Reverse lights BMW 318i 1997 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 318i, Model: BMW 318i 1997 E36Pages: 759

Page 141 of 759

2

.

Remove

cooling

duct

or

terminal

cover

from

rear

of

al-

2

.

Remove

air

cleaner

upper

section

with

mass

air

flow

ternator

.

sensor

.

3

.

Check

for

battery

voltage

between

ground

and

terminal

3

.

Remove

terminal

cover

from

rear

of

alternator

.

Discon

B+

at

back

of

alternator

.

Then

turn

ignition

on

and

nect

wiring

.

check

for

battery

voltage

between

terminal

D+

and

ground

.

See

Fig

.

3

.

lf

voltage

is

not

present

at

either

4

.

Remove

drive

belt

from

alternator

pulley

.

See

020

point,

check

wiring

for

faults

.

Maintenance

program

.

001

¡987

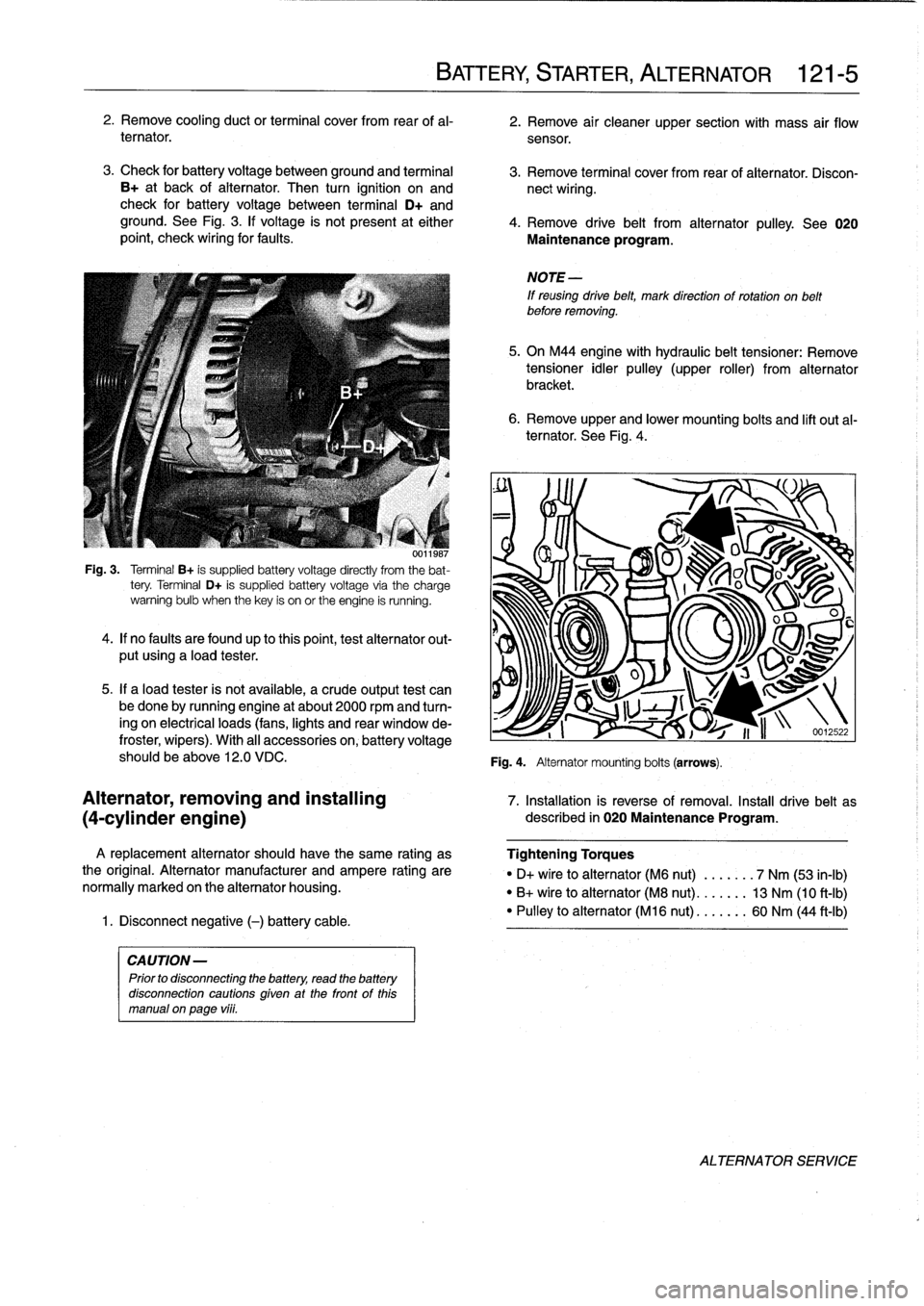

Fig

.

3

.

Terminal

B+

is

supplied

battery

voltage

directly

from

the

bat-

tery

.

Terminal

D+

is

supplied

battery

voltage

via

the

charge

warning

bulb

when

thekey

is

on

or

the

engine

is

running

.

4

.

lf

no

faults

are

foundup

to

thispoint,test

alternator

out-

put

using

a

load

tester

.

5

.

If

a

load

tester

is

not

available,

a

crude

output

test

can

be

done

by

running

engine

at

about

2000

rpmand

turn-

ing

on

electrical

loads

(fans,

lights

and

rear

window

de-

froster,

wipers)

.

With

al¡

accessories

on,

battery

voltage

should

be

above

12

.0

VDC

.

A

replacement

alternator

should

have

the

same

rating

as

the

original

.

Alternator

manufacturer

and

ampere

rating

are

normally

marked

on

the

alternator

housing

.

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

BATTERY,

STARTER,

ALTERNATOR

121-

5

6

.

Remove

upper

and

lower

mounting

bolts

and

lift

out

al-

ternator

.

See

Fig

.

4

.

NOTE

-

If

reusing

drive

belt,

mark

direction

of

rotation

on

belt

before

removing

.

5

.

On

M44

engine

with

hydraulic

belt

tensioner

:

Remove

tensioner

idler

pulley

(upper

roller)

from

alternator

bracket

.

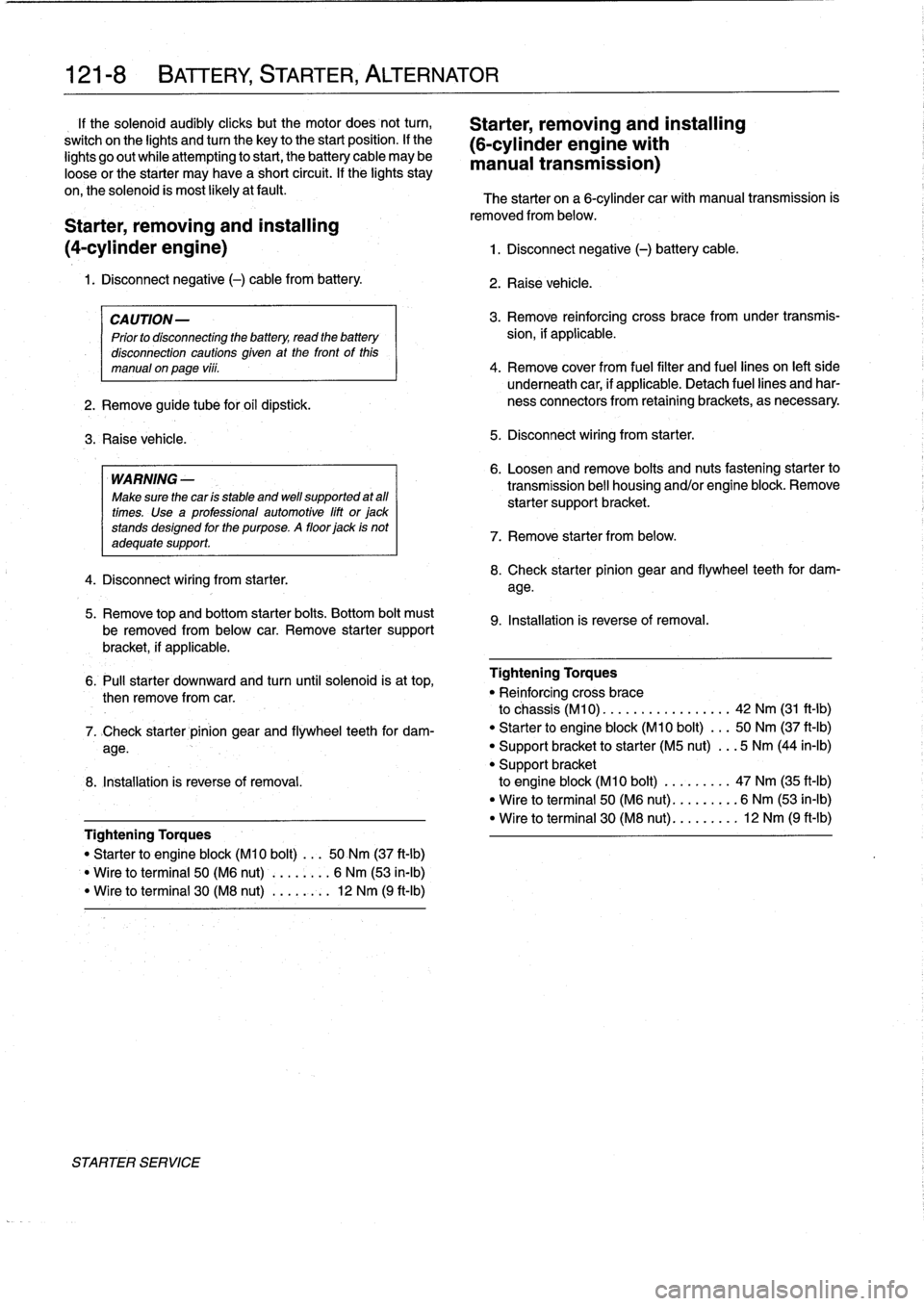

Fig

.

4

.

Alternator

mounting

bolts

(arrows)

.

O

u

J

S

v~~

U

I

1

i

n

-12

.22

Alternator,

removing

and

installing

7

.

Installation

is

reverse

of

removal

.

Install

drive

belt

as

(4-cylinder

engine)

described

in

020

Maintenance

Program

.

Tightening

Torques

"

D+

vire

to

alternator

(M6

nut)

.

...

.

.

.

7

Nm

(53

in-lb)

"

B+

wire

to

alternator

(M8

nut)

..

.

.

.

.

.

13

Nm

(10

ft-Ib)

"

Pulley

to

alternator

(M16

nut)

...

..

..

60

Nm

(44

ft-Ib)

ALTERNATOR

SERVICE

Page 144 of 759

121-

8

BATTERY,

STARTER,

ALTERNATOR

1f

the

solenoid

audibly

cliicks

but

the

motor

does

not

turn,

Starter,

removing

and

installing

switch

on

the

lights

andtum

the

key

to

the

start

position

.

lf

the

(6-cylinder

engine

with

lights

go

out

while

attempting

to

start,

the

battery

cable

may

be

manual

transmission)

loose

or

the

starter

may

have

a

short

circuit

.

If

the

lights

stay

on,the

solenoid

is

most

likely

atfault

.

The

starter

on

a

6-cylinder

car

with

manual

transmission

is

Starter,

removing

and

installing

(4-cylinder

engine)

1

.

Disconnect

negative

(-)

battery

cable

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Remove

guide

tube

for

oil

dipstick

.

3

.

Raise

vehicle

.

WARNING

-

Make

sure

the

car

ís

stable

and

wefl

supported

at

all

times

.

Use

a

professional

automotive

lift

or

jack

stands

designed

forthe

purpose

.

A

floor

jack

is

not

adequate

support

.

4

.

Disconnect

wiring

from

starter

.

5

.

Remove

top

and

bottom

starter

bolts

.

Bottom

bolt

must

be

removed

from

below

car

.

Remove

starter

support

bracket,

if

applicable

.

removed

from

below

.

2

.

Raise

vehicle

.

3

.

Remove

reinforcing

cross

bracefromunder

transmís-

sion,

if

applicable

.

4

.

Remove

cover

from

fuel

filter

and

fuel

lines

on

left

side

underneath

car,

if

applicable

.

Detach

fuel

lines

and

har-

ness

connectors

from

retainingbrackets,

as

necessary

5

.

Disconnect

wiring

from

starter

.

6

.

Loosen

andremove

bolts

and

nuts

fastening

starter

to

transmission

bell

housing

and/or

engine

block

.

Remove

starter

supportbracket

.

7

.

Remove

starter

from

below

.

8

.

Check

starter

pinion

gear

and

flywheel

teeth

for

dam-

age

.

9

.

Installation

is

reverse

of

removal

.

6

.

Pull

starter

downward

and

turn

until

solenoid

is

at

top,

Tightening

Torques

then

remove

from

car

.

"

Re¡

nforcing

cross

brace

to

chassis

(M10)

..

...............

42

Nm

(31

ft-Ib)

7

.

>Check

starter

pinion

gear

and

flywheel

teeth

for

dam-

"

Starter

to

engine

block

(M10

bolt)

...

50

Nm

(37

ft-Ib)

age

.

"

Support

bracket

to

starter

(M5

nut)

...

5

Nm

(44

in-lb)

"

Support

bracket

8

.

Installation

is

reverse

of

removal

.

to

engine

block

(M10

bolt)

.........

47

Nm

(35

ft-Ib)

"

Wire

to

terminal

50

(M6

nut)

.........

6

Nm

(53

ín-Ib)

"

Wire

to

terminal

30

(M8

nut)

.........

12

Nm

(9

ft-lb)

Tightening

Torques

"

Starter

to

engine

block

(M10

bolt)

...

50

Nm

(37

ft-lb)

Wire

to

terminal

50

(M6

nut)

........

6

Nm

(53

in-lb)

"

Wire

toterminal

30

(M8

nut)

...

,

..:.

12

Nm

(9

ft-Ib)

STARTER

SERVICE

Page 329 of 759

BMW

emblem,

removing

and

installing

The

procedure

given

below

applies

to

both

front

and

rear

emblems

.

1

.

Wrap

and

of

a

screwdriver

with

tape

.

CAUTION-

Protect

hood

paint

by

coveringarea

aroundem-

blem

with

tape

.

2

.

Carefully

pryout

emblem

.

See

Fig

.

15

.

UVI1'¿.

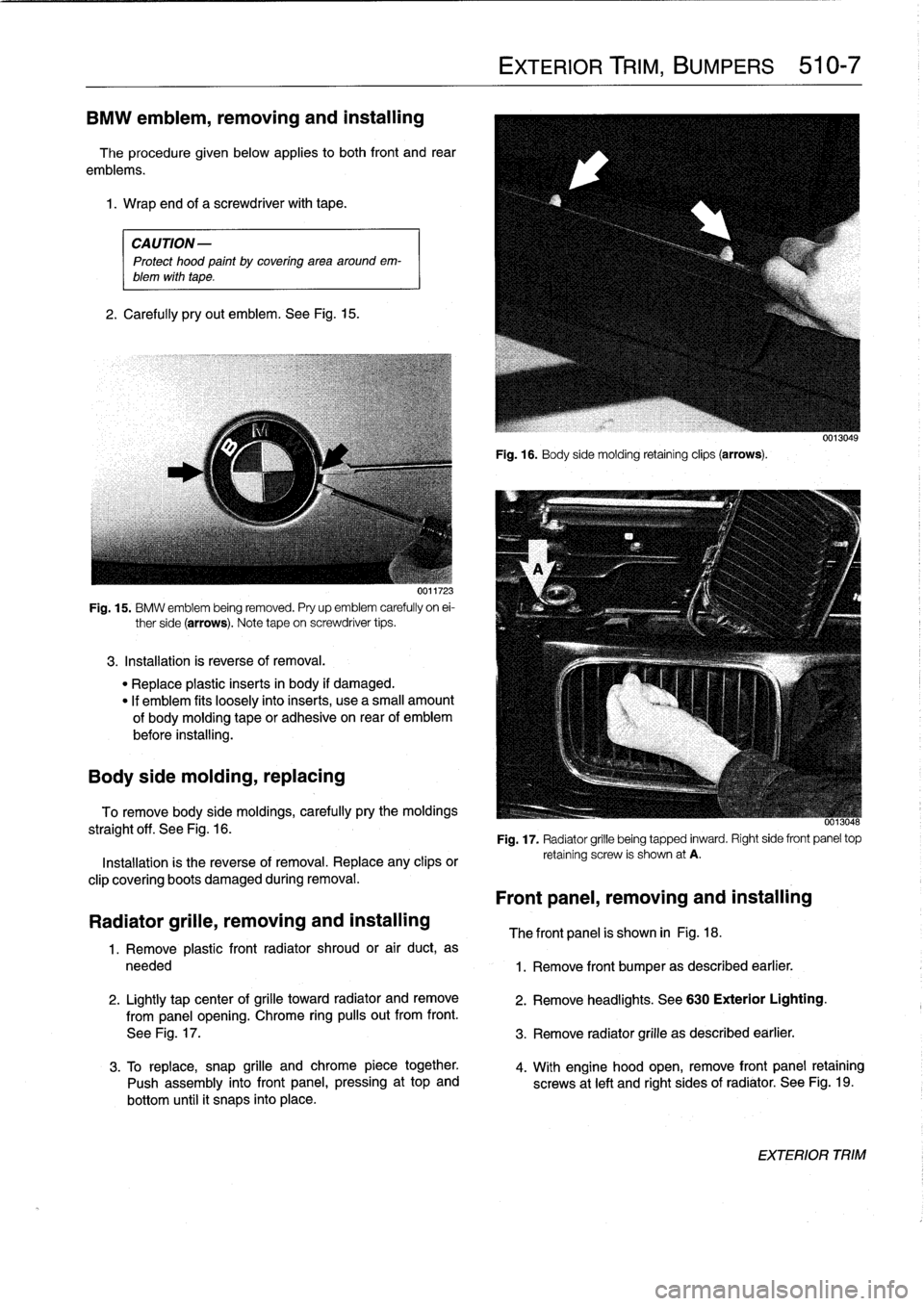

Fig

.

15

.

BMW

emblem

being

removed

.

Pry

up

emblem

carefully

on

ei-

ther

side

(arrows)

.

Note

tape

on

screwdriver

tips

.

3

.

Installation

is

reverse

of

removal

.

"

Replace

plastic

inserts

in

body

if

damaged

.

"

If

emblem

fits

loosely

intoinserts,

use

a

small

amount

of

bodymoldingtape

or

adhesiva

on

rear

of

emblem

before

installing

.

Body

side

molding,

replacing

To

remove

body

side

moldings,

carefully

pry

the

moldings

straight

off

.

See

Fig

.

16

.

Installation

is

the

reverse

of

removal

.

Replace

any

clips

or

clip

covering

boots

damaged

during

removal

.

Radiator

grille,

removing

and

installing

1

.

Remove

plastic

front

radiator

shroud

or

air

duct,

as

needed

2

.

Lightly

tap

center

of

grilla

toward

radiator

andremove

from

panel

opening

.

Chrome

ring

pulís

out

from

front

.

See

Fig

.

17

.

3

.

To

replace,

snap

grille

andchrome

piece

together

.

Push

assembly

into

front

panel,

pressing

at

top

and

bottom

until

it

snaps

into

place

.

EXTERIOR

TRIM,

BUMPERS

510-7

Fig

.

16

.

Body

sida

molding

retainingclips

(arrows)

.

-

0013048

Fig

.

17

.

Radiator

grille

being

tapped

inward

.

Right

side

front

panel

top

retaining

screw

is

shown

at

A

.

Front

panel,

removing

and

installing

The

front

panel

is

shown

in

Fig

.

18

.

1

.

Remove

front

bumper

as

described

earlier

.

2

.

Remove

headlights

.

See

630

Exterior

Lighting

.

3

.

Remove

radiator

grille

as

described

earlier

.

4

.

With

engine

hood

open,

remove

front

panel

retaining

screws

at

left

and

right

sides

of

radiator

.

See

Fig

.

19

.

EXTERIOR

TRIM

Page 433 of 759

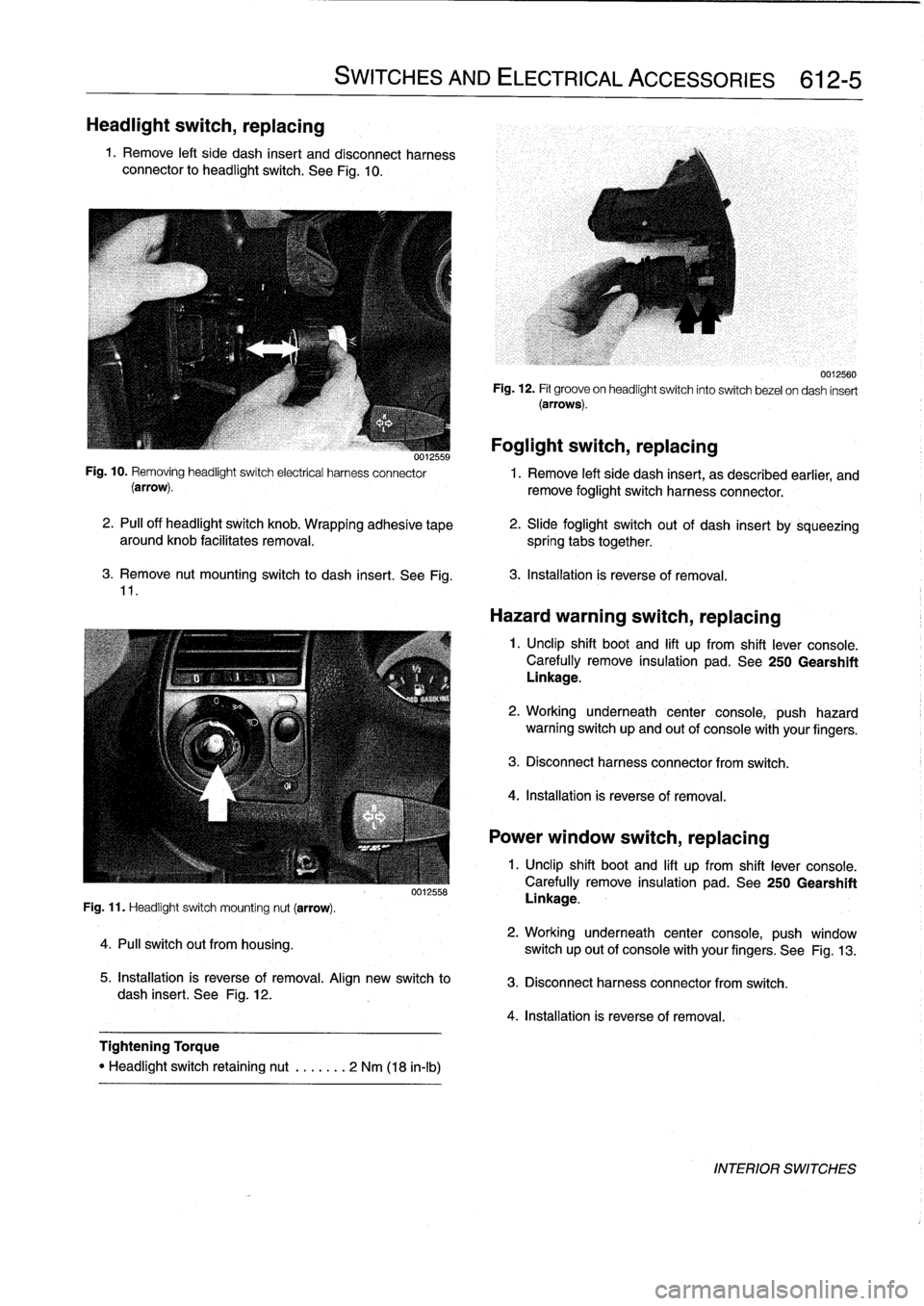

Headlight

switch,

replacing

1

.

Remove

left

side

dash

insert

and

disconnect

harness

connector

to

headlight

switch

.

See

Fig

.

10

.

3

.

Remove

nut

mounting

switch

to

dash

insert

.

See

Fig

.

11

.

Fig

.

11

.

Headlight

switch

mounting

nut

(arrow)

.

4

.

Pull

switch

out

from

housing

.

SWITCHES

AND

ELECTRICAL

ACCESSORIES

612-5

0012558

5

.

Installation

is

reverse

of

removal

.

Align

new

switch

to

dash

insert

.

See

Fig

.

12

.

Tightening

Torque

"

Headlight

switch

retaining

nut

.

......

2

Nm

(18

in-lb)

Foglight

switch,

replacing

0012559

Fig

.

10

.

Removing

headlightswitch

electrical

harness

connector

1

.

Remove

left

side

dash

insert,

as

described

earlier,

and

(arrow)

.

remove

foglight

switch

harness

connector

.

2

.

PA

off

headlight

switch

knob

.

Wrapping

adhesive

tape

aroundknob

facilitates

removal

.

spring

tabs

together

.

0012560

Fig

.

12

.

Fit

groove

on

headlightswitch

into

switch

bezel

ondash

insert

(arrows)

.

2

.

Slide

foglight

switch

out

of

dash

insert

by

sqúeezing

3

.

Installation

is

reverse

of

removal

.

Hazard

warning

switch,

replacing

1

.

Unclip

shift

boot

and

lift

up

from

shift

lever

console

.

Carefully

remove

insulation

pad

.

See

250

Gearshift

Linkage

.

2

.

Working

underneath

center

console,

push

hazard

warning

switch

up

and

out

of

console

with

your

fingers

.

3

.

Disconnect

harness

connector

from

switch

.

4

.

Installation

is

reverse

of

removal

.

Power

window

switch,

replacing

1

.

Unclip

shift

boot

and

lift

up

from

shift

lever

console

.

Carefully

remove

insulation

pad

.

See250

Gearshift

Linkage

.

2

.

Working

underneath

center

console,

push

window

switch

up

out

of

console

with

your

fingers

.

See

Fig

.

13

.

3

.

Disconnect

harness

connector

from

switch

.

4

.

Installation

is

reverse

of

removal

.

INTERIOR

SWITCHES

Page 434 of 759

612-6

SWITCHES

AND

ELECTRICAL

ACCESSORIES

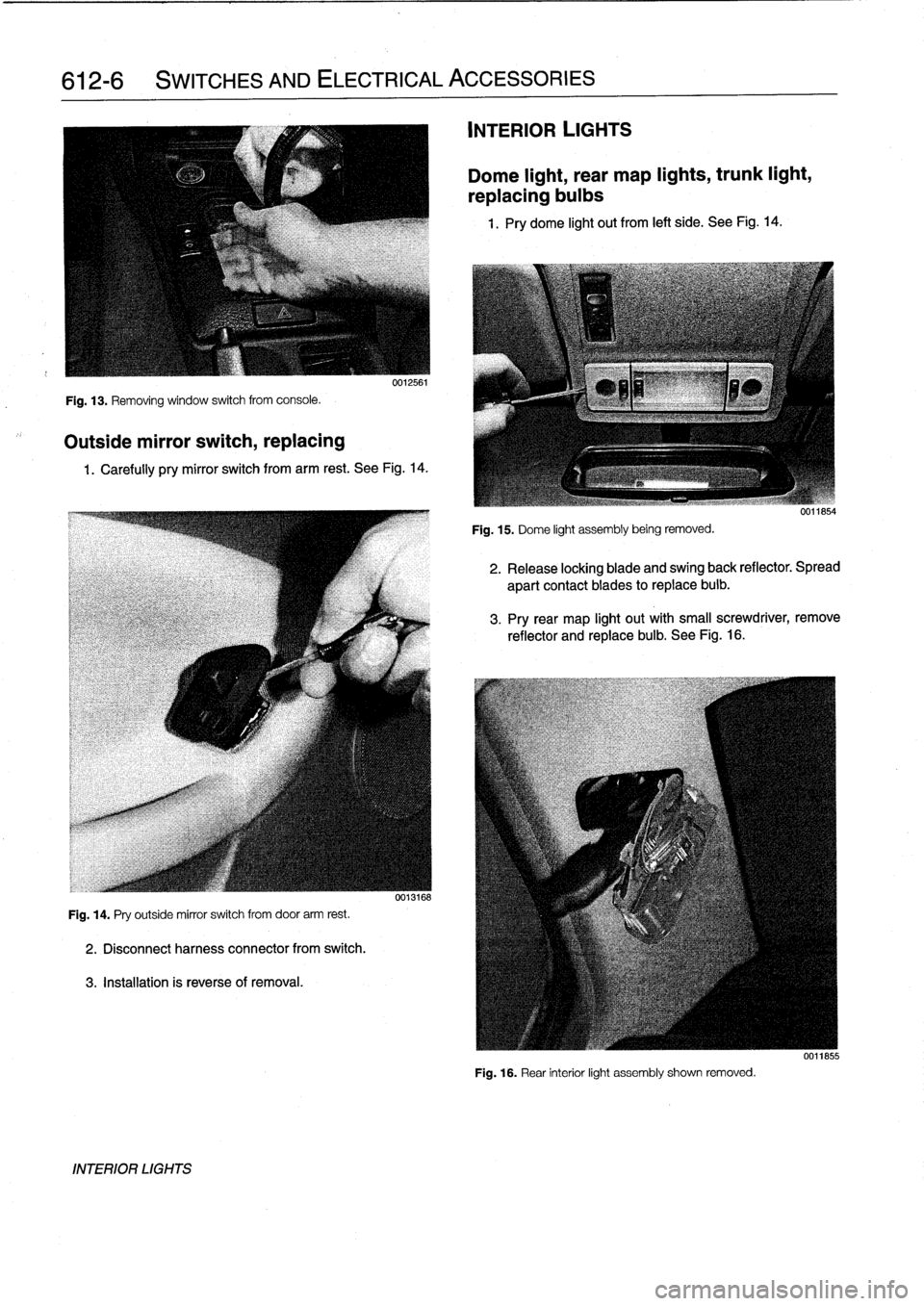

Fig

.

13

.

Removing

window

switch

from

console

.

Outside

mirror

switch,

replacing

0012561

1

.

Carefully

pry

mirror

switch

from

arm

rest

.

See

Fig

.

14

.

Fig

.

14

.

Pry

outside

mirror

switch

from

door

arm

rest

.

2

.

Disconnectharness

connector

from

switch

.

3

.

Installation

is

reverseof

removal

.

INTERIOR

LIGHTS

0013168

INTERIOR

LIGHTS

Dome

light,

rear

map

lights,

trunk

light,

replacing

bulbs

1

.

Pry

dome

light

out

from

left

side

.

See

Fig

.

14

.

Fig

.

15

.

Dome

light

assembly

being

removed

.

2

.

Release

locking

blade

and

swing

back

reflector

.

Spread

apart

contact

blades

toreplace

buib

.

3

.

Pry

rear

map

light

out

with

small

screwdriver,

remove

reflector

and

replace

bulb

.

See

Fig

.

16

.

Fig

.

16

.

Rear

interior

light

assembly

shown

removed

.

0011855

Page 438 of 759

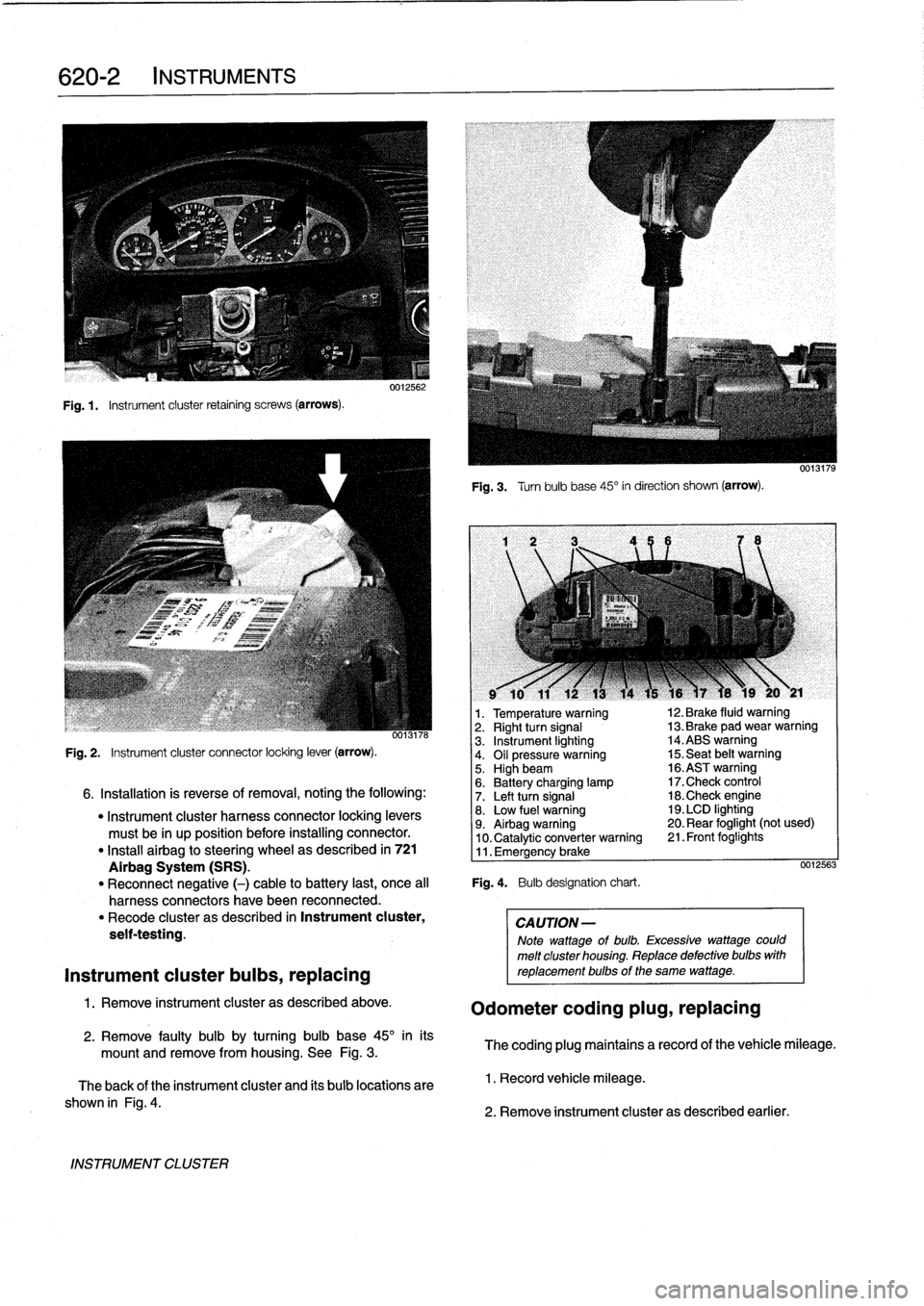

620-2

INSTRUMENTS

Fig

.1.

Instrument

cluster

retaining

screws

(arrows)

.

INSTRUMENT

CLUSTER

0012562

Fig

.

3

.

Turnbulb

base

45°

in

direction

shown

(arrow)

.

l

v

w

r

v

9

10

11

12

13

14

15

16

)7

18

19

20

y

21

1

.

Temperature

warning

12

.

Brake

fluid

warning

oo13n6

2

.

Right

turn

signal

13

.

Brake

pad

wear

warning

3

.

Instrument

lighting

14

.ABS

warning

Fig

.

2

.

Instrument

cluster

connector

locking

lever

(arrow)

.

4

.

Oil

pressure

warning

15

.

Seat

belt

warning5

.

Highbeam

16

.ASTwarning

6

.

Battery

charging

lamp

17

.Check

control

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

7

.

Left

turn

signal

18

.Check

engine

"

Instrument

cluster

harness

connector

locking

levers

8

.

Low

fuel

warning

19

.

LCD

lighting

must

be

in

up

position

before

installing

connector

.

9

.

Airbag

warning

20

.

Rear

foglight

(not

used)

10

.

Catalytic

converter

warning

21

.

Front

foglights

"

Install

airbag

to

steering

wheel

as

described

in

721

11

.

Emergency

brake

Airbag

System

(SRS)

.

0012563

"

Reconnect

negative

(-)

cable

to

battery

last,

once

al¡

Fig

.

4

.

Bulb

designation

chart

.

harness

connectors

have

been

reconnected

.

"

Recode

cluster

as

described

in

Instrument

cluster,

CAUTION-

seif-testing

.

Note

wattage

of

bulb

.

Excessive

wattage

could

melt

cluster

housing

.

Replace

defective

bulbs

with

Instrument

cluster

bulbs,

replacing

reptacementbulbs

of

the

same

wattage

.

1

.

Remove

instrument

cluster

as

described

above

.

Odometer

coding

plug,

replacing

2

.

Remove

faulty

bulb

by

turning

bulb

base

45°

inits

mount

and

remove

from

housing

.

See

Fig

.

3

.

The

coding

plug

maintains

a

record

of

thevehicle

mileage

.

The

back

of

the

instrument

cluster

and

its

bulb

locations

are

1

.

Record

vehicle

mileage

.

shown

in

Fig

.

4

.

2

.

Remove

instrument

cluster

as

described

earlier

.

Page 441 of 759

FRONT

LIGHTING

.

...........

.

....

.

.

.

.

630-1

Headlight

buib,

replacing

............

.

.

.

.

630-1

Headlight

assembly,

removing

and

installing

.......

.

....

.

.

.

.

630-2

Foglight

assembly,

removing

and

installing

..

630-3

Front

turn

signal

assembly,

removing

and

installing

.....

.

.

.

........

630-4

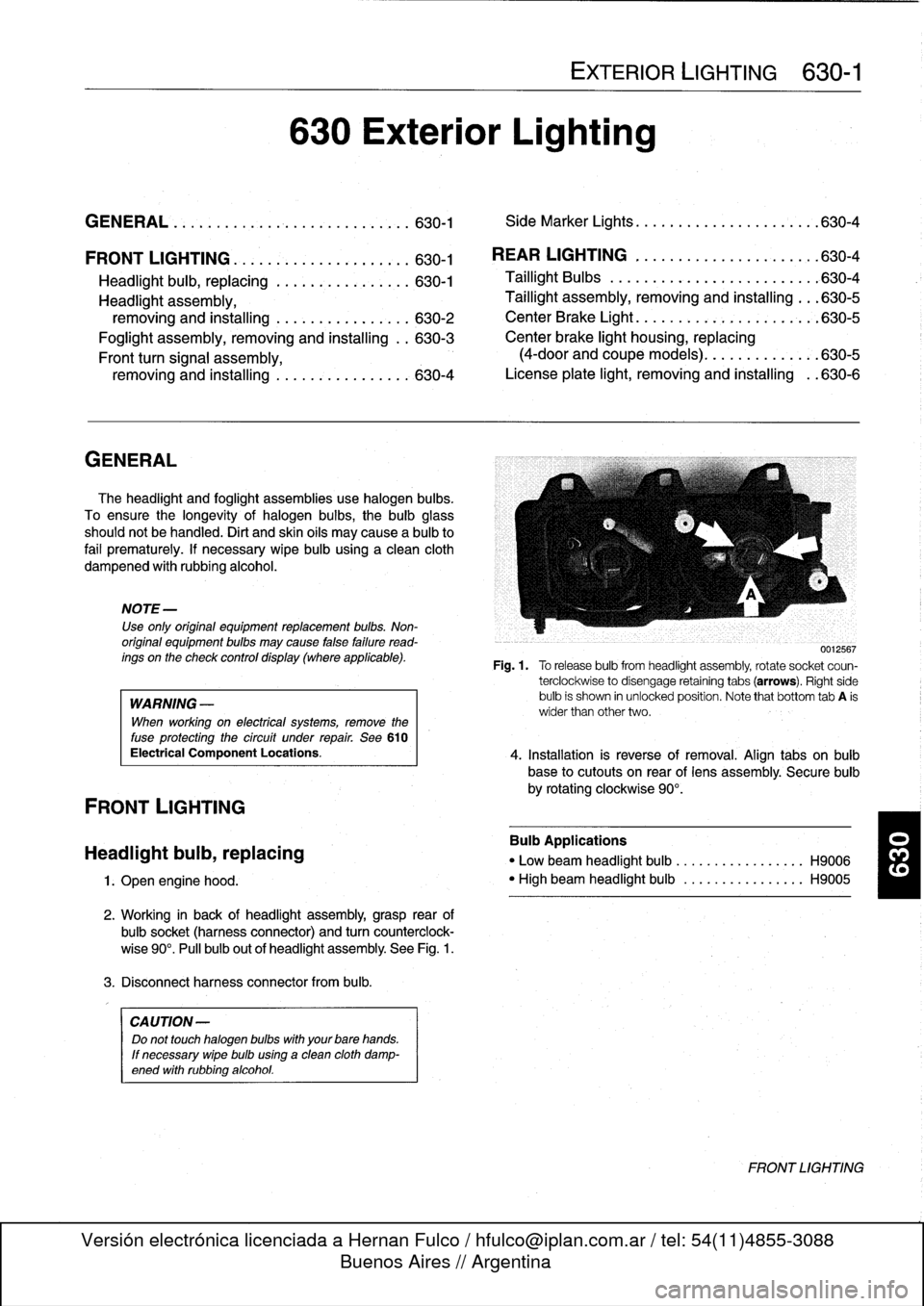

GENERAL

The

headlight

and

foglight

assemblies

usehalogen

bulbs

.

To

ensure

the

longevity

of

halogen

bulbs,

the

bulb

glass

should

not

be

handied

.

Dirt

and

skin

oíls

may

cause

a

bulbto

fail

prematurely

.

If

necessarywipe

bulb

using

a

clean

cloth

dampened

with

rubbing

alcohol

.

NOTE-

Use

only

original

equipment

replacement

bulbs

.

Non-

original

equipment

bulbs

may

cause

false

failure

read-

ings

on

the

check

control

display

(where

applicable)

.

WARNING

-

INhenworking

on

electrical

systems,

remove

the

fuse

protecting

the

circuit

under

repair

.

See

610

Electrical

Component

Locations

.

FRONT

LIGHTING

Headlight

bulb,

replacing

1

.

Open

engine

hood

.

2

.

Working

in

back

of

headlight

assembly,grasp

rear

of

bulbsocket

(harnessconnector)

and

turn

counterclock-

wise

90°

.

Pull

bulb

out

of

headlight

assembly

.

See

Fig

.

1

.

3

.

Disconnect

harness

connector

from

bulb

.

CA

UTION-

Do

not

touch

halogen

bubs

with

yourbare

hands

.

If

necessary

wipe

bulb

using

a

clean

cloth

damp-

ened

with

rubbing

alcohol

.

630

Exterior

Lighting

EXTERIOR

LIGHTING

630-1

GENERAL

.

.

.

.

...

.

................

.

.

.

.

630-1

Side

Marker

Lights

.......

.

.

.

.

.

.......

.

..

630-4

REAR

LIGHTING

.

......

.

.

.

.

.

.

.

...

.

.

.

..

630-4

Taillight

Bulbs

..........

.

.

.

.

.

.....

.

.

.

.

.

630-4

Taillight

assembly,

removing

and

installing

.

.

.

630-5

CenterBrake

Light

.......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

630-5

Center

brake

light

housing,

replacing

(4-door

and

coupe

models)

.

.

.

.

.......

.

.

.630-5

License

plate

light,

removingand

installing

.

.630-6

0012567

Fig

.1.

Torelease

bulbfrom

headlight

assembly,

rotate

socket

coun-

terclockwise

to

disengage

retaining

tabs

(arrows)

.

Right

side

bulb

is

shown

in

unlocked

position

.

Note

that

bottom

tab

A

is

wider

than

other

two

.

4

.

Installation

is

reverse

of

removal

.

Align

tabs

on

bulb

base

to

cutouts

on

rear

of

lens

assembly

.

Secure

bulb

by

rotating

clockwise

90°

.

Bulb

Applications

"

Low

beam

headlight

bulb

...

.

..

..

.........

H9006

"

High

beam

headlight

bulb

..

.

..

..

.........

H9005

FRONT

LIGHTING

Page 580 of 759

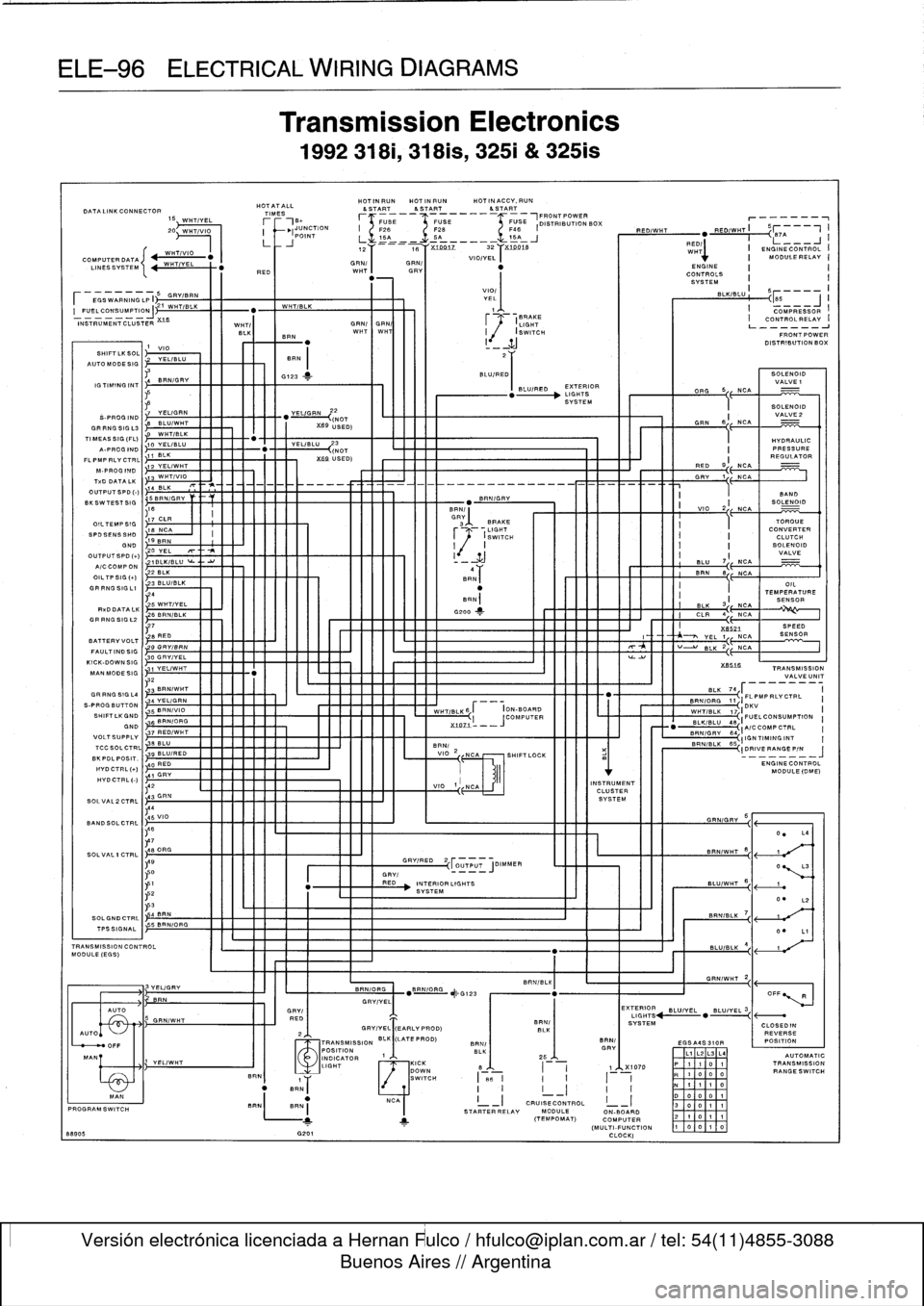

ELE-96

ELECTRICAL

WIRING

DIAGRAMS

DATA

LINK

CONNECTOR

WHT/1110

COMPUTER

DATA

~~

LINES

SYSTEM

W

H

7VEL

~~

1

6

GRV/B

RN

EGS

WARNING

LP

I~

I_

_

__

HT

S

1K

FUELCONSUMPTION

21

W

INSTRUMENTCLUSTER

X16

BRN

-

1

VIO

SHIFT

LK

SOL

VEL/BLU

BRN

AUTOMODE

SIG

~,3

4

BR

1

N/GRV

G123

4-

IG

TIMING

IN

T

VALVE1

LIGHTS

BLU/RED

DR

ORG

5

NCA

I

SYSTEM

S-FROG

IND

7

YELIGRN

"

VEL/GRN

22

SOLENOID

VALVE2

GR

NOT

RNGSIGL3

9

BLU/WHT

-XK

USED)

GRN

6

I

NCA

TIM

EASSIG(FL)

WH7/BLK

I

B

-PROGIND

((NOT

10

YEL/BLU

A

"

VEL/BLU

23

I

PRESSURE

FL

PMPFLY

CTRL

11

ELK

%69

USED)

I

REGULATOR

M-PROGIND

12

YELIWHT

RED

9

NCAT%DDATA

LK

13

WHTIVIO

GRY

1

NCA

14

BLK

Do

TPUT

BPD

(-I

I

BAND

5BRNIGRV

BRNIGRY

KSWTESTSIG

"

I

I

SOLENOID

SW

1

I

BRN/I

110

2

NCA

)176

CLR

GRY'

OILTEMPSIG

8

BRAKE

I

I

TOROUE

S

PDSENSSHD

16

NCA

r

LIGHT

I

CONVERTER

~

(ITCH

I

C

LUTON

19

BR

N

GND

I

I

I

I

SOLENOID

OUTPUTSPD(+)

20V

EL

T

y1

I

-

ZJ

I

I

VALVE

P/COOMPON

1BLK/BLU~-

-

BLU

7

NCA

22

ELK

BR

`N

8

NOA

OILTPSIG(+)

BRN

I

3

BLUIBLK

I

OIL

GRRNGSIGLI

"

TEMPERATURE

4

I

BRNI

RxDDATALK

~6WHT/VEL

1

BLK

3I

NCA

S

ENSOR

6

BRN/BLK

G200

-

I

CLR

4

NCAGR

RNG

SIG

L2

1

,27

I

xIiS21

SPEED

1

I

~~

NCASENSOR

BATTERY

VOLT

B

RED

YE

L

1

FAULTINDBIG

9GRV/B

RN

-v

BLK

2

NLA

0

GRV/VEL

3

ICK-DO

W

N

SIG

1

VEL/WH7

"511

TRANSMISSION

WHT/

BLK

Transmission

Electronics

1992

3181,

318is,

3251

&

325is

HOTATALL

TIMES

r

_JFRONTPOWER

r_

__

__

_1

_,

B+

FUBE

FUSE

FUSE

DISTRIBUTION

BOX

'

JUNCTION

I

F26

F28

F48

I

L

L

161L

--

121l

16-J

RED/WHT

RED

"

RED/WHT

"

167q

3z

xi

.DOiB

{L

_CON7R

__

J

I

6

xiDD-tz

WHT

I

ENGINEOL

I

VIO/VEL

I

MODULERELAY

I

GRN/

OR

./

SYSTEM

RED

I

WHT

GRYI

"

ENGINE

I

I

"

~

CONTROLS

I

I

YSTEM

{5

___J

I

HOTINRUN

HOT

IN

SUN

HOT

IN

ACCV,RUN

&START

&51ART

&START

K

MAN

MODESIG

"

VALVE

UNIT

~

J

32

3BR

.IW

.T

BLK

74

GO

RNG

BIGL4f

ION-BOARD

FLPT

MPRLYCTRL

S-PROGBUTTON

4

VEL/GRN

5BRN/VID

WHT/BLK6'

ION-BOARD

B

W

RN/HT/

OB

R

L

G

K

1117IDKV

I

SHIFTLKGND

COMPUTER

FUELCONSUMPTION

GND

68RNIOMG

X1D

Zt

I

__J

"

--

BLKIBL

U

48

VOLTSUPPLV

OMPCTRL

I

37

RED/WHT

BRN/GRV

64

I

TCCSOLCTRL

6BLU

2

BR

IDRNVERANGEP/N

I

BRN/

SKPDLPOSIT

.

.

9

BLU/RED

VIO

NCA

SHIFTLOCK

II

J

HVO

CTRL

(+)

ENGINE

CONTROL

F

M

MODULE(0E)HVD

CTRL(-)

INSTRUMENT

CLUSTER

SYSTEM

0

RED

41

GRY

I

,42

VIO

1I

NCA

SOLVAL2CTRL

43

GRN

'44/45

VIO

VID/

E

~~~

1I1

..

L

BRAKE

(

LIGHT

I

(SWITCH

!

_

ZJ

2

T

EO

BLU/R

BLK/BLU

BANDSOLCTRL

,

-

'46'vi78

DR.

SOLVAL

1

CTRL

14

_

g

GRY/RED

2

r

J

(OUTPUT

DINNER

t0

GRV/51

I

RED

INTERIORLIGHTS

12

SYSTEM

Y53

SOLGNDCTRL14

SRN

TPSSIGNAL

5BRNIORG

TRANSMISSION

CONTROL

"

BLU/BLK

MODULE

LEGS)

GRNIGRY

BRN/WHT

9

0

BLU/

E

14

BRNI

I

COMPRESSOR

I

CONTROLRELAV

I

FRONTPOWER

DISTRIBUTION

BOX

SOLENOID

BRN/6LKI

GRNIWHT

2

BRNIORG

"

BRN/ORG

J~G7-

3

"

OFFGRV/VE

'I

L

RE

.'

E%LEGHOS,'

BLU/VEL

"

BLU/YEL

BRN/

SYSTEM

CLOSEDIN

GRV/VEL~(EARLV

PROD)

BLK

R

REVERSE

SMISS

BLK

(LATEPROD)

TRAN

ON

BRN/

EGSA4S310R

POSITION

I

BRN/POSITION

GRY

ELK

1

I

L1

L2

L3

L4

AUTOMATIC

INDICATOR

25

I

r

LIGHT

KICK

P

11

0

1

TRANSMISSION

DOWN

8

II

1

X1070

R

10

00

RANGESWITCH

.ONI

1

SWITCH

I

e6

I

I

I

I

I1

"

BRN

I

I

I)

I

11

0

I

-

MAN

I

"

NCA

I)

CRUISE

CONTROL

II

D

00

D

1

-

_

BRN

B

3

0011

PROGRAM

SWITCH

RNI

STARTER

RELAY

MODULE

ON-BOARD

2

1

0

1

1

1

(TEMPOMA7)

COMPUTER

(M

-A

L

ULTI-FUNCTION

100

10

88905

G201

OLOOKI

Page 581 of 759

DATA

LINK

CONNECTOR

15

W~

20,

WHT/vI0

COMPUTER

DATA

LINESSVSTEM

WHTT/EEL

I/

15

-GRV/B~RN~

I~

EGS

WARNINGLPI~

I

FUEL

CONSUMPTIO~

21

W=

INTRUMENTCLUTTER

%1RBLK

BRN

1

V

GHIFTLKSOL

VE

IO

L/BLU

BRN

AUTO

MODE

SIG

4

BRN/

GRY

6723

J-

IGTIMING

INT

SOLENOID

VALVE1

BLU/REO

BLD

EXTERIOR

oRG

>s

III(III

111111

(

U/RELIGHTS

SOLE

NOIO

22

"

--

"

-

"

"""

SYSTEM

"

(NOT

I

VALVE2

GRRNGSIGL3

6

BLU/WH7

Xfi9

USED)

GRN

8

NCA

WHT/BLK

BLU/RED(

II

I

1

-~

MEAS

SIG

(FL)

A-PPOGIND

10

YEL/BLU

"

VELIBLU

23

I

HYDRAULIC

I

11

BRN/GRN

n9

(NOT

PRESSURE

FLPMPRLYCTRL

4

USED)

REGULATOR

M-PROGIND

12

VEL/WHT

RED

9

I

NCA

TKD

DATA

LK13

WHT/VIO

GRV

1

NOA

UTPUTSPO(-)

14

BLK

---

----

--

---------

--------

-

-

O

SWTESTSIG

5BRN/GRY

T

"

BRNIGRY

,

1fi

BRN/

I

VI

I

I

III

III

O

I

BAND

BK

SOLEN010

2i,

NCA

17

CLR

OILTEMPSIG

1&

NCASPDSENSSHDGND

1

0S

BRN

2

YEL

III

OUTPUT

SPD

(+)

1BLK/BLU

~-

AID

COMP

ON

22

BLK

OILTPSIG(+)

3B~2

LU/BLK

GRRNG

SIG

L14

~BW

j2

HT/VEL

RxD

DATA

LK

126

BRN/BLK

GRRNGSIGL2

~~

BATTERYVOLT

6R

/

2

ED

FAULTINDSIG

0

G

,2

FY

I

BRN

30

GEV/VEL

KICK-DOWNS

IG

MANMODESIG

I1

V

,3

/u321

~38RN/WHT

GRRNGSIGL4

S-FROG

BUTT

ON

734

VE

}

L/GRN

5

BRN/VIO

SHIFTLKGND

GND

e36

BR~

/

ORG

VOLTSUPPLY

7

R

~3

/

TCCSOLCTRL

l

&

BL

~

UB

B~

LU/RED

BK

PDL

POSIT

.

00

F~

HYD

CTRL

(+)

HVDCTRLI-)

41

G}~

'42

SOLVAL2CTRL

BANDSOLCTRL

'487

SOLVALICTRLI~

~

X49

Ipso

P

3

SOLGNDCTRL

4B/5

RN

TPSSIGNAL

I

5BRNIORG

51

/

P2

WHT/

GRY

3_,~_

_

BRAKE

TORQUE

LIGHT

CONVERTER

r

(SWITCH

CLUTCH

I

SOLENOID

I

_

~J

VALVE

BLU

7{

NCA

4

BRN

&

NCA

BFNj

OIL

TEMPERATUREBRN(

SENSOR

G200

J-

SILK

3

NCA

CLR

4

NCA

XflS21

SPEED

Y-1

NCASENSOR

BLK

2

NCA

X651fi

TRANSMISSIOI

VALVE

UNIT

"

BRNIGRN

1

r

_

-

-

-

SRN/ORG

11

IFLPMPRLVCTRL

I

WHT/BLKSf

ION-BOARD

WHT/BLK

17IDKV

I(

COMPUTER

BLKIBLU

48

I

PUELCONSUMPTION

I

A/CCOMPDT

RL

I

BRNIGRY

B4

II

~

IIGNTIMINGINT

I

BRN(

BRN/BLK

65

T

I

-(ID=IVENMODUE(DME)

VIO

NCA

SHIFTLOC

~

K

VIO

1

(0-a

II

UTPUT

GRVIREO

2

J

DIMMER

1III

rO

_

_

_

GRYT

"

RED

INTERIOR

LIGHTS

SYSTEM

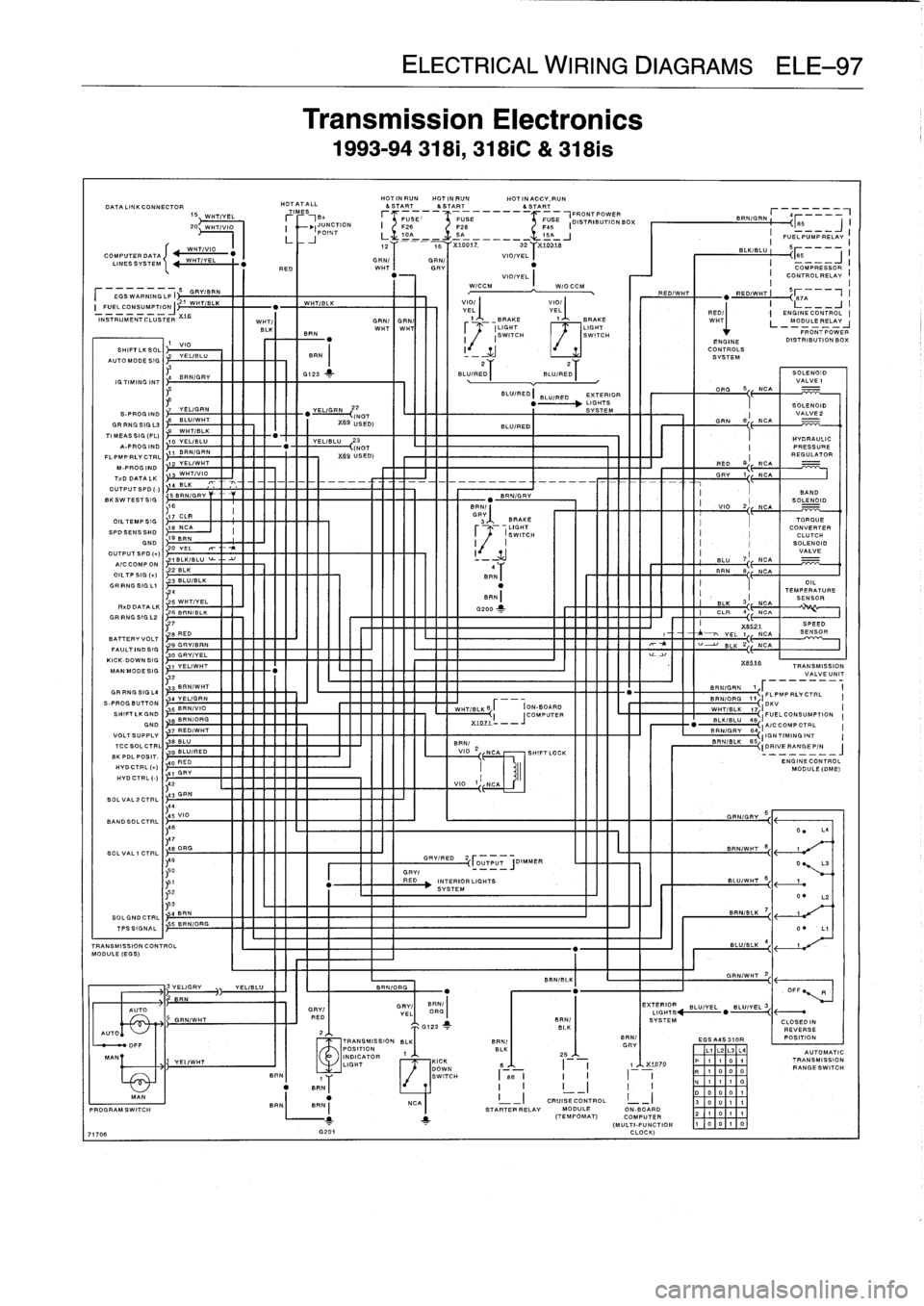

Transmission

Electronics

1993-94

318i,

318iC

&

318is

HOTINRUN

HOT

IN

RUN

HOT

INADDY,

RUNHOTATALL

&START&START&START

TIMES

~-

-

_-

FRONTPOWER

r

-

[

IB+

FS

FUSE

FUSE

F2

F46

DISTRIBUTIQN00X

5

-

BRNIGRN

~

I

PU

O

NICTION

US

E

I

I

F26

8

I

--

I

LJ

L

1

__SA

1

--J

i

FUELPUMPRELAY

"

-

Y

--

-

16

X19077

32

X14416

5

BLK/BLU

I

GRN/I

GRN/

VIO/VELr

r5

--

REO

WHT

GRY

"

I

COMPRESSOR

I

"

1

VIO/VEL

I

i

CONTROLRELAYW

_

/CCM

W/OCCM

,

qED/WHT

_RED/WHT(

S

r_

-

II

VEL

VEL

_

BRAKE

BRAKE

r

(LIGHT

I

I~+

'LIGHT

.

iSWITCH

1

/

WIT(

RE

V

D

I

GYEL1

ORG

BRN(

1

"

BANr

BRNBRN(

1

ELECTRICAL

WIRING

DIAGRAMS

ELE-97

TRANS

MISSIONCONTROL

I

I

BLU/BLK

4

MODULE

(EGS)

BRN/BLK

GRNlWHT

2

VEL/BLU

BRN/ORG

OFF

R

EXTERIOR

BLU/VEL

BLU/YEL

3

LIGHTS,

"

(-~

BRN/

SYSTEM

CLOSEDIN

T

REVERSE

G123

`

BLK

TRANSMISSION

BLKk'/

BRN(

.RN/

EG

POSITION

S

A4S

310R

GRY

POSITION

1

BLK

2B

L7

L2L3

L4

AUTOMATIC

t

INDICATOR

I-

~I

KICK

t

P

11

0

1

TRANSMISSION

B

LIGHT

1

1DOWN

I

I

1

X1974

gANGESWITCHR

1

000

SWITCH

I

&B

I

I

I

I

I'

N

111

0

0

000

1

300

11

2

1

0

111a

o

1

0

I

-I

CRUISE

CONTROL

I

_I

STARTER

RELAY

MODULE

ON-BOARD

1_

(TEMPOMAT)

.

.COMPUTER

(MULTI-FUNCTION

71706

G201

CLOCK)

I

L___JI

RED/I

,I

ENGINE

CONTROL

WHT

MODULERELAY

L_

_j

VIO/j

VIOL

"

67A

-

FRONT

POWER

ENGINE

DISTRIBUTION

BOX

CONTROLS

SYSTEM

Page 582 of 759

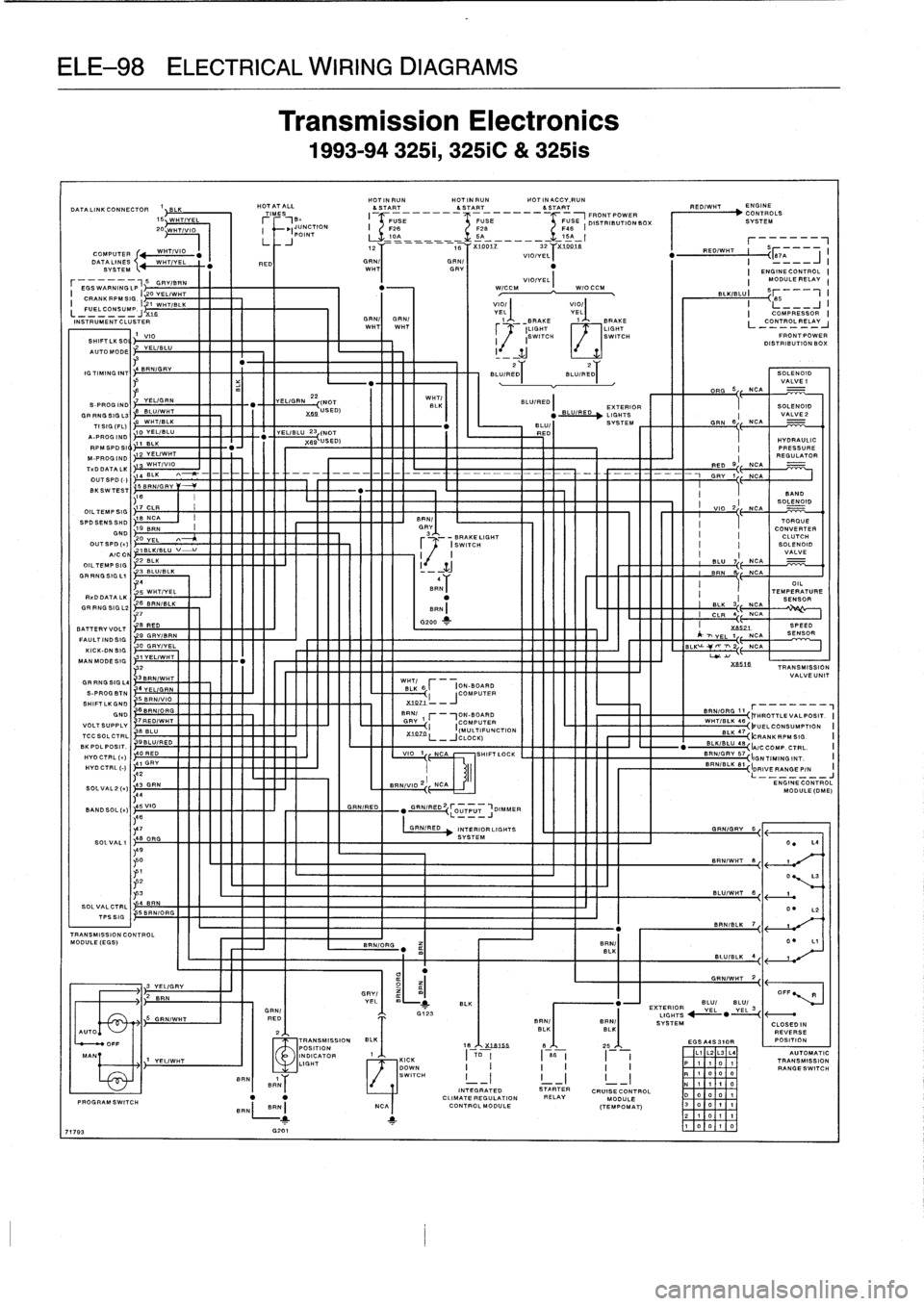

ELE-98

ELECTRICAL

WIRING

DIAGRAMS

DATA

LINK

CONNECTOR

1

5LK

15~

WHT

20

COMPUTER

W,.

HT/VIO

DATA

LINES

WHT/VEL

I

RED

SYSTEM

~,

-------

I

B

GRV/BRN

EGSWARNINGLP

I

120

VEL/WHT

CRANKRPMSIG

I

ELLONSUMPI

1

WHT/BLK

FU

.

L

~

-----j

X1fi

SOLENOID

VALVE

ORG

`'

NCA

BLUIRED

EXTERIOR

SOLENOID

"

BLU/

BD

fLIGHTS

I

VALVE2

BLU/

SYSTEM

GRN6NCA

L/BLU

23

(NOT

RED

xBg{USED)

HYDRAULIC

PRESSURE

M-PROGIND

REGULATOR

T

.

.

DATA

LK13

WHT/VIO

RED

9~

NCA0UTSPD()

14

BLK

n-Ir---

---

------

---

-__----_

-

-

--

----~

GRV

1

NCA

-

5

BRN/GRV

BKSWTEST

16

"

I

BANDSOLENOID

OILTEMPSIG

>17

OLR

I

~

I

VIO

2

I

NCA

SPDSENSGND

19SPIN

CONVERTER

SPROGIND

7

VEL/GRN

-

GRRNGSIGL3

&

BLU/WHT

WHT/BLK

TI

SIG

(FL)10YELI.L

U

APROGIND

-

RPM

SPDSI

I1

BLK

X27

1

SATTERYVOLT

S

RED

FAULTINDSIG

9

GRY/BRN

30

GRV/VEL

KICK-ON

3

1

G

MANMODESIG

1YEL/WHT

w32

OR

PING

SIG

L4

I

3

BRN/WHT

WHTI

r

I

ION-BOARD

S-PROGSTN

S

BVERL

S

GN/VRIO

N

BLK

6

I

COMPUTER

6

HIFT

LK

GNO

X1071

-

-

6BRNIORG

BRN/

BRN/ORG

11

_

GND

7REDIWHT

GRYI-

,ON-BOARD

ON-BOARD

WHTlBLK46ILHROTTLEVALPOSIT,

I

VOLTSUPPLV

I

(COMPUTER

IFUELCONSUMPTION

I

S

BLU

(MULTIFUNCTION

BLK

47

TCCSOL

CTRL

X

"

1-07

.0L

-J

CLOCK)

(CRANK

RPM

SIG

.

I

9BLU/RED

BLK/BLU

48BK

PDL

POSIT

.

"

CIA/C

COMP

.

CTRL

.

I

ORED

VIO

1

NCA

SHIF7LOCK

BRN/GRV67

HVD

CTRL

(+)

BRN/BLK

81

(ION

TIMING

INT

.

I

41

GRY

HVOC7RL(-)

I~

IDRIVERANGEPIN

I

,42

SOLVAL2(a)

43

GRN

,44

BAND

SOL(t)/45VIC

'46I

r7

SOLVALI

48

ORO

SOLVALCTRL

4

BRN

BBRNIORG

TPS

SIG

TRANS

MISSIONCONTROL

MODULE

(EGS)

AUTO+

MANT

OFF

X53

BRN

I

YEL/WHT

HOTATALL

TIMES

JUNCTION

I

(POINT

LLJ

GRN/

EXTERIOR

~

G123

YEL

YEL

3

f

5

GRN/WHT

RED

LIGHTSSRN/BRN/

SYSTEM

CLOSEDIN

2

BLK

BLK

K

EGSA4S310R

16X

.]-B]$-S

6

26

TRANSMISSION

BLPOSITION

REVERSE

POSITION

Transmission

Electronics

1993-94

325i,

325iC

&

3251s

INDICLIGHT

ATOR

HOTINRUNHOTINRUN

HOTINACCY,RUN

&START

&START

&START

RED/WHT

I

-

..

.y111CCC

---

-

-

-

-

-

,,,

1

111~~~

~

FRONTPOWER

1'

1

(

F26

B

F28

B

/

F46

E

I

FUS

DISTRIBUTION

BOX

10

_16A

-

I

ENGINE

CONTROLS

SYSTEM

----z-------

1z16

X19oI

s2

X]9llifl

r

Br

GRINGRN/

VIOIYELT

"

RED/WHT

\I87---~

I

"

I

I

WHTI

GRV

I

E

NGINECONTROL

I

VIO/YEL(

I

MODULE

RELAY

I

"

WILCM

WIOCCM

I

SL

.I

.LUI

Br

I

GRN/I

GRN/

WHTWHT

BRN/VI0

2I

NCA

SYSTEM

BRN/ORG

"

mI

I

BBL~K

VIO

L

/I

VI0I~

I

L-

-J

I

VE

JJJI

,,,

VELA(

...

I

COM-PRESSOR

I

1

_

_BRAKE

1

BRAKE

CO

NTROLRELAY

(LIGHT

LIGHT

L_

_

----J

(

SWITCH

SWITCH

FRO

NTPOWEP

I

DISTRIBUTION

BOX

z

```yyy

SLUIREDI

SLU/RE

DI

GRN/RED

"

GRN/PEp2rOUTPUT

,DIMMER

~~---J

GRN/RED

INTERIORLIGHTS

III

II

I

II

I

GRN/GRY

B

GRN/WHT

2

GRY/

m

YEL

m

`~

BLK

"

J

BLU/

BLU/

.RN(

17

SWITCH

-

I

I

-

I

I

-

I

R

1

0

0

0B

RN'

INTEGRATED

STARTER

CRUISE

CONTROL

H

1

1

1

0

PROS

RAM

SWITCH

"

"

CLIMATE

REGULATION

RELAY

MODULE

D

0

0

0

1

BRN

BN(

NCA

CONTROLMODULE

(TEMPOMAT)

3

0

0

1

1

11

2

1

0

1

1

71793

G201

1

00

1

0

TRANSMISSION

ENGINECONTROL

MODULE

(DME)

I

70

I

I

S6-1

L1

_211_31

L4

AUTOMATIC

TRANSMISSION

4

DOWN

I

I

I

I

I

I

P

11

O1

RANGESWITCH