130 BMW 323i 1996 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 323i, Model: BMW 323i 1996 E36Pages: 759

Page 412 of 759

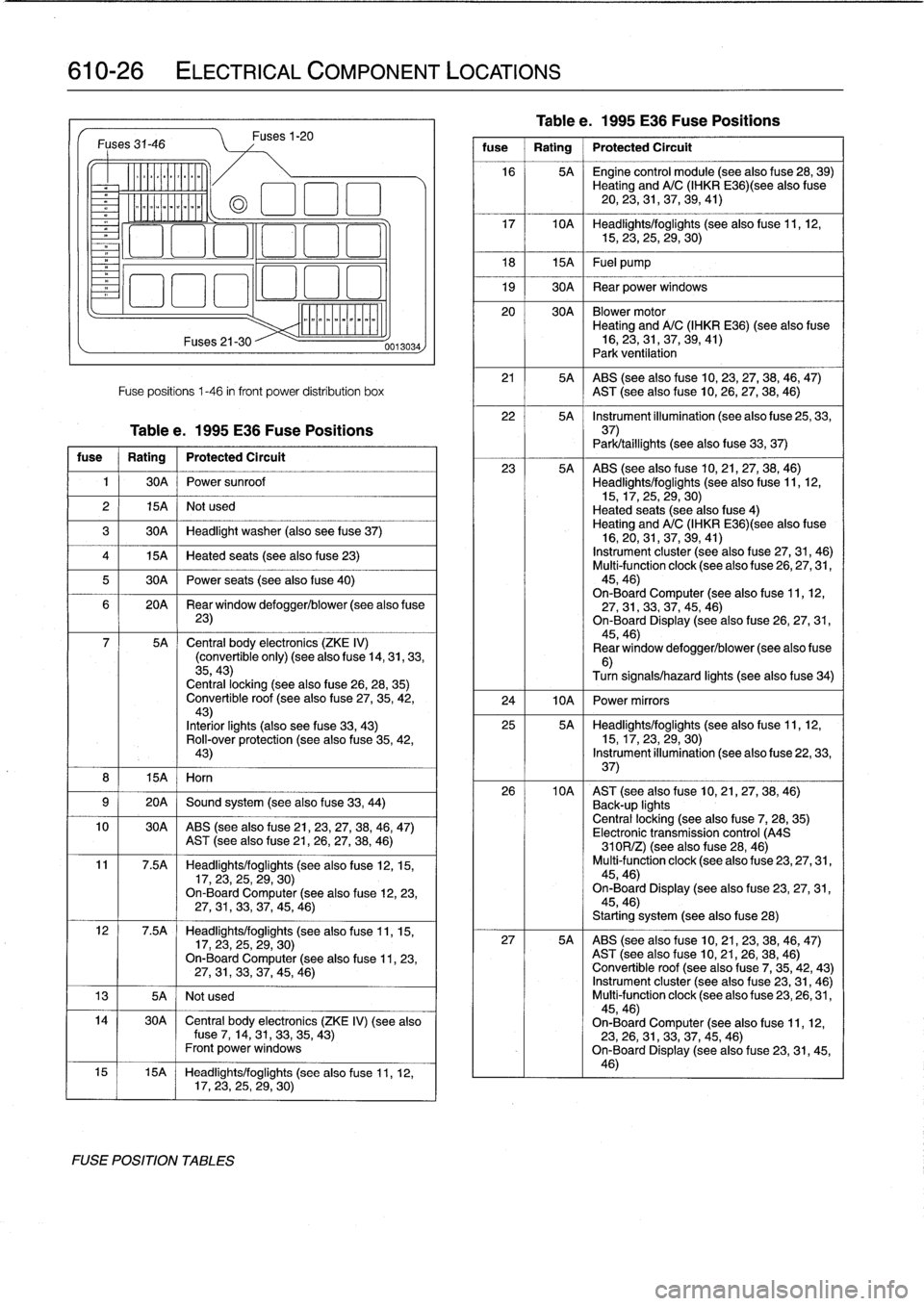

610-26

ELECTRICAL

COMPONENT

LOCATIONS

Fuses31-46

v

.

-------------

Fuses

21-30

Fuses1-20

Fuse

positions

1-46

in

front

power

distribution

box

Tablee

.

1995

E36

Fuse

Positions

fuse

Rating

Protected

Circuit

1

30A

Power

sunroof

2

15A

Not

used

3

30A

Headlight

washer

(also

see

f

use

37)

4

15A

Heated

seats

(see

alsofuse

23)

5

30A

Power

seats

(see

alsofuse

40)

6

20A

Rear

window

defogger/blower(see

also

f

use

23)

7

5A

Central

body

electronics

(ZKE

IV)

(convertible

only)

(see

also

fuse

14,31,33,

35,43)

Centrallocking

(see

also

fuse

26,28,

35)

Convertible

roof

(see

also

fuse

27,

35,

42,43)

Interiorlights

(also

see

fuse

33,

43)

Roll-over

protection

(seealsofuse

35,42,

43)

8

I

15A

I

Horn

9

1

20A

1

Sound

system

(seealsofuse

33,

44)

0013034

10

30A

ABS

(seealsofuse

21,23,

27,

38,46,

47)

AST

(see

also

fuse

21,

26,27,38,

46)

11

7

.5A

Headlights/foglights

(see

also

fuse

12,

15,

17,

23,

25,29,

30)

On-Board

Computer

(seealsofuse

12,23,27,

31,

33,37,45,

46)

12

7

.5A

Headlights/foglights

(see

also

fuse

11,

15,

17,

23,25,

29,

30)

On-BoardComputer

(see

also

fuse

11,

23,27,

31,

33,37,45,

46)

13

I

5A

I

Notused

14

30A

~

Central

body

electronics

(ZKE

IV)

(see

alsofuse

7,

14,31,

33,

35,

43)

Front

power

Windows

15

15A

Headlights/foglights

(seealso

fuse

11,

12,

17,23,25,

29,30)

FOSE

POSITION

TABLES

Tablee

.

1995

E36

Fuse

Positions

fuse

1

Rating

1

Protected

Circuit

16

5A

~

Engine

control

module

(see

also

f

use

28,39)

Heating

andA/C

(IHKR

E36)(see

alsofuse

20,

23,31,

37,

39,

41)

17

10A

Headlights/foglights

(see

also

fuse

11,12,15,23,25,

29,

30)

18

1

15A

1

Fuel

pump

19

1

30A

1

Rear

power

Windows

20

30A

Blowermotor

Heating

andA/C

(IHKR

E36)

(see

also

fuse

16,23,31,

37,

39,

41)

Park

ventilation

21

5A

ABS

(seealsofuse

10,23,27,38,

46,47)

AST

(see

also

fuse

10,26,

27,

38,

46)

22

5A

~

Instrument

illumination

(see

also

f

use

25,

33,37)

Park/taillights

(see

also

fuse

33,

37)

23

5A

ABS

(seealsofuse

10,

21,

27,38,

46)

Headlights/foglights

(see

also

fuse

11,12,15,17,25,

29,

30)

Heated

seats

(see

also

fuse

4)

Heating

andA/C

(IHKR

E36)(see

alsofuse

16,20,31,

37,39,41)

Instrument

cluster

(see

also

f

use

27,31,

46)

Multi-function

clock

(see

also

fuse

26,27,31,

45,46)

On-Board

Computer

(seealso

f

use

11,

12,

27,

31,33,

37,

45,

46)

On-Board

Display

(seealso

fuse

26,27,31,

45,46)

Rear

window

defogger/blower

(see

also

f

use

6)

Turn

signals/hazard

lights

(see

also

f

use

34)

24

I

10A

I

Power

mirrors

25

5A

Headlights/foglights

(see

also

fuse

11,

12,

15,17,23,

29,

30)

Instrument

illumination

(see

also

fuse

22,33,

37)

26

10A

AST

(see

also

fuse

10,21,

27,

38,

46)

Back-up

lights

Centrallocking

(seealsofuse

7,

28,

35)

Electronic

transmission

control

(A4S

310R/Z)

(seealso

tuse

28,

46)

Multi-function

clock

(see

also

fuse

23,

27,31,

45,46)

On-Board

Display

(see

also

fuse

23,27,31,

45,46)

Starting

system

(see

alsofuse

28)

27

5A

ABS

(seealso

fuse

10,

21,

23,38,

46,47)

AST

(see

also

fuse

10,21,

26,

38,

46)

Convertible

roof

(see

also

f

use

7,

35,42,43)

Instrument

cluster

(seealso

f

use

23,

31,

46)

Multi-function

clock

(see

also

fuse

23,26,31,

45,46)

On-Board

Computer

(seealsofuse

11,

12,

23,

26,

31,33,

37,

45,

46)

On-Board

Display

(see

also

f

use

23,31,45,

46)

Page 414 of 759

![BMW 323i 1996 E36 Workshop Manual

610-28

ELECTRICAL

COMPONENT

LOCATIONS

Fuses

31-46

k

Lírcoo)]

LE

7a

Maz

Fuses

21-30

Fuse

positions

1-46

in

front

power

distribution

box

Table

f

.

1996

E36

Fuse

Positions

fuse

Rating

BMW 323i 1996 E36 Workshop Manual

610-28

ELECTRICAL

COMPONENT

LOCATIONS

Fuses

31-46

k

Lírcoo)]

LE

7a

Maz

Fuses

21-30

Fuse

positions

1-46

in

front

power

distribution

box

Table

f

.

1996

E36

Fuse

Positions

fuse

Rating](/img/1/2800/w960_2800-413.png)

610-28

ELECTRICAL

COMPONENT

LOCATIONS

Fuses

31-46

k

Lírcoo)]

LE

7a

Maz

Fuses

21-30

Fuse

positions

1-46

in

front

power

distribution

box

Table

f

.

1996

E36

Fuse

Positions

fuse

Rating

Protected

Circuit

1

30A

Power

sunroof

(see

also

fuse

13)

2

15A

Notused

3

30A

Headlight

washer

(also

see

fuse

37)

4

15A

Heated

seats

(seealsofuse

23)

5

30A

Power

seats

(see

also

f

use

40)

6

20A

Rear

window

defogger/blower

(see

also

f

use

23)

7

5A

Central

body

electronics

(ZKE

IV)

(convertible

only)

(see

also

f

use

14,33,

35,

43)

Central

locking

(seealso

fuse

26,28,

35)

Convertible

roof

(seealsofuse

27,35,42,43)

Interiorlights

(also

see

fuse

33,

43)

Rol¡-oven

protection

(see

also

fuse

35,

42,

43)

8

I

15A

I

Horn

9

1

20A

1

Sound

system

(see

also

fuse

44)

10

30A

ABS

(seealsofuse

21,23,

27,38,46,

47)

AST

(see

also

fuse

21,26,27,

38,46)

11

7.5A

Headlights/foglights

(see

also

fuse

12,15,17,23,25,

29,30)

On-Board

Computer

(seealso

fuse

12,23,27,31,33,

37,45,46)

12

7

.5A

Headlights/foglights

(see

also

fuse

11,15,17,

23,

25,

29,30)

On-Board

Computer

(see

also

f

use

11,23,27,

31,

33,37,

45,46)

13

1

5A

1

Power

sunroof

(seealsofuse

1)

14

30A

~

Central

body

electronics

(ZKE

IV)

(see

also

fuse

7,

14,33,35,

43)

Front

power

windows

15

15A

Headlights/foglights

(see

also

fuse

11,12,17,23,25,29,

30)

FUSE

POSITION

TABLES

Fuses

1-20

0013034

Table

f

.

1996

E36

Fuse

Positions

fuse

1

Rating

1

Protected

Circult

16

5A

~

Engine

control

module

(see

also

f

use

28,

39)

Heating

andA/C

(IHKR

E36)(see

also

fuse

20,

23,31,37,39,41,

48)

17

10A

Headlights/foglights

(see

also

f

use

11,12,

15,23,25,29,

30)

18

1

15A

1

Fuel

pump

19

1

30A

1

Rear

power

windows

20

30A

Blower

motor

Heating

andA/C

(IHKR

E36)

(see

also

fuse

16,23,31,37,39,41,

48)

Park

ventilatíon

21

5A

ABS

(seealsofuse

10,23,

27,38,

46,

47)

AST

(see

alsofuse

10,

26,

27,38,

46)

22

5A

Instrument

illumínation

(see

also

f

use

25,33,

37)

23

5A

ABS

(see

also

fuse

10,21,

27,38,

46)

Headlights/foglights

(see

alsofuse

11,12,

15,17,25,29,

30)

Heated

seats

(seealsofuse

4)

Heating

andA/C

(IHKR

E36)(see

also

fuse

16,20,

31,

37,39,

41,48)

Instrument

cluster

(see

alsofuse

27,

31,46)

Multi-function

clock

(see

alsofuse

26,27,31,

45,46)

On-BoardComputen

(seealso

f

use

11,12,27,31,

33,

37,45,

46)

On-Board

Display

(see

alsofuse

26,

27,31,

45,46)

Rear

window

defogger/blower

(see

also

fuse

6)

Turn

signals/hazard

lights

(seealsofuse

34)

24

I

10A

I

Power

mirrors

25

5A

Headlights/foglights

(see

also

fuse

11,

12,15,

17,

23,

29,

30)

Instrument

illumination

(seealso

fuse

22,

33,

37)

26

10A

Airbag

(SRS)

(see

also

fuse

43)

AST

(see

also

f

use

10,21,

27,

38,

46)

Back-up

lights

Central

locking

(seealsofuse

7,

28,

35)

Electronic

transmission

control

(A4S

310R/Z)

(seealso

f

use

28,

46)

Multi-function

clock

(see

alsofuse

23,27,31,

45,46)

On-Board

Display

(see

also

fuse

23,

27,

31,

45,46)

Starting

system

(see

also

fuse

28)

.

27

5A

ABS

(see

also

fuse

10,21,

23,38,

46,

47)

AST

(see

also

fuse

10,

21,

26,38,

46)

Convertible

roof

(see

also

f

use

7,

35,42,

43)

Instrument

cluster

(see

alsofuse

23,

31,46)

Multi-function

clock

(see

alsofuse

23,26,

31,

45,46)

On-Board

Computer

(seealsofuse

11,12,

23,

26,31,33,37,

45,46)

On-Board

Display

(see

also

fuse

23,

31,45,

46)

Page 416 of 759

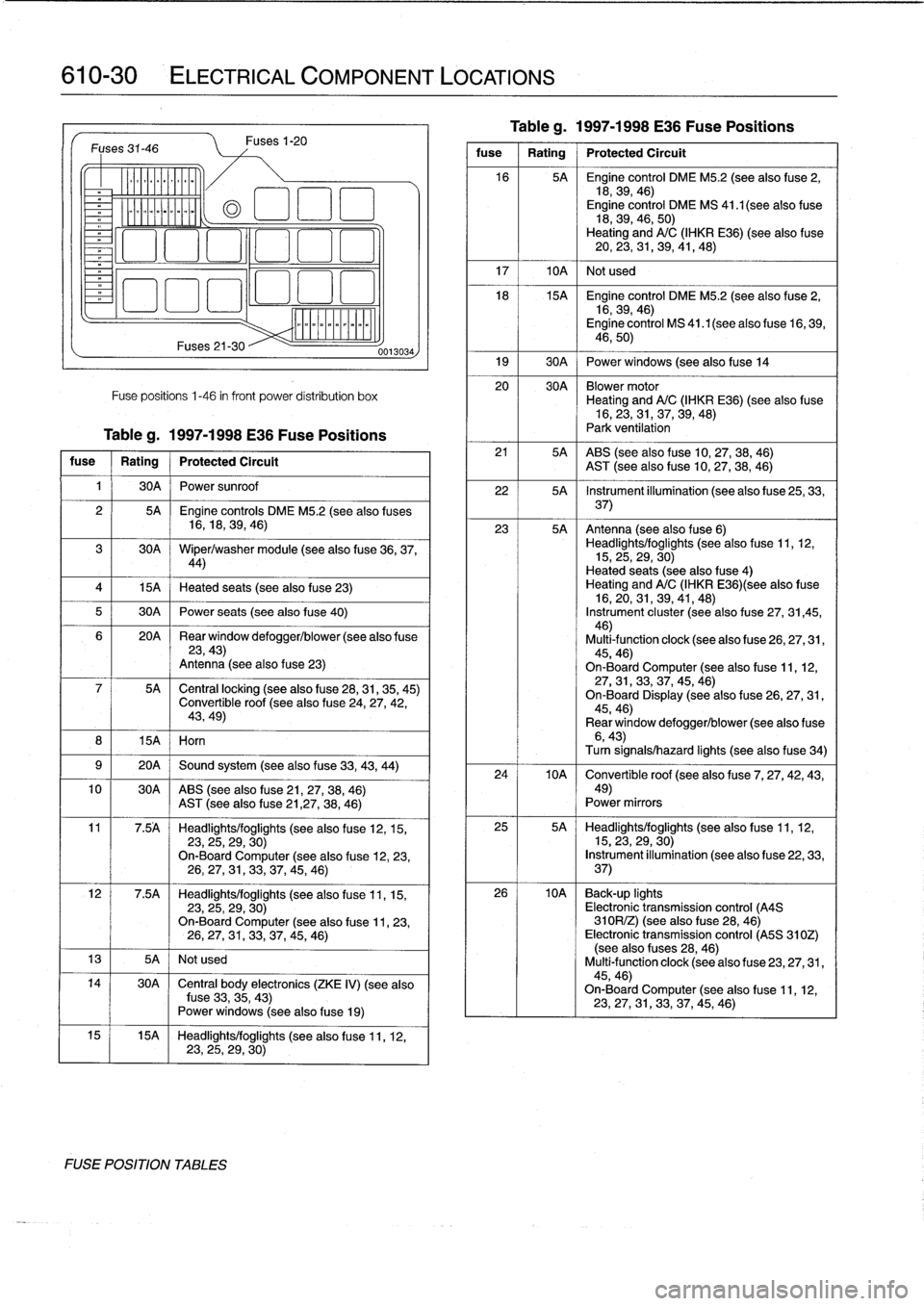

610-30

ELECTRICAL

COMPONENT

LOCATIONS

Fuses

31-46

v

--------------

15A

I

Horn

Fuses21-30

Fuses

1-20

Fuse

positions

1-46

in

front

power

distribution

box

Tableg

.

1997-1998

E36

Fuse

Positions

fuse

Rating

Protected

Circuit

1

I

30A

I

Power

sunroof

4

1

15A

1

Heated

seats

(see

also

fuse

23)

5

1

30A

1

Power

seats

(see

also

fuse

40)

10

30A

ABS

(see

also

fuse

21,27,38,

46)

AST

(see

alsofuse21,27,

38,

46)

13

I

5A

I

Not

used

FUSE

POSITION

TABLES

0013034

2

I

5A

Engine

controls

DME

M5

.2

(see

also

fuses

16,18,

39,

46)

30A

Wiper/washer

module

(seealso

fuse

36,37,44)

20A

~

Rear

window

defogger/blower

(see

also

f

use23,43)

Antenna

(see

also

fuse

23)

5A

~

Central

locking

(seealso

fuse

28,31,35,

45)

Convertible

roof

(see

also

fuse

24,

27,42,

43,49)

9

1

20A

1

Sound

system

(see

also

fuse

33,43,

44)

11

7

.5A

Headlights/foglights

(see

also

fuse

12,15,

23,

25,29,

30)

On-Board

Computer

(see

also

fuse

12,23,

26,

27,31,33,

37,45,

46)

12

7

.5A

Headlights/foglights

(see

also

fuse

11,15,

23,

25,29,

30)

On-Board

Computer

(see

also

f

use

11,23,

26,27,

31,33,

37,45,

46)

14

I

30A

~

Central

body

electronics

(ZKE

IV)

(see

also

fuse

33,

35,43)

Power

windows

(seealso

f

use

19)

15

15A

Headlights/foglights

(see

alsofuse

11,

12,23,25,

29,

30)

Tableg

.

1997-1998

E36

Fuse

Positions

fuse

1

Rating

1

Protected

Circuit

16

5A

Engíne

control

DME

M5

.2

(see

alsofuse

2,

18,39,

46)

Engine

control

DME

MS

41

.1

(see

also

fuse

18,39,46,

50)

Heating

andA/C

(IHKR

E36)

(see

also

fuse

20,

23,31,39,41,

48)

17

I

10A

1

Not

used

18

15A

Engine

control

DME

M5

.2

(seealso

fuse

2,

16,39,

46)

Engine

control

MS

41.1(seealso

fuse

16,

39,

46,50)

19

1

30A

j

Power

windows

(seealsofuse

14

20

30A

Blowermotor

Heating

andA/C

(IHKR

E36)

(see

also

fuse

16,

23,

31,37,39,

48)

Park

ventilation

21

5A

ABS

(seealso

f

use

10,

27,38,

46)

AST

(see

also

fuse

10,27,38,

46)

22

5A

Instrument

illumination

(see

also

f

use

25,

33,

37)

23

5A

Antenna

(see

also

fuse

6)

Headlights/foglights

(see

also

fuse

11,

12,

15,

25,

29,

30)

Heated

seats

(see

also

fuse

4)

Heating

andA/C

(IHKR

E36)(see

also

fuse

16,

20,

31,39,41,

48)

Instrument

cluster

(seealso

f

use

27,

31,45,

46)

Multi-function

clock

(seealsofuse

26,27,31,

45,46)

On-Board

Computer

(see

also

fuse

11,12,27,

31,

33,37,45,

46)

On-Board

Display

(seealsofuse

26,27,

31,

45,46)

Rear

window

defogger/blower

(see

also

f

use6,43)Turn

signals/hazard

lights

(seealsofuse

34)

24

10A

~

Convertible

roof

(see

also

f

use

7,

27,42,43,

49)

Power

mirrors

25

5A

Headlights/foglights

(seealso

fuse

11,12,

15,23,

29,30)

Instrument

illumination

(seealso

fuse

22,33,

37)

26

10A

Back-up

lights

Electronic

transmission

control

(A4S

310R/Z)

(see

also

f

use

28,

46)

Electronic

transmission

control

(A5S

310Z)

(see

also

fuses

28,46)

Multi-function

clock

(see

also

fuse

23,

27,

31,

45,46)

On-Board

Computer

(see

alsofuse

11,

12,

23,

27,31,33,37,45,

46)

Page 421 of 759

4

.

Installation

is

reverse

of

removal

.

Recheck

wiper

arm

tightening

torque

after

waiting

15minutes

.

Tightening

Torque

"

Wiper

arm

to

wiper

shaft

..........

25

Nm

(18

ft-Ib)

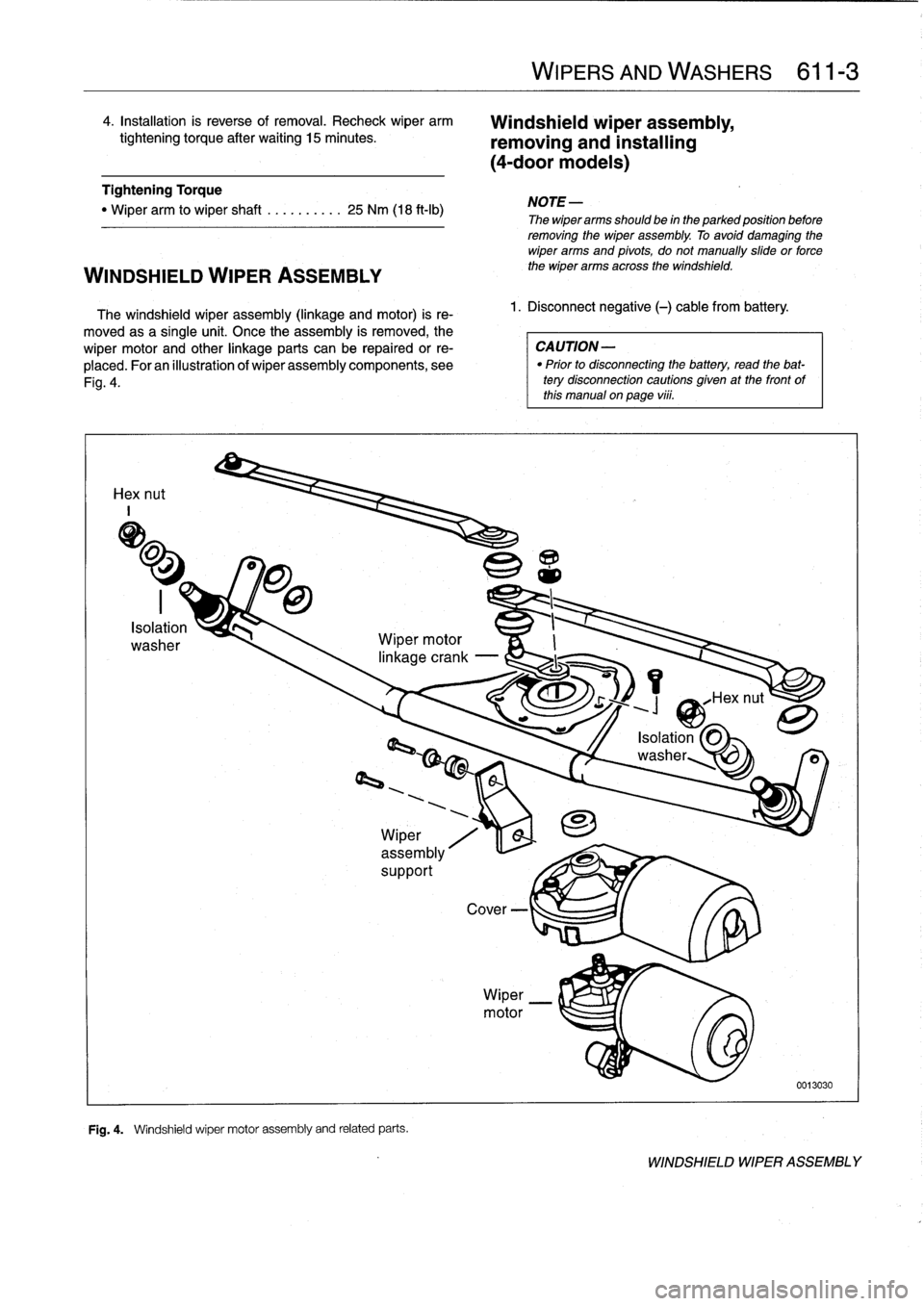

WINDSHIELD

WIPER

ASSEMBLY

The

windshield

wiper

assembly

(linkage

and

motor)

is

re-

moved

asa

single

unit

.

Once

the

assembly

is

removed,

the

wiper

motor

and

other

linkage

parts

can

be

repairedor

re-

placed

.

Foran

illustration

of

wiper

assembly

components,

see

Fig

.

4

.

Hex

nut

I

J

Wiper

motor

Fig

.

4

.

Windshield

wiper

motor

assembly

and

related

parts

.

WIPERS

AND

WASHERS

611-

3

Windshield

wiperassembly,

removing

and

installing

(4-door

modeis)

1

.

Disconnect

negative

(-)

cable

from

battery

.

NOTE

-

Thewiperarms

should

be

in

the

parked

position

before

removing

the

wiper

assembly

.

To

avoid

damaging

the

wiper

arms

and

pivots,

do

not

manually

slide

or

force

the

wiper

arms

across

the

windshield

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

0013030

WINDSHIELD

WIPER

ASSEMBLY

Page 439 of 759

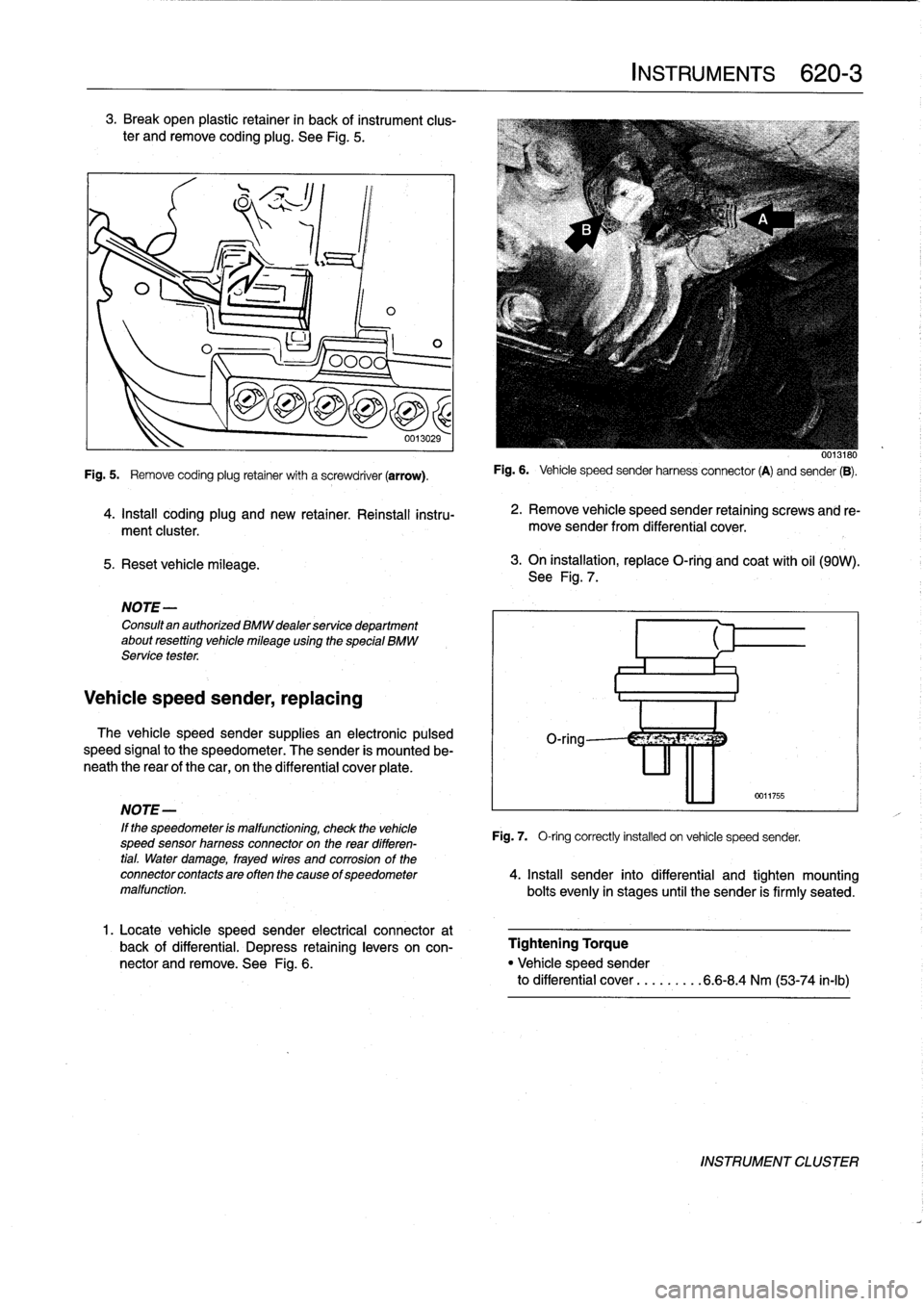

3

.

Break

open

plastic

retainer

in

back

of

instrument

clus-

ter

andremove

coding

plug

.

See

Fig

.

5

.

5

.

Reset

vehicle

mileage

.

1

ILO

NOTE-

Consultan

authorized

BMW

dealer

service

department

about

resetting

vehicle

mileage

using

the

special

BMW

Service

tester

.

Vehicle

speed

sender,

replacing

0

0013029

Fig

.

5

.

Remove

coding

plug

retainer

with

a

screwdriver

(arrow)

.

4

.

Install

coding

plug

and

new

retainer

.

Reinstall

instru-

ment

cluster

.

The

vehicle

speed

sender

supplies

an

electronic

pulsed

speed

signal

to

the

speedometer

.

The

sender

is

mounted

be-

neath

the

rear

of

the

car,

on

the

differential

cover

plate

.

1

.

Locate

vehicle

speed

sender

electrical

connector

at

back

of

differential

.

Depress

retaininglevers

on

con-

nector

and

remove

.

See

Fig

.

6

.

INSTRUMENTS

620-

3

0013180

Fig

.

6

.

Vehicle

speed

sender

harnessconnector

(A)

and

sender

(B)

.

2

.

Remove

vehicle

speed

sender

retaining

screws

and

re-

move

sender

from

differential

cover

.

3

.

On

installation,

replace

O-ring

and

coat

with

oil

(90W)

.

See

Fig

.

7

.

0011755

NOTE-

'

If

the

speedometer

is

malfunctioning,

check

the

vehicle

Fig

.

7,

O-ring

correctly

installed

on

vehicle

speed

sender,

speed

sensor

hamess

connectoron

the

rear

differen-

tial

.

Water

damage,

frayed

wires

and

corrosion

of

the

connectorcontactsareoftenthecause

ofspeedometer

4

.

Insta¡¡

sender

into

differential

and

tighten

mounting

malfunction

.

bolts

evenly

in

stages

until

the

sender

is

firmly

seated

.

Tightening

Torque

"

Vehicle

speed

sender

to

differential

cover

...

.

.....

6

.6-8

.4

Nm

(53-74

in-lb)

INSTRUMENT

CLUSTER

Page 440 of 759

620-

4

INSTRUMENTS

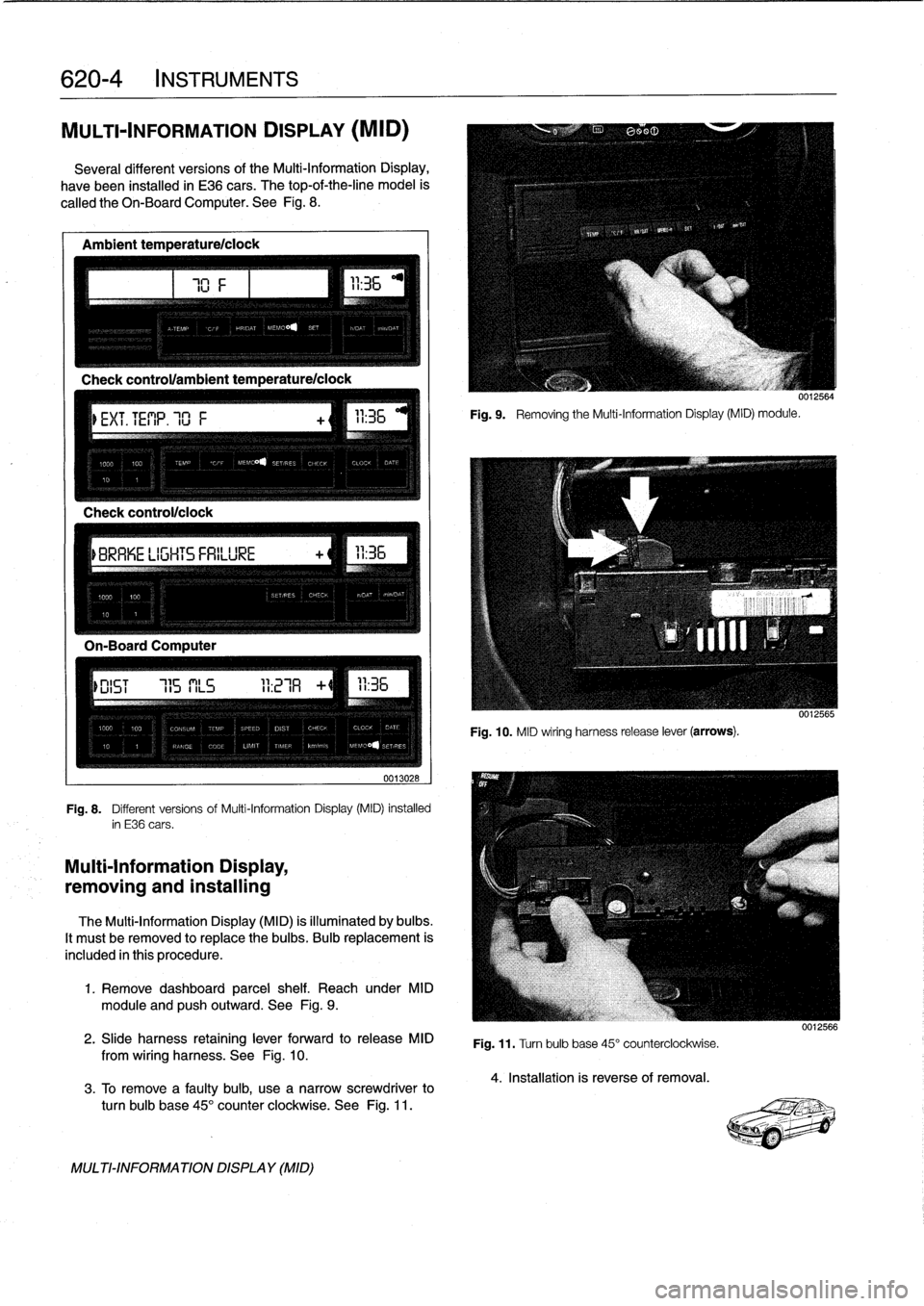

MULTI-INFORMATION

DISPLAY

(MID)

Severa¡

different

versionsof

the

Multi-Information

Display,

have

been

installed

in

E36

cars

.

The

top-of-the-line

model

is

called

the

Oh-BoardComputer

.

See

Fig

.

8

.

Ambient

temperature/ciock

Check

control/clock

0013028

Fig

.

8

.

Different

versions

of

Multi-Information

Display

(MID)

installed

in

E36

cars

.

Multi-Information

Display,

removing

and

installing

The

Multi-Information

Display

(MID)

is

illuminated

by

bulbs

.

It

mustbe

removed

to

replace

the

bulbs

.

Bulb

replacement

is

included

in

this

procedure

.

1

.

Remove

dashboard

parcel

shelf

.

Reach

under

MID

module

and

pushoutward

.

See

Fig

.

9

.

2

.

Slide

harness

retaining

lever

forward

to

release

MID

from

wiring

harness

.

See

Fig

.

10

.

3

.

To

Rmove

a

faulty

bulb,

use

anarrow

screwdriver

to

turn

bulb

base

45°

counter

clockwíse

.

See

Fig

.

11

.

MULTI-INFORMATIONDISPLAY

(MID)

111

Fig

.

9

.

Removing

the

Multi-Information

Display(MID)

module

.

0012564

Fig

.

10

.

MID

wiring

harness

release

lever

(arrows)

.

Fig

.

11

.

Turn

bulb

base

45°

counterclockwise

.

4

.

Installation

is

reverse

of

removal

.

0012566

Page 447 of 759

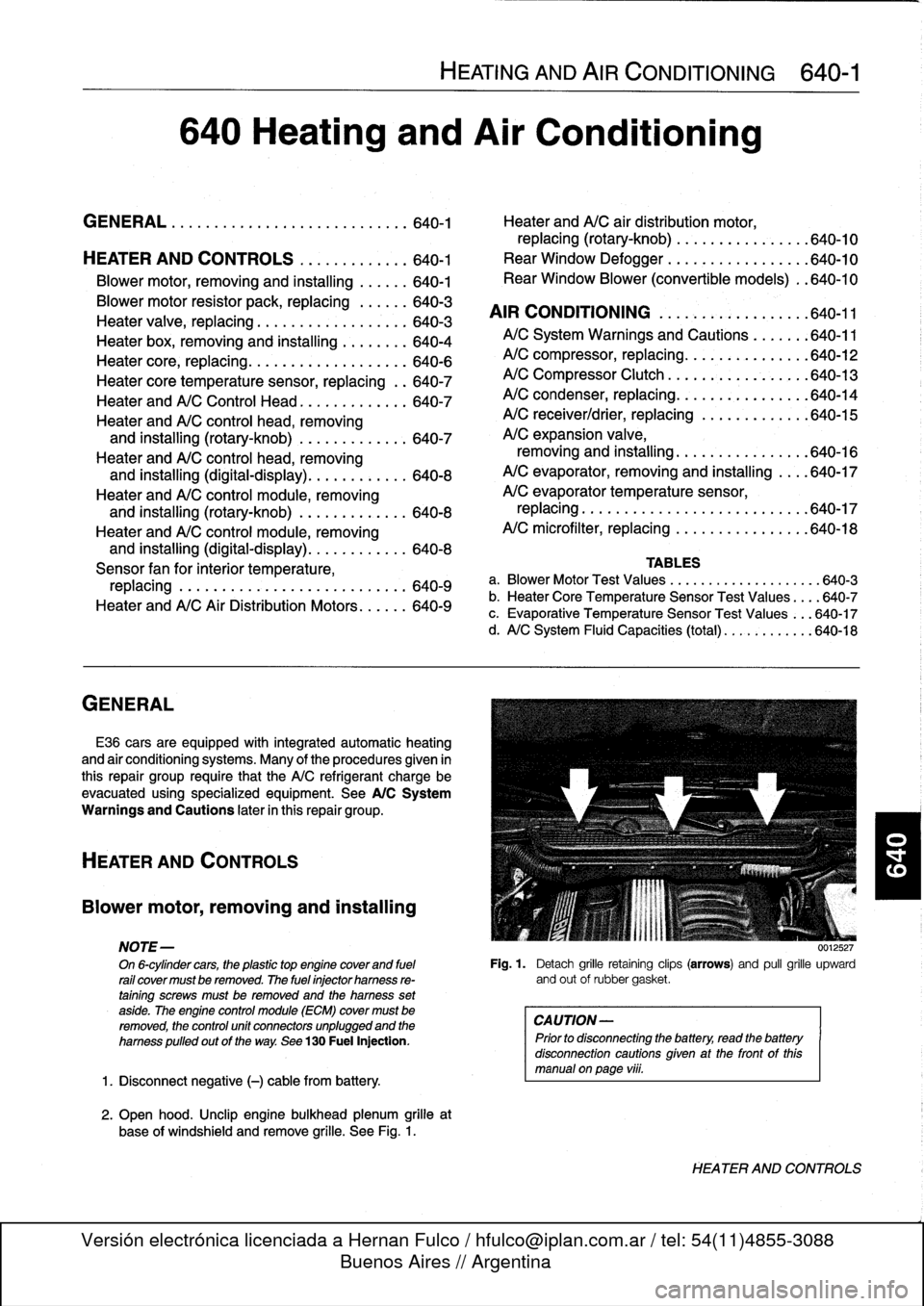

GENERAL

E36

cars

are

equipped

with

integrated

automatic

heating

and

air

conditioning

systems

.

Many

of

the

procedures

given

in

this

repair

group

require

that

the

A/C

refrigerant

charge

be

evacuated

using

specialized

equipment

.

See

A/C

System

Warningsand

Cautions

later

in

this

repair

group

.

HEATER

AND

CONTROLS

Blower

motor,

removing

and

installing

NOTE-

On

6-cylinder

cars,

the

plastic

top

enginecover

and

fuel

rail

covermustbe

removed

.

The

fuel

injectorhamess

re-

taining

screws

must

be

removed

and

the

harness

set

aside

.

The

engine

control

module

(ECM)

cover

must

be

removed,

the

control

unit

connectors

unplugged

and

the

harness

pulled

out

of

the

way

.

See

130

Fuel

Injection

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

2

.

Open

hood

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

windshíeld

and

remove

grille

.

See

Fig

.

1

.

HEATING

AND

AIR

CONDITIONING

640-1

640

Heating

and

Air

Conditioning

GENERAL

.

...

.

....

.

.

.

.

.

.

.

.

.

.......

.

.

.

640-1

Heater

andA/C

air

distribution

motor,

replacing(rotary-knob)

.

.

...

.

.

.

.......

.

640-10

HEATER

AND

CONTROLS

.

.....

.

.

.

.

.

.

.640-1

Rear

Window

Defogger

.

.

.

.

.

.

.

.

.

.

...

.

.

.

640-10

Blower

motor,

removing

and

installing

.

.

.

.

.

.

640-1

Rear

Window

Blower

(convertible

models)

.

.640-10

Blowermotor

resistor

pack,

replacing

.

.

.

.

.

.

640-3

AIR

CONDITIONING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-11

Heater

valve,

replacing

...........

.

.

.

.

.

.

.

640-3

Heater

box,

removing

and

installing

.

.

.

.

.

.

.

.

640-4

A/CSystem

Warnings

and

Cautions

.

.

.

.

.

.

:640-11

Heater

core,

replacing

.....

.

.

:

....

.

.

.

.

.

.

.

640-6

A/C

compressor,

replacing

.

.

::.

:

:

.

.

.

.

.

.

.

.640-12

Heater

core

temperature

sensor,

replacing

.

.

640-7

A/C

Compressor

Clutch

.

.

.

.

.

.

.

:

.

.

.

.

.

.

.

.

.

640-13

Heater

andA/C

Control

Head

.

.

....

.

.....

.

640-7

A/C

condenser,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-14

Heater

andA/C

control

head,

removing

A/C

receiver/drier,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

640-15

and

installing

(rotary-knob)

.

.

....

.

......

640-7

A/C

expansion

valve,

Heater

andA/C

control

head,

removing

removing

and

installing

...

.

.....

.

.

.

.

.

.

.

640-16

and

installing

(digital-display)

.

.....

.

.....

640-8

A/C

evaporator,

removing

and

installing

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

evaporator

temperature

sensor,

and

installing

(rotary-knob)

.

.

...

.

.

.

.

.

.

.

.

640-8

replacing

.

.

.

.

.

.

..............

.

.

.

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

microfilter,

replacing

......

.

....

.

.

.

..

640-18

and

installing

(digital-display)

.

...

.

.

.

.

.

...

640-8

Sensor

fan

for

interior

temperature,

TABLES

replacing

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-9

a

.

Blower

Motor

Test

Values

.........

...

.

.

......

640-3

Heater

andA/C

AirDistribution

Motors

.

.

.

.

.

.

640-9

b

.

Heater

Core

Temperature

Sensor

Test

Values

...

.640-7

c

.

Evaporative

Temperature

Sensor

Test

Values

...

640-17

d

.

A/C

System

Fluid

Capacities

(total)

..

..........

640-18

0012527

Fig

.

1

.

Detach

grille

retaining

clips

(arrows)

and

pull

grille

upward

and

out

of

rubbergasket

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

HEATER

AND

CONTROLS

Page 454 of 759

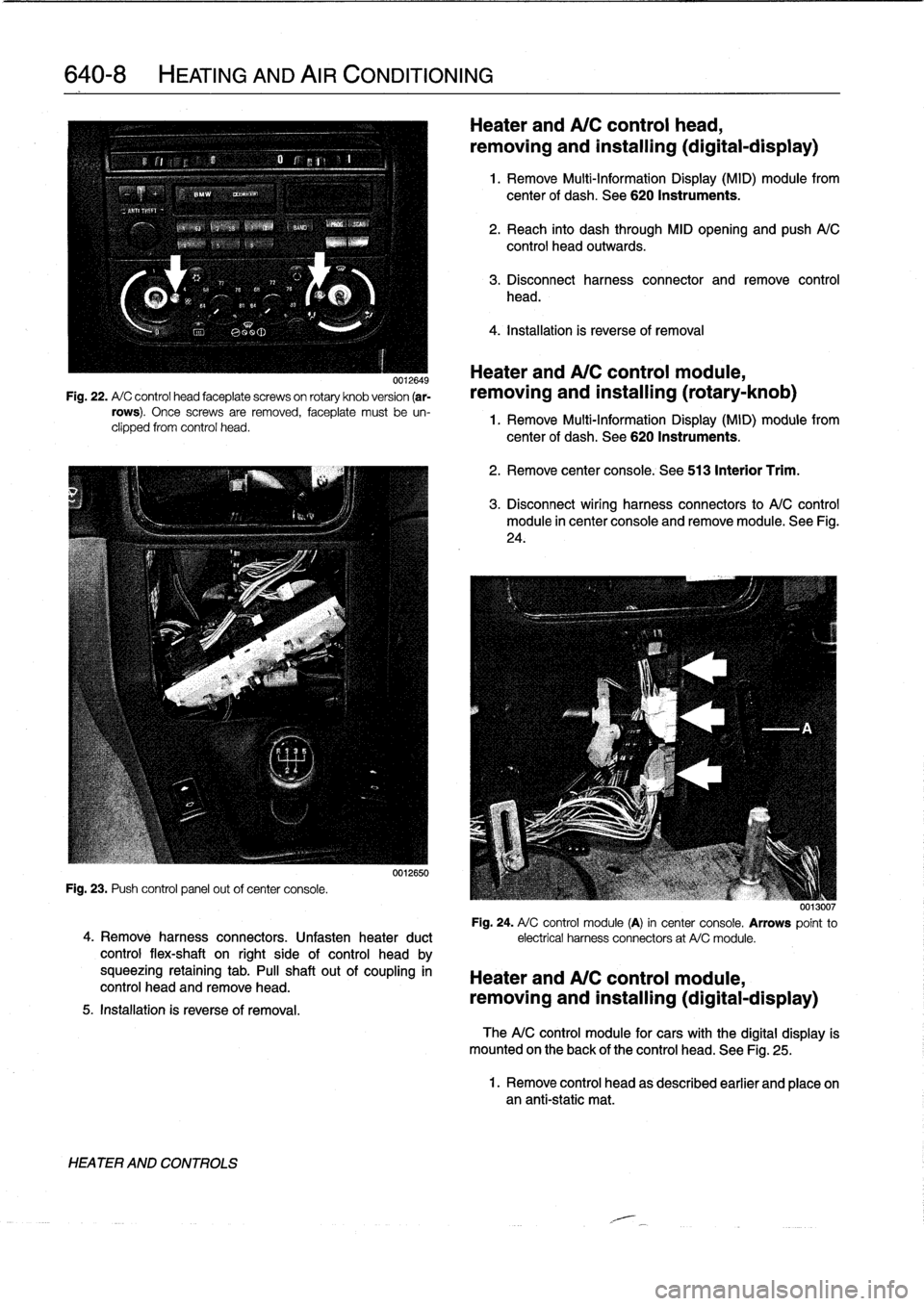

640-8

HEATING

AND

AIR

CONDITIONING

0012649

Fig

.

22

.

A/

C

control

head

faceplate

screwson

rotary

knob

version

(ar-

rows)

.

Once

screws

are

removed,

faceplate

must

be

un-

clipped

from

control

head

.

Fig

.

23

.

Push

control

panel

out

ofcenter

console

.

4

.

Remove

harness

connectors

.

Unfasten

heater

duct

control

flex-shaft

on

right

side

of

control

head

by

squeezing

retaining

tab

.

PA

shaftout

of

coupling

in

control

head

and

remove

head

.

5

.

Installation

is

reverseof

removal

.

HEATER

AND

CONTROLS

0012650

Heater

and

A/C

control

head,

removing

and

installing(digital-display)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Reach

into

dash

through

MID

opening

and

push

A/C

control

head

outwards

.

3

.

Disconnect

harness

connector

and

remove

control

head

.

4

.

Installation

is

reverse

of

removal

Heater

andA/C

control

module,

removing

and

installing

(rotary-knob)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Disconnect

wiring

harness

connectors

to

A/C

control

module

in

center

console

and

removemodule

.

See

Fig

.

24

.

0013007

Fig

.

24

.

A/

C

control

module

(A)

in

center

console

.

Arrows

point

to

electrical

harness

connectors

at

A/Cmodule

.

Heater

and

A/C

control

module,

removing

and

installing(digital-display)

TheA/C

control

module

for

cars

with

the

digital

display

is

mounted

on

the

back

of

the

control

head

.

See

Fig

.

25

.

1

.

Remove

control

head

as

described

earlier

and

place

onan

anti-static

mat

.

Page 456 of 759

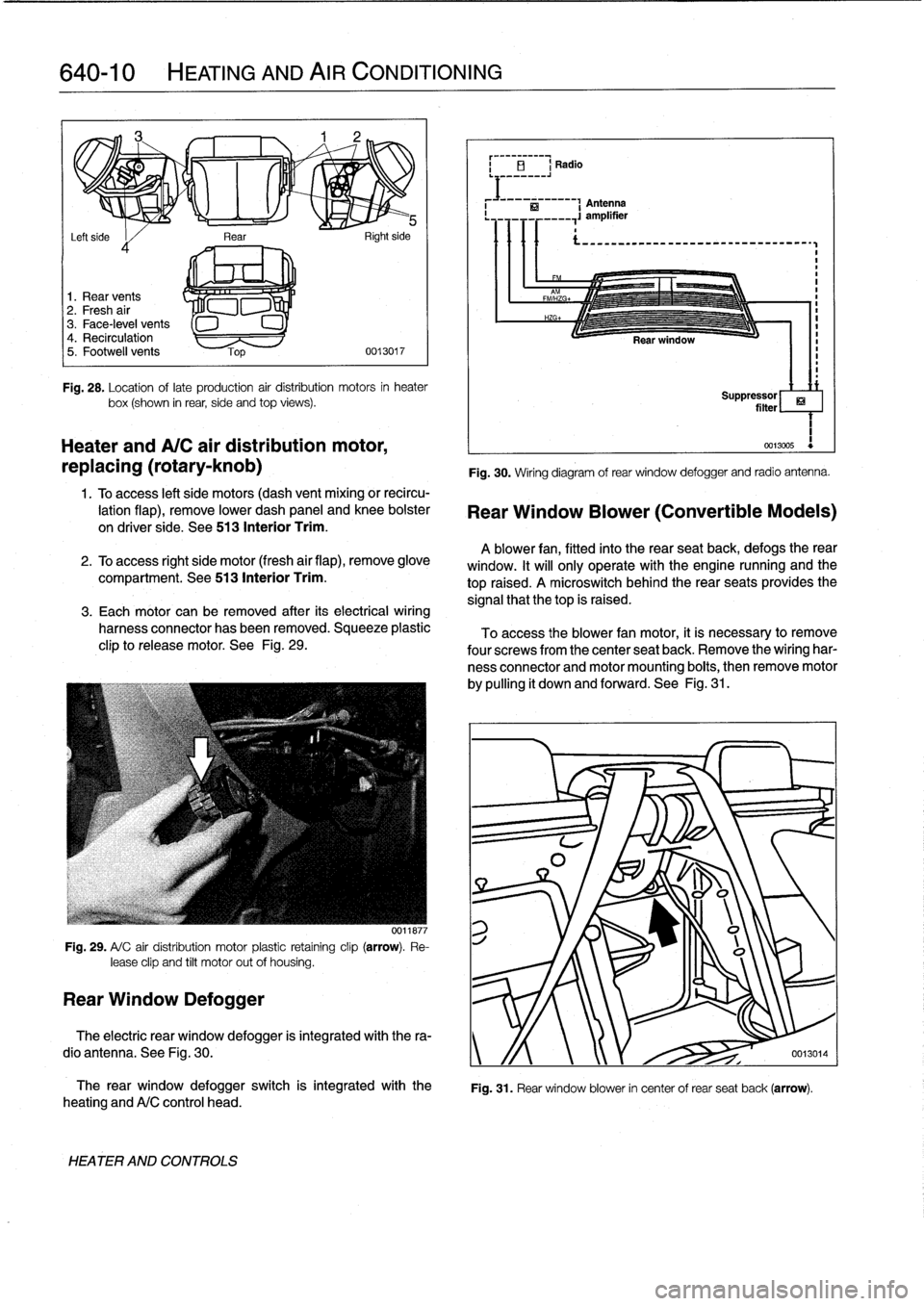

640-10

HEATING

AND

AIR

CONDITIONING

i

El

Radio

Antenna

Rear

.

,

si,-

Left

side

I

d

1

.

Rear

vents

2

.

Fresh

air

3

.

Face-level

vents

4

.

Recirculation

5

.

Footwell

vents

0013017

Fig

.

28

.

Location

oflate

production

air

distribution

motors

in

heater

box(shown

in

rear,

side

and

top

views)

.

Heater

andA/C

air

distribution

motor,

replacing

(rotary-knob)

1

.

Toaccess

left

side

motors

(dash

vent

mixing

or

recircu-

lation

flap),

remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

2

.

To

access

right

side

motor

(fresh

air

flap),

remove

glove

compartment

.

See513

Interior

Trim

.

3

.

Each

motor

can

be

removed

after

its

electrical

wiring

harness

connector

has

been

removed

.

Squeeze

plastic

clip

to

release

motor

.

See

Fig

.

29

.

Fig

.

29

.

A/

C

air

distribution

motor

plastic

retaíning

clip

(arrow)

.

Re-

lease

clip

and

tilt

motor

out

of

housing

.

Rear

Window

Defogger

0011877

The

rear

window

defogger

switch

is

integrated

with

the

heating

andA/C

control

head

.

HEATER

AND

CONTROLS

Fig

.

30

.

Wiring

diagram

of

rear

window

defogger

and

radio

antenna

.

Rear

Window

Blower

(Convertible

Models)

A

blower

fan,

fitted

into

the

rear

seatback,

defogs

therear

window

.

It

will

only

operate

with

the

engine

nunning

and

the

top

raised

.

A

microswitch

behindthe

rear

seats

provides

the

signal

that

thetop

is

raised

.

To

access

the

blower

fan

motor,

it

is

necessary

to

remove

four

screwsfrom

the

center

seat

back

.

Remove

the

wiring

har-

ness

connector

and

motor

mounting

boits,

then

remove

motor

by

pulling

it

down

and

forward

.

See

Fig

.

31

.

ri

Suppressor

filter

1

0013005

Fig

.

31

.

Rear

window

blower

in

center

of

rear

seat

back

(arrow)

.

The

electric

rear

window

defogger

is

integrated

with

the

ra-

dio

antenna

.

See

Fig

.

30

.

y

/f

0013014

Page 457 of 759

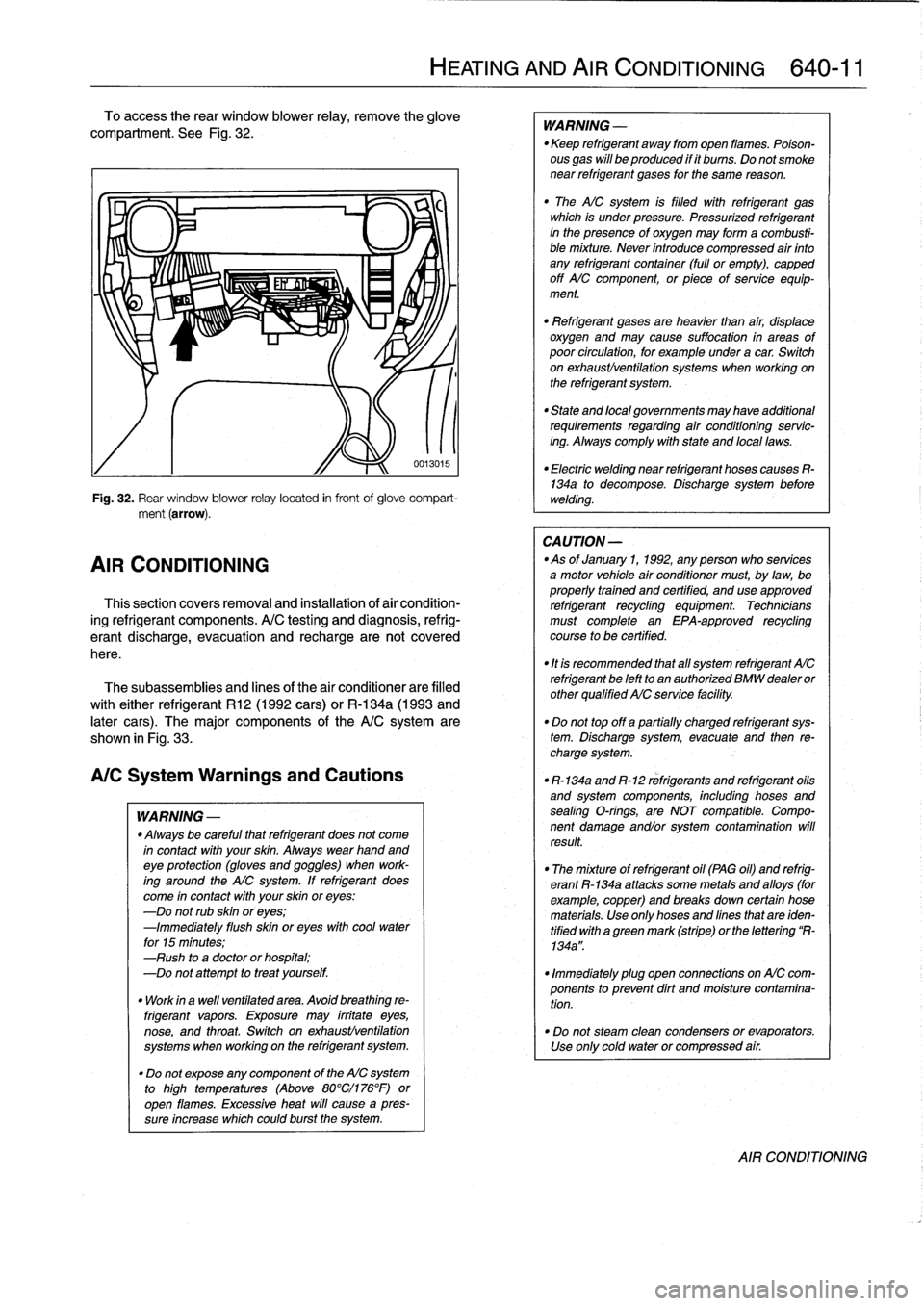

To

access

the

rear

window

blower

relay,

remove

the

glove

compariment

.

See

Fig

.

32

.

Fig

.

32

.

Rear

window

blower

relay

located

in

frontof

glove

compart-

ment

(arrow)

.

AIR

CONDITIONING

Thissection

covers

removal

and

installation

of

air

condition-

ing

refrigerant

components

.

A/C

testing

and

diagnosis,

refrig-

erantdischarge,

evacuatíon

and

recharge

are

not

covered

here

.

The

subassemblies

and

lines

of

the

air

conditionerare

filled

with

either

refrigerant

R12

(1992

cars)

or

R-134a

(1993

and

later

cars)

.

The

major

components

of

the

A/Csystem

are

shown

in

Fig

.

33

.

A/CSystem

Warnings

and

Cautions

WARNING

-

"

Always

be

careful

that

refrigerant

does

not

come

in

contact

with

your

skin

.

Always

wearhand

andeye

protection

(gloves

and

goggles)

when

work-

ing

around

the

AIC

system

.

If

refrigerant

does

come

in

contact

with

your

skin

oreyes

:

-Do

not

rub

skin

oreyes

;

-Immediately

flush

skin

oreyes

withcool

water

for

15

minutes

;

-Rush

to

a

doctor

orhospital

;

-Do

not

attempt

to

treat

yourself

.

"

Work

in

a

wefl

ventilated

area

.

Avoid

breathing

re-

frigerant

vapors

.

Exposure

may

irrítate

eyes,

nose,

and

throat

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

Do

not

expose

any

component

of

the

AIC

system

to

high

temperatures

(Above

80°Cl176°F)or

open

flames

.

Excessive

heat

will

cause

a

pres-

sureincrease

whichcould

burst

the

system

.

HEATING

AND

AIR

CONDITIONING

640-

1

1

0013015

WARNING

-

"

Keep

refrigerant

away

from

open

llames

.

Poison-

ous

gas

will

be

produced

if

it

bums

.

Do

not

smoke

near

refrigerant

gases

for

the

same

reason

.

"

The

AICsystem

is

filled

with

refrigerant

gas

which

is

under

pressure

.

Pressurized

refrigerant

in

the

presenceof

oxygen

may

forma

combusti-

ble

mixture

.

Never

introduce

compressed

air

finto

any

refrigerant

container

(full

or

empty),

capped

off

AIC

component,

or

piece

of

service

equip-

ment

.

"

Refrígerant

gases

are

heavier

than

air,

displace

oxygen

and

may

cause

suffocation

in

areas

of

poor

círculation,

for

example

under

a

car

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

State

and

local

governments

may

have

additional

requirements

regarding

air

conditioning

servic-

ing

.

Alwayscomply

with

state

and

local

laws

.

"

Electric

welding

near

refrigerant

hoses

causes

R-134a

to

decompose

.

Discharge

system

before

welding

.

CA

UTION

-

-As

of

January

1,

1992,

any

person

who

services

a

motor

vehicle

air

conditioner

must,

by

law,

be

properly

trained

and

certified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-approved

recycling

course

to

be

certified

.

"

It

is

recommended

that

al¡

system

refrigerant

AIC

refrigerant

be

left

to

an

authorized

BMW

dealer

or

other

qualified

AIC

service

facility

.

"

Do

not

top

off

a

partially

charged

refrigerant

sys-

tem

.

Dischargesystem,evacuate

and

then

re-

charge

system

.

"

R-134a

and

R-12

refrigerants

and

refrigerant

oils

and

system

components,

including

hoses

and

sealing

O-rings,

are

NOT

compatible

.

Compo-

nent

damage

andlor

system

contamination

will

result

.

"

The

mixture

of

refrigerant

oil

(PAG

oil)

and

refrig-

erant

R-134a

attacks

some

metals

and

alloys

(for

example,copper)

and

breaks

down

certain

hose

materials

.

Use

only

hoses

and

lines

that

are

iden-

tified

with

a

green

mark

(stripe)

or

the

lettering

R-

134a"

.

"

Immediately

plug

open

connections

on

AIC

com-

ponents

to

prevent

dirt

and

moisture

contamina-

tion

.

"

Do

not

steam

clean

condensers

or

evaporators

.

Use

only

cold

water

or

compressed

air

.

AIR

CONDITIONING