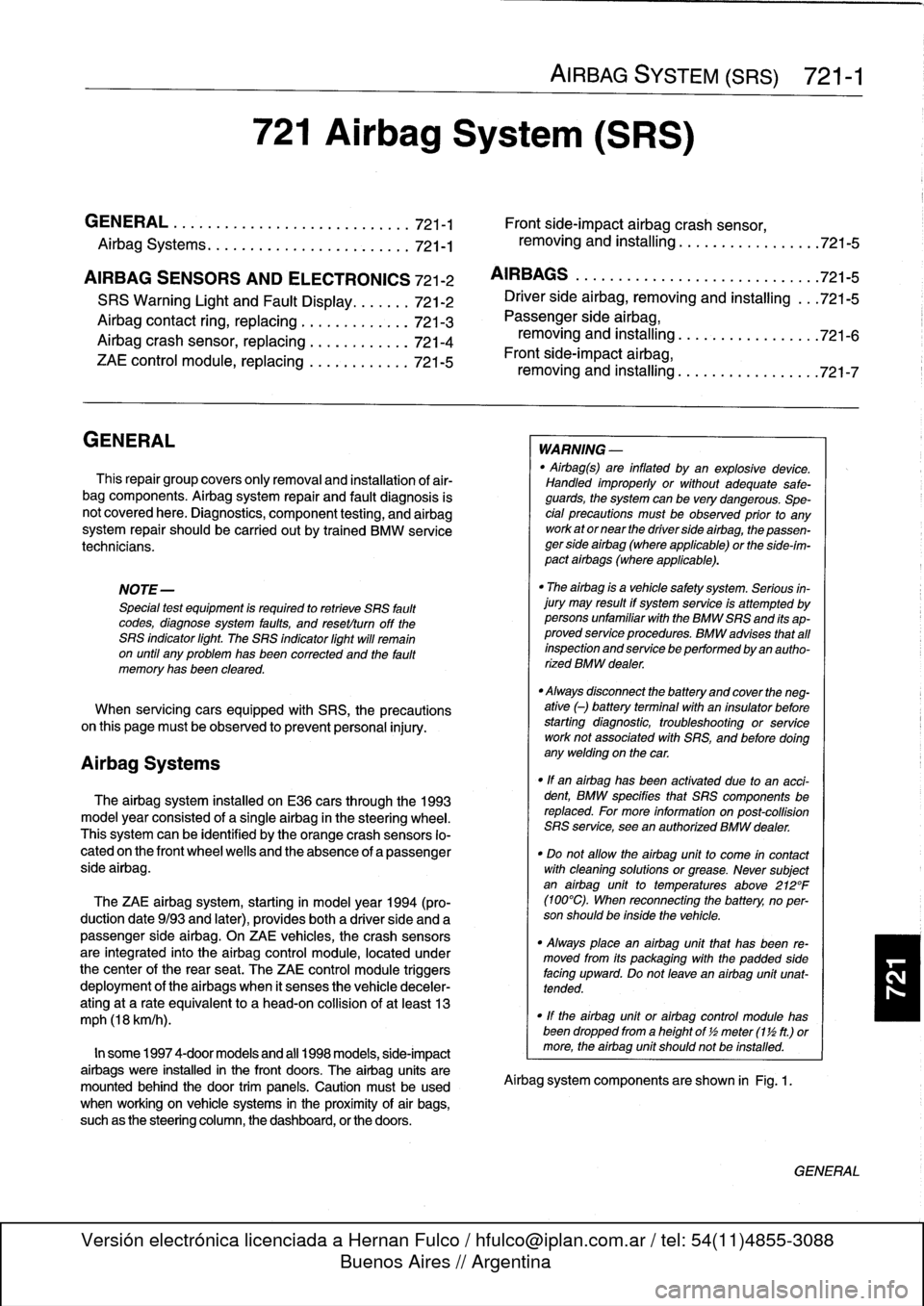

GENERAL

This

repair

group

covers

only

removal

and

installation

of

air-

bag

components

.

Airbag

system

repair

and

fault

diagnosis

is

not

covered

here

.

Diagnostics,

component

testing,

and

airbag

system

repair

should

be

carried

out

by

trained

BMW

service

technicians

.

NOTE-

Special

test

equipment

is

required

to

retrieve

SRS

fault

codes,

diagnose

system

faults,

and

resetltum

off

the

SRS

indicator

light

.

The

SRS

indicator

light

will

remain

on

until

any

problem

has

been

corrected

and

the

fault

memory

has

been

cleared

.

When

servicing

cars

equipped

with

SRS,

the

precautions

on

this

page

mustbeobserved

to

prevent

personal

injury

.

Airbag

Systems

The

airbag

system

installed

on

E36

cars

through

the

1993

model

year

consisted

of

a

single

airbag

in

the

steering

wheel

.

This

systemcan

be

identified

by

the

orange

crash

sensors

lo-

cated

on

the

front

wheel

wells

and

the

absence

of

a

passenger

side

airbag

.

The

ZAE

airbag

system,

starting

in

model

year

1994

(pro-

duction

date9/93

and

later),

provides

both

a

driver

side

and

a

passenger

sideairbag

.

On

ZAE

vehicles,

the

crash

sensorsare

integrated

into

the

airbag

control

module,

located

under

thecenter

of

the

rear

seat

.

The

ZAE

control

module

triggers

deployment

of

the

airbags

When

it

sensos

the

vehicle

deceler-

ating

at

a

rate

equivalent

to

a

head-on

collisionof

at

least

13

mph

(18

km/h)

.

In

some

1997

4-door

models

and

all

1998

models,

side-impact

airbags

were

installed

in

the

front

doors

.

The

airbag

units

are

mounted

behindthe

door

trim

panels

.

Caution

mustbeused

when

working

on

vehicle

systems

in

the

proximity

of

air

bags,

such

as

the

steering

column,

the

dashboard,

or

the

doors

.

AIRBAG

SYSTEM

(SRS)

721-1

GENERAL

.

.

.

.

.

.

.

.

.

.

.......

.

......

.

.

.

.

721-1

Front

side-impact

airbag

crash

sensor,

removing

and

installing

....

.

.....

.

.....

.

721-5

AIRBAGS

..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

721-5

Driver

side

airbag,

removing

and

installing

.

.

.

721-5

Passenger

side

airbag,

removing

and

installing

..............

.

.

.721-6

Front

side-impact

airbag,

removing

and

installing

.

.

.

.

.

.

.

.

.

.

......

.721-7

WARNING

-

"

Airbag(s)

are

inflated

byan

explosive

device

.

Handled

improperly

or

without

adequate

safe-

guards,

the

System

can

be

very

dangerous

.

Spe-

cial

precautions

must

be

observed

prior

to

any

work

ator

near

the

driverside

airbag,

the

passen-

ger

side

airbag

(where

applicable)

or

the

side-im-

pact

airbags

(where

applicable)

.

"

The

airbag

is

a

vehicle

safety

system

.

Serious

in-

jury

may

result

if

System

service

is

attempted

by

persons

unfamiliar

with

the

BMW

SRS

and

its

ap-

proved

service

procedures

.

BMW

advises

that

all

inspection

and

service

be

performed

by

an

autho-

rized

BMW

dealer

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

()

battery

terminal

with

an

insulator

before

startingdiagnostic,

troubleshooting

or

service

worknot

associated

with

SRS,

and

before

doing

any

welding

on

the

car

.

"

If

an

airbag

has

been

activated

due

to

an

acci-dent,

BMW

specifies

that

SRS

components

be

replaced

.

For

more

information

on

post-collision

SRS

service,

see

an

authorized

BMW

dealer

.

"

Do

not

allow

the

airbag

unit

to

come

in

contact

with

cleaning

solutions

orgrease

.

Never

subject

an

airbag

unit

to

temperatures

aboye

212°F

(100°C)

.

When

reconnecting

the

battery,

no

per-

son

should

be

inside

the

vehicle

.

"

Always

place

an

airbag

unitthat

has

been

re-

moved

from

its

packaging

with

the

padded

sidefacing

upward

.

Do

not

leave

an

airbag

unlt

unat-

tended

.

"

!f

the

airbag

unit

or

airbag

control

modulehas

been

dropped

froma

height

of

!

1

2

meter

(1

Y2

ft.)

ormore,

theairbag

unit

should

not

be

installed

.

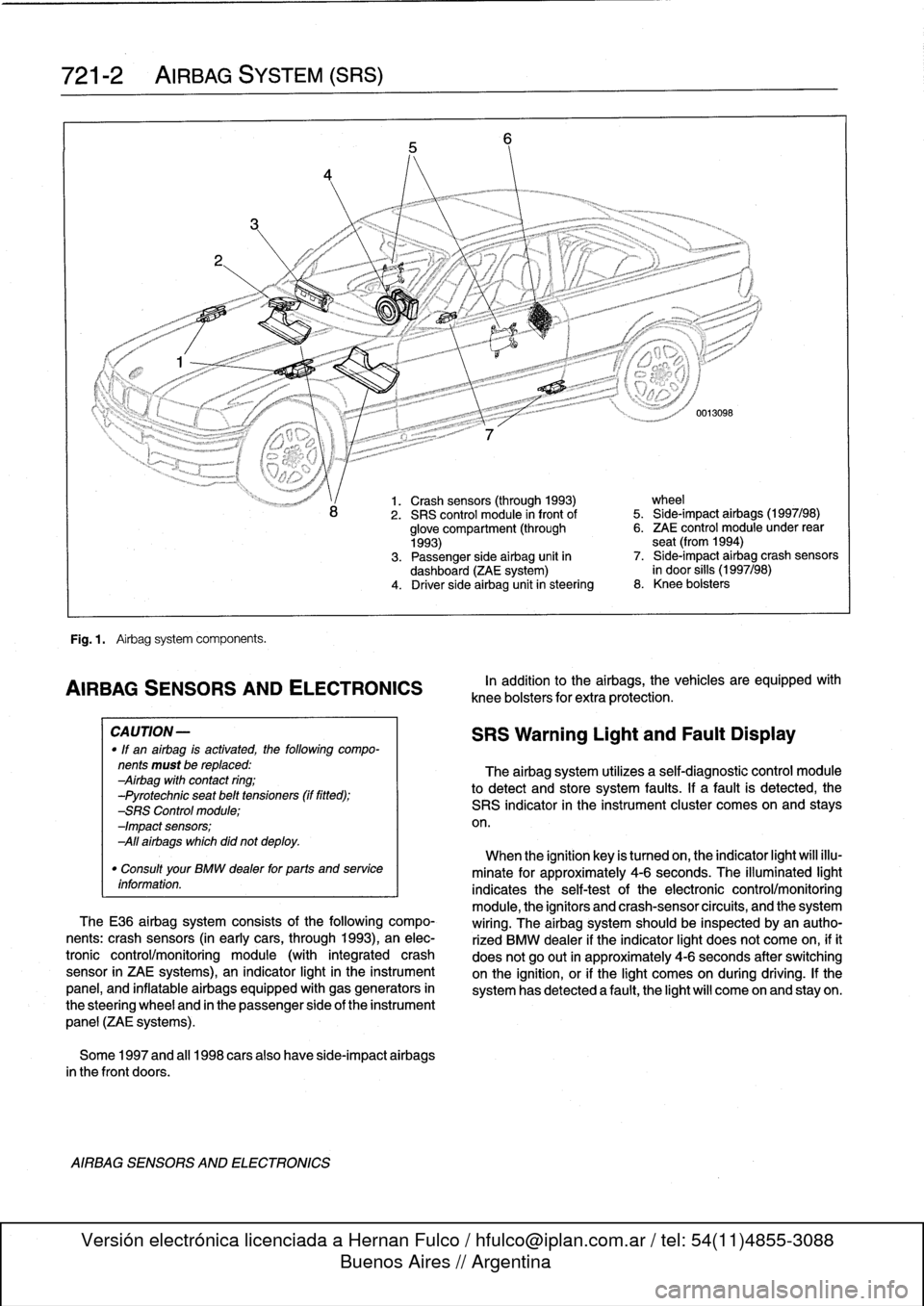

Aírbag

system

components

are

shown

in

Fig

.

1.

GENERAL

Page 478 of 759

721-2

AIRBAG

SYSTEM

(SRS)

Fig

.

1

.

Airbag

system

components

.

AIRBAG

SENSORSAND

ELECTRONICS

CA

UTION-

"

If

an

airbag

is

activated,

the

following

compo-

nents

must

be

replaced

:

Airbag

with

contact

ring

;

-Pyrotechnic

seat

belt

tensioners

(if

fitted)

;

-SRS

Control

module

;

-Impact

sensors

;

All

airbags

which

did

not

deploy

.

"

Consult

your

BMW

dealer

for

parts

and

service

information

.

TheE36

airbag

system

consists

of

the

following

compo-

nents

:

crash

sensors

(in

earlycars,

through

1993),

an

elec-

tronic

control/monitoring

module

(with

integrated

crash

sensor

in

ZAE

systems),

an

indicator

light

in

the

instrument

panel,

and

inflatable

airbags

equipped

with

gas

generators

in

the

steering

wheel

and

in

the

passenger

side

of

the

instrument

panel

(ZAE

systems)

.

Some

1997

and

al¡

1998

carsalso

have

side-impact

airbags

in

the

front

doors

.

AIRBAG

SENSORS

AND

ELECTRONICS

1.

Crash

sensors

(through

1993)

wheel

2

.

SRS

control

module

in

front

of

5

.

Side-impact

airbags

(1997/98)

glove

compartment

(through

6

.

ZAE

control

module

under

rear

1993)

seat

(from

1994)

3

.

Passenger

side

airbag

unit

in

7

.

Side-impact

airbag

crash

sensors

dashboard

(ZAE

system)

in

door

silis

(1997/98)

4

.

Driver

side

airbag

unitin

steering

8

.

Knee

bolsters

In

addition

to

the

airbags,

the

vehicles

are

equipped

wíth

knee

bolsters

for

extra

protection

.

SRS

Warning

Light

and

Fault

Display

The

airbag

system

utilizes

a

self-diagnostic

control

module

to

detect

and

store

system

faults

.

If

a

fault

is

detected,

the

SRS

indicator

in

the

instrument

cluster

comes

on

and

stays

on

.

When

the

ignition

key

is

tumed

on,

the

indicator

light

will

illu-

minate

for

approximately

4-6

seconds

.

The

illuminated

light

indicates

the

self-testof

the

electronic

control/monitoring

module,

the

ignítors

and

crash-sensorcircuits,

and

the

system

wiring

.

The

airbag

system

should

be

inspected

byan

autho-

rized

BMW

dealer

if

the

indicator

light

does

not

come

on,

ifit

does

not

go

out

in

approximately

4-6

seconds

after

switching

onthe

ignition,

or

if

the

light

comes

on

during

driving

.

If

the

system

has

detected

a

fault,

the

light

will

come

on

and

stay

on

.

Page 479 of 759

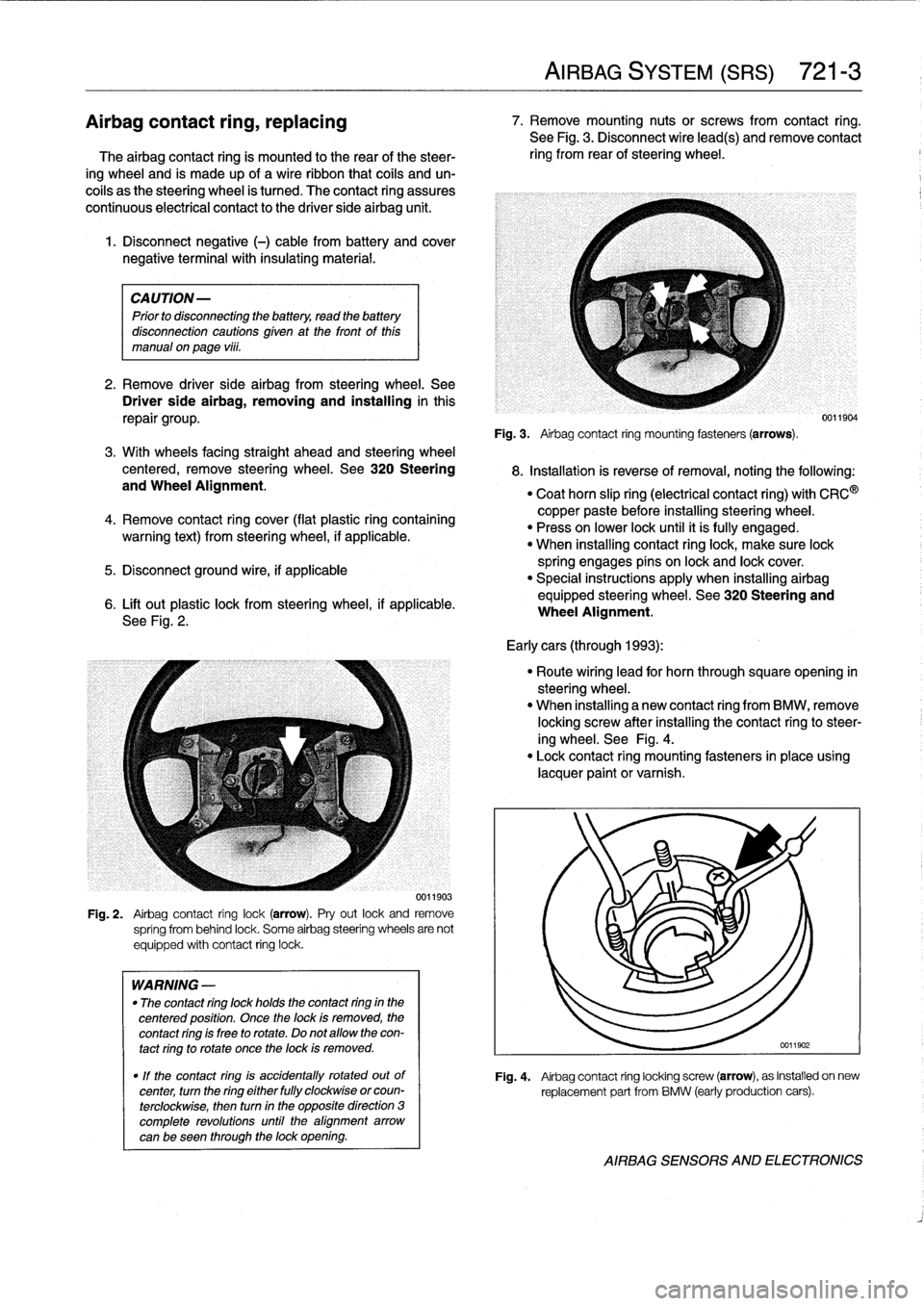

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

CA

UTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Remove

driver

sideairbag

from

steering

wheel

.

See

Driver

side

airbag,

removing

and

installing

in

this

repair

group

.

3

.

With

wheels

facing

straight

ahead

and

steering

wheel

centered,

remove

steering

wheel

.

See320

Steering

and

Wheel

Alignment

.

4

.

Remove

contact

ring

cover

(flat

plastic

ring

containing

warning

text)

from

steering

wheel,

íf

applicable

.

5

.

Disconnect

ground

wire,

if

applicable

6

.

Lift

out

plastic

lock

from

steering

wheel,

if

applicable

.

See

Fig

.

2

.

0011903

Fig

.

2

.

Airbag

contact

ring

lock(arrow)

.

Pry

out

lock

and

remove

spríng

from

behind

lock

.

Some

airbag

steering

wheels

are

not

equipped

with

contact

ring

lock

.

WARNING

-

"

The

contact

ring

lock

holds

the

contact

ring

in

the

centered

position

.

Once

the

lock

is

removed,

the

contact

ring

is

free

to

rotate

.

Do

not

allow

the

con-

tact

ring

to

rotate

once

the

lock

is

removed

.

"

If

the

contact

ring

is

accidentally

rotated

outof

center,

turn

the

ring

either

fully

clockwise

orcoun-

terclockwise,

then

turn

in

the

opposite

direction

3

complete

revolutions

until

the

alignment

arrow

canbe

seen

through

the

lock

opening

.

AIRBAG

SYSTEM

(SRS)

721-

3

Airbagcontact

ring,

replacing

7

.

Remove

mounting

nutsor

screws

from

contact

ring

.

See

Fig

.

3

.

Disconnect

wire

lead(s)

andremove

contact

The

airbag

contact

ring

is

mounted

to

the

rear

of

the

steer-

ring

from

rear

of

steering

wheel

.

ing

wheel

and

is

made

up

of

a

wireribbon

that

cofs

and

un-

coils

as

the

steering

wheel

is

tumed

.

The

contact

ring

assures

continuous

electrical

contact

to

the

driver

side

airbag

unit

.

Fig

.

3

.

Airbag

contact

ring

mounting

fasteners(arrows)

.

8

.

Installation

is

reverse

ofremoval,noting

the

following

:

"

Coat

horn

slip

ring

(electrical

contact

ring)

with

CRC

®

copper

paste

before

installing

steering

wheel

.

"

Press

on

lower

lock

until

it

ís

fully

engaged

.

"

When

installing

contact

ringlock,

make

sure

lock

spring

engages

pins

on

lock

and

lock

cover

.

"

Special

instructions

apply

when

installing

airbag

equipped

steering

wheel

.

See320

Steering

and

Wheel

Alignment

.

Early

cars

(through

1993)

:

"

Route

wiring

lead

for

horn

through

squareopening

in

steering

wheel

.

"

When

installing

a

new

contact

ring

from

BMW,

remove

locking

screw

after

installing

the

contact

ringto

steer-

ing

wheel

.

See

Fig

.

4

.

"

Lock

contact

ring

mounting

fasteners

in

place

using

lacquer

paint

or

varnish

.

0011904

Fig

.

4

.

Airbag

contact

ring

locking

screw

(arrow),

as

installed

on

new

replacement

part

from

BMW

(early

production

cars)

.

AIRBAG

SENSORS

AND

ELECTRONICS