TDC BMW 318i 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 318i, Model: BMW 318i 1992 E36Pages: 759

Page 70 of 759

113-4

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

20

.

Disconnect

main

engine

wiring

harness

connector

.

La-

bel

and

disconnect

harness

connectors

for

crankshaft

and

camshaft

sensors

.

See

Fig

.

8

.

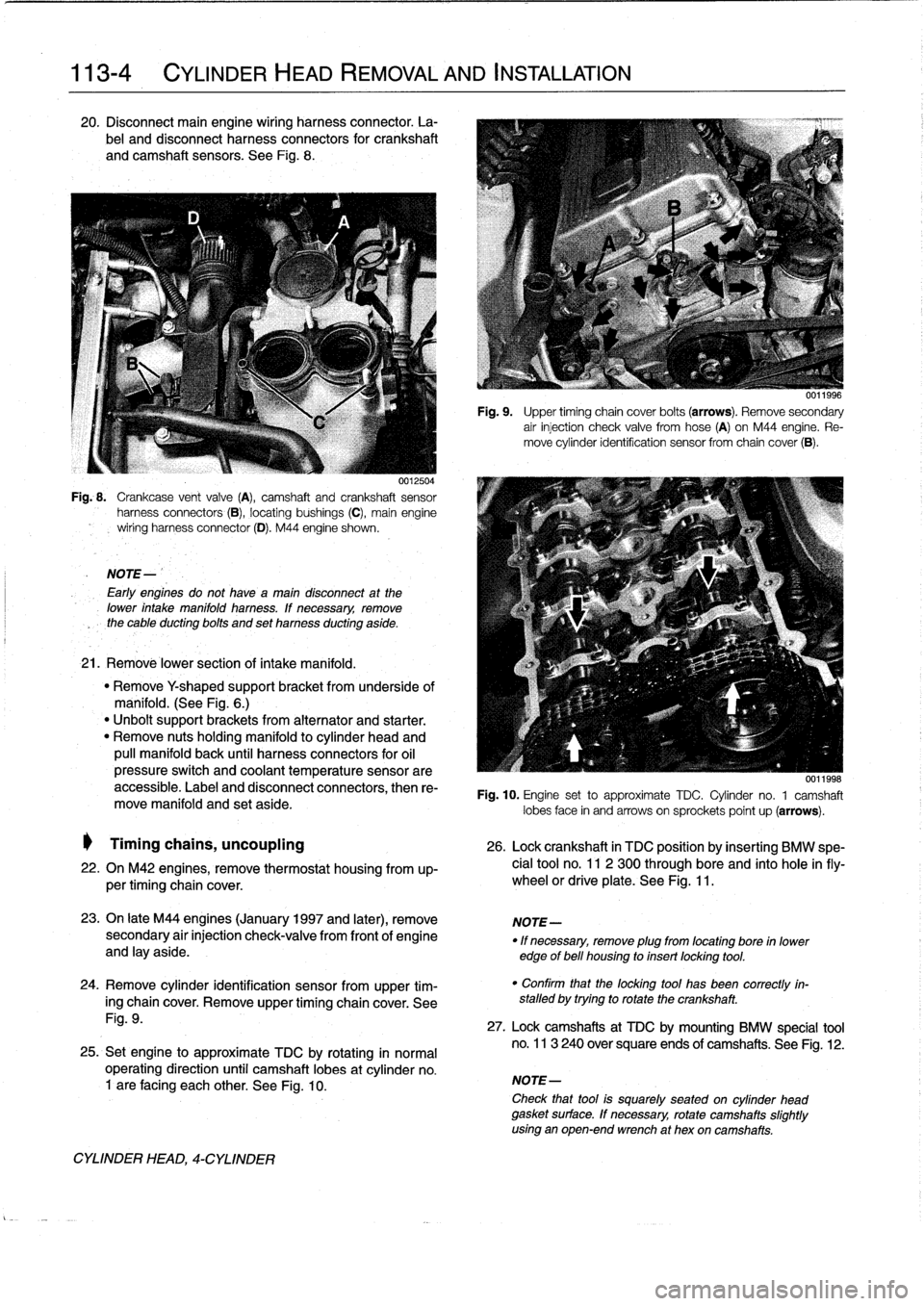

0012504

Fig

..

Crankcase

vent

valve

(A),

camshaft

and

crankshaft

sensor

harness

connectors

(B),

locating

bushings

(C),

main

engine

wiring

harnessconnector

(D)

.

M44

engine

shown

.

NOTE-

Early

engines

do

not

havea

maín

disconnect

at

the

lower

intake

manifold

harness

.

lf

necessary,

remove

the

cable

ducting

bolts

and

set

harness

ducting

aside

.

21

.

Remové

lower

section

of

intake

manifold

.

"

Remove

Y

shaped

supportbracket

from

underside

of

manifold

.

(See

Fig

.

6

.)

"

Unbolt

support

brackets

from

alternator

and

starter

.

"

Remove

nuts

holding

manifold

to

cylinder

head

and

pull

manifold

back

until

harness

connectors

for

oil

pressure

switch

and

coolant

temperature

sensorare

accessible

.

Label

and

disconnect

connectors,

then

re-

move

manifold

and

set

aside

.

Timing

chains,

uncoupling

26

.

Lock

crankshaft

in

TDC

position

by

insertíng

BMW

spe-

22

.

On

M42

engines,

remove

thermostat

housing

from

up-

cial

tool

no

.

11

2

300

through

bore

and

into

hole

infly-

per

timing

chaincover

.

wheel

or

driveplate

.

See

Fig

.

11

.

23

.

On

late

M44

engines

(January

1997

and

later),

remove

NOTE-

secondary

air

injection

check-valve

from

front

of

engine

"

If

necessary,

remove

plug

from

locating

bore

in

lower

and

lay

aside

.

edge

of

bell

housing

to

insert

locking

tool

.

24

.

Remove

cylinder

identification

sensor

from

upper

tim-

ing

chaincover

.

Remove

upper

timing

chaincover

.

See

Fig

.

9

.

25

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

10

.

CYLINDER

HEAD,

4-CYLINDER

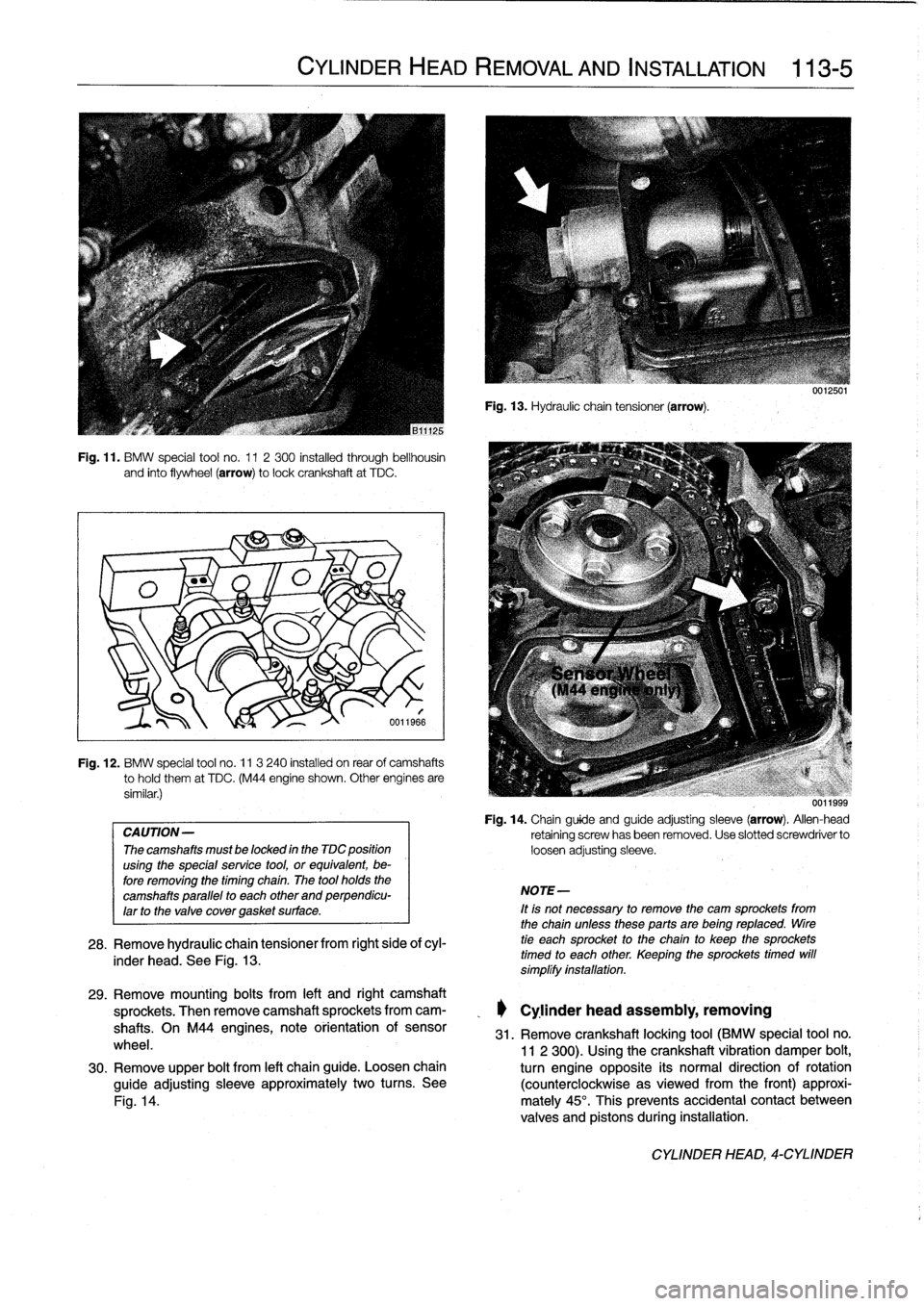

Fig

.

9

.

Upper

timing

chain

cover

bolts

(arrows)

.

Remove

secondary

air

injection

check

valve

fromhose

(A)

on

M44

engine

.

Re-

move

cylinder

identification

sensor

from

chaincover

(B)

.

0011998

Fig

.

10

.

Engine

set

to

approximate

TDC

.

Cylinder

no

.

1

camshaft

lobes

face

in

and

arrows

on

sprockets

poínt

up

(arrows)

.

"

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotate

the

crankshaft

.

27

.

Lock

camshafts

at

TDC

by

mounting

BMW

specíal

tool

no

.

113

240

over

square

ends

of

camshafts

.

See

Fig

.

12

.

NOTE-

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

camshafts

slightly

using

an

open-end

wrench

at

hex

oncamshafts

.

Page 71 of 759

Fig

.

11

.

BMW

special

tool

no

.

11

2300

installed

through

bellhousin

and

finto

flywheel

(arrow)

tolockcrankshaft

at

TDC

.

Fig

.

12

.

BMW

special

tool

no

.

11

3

240

installed

on

rear

of

camshafts

tohold

them

at

TDC

.

(M44

engine

shown

.

Other

engínes

are

similar

.)

CAUTION-

The

camshafts

must

be

locked

in

the

TDC

position

using

the

special

service

tool,

or

equivalent,

be-

fore

removing

the

timing

chaín

.

The

tool

holds

the

camshafts

parallel

to

each

other

and

perpendicu-

larto

the

valve

covergasket

surface

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-5

6011966

28

.

Remove

hydraulic

chain

tensiones

from

right

side

ofcyl-

inder

head

.

See

Fig

.

13

.

Fig

.

13

.

Hydraulic

chain

tensioner

(arrow)

.

NOTE-

It

is

not

necessary

to

remove

the

cam

sprockets

from

the

chainuntessthese

parts

are

being

reptaced

.

tire

tie

each

sprocket

to

the

chain

to

keep

the

sprockets

timed

to

each

other

.

Keeping

the

sprockets

timed

will

símplífy

instaftation

.

uu

11999

Fig

.

14

.

Chainguide

and

guide

adjusting

sleeve

(arrow)

.

Allen-head

retaining

screwhasbeen

removed

.

Use

slotted

screwdriver

to

loosen

adjusting

sleeve

.

29

.

Remove

mounting

bolts

from

left

and

right

camshaft

sprockets

.

Then

remove

camshaft

sprockets

from

cam-

_

Cylinder

head

assembly,

removing

shafts

.

On

M44

engines,

note

orientation

of

sensor

31

.

Remove

crankshaft

locking

tool

(BMW

special

tool

no

.

wheel

.

11

2

300)

.

Usingthe

crankshaft

vibration

damper

bolt,

30

.

Remove

upper

bolt

from

left

chainguide

.

Loosen

chain

turn

engine

opposite

its

normal

direction

of

rotation

guide

adjusting

sleeve

approximately

two

turns

.

See

(counterclockwise

asviewed

from

the

front)

approxi

Fig

.

14

.

mately

45°

.

This

prevents

accidental

contact

between

valves

and

pistons

during

installation

.

CYLINDER

HEAD,

4-CYLINDER

Page 72 of 759

113-

6

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

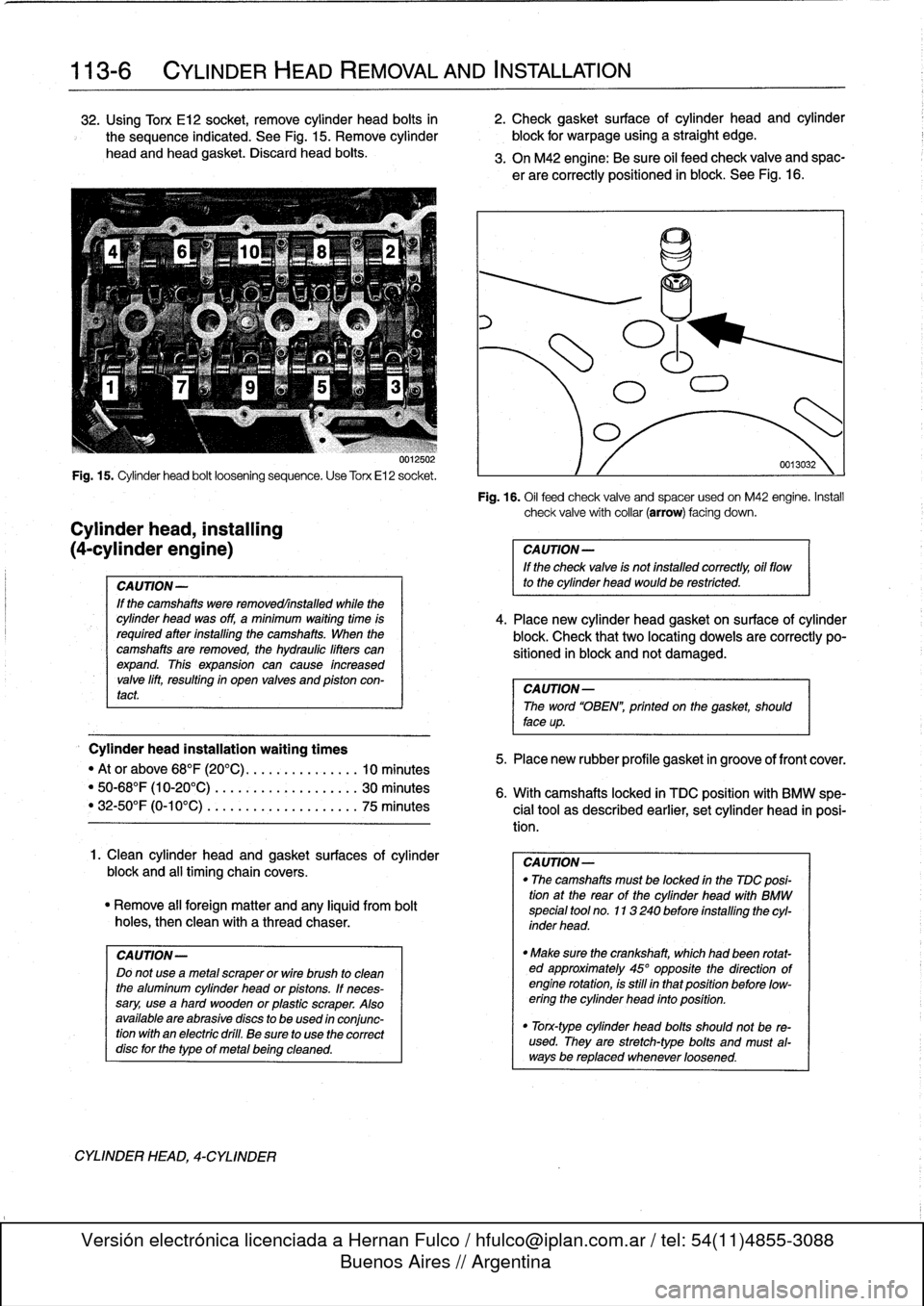

32

.

Using

Torx

E12

socket,

remove

cylinder

head

bolts

in

2

.

Check

gasket

surface

of

cylinder

head

and

cylinder

the

sequence

indicated

.

See

Fig

.

15

.

Remove

cylinder

block

for

warpage

using

a

straight

edge

.

head

and

head

gasket

.

Discard

head

boits

.

3

.

On

M42

engine

:

Be

sure

oil

feed

check

valve

and

spac-

er

are

correctly

positioned

in

block

.

See

Fig

.

16

.

0012502

Fig

.

15

.

Cylinder

head

bolt

loosening

sequence

.

Use

Torx

El

2

socket

.

Cylinder

head,

installing

(4-cylinder

engine)

CAUTION-

If

the

camshafts

were

removedrínstalled

while

the

cylinder

head

was

off,

a

minimum

wafting

time

ís

requíred

after

installing

the

camshafts

.

When

the

camshafts

are

removed,

the

hydraulic

lifters

canexpand

.

This

expansion

can

cause

fncreased

valve

lift,

resultíng

in

open

valves

and

pfston

con-

tact

Cylinder

head

installation

waiting

times

"

Ator

above

68°F

(20°C)

...............

10

minutes

"50-68°F

(10-20°C)

.

.

..

...............

30

minutes

"

32-50°F

(0-10°C)

..

.

..

...............

75

minutes

1

.

Clean

cylinder

head

and

gasket

surfaces

of

cylinder

block

and

al¡

timing

chain

covers

.

"

Remove

al¡

foreign

matter

and

any

¡¡quid

from

bolt

holes,

then

clean

with

a

thread

chaser

.

CAUTION-

Do

not

useametal

scraper

or

wire

brush

to

clean

the

alumfnum

cylinder

head

or

pistons

.

If

neces-

sary,

useahard

wooden

or

plastic

scraper

.

Also

available

are

abrasivediscs

to

be

used

ín

conjunc-

tionwíth

an

electric

dril¡

.

Be

sure

to

use

the

correct

disc

for

the

type

of

metalbeingcleaned

.

CYLINDER

HEAD,

4-CYLINDER

Fig

.

16

.

Oil

feed

check

valve

and

spacer

used

on

M42

engine

.

Install

check

valvewíth

collar

(arrow)

facing

down

.

CAUTION-

If

the

check

valve

is

not

installed

correctly,

oil

flow

to

the

cylinder

head

would

be

restrícted

.

4

.

Place

new

cylinder

head

gasket

on

surface

of

cylinder

block

.

Check

that

two

locating

dowels

are

correctly

po-

sitioned

in

block

and

not

damaged

.

CAUTION-

The

word

"OBEN",

prfnted

on

the

gasket,

should

face

up

.

5

.

Place

new

rubber

profile

gasket

in

groove

of

front

cover

.

6

.

With

camshafts

locked

in

TDC

positionwith

BMW

spe-

cial

tool

as

described

earlier,

set

cylinder

head

in

posi-

tion

.

CAUTION-

"

The

camshafts

mustbe

focked

in

the

TDC

posi-

tion

at

the

rear

of

the

cylinder

head

with

BMW

specfal

tool

no

.

113240

before

installing

the

cyl-

inder

head

.

"

Make

sure

the

crankshaft,

which

had

been

rotat-

ed

approximately

45°

opposite

the

dfrection

of

engine

rotation,

is

still

in

thatposition

before

low-

ering

the

cyffnder

head

ínto

position

.

"

Torx-type

cylinder

head

bolts

should

not

be

re-

used

.

They

are

stretch-type

bolts

and

must

al-

waysbe

replaced

whenever

loosened

.

Page 73 of 759

7

.

Lightly

lubricate

new

cylinder

head

bolts

.

Loosely

instan

bolts

and

their

washers,

then

thread

them

in

until

they

are

finger

tight

.

NOTE-

Check

that

all

washers

for

the

cylinder

head

bolts

are

in

place

before

installing

the

bolts

.

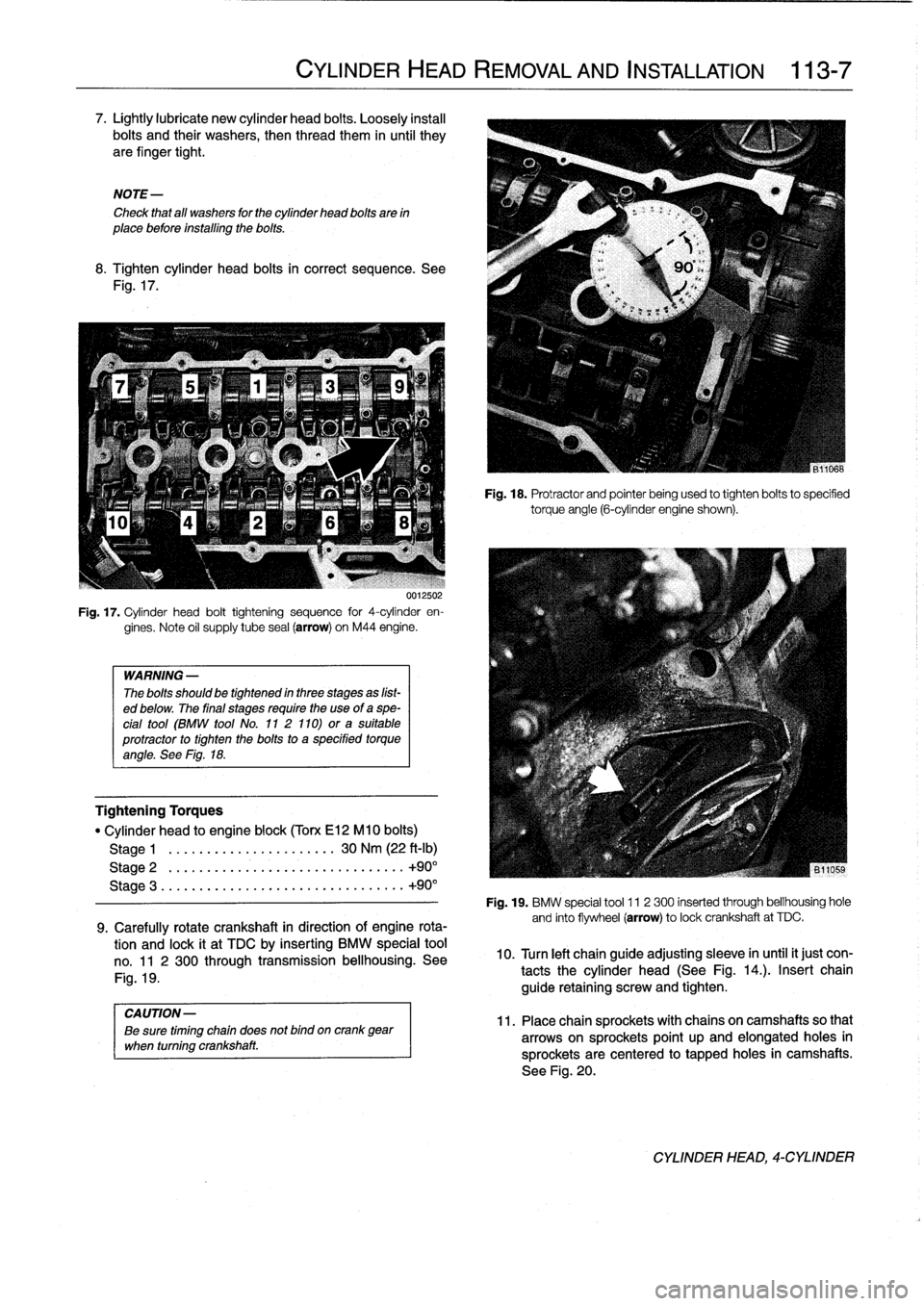

8

.

Tighten

cylinder

head

bolts

in

correct

sequence

.

See

Fig

.

17

.

UU125U2

Fig

.

17

.

Cylinder

head

bolt

tightening

sequence

for

4-cylinder

en-

gines

.

Note

oil

supply

tube

seal

(arrow)

on

M44

engine

.

WARNING

-

The

bolts

should

be

tightennd

in

three

stages

as

líst-

ed

below

.

The

final

stages

require

the

use

of

a

spe-

cial

tool

(BMW

tool

No

.

11

2

110)

ora

suitable

protractor

to

tighten

the

bolts

to

a

specified

torqueangle

.

See

Fig

.

18

.

Tightening

Torques

"

Cylinder

head

to

engine

block

(Torx

El2

M10

bolts)

Stage

1

.

.

.....

.

.

.............

30

Nm

(22

ft-Ib)

Stage

2

.

...

...

.

.

...................

..

.

+90°

Stage

3

.....

...

.

..

...................

..

+90°

9

.

Carefully

rotate

crankshaft

in

direction

of

engine

rota-

tion

and

lock

it

at

TDC

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

.

See

Fig

.

19

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-

7

Fig

.

18

.

Protractor

and

pointer

being

used

to

tighten

bolts

to

specified

torqueangle

(6-cylinder

engine

shown)

.

Fig

.

19

.

BMW

special

tool

11

2

300

inserted

through

bellhousing

hole

and

finto

flywheel

(arrow)

to

lockcrankshaft

at

TDC

.

10

.

Turn

left

chainguide

adjusting

sleeve

in

until

it

just

con-

tacts

the

cylinder

head

(See

Fig

.

14

.)

.

Insert

chain

guide

retaining

screw

and

tighten

.

CAUTION-

11

.

Placechain

sprockets

with

chains

oncamshaftsso

that

Be

sure

timing

chain

does

not

bind

oncrank

gear

when

turning

crankshaft

.

arrowson

sprockets

point

up

and

elongated

holes

in

sprocketsare

centered

to

tapped

holes

in

camshafts

.

See

Fig

.

20

.

CYLINDER

HEAD,

4-CYLINDER

Page 78 of 759

113-12

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

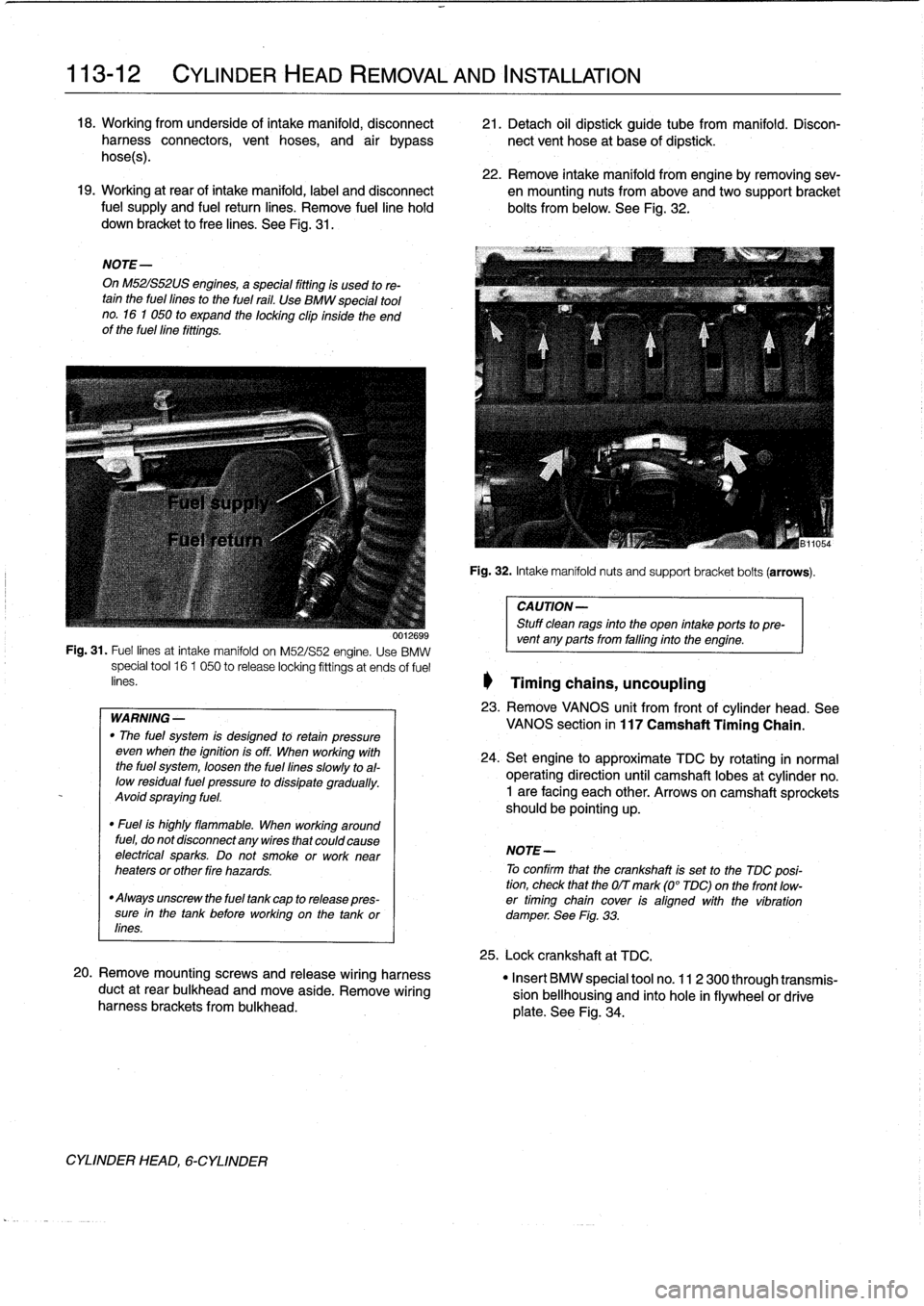

18

.

Working

from

underside

of

intake

manifold,

disconnect

21

.

Detach

oil

dipstick

guide

tube

from

manifold

.

Disconharness

connectors,

vent

hoses,

and

air

bypass

nectvent

hose

at

base

of

dipstick

.

hoses)

.

22

.

Remove

intake

manifold

from

engine

byremoving

sev-19

.

Working

at

rear

of

intake

manifold,

label

and

disconnect

en

mounting

nuts

from

above

andtwo

support

bracket

fuel

supply

and

fuel

return

lines

.

Remove

fuelline

hold

bolts

from

below

.

See

Fig

.

32

.

down

bracket

to

free

lines

.

See

Fig

.

31

.

NOTE-

On

M52IS52US

engines,

a

special

fitting

is

used

to

re-tain

the

fuel

fines

to

the

fuel

rail

.

Use

BMW

special

tool

no

.

16

1

050

to

expand

the

locking

clip

inside

the

end

of

the

fuellíne

fittings

.

WARNING

-

"

The

fuel

system

is

desígned

to

retan

pressure

even

wheh

the

ignition

is

off

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrfcal

sparks

.

Do

not

smoke

orwork

near

heaters

or

other

fire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

lines

.

20

.

Remove

mountingscrews

and

release

wiring

harness

duct

at

rear

bulkhead

and

move

aside

.

Remove

wiring

harness

brackets

frombulkhead

.

CYLINDER

HEAD,

6-CYLINDER

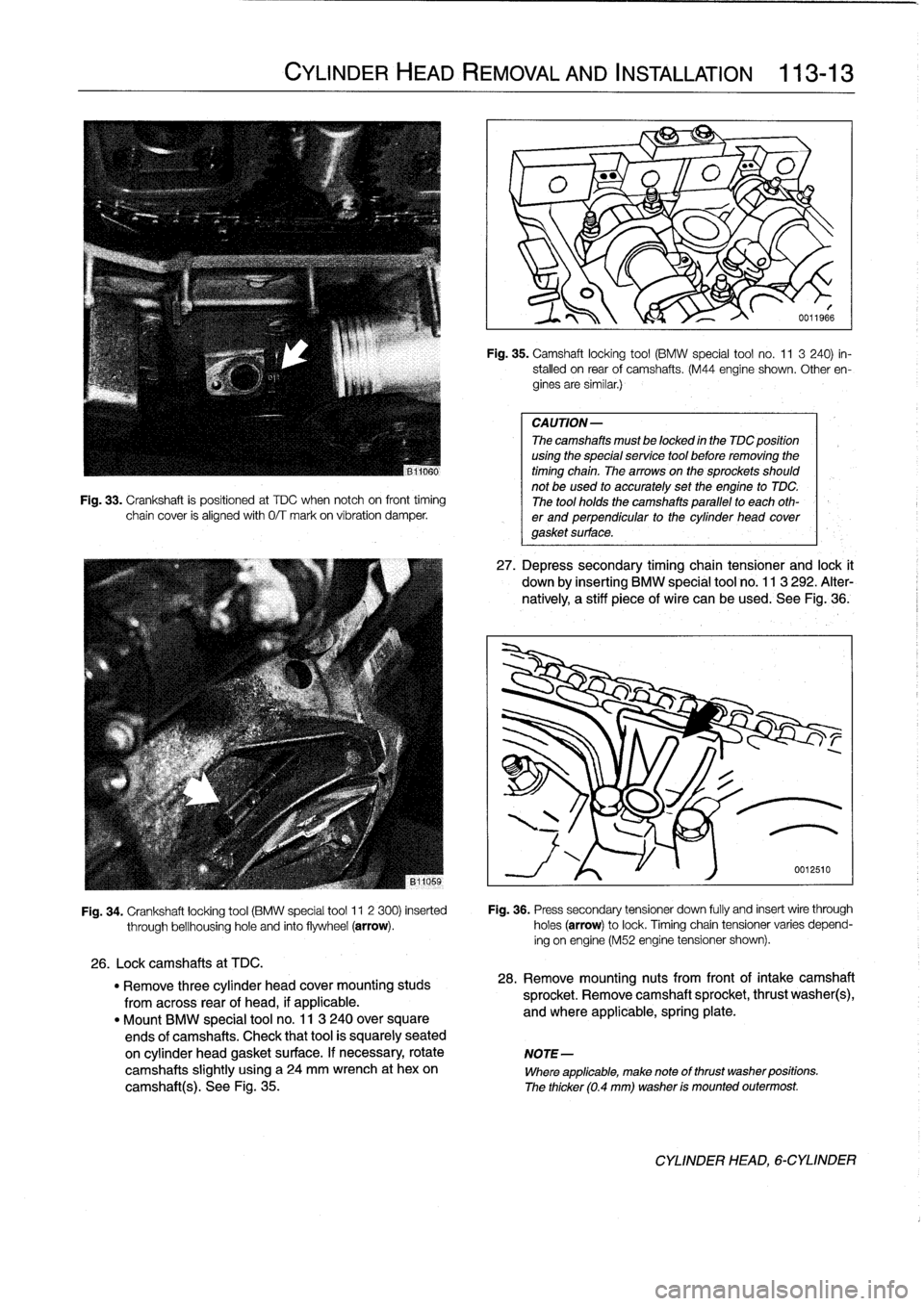

Fig

.

32

.

Intake

manifoldnuts

and

support

bracket

bolts

(arrows)

.

CAUTION-

Stuff

clean

rags

into

the

open

intake

ports

topre-

001269s

vent

any

ports

from

falfing

into

the

engine

.

Fig

.

31

.

Fuel

lines

at

intake

manifold

on

M52/S52

engine

.

Use

BMW

special

tool

16

1

050

to

release

locking

fittings

at

ends

of

fuel

enes

.

1

Timing

chains,

uncoupling

23

.

Remove

VANOS

unit

from

frontof

cylinder

head

.

See

VANOS

section

in

117

Camshaft

Timing

Chain

.

24

.

Setengine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

Arrows

on

camshaft

sprockets

should

be

pointing

up

.

NOTE-

To

confirm

that

the

crankshaft

is

set

to

the

TDC

posi-

tion,

check

that

the

OIT

mark

(0°

TDC)on

the

front

low-

er

timing

chain

cover

ís

aligned

with

the

víbration

damperSee

Fig

.

33

.

25

.

Lock

crankshaft

at

TDC

.

"

Insert

BMW

special

tool

no

.

11

2

300

through

transmis-

sion

bellhousing

and

finto

hole

in

flywheelor

drive

plate

.

See

Fig

.

34

.

Page 79 of 759

Fig

.

33

.

Crankshaft

is

positioned

at

TDC

when

notch

oh

front

timing

chain

cover

is

alignedwith

0/T

mark

on

víbration

damper

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-

1

3

Fig

.

35

.

Camshaft

locking

tool

(BMW

special

tool

no

.

11

3

240)

in-

stalled

on

rear

of

camshafts

.

(M44

engine

shown

.

Other

en-

gines

are

similar

.)

CAUTION-

The

camshafts

must

be

locked

in

the

TDC

position

using

the

special

service

tool

before

removing

the

timing

chain

.

Thearrowson

the

sprockets

should

not

be

used

to

accurately

set

the

engine

to

TDC

.

The

tool

holds

the

camshafts

parallel

to

each

oth-

er

and

perpendicular

to

the

cylinder

head

covergasket

surface

.

27

.

Depress

secondary

timing

chain

tensioner

and

lock

t

down

by

inserting

BMW

special

tool

no

.

113

292

.

Alter-

natively,

a

stiff

piece

of

wire

can

be

used

.

See

Fig

.,36

.

Fig

.

34

.

Crankshaft

locking

tool

(BMW

special

tool

11

2

300)

inserted

Fig

.

36

.

Press

secondary

tensioner

down

fully

and

insert

wire

through

through

bellhousinghole

and

finto

flywheel

(arrow)

.

holes

(arrow)

to

lock

.

Timingchain

tensioner

varies

depend-

ing

on

engine

(M52

engine

tensioner

shown)

.

26

.

Lockcamshafts

at

TDC

.

"

Remove

three

cylinder

head

cover

mounting

studs

28

.

Remove

mounting

nuts

from

front

of

intake

camshaft

from

across

rear

of

head,

if

applicable

.

sprocket

.

Remove

camshaft

sprocket,

thrust

washer(s),

"

Mount

BMW

special

tool

no

.

11

3

240

over

square

and

where

applicable,

spring

plate

.

ends

of

camshafts

.

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

NOTE-

camshafts

slightly

using

a

24

mm

wrench

at

hexon

Where

applicable,

make

note

of

thrust

washer

positions

.

camshaft(s)

.

See

Fig

.

35

.

The

thicker

(0

.4

mm)

washer

is

mounted

outermost

.

CYLINDER

HEAD,6-CYLINDER

Page 81 of 759

NOTE-

Cylinder

head,

installing

(6-cylinder

engine)

CAUTION-

If

the

camshafts

were

removed

and

installed

while

the

cylinder

head

was

off,

a

minimum

waiting

time

is

required

after

ínstalling

the

camshafts

.

When

the

camshaftsareremoved,

the

hydraullc

lifters

can

expand

.

This

expansion

can

cause

increased

valve

lift

when

the

camshafts

are

bolted

down,

re-

sulting

in

open

valves

.

Cylinder

head

installation

waiting

times

"

68°F

(20°C)

and

higher

.

.

.

..

..........

10

minutes

"

50-68°F

(10-20°C)

........

..

.........

30

minutes

"

32-50°F

(0-10

°C)

.........

...

........

75

minutes

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-

1

5

1

.

Clean

cylinder

head

and

gasket

surfaces

of

cylinder

block

and

al¡

timing

chain

covers

.

"

Remove

all

foreign

matter

and

any

¡¡quid

from

bolt

holes,

then

clean

with

a

thread

chaser

.

CA

UTION-

Do

not

use

ametal

scraper

or

wire

brush

to

clean

the

aluminum

cylinder

head

or

pistons

.

If

neces-

sary,

use

a

hard

wooden

or

plastic

scraper

.

Also

available

are

abrasive

discs

to

be

used

in

conjunc-

tion

with

an

electric

drill

.

Be

sure

to

use

the

correct

disc

for

the

typeof

metal

being

cleaned

.

2

.

Check

gasket

surface

of

cylinder

head

and

cylinder

block

for

warpage

using

a

straight

edge

.

NOTE-

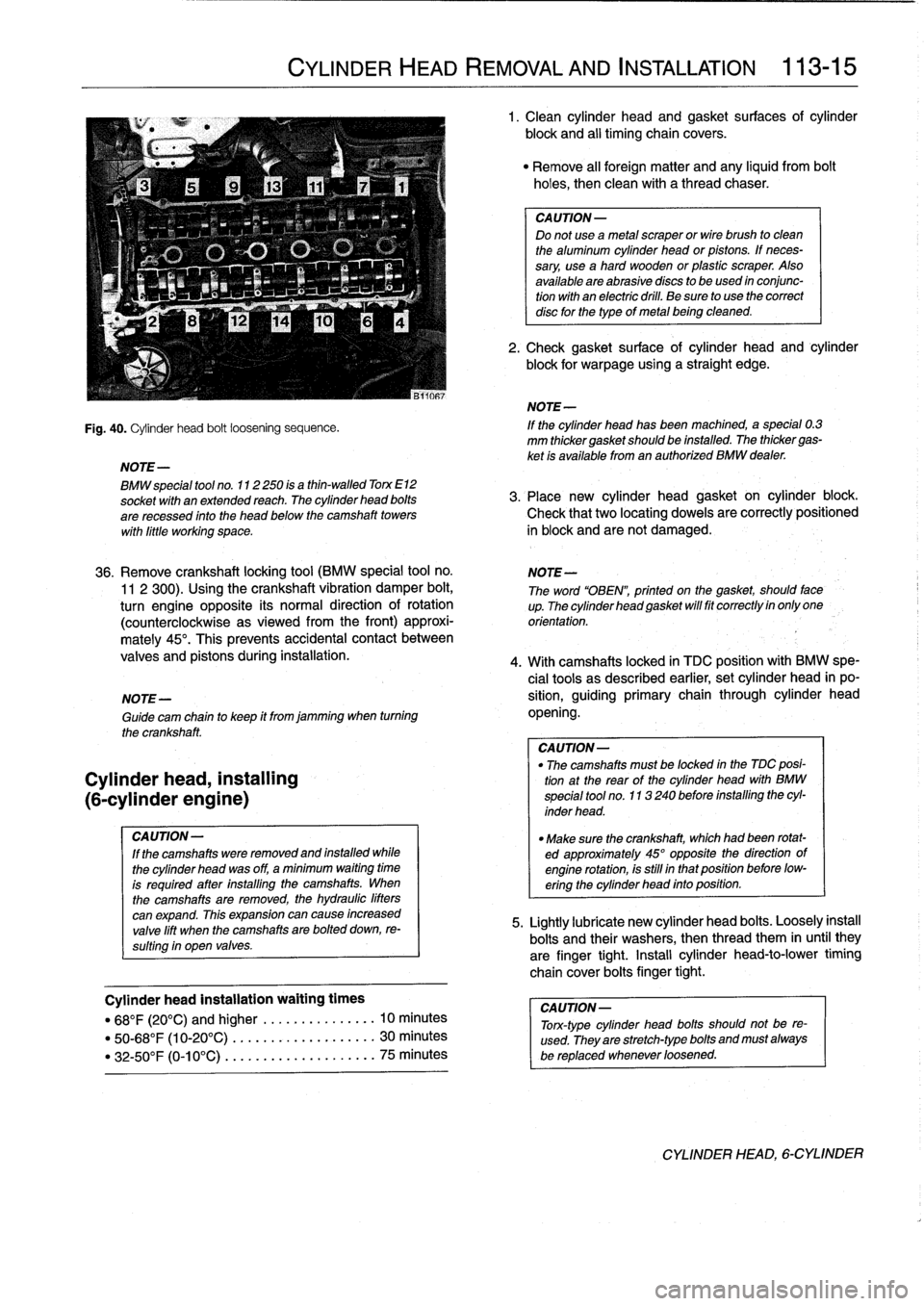

Fig

.

40

.

Cylinder

head

bolt

loosening

sequence

.

If

the

cylinder

head

has

been

machined,a

special

0

.3

mm

thickergasketshould

be

installed

.

The

thickergas-

ket

is

available

from

an

authorized

BMW

dealer

.

BMW

special

tool

no

.

112250

is

a

thin-walled

Torx

E12

socket

wíth

anextended

reach

.

The

cylinder

head

bolts

3

.

Place

new

cylinder

head

gasket

on

cylinder

block

.

are

recessed

finto

the

head

below

the

camshaft

towers

Check

that

two

locating

dowels

are

correctly

positioned

wíth

liffle

working

space

.

in

block

and

arenot

damaged

.

36

.

Remove

crankshaft

locking

tool

(BMW

special

tool

no

.

NOTE-

11

2

300)

.

Using

the

crankshaft

vibration

damper

bolt,

The

word

"OBEN",

printed

on

the

gasket,

should

face

turn

engine

opposite

its

normal

direction

of

rotation

up

.Thecylinderheadgasketwillfitcorrectlyinonlyone

(counterclockwise

asviewed

from

the

front)

approxi-

orientation

.

mately

45°

.

This

prevents

accidental

contact

between

valves

and

pistons

during

installation

.

4

.

With

camshafts

locked

in

TDC

positionwith

BMW

spe-

cial

tools

as

described

earlier,

set

cylinder

head

in

po

NOTE-

sition,

guiding

primary

chain

through

cylinder

head

Guide

cam

chain

to

keep

it

from

jamming

when

turning

opening

.

the

crankshaft

.

CA

UTION-

"

The

camshafts

must

be

locked

in

the

MC

posi-

tion

at

the

rear

of

the

cylinder

head

with

BMW

special

tool

no

.

113240

before

installing

the

cyl-

inder

head

.

"

Make

sure

the

crankshaft,

which

had

been

rotat-

ed

approximately

45°

opposite

thedirection

of

engine

rotation,is

still

in

that

position

before

low-

ering

the

cylinder

head

into

position

.

5

.

Lightly

lubricate

new

cylinder

head

bolts

.

Loosely

instan

bolts

and

their

washers,

then

thread

them

in

until

they

are

finger

tight

.

Install

cylinder

head-to-lower

timing

chaincover

boitsfinger

tight

.

CAUTION-

Tonc-type

cylinder

head

bolts

should

not

be

re-

used

.

They

are

stretch-typebolts

and

must

always

be

replaced

whenever

loosened

.

CYLINDER

HEAD,

6-CYLINDER

Page 82 of 759

113-16

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

NOTE-

Check

that

all

washers

for

the

cylinder

head

bolts

are

in

place

before

installlng

the

bolts

.

Some

of

the

washers

may

be

staked

to

the

cylinder

head

.

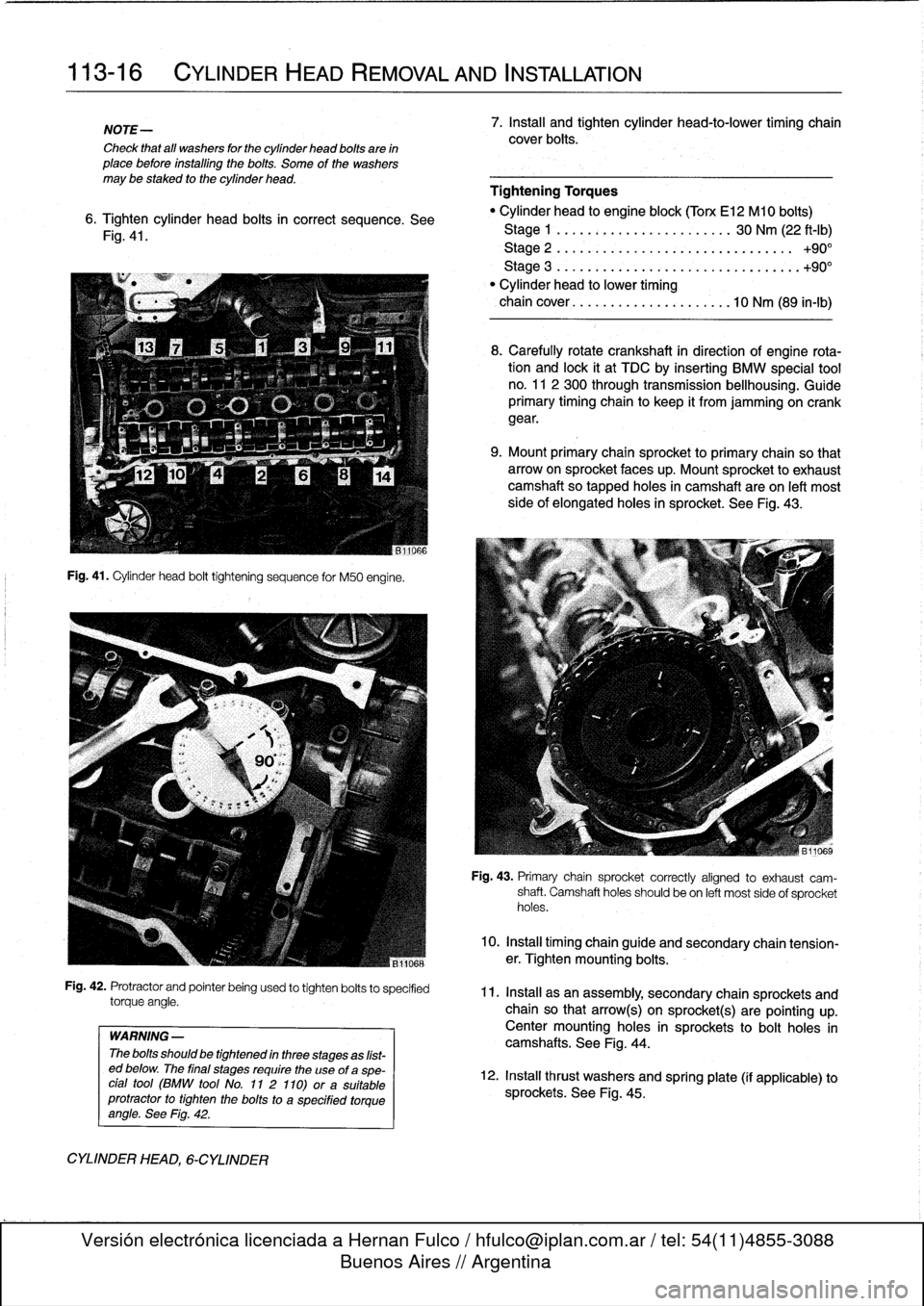

6

.

Tighten

cylinder

head

bolts

in

correct

sequence

.

See

Fig

.

41

.

Fig

.

41

.

Cylinder

head

bolt

tightening

sequence

for

M50

engine

.

Fig

.

42

.

Protractor

and

pointer

being

used

to

tighten

bolts

to

specified

torque

angle

.

WARNING

-

The

bolts

should

be

tightened

in

three

stages

as

list-

ed

below

.

The

final

stages

require

the

use

of

aspe-

cial

tool

(BMW

tool

No

.

11

2

110)

ora

suitable

protractor

to

tighten

the

bolts

to

a

specified

torque

angle

.

See

Fig

.

42

.

CYLINDER

HEAD,

6-CYLINDER

7

.

Install

and

tighten

cylinder

head-to-lower

timing

chain

cover

bolts

.

Tightening

Torques

"

Cylinder

head

to

engine

block(Torx

El

2

Ml

0

bolts)

Stage

1

.........

..

.

.

.

...

.

...

..

30

Nm

(22

ft-Ib)

Stage

2

.........

..

..

....

.

...

..........

+90°

Stage

3

...

.

.....

..

.

.

.

...

.

...

..........

.+90°

"

Cylinder

head

lo

lower

timing

chaincover

.......

..

..

..

...

.

....

10

Nm

(89

in-lb)

8

.

Carefully

rotate

crankshaft

in

direction

of

engine

rota-tion

and

lock

it

at

TDC

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

.

Guide

primary

timing

chain

to

keep

it

from

jamming

on

crank

gear

.

9

.

Mount

primary

chain

sprocketto

primary

chain

so

that

arrowon

sprocket

faces

up

.

Mount

sprocket

to

exhaust

camshaftso

tapped

holes

in

camshaft

are

on

left

most

side

of

elongated

holes

in

sprocket

.

See

Fig

.

43

.

Fig

.

43

.

Primary

chain

sprocket

correctly

afgned

to

exhaust

cam-

shaft

.

Camshaft

holes

should

be

on

left

most

sideof

sprocket

holes

.

10

.

Install

timing

chain

guide

and

secondary

chain

tension-er

.

Tighten

mounting

bolts

.

11

.

Install

asan

assembly,

secondary

chain

sprockets

and

chain

so

that

arrow(s)

on

sprockt(s)

are

pointing

up

.

Centermounting

holes

in

sprockets

tobolt

holes

in

camshafts

.

See

Fig

.

44

.

12

.

Install

thrust

washers

and

spring

plate

(if

applicable)

to

sprockets

.

See

Fig

.

45

.

Page 86 of 759

116-2

CYLINDER

HEADAND

VALVETRAIN

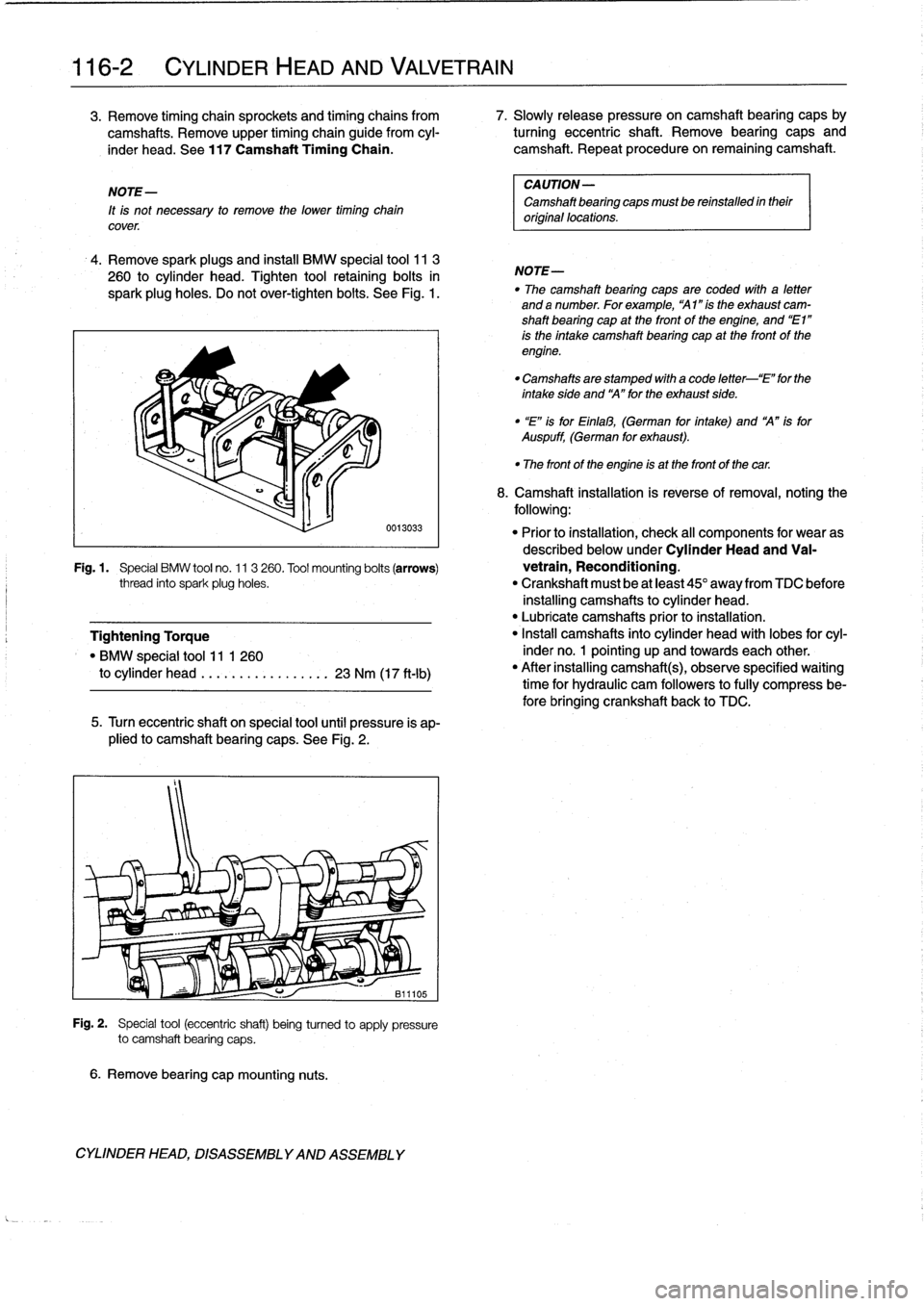

3

.

Remove

timing

chain

sprockets

and

timing

chains

from

7

.

Slowly

release

pressure

oncamshaft

bearing

capsby

camshafts

.

Remove

upper

timing

chain

guidefrom

cyl-

turningeccentric

shaft

.

Remove

bearing

caps

and

inder

head

.

See117

Camshaft

Timing

Chain

.

camshaft

.

Repeat

procedureon

remaining

camshaft

.

NOTE-

It

is

not

necessary

lo

remove

the

lower

timing

chain

cover

.

4

.

Remove

spark

plugs

and

instaf

BMW

special

tool

11

3

260

to

cylinder

head

.

Tighten

tool

retaining

bolts

in

spark

plug

holes

.

Do

not

over-tighten

bolts

.

See

Fig

.

1

.

6

.

Remove

bearing

cap

mounting

nuts

.

0013033

5

.

Turn

eccentric

shaft

on

special

tool

until

pressure

is

ap-

plied

to

camshaft

bearing

caps

.

See

Fig

.

2

.

Fig

.

2

.

Special

tool

(eccentric

shaft)

being

turned

to

apply

pressure

to

camshaft

bearing

caps

.

CYLINDER

HEAD,

DISASSEMBLYAND

ASSEMBLY

CAUTION-

Camshaft

bearing

caps

mustbe

reinstalled

intheir

original

locations

.

NOTE-

"

The

camshaft

bearing

caps

are

coded

wíth

a

letter

anda

number

.

Forexample,

"Al

"ís

the

exhaust

cam-

shaft

bearing

cap

at

the

front

of

the

engíne,

and

"El"

is

the

intake

camshaft

bearing

cap

at

the

front

of

the

engine

.

"

Camshafts

are

stamped

with

a

code

letter-`E"

for

the

intakeside

and

`A"forthe

exhaust

side

.

"

"E"

isforEinlal3,

(German

for

íntake)

and

A"

isfor

Auspuff,

(German

for

exhaust)

.

"

The

front

of

the

engine

is

at

the

front

of

thecar

.

8

.

Camshaft

installation

is

reverse

of

removal,noting

the

following

:

"

Prior

to

installation,

check

al¡

components

for

wear

as

described

below

underCylinder

Head

and

Va¡-

Fig

.1

.

Special

BMW

tool

no

.

11

3

260

.

Tool

mounting

bolts

(arrows)

vetrain,

Reconditioning

.

thread

into

spark

plug

holes

.

"

Crankshaft

must

be

at

least

45°

away

from

TDC

before

installing

camshafts

to

cylinder

head

.

"

Lubricate

camshafts

prior

to

installation

.

Tightening

Torque

"

Install

camshafts

into

cylinder

head

with

lobes

for

cyl-

"

BMW

special

tool

11

1

260

inder

no

.

1

pointing

up

and

towards

each

other

.

to

cylinder

head

.

...

.

.

...........

23

Nm

(17

ft-Ib)

"

After

installing

camshafts),observe

specified

waiting

time

for

hydraulic

cam

followers

to

fully

compress

be-

fore

bringing

crankshaft

back

to

TDC

.

Page 88 of 759

116-

4

CYLINDER

HEAD

AND

VALVETRAIN

NOTE-

"

The

camshaft

bearing

caps

are

coded

with

a

letter

anda

number

.

Forexample,

'541"is

the

exhaustcam-

shaft

bearing

cap

at

the

front

of

the

engine,

and

`El"

is

the

intake

camshaft

bearing

cap

at

the

front

of

the

engine

.

"

Camshafts

are

stamped

with

a

code

letter-'E"

for

the

intakeside

and

A"

for

the

exhaust

side

.

"

"E"

isfor

Einla3,

(German

for

intake)

and

A"

is

for

Auspuff,

(Germen

for

exhaust)

.

"

The

front

of

the

engine

is

at

the

front

of

the

car

.

8

.

Camshaft

installation

is

reverse

of

removal,

noting

the

following

:

"

Prior

to

installation,

check

all

components

for

wear

as

described

below

underCylinder

Head

and

Val-

vetrain

Reconditioning

.

"

Lubricate

camshafts

prior

to

installation

.

"

Reinstall

timing

chain

sprockets

and

tensioner

and

set

valve

timing

before

reinstalling

rocker

arms,as

spe-

cifically

described

in

117

Camshaft

Timing

Chain

.

"

Be

sure

corresponding

camshaft

lobe

is

pointing

up

before

installing

rocker

arms

.

Note

that

each

rocker

arm

angles

away

from

corresponding

spark

plug

hole

.

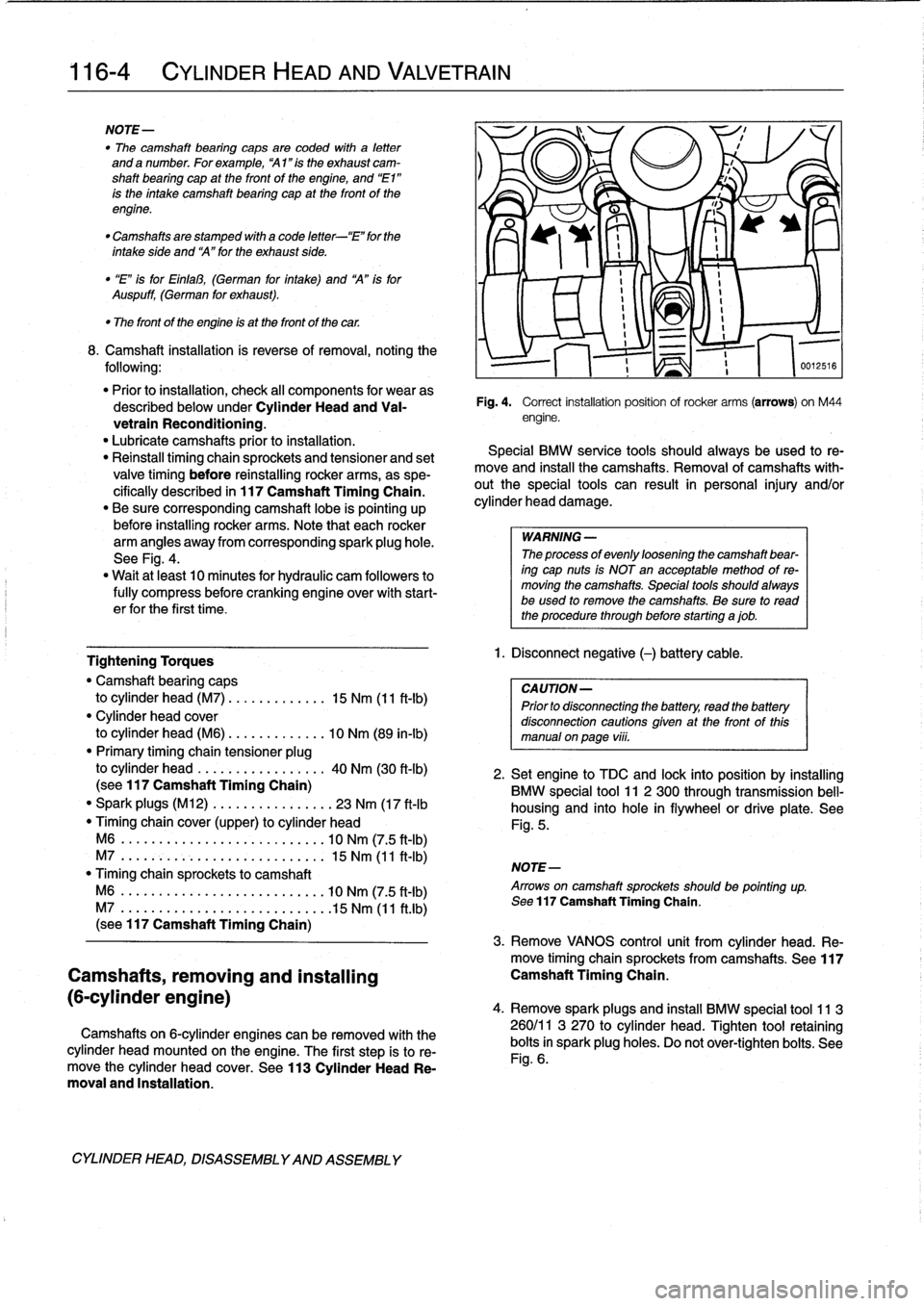

See

Fig

.

4

.

"

Wait

at

least

10

minutes

for

hydraulic

cam

followers

to

fully

compress

before

cranking

engine

over

with

start-

er

for

the

first

time

.

Tightening

Torques

"

Camshaft

bearing

caps

to

cylinder

head

(M7)

.............

15

Nm

(11

ft-Ib)

"

Cylinder

head

cover

to

cylinder

head

(M6)

.............

10

Nm

(89

in-lb)

"

Primary

timing

chain

tensioner

plug

to

cylinder

head

.

................

40

Nm

(30

ft-lb)

(sea

117

Camshaft

Timing

Chain)

"

Spark

plugs

(M12)

.............

...

23

Nm

(17

ft-lb

Timing

chaincover

(upper)

to

cylinder

head

M6

.....

.

.

...

................

.

10

Nm

(7

.5

ft-Ib)

M7

....

..

.

.

........

.

.....

.

...

.

15

Nm

(11

ft-Ib)

"

Timing

chain

sprockets

to

camshaft

M6

....

.

.

..

..............

.

..

..

10

Nm

(7

.5

ft-Ib)

M7

....

....

..............

.

..

..

.15

Nm

(11

ft

.lb)

(sea

117

Camshaft

Timing

Chain)

Camshafts,

removing

and

installing

(6-cylinder

engine)

Camshafts

on

6-cylinder

engines

can

be

removed

with

the

cylinder

head

mounted

on

the

engine

.

The

first

step

is

to

re-

move

the

cylinder

head

cover

.

See

113

Cylinder

Head

Re-

moval

and

Installation

.

CYLINDER

HEAD,

DISASSEMBLYAND

ASSEMBLY

Fig

.

4

.

Correct

installation

position

ofrocker

arms

(arrows)

on

M44

engine

.

Special

BMW

service

tools

should

always

be

used

to

re-

move

and

instan

the

camshafts

.

Removal

of

camshafts

with-

outthe

special

tools

can

result

in

personal

injury

and/or

cylinder

head

damage

.

WARNING

-

The

processof

evenly

loosening

the

camshaft

bear-

ing

cap

nuts

is

NOT

en

acceptable

method

of

re-

moving

the

camshafts

.

Special

tools

shouldalways

be

used

lo

remove

the

camshafts

.

Be

sure

to

read

the

procedure

through

before

starting

ajob

.

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpaga

viii

.

516

2

.

Setengine

to

TDC

and

lock

into

position

by

installing

BMW

special

tool

11

2

300

through

transmission

bell-

housing

and

into

hole

in

flywheel

or

drive

platea

See

Fig

.

5

.

NOTE-

Arrows

on

camshaft

sprockets

shouldbe

pointing

up

.

Sea

117

Camshaft

Timing

Chain

.

3

.

Remove

VANOS

control

unit

from

cylinder

head

.

Re-

move

timing

chainsprockets

from

camshafts

.

See117

Camshaft

Timing

Chain

.

4

.

Remove

sparkplugs

and

insta¡¡

BMW

special

tool

11

3

260/11

3

270

to

cylinder

head

.

Tighten

tool

retaining

bolts

in

spark

plug

holes

.

Do

not

ovar-tighten

bolts

.

See

Fig

.

6

.