idle air BMW 318i 1997 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 318i, Model: BMW 318i 1997 E36Pages: 759

Page 241 of 759

DRIVESHAFT

SERVICE

.

...

.

.

.

...

.

..

.

.

.260-3

Driveshaft,

aligning

...............

.

...

.

.

260-3

Driveshaft,

removing

..............

.

.

.

.

.

.

260-4

260

Driveshaft

DRIVESHAFT

260-1

GENERAL

.

.

.

.

.

.

.

.....

.

.

.

........

.

...

.

260-1

Driveshaft,

installing

.

....

.

..

.

............

260-4

Flex-disc,

replacing

.....

.

.

.

.............

260-5

TROUBLESHOOTING

..

.

.

.

...

.

.........

260-1

Center

bearing

assembly,

replacing

.

......

.260-6

Frontcentering

guide,

replacing

..

.

.......

.

260-7

TABLE

a

.

Driveshaft

Troubleshooting

.

.

...

......

.

....

..

.

.

260-2

GENERAL

NOTE-

For

rear

drive

axlerepair

information,

see330

Rear

The

two-piece

driveshaft

is

joined

in

thecenter

by

a

sliding

Suspension

.

splined

coupling

.

This

coupling

compensates

for

fore

and

aft

movement

of

the

drive

line

.

The

driveshaft

ís

connected

to

the

Driveshaft

noise

or

vibration

may

be

caused

by

worn

or

transmission

bya

rubber

flex-disc

and

to

the

final

drive

by

a

damaged

components

.

Check

the

universal

joints

for

play

.

universal

joint

.

It

is

supported

in

the

micidle

by

a

center

support

With

the

driveshaft

installed,

pull

and

twist

the

driveshaft

while

bearing

.

The

bearing

is

mounted

in

rubber

to

isolate

vibration

.

watching

the

joint

.

The

BMW

specificationfor

play

is

very

See

Fig

.

1

.

small,

so

almost

any

noticeableplay

could

indicate

a

problem

.

TROU

BLESHOOTING

Check

thetorque

of

thefasteners

at

the

flange

connections

.

Check

therubber

of

the

flex-disc

and

center

bearing

for

dete

The

source

of

driveline

vibrations

and

noise

can

be

difficult

rioration

or

tearíng

and

check

for

preload

at

the

center

bearing

to

pinpoint

.

Engine,

transmission,

rear

axle,

or

wheel

vibra-

with

a

visual

inspection

.

Check

the

driveshaft

for

broken

or

tions

can

be

transmitted

through

the

driveshaft

to

the

car

missing

balance

weights

.

The

weights

are

welded

tabs

on

the

body

.

Noises

from

the

rear

of

thecar

may

be

caused

by

final

driveshaft

tubes

.

In

addition

to

inspecting

for

faulty

driveshaft

drive

problems,

orby

faulty

wheel

bearings,

drive

axies,

or

parts,

the

installed

angles

of

the

driveshaft

should

also

be

evenworn

or

improperly

inflatedtires

.

considered

.

Flex-disc

Center

universal

joint

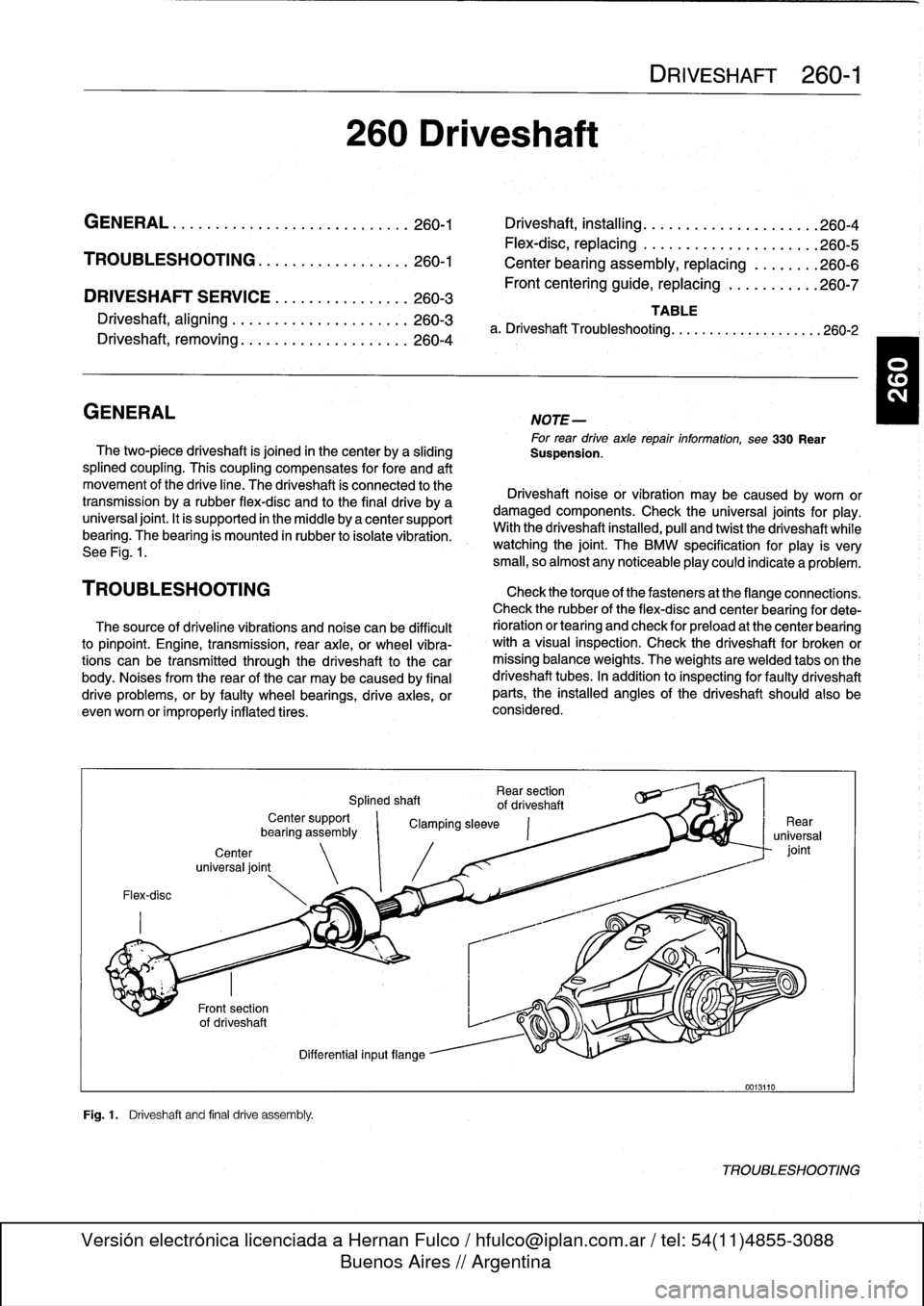

Fig

.1

.

Driveshaft

and

final

drive

assembly

.

Rear

section

Splined

shaft

of

driveshaft

Center

support

`

Clamping

sleeve

bearíng

assembly

Differential

inputflange

0013110

TROUBLESHOOTING

Page 252 of 759

300-4

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Three-channel

ABS

ís

used

on

al[

E36

cars

equipped

with

Al¡

Season

Traction

(AST)

standard

ABS

.

Each

front

wheelhas

a

separate

solenoid

valve

to

modulate

hydraulic

pressure

to

that

brake

caliper

.

The

traction

control

system

works

in

conjunction

with

ABS

The

rear

wheels

are

modulated

asa

pair,

controlled

by

a

sin-

and

the

engine

management

system

to

enhance

vehicle

con

gle

solenoid

valve

.

trol

.

The

main

function

of

the

AST

system

is

to

maintain

the

rolling

contact

between

the

tires

and

the

road

surface

under

al¡

driving

E36

cars

equipped

with

ABS/AST

utilize

a

four

channel

sys-

conditions

.

This

is

achieved

through

exact

application

and

tem,

which

functionsexactly

as

the

three

channelsystem

management

of

braking

and

drivetrain

forces

.

above,except

that

the

rear

wheels

are

modulated

individually

.

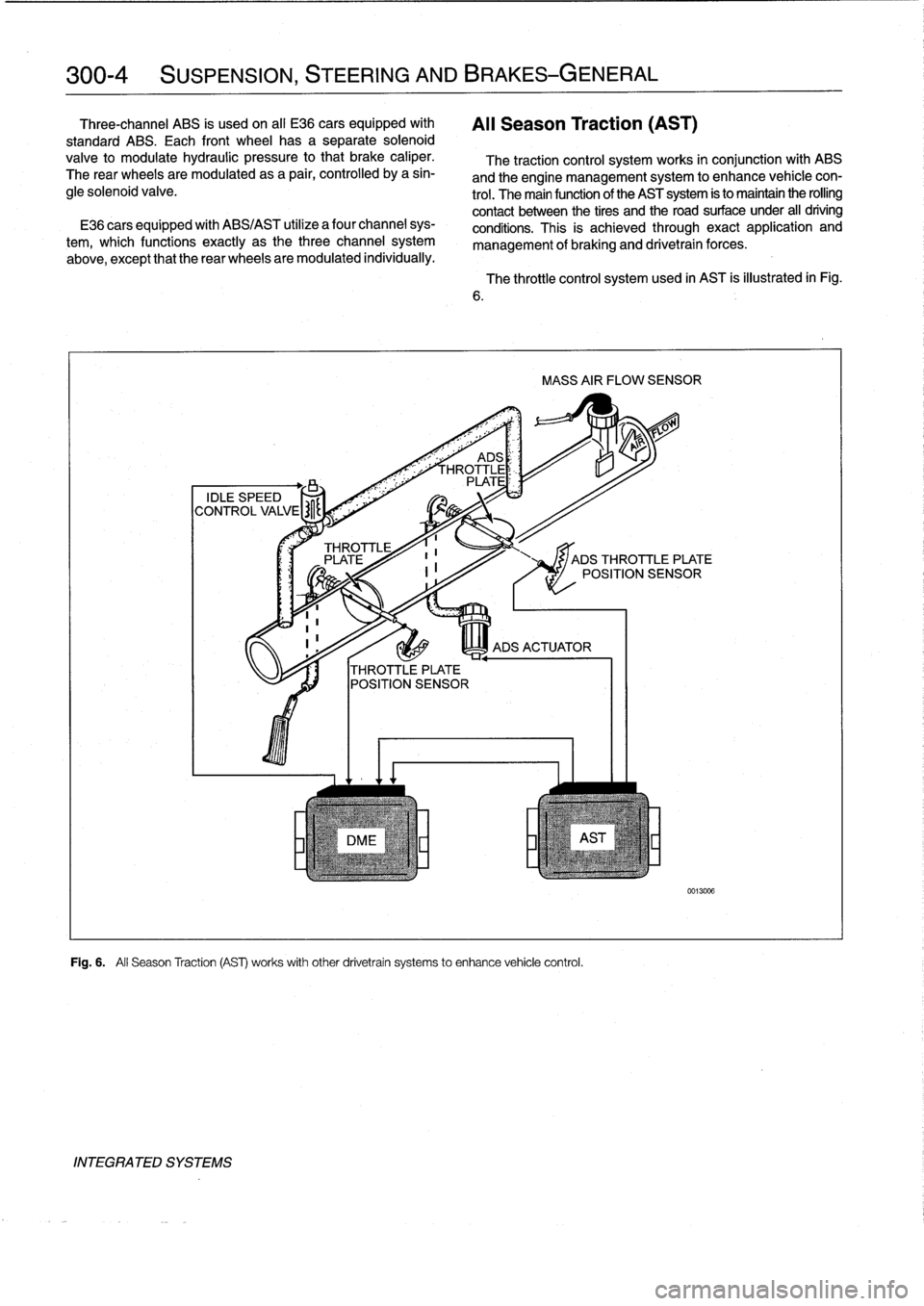

IDLE

SPEED

CONTROL

VALVE

HROTTLE

PLATE

6

.

Í

III

i

ADS

ACTU

AT

OR

THROTTLE

PLATE

POSITION

SENSOR

DME

Fig

.

6

.

All

Season

Traction

(AS)

works

withother

drivetrain

systems

to

enhance

vehicle

control

.

INTEGRATED

SYSTEMS

The

throttle

control

system

used

in

AST

is

illustrated

in

Fig

.

MASS

AIR

FLOW

SENSOR

JADS

THROTTLE

PLATE

POSITION

SENSOR

0013006

Page 292 of 759

340-2

BRAKES

When

troubleshooting,

keep

in

mind

that

tire

inflation,

wear

and

temperature

can

affect

braking

and

suspension

.

See310

Front

Suspension

for

more

information

on

front

suspension

parts

inspection

.

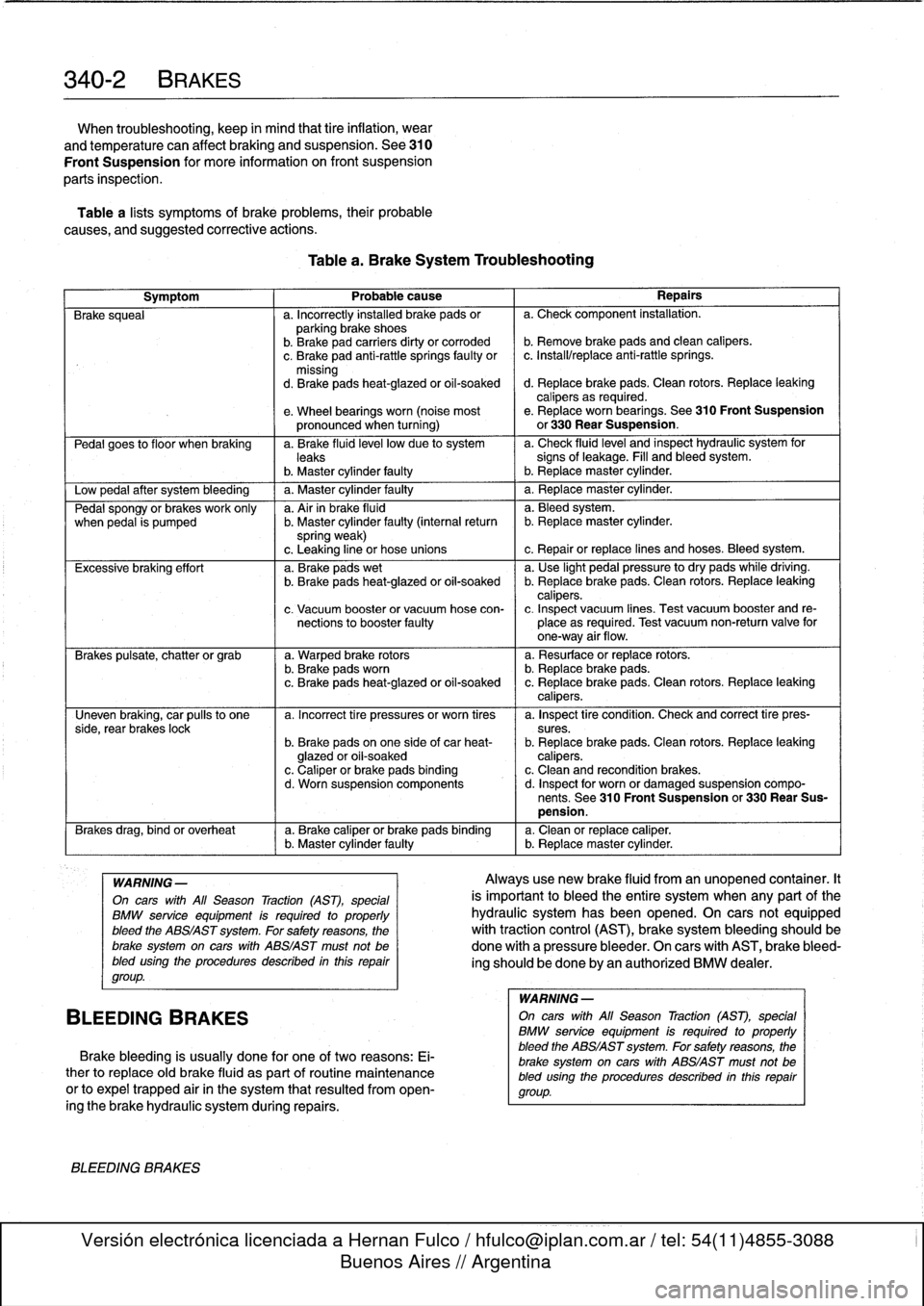

Table

a

lists

symptoms

of

brake

problems,

their

probable

causes,

and

suggested

corrective

actions

.

Table

a

.

Brake

System

Troubleshooting

Symptom

1

Probable

cause

1

Repairs

Brake

squeal

a

.

Incorrectly

installed

brake

pads

or

a

.

Check

component

installation

.

parking

brake

shoes

b

.

Brakepad

carriers

dirty

or

corroded

b

.

Remove

brake

pads

and

clean

calipers

.

c

.

Brake

pad

anti-rattle

springs

faulty

or

c

.

Install/replace

anti-rattle

springs

.

missing

d

.

Brakepads

heat-glazed

or

oil-soaked

d

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

as

required

.

e

.

Wheel

bearings

worn

(noise

most

e

.

Replace

worn

bearings

.

See310

Front

Suspension

pronounced

when

turning)

or

330

Rear

Suspension

.

Pedal

goes

to

f

loor

when

braking

a

.

Brake

fluid

leve¡

low

due

to

system

a

.

Check

fluidlevel

and

inspect

hydraulic

system

for

leaks

signs

of

leakage

.

Fill

and

bleed

system

.

b

.

Master

cylinder

faulty

I

b

.

Replacemaster

cylinder

.

Low

pedal

after

system

bleeding

1

a

.

Master

cylinder

faulty

1

a

.

Replace

master

cylinder

.

Pedal

spongy

or

brakes

work

only

a

.

Air

in

brake

fluid

a

.

Bleedsystem

.

when

pedal

is

pumped

b

.

Master

cylinder

faulty

(interna¡

return

b

.

Replacemaster

cylinder

.

spring

weak)

c

.

Leaking

line

or

hose

unions

c

.

Repair

or

replace

lines

and

hoses

.

Bleed

system

.

Excessive

braking

effort

a

.

Brake

pads

wet

a

.

Use

light

pedal

pressure

to

dry

pads

while

driving

.

b

.

Brake

pads

heat-glazed

oroil-soaked

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

c

.

Vacuum

booster

or

vacuum

hose

con-

c

.

Inspect

vacuum

lines

.

Test

vacuum

booster

and

re

nections

to

booster

faulty

place

as

required

.

Test

vacuum

non-return

valve

for

one-way

air

flow

.

Brakes

pulsate,

chatter

or

grab

a

.

Warped

brake

rotors

a

.

Resurface

or

replace

rotors

.

b

.

Brake

padsworn

b

.

Replace

brake

pads

.

c

.

Brake

pads

heat-glazed

or

oil-soaked

c

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

Uneven

braking,

car

pulís

to

one

a

.

Incorrect

tire

pressures

or

worn

tires

a

.

Inspect

tire

condition

.

Check

and

correct

tire

pres-

side,

rear

brakes

lock

sures

.

b

.

Brake

pads

on

one

side

of

car

heat-

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

glazed

or

oil-soaked

calipers

.

c

.

Caliper

or

brake

pads

binding

c

.

Clean

and

recondition

brakes

.

d

.

Worn

suspension

components

d

.

Inspect

for

worn

or

damaged

suspension

compo-

nents

.

See

310

Front

Suspension

or

330

Rear

Sus-

pension

.

Brakes

drag,

bind

or

overheat

a

.

Brake

caliper

or

brake

pads

binding

a

.

Clean

or

replace

caliper

.(

b

.

Master

cylinder

faulty

b

.

Replacemaster

cylinder

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

required

to

properly

bleed

the

ABS/AST

system

.

For

safety

reasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthis

repair

group

.

BLEEDING

BRAKES

Brake

bleeding

is

usually

done

for

one

of

two

reasons

:

Ei-

ther

to

replace

oíd

brake

fluid

as

part

of

routine

maintenance

or

to

expel

trapped

air

in

the

system

that

resulted

from

open-

ingthe

brake

hydraulic

system

during

repairs

.

BLEEDING

BRAKES

Alwaysuse

new

brake

fluid

from

an

unopened

container

.It

is

important

to

bleed

the

entire

system

when

any

part

of

the

hydraulic

system

has

been

opened

.

On

cars

not

equipped

with

traction

control

(AST),

brake

system

bleeding

should

be

done

with

a

pressure

bleeder

.

On

cars

with

AST,

brake

bleed-

ing

should

be

done

by

an

authorized

BMW

dealer

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

requíred

to

properly

bleed

the

ABS/AST

system

.

For

safetyreasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthís

repair

group

.

Page 393 of 759

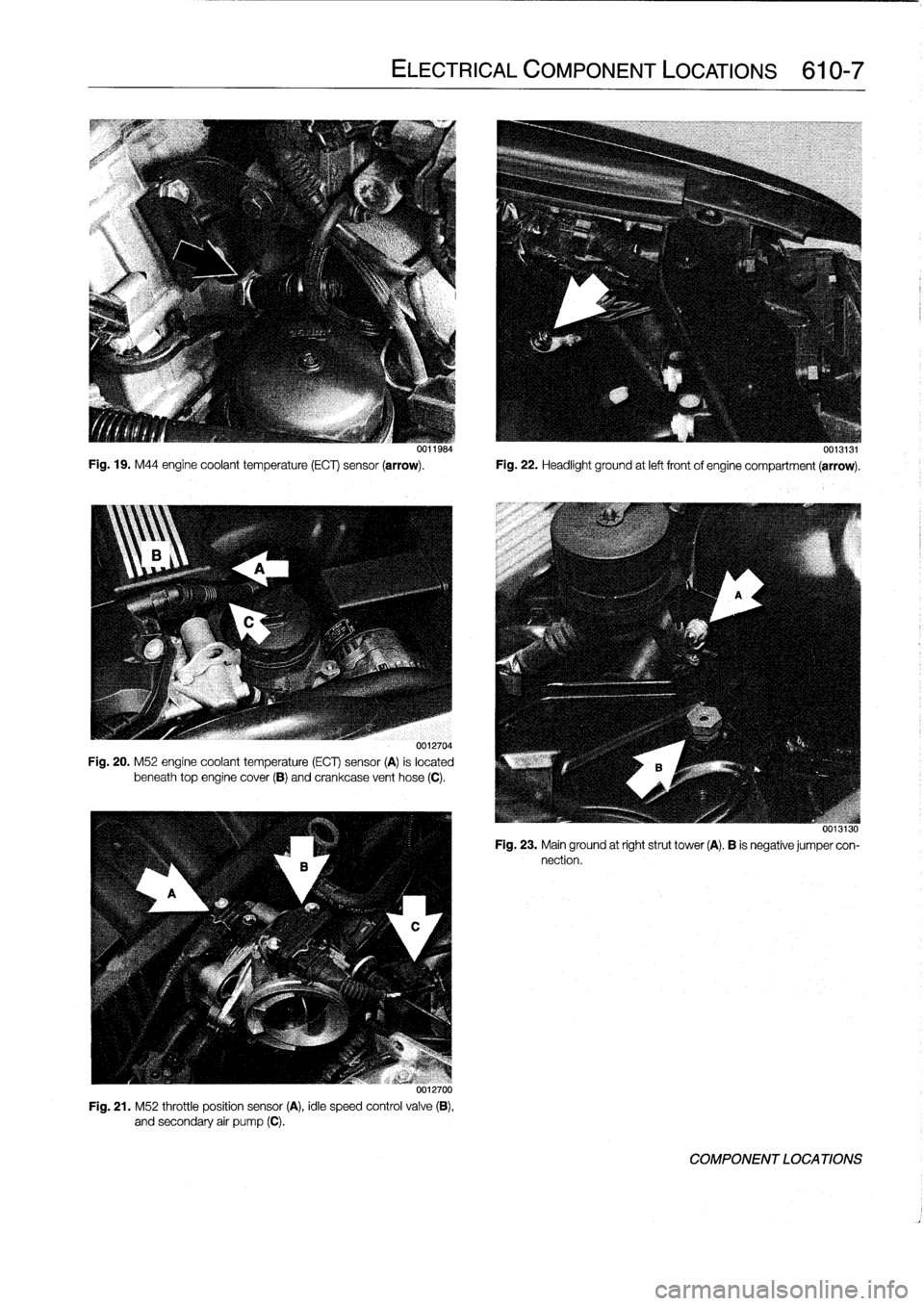

Fig

.

19

.

M44

engine

coolant

temperature

(ECT)

sensor

(arrow)

.

Fig

.

22

.

Headlight

ground

at

left

frontof

engine

compartment

(arrow)

.

0012704

Fig

.

20

.

M52

engine

coolant

temperature

(ECT)

sensor

(A)

is

located

beneath

top

enginecover

(B)

and

crankcase

vent

hose

(C)

.

uu12700

Fig

.

21

.

M52

throttle

position

sensor

(A),

idle

speed

control

valve

(B),

and

secondary

air

pump

(C)

.

ELECTRICAL

COMPONENT

LOCATIONS

610-7

00119s4

0013131

uvijijo

Fig

.

23

.

Mainground

at

right

strut

tower

(A)

.

B

is

negative

jumper

con-

nection

.

COMPONENT

LOCA

TIONS

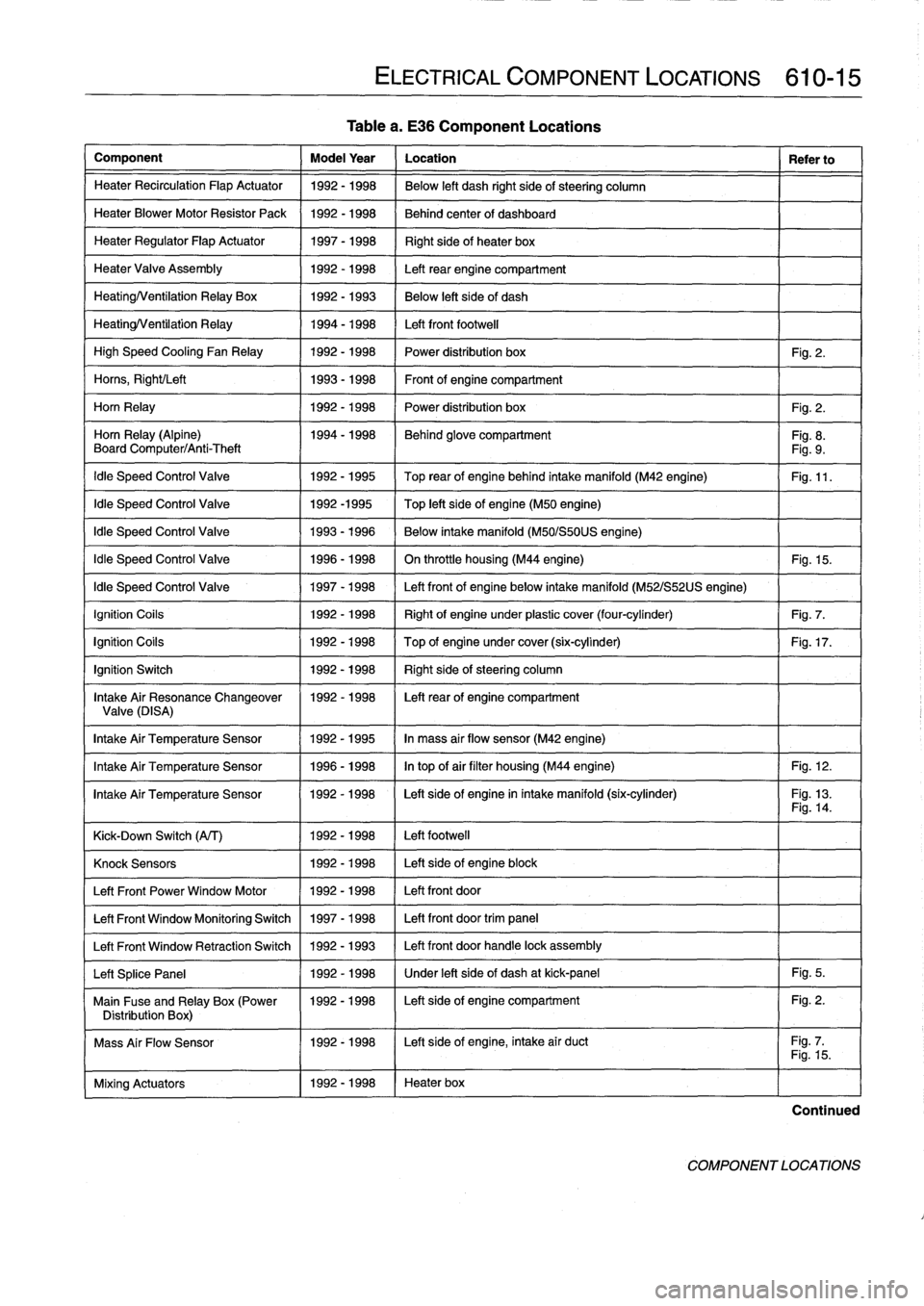

Page 401 of 759

Component

Model

Year

Location

Refer

to

Heater

Recirculation

Flap

Actuator

1992-1998

Below

left

dash

right

side

of

steering

column

HeaterBlowerMotor

Resistor

Pack

1992-1998

Behind

center

of

dashboard

Heater

Regulator

FlapActuator

1997-1998

Right

side

of

heater

box

HeaterValve

Assembly

1992-1998

Left

rear

engine

compartment

HeatingNentilation

Relay

Box

1992-1993

Below

left

side

of

dash

HeatingNentilation

Relay

1994-1998

Left

front

footwell

High

Speed

Cooling

Fan

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Homs,

Right/Left

1993-1998

Front

of

engine

compartment

Horn

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Horn

Relay

(Alpine)

1994-1998

Behind

glove

compartment

Fig

.

8

.

Board

Computer/Anti-Theft

Fig

.

9

.

Idle

Speed

Control

Valve

1992-1995

Top

rearof

enginebehind

intake

manifold

(M42

engine)

Fig

.

11

.

Idle

Speed

Control

Valve

1992-1995

Top

left

side

of

engine

(M50

engine)

Idle

Speed

Control

Valve

1993-1996

Below

intake

manifold

(M50/S50US

engine)

Idle

Speed

Control

Valve

1996-1998

On

throttle

housing

(M44

engine)

Fig

.

15

.

Idle

Speed

Control

Valve

1997-1998

Left

front

of

engine

below

intake

manifold

(M52/S52US

engine)

Ignition

Coils

1992-1998

Right

of

engineunder

plastic

cover

(four-cylinder)

Fig

.

7

.

Ignition

Cofs

1992-1998

Top

of

engine

undercover

(six-cylinder)

Fig

.

17

.

Ignition

Switch

1992-1998

Right

sídeofsteering

column

Intake

Air

Resonance

Changeover

1992-1998

Leftrear

of

engine

compartment

Valve(DISA)

Intake

Air

Temperature

Sensor

1992-1995

In

mass

air

flow

sensor

(M42

engine)

Intake

Air

TemperatureSensor

1996-1998

In

top

ofair

filter

housing

(M44

engine)

Fig

.

12

.

Intake

Air

Temperature

Sensor

1992-1998

I

Left

sídeof

engine

in

intake

manifold

(six-cylinder)

-

-

I

Fig

.

13

.

Fig

.

14

.

Kick-Down

Switch

(A/T)

1

1992-1998

1

Left

footwell

Mixing

Actuators

1

1992-1998

1

Heater

box

ELECTRICAL

COMPONENT

LOCATIONS

610-15

Table

a

.

E36

Component

Locations

Knock

Sensors

1

1992-1998

1

Left

side

of

engine

block

Left

Front

Power

Window

Motor

11992-1998

/

Left

front

door

Left

Front

Window

Monitoring

Switch

1

1997-1998

1

Left

front

door

trim

panel

Left

Front

Window

Retraction

Switch

1

1992

-

1993

1

Left

front

door

handle

lock

assembly

Left

Splice

Panel

1

1992-1998

1

Under

left

side

of

dash

at

kick-panel

1

Fig

.

5

.

Main

Fuse

and

Relay

Box

(Power

1992-1998

I

Left

sideof

engine

compartment

Fig

.

2

.

Distribution

Box)

1

I

Mass

Air

Flow

Sensor

1992-1998

I

Left

side

of

engine,

intake

air

duct

Fig

.

7

.1

I

Fig

.

15

.

Continued

COMPONENT

LOCATIONS

Page 554 of 759

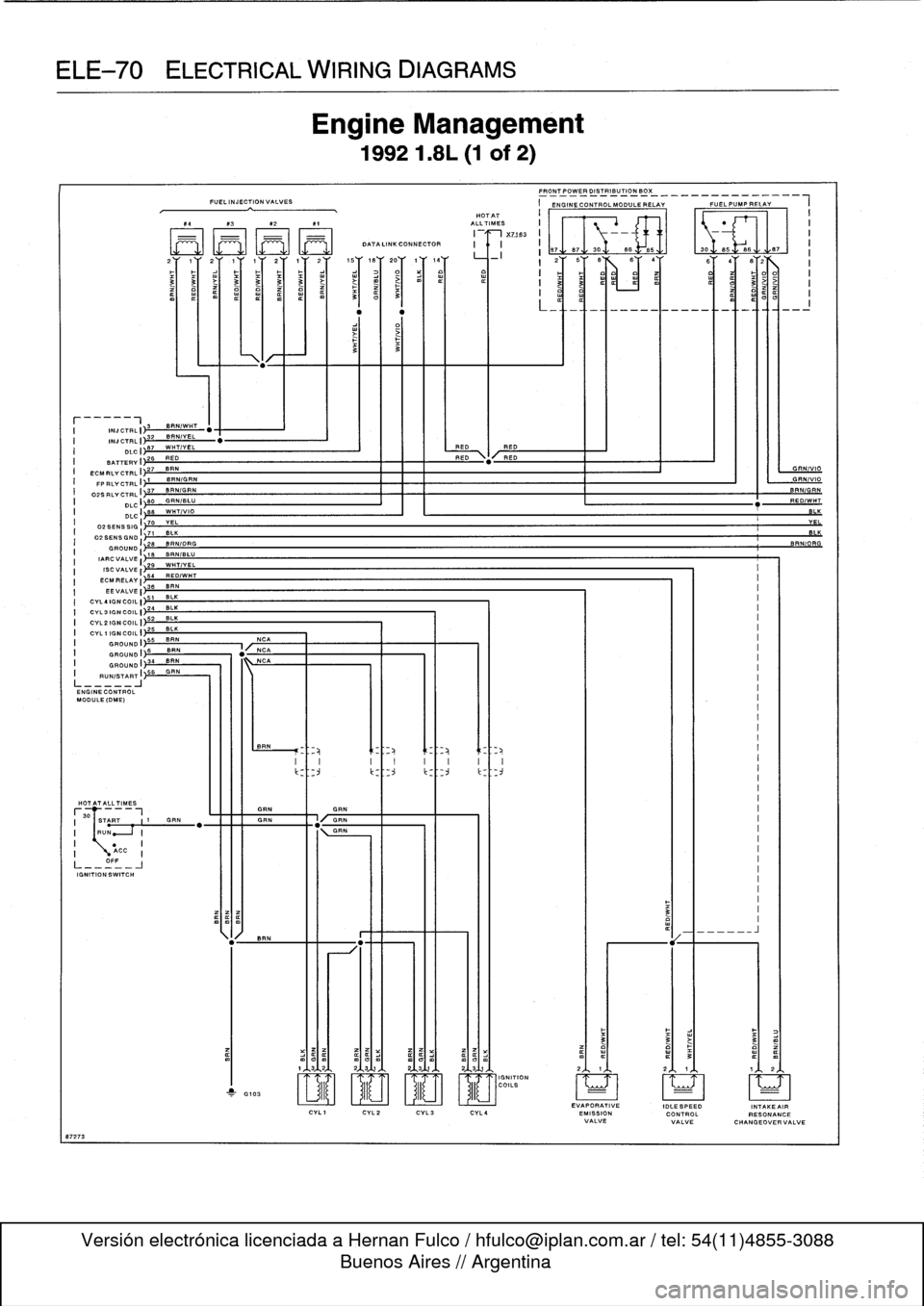

ELE-70

ELECTRICAL

WIRING

DIAGRAMS

I

02

SENS

SIB

I"7

7

I

02SENSGNDI)

I

GROUNDI

2

BR

,

'IB

BRN/BLU

I

IARCVALVEI

I

IsCVALVEI}

I

ECM

RELAY

I

EEVALVEI~

I

CVL4IGNCOILI

S7~LK

I

CVL3IGNCOILI

24L

BL1(

I

CVL2IGN

COILI'

B2

~

BLK

I

CVLIIGNCOILI

2

I

GROUNDI

B'=RN

I

GF

.uNDI

),

BRN

I

GROUNOI

3~

BR"

I

RUNIST

GRN

ARTI

S~

ENGINECONTROL

MODULE

(DME)

13B

START

1

GRN

I

DN

OFF

IGNITION

S

WITCH

8727

3

HOTATALLTIMES

UELINJECTION

VALVES

NCA"

=

It,

INCA

SPIN

BRN

GRN

~GRN

OF

N

/

GRN"

\

GRN

Engine

Management

19921

.8L

(1

of

2)

HOTAT

F4

X3X2

R1

ALLTIMES

I

XZ793

M

M

[]M[IM

AT

.

LINK

CONNECTOR

8B

3Dy

eB=85

.1

.1308

I

ii

w

>

3~

3

3

BRNIWH

INJCTRLI

32

BRNIYEL

T

INJCTRLI~

DLCI

je7

L

REO

I

RED

BATTERY

I

2S

RED

RED

FRONT_POWERDISTRIBUTIONBO%

_

_

___

_

_

_

____

_

_

I

ENGINE

CONTROL

MODULE

RELAY

FUEL

PUMP

RELAY

L

ECMFLY

CTRL

1)27

BFN

FP

FLY

CTRL

I

I'

SWORN

02SFLYCTRL

I

37

BRNIGRN

BRN

GRN

DLCI

80

GRNIBLU

RE

O

DLCI

,88

WHTIVIO

1

~1~

2oY

1

Y

I4Y

_

i

2Y

SY

BX

BY

4YBY

EVAPORATIVE

IDLESPEED

INTAKE

AIR

EMISSION

CONTROL

RESONANCE

VALVE

VALVE

CHANGEOVER

VALVE

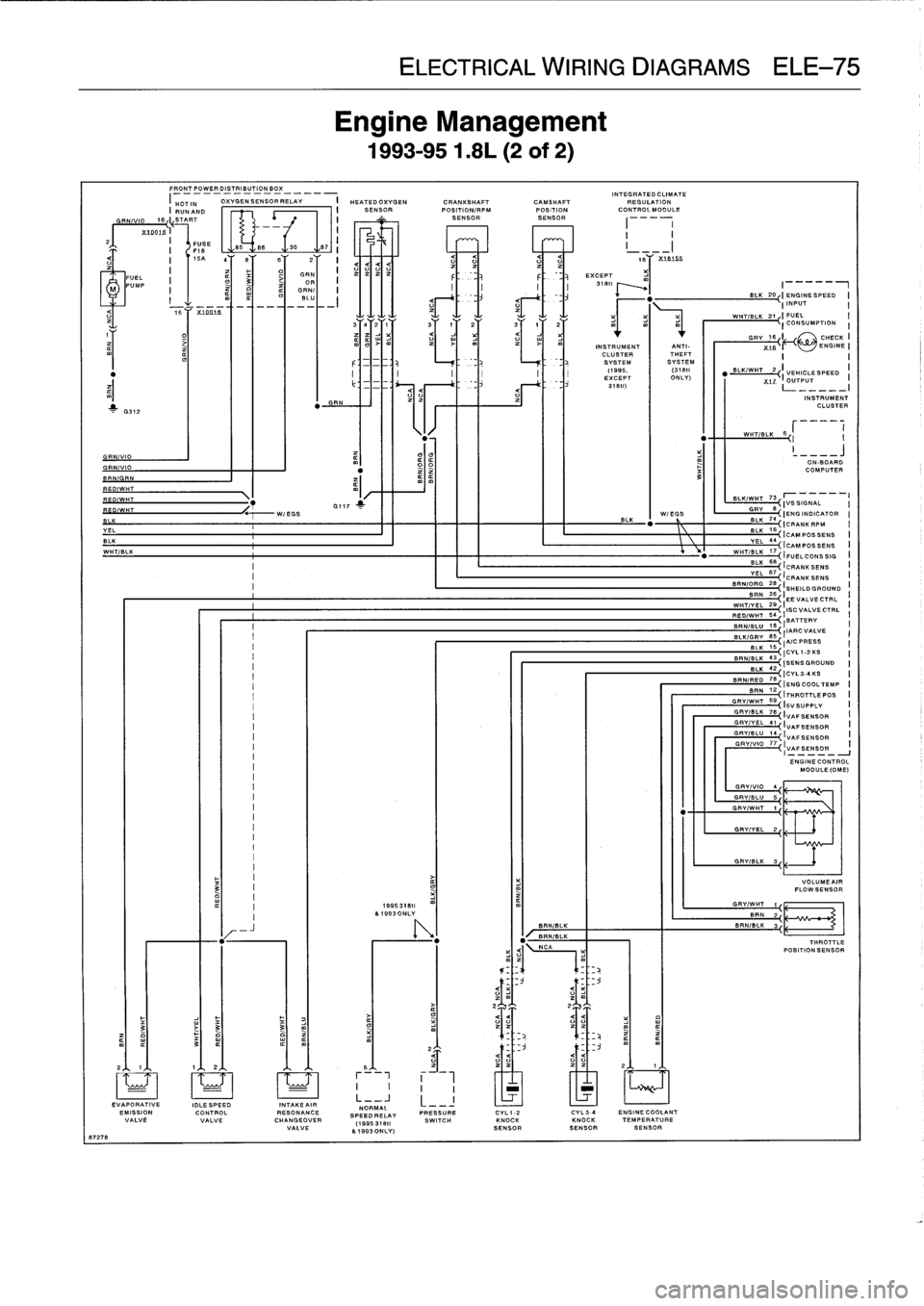

Page 559 of 759

8727

8

GR

FUEL

PUMP

FRONT

POWER

DISTRIBUTION

BOX

-

-

-

-

-

-

----

-

-

-

-

-

-

I

H

OTIN

OXYGENSENSOR

RELAY

I

HEATEDOXYOEN

I

RUNAND

SENSOR

VII

O

I

k

I

FUSE

I

F18

I

1sA

GRN

EXCEPT

zl¢I

alGBN/~I

31811~

"

BLK

20

ENGINESPEED

--\

INPUT

WHTIBLK

21

FUEL

GIN/VIO

I

mI

QGRN

VIO

BRNGRNRED

WHT

ml

flED/WHTflED/WHT

LT

6117

I

DRY

~~

W1EGS

I

W/EGS

L

IENGINDICATOR

BLK

BLK

.

ELK

74

7

ELK

16

ICRANKRPHI

ICAMPOSSENS

ELK

VEL

44

I

CAMPOS

SENS

WH7/BLK

_

WHT/BLK

17I

FUELCONSSIG

68

87

2Y

GRN

Engine

Management

1993-951

.8L

(2

of

2)

a

ELECTRICAL

WIRING

DIAGRAMS

ELE-75

I

ELK

,

ICRANKSENS

YEL67i

ICRANKSENS

B

R

N/

ORG

28

,I

SHEILO

GROUND

_____SRN

36

I;

EEVALVECTRL

WHT/YEL

2B,

L

ISCVALVECTRL

,ED/W

.I

199531811

m

819930NLY

INTEGRATED

CLIMATE

CRANKSHAFT

CAMSHAFT

REGULATION

POSITION/RPM

POSITION

CON7ROLM000LE

SENSOR

SENSOR

I

~~BRNIBL

gRNIBLCA

INSTRUMENT

CLUSTER

SYSTEM

11995,

EXCEPT

-U)

2,J

1

J

.

1

.l

2A,

A,

I,

i

l

_

I

I

I

I

L__i

EL

LT

VAPORATIVE

IDLESPEED

INTAKEAIR

NORMAL

EMISSION

CONTROL

RESONANCE

SPE

EDR

PRESSURE

CVLl-2

CYL3-4

ENGINECOOLANT

VALVEVALVE

CHANGEOVER

SWITCH

KNOCKKNOCK

TEMPERATURE

VALVE

9930NLY)

(1

9

953

1

BlI811

SENSOR

SENSOR

SENSOR

81

ANTI-

THEFT

SYSTEM

(31811

ONLY)

(CONSUMPTION

I

GR

~

CHECK

ENGINE

I

BATTERY

BRNN/BU

f

"

-

IARCVALVE

BLKIG

RR

e5

(

i

K

15

I

AIC

PRESS

I

CYL

l-2

KS

BRN/BLK

4ISENSGROUND

~ICVL3-4KS

BRNIFEI

78

IENOCOOLTEMP

BR

N

12,;THROTTLEPOS

GRY/WHT

5

9,

I5VSUPPLY

GRVIBLK~

I

VAF

SENSOR

GRY/VEL

<1,

I

VAFSENSOR

GRY

RY/BI

VAFSENSOR

I

GRV/VID

77

{

,

VAFSENSOR

I

GRY

I

VIO

4

GRV/BLU

5

GRY/WHT

1

GRYIYEL

2

GRYISL

GRYIWHT

t

BRN

2

BRNIBLK

3

ENG

ME

CONTROL

MODULE

(OME)

VOLUMEAIR

FLOW

SENSOR

jT

;RT~dl

-

8,

THROTTLE

POSITION

SENSOR

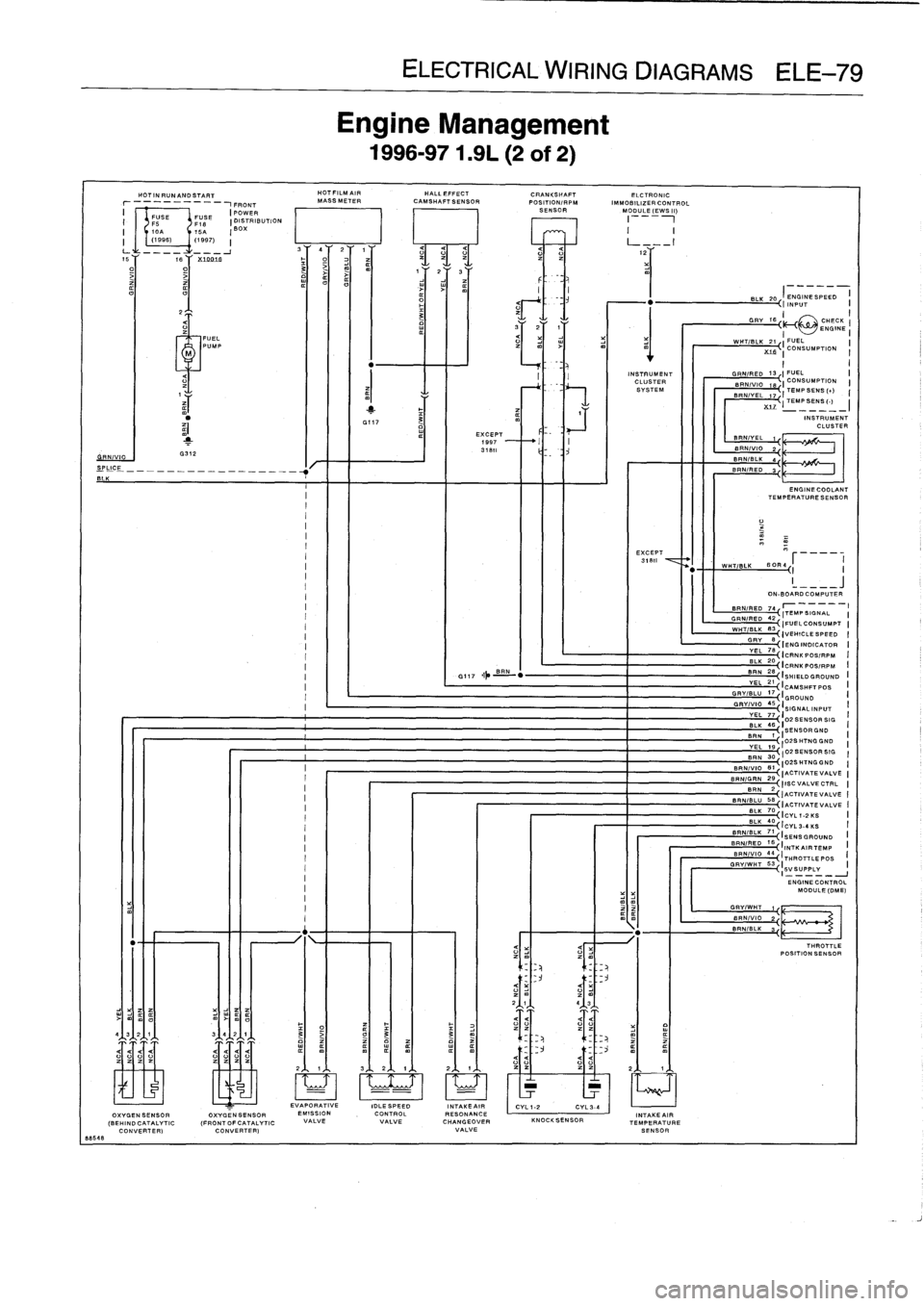

Page 563 of 759

GRN/VIO

HOT

IN

RUNAND

START

HOT

FILM

AIR

HALLEFFECT

CRANKSHAFT

ELCTRONIC

r

-1FRONT

MASSMETER

CAMSHAFTSENSOR

POSITION/RPM

IMMOBILIZERCONTROL

I

(POWER

r

-

-

1

1

1

SENSOR

MODULE

(EWS11)

FUSE

I

FSSE

F

IDIS7RIBUTION

I

iDA

ISA

(BOX

I

I

(199fi)

(1997)

I

is

Y

iBy

$

1D01B

I

D

-

22

OXYGENSENSOR

(BEHIND

CATALYTIC

CONVERTER)

88648

FUEL

PUMP

SPLICE

BLK

-----

.--_

.-------

OXYGENSENSOR

(FRONT

OFCATALYTIC

CONVERTER)

Engine

Management

1996-971

.91-(2

of

2)

EVAPORATIVE

IDLESPEED

EMISSION

CONTROL

VALVEVALVE

ELECTRICAL

WIRING

DIAGRAMS

ELE-79

EXCEPT

1997

318

ti

INSTRUMENT

CLUSTER

SYSTEM

EXCEPT

31811

INTAKEAIR

I

CYL1-2

CYL3-4

RESONANCE

INTAKEAIR

CHANGEOVERKNOCKSENSORTEMPERATURE

VALVE

SENSOR

BLK

IENGINESPEED

I

-

2

k

I

INPUT

I

GRG=1fi~

CHECK

ENGINE

I

WHT/BLK

21

I

FUEL

X

t

fi

'C

CONSUMPTION

I

~GRN/RED

13

3

I

FUEL

I

CONSUMPTION

SRN/VI

jg

TEMPSENS

(L)

BRN/V=L

17{iTEMPSENS(-)

INSTRUMENT

CLUSTER

ENGINECOOLANT

TEMPERATURESENSOR

WW=TIBLK

BOR4

(I

I

__J

ON-BOARD

COMPUTER

BRN/RED

74,

r

_

----

I

~ITEMPSIGNAL

I

-

~GRN/RED

42

J

~IFUELCONSUMPT

I

WHT/BLK

83

~~

I

VEHICLE

SPEED

I

GRV

S,

IENGINDICATOR

I

VEL

78

-

-~{ICRNKPOS/RPM

_ILL

-(ICRNKPOSIRPM

BRN

(SHIELD

GROUND

YEL

I21

CAMSHFTPOS

GRV/BLU

17

'GROUND

GRV/V

-

10

4S

`

VEL77,

:SIGNAL

8-{

I02

SENSOR

SIG

B-

:

..

.SORGND

OISHTNGGND

VEL

19

I

B

3D~I023ENSORBIG

02SHTNGGND

BRN/VIO

B7

I

{

ACTIVATEVALVE

-

-

~BRNIG

RN29

J

I

~

I

ISC

VALVE

CTRL

BRN

2

BRNIBLU~JACTIVATE

VALVE

BIACTIVATEVALVE

-

BILK

70

'

~

BLK

40

;CVL

1-2KS

-~{

I

CYL

3-6

KS

BRN/BLK

711

SENSGROUND

BRN/RED

~

IINTKAIRTEMP

BRN/VIO

44

I

I

~

W

L~~~

THROTTLEPOS

GRVRY/

-

W

I

SVSUPPLY

I

ENGINECONTROL

MODULE

(DME)

THROTTLE

POSITION

SENSOR

Page 566 of 759

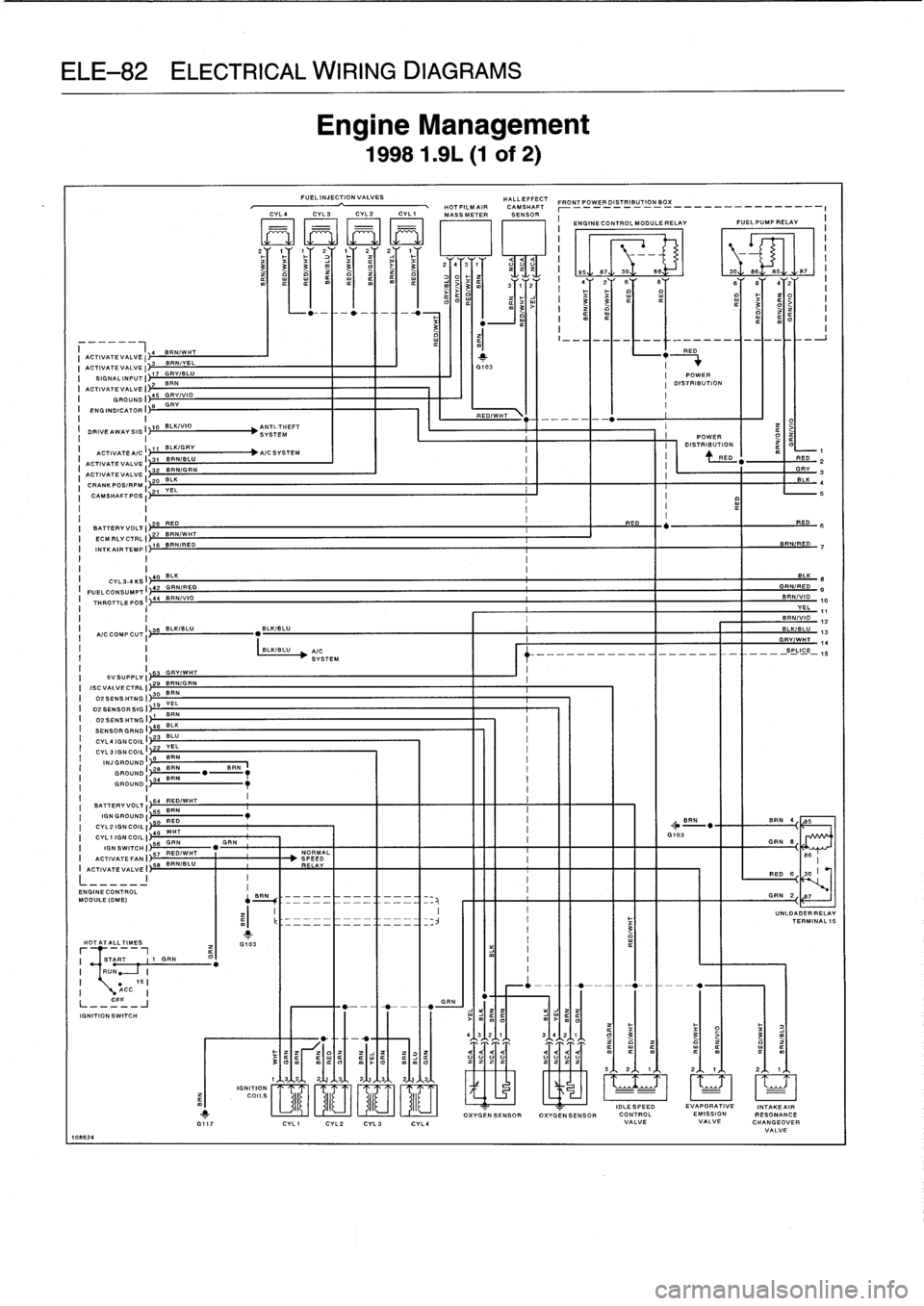

ELE-82

ELECTRICAL

WIRING

DIAGRAMS

I

AC7IVATEVALVEII

BRNIWHT

I

ACTIVATE

VALVE

I'3

BRN/V

EL

10862

4

SIGNPLINPUTI

1T2

B

AN

ACTIVATE

VALVE

I--

GROUND

I

4B6~GRV/VIO

ENGINO1CATOR

I

~

10

BLK/VIO

DRIVE

AWAY

SIG

II

11

BLKIGRY

AC

TIVATEAIC

ACTIVATE

VALVEI

31

BRNIBLU

ACTIVATE

VALVE

I

32~BRTI/GRN

120

BLK

CRANKPOSIRPMI

Y-

CAMSHAFTPOSI

21

I

BATTERYVOLTI126

RED

ECM

RLV

CTRL

1

)21

8RN/WHT

18

BRNIRED

INTKAIRTEMPI

I

I

406

CVL3-4KSI

42

GRNIRED

FU

ELCONSUMPTI

THROTTLE

POST

44

B

RN/VIO

I

A/CCOMPCUT136

8LK/BLU

"

8LK/BLU

II

5VSUPPLVI

53

ISCVALVE

CTRLI

2

/GRN

30

BRN

02SENSH7NGI~-

19

VEL

02SENSORSIGI~

1

BRN

02

SENS

HTNG

I

SENSORGRNOI

4

23

BLU

CVL4IGNCOIL

CVL3

ON

co

ILI

2r-

INJGROUND

I

128

BRN

GROUND

GROUNDI)~pl

L_____!

ENG

ME

CONTROL

MODULE

(DME)

HOTPTALLTIMES

___

I

START

.1

1

GRN

I

RUN

~_I

I

18

I

~

ACC

I

OFF

IGNITION

SWITCH

BA7TERVVOLTI

54

RED/W~

H

IGNGROUNDI

50

READ

CYL21GN

COIL

ED

I

l

~~

CYL1IGNCOIL

49

WHT

I

IGNSWITCH

I

56

GR

"GRN

B7

REOIWHT

ACTIVATE

FAN

ACTIVATE

VALVE

I

8

tf

FUELINJECTIONVALVES

HALLEFFECT

HOTFILMAIR

CAMSHAFT

FRONT

POWER

DISTBIU710NBOX

______

.

___

CVL4CVL3

CVL2

CYLl

MASSMETERSENSOR

r

i

SYSTEM

NORMAL

SPEEDRELAY

Engine

Management

19981

.9L

(1

of

2)

IGNITION

JJ

U

COILS

II

GA

.

4

3~2

1

a

mIm

a

OXVGENSENSOROXVGENSENSOR

IDLESPEED

EVAPORATIVE

INTAKEAIR

CONTROL

EMISSION

RESONANCE

VALVEVALVE

CHANGEOVER

VALVE

I

-

"HIRED

2

Page 568 of 759

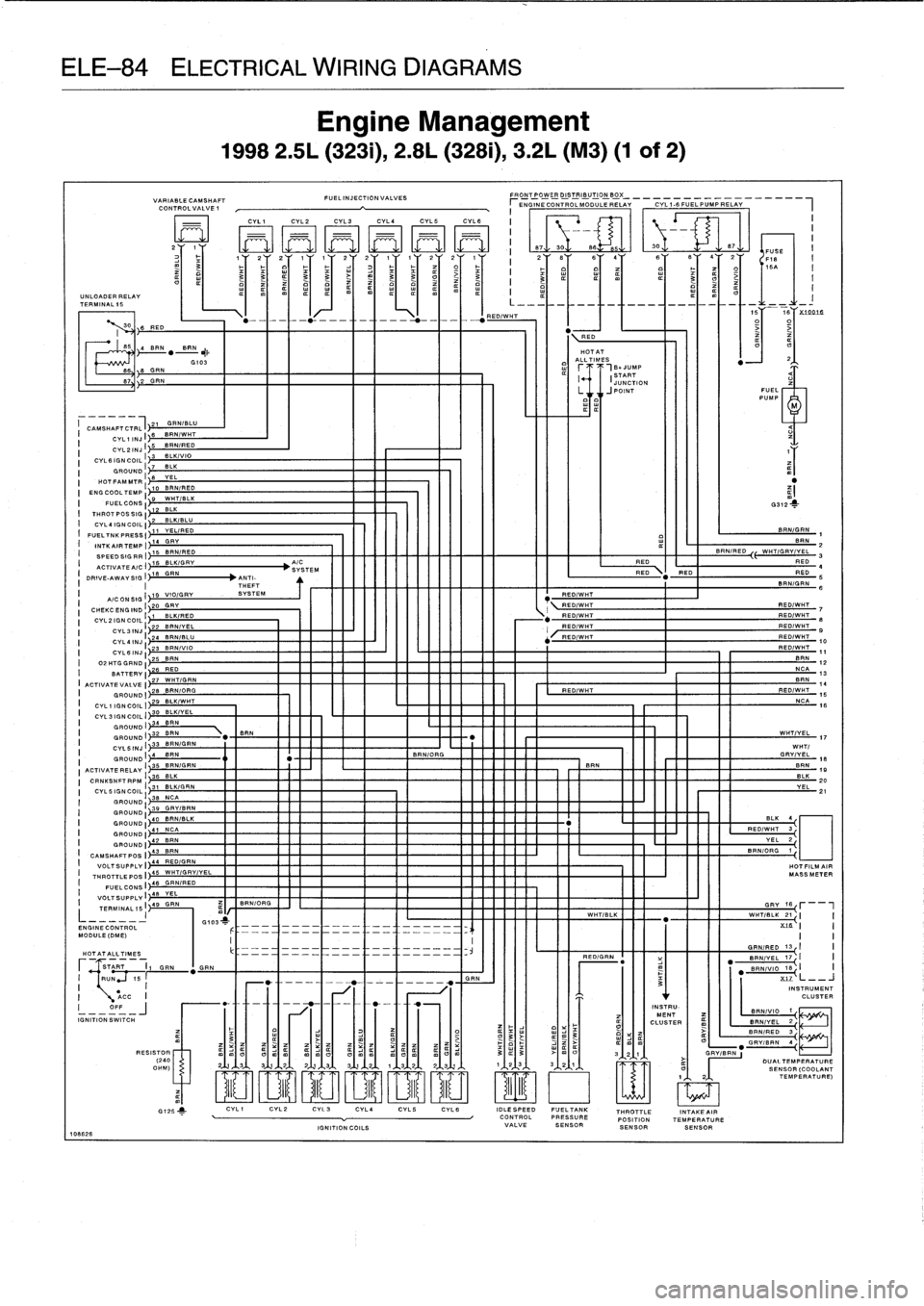

ELE-84

ELECTRICAL

WIRING

DIAGRAMS

UNLOADERRELAY

TERMINAL15

106626

VARIABLECAMSHAFT

CONTROLVALVE1

I

CAMSHAFTCTRL'f21

GRNIBLU

CYLIINJI

6B

L

N/WHT

CYL21NJ)

5

BAN/RED

CYL61GNCOILI

1

3

BLK/VIO/VIO

GROUNDL7

B7

HOTFAMMTRIj3

YEL

]

10

BRN/RED

ENGCOOLTEMPI

WHTIBL

PK

FUELCONSI

THRO7

POS

SIG

I

12

CYL41GNCOILI

2

BK/BLU

Engine

Management

19982

.5L

(3231),

2

.8L

(3281),

3

.2L

(M3)

(1

of

2)

FUEL

INJECTION

VALVES

RED

11

I1

1

1111I11III

1II

1

I1

1I

1

BRN/GRN

FUELTNKPRESSI

1

1

INTKAIRTEMPI

14

GRV

,K

II

II

SPIN

2

SPEED

SIGRRI

15

SRN/RED

BRN/RED

WHT//YELL

3

I

16

BLK/GRV

A/C

REO

RED

ACTIVATEpiC

4

DRIVE-AWAY

SIG

18

GRN

ANTI-

SYSTEM

REO

RED

RED

I

THEFT

"

5

BRN/GRN

A/C

ON

SIG

)1D

VIO/GRY

SYSTEM

I

RED/WHT

KCENGIND)

20

GRY

RED

/WHT

REDIWHT

7

21GNCOIL)

l

BLKIREO

+

RED/WHT

CVL3INJ

22

BRN/YEL

REDO

//WHWH

TT

6

II

i

123

BRN/VIO

F

I

RED/WHT

1

25

SPIN

RED/WH7

RE

G

SV

20

BRN/BLU

`

REDIWHT

RED/WHT

1

L4INJ

CVL6INJI

BRN

CHE

CYL

0

02HTGGRNOI

13

I

BATTERY]

26

RED

NCA

1

27

WH7/GRN

BRN

I

pCTIVAT

GROUND

I

14

I

o28

BRN/ORG

RIDIWHT

RED/WHT

15

CYLIIGN

COIL]

29

BLK/WHT

NCA

16

CYL31GN

COIL]

30

BLKIVEL

GROUND]

34

BR`

N

I

GROUND

I

32

BR~

N~

"

BRN

.

WHT/YEL

17

I

CYL51NJI

33

BRN/GRN

WHT]

I

GROUND)

44

BRN

.

BRN/ORG

GRV/YEL

18

]

35

BRN/GRN

BRN

BRN

I

ACTIVATERELAY

1

.

I

CRNKSHFTRPM

136

BLK

BLK

2,1

I

CYLIIGN

COIL]

31

BLKIGRN

YEL

21

ROUND138

NCA

G

]

I

GROUND]

39

DRY/SRN

I

GROUND

40

BRN/BLK

.

BLK

4

I

GROUND]

41

NCA

RED/WHT

3

I

GRE

OUNOI

42

BRN

1'E

CAMSHAFTPOSI

43

BRN

BRN/ORG

1

VOLTSUPPLYI

44

RED/GRN

HOTFILMAIR

]

THROTTLEPOSI

45

WHT/GRY/YEL

MASSMETER

I

FUELCONSI

46

GRN/RED

I

46

YEL

MODULE

(DME)

HOTAT

ALLTIMES

T

.

.-

171

,

71

,

17

,

171

,

711

[Tilu

IV]

1

-

1

G125

1

.

CVL1

CYL2

CYL3

CYL4

CVLS

CYL6

IDLESPEED

FUELTANK

CONTROL

PRESSURE

VALVE

SENSOR

IGNITION

COILS

FRO_NT_POWWE_RD_IST_RI_BU_TIO_NB_0%_________________

rENGINE

CONTROLMODULE

RELAY

CVL1-6FUEL

PUMP

RELAY

THROTTLE

IHTAKEAIR

POSITION

TEMPERATURESENSOR

SENSOR

G

~

r

___

I

WHT/6LK

21~I

I

I

I

GRN/RED

I

I

BRN/YEL

17,

I

I

I

I

%

;7

L__J

INSTRUMENT

31

4

:1

BI

>I.1

.1

3

1211

I

GRV/BRN

-1

I

DUALTEMPERA7URESENSOR

(C00

TEMPERATURE)

1~

2

TEMPERAT

RE)