running light BMW 318i 1996 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 318i, Model: BMW 318i 1996 E36Pages: 759

Page 138 of 759

121-2

BATTERY,

STARTER,

ALTERNATOR

CHARGING

SYSTEM

TROUBLESHOOTING

Static

currentdraw,

checking

Charging

system

diagnostics

requires

special

test

equip-

ment

.

If

the

test

equipment

is

not

available,

charging

system

fault

diagnosis

can

be

performedby

an

authorized

BMW

deal-

eror

other

qualified

repair

shop

.

A

general

troubleshooting

guide

is

given

in

Table

a

.

Charging

System

Quick-Check

As

a

quick-check,

use

a

digital

multimeter

lo

measure

volt-

2

.

Disconnect

battery

negative

(-)

cable

.

age

across

the

battery

terminals

with

the

key

off

and

then

again

with

the

engine

running

.

The

battery

voltage

should

be

CAUTION-

about12

.6

volts

with

key

off

and

approximately

14

.0

volts

with

Prior

to

disconnecting

the

battery,

read

the

battery

the

engine

running

.

If

the

voltage

does

not

increase

when

the

disconnection

cautions

given

at

the

front

of

this

engine

is

running,there

is

a

fault

in

the

charging

system

.

manual

onpaga

viii

.

NOTE

-

The

regulated

voltage

(engine

running)

should

be

be-

tween

13

.5

and

14

.5,

depending

on

temperatura

and

operating

conditions

.

If

the

voltage

is

higher

than

14

.8,

the

voltage

regulator

is

most

Mely

faulty

.

Check

for

clean

and

tight

battery

cables

.

Check

the

ground

cable

running

from

the

negative

(-)

battery

terminal

lo

the

chassis

and

the

ground

cable

running

from

the

engine

lo

the

chassis

.

Check

the

alternator

drive

belt

condition

and

tension

.

If

the

battery

discharges

over

time,

there

may

be

a

constant

drain

or

current

draw

on

the

battery

.

A

small

static

drain

on

the

battery

is

normal,

but

a

largedrain

will

cause

the

battery

lo

quickly

discharge

.

Make

a

static

current

draw

test

asthe

first

step

when

experiencing

battery

discharge

.

1

.

Make

sure

ignition

and

al¡

electrical

accessories

are

switched

off

.

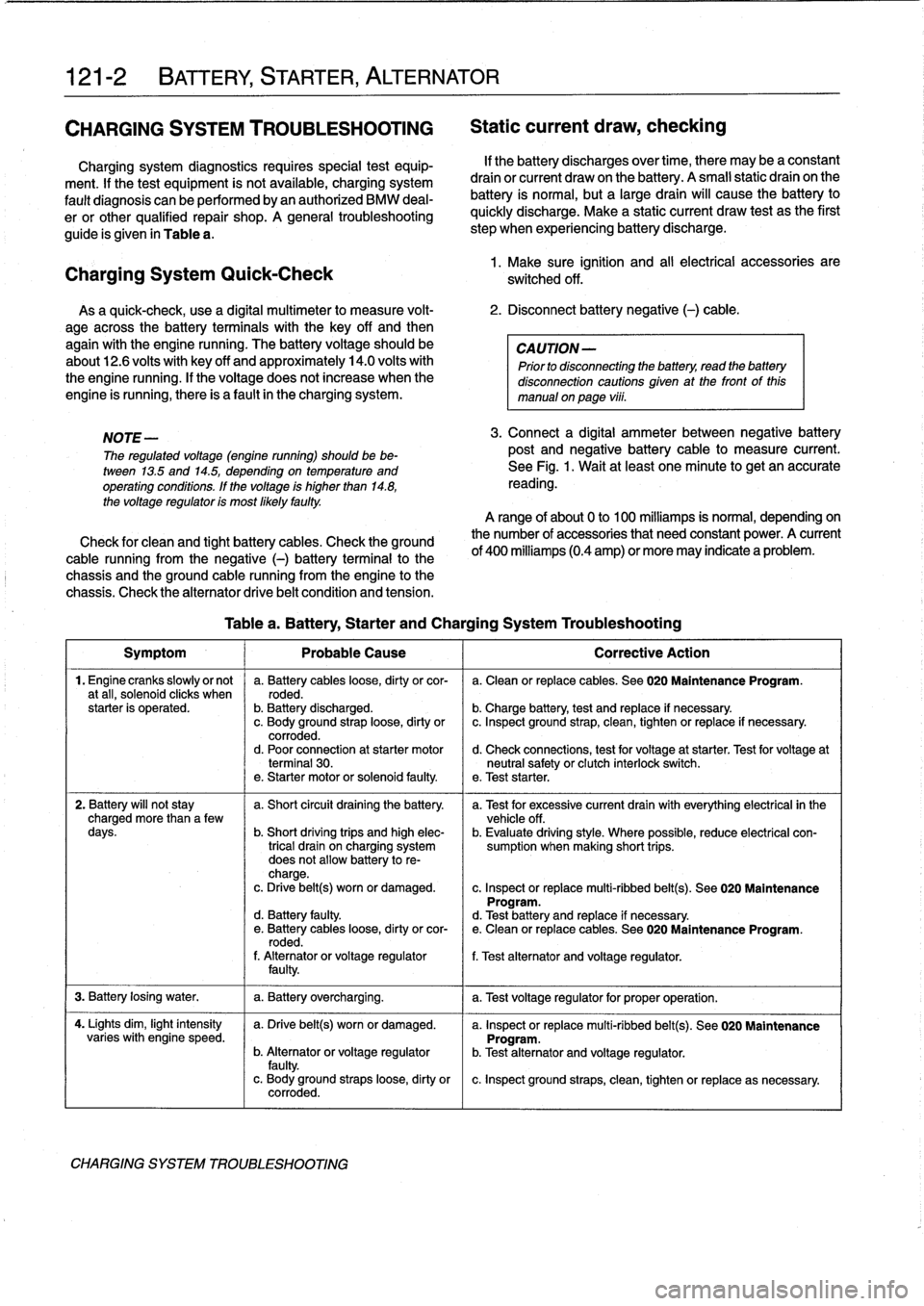

3

.

Connect

a

digital

ammeter

between

negative

battery

post

and

negative

battery

cable

lo

measure

current

.

See

Fig

.

1

.

Wait

at

least

one

minuta

lo

get

an

accurate

reading

.

A

range

of

about

0

lo

100

milliamps

is

normal,

dependingon

the

number

of

accessories

that

need

constant

power

.

A

current

of

400

milliamps

(0.4

amp)

or

more

may

indicate

a

problem

.

Table

a

.

Battery,

Starter

and

Charging

System

Troubleshooting

Symptom

1

Probable

Cause

1

Correctiva

Action

1

.

Engine

cranks

slowlyor

not

a

.

Battery

cables

loose,

dirty

orcor-

a

.

Clean

or

replace

cables

.

See020

Maintenance

Program

.

a

tall,

solenoíd

clicks

when

roded

.

starter

is

operated

.

b

.

Battery

discharged

.

b

.

Charge

battery,

test

and

replace

if

necessary

.

c

.

Body

ground

straploose,

dirty

or

c

.

Inspect

ground

strap,

clean,

tighten

or

replace

if

necessary

.

corroded

.

d

.

Poor

connection

at

starter

motor

d

.

Check

connections,

test

for

voltage

at

starter

.

Test

for

voltage

at

terminal

30

.

neutral

safety

or

clutch

interlock

switch

.

e

.

Starter

motor

or

solenoid

faulty

.

e

.

Test

starter

.

2

.

Battery

will

not

stay

a

.

Short

circuit

draining

the

battery

.

a

.

Test

for

excessive

current

drainwith

everything

electrical

in

the

charged

more

than

a

few

vehicle

off

.

days

.

b

.

Short

driving

trips

and

high

elec-

b

.

Evaluate

driving

style

.

Where

possible,

reduce

electrical

con

trical

drain

on

charging

system

sumption

when

making

short

trips

.

does

not

allow

battery

to

re-

charge

.

c

.

Drive

belt(s)

worn

or

damaged

.

c

.

Inspect

or

replace

multi-ribbed

belt(s)

.

See

020

Maintenance

Program

.

d

.

Battery

faulty

.

d

.

Test

battery

and

replace

íf

necessary

.

e

.

Battery

cables

loose,

dirty

orcor-

e

.

Clean

or

replace

cables

.

See

020

Maintenance

Program

.

rodad

.

f

.

Alternatoror

voltage

regulator

f

.

Test

alternator

and

voltage

regulator

.

faulty

.

3

.

Battery

losing

water

.

1

a

.

Battery

overcharging

.

1

a

.

Test

voltage

regulator

for

proper

operation

.

4

.

Lights

dim,

light

intensity

a

.

Drive

belt(s)

worn

or

damaged

.

a

.

Inspect

or

replace

multi-ribbed

belt(s)

.

See

020

Maintenance

varies

with

engine

speed

.

Program

.

b

.

Alternatoror

voltage

regulator

b

.

Test

alternator

and

voltage

regulator

.

faulty

.

c

.

Body

ground

straps

loose,

dirty

or

c

.

Inspect

ground

straps,

clean,

tighten

or

replace

as

necessary

.

corroded

.

CHARGING

SYSTEM

TROUBLESHOOTING

Page 139 of 759

Fig

.1.

Electrical

system

static

current

draw

being

measured

.

To

determine

the

circuit

or

component

causing

the

problem,

remove

one

Puse

at

a

time

until

the

current

drops

to

a

normal

range

.

BATTERY

SERVICE

The

E36

uses

a

six-cell,

12-volt

leadacid

battery

mounted

in

the

luggage

compartment

.

See

Fig

.

2

.

NOTE-

E36

convertible

models

require

a

specialbattery

which

is

designed

for

constant

vibratfon

.

A

battery

not

de-signed

for

this

will

fail

much

earlier

.

Battery

capacity

is

determined

by

the

amount

of

current

needed

tostart

the

vehicle,

and

by

the

amount

of

current

con-

sumed

by

the

electrical

system

.

BMW

batteries

are

rated

by

ampere/hours

(Ah)

and

cold

cranking

amps

(CCA)

rating

.

The

Ah

rating

is

determined

by

the

average

amount

of

current

the

battery

can

deliver

over

time

without

dropping

below

a

specified

voltage

.

The

CCA

is

determined

by

the

battery's

ability

to

deliver

starting

current

at

0°

F

(-18°

C)

without

dropping

below

a

specified

voltage

.

Battery

Testing

noN~A

B9517

Battery

testing

determines

the

state

of

battery

charge

.

On

conventional

or

low-maintenance

batteries

the

most

common

method

of

testing

the

battery

is

that

of

checking

the

specific

gravity

of

the

electrolyte

using

a

hydrometer

.

Before

testing

the

battery,

check

that

the

cables

are

tight

and

free

of

corro-

sion

.

See

Fig

.

2

.

Hydrometer

Testing

The

hydrometer

consists

of

a

glass

cylinder

with

a

freely

moving

float

inside

.

When

electrolyte

is

drawn

into

the

cylin-

der,

the

levelto

which

the

float

sinks

indicates

the

specific

BATTERY,

STARTER,

ALTERNATOR

121-

3

Fig

.

2

.

Battery

in

right

sideof

luggage

compartment

.

gravity

of

the

electrolyte

.

The

more

dense

the

concentration

of

sulfuric

acid

in

the

electrolyte,

the

less

the

float

will

sink,

result-

ing

in

a

higher

reading

and

indicating

a

higher

state

of

charge)

.

NOTE-

Electrolyte

temperature

affects

hydrometer

reading

.

Check

the

electrolyte

temperaturewith

a

thermometer

.

Add

0

.004

to

the

hydrometer

reading

for

every

10°F

(6°C)

that

the

electrolyte

is

above

80°F

(27°C)

.

Sub-

tract

0

.004

from

the

reading

for

every

10°F

(6°C)

that

the

electrolyte

is

below

80°F

(27°C)

.

Before

checking

the

specificgravity

of

a

battery,

load

the

battery

with

15

amperes

for

one

minute

.

lf

the

battery

is

in-

stalled

in

the

vehicle,

this

can

be

done

by

turning

on

the

head-

lights

without

the

engine

running

.

Table

b

lists

the

percentage

of

charge

based

on

specific

gravity

values

.

Table

b

.

Specific

Gravity

of

Battery

Electrolyteat

80

°

F

(27°C)

Specific

gravity

1

Stateof

charge

1

.265

Fully

charged

1

.225

75%

charged

1

.190

50%

charged

1

.155

25%

charged

1

.120

Fully

discharged

The

battery

isin

satisfactory

condition

if

theaverage

specif-

ic

gravity

of

the

six

cells

is

at

least

1

.225

.

If

the

specific

gravity

is

above

this

leve¡,

butthe

battery

lacks

power

for

starting,

de-

termine

the

battery's

senrice

condition

with

a

load

voltage

test,

as

described

below

.

If

the

average

specific

gravity

of

the

six

cells

is

below

1

.225,

remove

the

battery

from

the

luggage

compartment

and

recharge

.

If,

after

recharging,

the

specific

gravity

varies

by

more

than

0

.005

between

any

two

celis,

re-

place

the

battery

.

CHARGING

SYSTEM

TROUBLESHOOTING

Page 140 of 759

121-

4

BATTERY,

STARTER,

ALTERNATOR

BatteryOpen-Circuit

Voltage

Test

Battery

Charging

Before

making

the

test,

load

the

battery

with

15

amperes

for

Discharged

batteries

can

be

recharged

using

a

battery

one

minute

with

a

batteryload-tester

or

turn

on

the

headlights

charger

.

The

battery

should

be

removed

from

the

luggage

for

about

one

minute

without

the

engine

running

.Then

discon-

compartment

during

charging

.

nect

the

battery

negative

(-)

cable

and

connect

a

digital

volt-

meter

acrossthe

battery

terminals

.

Open-circuit

voltage

Prolonged

charging

causes

electrolyte

evaporation

to

a

lev

levels

are

given

in

Table

c

.

el

that

can

damage

the

battery

.

Itis

bestto

use

a

low-current

charger

(6

amperes

or

less)

to

prevent

battery

damage

If

the

open-circuit

voltage

ís

OK

butthe

battery

still

lacks

caused

by

overheating

.

power

for

starting,

make

a

load

voltage

test

.

If

the

open-circuit

voltage

is

below

12

.4

volts,

recharge

the

battery

and

retest

.

WARNING

-

Hydrogen

gas

given

off

by

the

battery

duringcharg-

Table

c

.

Open-Circuit

Voltage

and

Battery

Charge

ing

is

explosive

.

Do

not

smoke

.

Keep

open

llames

away

from

the

top

of

the

battery,

and

prevent

elec

Open-circuit

voltage

State

of

charge

trical

sparks

by

turning

offthe

battery

charger

be-

12

.6

V

or

more

Fully

charged

fore

connecting

or

disconnecting

it

.

12

.4

V

1

75%

charged

12

.2

V

50%

charged

CAUTION-

12

.0

V

25%

charged

"

Battery

electrolyte

(sulfuric

acid)

can

damage

the

car

.

If

electrolyte

isspilled,

clean

the

area

11

.7

V

or

less

Fully

discharged

with

a

solution

of

baking

soda

and

water

.

Battery

Load

Voltage

Test

A

battery

load

tester

is

required

for

a

load

voltage

test

.

The

-

Always

disconnect

both

battery

cables

and

re-

test

is

made

by

applying

a

high

resistive

load

to

the

battery

ter-

move

battery

from

vehicle

during

battery

charg-

ing

.

Do

not

exceed

16

.5volts

at

the

battery

.

minals

and

then

measuring

battery

voltage

.

The

battery

should

be

fully

charged

for

the

most

accurate

results

.

The

battery

ca-

bles

mustbe

disconnected

before

making

the

test

.

If

the

volt-

ALTERNATOR

$ERVICE

age

is

below

that

listed

in

Table

d,

the

battery

should

be

replaced

.

WARNING

-

Always

wear

protective

goggles

and

clothing

when

performing

aload

test

.

Table

d

.

Battery

Load

Test-Minimum

Voltage

(apply

200

amp

load

for

15

seconds)

Ambient

temperature

Voltage

80°F

(27°C)

9

.6

V

60°F

(16°C)

9

.5

V

40°F

(4°C)

9

.3

V

20°F

(-7°C)

8

.9

V

0°F

(-18°C)

8

.5

V

ALTERNATOR

SERVICE

"

Always

allow

a

frozen

battery

to

thaw

before

at-

tempting

to

recharge

it

.

Before

checking

the

alternator

and

regulator,

make

sure

the

battery

is

fully

charged

and

capable

of

holding

acharge

.

Check

that

the

battery

terminals

are

clean

and

tight

and

the

al-

ternator

drive

belt

is

properly

tensioned

and

not

severely

worn

.

Charging

system,

checking

CAUTION-

Do

not

disconnect

the

battery

while

the

engine

is

running,

.

Damage

to

the

alternator

andlorengine

electronic

systems

may

result

.

1.

Turn

ignition

key

on

.

Check

that

the

chargewarning

lamp

comes

on

.

NOTE-

If

the

warning

light

does

not

come

on,

repair

any

wiring

or

bulb

faults

before

continuing

to

check

the

charging

system

.

Page 141 of 759

2

.

Remove

cooling

duct

or

terminal

cover

from

rear

of

al-

2

.

Remove

air

cleaner

upper

section

with

mass

air

flow

ternator

.

sensor

.

3

.

Check

for

battery

voltage

between

ground

and

terminal

3

.

Remove

terminal

cover

from

rear

of

alternator

.

Discon

B+

at

back

of

alternator

.

Then

turn

ignition

on

and

nect

wiring

.

check

for

battery

voltage

between

terminal

D+

and

ground

.

See

Fig

.

3

.

lf

voltage

is

not

present

at

either

4

.

Remove

drive

belt

from

alternator

pulley

.

See

020

point,

check

wiring

for

faults

.

Maintenance

program

.

001

¡987

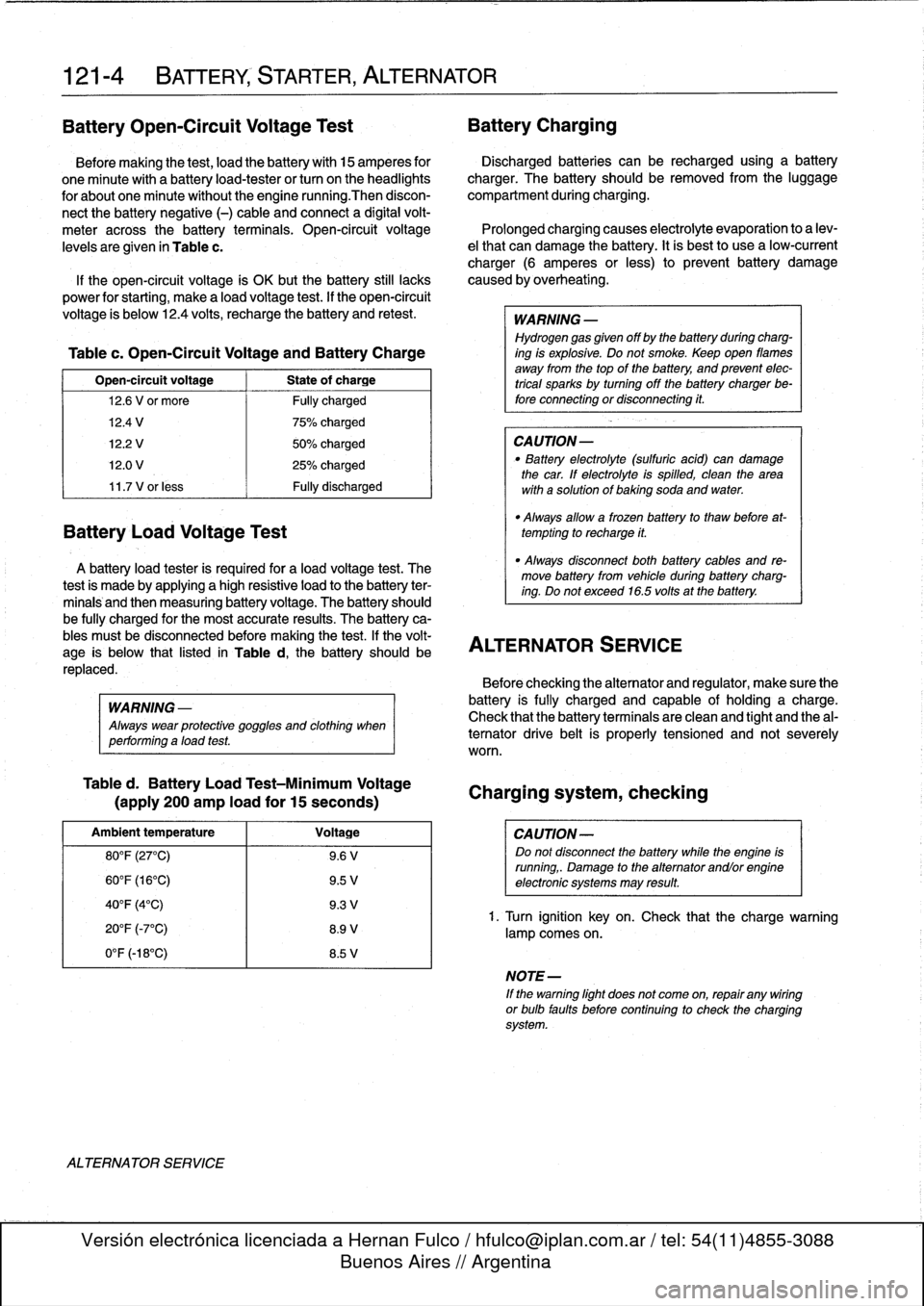

Fig

.

3

.

Terminal

B+

is

supplied

battery

voltage

directly

from

the

bat-

tery

.

Terminal

D+

is

supplied

battery

voltage

via

the

charge

warning

bulb

when

thekey

is

on

or

the

engine

is

running

.

4

.

lf

no

faults

are

foundup

to

thispoint,test

alternator

out-

put

using

a

load

tester

.

5

.

If

a

load

tester

is

not

available,

a

crude

output

test

can

be

done

by

running

engine

at

about

2000

rpmand

turn-

ing

on

electrical

loads

(fans,

lights

and

rear

window

de-

froster,

wipers)

.

With

al¡

accessories

on,

battery

voltage

should

be

above

12

.0

VDC

.

A

replacement

alternator

should

have

the

same

rating

as

the

original

.

Alternator

manufacturer

and

ampere

rating

are

normally

marked

on

the

alternator

housing

.

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

BATTERY,

STARTER,

ALTERNATOR

121-

5

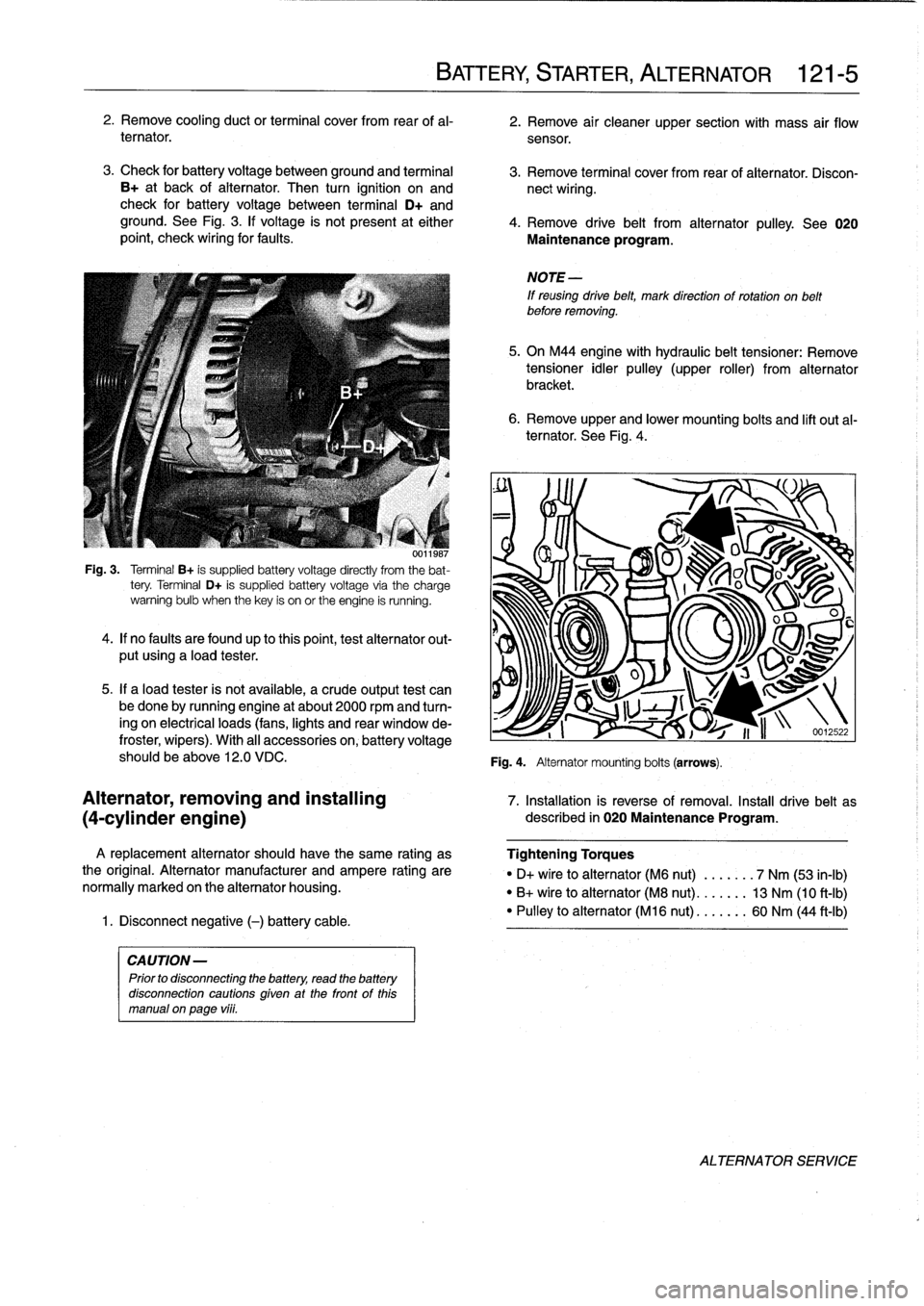

6

.

Remove

upper

and

lower

mounting

bolts

and

lift

out

al-

ternator

.

See

Fig

.

4

.

NOTE

-

If

reusing

drive

belt,

mark

direction

of

rotation

on

belt

before

removing

.

5

.

On

M44

engine

with

hydraulic

belt

tensioner

:

Remove

tensioner

idler

pulley

(upper

roller)

from

alternator

bracket

.

Fig

.

4

.

Alternator

mounting

bolts

(arrows)

.

O

u

J

S

v~~

U

I

1

i

n

-12

.22

Alternator,

removing

and

installing

7

.

Installation

is

reverse

of

removal

.

Install

drive

belt

as

(4-cylinder

engine)

described

in

020

Maintenance

Program

.

Tightening

Torques

"

D+

vire

to

alternator

(M6

nut)

.

...

.

.

.

7

Nm

(53

in-lb)

"

B+

wire

to

alternator

(M8

nut)

..

.

.

.

.

.

13

Nm

(10

ft-Ib)

"

Pulley

to

alternator

(M16

nut)

...

..

..

60

Nm

(44

ft-Ib)

ALTERNATOR

SERVICE

Page 152 of 759

130-

6

FUEL

INJECTION

Warnings

and

Cautions

For

personal

safety,

as

well

as

the

protection

of

sensitive

electronic

components,

the

following

warnings

and

cautions

should

be

adhered

to

when

working

on

the

engine

manage-

ment

system

.

GENERAL

WARNING

-

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

termi-

nals

.

Use

extreme

caution

when

working

onacar

with

the

ignition

switched

on

or

the

engine

run-

ning

.

"

Do

not

touch

or

disconnect

any

high

voltage

ca-

bles

from

the

coils

or

spark

plugs

while

the

engine

is

running

or

beingcranked

by

the

starter

.

"

Connect

and

disconnect

the

DME

system

wiring

and

test

equipment

leads

only

when

the

ignition

is

switched

off

.

"

Gasoline

is

highly

flammable

and

fts

vaporsare

explosive

.

Do

not

smoke

or

work

on

a

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repalring

fuel

system

problems

.

Have

a

tire

extinguisher

avaílable

in

case

of

an

emergency

.

"

When

working

onan

open

fuel

system,

wear

suit-

able

hand

protection,

asprolonged

contact

wfth

fuel

can

cause

illnesses

and

skin

disorders

.

"

Renew

fuel

system

hoses,

clamps

and

O-rings

any

timethey

are

removed

.

"

Before

makingany

electrical

tests

that

require

the

engine

to

be

cranked

using

the

starter,

disable

the

ignition

system

as

described

in

120

Ignition

System

.

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnectinn

cautions

given

at

the

front

of

this

manual

onpage

vifi

.

"

Do

not

connect

any

test

equipment

that

delivers

a

12-volt

power

supply

to

terminal

15

(+)

of

the

ig-

nitioncoil

.

The

current

flow

may

damage

the

ECM

.

In

general,

connect

test

equipment

only

as

speclfied

by

BMW,

this

manual,

or

the

equipment

maker

.

"

Only

use

a

digital

multlmeter

for

electrical

test

.

"

Only

use

an

LED

test

light

for

quick

tests

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

memory

.

Check

for

fault

codes

prior

to

disconnecting

the

battery

cables

.

ff

the

Check

Engine

light

ís

illuminated,

see100En-

gine-General

for

DME

fault

code

information

.

ff

any

other

system

faults

have

been

detected

(indi-

catedbyan

illuminated

warning

light),

see

an

au-

thorized

BMW

dealer

.

Additional

systems

with

self-diagnostic

capabilities

include,

ABS

(Anti-

lock

brakes),

SRS

(Airbags),

EML

and

ASC+T

and

AST

(Traction

Control)

.

"

Do

not

run

the

engine

wfth

any

of

the

spark

plug

wires

dlsconnected

.

Catalytic

converter

damage

may

result

.

"

Always

waitat

least

40

seconds

afterturning

off

the

ignition

before

removing

the

engine

control

module

(ECM)

connector

.

ff

the

connector

isre-

moved

before

this

time,

residual

power

in

the

sys-

tem

relay

may

damage

the

control

module

.

"

Cleanliness

is

essential

when

working

onan

open

fuel

system

.

Thoroughly

clean

fuel

line

con-

nections

and

surroundlng

areas

before

loosen-

ing

.

Avoid

moving

the

car

.

Only

fnstall

cleanparts

.

"

Fuel

system

cleaners

and

other

chemical

addi-

tives

other

than

those

specifically

recommended

by

BMW

may

damage

the

catalytic

converter,

the

oxygensensor

or

other

fuel

supply

components

.

Page 157 of 759

3

.

Observe

fuel

pressure

gauge

after

20

minutes

.

The

pressure

shouldnot

drop

off

more

than

0

.5

bar

from

system

pressure

listed

in

Tablec

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuel

line

.

If

the

fuel

system

does

not

maintain

pressure,

check

visual-

¡y

for

leaks

in

fuel

lines

orat

unions

.

Leaks

can

also

be

due

to

a

leaking

injector

or

a

faulty

fuel

pump

check

valve

.

Check

the

pump

check

valve

by

repeating

the

test,

butbefore

turning

the

fuel

pump

off,

pinch

off

theretum

line

at

the

fuel

rail

.

If

the

pressure

is

now

maintained,

the

fault

is

most

likely

the

fuel

pump

check

valva

.

Tabla

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cytinder

1

3

.0

t

0

.2

bar

(43

.5

t

2

.9psi)

6-cytinder

M50/S50US

engine

3

.0

t

0

.2

bar

(43

.5

±2

.9psi)

M52/S52US

engine

3

.5

f

0

.2

bar

(51

t

2.9psi)

Fuel

pressure

regulator

response

to

engine

load,

testing

1

.

With

fuel

pressure

gauge

connected,

reinstallfuel

pump

relay

.

Start

engine

and

allow

it

to

idle

.

NOTE-

The

fuel

pressure

should

be

lower

by0

.4-0.7

bar

from

the

specifications

listed

in

Table

c

.

Engine

vacuum

act-

ing

on

the

fuel

pressure

regulator

diaphragm

reduces

the

fuel

pressure

.

2

.

With

engine

idling,

remove

vacuum

hose

from

regula-

tor

.

Pressure

should

increase

.

3

.

Reconnecthose

and

check

that

pressure

decreases

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuelline

.

Tighten

hose

clamp

.

0013190

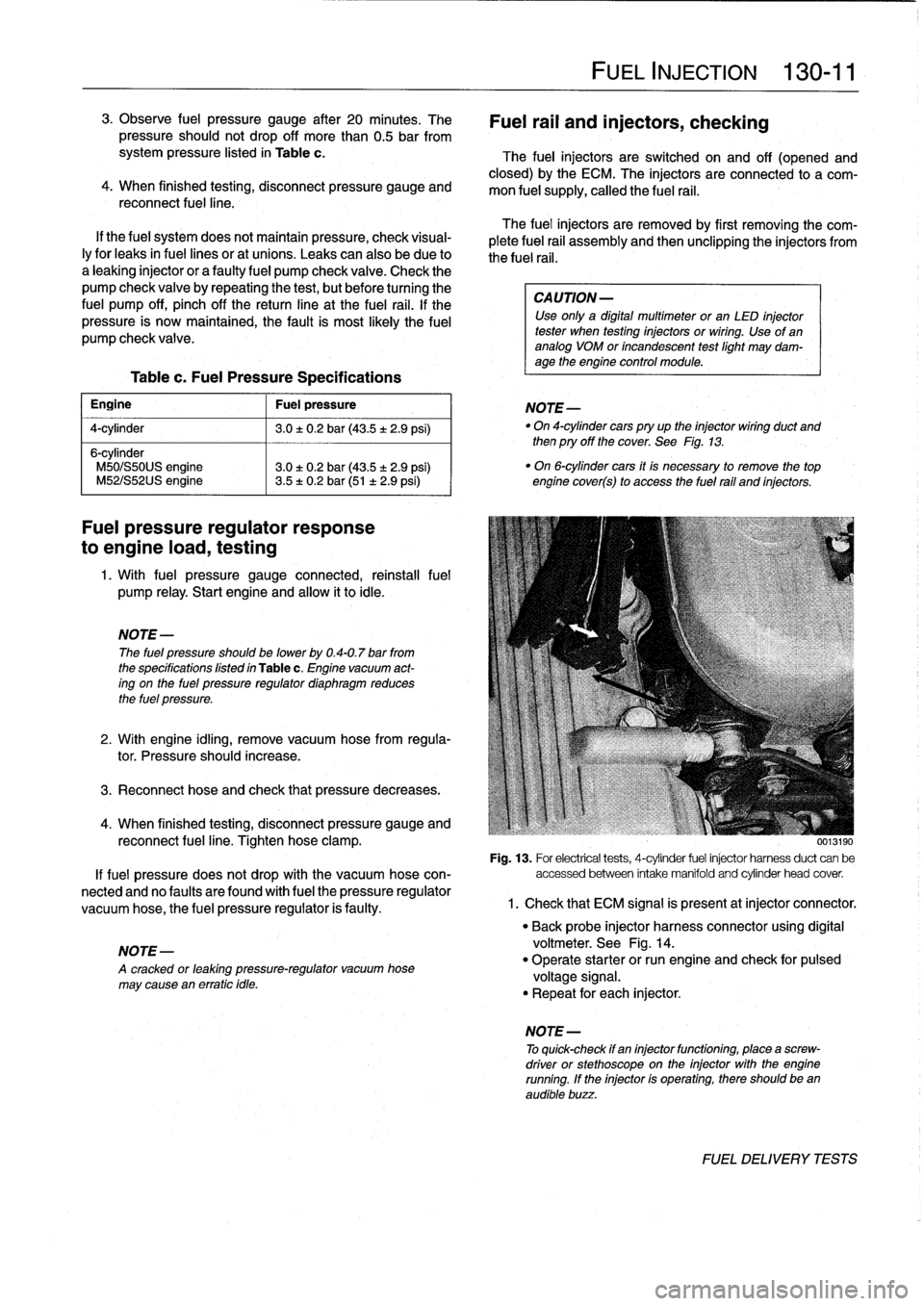

Fig

.

13

.

For

electrical

tests,

4-cytinder

fuel

injector

harnessduct

can

be

If

fuel

pressure

does

not

drop

with

the

vacuum

hose

con-

accessed

between

intake

manifold

and

cytinder

head

cover

.

nected

and

no

faulty

are

found

with

fuel

the

pressure

regulator

vacuum

hose,

the

fuel

pressure

regulator

is

faulty

.

1

.

Check

that

ECM

signal

is

present

atinjector

connector

.

NOTE-

A

cracked

or

leaktng

pressure-regulator

vacuum

hose

may

cause

en

erratic

tdle

.

FUEL

INJECTION

130-

11

Fuel

rail

and

injectors,

checking

The

fuel

injectors

are

switched

on

and

off

(opened

and

closed)

by

the

ECM

.

The

injectors

are

connected

to

a

com-

mon

fuel

supply,

callad

the

fuel

rail

.

The

fuel

injectors

are

removed

by

first

removing

the

com-

plete

fuel

rail

assembly

and

then

unclipping

the

injectors

from

the

fuel

rail

.

CA

UTION-

Use

only

a

digital

multimeter

or

an

LED

injector

tester

when

testing

injectors

or

wiring

.

Use

of

ananalog

VOM

or

incandescent

testlight

may

dam-

age

the

engine

control

module

.

NOTE-

"

On

4-cytindercars

pry

up

the

injector

wiring

duct

and

then

pry

off

the

cover

.

See

Fig

.

13

.

"

On

6-cytinder

cars

it

is

necessary

to

remove

the

top

engine

cover(s)

to

access

the

fuel

rail

and

injectors

.

"

Back

probe

injector

harness

connector

using

digital

voltmeter

.

See

Fig

.

14

.

"

Operate

starter

or

run

engine

and

check

for

pulsad

voltage

signal

.

"

Repeat

for

each

injector

.

NOTE

-

To

quick-check

if

en

injectorfunctioning,

place

a

screw-

driver

or

stethoscope

on

the

injector

with

the

engine

running

.

If

the

injector

is

operating,there

should

been

audible

buzz

.

FUEL

DELIVERYTESTS

Page 162 of 759

130-

1

6

FUEL

INJECTION

Throttie

position

sensor

(TPS),

Idie

speed

control

valve,

testing

and

replacing

testing

and

replacing

The

throttie

position

sensor

(TPS)

is

mounted

on

the

side

of

¡die

speed

is

maintained

by

the

ECM

via

the

¡die

speed

con-

the

throttie

housing

and

is

directly

connected

to

the

throttie

trol

valve

.

See

Fig

.

24

.

¡die

speed

is

adaptive

through

the

valve

shaft

.

The

ECM

sends

a

voltage

signal

to

the

potentiom-

ECM

and

no

¡die

speed

adjustments

can

be

made

.

Before

eter-type

sensor

and

monitors

the

voltage

that

comes

back

.

testing

the

valve,

confirm

that

the

throttie

position

sensor(TPS)

is

working

correctly

.

Check

TPS

function

by

disconnecting

the

harnessconnec-

tor

and

checking

reference

voltage

and

sensor

resistance

.

See

Table

e

and

Fig

.

23

.

If

voltage

is

not

present,

check

the

output

voltage

signal

from

the

ECM

and

check

the

wiring

be-

tween

the

sensor

and

the

ECM

.

If

the

sensor

resistance

is

in-

correct,

replace

the

throttie

position

sensor

.

NOTE

-

The

throttie

position

sensor

is

not

adjustable

.

If

test

re-

sults

are

íncorrect,

the

sensor

should

be

replaced

.

Table

e

.

Throttle

Position

Sensor

Tests

(DME

1

.7)

Testconditions

1

Terminais

1

Test

value

Harness

connec-

(

1

and

ground

in

15

VDC

(approx

.)

tor

disconnected,

harness

connector

ignition

on

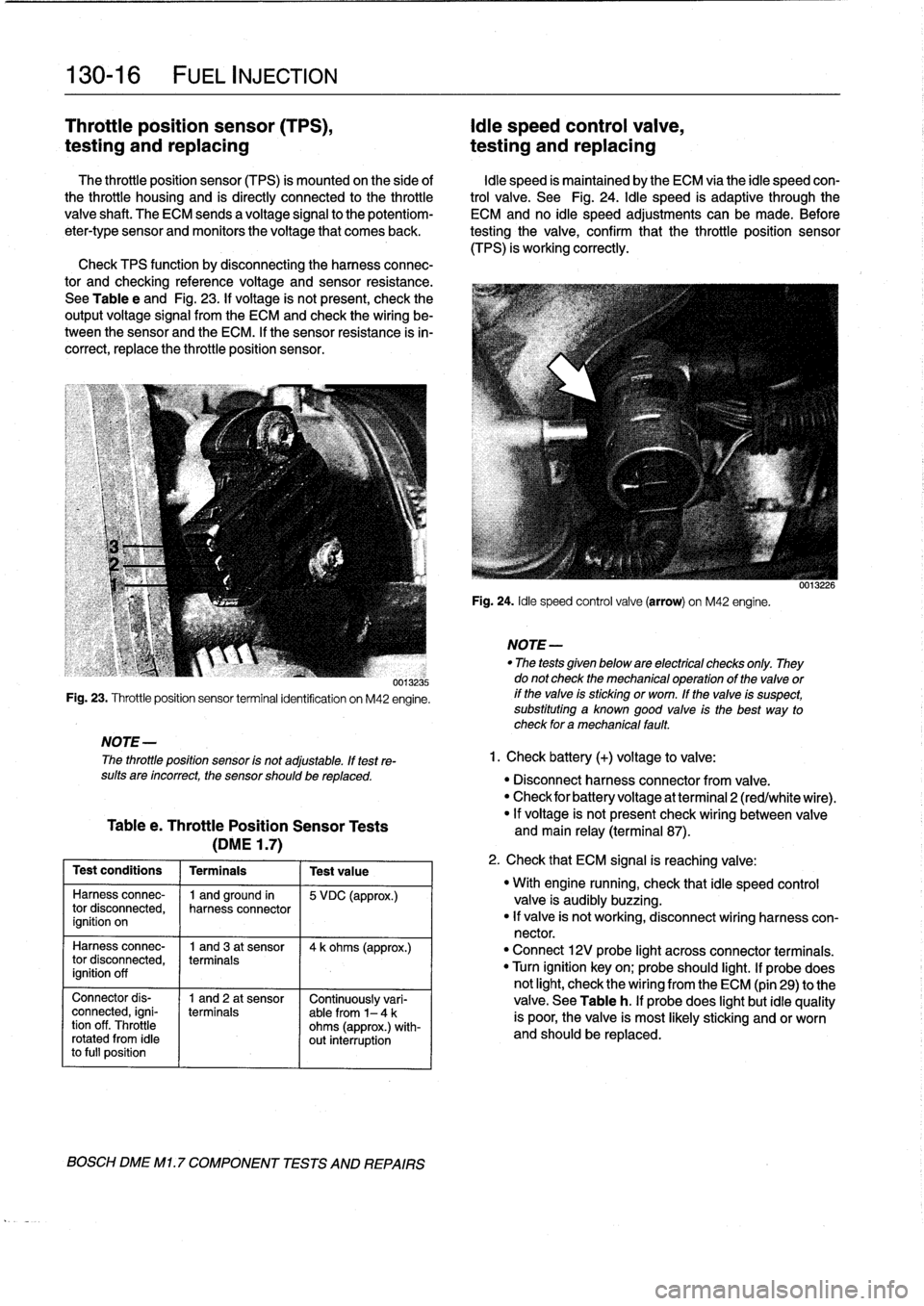

0013235

Fig

.

23

.

Throttieposition

sensor

terminal

identification

on

M42

engine

.

Harnessconnec-

I

1

and

3

at

sensor

(

4k

ohms

(approx

.)

tor

disconnected,

terminais

ignition

off

Connector

dis-

1

and

2

at

sensor

Continuously

vari-

connected,

igni-

terminais

able

from

1-4

k

tion

off

.

Throttle

ohms

(approx

.)

with

rotated

from

¡die

out

interruption

to

fui]

position

BOSCH

DME

Ml

.

7

COMPONENT

TESTS

AND

REPAIRS

Fig

.

24

.

¡die

speed

control

valve

(arrow)

on

M42

engine

.

NOTE

-

"

The

tests

given

below

are

electrical

checks

only

.

They

do

not

check

the

mechanical

operation

of

the

valve

or

if

the

valve

is

sticking

or

worn

.

If

the

valve

is

suspect,

substituting

a

known

good

valve

is

the

best

way

to

check

for

amechanical

fault

.

1

.

Check

battery

(+)

voltage

to

valve

:

0013226

"

Disconnect

harness

connector

from

valve

.

"

Check

for

battery

voltage

at

terminal

2

(red/white

wire)

.

"

If

voltage

is

not

present

check

wiring

between

valve

and

main

relay

(terminal

87)

.

2

.

Check

that

ECM

signal

is

reaching

valve

:

"

With

engine

running,

check

that

¡die

speed

control

valve

is

audibly

buzzing

.

"

If

valve

is

not

working,

disconnect

wiring

harness

con-

nector

.

"

Connect

12V

probe

light

across

connector

terminais

.

"

Turn

ignition

key

on

;

probe

should

light

.

lf

probe

does

nof

light,

check

the

wiring

from

the

ECM

(pin

29)

to

the

valve

.

See

Table

h

.

lf

probe

does

light

but

¡die

quality

is

poor,

the

valve

is

most

likely

sticking

and

or

worn

and

should

be

replaced

.

Page 163 of 759

BOSCH

DME

MM

AND

M33

.1

COMPONENT

TESTS

AND

REPAIRS

Consult

Table

a

for

engine

application

information

for

the

Bosch

DME

3

.1

and

3

.3.1

systems

.

The

DME

3

.1

and

DME

3

.3

.1

systems

are

similar

in

opera-

tion,

with

knock

control

and

VANOS

operation

being

the

key

differences

.

DME

3

.1

engines

arenot

equipped

with

VANOS

or

knock

detectors,

while

the

DM

E3

.3

.1

system

is

.

CA

UTION-

Use

onty

a

digital

multimeter

when

testing

wiring

.

Use

of

an

analog

VOM

may

damage

the

engine

control

module

.

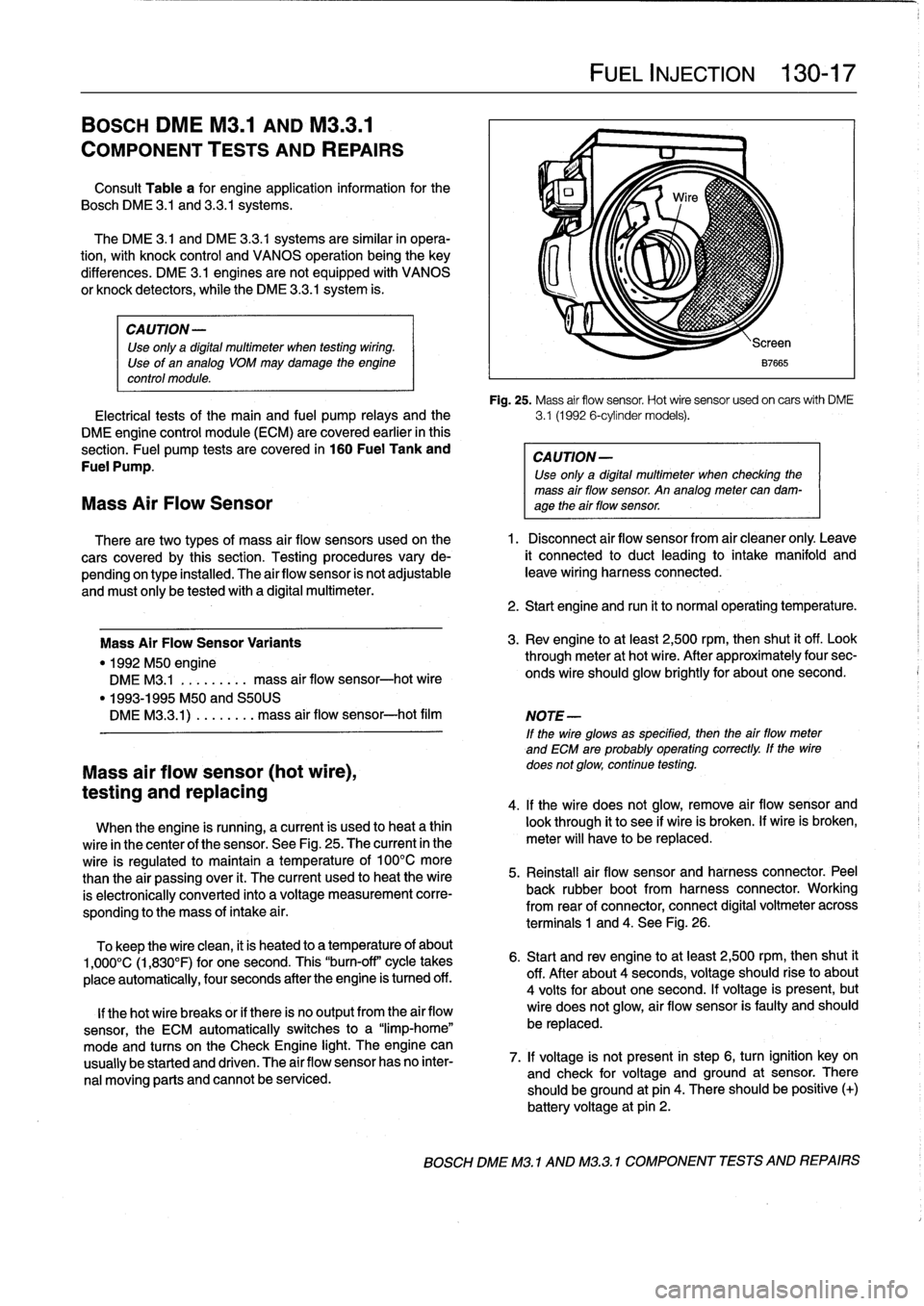

Fig

.

25

.

Mass

air

flow

sensor

.

Hot

wire

sensor

usedon

carswith

DME

Electrical

tests

of

the

main

and

fuel

pump

relays

and

the

3

.1

(1992

6-cylinder

models)

.

DME

engine

control

module

(ECM)

are

covered

earlier

in

this

section

.

Fuel

pump

tests

are

covered

in

160

Fuel

Tank

and

CAUTION-

Fuel

Pump

.

Use

only

a

digital

multimeter

when

checking

the

mass

air

flow

sensor

.

An

analog

meter

can

dam-

Mass

Air

Flow

Sensor

age

theair

flow

sensor

.

There

are

two

types

of

mass

air

flow

sensors

used

onthe

1

.

Disconnect

air

flow

sensor

from

air

cleaner

only

.

Leave

cars

covered

by

this

section

.

Testing

procedures

vary

de-

it

connected

to

duct

leading

to

intake

manifold

and

pending

on

type

installed

.

The

airflow

sensor

is

not

adjustable

leave

wiring

harness

connected

.

and

must

only

be

tested

with

a

digital

multimeter

.

Mass

Air

FlowSensor

Variants

"

1992

M50

engine

DME

M3

.1

.

.

.

.

...

..

mass

air

flow

sensor-hot

wire

"

1993-1995

M50

and

S50US

DMEM33

.1)

.

...

...

.

mass

air

flow

sensor-hot

film

Mass

air

flow

sensor

(hot

wire),

testing

and

replacing

When

the

engine

is

running,

a

current

is

used

to

heat

a

thin

wire

in

the

center

of

the

sensor

.

See

Fig

.

25

.

The

current

in

the

wire

is

regulated

to

maintain

a

temperature

of

100°C

more

than

the

air

passing

over

it

.

The

current

used

to

heat

the

wire

is

electronically

conneced

into

a

voltage

measurement

corre-

sponding

to

the

mass

of

intake

a¡

r

.

To

keep

the

wire

clean,

it

is

heated

to

a

temperature

of

about

1,000°C

(1,830°F)

for

one

second

.

This

"burn-off"

cycle

takes

place

automatically,

four

seconds

after

the

engine

is

tumed

off

.

lf

thehot

wire

breaks

or

if

there

is

no

output

from

the

air

flow

sensor,

the

ECM

automatically

switches

to

a

"limp-home"

mode

and

tucos

on

the

Check

Engine

light

.

The

engine

can

usually

be

started

and

driven

.

The

air

flow

sensor

has

no

inter-

nal

moving

parts

and

cannot

be

serviced

.

FUEL

INJECTION

130-

1

7

2

.

Start

engine

and

run

it

to

normal

operating

temperature

.

3

.

Rev

engine

toat

least

2,500

rpm,then

shut

it

off

.

Look

through

meter

at

hot

wire

.

After

approximately

four

sec-

onds

wire

should

glow

brightly

for

about

one

second

.

NOTE

-

If

the

wire

glowsas

specified,

then

the

airflow

meter

and

ECM

are

probably

operating

correctly

.

lf

the

wire

does

not

glow,

continue

testing

.

4

.

lf

the

wire

does

not

glow,

remove

air

flow

sensor

and

look

through

it

to

see

if

wire

is

broken

.

lf

wire

is

broken,

meter

will

have

to

be

replaced

.

5

.

Reinstall

air

flow

sensor

and

harness

connector

.

Peel

back

rubber

bootfrom

harness

connector

.

Working

from

rear

of

connector,

connect

digital

voltmeter

across

terminals

1

and

4

.

See

Fig

.

26

.

6

.

Start

and

rev

engine

toat

least

2,500

rpm,thenshut

it

off

.

After

about

4

seconds,

voltage

should

riseto

about

4

volts

for

about

one

second

.

lf

voltage

is

present,

but

wire

does

not

glow,

air

flow

sensor

is

faulty

and

should

be

replaced

.

7

.

lf

voltage

is

not

present

in

step

6,

turn

ignition

key

on

and

check

for

voltage

and

ground

at

sensor

.

There

should

beground

at

pin

4

.

There

should

be

positive

(+)

battery

voltage

at

pin

2

.

BOSCH

DME

M3

.1

AND

M32

.1

COMPONENT

TESTS

AND

REPAIRS

Page 164 of 759

130-18

FUEL

INJECTION

The

engine

coolant

temperature

(ECT)

sensor

sends

con-

tinuous

engine

coolant

temperature

information

to

the

ECM

.

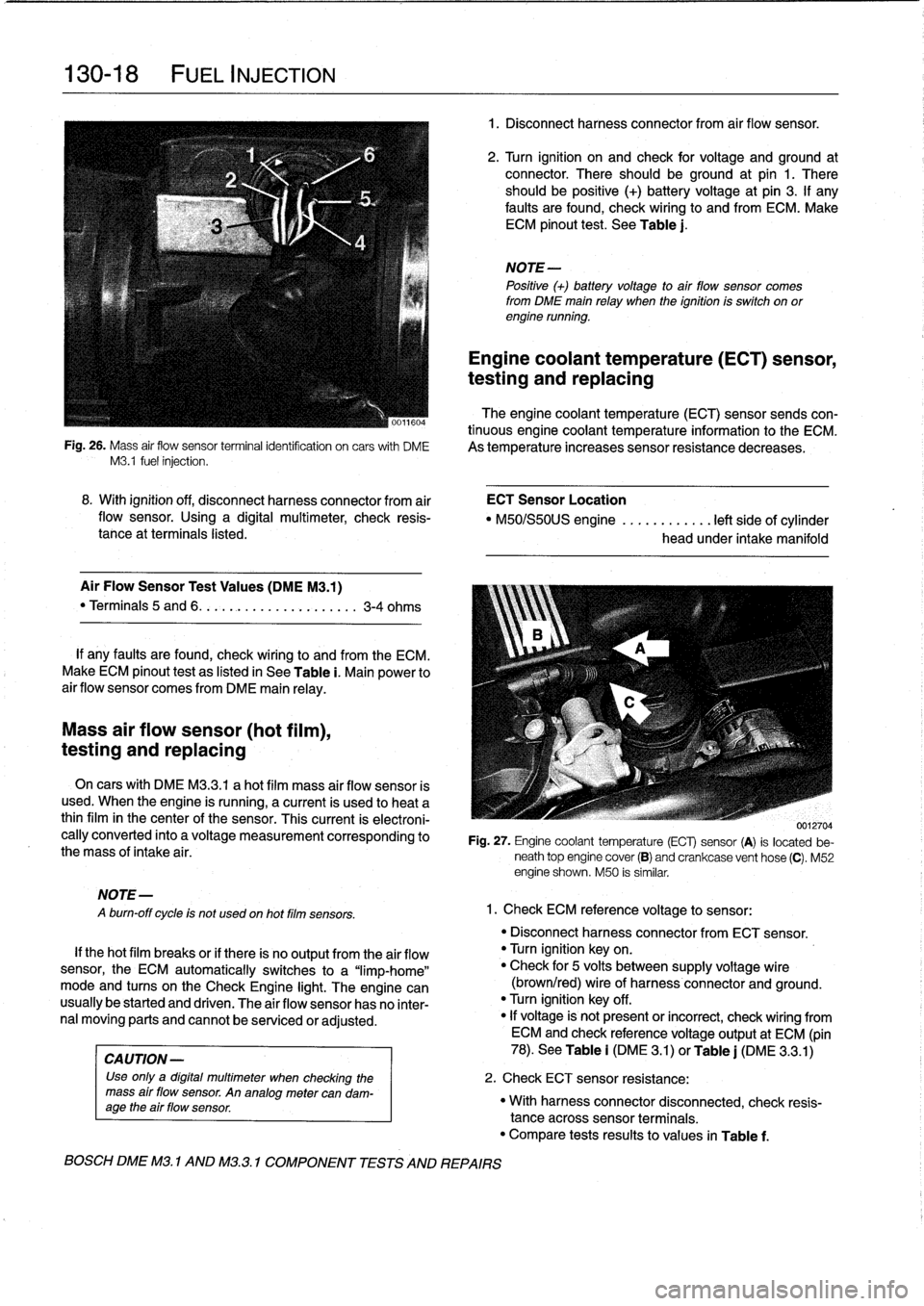

Fig

.

26

.

Mass

air

flow

sensor

terminalidentifcation

on

carswith

DME

As

temperature

increases

sensor

resistance

decreases

.

M3

.1

fuel

injection

.

Mass

air

flow

sensor

(hot

film),

testing

and

replacing

MOTE-

A

burn-off

cycle

is

not

used

on

hot

film

sensors

.

8

.

With

ignition

off,

disconnect

harness

connector

from

air

ECT

Sensor

Location

flow

sensor

.

Using

a

digital

multimeter,

check

resis-

"

M50/S50US

engine

............

left

side

of

cylinder

tance

at

terminals

listed

.

head

under

intake

manifold

Air

Flow

Sensor

Test

Values

(DMEM3

.1)

"

Terminals

5

and

6

.

.

.

.........

..

.

..

....

3-4

ohms

If

any

faults

are

found,

check

wiring

lo

and

from

the

ECM

.

Make

ECM

pinout

test

as

listed

in

See

Table

i

.

Main

power

to

air

flow

sensor

comes

from

DME

main

relay

.

On

cars

with

DME

M3

.3

.1

a

hot

film

mass

air

flow

sensor

is

used

.

When

the

engine

is

running,

a

current

is

used

lo

heat

a

thinfilm

in

the

center

of

the

sensor

.

This

current

is

electroni-

cally

converted

into

a

voltage

measurement

corresponding

to

the

mass

of

intake

air

.

If

thehot

film

breaks

or

if

there

is

no

output

from

the

air

flow

sensor,

the

ECM

automatically

switches

to

a

"limp-home"

mode

and

tucos

on

the

Check

Engine

light

.

The

engine

can

usually

be

started

and

driven

.

The

air

flow

sensor

has

no

inter-

nal

moving

parts

and

cannot

be

senricedor

adjusted

.

CA

UTION-

Use

only

a

digital

multimeter

when

checking

the

mass

air

flow

sensor

.

An

analogmetercan

dam-

age

the

air

flow

sensor

.

BOSCH

DME

M3

.

1

AND

M32

.1

COMPONENT

TESTS

AND

REPAIRS

1

.

Disconnect

harnessconnector

from

air

flow

sensor

.

2

.

Turn

ignition

on

and

check

for

voltage

and

ground

at

connector

.

There

should

beground

at

pin

1

.

There

should

be

positive

(+)

battery

voltage

at

pin

3

.

If

any

faults

are

found,

check

wiring

to

and

from

ECM

.

Make

ECM

pinout

test

.

See

Table

j

.

NOTE-

Positive

(+)

battery

voltage

to

air

flow

sensor

comes

from

DME

main

relay

when

the

ignition

is

switch

on

orengine

running

.

Engine

coolant

temperature

(ECT)

sensor,

testing

and

replacing

0012704

Fig

.

27

.

Engine

coolant

temperature

(ECT)

sensor

(A)

is

located

be-

neath

top

engine

cover

(B)

and

crankcase

vent

hose

(C)

.

M52

engine

shown

.

M50

is

similar

.

1

.

Check

ECM

reference

voltage

to

sensor

:

"

Disconnect

harnessconnector

from

ECT

sensor

.

"

Turn

ignition

keyon

.

"

Check

for

5

volts

between

supply

voltage

wire

(brown/red)

wire

of

harness

connector

and

ground

.

"

Turn

ignition

key

off

.

"

If

voltage

is'

not

present

or

incorrect,

check

wiring

from

ECM

and

check

referencevoltage

output

at

ECM

(pin

78)

.

See

Table

i

(DM

E

3

.1)

or

Table

j

(DME

3

.3

.1)

2

.

Check

ECT

sensor

resistance

:

"

With

harnessconnector

disconnected,

check

resis-

tance

acrosssensor

terminals

.

"

Compare

tests

results

to

values

in

Table

f

.

Page 166 of 759

130-20

FUEL

INJECTION

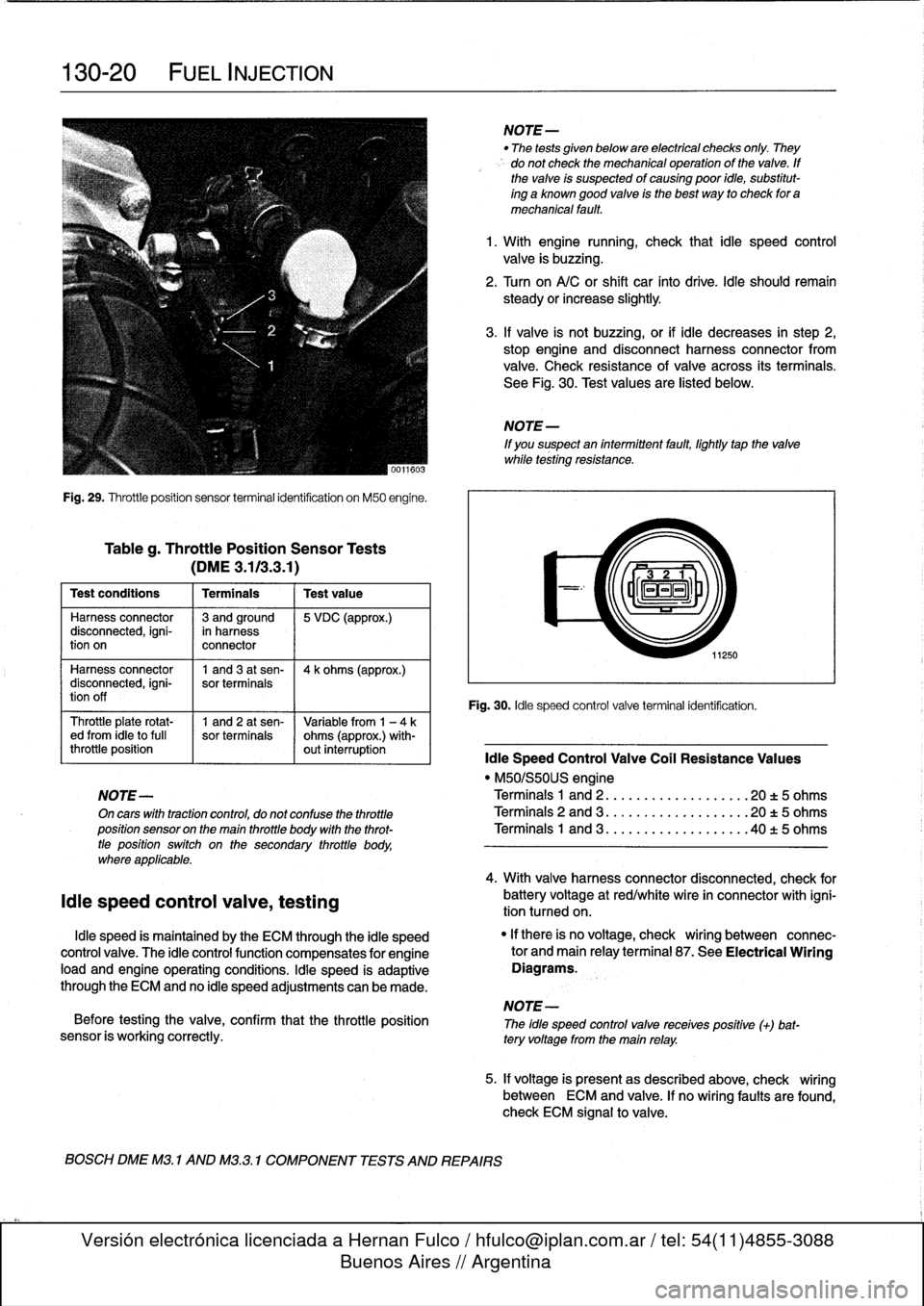

Fig

.

29

.

Throttleposition

sensor

terminal

identification

on

M50

engine

.

Tableg

.

Throttle

Position

Sensor

Tests

(DME3

.113

.3

.1)

Test

conditions

I

Terminals

I

Testvalue

Harness

connector

13

andground

15

VDC

(approx

.)

disconnected,

igni-

in

harness

tion

on

connector

Harness

connector

1

and3

at

sen-

14

k

ohms

(approx

.)

disconnected,

igni-

sor

terminals

tion

off

Throttle

plate

rotat-

1

and

2

at

sen-

Variable

from

1

-

4ked

from

¡dieto

full

sor

terminals

ohms

(approx

.)

with-

throttle

position

out

interruption

¡die

Speed

Control

Valve

Coil

Resistance

Values

"

M50/S50US

engine

NOTE-

Terminals

1

and

2

..

.

................

20

t

5

ohms

On

cars

with

tractioncontrol,

do

not

confuse

the

throttle

Terminals

2

and

3

...................

20

t5

ohms

position

sensor

on

the

main

throttle

body

with

the

throt-

Terminals

1

and

3

..

.

..

:

............

.40

t

5

ohms

tle

positionswitch

on

the

secondary

throttle

body,

where

applicable

.

¡die

speed

control

valve,

testing

¡die

speed

is

maintained

by

the

ECM

through

the

¡die

speed

control

valve

.

The

¡die

controlfunction

compensates

for

engine

load

and

engine

operating

conditions

.

¡die

speed

is

adaptive

through

the

ECM

and

no

¡die

speed

adjustments

can

be

made

.

NOTE-

Before

testing

the

valve,

confirm

that

the

throttle

position

The

idle

speed

controlvalve

receives

positive

(+)

bat-

sensor

is

working

correctly

.

tery

voltage

from

the

main

relay

.

BOSCH

DME

M3

.

1

AND

M3

.3

.1

COMPONENT

TESTS

AND

REPAIRS

NOTE-

"

The

tests

given

below

are

electrical

checks

only

.

They

do

not

check

the

mechanical

operation

of

the

valve

.

If

the

valve

is

suspected

of

causing

poor

idie,

substitut-

ing

a

known

good

valve

is

the

best

way

to

check

for

a

mechanical

fault

.

1

.

With

engine

running,

check

that

¡die

speed

control

valve

is

buzzing

.

2

.

Turn

on

A/C

or

shift

car

finto

drive

.

¡die

should

remain

steady

orincrease

slightly

.

3

.

If

valve

is

not

buzzing,or

if

¡die

decreases

in

step

2,

stop

engine

and

disconnect

harness

connector

from

valve

.

Check

resistance

of

valve

across

its

terminals

.

See

Fig

.

30

.

Test

values

are

listed

below

.

NOTE

-

If

you

suspect

an

intermittent

fault,

lightly

tapthe

valve

while

testing

resistance

.

11250

Fig

.

30

.

¡die

speed

control

valve

terminal

identification

.

4

.

With

valve

harnessconnector

disconnected,

check

for

battery

voltage

at

red/white

wire

in

connector

with

igni-

tion

tumed

on

.

"

If

there

is

no

voltage,

check

wiring

between

connec-

tor

and

main

relayterminal

87

.

See

Electrical

Wiring

Diagrams

.

5

.

If

voltage

is

presentas

described

above,

check

wiring

between

ECM

and

valve

.

If

no

wiring

faults

are

found,

check

ECM

signal

to

valve

.