130 BMW 323i 1996 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 323i, Model: BMW 323i 1996 E36Pages: 759

Page 254 of 759

300-6

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

BATTE

RY

KL

30

ECM

MAIN

C~

RELAY

KL

15

DSC

SWITCH

LF1

;1~lZZ~

nSLn

l'

z

sJ

WHEEL

RF

c_

.

LR

r_

.

>

RR

ELECTRONIC

BRAKE

LIGHT

SWITCH

SPEED

SENSORS

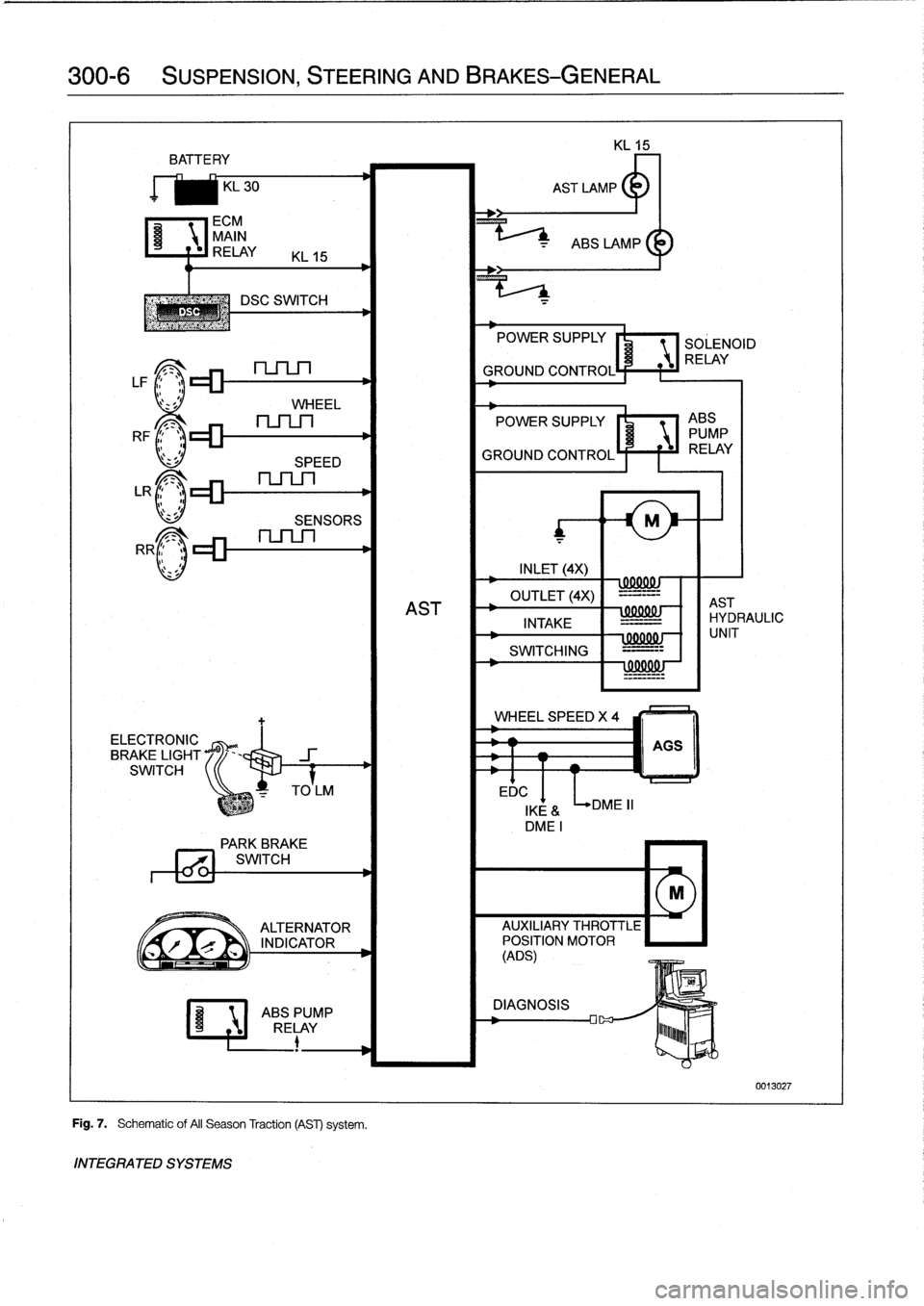

Fig

.

7

.

Schematic

of

AII

Season

Traction

(AST)

system

.

INTEGRATED

SYSTEMS

EDC

POWER

SUPPLY

SOLENOID

RELAY

GROUND

CONTROL

POWER

SUPPLY

I'

1

ABS

PUMP

GROUND

CONTROLÍ

F

f

iJ

RELAY

INLET

(4X)

wxxuw

OUTLET

(4X)

-=-=--

AST

AST

INTAKE

IHYDRAULIC

-

=-

SWITCHING

=---

!

99001

!J

WHEEL

SPEED

X

4

DME

II

000001

-

f

1

UNIT

AGS

IKE

&

DMEI

PARK

BREVE

771

SWITCH

M

ALTERNATOR

AUXILIARY

THROTTLE

r

`

INDICATOR

POSITION

MOTOR

(ADS)

ABSPUMP

DIAGNOSIS

RELAY

lu~~~b

0013027

Page 303 of 759

GENERAL

.

....

.

.

.

.

.

.......

.

.

.

.

.

...

.

.

.

400-1

INTERIOR

EQUIPMENT

......

.

.

.

.......

400-4

Seats

and

Seatbelts

.

.

.

.

.

.

.....

.

.

.

.

.

..

.

..

400-4

BODY

ASSEMBLY

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

.400-2

Instruments

and

Controls

.

..

....

.

.

.

.

.

.

.

...

400-4

Exterior

and

Aerodynamics

....

.

.

.

.

.

.

.

.

.

.

.

400-2

Central

Body

Electronics

.......

.

.

.

...

.

...

400-5

Coupe

Models

..

.

.

.

.

.

.......

.

.

.

.

.

.

.

.

.

..

400-3

Electronic

Immobilization

System

.

.

.

...

.

...

400-5

Convertible

Models

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

..

400-3

Heating

and

Air

Conditioning

.

...

.

.

.

.

.

.

.

...

400-6

GENERAL

This

section

covers

system

descriptions

and

general

ser-

vice

information

for

the

repair

groupsfound

in

4

Body

and

5

Body

Equipment

.

When

working

or

servicing

cars

equipped

with

SRS

air-

bag(s),

the

following

precautions

must

be

observed

to

prevent

injury

.

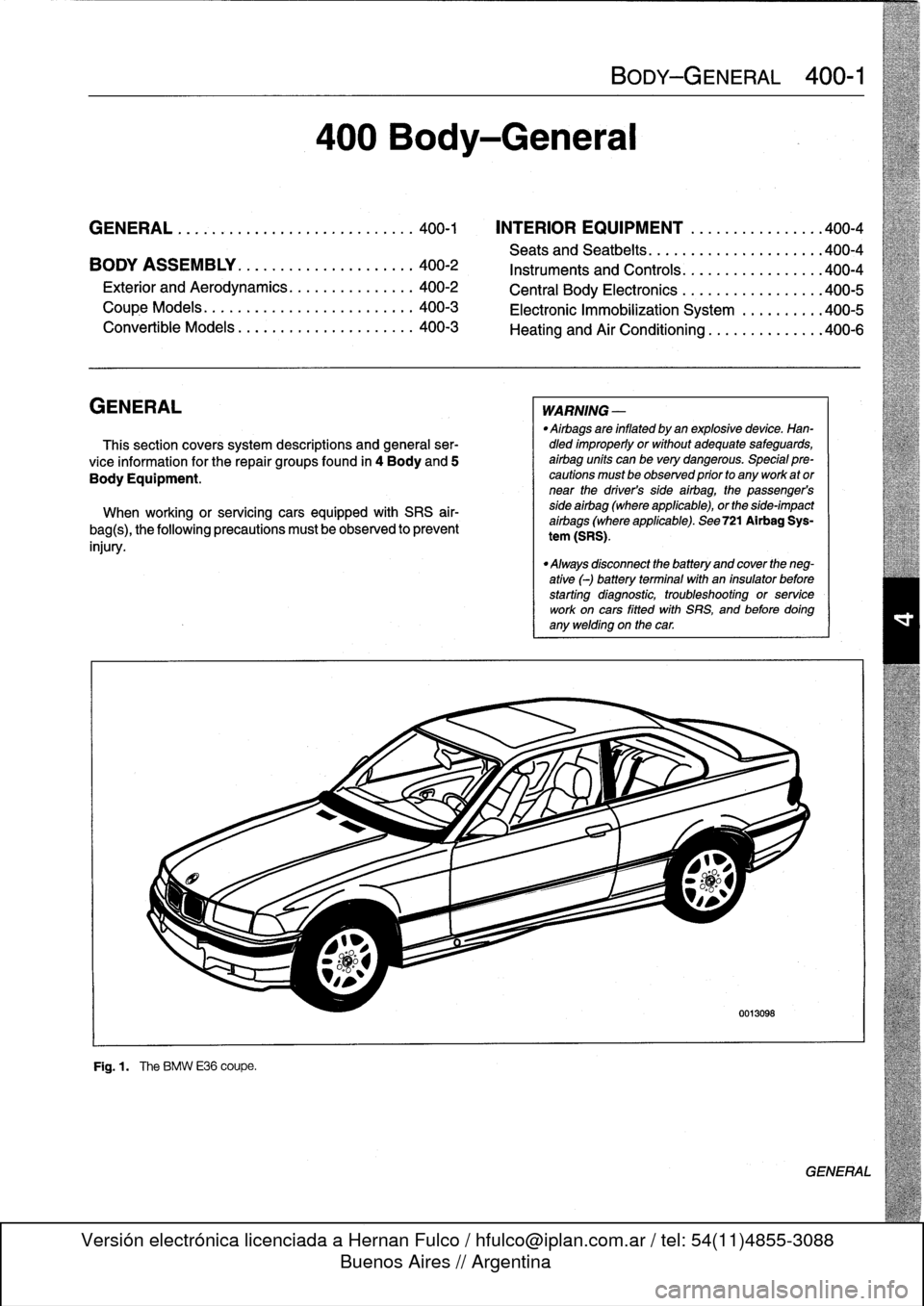

F19

.1

.

The

BMW

E36

coupe

.

400

Body-General

BODY-GENERAL

400-1

WARNING

-

"

Airbags

are

inflated

by

an

explosivedevice

.

Han-dled

improperly

or

without

adequate

safeguards,

airbag

units

can

be

very

dangerous

.

Special

pre-cautions

must

be

observed

prior

to

any

work

ator

near

the

driver's

side

airbag,

the

passenger's

side

airbag

(where

applicable),

or

the

side-impact

aírbags

(where

applicable)

.

See

721

Airbag

Sys-

tem

(SRS)

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

(-)

battery

terminalwith

an

insulator

before

starting

diagnostic,

troubleshooting

or

service

work

oncars

fitted

with

SRS,

and

before

doíng

any

welding

on

the

car

.

0013098

GENERAL

Page 304 of 759

400-2

BODY-GENERAL

4-door

Sedan

Coupe

-

saas3

.7""

351

/

37

.3

O

I

x

`-193

267

o

oa

'3281

model

"M3

model

Convertible

BODYASSEMBLY

55

ass

.e

iss

""

-

66

.9

-

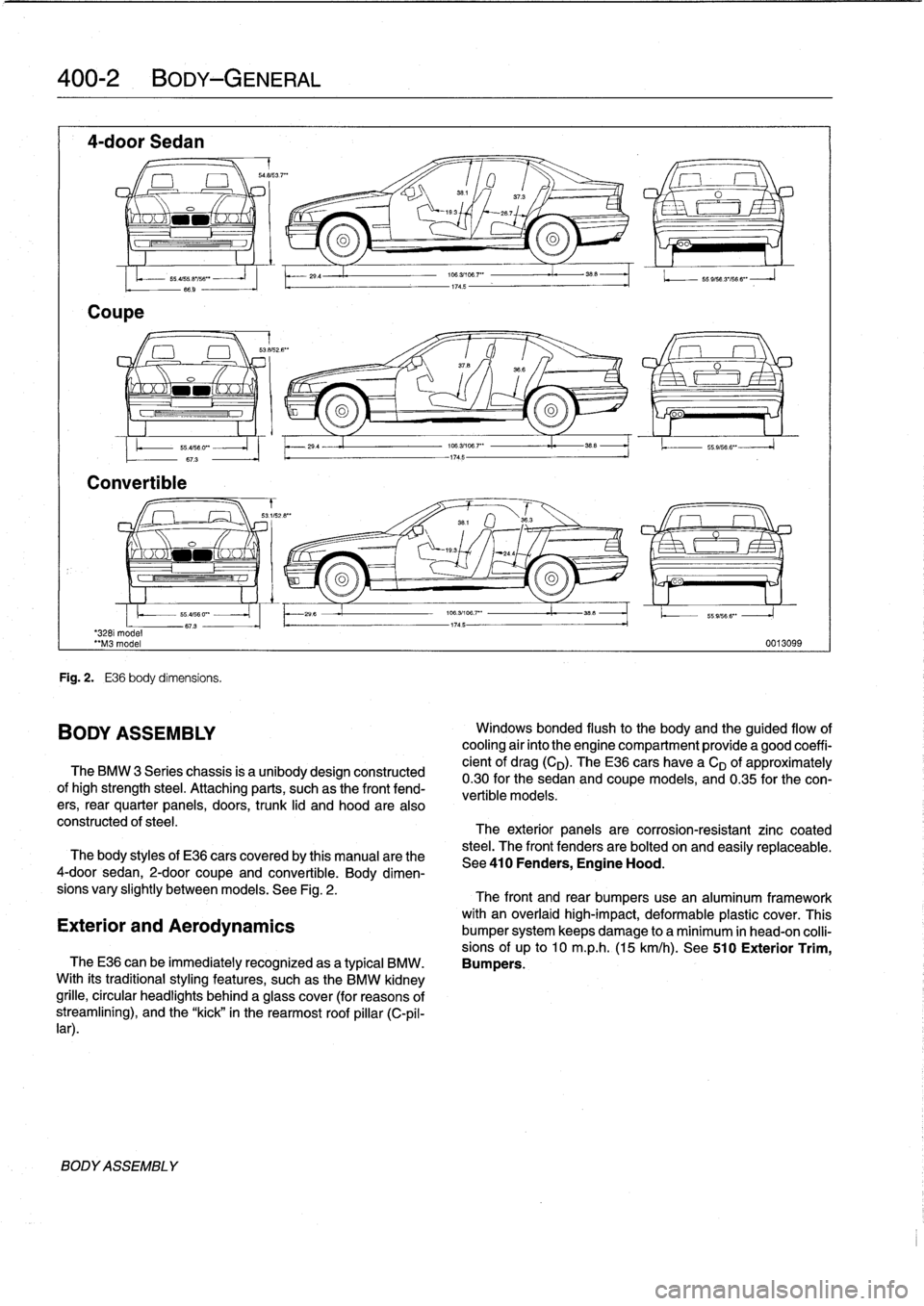

Fig

.

2

.

E36

body

dimensíons

.

BODY

ASSEMBLY

29

.4

29

4

The

BMW

3

Series

chassis

is

a

unibodydesign

constructed

ofhigh

strength

steel

.

Attaching

parts,

suchas

the

front

fend-

ers,

rear

quarter

panels,

doors,

trunk

lid

and

hood

are

also

constructed

of

steel

.

706

.31108

.7"

I

38

.5

174

.5

174

.5

O

oo

196

.3/106

.7'

"

35_5

1.

.

55

.9,566

".

106

.3/196

.7""

i.

358

-1745-

55

9/56

3'/56

6"

-

J

0013099

Windows

bonded

flush

to

the

body

and

the

guided

flow

of

cooling

air

into

the

engine

compartment

provide

a

good

coeffi-

cient

of

drag(CD)

.

TheE36

cars

have

a

CD

of

approximately

0

.30for

the

sedan

and

coupe

models,

and

0

.35

for

the

con-

vertible

models

:

The

exterior

panels

are

corrosion-resistant

zinc

coated

steel

.

The

front

fenders

are

bolted

on

and

easily

replaceabie

.

The

body

styles

of

E36

cars

coveredby

this

manual

arethe

See410

Fenders,

Engine

Hood

.

4-door

sedan,

2-door

coupe

and

convertible

.

Body

dimen-

sions

vary

slightly

betweenmodels

.

See

Fig

.

2

.

The

front

and

rear

bumpers

use

an

aluminum

framework

with

an

overlaid

high-impact,

deformable

plastic

cover

.

This

Exterior

and

Aerodynamics

bumper

system

keeps

damage

to

a

minimum

in

head-on

colli-

sions

of

up

to

10

m

.p

.h

.

(15

km/h)

.

See

510

Exterior

Trim,

TheE36

can

be

immediatelyrecognized

asa

typical

BMW

.

Bumpers

.

With

its

traditionalstyling

features,

suchas

the

BMW

kidney

grille,

circular

headlights

behind

a

glass

cover

(for

reasons

of

streamliníng),

and

the

"kick"

in

the

rearmost

roof

pillar

(C-pil-

lar)

.

Page 307 of 759

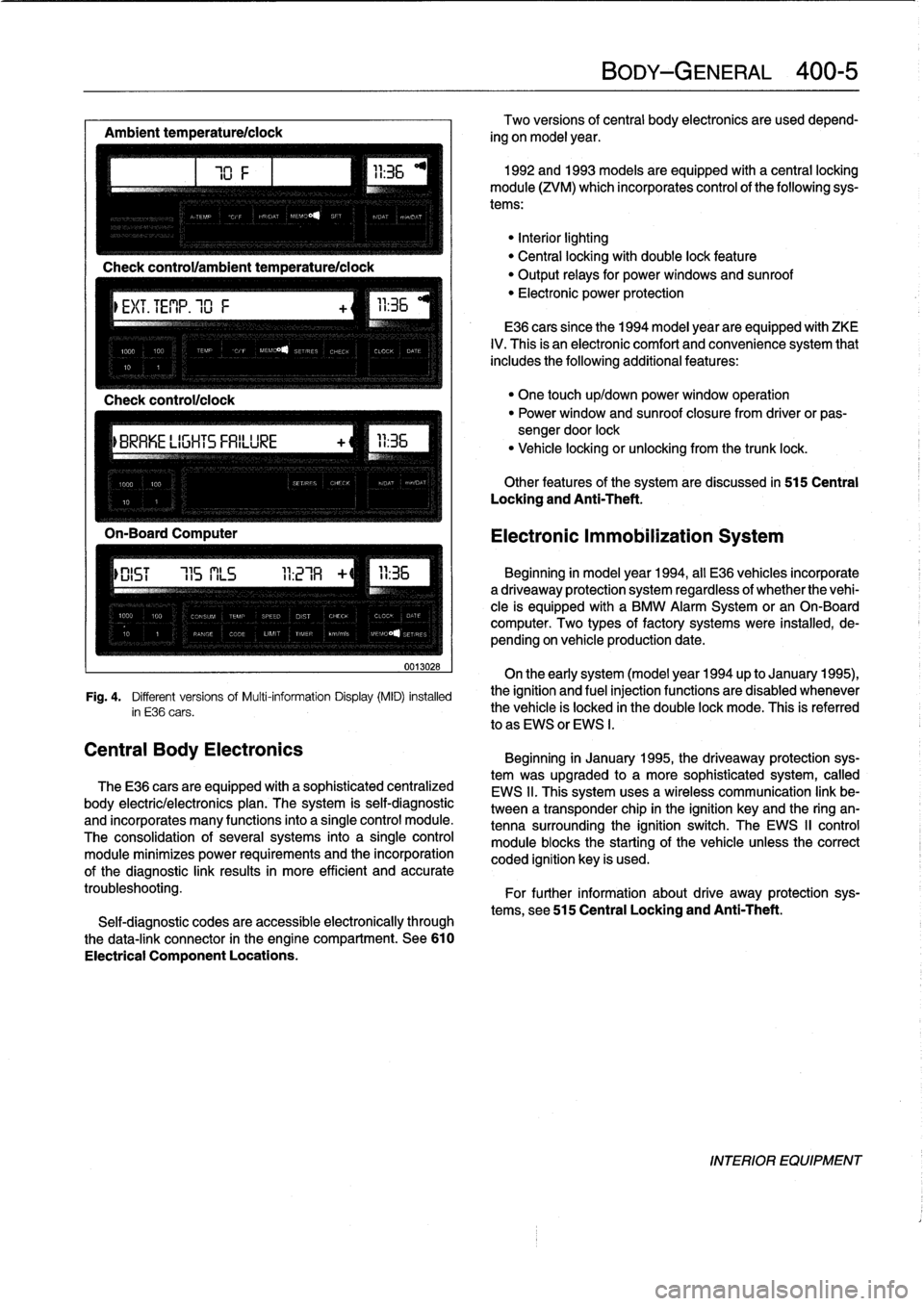

Ambient

temperaturelclock

MÍM

Aa

.Mi}rm

-Mil"

IMua~naa~u~itacar

"

za

.~

Central

Body

Electronics

0013028

Fig

.

4

.

Different

versionsof

Multi-information

Display(MID)

installed

in

E36

cars

.

The

E36

cars

are

equipped

with

a

sophisticated

centralized

body

electric/electronics

plan

.

The

system

is

self-diagnostic

and

incorporates

many

functions

into

a

single

control

module

.

The

consolidation

of

several

systems

into

a

single

control

module

minimizes

power

requirements

and

the

incorporation

of

the

diagnostic

link

results

in

more

efficient

and

accurate

troubleshooting

.

Self-diagnostic

codes

are

accessible

electronically

through

the

data-link

connector

in

the

engine

compartment

.

See610

Electrical

Component

Locations

.

BODY-GENERAL

400-

5

Two

versions

of

central

body

electronics

are

used

depend-

ing

on

model

year

.

1992

and

1993

models

are

equipped

with

a

central

locking

module

(ZVM)

which

incorporates

control

of

the

following

sys-

tems

:

"Interiorlighting

"

Central

locking

with

double

lock

feature

"

Output

relays

for

powerwindows

and

sunroof

"

Electronic

power

protection

E36

cars

since

the

1994

model

year

are

equipped

with

ZKE

IV

.

This

is

an

electronic

comfort

and

convenience

system

that

includes

the

following

additional

features

:

"

One

touch

up/down

power

window

operation

"

Power

window

and

sunroof

closure

from

driver

or

pas-

sengerdoor

lock

"

Vehicle

locking

or

unlocking

from

the

trunk

lock

.

Other

features

of

the

system

are

discussed

in

515

Central

Locking

and

Anti-Theft

.

Electronic

Immobilization

System

Beginning

in

model

year

1994,

all

E36

vehicles

incorporate

adriveaway

protection

system

regardless

of

whether

the

vehi-

cle

is

equipped

with

a

BMW

Alarm

System

or

an

On-Board

computer

.

Two

types

of

factory

systems

were

installed,

de-

pending

on

vehicle

production

date

.

On

the

early

system

(model

year

1994

up

to

January

1995),

the

ignition

and

fuel

injection

functions

are

disabled

whenever

the

vehicle

is

locked

in

the

double

lock

mode

.

This

is

referred

lo

as

EWS

or

EWS

I

.

Beginning

in

January

1995,

the

driveaway

protection

sys-

tem

was

upgraded

to

a

more

sophisticated

system,

called

EWS

II

.

This

system

uses

a

wireless

communication

link

be-

tween

a

transponder

chip

in

the

ignition

keyand

the

ring

an-

tenna

surrounding

the

ignition

switch

.

The

EWS

II

control

module

blocksthe

starting

of

the

vehicle

unlessthe

correct

coded

ignition

key

is

used

.

For

further

information

about

drive

away

protection

sys-

tems,

see

515

Central

Locking

and

Anti-Theft

.

INTERIOR

EQUIPMENT

Page 323 of 759

GENERAL

.

.

.

.

.

.

.

.

.

...

.

..

.

...

.

.........

510-1

Front

bumper

impact

absorber,

replacing

....

510-4

Rear

bumper,

removing

and

installing

.....

.510-4

OUTSIDE

REAR

VIEW

MIRRORS

.

...

.

.....

510-1

Rear

bumper

impact

absorber,

replacing

...

.

510-6

Outside

mirrorglass,

replacing

.

.

.........

510-1

Bumper

height,

adjusting

...

.

...

.

...

.

.

.

.

.

510-6

Outside

mirror

housing,

removing

and

installing

....

.

.....

.

.

.

.

.

.

510-1

EXTERIOR

TRIM

...

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

510-6

Outside

mirror,

removing

and

installing

.

.

.

.

.

510-2

BMW

embiem,

removing

and

installing

.

.

.

.

.

.

510-7

Body

side

molding,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

510-7

BUMPERS

.

.

.

.

.

....

.

.....

.

.....

.

.

.

.

.

.

510-3

Radiator

grille,

removing

and

installing

.

.

.

.

.

.510-7

Front

bumper,

removing

and

installing

.

.

.

.

.

.

510-3

Front

panel,

removing

and

installing

...

.

.

.

.

.

510-7

GENERAL

510

Exterior

Trim,

Bumpers

This

repair

group

includes

repair

information

for

the

outside

rear

view

mirror,

front

and

rear

bumpers,

and

the

easily

re-

movable

exterior

trim

parts

.

OUTSIDE

REAR

VIEW

MIRRORS

The

remove

controlled

mirrors

come

in

two

styles

:

heated

and

unheated

.

Many

of

the

mirror

components

are

separately

available

from

an

authorized

BMW

dealer,

including

the

glass

and

outside

plastic

housing

.

Outside

mirror

glass,

replacing

CAUTION-

Mirror

shouldbe

ator

above

room

temperature

before

removal

.

Otherwise,

small

plastic

parts

or

glass

will

break

.

1

.

Insert

thin

pry

tool

(wooden

or

tape-wrapped

screwdriv-

er)

between

bottom

mirror

edge

and

mirror

housing

and

carefully

pry

out

mirror

glass

from

housing

.

See

Fig

.

1

.

2

.

Heated

mirror

:

remove

heating

element

harness

con-

nectors

from

back

of

mirror

glass

.

3

.

Install

new

glass

into

position

by

pressing

firmly

until

it

snaps

into

place

.

EXTERIOR

TRIM,

BUMPERS

510-1

00130

..

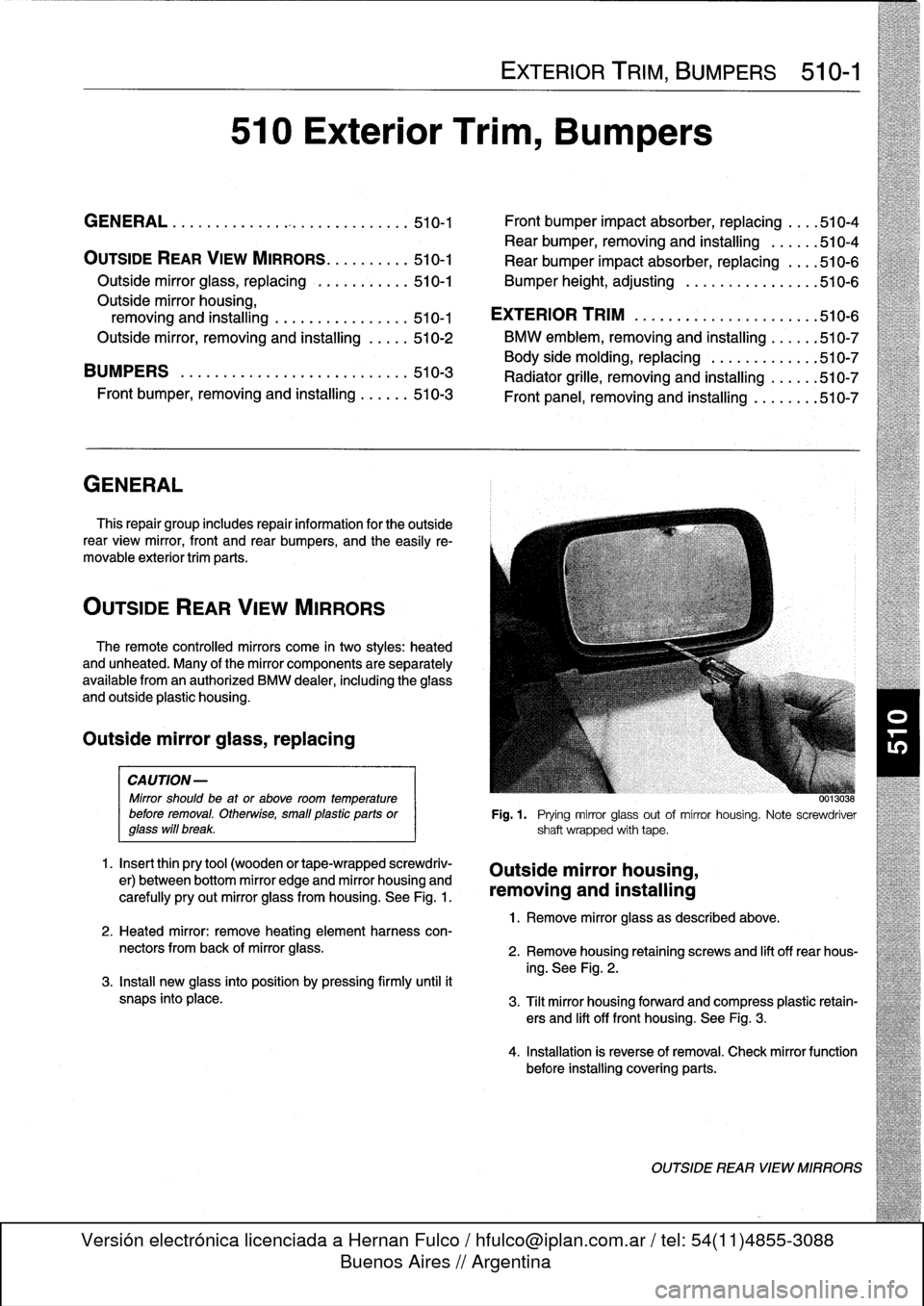

Fig

.1

.

Prying

mirror

glass

out

of

mirror

housing

.

Note

screwdriver

shaft

wrapped

with

tape

.

Outside

mirror

housing,

removing

and

installing

1

.

Remove

mirror

glass

as

described

above

.

2

.

Remove

housing

retaining

screws

and

lift

off

rear

hous-

ing

.

See

Fig

.

2

.

3

.

Tilt

mirror

housing

forward

and

compress

plastic

retain-

ers

and

lift

off

front

housing

.

See

Fig

.

3

.

4

.

Installation

is

reverse

of

removal

.

Check

mirror

function

before

installing

covering

parts

.

OUTSIDE

REAR

VIEW

MIRRORS

Page 324 of 759

510-2

EXTERIOR

TRIIVI,

BUMPERS

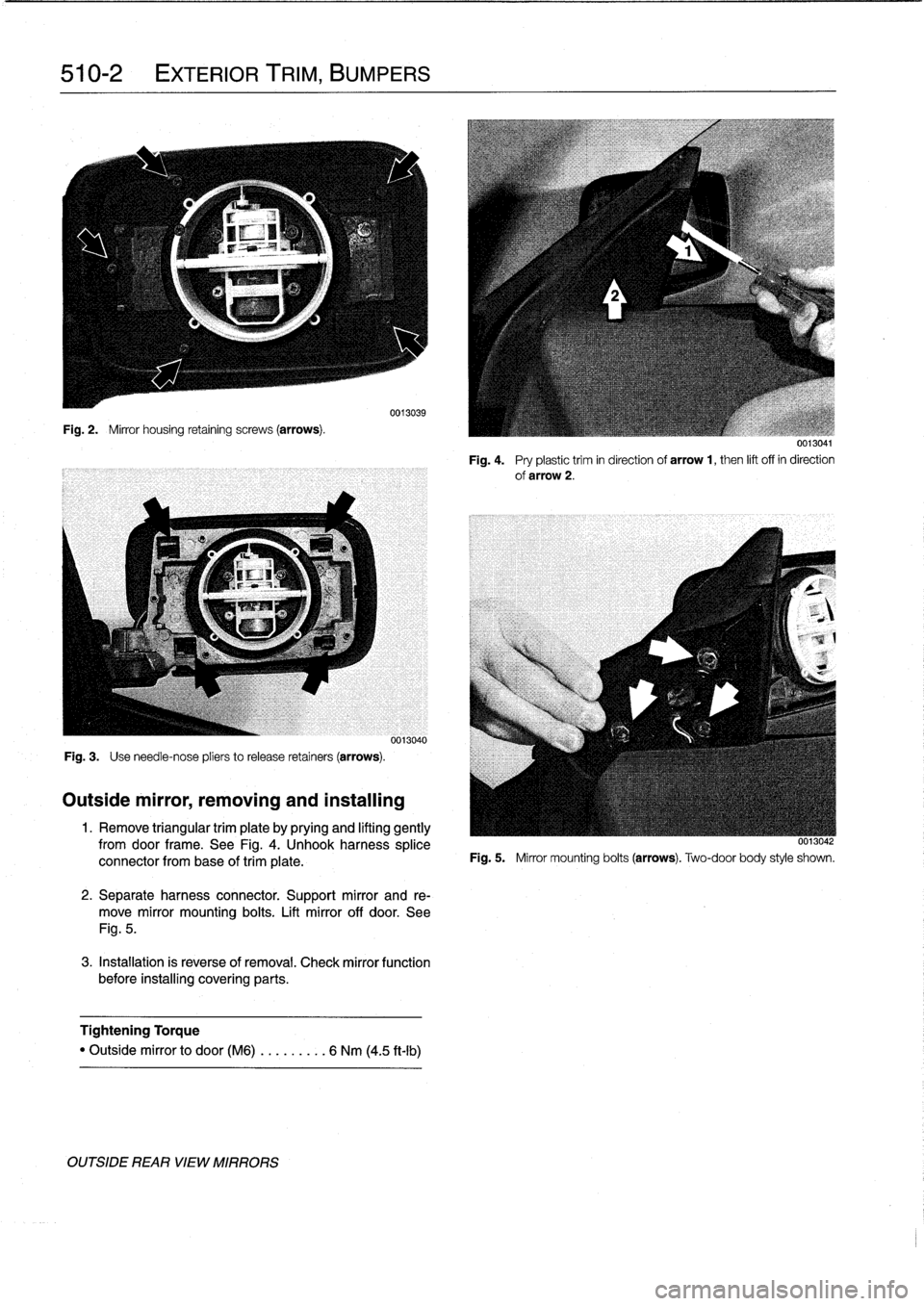

Fig

.

2

.

Mirror

housing

retaining

screws

(arrows)

.

Fig

.

3

.

Use

need1e-nose

pliers

to

release

retainers

(arrows)

.

Outside

mirror,

removing

and

installing

0013039

0013040

1

.

Remove

triangular

trim

plate

by

prying

and

lifting

gently

fromdoor

frame

.

See

Fig

.

4

.

Unhook

harness

splice

connector

from

base

of

trim

píate

.

2

.

Separate

harness

connector

.

Support

mirror

and

re-

move

mirror

mounting

bolts

.

Lift

mirror

off

door

.

See

Fig

.

5

.

3

.

Installation

is

reverse

of

removal

.

Check

mirror

function

before

installing

covering

parts

.

Tightening

Torque

"

Outside

mirror

to

door(M6)

..

.

..

.

..

.

6

Nm

(4

.5

ft-Ib)

OUTSIDE

REAR

VIEW

MIRRORS

0013041

Fig

.

4

.

Pry

plastictrim

in

direction

of

arrow

1,

then

lift

off

in

direction

of

arrow

2

.

0013042

Fig

.

5

.

Mirror

mounting

bolts

(arrows)

.

Two-door

body

style

shown

.

Page 326 of 759

510-4

EXTERIOR

TRIM,

BUMPERS

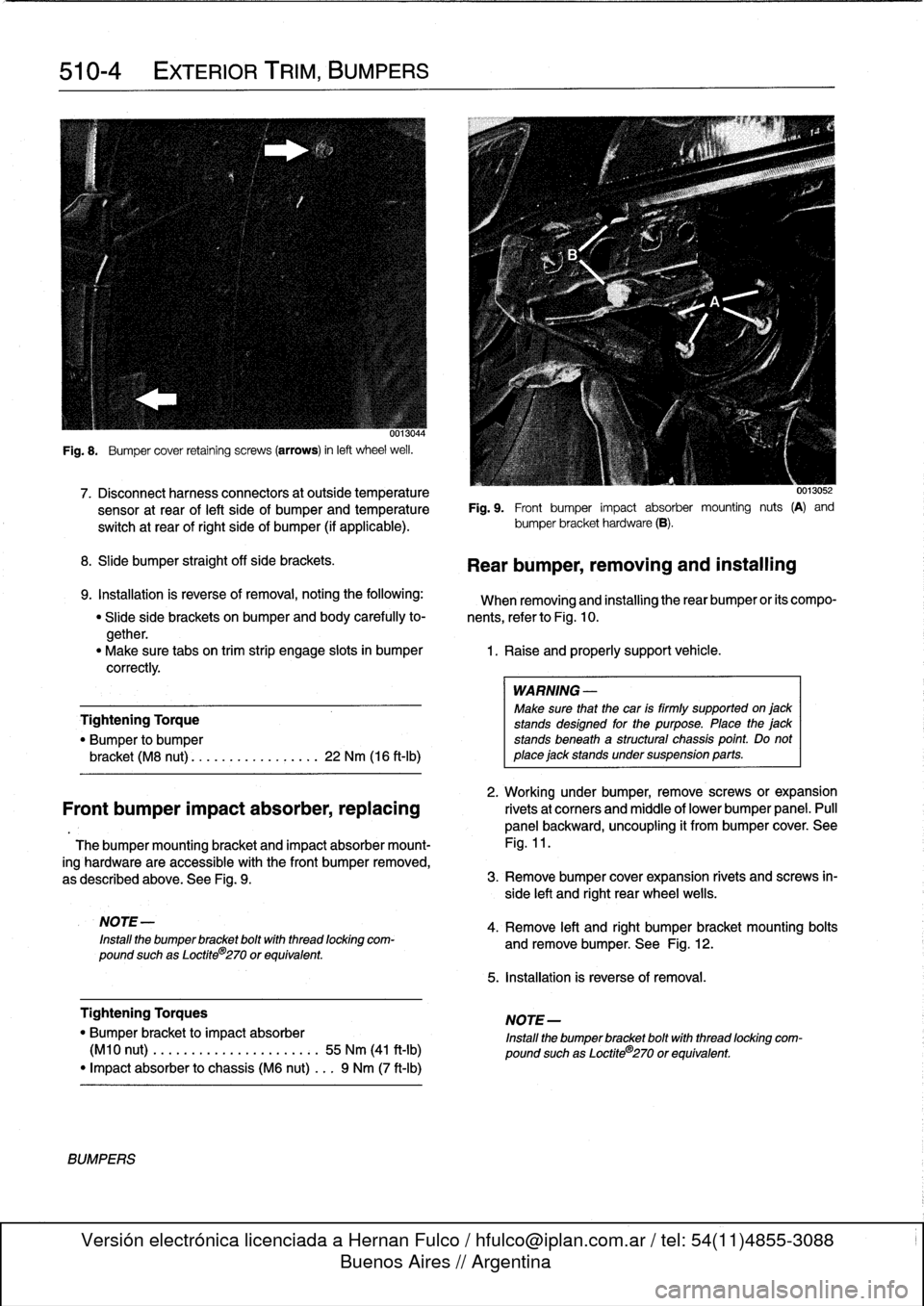

Fig

.

8

.

Bumper

cover

retaining

screws

(arrows)

in

left

wheel

weil

.

7

.

Disconnect

harnessconnectors

at

outside

temperature

0013052

sensor

at

rear

of

left

side

of

bumperand

temperatura

Fig

.

9

.

Front

bumper

impact

absorber

mounting

nuts

(A)

and

switch

at

rear

of

right

side

of

bumper

(if

applicable)

.

bumper

bracket

hardware

(B)

.

8

.

Slide

bumper

straight

off

sida

brackets

.

9

.

Installation

is

reverse

of

removal,

notingthe

following

:

When

removing

and

installing

therear

bumper

or

its

compo-

"

Slide

side

brackets

on

bumper

and

body

carefully

to-

nents,

referto

Fig

.

10

.

gether

.

"

Make

sure

tabs

on

trim

strip

engage

slots

in

bumper

1

.

Raise

and

properly

support

vehicle

.

correctly

.

Tightening

Torque

"

Bumper

to

bumper

bracket

(M8

nut)

............

...

.

.

22

Nm

(16

ft-Ib)

2

.

Working

under

bumper,

remove

screws

or

expansion

Front

bumper

impact

absorber,replacing

rivetsat

corners

and

middle

of

lower

bumper

panel

.

Pull

panel

backward,

uncoupling

it

from

bumper

cover

.

See

Thebumper

mounting

bracket

and

impact

absorber

mount-

Fig

.

11

.

ing

hardware

are

accessible

with

the

Font

bumper

removed,

as

described

above

.

See

Fig

.

9

.

3

.

Remove

bumper

cover

expansion

rivets

and

screws

in-

side

left

and

right

rear

wheel

wells

.

NOTE

-

Install

the

bumper

bracket

boltwith

thread

locking

com-

pound

suchas

Loctite

8

270

or

equivalent

.

Tightening

Torques

"

Bumper

bracket

to

impact

absorber

(M10

nut)

.

..

.

...

.............:.

55

Nm

(41

ft-Ib)

"

Impact

absorber

to

chassis

(M6

nut)

...

9

Nm

(7

ft-Ib)

BUMPERS

Rear

bumper,

removing

and

installing

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

stands

designad

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

4

.

Remove

left

and

right

bumper

bracket

mounting

bolts

and

remove

bumper

.

See

Fig

.

12

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

Install

the

bumper

bracket

bolt

with

thread

locking

com-

pound

suchas

Loctite®270

or

equivalent

.

Page 327 of 759

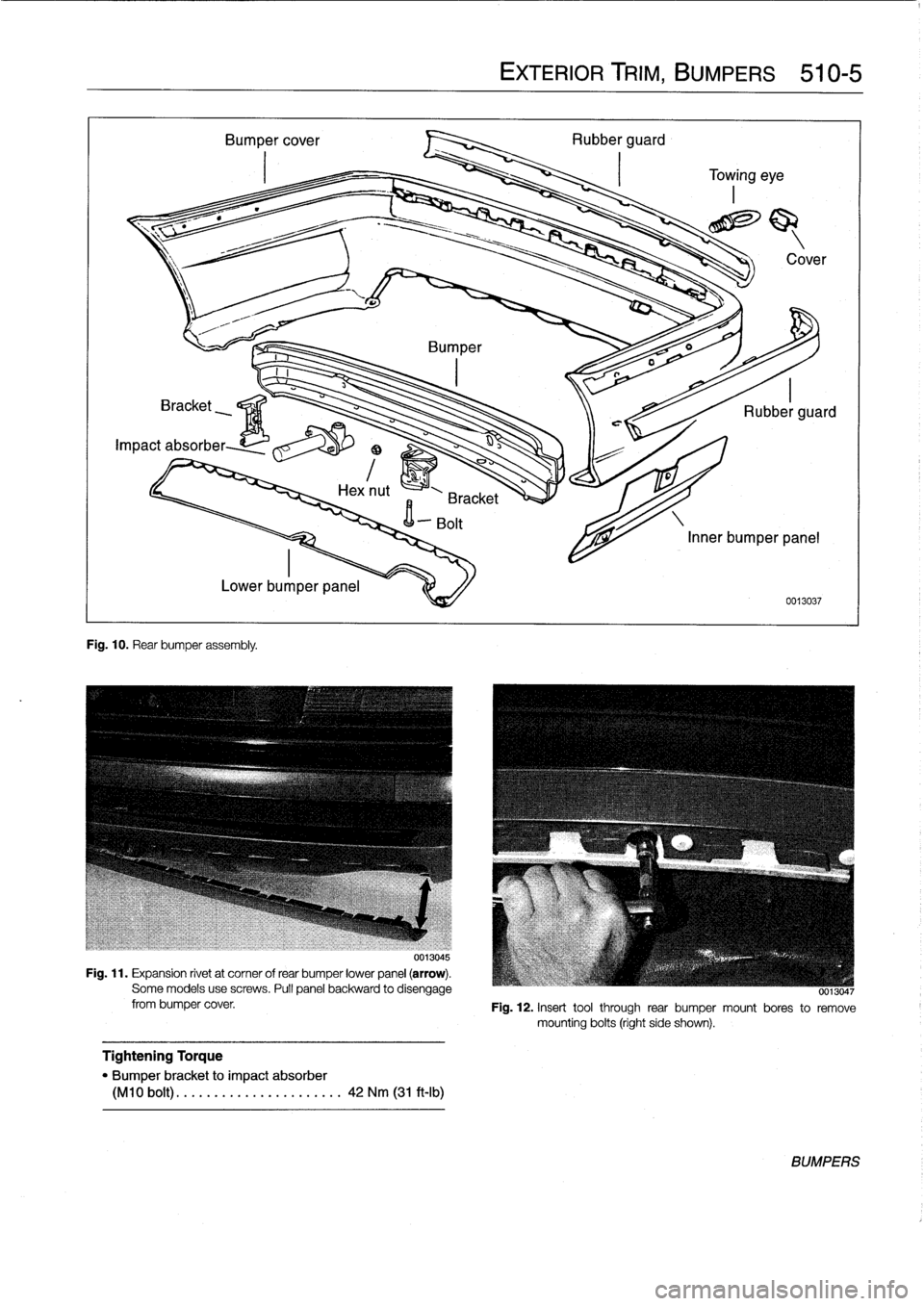

Fig

.

10

.

Rear

bumper

assembly

.

0013045

Fig

.

11

.

Expansion

rivet

at

corner

of

rear

bumper

lower

panel

(arrow)

.

Some

models

usescrews

.

Pull

panel

backward

to

disengage

from

bumper

cover

.

Tightening

Torque

"

Bumper

bracket

to

impact

absorber

(M10

bolt)

.

..

...........

...

.

..

..

42

Nm

(31

ft-Ib)

EXTERIOR

TRIM,

BUMPERS

510-5

0013047

Fig

.

12

.

Inserttool

through

rear

bumper

mount

bores

to

remove

mounting

bolts

(right

side

shown)

.

BUMPERS

Page 329 of 759

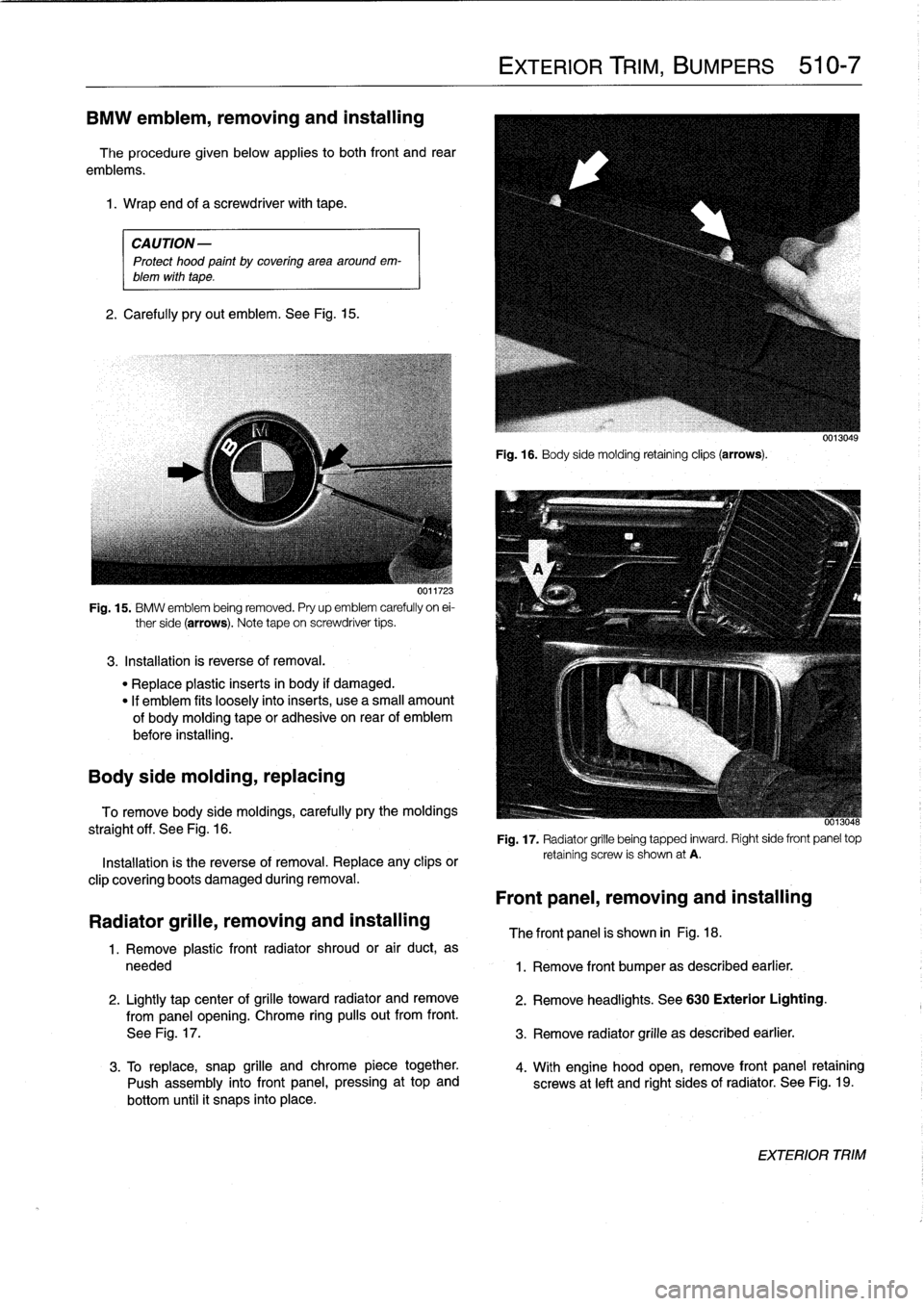

BMW

emblem,

removing

and

installing

The

procedure

given

below

applies

to

both

front

and

rear

emblems

.

1

.

Wrap

and

of

a

screwdriver

with

tape

.

CAUTION-

Protect

hood

paint

by

coveringarea

aroundem-

blem

with

tape

.

2

.

Carefully

pryout

emblem

.

See

Fig

.

15

.

UVI1'¿.

Fig

.

15

.

BMW

emblem

being

removed

.

Pry

up

emblem

carefully

on

ei-

ther

side

(arrows)

.

Note

tape

on

screwdriver

tips

.

3

.

Installation

is

reverse

of

removal

.

"

Replace

plastic

inserts

in

body

if

damaged

.

"

If

emblem

fits

loosely

intoinserts,

use

a

small

amount

of

bodymoldingtape

or

adhesiva

on

rear

of

emblem

before

installing

.

Body

side

molding,

replacing

To

remove

body

side

moldings,

carefully

pry

the

moldings

straight

off

.

See

Fig

.

16

.

Installation

is

the

reverse

of

removal

.

Replace

any

clips

or

clip

covering

boots

damaged

during

removal

.

Radiator

grille,

removing

and

installing

1

.

Remove

plastic

front

radiator

shroud

or

air

duct,

as

needed

2

.

Lightly

tap

center

of

grilla

toward

radiator

andremove

from

panel

opening

.

Chrome

ring

pulís

out

from

front

.

See

Fig

.

17

.

3

.

To

replace,

snap

grille

andchrome

piece

together

.

Push

assembly

into

front

panel,

pressing

at

top

and

bottom

until

it

snaps

into

place

.

EXTERIOR

TRIM,

BUMPERS

510-7

Fig

.

16

.

Body

sida

molding

retainingclips

(arrows)

.

-

0013048

Fig

.

17

.

Radiator

grille

being

tapped

inward

.

Right

side

front

panel

top

retaining

screw

is

shown

at

A

.

Front

panel,

removing

and

installing

The

front

panel

is

shown

in

Fig

.

18

.

1

.

Remove

front

bumper

as

described

earlier

.

2

.

Remove

headlights

.

See

630

Exterior

Lighting

.

3

.

Remove

radiator

grille

as

described

earlier

.

4

.

With

engine

hood

open,

remove

front

panel

retaining

screws

at

left

and

right

sides

of

radiator

.

See

Fig

.

19

.

EXTERIOR

TRIM

Page 330 of 759

510-

8

EXTERIOR

TRIM,

BUMPERS

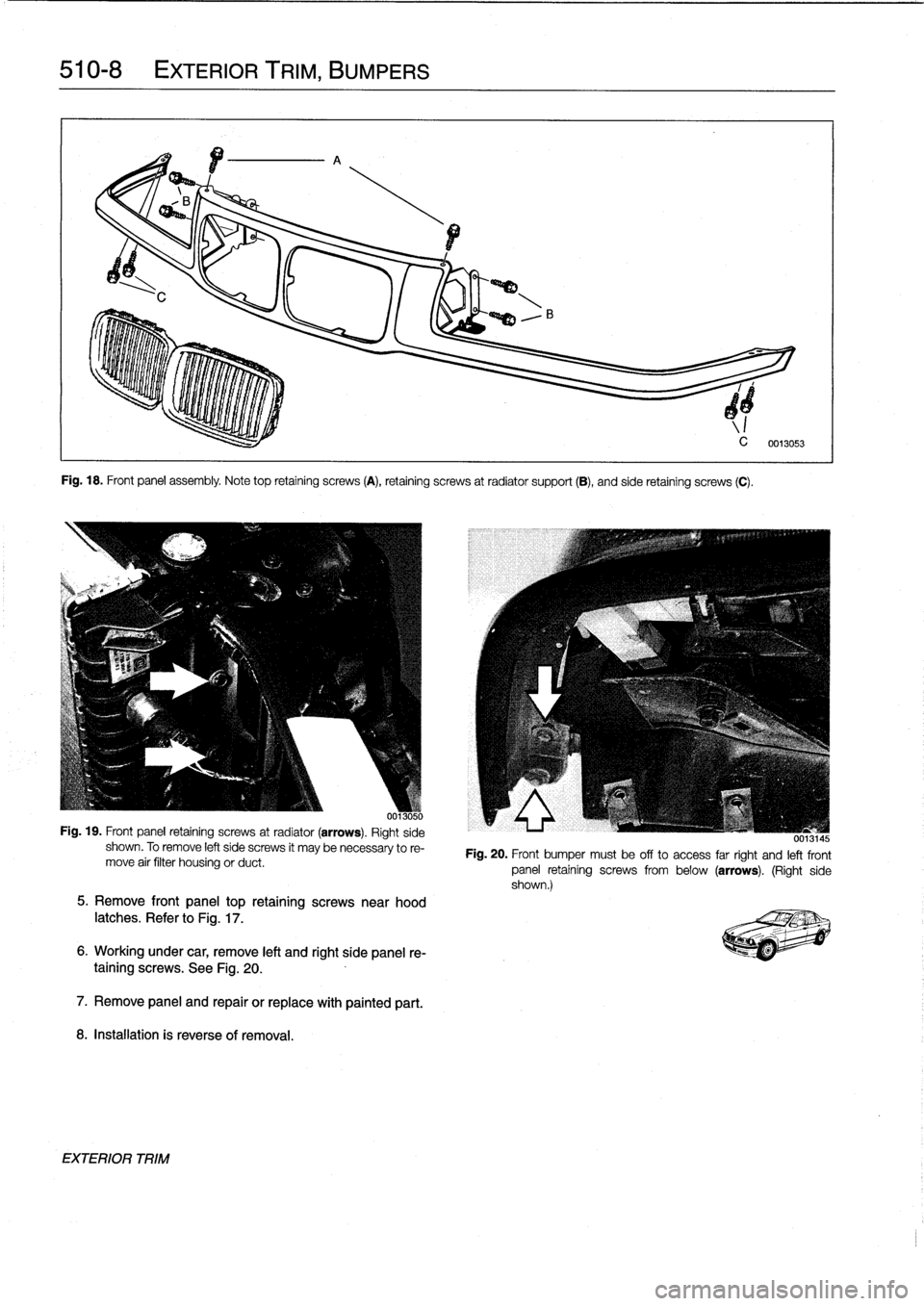

Fig

.

18

.

Front

panel

assembly

.

Note

top

retaining

screws

(A),

retaining

screws

at

radiator

support

(B),

and

side

retaining

screws

(C)

.

00130~,

u

Fig

.

19

.

Front

panel

retaining

screws

at

radiator

(arrows)

.

Right

side

shown

.

To

remove

left

side

screws

it

may

be

necessary

tore-

move

airfilter

housing

or

duct

.

5

.

Remove

front

paneltop

retaining

screws

near

hood

latches

.

Refer

to

Fig

.

17

.

6

.

Working

under

car,

remove

left

and

right

side

panel

re-

taining

screws

.

See

Fig

.

20

.

7

.

Remove

panel

and

repair

orreplace

with

painted

part

.

8

.

Installation

is

reverseof

removal

.

EXTERIOR

TRIM

0013145

Fig

.

20

.

Front

bumper

mustbe

off

to

access

far

right

and

left

front

panel

retaining

screws

from

below

(arrows)

.

(Right

side

shown

.)