wire BMW 318i 1997 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 318i, Model: BMW 318i 1997 E36Pages: 759

Page 7 of 759

Please

read

these

warnings

and

cautions

before

proceeding

with

maintenance

and

repair

work

.

WARNING-

"

Friction

materials

(such

as

brake

pads

or

shorts

or

clutchdiscs)

contain

asbestos

fibers

or

other

friction

materials

.

Do

notcreate

"

See

also

Cautionson

page

viü

dustby

grinding,

sanding,

orby

cleaning

with

compressed

air

.

"

Some

repairs

may

be

beyond

your

capability

.

If

you

lack

the

Avoid

breathing

dust

.

Breathing

any

friction

material

dust

can

lead

skills,

tools

and

equipment,

or

a

suitable

workplace

for

any

proce-

to

serious

diseases

and

may

result

in

death

.

duredescribed

in

this

manual,

we

suggestyou

leave

such

repairs

"

Batteries

give

off

explosive

hydrogen

gas

during

charging

.

to

an

authorized

BMW

dealer

service

department

or

other

quali-

Keep

sparks,

lighted

matches

and

open

flame

away

from

the

top

fied

shop

.

of

the

battery

If

hydrogen

gas

escaping

from

the

cap

vents

is

"Do

not

re-use

any

fasteners

that

are

worn

or

deformed

in

normal

ignited,

it

will

ignite

gas

trapped

in

the

cells

and

cause

the

battery

use

.

Many

fasteners

are

designed

to

be

used

only

once

and

to

explode

.

become

unreliable

and

may

fail

when

used

a

second

time

.

This

"

Connect

and

disconnect

battery

cables,

jumper

cablesora

bat-

includes,

but

is

not

limited

to,

nuts,

bolts,

washers,

self-locking

nuts

or

bolts,

circlips

and

cotterpins

.

Always

replace

these

fasteners

with

new

parts

.

"Do

not

quick-charge

the

battery

(for

boost

starting)

for

longer

"

Never

work

under

a

lifted

car

unless

it

is

solidly

supportedon

than

one

minute

.

Wait

at

least

one

minute

before

boosting

the

bat-

stands

designed

for

the

purpose

.

Do

not

support

a

car

on

cinder

tery

a

second

time

.

blocks,

hollow

tiles

or

other

props

that

may

crumble

under

contin-

uous

load

.

Never

work

under

acar

that

is

supported

solely

by

a

"Do

not

allow

battery

charging

voltage

to

exceed

16

.5

volts

.

If

the

jack

.

Never

work

under

thecar

while

the

engine

is

running

.

battery

beginsproducing

gas

or

boiling

violently,

reduce

the

charg-

ing

rate

.

Boosting

a

sulfated

battery

at

a

high

charging

rate

can

"

If

you

are

going

to

work

under

acar

on

the

ground,

make

sure

cause

an

explosion

.

that

the

ground

is

level

.

Block

the

wheels

to

keep

the

carfrom

roll-

ing

.

Disconnect

the

battery

negative

(-)

terminal

(ground

strap)to

"

The

air-conditioning

system

is

filled

with

chemical

refrigerant,

prevent

others

from

starting

thecar

while

youare

under

it

.

which

is

hazardous

.

TheA/C

system

should

be

servicedonly

by

trained

technicians

using

approved

refrigerant

recovery/recycling

"

Never

run

the

engine

unless

the

work

area

is

well

ventilated

.

equipment,

trained

in

related

safetyprecautions,

and

familiar

with

Carbon

monoxide

kills

.

regulations

governing

the

discharging

and

disposal

of

automotive

"

Finger

rings,

bracelets

and

other

jewelry

shouldbe

removed

so

chemical

refrigerants

.

tery

charger

only

with

the

ignition

switched

off,

to

prevent

sparks

.

Do

not

disconnect

the

battery

while

the

engine

is

running

.

that

theycannot

cause

electrical

shorts,

get

caught

in

running

"

Do

not

expose

any

partof

the

A/Csystem

to

high

temperatures

machinery,

or

be

crushed

by

heavy

parts

.

suchas

open

flame

.

Excessiveheat

will

increase

system

pressure

"

Tie

long

hair

behind

your

head

.

Do

not

wear

a

necktie,

a

scarf,

and

may

cause

the

system

to

burst

.

loose

clothing,

or

a

necklace

when

you

work

near

machine

tools

or

"

Some

aerosol

tire

inflators

are

highly

flammable

.

Be

extremely

running

engines

.

If

your

hair,

clothing,

or

jewelry

were

to

get

caught

cautious

when

repairing

a

tire

that

may

havebeen

inflated

using

in

the

machinery,

severe

injury

could

result

.

an

aerosol

tire

inflator

.

Keep

sparks,

open

flame

or

other

sources

"

Do

not

attempt

to

work

onyourcar

if

you

do

not

feel

well

.

You

of

ignition

away

from

the

tire

repair

area

.

Inflate

and

deflate

the

tire

increase

the

danger

of

injury

toyourself

and

others

if

you

are

tired,

at

least

four

times

before

breaking

the

bead

from

therim

.

Com-

upset

or

have

takenmedication

or

any

other

substance

that

may

Pletely

remove

the

tire

from

the

rim

beforeattempting

any

repair

.

keep

you

from

being

fully

alert

.

"

Illuminate

your

work

areaadequately

but

safety

.

Use

a

portable

safety

light

for

working

inside

or

under

thecar

.

Make

surethe

bulb

is

enclosedbya

wire

cage

.

The

hot

filament

of

an

accidentally

bro-

ken

bulb

can

ignite

spilled

fuel

or

oil

.

"

Catch

draining

fuel,

oil,

orbrake

fluid

in

suitable

containers

.

Do

not

use

food

or

beverage

containers

that

mightmislead

someone

into

drínking

from

them

.

Store

flammable

fluids

away

from

fire

haz-

ards

.

Wipe

up

spills

at

once,

but

do

not

store

the

oily

rags,

which

can

ignite

and

burn

spontaneously

.

"

Always

observe

good

workshop

practices

.

Wear

goggles

when

youoperate

machine

tools

or

work

with

battery

acid

.

Gloves

or

other

protectioeclothing

should

be

worn

whenever

thejob

requires

working

with

harmful

substances

.

"

Greases,

lubricants

and

other

automotive

chemicals

contain

toxic

substances,

many

of

which

are

absorbed

directly

through

the

skin

.

Read

the

manufacturer's

instructions

and

warnings

carefully

.

Use

hand

andeye

protection

.

Avoid

direct

skin

contact

"

Cars

covered

by

this

manual

are

equipped

with

a

supplemental

restraint

system

(SRS),

that

automatically

deploys

an

airbag(s)

in

theevent

of

a

frontal

ímpact

.

The

airbag(s)

is

inflated

byan

explo-

sive

device

.

Handled

improperly

or

without

adequate

safeguards,

can

be

accidently

activated

and

cause

serious

injury

.

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

terminals

and

use

extreme

care

when

working

ona

car

with

the

engine

running

or

the

ígnition

switched

on

.

"

Place

jack

stands

only

at

locations

specified

bymanufacturer

.

The

vehicle

lifting

jacksupplied

with

the

vehicle

is

intended

for

tire

changes

only

.

A

heavy

duty

floor

jack

shouldbe

used

to

lift

vehicle

before

installing

jack

stands

.

See

010

Fundamentals

for

theDo-

.

it-Yourself

Owner

.

"

Battery

acid

(electrolyte)

can

cause

severeburns

.

Flush

contact

area

with

water,

seek

medical

attention

.

"

Aerosolcleaners

and

solvents

may

contain

hazardous

ordeadly

vapors

and

are

highly

flammable

.

Use

only

in

a

wellventilated

area

.

Do

not

use

on

hot

surfaces

(engines,

brakes,

etc

.)

.

"

Disconnect

the

battery

negative

(-)

terminal

(Ground

strap)

"

Do

not

remove

coolant

reservoir

or

radiator

cap

with

theengine

whenever

you

work

on

the

fuel

system

orthe

electrical

system

.

Do

hot

.

Danger

of

bums

and

engine

damage

.

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

Keep

an

approved

fire

extinguisher

handy

.

continued

on

next

page

vii

Page 9 of 759

GENERAL

FUNDAMENTALS

FORTHE

DO-IT

YOURSELF

OWNER

010-1

010

Fundamentals

for

the

Do-lt-Yourself

Owner

GENERAL

.......

.

.

.

......

.

.........

.

.

.010-1

TOOLS

.

.

...

.

............

.

............

010-8

Basic

Tool

Requirements

......

.

.

.

.

.

.

.

.

.

.

010-8

HOW

TO

USE

THIS

MANUAL

.

...

.

...

.

.

.

010-2

JackStands

.

.

.

.

.

.

.

.

.

.......

.

.

.

.

...

.

.

010-9

Warnings,

Cautions

and

Notes

.........

.

.

.

010-2

Oil

Change

Equipment

.

....

.

......

.

...

.

.

010-9

GETTING

STARTED

.

.......

.

.

.

.

.

......

.010-2

Torque

Wrench

....

.

.

.

....

.

..

.

.

.

.

.

...

.

010-10

Feeler

Gauges

.

...

.

.

.

.......

.

.

.

.

.

.

.

.

.

010-10

Safety

....

.

.....

.....

.

.

.

.

.

...

.

.

.

.

.

.

.

010-2

Digital

Multimeter

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

.

010-10

Lífting

the

Car

...........

.

.

.

.

.

.

.

.

.

...

.

.

.

010-3

gMW

Special

Tools

...

.

....

..

.....

.

...

.

010-11

Raising

car

safely

...

..

...

.

...

.

.....

.

...

010-3

Working

under

car

safely

...

..

....

.

.....

.

...

010-4

EMERGENCIES

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

...

.

010-11

ADVICE

FOR

THE

BEGINNER

.......

.

.

.

010-4

Changing

a

Tire

.

.

.

.

.

.

....

..

.

.

.

.

.

.

.

.

.

.010-11

Car

Will

Not

Start

....

.

....

.

.

.

........

.010-11

Planning

Ahead

....

.

...........

.

....

.

.

.

010-4

Jump

Starting

Car

..

.

.

.

....

.

...........

010-12

Cleanliness

.

.

.

.

.

.

.

..

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

010-4

Overheating

.

.....

.

.

.

.........

.

.

.

...

.

010-12

Non-reusable

Fasteners

...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

010-5

Low

Oil

Pressure

...

...

.

.

...

.

.

.

..

...

....

010-13

Tightening

Fasteners

.....

.

.

.

...

.

.

.

.

.

.

.

.

.

010-5

Brake

Fluid

Level

.

.

.....

.

.

.

.

.

...

.

.....

010-13

Gaskets

and

Seals

.......

.

.

.

...

.

.....

.

.

.

010-5

Check

Engine

Warning

Light

.

.

.

...

.

.....

010-13

Electrical

Testing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

010-6

pim

Lights

.....

.

..

.

.

.

....

.

.

.

.........

010-13Wire

Repairs

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

......

010-6

Towíng

.

.

...

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

...

.

.010-13

BUYINGPARTS

.

.

.

.....

.

.

.

...

.

.

.

...

.

.

.

010-6

Spare

Parts

Kit

.

.

.

.

.

.

.......

.

.

.

.

.

.....

010-14

Genuine

BMW

Parts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

......

010-6

Non-returnable

Parts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

......

010-7

TABLES

Information

You

Need

to

Know

.

.

.

.

.

.

......

010-7

a

.

General

Bolt

Tightening

Torques

SERVICE

.

.

.

.

.

.

.

.

.

.

.

.

.......

.

..........

010-7

Although

the

BMW

is

a

sophisticated

and

complex

machine,

basic

maintenance

can

be

accomplished

byan

interested

own-

er

with

mechanical

skills

and

the

right

information

.

Most

of

the

preventive

maintenance

that

is

required

in

the

lifetime

of

theav-

erage

BMW

is

weil

within

the

capabilitiesof

the

do-it-yourseifer

.

WARNING

-

Do

not

use

this

manual

unless

you

are

familiar

with

basicautomotive

repair

procedures

and

sale

work-

shop

practices

.

This

manual

illustrates

the

work-

shop

procedures

required

for

most

service

work

;it

is

not

a

substitute

for

full

and

up-to-date

information

from

the

vehicle

manufacturer

or

for

proper

training

asan

automotive

technician

.

Note

that

it

is

not

pos-

sible

for

us

to

anticipate

al¡

of

the

ways

orconditions

underwhich

vehicles

may

be

serviced

or

to

provide

cautions

as

to

all

of

the

possible

hazards

that

may

result

'

in

Nm

(max

.

permissible)

.

..

.

...

............

.

010-5

WARNING

-

Your

common

sense

and

good

judgment

are

crucial

tosale

and

successful

service

work

.

Read

proce-

dures

through

before

starting

them

.

Thinkabout

whether

the

condition

ofyour

car,

your

leve¡

of

me-

chanical

skill,

or

your

leve¡

of

reading

comprehen-

sion

might

result

in

orcontribute

in

some

way

to

an

occurrence

that

might

cause

you

injury

damage

your

car,

or

result

in

an

unsafe

repair

.

lf

you

havedoubts

for

these

or

other

reasonsaboutyour

abilíty

to

perform

sale

repair

work

onyour

car,

have

the

work

done

at

an

authorized

BMW

dealer

or

other

qualified

shop

.

This

section

of

the

manual

is

intended

to

helpthe

beginner

get

started

.

To

begin

with

there

is

a

discussion

on

How

To

Use

This

Manual

.

Tips

on

mechanicas

skills

and

workshop

practic-

es

that

can

help

the

beginner

do

a

faster

and

more

thorough

job

can

be

foundunderGettingStarted

.

The

basic

tools

needed

to

do

most

of

the

procedures

in

this

manual

are

foundunder

Tools

.

The

section

ends

with

a

quick

reference

guide

to

Emer-

gencies,

including

basictroubleshooting

and

information

on

how

to

gauge

the

seriousness

of

a

problem

.

GENERAL

Page 14 of 759

010-

6

FUNDAMENTALS

FOR

THE

DO-ITYOURSELF

OWNER

In

places

where

a

shaft

mustpass

through

a

housing,

flexible

lip

seals

areused

to

keep

the

lubricating

oil

or

grease

from

leak-

ingout

past

the

rotating

shaft

.

Seals

should

never

be

reused

once

they

have

been

removed

.

When

removing

a

seal,

be

care-

ful

not

lo

scratch

or

otherwise

damage

the

metal

surfaces

.

Even

minor

damage

to

sealing

surfaces

can

cause

sea¡

damage

and

leakage

.

The

key

to

sea¡

installation

is

to

get

the

sea¡

in

straight

without

damaging

¡t

.

Use

a

sea¡

driver

that

is

the

same

diameter

as

the

seal

housing

to

gently

and

evenly

insta¡I

into

place

.

If

a

proper

size

seal

driver

is

not

available,

a

socket

of

the

right

size

will

do

.

When

installing

a

seal,

¡t

a

good

idea

to

coat

the

sea¡

with

o¡I

to

aid

installation

.

Some

seals

are

directional

and

special

instal-

lation

instructions

apply

.

Make

sure

¡t

is

installed

with

the

lip

fac-

ing

the

correct

way

.

Normally

the

lip

faces

the

inside

.

Note

the

installation

direction

of

the

old

sea¡before

removing

¡t

.

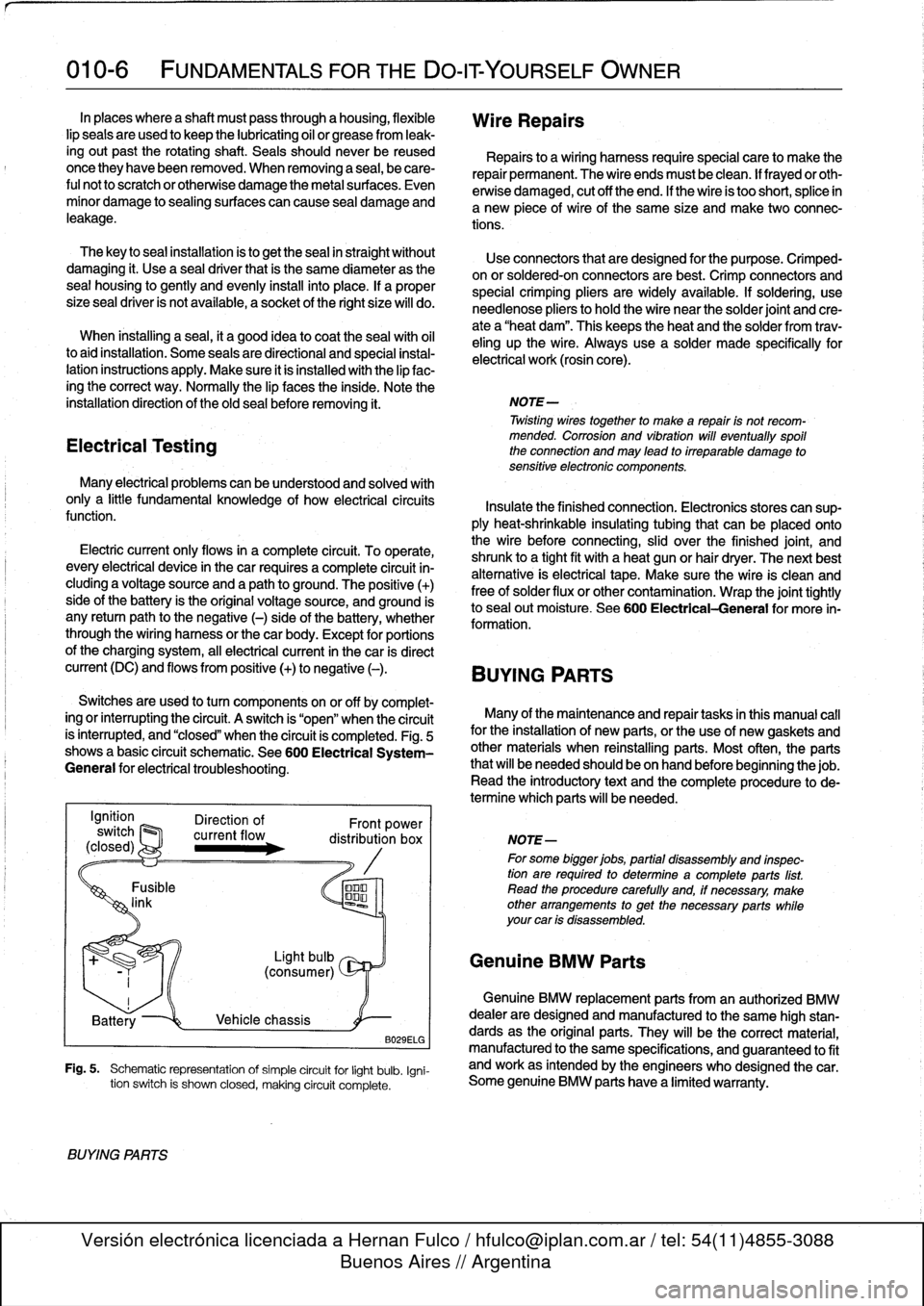

Electrical

Testing

Many

electrical

problems

canbe

understood

and

solved

with

only

a

little

fundamental

knowledge

of

how

electrical

circuits

Insulate

the

finished

connection

.

Electronics

stores

can

sup-

function

.

ply

heat-shrinkable

insulating

tubing

that

can

be

placed

onto

the

wire

before

connectiog,

slid

over

the

finished

joint,

and

Electric

current

only

flows

in

a

complete

circuit

.

To

operate,

shrunk

to

a

tight

fit

with

a

heat

gun

orhair

dryer

.

The

nextbest

every

electrical

device

in

thecar

requires

a

complete

circuit

in-

alternative

is

electrical

tape

.

Make

sure

the

wire

is

clean

and

cluding

a

voltage

source

and

a

pathto

ground

.

The

positive

(+)

free

ofsolder

flux

or

other

contamination

.

Wrap

the

joint

tightly

side

of

the

battery

is

the

original

voltagesource,

and

ground

is

to

sea¡

out

moisture

.

See

600

Electrical-General

for

more

in-

any

retum

path

to

the

negative

()

-

side

ofth

e

battery°

whether

li

formation

.

through

the

wiring

harness

or

thecar

body

.

Except

for

portions

of

the

charging

system,

al¡

electrical

current

in

the

car

is

direct

current

(DC)

and

flows

from

positive

(+)

to

negative

(-)

.

BVYING

PART$

Switches

are

used

to

turn

components

on

or

off

by

complet-

ing

or

interrupting

#he

circuit

.

A

switch

is

"open"

when

the

circuit

Many

of

the

maíntenance

and

repair

tasks

in

this

manual

cal¡

is

ínterrupted,

and

"closed"

when

the

circuit

is

completed

.

Fig

.

5

for

the

installation

of

new

parte,

or

the

use

of

new

gaskets

and

shows

a

basic

circuit

schematic

.

See600

Electrical

System-

other

materials

when

reinstalling

parts

.

Most

often,

the

parts

General

for

electrical

troubleshooting

.

that

will

be

needed

should

be

on

hand

beforebeginningthe

job

.

Read

the

introductory

text

and

the

complete

procedure

to

de-

termine

which

parts

will

be

needed

.

B029ELG

Fig

.

5

.

Schematic

representation

of

simple

circuit

for

light

bulb

.

Igni-

tion

switch

is

shown

closed,

making

circuit

complete

.

BVYING

PARTS

Wire

Repairs

Repairs

to

a

wiring

harness

requirespecial

care

to

make

the

repair

permanent

.

The

wire

endsmust

be

clean

.

lf

frayedor

oth-

erwise

damaged,

cut

off

the

end

.

If

the

wire

is

too

short,

splice

in

a

new

piece

of

wire

of

the

same

size

and

make

two

connec-

tions

.

Use

connectors

that

are

designed

for

the

purpose

.

Crimped-

on

or

soldered-onconnectors

are

best

.

Crimp

connectors

and

special

crimping

pliers

are

widely

available

.

If

soldering,

use

needlenose

pliers

tohold

the

wire

near

the

solder

joint

and

cre-

ate

a

"heat

dam"

.

This

keeps

the

heat

and

the

solder

from

trav-

eling

up

the

wire

.

Always

use

a

solder

made

specifically

for

electrical

work

(rosin

core)

.

NOTE-

Twisting

wirestogether

to

make

a

repair

is

not

recom-

mended

.

Corrosion

and

vibration

will

eventually

spoil

the

connection

and

may

lead

to

irreparable

damage

to

sensitive

electronic

componente

.

NOTE-

For

some

bigger

jobs,

partial

disassembly

and

inspec-

tion

are

required

to

determine

acomplete

parts

list

.

Read

the

procedure

carefully

and,

if

necessary,

make

other

arrangements

to

get

the

necessary

parts

while

your

car

is

disassembled

.

Genuine

BMW

Parts

Genuine

BMW

replacement

parts

from

an

authorized

BMW

dealer

are

designed

and

manufactured

lo

the

same

high

stan-

dards

as

the

original

parts

.

They

will

be

the

correct

material,

manufactured

to

the

same

specifications,

and

guaranteed

lo

fit

and

work

as

intended

by

the

engineers

who

designed

thecar

.

Some

genuine

BMW

parts

have

a

limited

warranty

.

Page 21 of 759

If

steam

is

coming

from

the

engine

compartment

thenthere

is

With

the

engine

and

ignition

off,

check

for

loose

or

corroded

most

likely

a

burst

coolant

hose

or

a

large

leak

in

the

cooling

battery

cables

or

wires

at

the

battery

or

thealtemator

.

Discon-

system

.

To

find

the

leak,

look

for

signs

of

coolant

leakage

on

necting,

cleaning,

and

reinstalling

corroded

wires

and

connec-

hoses,

at

hose

connections,

or

on

the

radiator

.

Let

theengine

tors

may

solve

the

problem

.

Also

check

drive

belt

tension

as

cool

thoroughly,

then

add

coolant

or

water

to

fill

the

system

and

described

in

020

Maintenance

Program

.

start

the

engine

.

If

a

great

deal

of

water

or

coolant

flows

out

of

the

hole,

then

thecarshouldnot

be

driven

until

repairs

are

made

.

lf

there

is

slight

seepage,

then

it

may

be

possible

to

drive

TOWi

ng

a

short

distance,

adding

coolant

as

needed

.

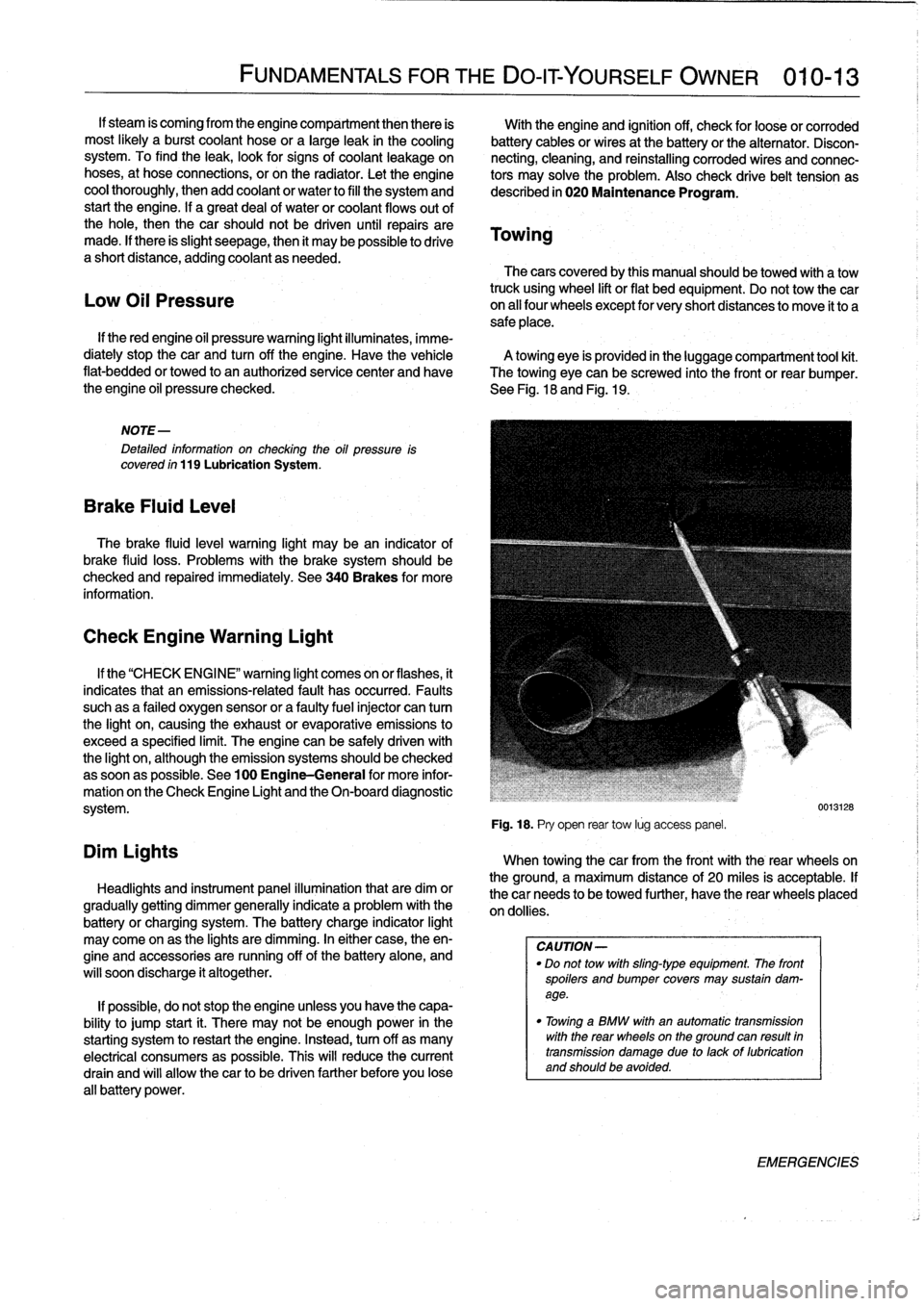

The

cars

covered

by

this

manual

should

be

towed

witha

tow

truck

using

wheel

lift

or

flat

bed

equipment

.

Do

not

tow

thecar

on

all

four

wheels

except

for

very

short

distances

to

move

it

to

a

safe

place

.

If

thered

engine

oil

pressure

warning

light

illuminates,

imme-

diately

stop

thecar

and

turn

off

the

engine

.

Have

the

vehicle

A

towing

eye

is

provided

in

the

luggage

compartment

tool

kit

.

flat-bedded

or

towed

to

an

authorized

service

center

and

have

The

towing

eye

can

be

screwed

into

the

front

or

rear

bumper

.

the

engine

oil

pressure

checked

.

See

Fig

.

18

and

Fig

.

19

.

Low

Oil

Pressure

NOTE-

Detafed

information

on

checking

the

oil

pressure

is

covered

ín

119

Lubrication

System

.

Brake

Fluid

Leve¡

The

brake

fluid

leve¡

warning

light

may

bean

indicator

of

brake

fluid

loss

.

Problems

with

the

brakesystem

should

be

checked

and

repaired

immediately

.

See

340Brakes

for

more

information

.

Check

Engine

Warning

Light

Dim

Lights

FUNDAMENTALS

FOR

THE

DO-IT

YOURSELF

OWNER

010-13

If

the

"CHECK

ENGI

NE"

warning

light

comes

on

or

flashes,

it

indicates

that

an

emissions-related

fault

has

occurred

.

Faults

suchas

a

failed

oxygen

sensor

or

a

faultyfuelinjector

can

tum

the

light

on,

causing

the

exhaust

or

evaporative

emissions

to

exceed

a

specified

limit

.

The

engine

can

be

safely

driven

with

the

light

on,

although

the

emission

systems

should

be

checked

assoonas

possible

.

See

100

Engine-General

for

more

infor-

mation

on

the

Check

Engine

Light

and

the

On-board

diagnostic

system

.

Headlights

and

instrument

panel

illuminationthat

are

dim

or

gradually

getting

dimmer

generally

indicate

a

problem

with

the

battery

or

charging

system

.

The

battery

charge

indicator

light

may

come

on

as

the

lights

are

dimming

.

In

either

case,

theen-

gine

and

accessories

are

running

off

of

the

battery

alone,

and

will

soon

discharge

it

altogether

.

If

possible,

do

not

stop

the

engine

unless

you

have

the

capa-

bility

to

jump

start

¡t

.

There

may

not

be

enough

power

in

the

starting

system

torestart

the

engine

.

Instead,turn

off

as

many

electrical

consumers

as

possible

.

This

will

reduce

the

current

drain

and

will

allow

thecar

to

be

driven

farther

before

you

lose

all

battery

power

.

Fig

.

18

.

Pry

open

rear

tow

lúg

access

panel

.

When

towingthecar

from

the

front

with

the

rear

wheelson

the

ground,

a

maximum

distance

of

20

miles

is

acceptable

.

If

thecar

needs

to

be

towed

further,

have

the

rear

wheels

placed

on

dollies

.

CA

UTION-

"

Do

not

tow

with

sling-type

equipment

The

front

spoilers

andbumper

covers

may

sustain

dam-

age

.

"

Towínga

BMW

with

an

automatic

transmission

with

the

rear

wheelson

the

ground

can

resuft

in

transmission

damage

due

to

lackof

lubrication

and

should

be

avoided

.

0013128

EMERGENCIES

Page 33 of 759

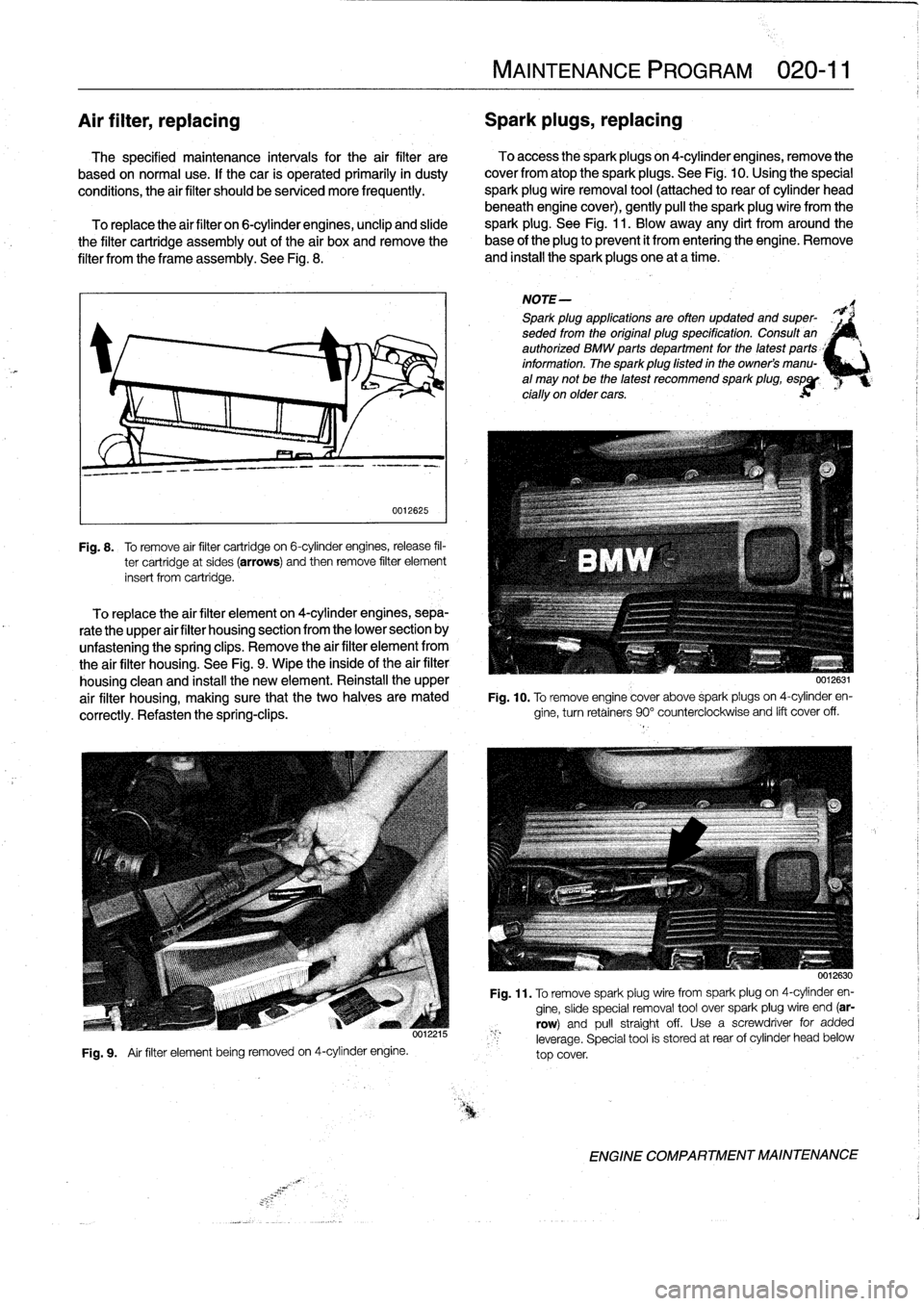

Air

filter,

replacing

Spark

plugs,

replacing

The

specified

maintenance

intervals

for

the

air

filter

are

To

access

the

spark

plugs

on

4-cylinder

engines,

remove

the

based

on

normal

use

.

If

thecar

is

operated

primarily

in

dusty

cover

fromatop

the

sparkplugs

.

See

Fig

.

10

.

Using

the

special

conditions,

the

air

filter

should

be

serviced

more

frequently

.

spark

plug

wire

removal

tool

(attached

to

rear

of

cylinder

head

beneath

engine

cover),

gently

pull

the

spark

plugwire

from

the

To

replace

the

air

filter

on

6-cylinder

engines,

unclip

and

sude

spark

plug

.

See

Fig

.

11

.

Blow

away

any

dirt

from

around

the

the

filter

cartridge

assembly

out

of

the

air

boxand

remove

the

base

of

the

plug

to

prevent

it

from

entering

theengine

.

Remove

filter

from

the

frame

assembly

.

See

Fig

.

8

.

and

install

the

spark

plugs

one

at

a

time

.

0012625

Fig

.

8

.

To

remove

air

filter

cartridge

on

6-cylinder

engines,release

fil-

ter

cartridge

at

sides

(arrows)

and

then

remove

filter

element

insert

from

cartridge

.

To

replace

the

air

filter

elementon

4-cylinder

engines,

sepa-

rate

the

upper

air

filter

housing

section

from

the

lower

section

by

unfastening

the

spring

clips

.

Remove

the

air

filter

element

from

the

air

filter

housing

.

See

Fig

.

9

.

Wipe

the

inside

of

the

air

filter

housing

clean

and

install

the

new

element

.

Reinstall

the

upper

air

filter

housing,

making

sure

that

the

two

halves

are

mated

correctly

.

Refasten

the

spring-clips

.

Fig

.

9

.

Air

filter

element

being

removed

on

4-cylinder

engine

.

MAINTENANCE

PROGRAM

020-

11

NOTE-

Spark

plug

applications

are

often

updated

and

super-

seded

from

the

original

plug

specification

.

Consuff

an

authorized

BMW

parts

department

for

the

latest

parts

_'

information

.

The

sparkplug

fisted

in

the

owners

manu-

al

may

not

be

the

latest

recommend

spark

plug,

espgp

cially

on

older

cars

.

0012631

Fig

.

10

.

To

remove

engine

cover

above

sparkpiugs

on

4-cylinder

en-

gine,

turnretainers

90°

counterclockwise

and

lift

cover

off

.

0012630

Fig

.

11

.

To

remove

spark

plugwirefrom

spark

plug

on

4-cylinder

en-

gine,

sude

special

removal

tool

over

spark

plug

wire

end

(ar-

row)

and

pull

straightoff

.

Usea

screwdriver

for

added

leverage

.

Special

tool

is

stored

at

rear

of

cylinder

head

below

top

cover

.

ENGINE

COMPARTMENT

MAINTENANCE

Page 34 of 759

020-

1

2

MAINTENANCE

PROGRAM

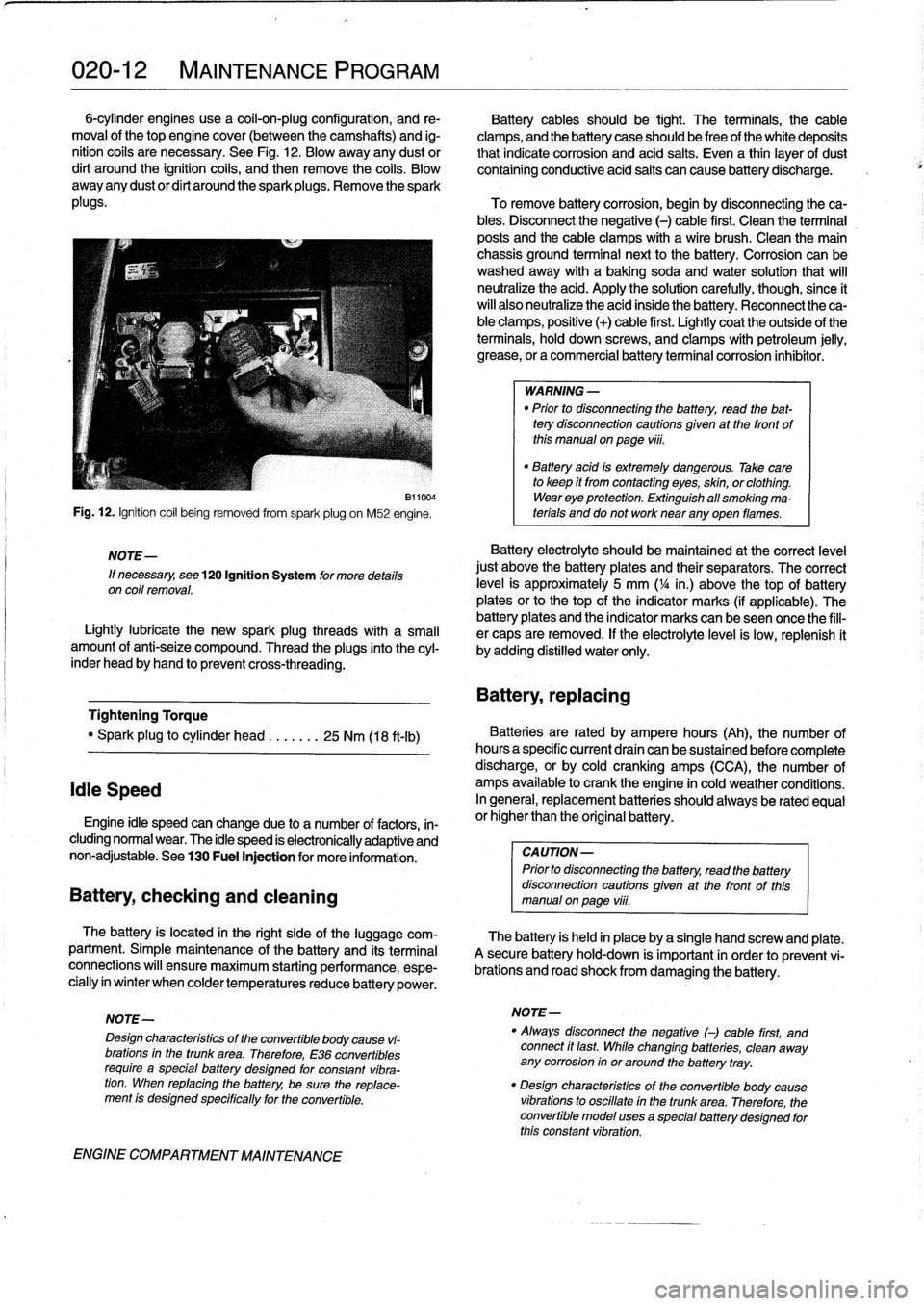

6-cylinder

engines

use

a

coil-on-plug

configuration,

and

re-

Battery

cablesshould

be

tight

.

The

terminals,

the

cable

moval

of

thetop

engine

cover

(between

the

camshafts)

and

ig-

clamps,

and

the

battery

case

should

be

freeof

the

white

deposits

nition

cofs

are

necessary

.

See

Fig

.

12

.

Blow

away

any

dust

or

that

indicate

corrosion

and

acid

salts

.

Even

a

thin

¡ayer

of

dust

dirt

around

the

ignition

coils,

and

then

remove

the

coils

.

Blow

containing

conductive

acid

salts

can

cause

battery

discharge

.

away

any

dustor

dirt

around

the

sparkplugs

.

Remove

the

spark

plugs

.

To

remove

battery

corrosion,

begin

by

disconnecting

theca-

bles

.

Disconnect

the

negative

(-)

cable

first

.

Clean

the

terminal

posts

and

the

cable

clamps

with

a

wire

brush

.

Clean

the

main

chassis

ground

terminal

next

to

the

battery

.

Corrosion

can

be

washedaway

with

a

baking

soda

and

water

solution

that

will

neutralize

the

acid

.

Apply

the

solution

carefully,

though,since

ít

will

also

neutralize

the

acid

inside

the

battery

.

Reconnect

the

ca-

ble

clamps,

positive

(+)

cable

first

.

Lightly

coat

the

outside

of

the

terminals,

hold

down

screws,

and

clamps

with

petroleum

jelly,

grease,

or

a

commercial

battery

terminal

corrosion

inhibitor

.

Fig

.

12

.

Ignition

coil

being

removed

from

spark

plug

on

M52

engine

.

NOTE-

If

necessary,

see

120

Ignition

System

for

more

details

on

coil

removal

.

B11004

Lightlylubricate

the

new

spark

plug

threads

with

a

small

amount

of

anti-seize

compound

.

Thread

the

plugs

into

the

cyl-

inder

head

byhand

to

prevent

cross-threading

.

Tightening

Torque

"

Spark

plug

to

cylinder

head

.......

25

Nm

(18

ft-ib)

Idie

Speed

Engine

¡dle

speed

canchange

due

to

a

number

of

factors,

in-

cluding

normal

wear

.

The

idle

speed

is

electronically

adaptive

and

non-adjustable

.

See

130

Fuel

Injection

for

more

information

.

Battery,

checking

and

cleaning

The

battery

is

located

in

the

right

side

of

the

luggage

com-

partment

.

Simple

maintenance

of

the

battery

and

its

terminal

connections

will

ensure

maximum

starting

performance,

espe-

cially

in

winter

when

colder

temperaturesreduce

battery

power

.

ENGINE

COMPARTMENT

MAINTENANCE

WARNING

-

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manualonpage

viii

.

"

Battery

acid

is

extremely

dangerous

.

Take

care

to

keep

it

from

contacting

eyes,

skin,

or

clothing

.

Wear

eye

protection

.

Extinguish

all

smoking

ma-

terials

and

do

not

worknear

any

oyen

flames

.

Battery

electrolyte

should

be

maintained

at

the

correct

level

just

above

the

battery

plates

and

their

separators

.

The

correct

leve¡

is

approximately

5

mm

(

1

/4

in

.)

above

thetop

of

battery

plates

orto

thetop

of

the

indicator

marks

(if

applicable)

.

The

battery

plates

and

the

indicator

marks

can

beseen

once

the

fill-

er

caps

are

removed

.

If

the

electrolyte

level

is

low,

replenish

it

by

adding

distilled

water

only

.

Battery,

repiacing

Batteries

are

rated

by

ampere

hours

(Ah),

the

number

of

hoursa

specific

current

draín

can

be

sustained

before

complete

discharge,

or

by

cold

cranking

amps

(CCA),

the

number

of

amps

available

to

crank

the

engine

in

cold

weather

conditions

.

In

general,

replacement

batteries

should

alwaysbe

rated

equal

or

higherthan

the

original

battery

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

thls

manual

on

page

viii

.

The

battery

is

held

in

place

bya

single

hand

screw

and

píate

.

A

secure

battery

hold-down

is

important

in

order

to

prevent

vi-

brations

and

road

shock

from

damaging

the

battery

.

NOTE-

NOTE-

"

Always

disconnect

the

negative

()

cable

first,

and

Design

characteristics

of

the

convertible

body

cause

vi-

connect

ft

last

While

changing

batteries,

clean

away

brations

in

the

trunk

area

.

Therefore,

E36

convertibles

any

corrosion

in

or

around

the

battery

tray

.

require

a

specialbattery

designed

for

constant

vibra-

tion

.

When

repiacing

the

battery,

be

sure

the

replace-

"

Design

characteristics

of

the

convertible

body

cause

ment

is

designed

specffically

for

the

convertible

.

vibrations

to

oscillate

in

the

trunk

area

.

Therefore,

the

convertible

model

uses

a

specialbattery

designed

for

this

constant

vibration

.

Page 37 of 759

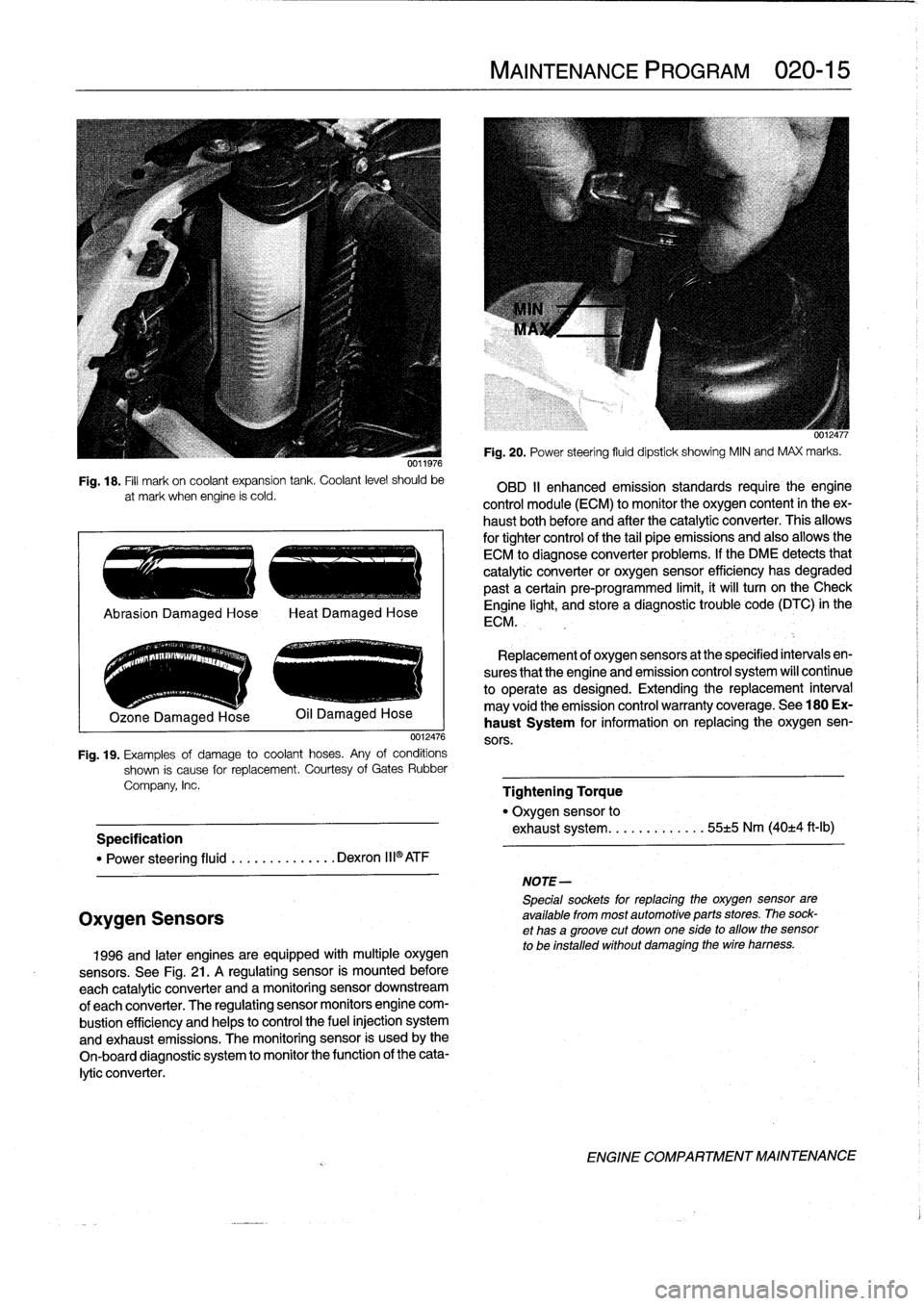

Fig

.

18

.

Fill

mark

on

coolant

expansion

tank

.

Coolant

level

should

be

at

mark

when

engine

ís

cold

.

.

..

e

..

.-

..

~

..

.-

.

Ozone

Damaged

Hose

0012476

Fig

.

19

.

Examples

of

damage

to

coolant

hoses

.

Any

of

conditions

shown

is

cause

for

replacement

.

Courtesy

of

Gates

Rubber

Company,

Inc

.

Specification

"

Power

steering

fluid

..........

.

...

Dexron

III®ATF

Oxygen

Sensors

1996

and

later

engines

are

equipped

withmultiple

oxygen

sensors

.

See

Fig

.

21

.

A

regulating

sensor

is

mounted

before

each

catalytic

converter

and

amonitoring

sensor

downstream

of

each

converter

.

The

regulating

sensor

monitors

engine

com-

bustion

efficiency

and

helps

to

control

the

fuel

injection

system

and

exhaust

emissions

.

The

monitoring

sensor

is

usedby

the

On-board

diagnostic

system

to

monitor

the

function

of

the

cata-

lytic

converter

.

MAINTENANCE

PROGRAM

020-

1

5

NOTE-

5pecialsockets

for

replacingthe

oxygen

sensor

are

available

from

most

automotive

parts

stores

.

The

sock-

et

has

agroove

cut

down

one

side

to

allow

the

sensor

to

be

installed

without

damaging

the

wire

hamess

.

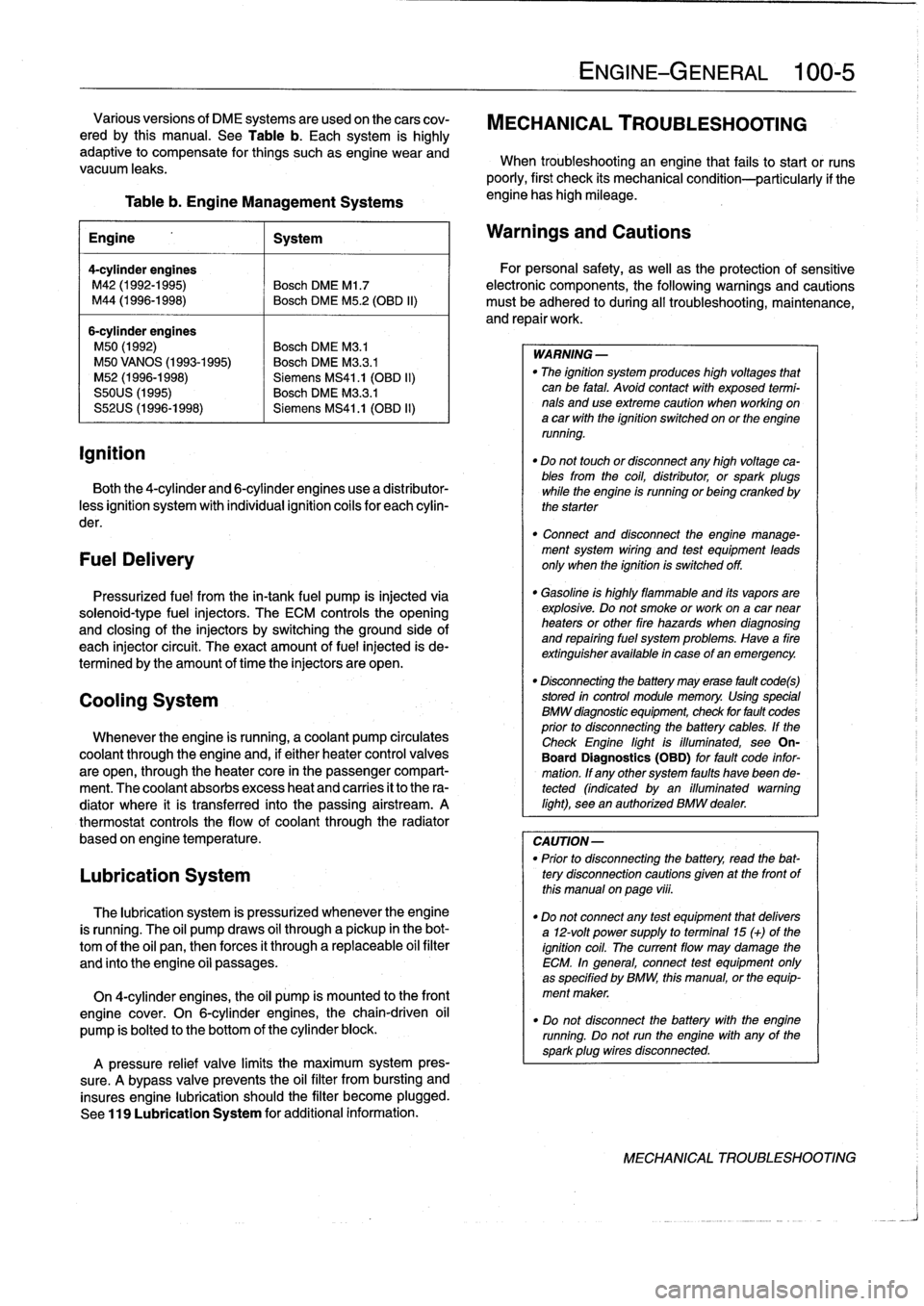

Fig

.

20

.

Power

steering

fluid

dipstick

showing

MIN

and

MAX

marks

.

OBD

II

enhanced

emission

standards

require

the

engine

control

module

(ECM)

to

monitor

the

oxygen

content

in

theex-

haust

bothbefore

and

after

the

catalytic

converter

.

This

allows

for

tightercontrol

of

the

tail

pipe

emissions

and

also

allowsthe

ECM

to

diagnose

converter

problems

.

lf

the

DME

detects

that

catalytic

converter

or

oxygen

sensor

efficiency

has

degraded

past

a

certain

pre-programmed

limit,

it

will

turn

on

the

Check

Engine

light,

and

store

a

diagnostic

trouble

code

(DTC)

in

the

ECM

.

Replacement

of

oxygen

sensors

at

the

specified

intervals

en-

sures

that

the

engine

and

emission

control

system

wíll

continue

to

operate

as

designed

.

Extending

the

replacement

interval

may

void

the

emission

control

warranty

coverage

.

See

180

Ex-

haust

System

for

information

on

replacing

the

oxygen

sen-

sors

.

Tightening

Torque

"

Oxygen

sensor

to

exhaust

system

........

.

.

.

..

55±5

Nm

(40±4

ft-Ib)

ENGINE

COMPARTMENT

MAINTENANCE

Page 47 of 759

ignition

Table

b

.

Engine

Management

Systems

engine

has

high

mileage

.

Engine

1

System

4-cylinder

engines

M42

(1992-1995)

Bosch

DME

Ml

.7

M44

(1996-1998)

Bosch

DME

M5

.2

(OBD

II)

6-cylinder

engines

M50

(1992)

Bosch

DME

M3

.1

M50

VANOS

(1993-1995)

Bosch

DME

M3

.3

.1

M52

(1996-1998)

Siemens

MS41

.1

(OBD

II)

S50US

(1995)

Bosch

DME

M3

.3

.1

S52US

(1996-1998)

Siemens

MS41

.1

(OBD

II)

Both

the

4-cylinder

and

6-cylinder

engines

use

a

distributor-

less

ignition

system

with

individual

ignition

coils

for

each

cylin-

der

.

FuelDelivery

Pressurized

fuel

from

the

in-tank

fuel

pump

is

injected

via

solenoid-type

fuel

injectors

.

The

ECM

controls

the

opening

and

closing

of

the

injectors

by

switchingthe

ground

side

of

each

injector

circuit

.

The

exact

amount

of

fuel

injected

is

de-

termined

by

the

amount

of

timethe

injectors

are

open

.

Cooling

System

Whenever

the

engine

is

running,

acoolant

pump

circulates

coolant

through

the

engine

and,

if

either

heater

control

valves

are

open,

through

the

heater

core

in

the

passenger

compart-

ment

.

The

coolant

absorbs

excess

heat

and

carries

it

to

the

ra-

diator

where

it

is

transferred

into

the

passing

airstream

.

A

thermostat

controls

the

flow

of

coolant

through

the

radiator

based

on

engine

temperature

.

Lubrication

System

The

lubrication

system

is

pressurized

whenever

theengine

is

running

.

The

oil

pump

draws

oil

through

a

pickup

in

the

bot-

tom

of

the

oil

pan,thenforces

it

through

a

replaceable

oil

filter

and

finto

the

engine

oíi

passages

.

On

4-cylinder

engines,

the

oil

pump

is

mounted

to

the

front

engine

cover

.

On

6-cylinder

engines,thechain-driven

oil

pump

is

bolted

to

the

bottom

of

the

cylinder

block

.

A

pressure

relief

valve

limits

the

maximum

system

pres-

sure

.

A

bypass

valve

prevents

the

oil

filter

from

bursting

and

insures

engine

lubrication

should

the

filter

become

plugged

.

See

119

Lubrication

System

for

additional

information

.

ENGINE-GENERAL

100-

5

Various

versions

of

DME

systems

are

usedon

thecars

cov-

MECHANICAL

TROUBLESHOOTING

ered

by

this

manual

.

See

Table

b

.

Each

system

is

highly

adaptive

to

compensate

for

things

suchasengine

wear

and

When

troubleshooting

an

engine

that

fails

to

start

or

runs

vacuum

leaks

.

poorly,

first

check

its

mechanical

condition-particularly

if

the

Warnings

and

Cautions

For

personal

safety,

as

well

asthe

protection

of

sensitive

electronic

components,

the

following

warnings

and

cautions

must

be

adhered

to

during

all

troubleshooting,

maintenance,

and

repairwork

.

WARNING

-

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

termi-

nals

anduse

extreme

caution

when

working

on

a

car

with

the

ignition

switched

on

or

the

engine

running

.

"

Do

not

touch

or

disconnect

any

high

voltage

ca-

bles

from

the

coil,

distributor,

orspark

plugs

while

the

engine

is

running

or

being

cranked

by

the

starter

"

Connect

and

disconnect

the

engine

manage-

ment

system

wiring

and

test

equipment

leads

only

when

the

ignition

is

switched

off

.

"

Gasoline

is

highly

flammable

and

its

vapors

are

explosive

.

Do

not

smoke

or

work

on

a

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repairing

fuel

system

problems

.

Have

a

fire

extínguisher

available

in

case

of

an

emergency

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

control

module

memory

.

Using

special

BMW

diagnosnnc

equipment,

check

for

fault

codes

prior

to

disconnecting

the

battery

cables

.

If

the

Check

Engine

lightis

illuminated,

see

On-

Board

Diagnostics

(OBD)

forfault

code

infor-

mation

.

If

any

other

system

faults

havebeen

de-tected

(indicated

byan

illuminated

warning

light),

see

an

authorized

BMW

dealer

.

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnection

cautions

gíven

at

the

front

of

this

manual

on

page

viii

.

"

Do

notconnect

any

test

equipment

that

delivers

a

12-volt

power

supply

to

terminal15

(+)

of

the

ignition

coil

.

The

current

flow

may

damage

the

ECM

.

In

general,

connect

test

equipment

only

as

specified

by

BMW,

this

manual,

or

the

equip-

ment

maker

.

"

Do

not

disconnect

the

battery

with

the

engine

running

.

Do

notrunthe

engine

with

any

of

the

sparkplug

wires

disconnected

.

MECHANICAL

TROUBLESHOOTING

Page 48 of 759

100-6

ENGINE-GENERAL

Cylinder

compression,

checking

A

compression

tester

is

needed

to

make

a

compression

test

.

To

obtain

accurate

test

results,

the

battery

and

starter

must

be

capable

of

cranking

the

engine

at

250-300

rpm,

and

theen-

gine

should

be

at

normal

operating

temperature

.

Use

com-

pressed

air

to

clean

aroundthe

spark

plugs

before

removal

.

1

.

Disable

the

ignítion

system

by

removing

the

engine

management

system

main

relay

and

the

fuel

pump

re-

¡ay

.

See

Fig

.

6

.

WARNING

-

The

ignítion

system

produces

high

voltages

that

canbe

fatal

.

Avoid

contact

with

exposed

termínals

and

useextreme

caution

when

working

on

acar

wíth

the

ignítion

switched

on

or

the

engine

running

.

Fuel

DM

E

pump

main

re

ay

rel

ay

o

oa

ooa

.,

o00

oao

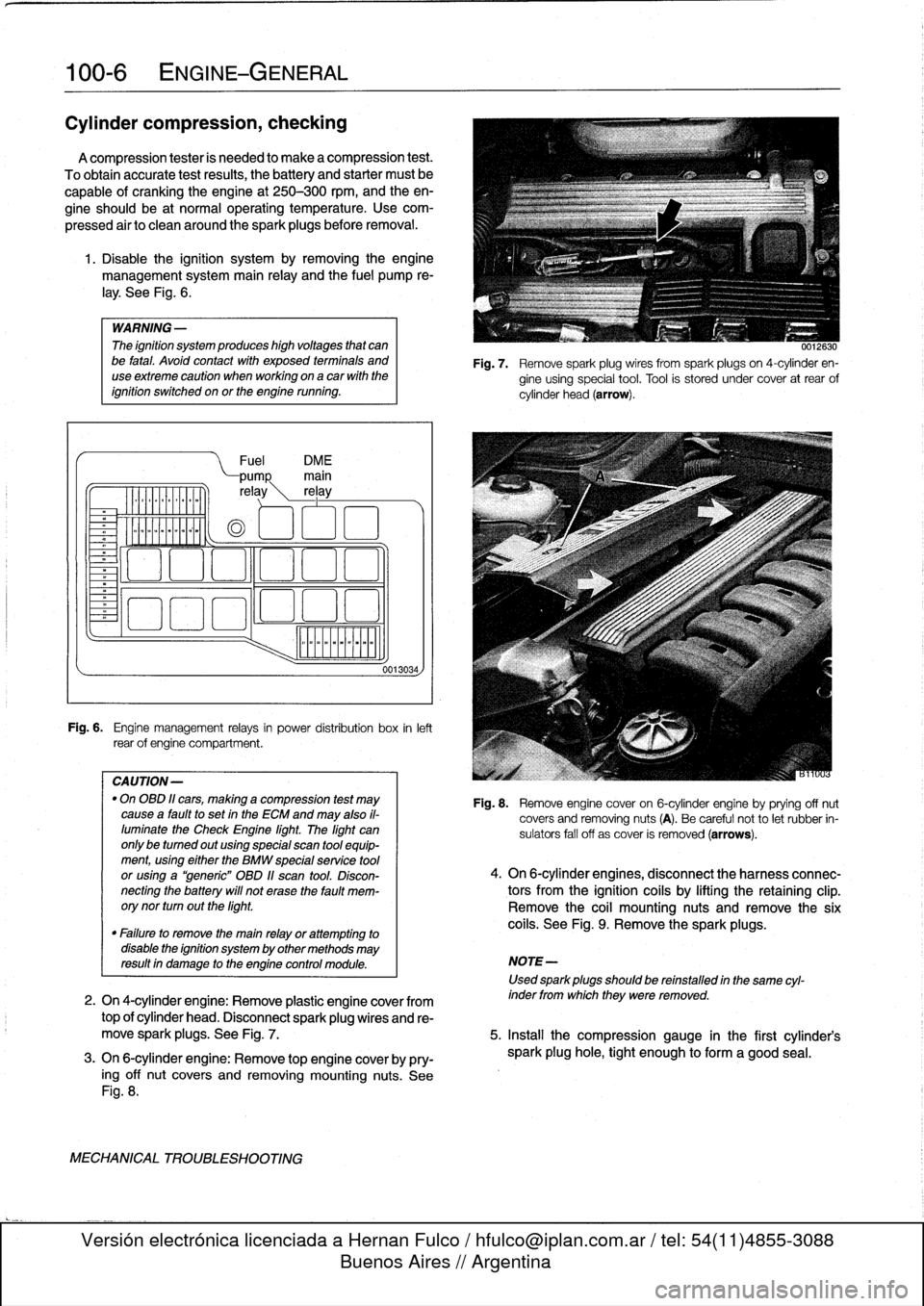

Fig

.

6

.

Engine

management

relays

in

power

distribution

box

inleft

rear

of

engine

compartment

.

CAUTION-

"

On

OBD

11

cars,

making

a

compression

test

may

causea

faultto

set

in

the

ECM

and

may

also

il-

luminate

the

Check

Engine

light

.

The

light

can

only

be

tumed

out

using

special

scan

tool

equip-

ment,using

eíther

the

BMW

specialservíce

tool

or

using

a

"generic"

OBD

11

scan

tool

.

Discon-

necting

the

battery

will

not

erase

the

fault

mem-

orynor

turn

outthe

light

.

0013034,

0012630

Fig

.

7

.

Remove

spark

plug

wires

from

spark

plugs

on

4-cylinder

en-

gine

using

special

tool

.

Tool

is

stored

under

cover

at

rear

of

cylinder

head

(arrow)

.

Fig

.

8

.

Remove

engine

cover

on

6-cylinder

engine

byprying

off

nut

covers

and

removing

nuts

(A)

.

Be

careful

not

to

let

rubber

in-

sulators

fall

off

as

cover

is

removed

(arrows)

.

4

.

On

6-cylinder

engines,

disconnect

the

harness

connec-

tors

from

the

ignítion

coils

by

lifting

the

retaining

clip

.

Remove

the

coil

mounting

nuts

andremove

the

six

coils

.

See

Fig

.

9

.

Remove

the

sparkplugs

.

"

Failure

to

remove

the

main

relay

or

attempting

to

disable

the

ignítion

system

by

other

methods

may

resultin

damage

to

the

engine

control

module

.

NOTE-

Used

sparkplugs

should

be

reinstalled

in

the

same

cyl-

2

.

On

4-cylinder

engine

:

Remove

plastic

engine

cover

from

inder

fromwhich

they

were

removed

.

top

of

cylinder

head

.

Disconnect

spark

plug

wires

and

re-

move

spark

plugs

.

See

Fig

.

7

.

5

.

Insta¡¡

the

compression

gauge

in

the

first

cylinder's

3

.

On

6-cylinder

engine

:

Remove

top

engine

coverby

pry-

spark

plug

hole,

tight

enough

to

form

a

good

seal

.

ing

off

nut

covers

and

removing

mounting

nuts

.

See

Fig

.

8

.

MECHANICAL

TROUBLESHOOTING

Page 49 of 759

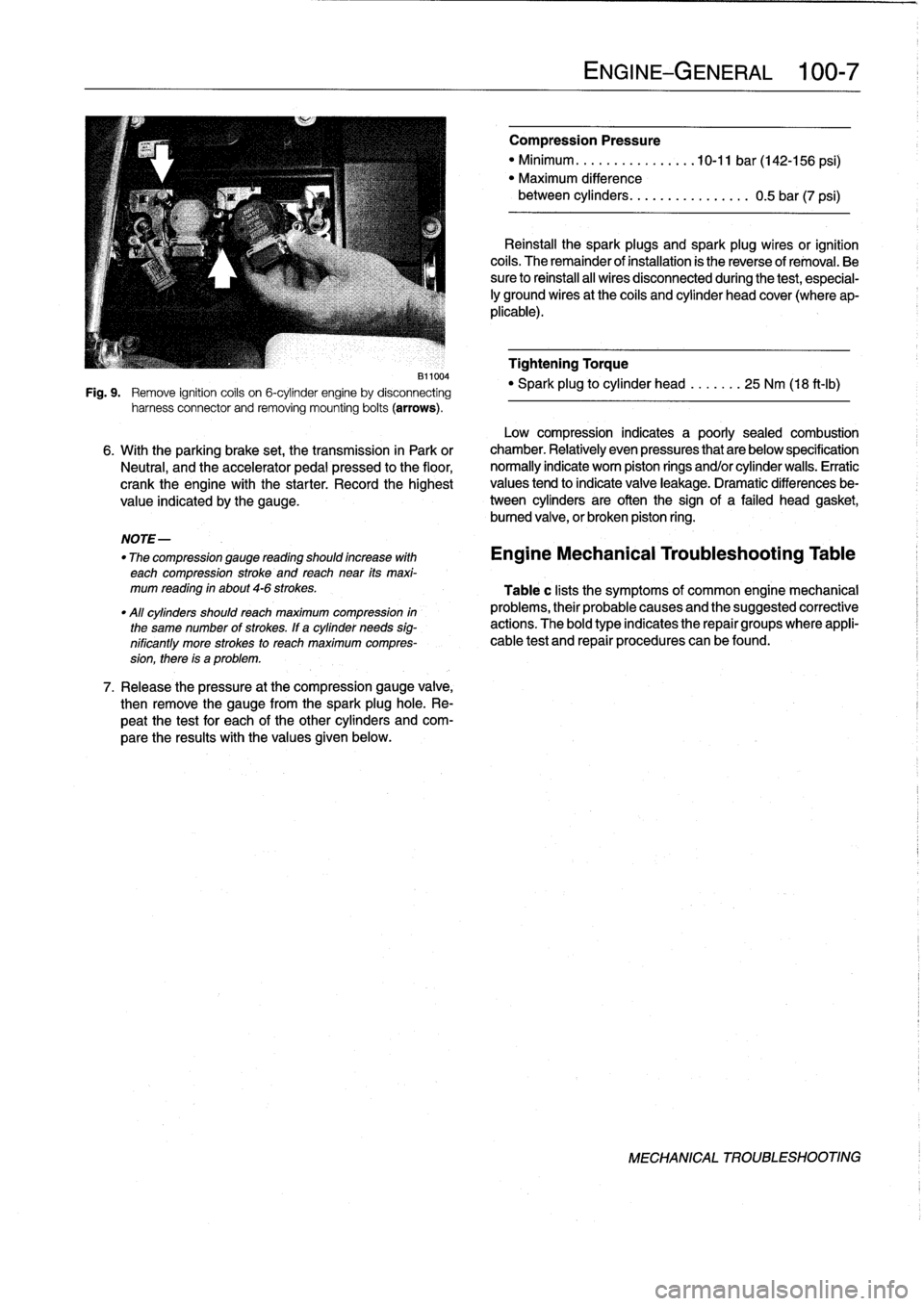

eiioo4

Fig

.

9

.

Remove

ignition

coils

on

6-cylinder

engine

by

disconnecting

harness

connector

and

removing

mounting

bolts

(arrows)

.

NOTE-

"

The

compression

gauge

reading

shoutd

increase

with

each

compression

stroke

and

reach

near

its

maxi-

mum

reading

in

about

4-6

strokes

.

"All

cylinders

shoutdreach

maximum

compression

in

the

same

number

of

strokes

.

If

a

cylinder

needs

sig-

nificantly

more

strokes

to

reach

maximum

compres-

sion,

there

is

a

problem

.

7

.

Release

the

pressure

at

the

compression

gauge

valve,

then

remove

the

gauge

from

the

spark

plughole

.

Re-

peat

the

test

for

each

of

the

other

cylinders

and

com-

pare

the

results

with

the

values

given

below

.

ENGINE-GENERAL

1

:00-

7

Compression

Pressure

"

Minimum

..........

.

.

..

..

10-11

bar

(142-156

psi)

"

Maximum

difference

between

cylinders

..

.....

.........

0

.5

bar

(7

psi)

Reinstall

the

spark

plugs

and

spark

plug

wires

or

ignition

cofs

.

The

remainder

of

installation

is

the

reverse

of

removal

.

Be

sure

to

reihstall

al¡

wires

disconnected

during

the

test,

especial-

¡y

ground

wires

at

the

coils

and

cylinder

head

cover

(where

ap-

plicable)

.

Tightening

Torque

"

Spark

plug

to

cylinder

head

.......

25

Nm

(18

ft-Ib)

Low

compression

indicates

a

poorly

sealed

combustion

6

.

With

the

parking

brake

set,

the

transmission

in

Park

or

chamber

.

Relatively

even

pressures

that

are

below

specification

Neutral,

and

the

accelerator

pedal

pressed

to

the

floor,

normally

indicate

worn

piston

rings

and/or

cylinder

walls

.

Erratic

crank

the

engine

with

the

starter

.

Record

the

highest

values

tend

to

indicate

valve

leakage

.

Dramatic

differences

be

value

indicated

by

the

gauge