rear lamp BMW 323i 1996 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 323i, Model: BMW 323i 1996 E36Pages: 759

Page 187 of 759

2

.

Remove

fuel

tank

filler

cap

.

3

.

Remove

rearseat

cushion

and

pull

back

insulation

mats

to

expose

fuel

tank

access

covers

.

See

Fig

.

2

.

uui3140

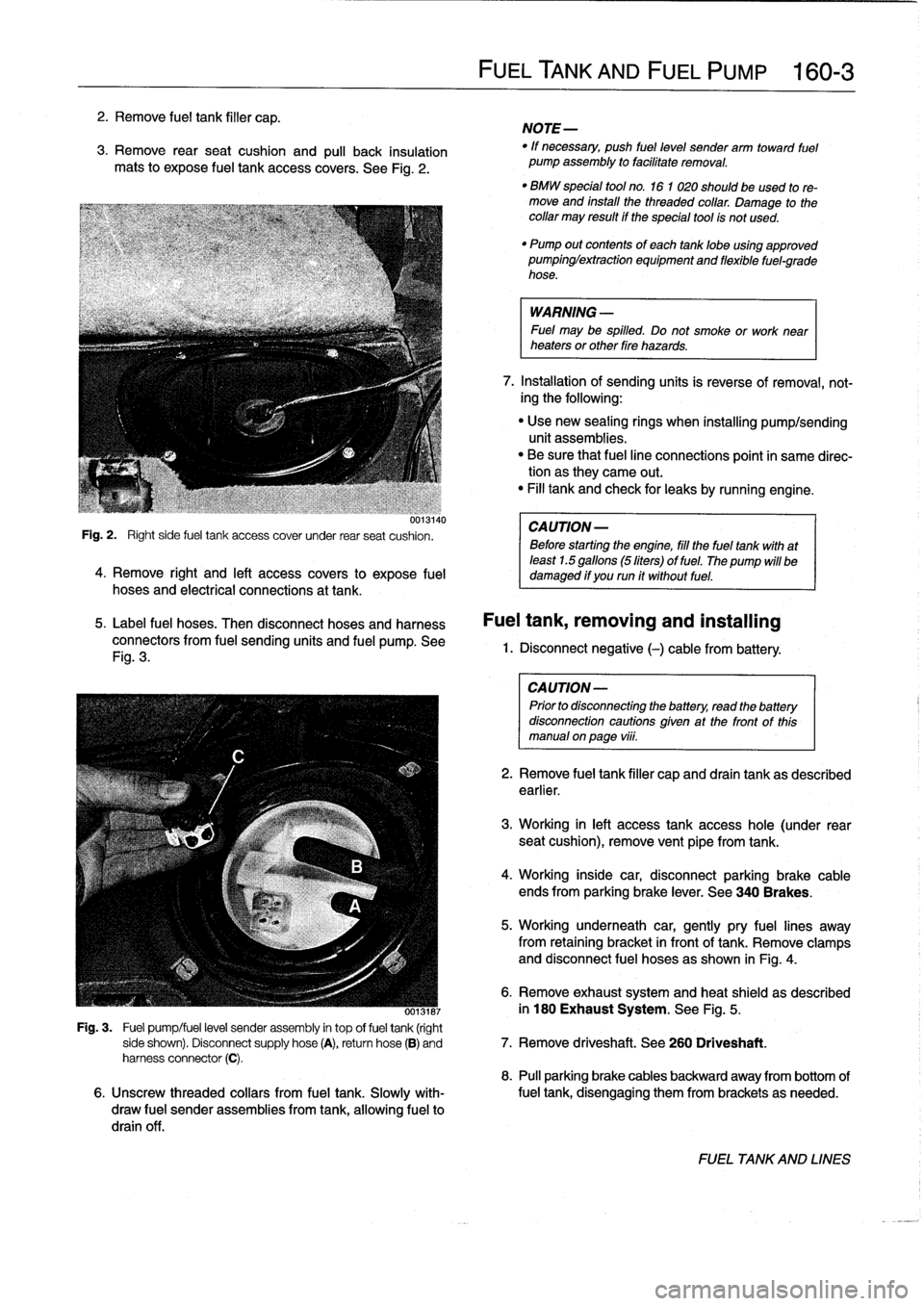

Fig

.

2

.

Right

side

fuel

tank

access

cover

under

rear

seat

cushion

.

4

.

Remove

right

and

left

access

covers

to

expose

fuel

hoses

and

electrical

connections

at

tank

.

5

.

Label

fuel

hoses

.

Then

disconnect

hoses

and

harness

connectors

from

fuel

sending

units

and

fuel

pump

.

See

Fig

.

3

.

FUELTANK

AND

FUEL

PUMP

160-

3

NOTE-

"

If

necessary,

push

fuel

level

sender

arm

toward

fuel

pump

assembly

to

facilitate

removal

.

"

BMW

special

tool

no

.

16

1

020

should

beused

tore-

move

and

install

the

threaded

collar

.

Damage

to

thecollar

may

result

if

the

special

tool

is

not

used

.

"

Pump

out

contents

of

each

tanklobe

using

approved

pumpinglextraction

equipment

and

flexible

fuel-grade

hose

.

WARNING

-

Fuel

may

be

spilled

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

7

.

Installation

of

sending

units

is

reverse

of

removal,

not-

ing

the

following

:

"

Use

new

sealing

rings

when

installing

pump/sending

unit

assemblies

.

"

Be

sure

that

fuel

line

connections

point

in

same

direc-tion

as

they

carne

out

.

"

Fill

tank

and

check

for

leaks

by

running

engine

.

CA

UTION-

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5liters)

of

fuel

.

The

pump

will

be

damaged

if

you

run

it

without

fuel

.

Fuel

tank,

removing

and

installing

1.

Disconnect

negative

(-)cablefrom

battery

:

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

fuel

tank

filler

capand

drain

tank

as

described

earlier

.

3

.

Working

in

left

access

tank

access

hole

(under

rear

seat

cushion),

remove

vent

pipe

fromtank

.

4

.

Working

inside

car,

disconnectparking

brake

cable

ends

from

parking

brake

lever

.

See

340

Brakes

.

5

.

Working

underneath

car,

gently

pry

fuel

lines

away

from

retaining

bracket

in

front

of

tank

.

Remove

clamps

and

disconnect

fuel

hoses

as

shown

in

Fig

.

4

.

6

.

Remove

exhaust

system

and

heat

shield

as

described

ooisiai

in

180

Exhaust

System

.

See

Fig

.

5

.

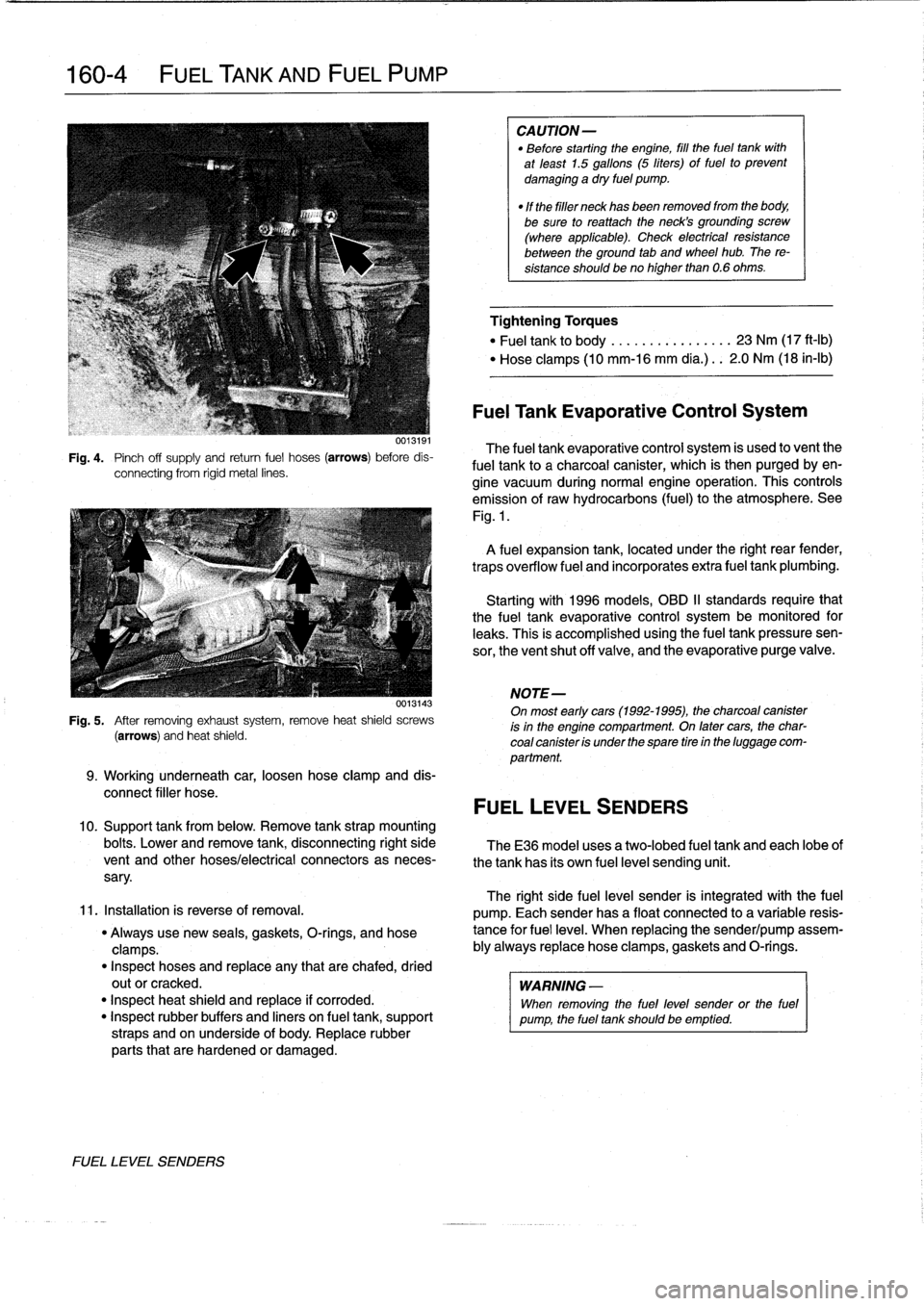

Fig

.

3

.

Fuel

pump/fuel

level

sender

assembly

in

top

offuel

tank

(right

side

shown)

.

Disconnect

supply

hose

(A),

return

hose

(B)

and

7

.

Remove

driveshaft

.

See

260

Driveshaft

.

harness

connector

(C)

.

8

.

Pull

parking

brake

cables

backward

away

from

bottom

of

6

.

Unscrew

threaded

collars

from

fuel

tank

.

Slowly

with-

fuel

tank,

disengaging

them

from

brackets

as

needed

.

draw

fuel

sender

assemblies

from

tank,allowing

fuel

to

drain

off

.

FUEL

TANKAND

LINES

Page 188 of 759

160-

4

FUEL

TANK

AND

FUEL

PUMP

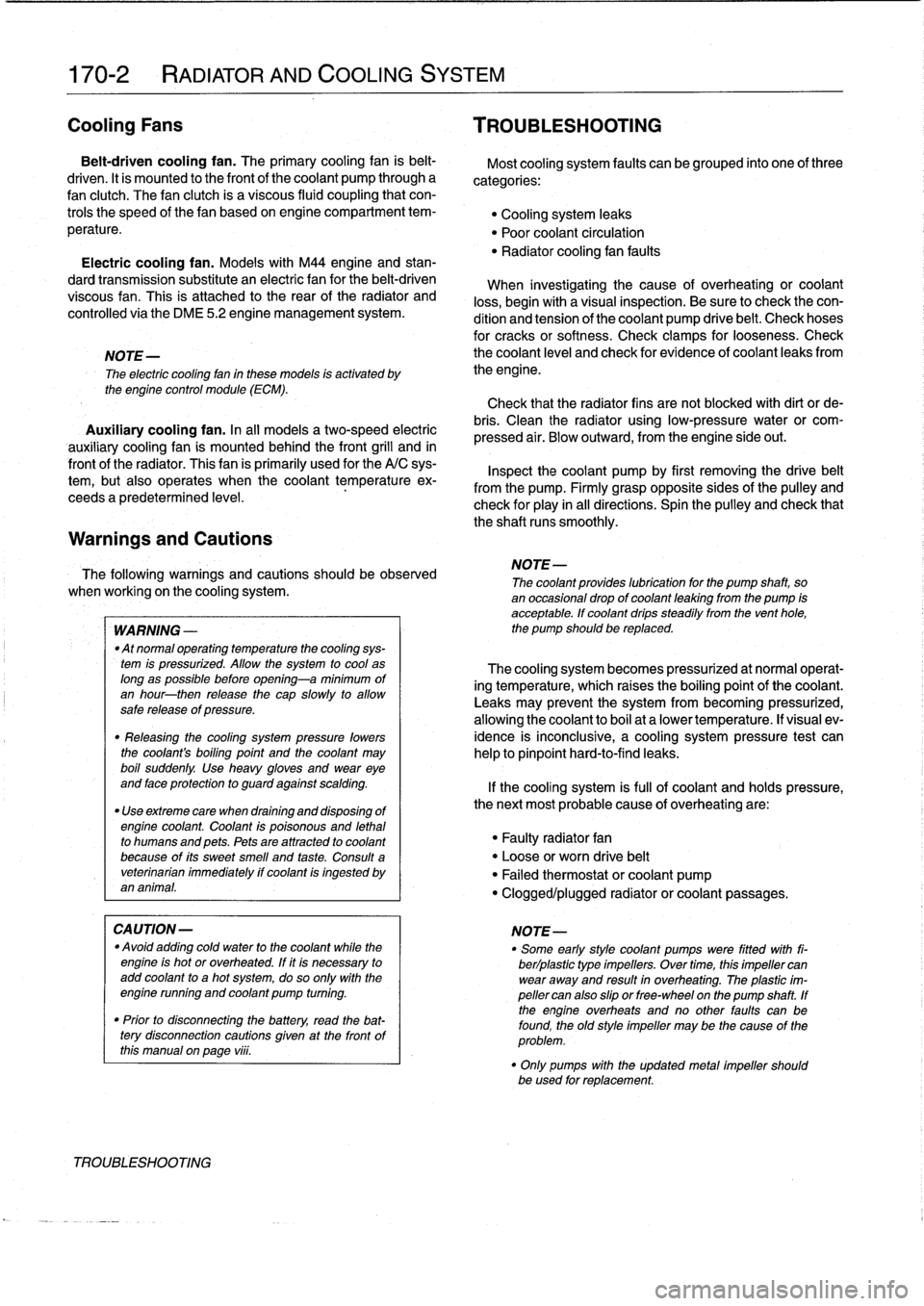

Fig

.

4

.

Pinch

off

supply

and

retum

fuel

hoses

(arrows)

before

dis-

connecting

from

rigid

metal

lines

.

0013143

Fig

.

5

.

After

removing

exhaustsystem,

remove

heat

shield

screws

(arrows)

and

heat

shield

.

9

.

Working

underneath

car,

loosen

hose

clamp

and

dis-

connect

filler

hose

.

10

.

Support

tank

from

below

.

Remove

tank

strap

mounting

bolts

.

Lower

and

remove

tank,

disconnecting

right

side

TheE36

model

uses

a

two-lobed

fuel

tank

and

each

lobeof

vent

and

other

hoses/electrical

connectors

as

neces-

the

tank

has

its

own

fuel

level

sending

unit

.

sary

.

11

.

Installation

is

reverse

of

removal

.

"

Always

use

new

seals,

gaskets,

O-rings,

and

hose

clamps

.

"

Inspect

hoses

and

replace

any

that

are

chafed,

dried

outor

cracked

.

"

Inspect

heat

shield

and

replace

if

corroded

.

"

Inspect

rubber

buffers

and

liners

on

fuel

tank,

support

straps

and

on

underside

of

body

.

Replace

rubber

parts

that

are

hardened

or

damaged

.

FUEL

LEVEL

SENDERS

CAUTION-

"

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5

liters)

of

fuel

to

prevent

damaging

a

dry

fuel

pump

.

"

If

the

filler

neck

has

been

removed

from

the

body,

be

sure

toreattach

theneck's

grounding

screw

(where

applicable)

.

Check

electrical

resistance

between

the

ground

tab

and

wheel

hub

.

The

re-

sistance

shouldbeno

higher

than

0

.6

ohms

.

Tightening

Torques

"

Fuel

tank

to

body

.............

...

23

Nm

(17

ft-Ib)

"

Hose

clamps

(10

mm-16

mm

día

.)

..

2

.0

Nm

(18

in-lb)

Fuel

Tank

Evaporative

Control

System

The

fuel

tank

evaporative

control

system

is

used

to

vent

the

fuel

tank

to

a

charcoal

canister,

which

is

then

purgedby

en-

gine

vacuum

during

normal

engine

operatíon

.

This

controls

emission

of

raw

hydrocarbons

(fuel)

to

the

atmosphere

.

See

Fig

.

1

.

A

fuel

expansion

tank,

located

under

the

right

rear

fender,

traps

overflow

fuel

and

incorporates

extra

fuel

tank

plumbing

.

Startingwith

1996

models,

OBD

II

standards

require

that

the

fuel

tank

evaporative

control

system

be

monitored

for

leaks

.

This

is

accomplished

usingthe

fuel

tankpressuresen-

sor,

the

ventshut

off

valve,

and

the

evaporative

purge

valve

.

NOTE-

On

most

early

cars(1992-1995),

the

charcoal

canister

is

in

the

engine

compartment

.

On

latercars,

the

char-

coal

canister

is

under

the

spare

tire

in

the

luggage

com-

partment

.

FUEL

LEVEL

SENDERS

The

right

side

fuel

leve¡

sender

is

integrated

with

the

fuel

pump

.

Each

senderhas

a

float

connected

to

a

variable

resis-

tance

for

fuel

leve¡

.

When

replacing

the

sender/pump

assem-

bly

always

replace

hose

clamps,gaskets

and

O-rings

.

WARNING

-

When

removing

the

fuel

level

sender

or

the

fuel

pump,

the

fuel

tank

should

be

emptied

.

Page 196 of 759

170-2

RADIATOR

AND

COOLING

SYSTEM

Cooling

Fans

TROUBLESHOOTING

Belt-driven

coolingfan

.

The

primary

cooling

fan

is

belt-

driven

.

It

is

mounted

to

the

frontof

the

coolant

pump

through

a

fan

clutch

.

The

fan

clutch

is

a

viscous

fluid

coupling

that

con-

trols

the

speed

of

thefan

based

on

engine

compartment

tem-

perature

.

Electric

cooling

fan

.

Models

with

M44

engine

and

stan-

dard

transmission

substitute

an

electric

fan

for

the

belt-driven

viscous

fan

.

This

is

attached

to

the

rear

of

the

radiator

and

controlledvia

the

DME

5

.2

engine

management

system

.

NOTE-

The

electric

cooling

fan

in

these

models

is

activated

by

the

engine

control

module

(ECM)

.

Auxiliary

coolingfan

.

In

al¡

models

a

two-speed

electric

auxiliary

cooling

fan

is

mounted

behind

the

front

grill

and

in

front

of

the

radiator

.

This

fan

is

primarily

used

for

the

A/C

sys-

tem,

but

also

operates

when

the

coolant

temperature

ex-

ceeds

a

predetermined

leve¡

.

Warnings

and

Cautions

The

following

warnings

and

Cautions

should

beobserved

when

working

on

the

cooling

system

.

WARNING

-

"

Atnormal

operating

temperature

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

as

long

as

possible

before

opening-a

minimum

of

an

hour-then

release

the

cap

slowly

to

allow

sale

release

of

pressure

.

"

Releasing

the

cooling

system

pressure

lowers

the

coolants

boiling

point

and

the

coolant

may

boíl

suddenly

.

Use

heavy

gloves

and

wear

eye

and

laceprotection

to

guard

against

scalding

.

"

Use

extreme

care

when

draining

and

disposing

of

engine

coolant

.

Coolant

is

poisonous

and

lethal

to

humans

and

pets

.

Pets

are

attracted

to

coolant

because

of

its

sweet

smell

and

taste

.

Consult

a

veterinarian

immediately

if

coolant

is

ingested

byan

animal

.

CAUTION-

"

Avoidadding

cold

water

to

the

coolant

while

the

engine

is

hot

or

overheated

.

If

it

is

necessary

to

add

coolant

to

ahot

system,

do

so

only

with

the

engine

running

and

coolant

pump

tuming

.

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

TROUBLESHOOTING

Most

cooling

system

faults

can

be

grouped

into

one

of

three

categories

:

"

Cooling

system

leaks

"

Poor

coolant

circulation

"

Radiator

cooling

fan

faults

When

investigating

the

cause

of

overheating

or

coolant

loss,

begin

with

a

visual

inspection

.

Be

sure

to

check

the

con-

dition

and

tension

of

the

coolant

pump

drive

belt

.

Check

hoses

for

cracks

or

softness

.

Check

clamps

for

looseness

.

Check

the

coolant

leve¡

and

check

for

evidence

of

coolantleaks

from

the

engine

.

Check

that

the

radiator

fins

are

not

blocked

with

dirt

or

de-

bris

.

Clean

the

radiator

using

low-pressure

water

or

com-

pressed

air

.

Blow

outward,

fromthe

engine

side

out

.

Inspect

the

coolant

pump

by

first

removing

the

drive

belt

from

the

pump

.

Firmly

grasp

opposite

sídes

of

the

pulley

and

check

for

play

in

all

directions

.

Spin

the

pulley

and

check

that

the

shaft

runs

smoothly

.

NOTE-

The

coolant

provides

lubrication

for

the

pump

shaft,

soan

occasional

drop

of

coolant

leaking

from

the

pump

is

acceptable

.

If

coolant

drips

steadily

from

the

vent

hole,

the

pump

should

be

replaced

.

The

cooling

system

becomes

pressurized

at

normal

operat-

ing

temperature,

which

raises

the

boiling

point

of

the

coolant

.

Leaks

may

prevent

the

system

from

becoming

pressurized,

allowing

the

coolant

to

boil

at

a

lower

temperature

.

If

visual

ev-

idence

is

inconclusive,

a

cooling

system

pressure

test

can

help

to

pinpointhard-to-find

leaks

.

If

the

cooling

system

is

full

of

coolant

and

holds

pressure,

the

next

most

probable

cause

of

overheating

are

:

"

Faulty

radiator

fan

"

Loose

or

worn

drive

belt

"

Failed

thermostat

or

coolant

pump

"

Clogged/plugged

radiator

or

coolant

passages

.

NOTE

-

"

Some

early

style

coolant

pumps

were

fitted

wíth

fi-

berlplastic

type

impellers

.

Over

time,

this

impeller

can

wear

away

and

result

in

overheating

.

The

plastic

im-

peller

can

also

slip

or

free-wheel

on

the

pump

shaft

.

If

the

engine

overheats

and

no

other

faults

canbe

found,

theold

style

impeller

may

be

the

cause

of

the

problem

.

"

Only

pumps

with

the

updated

metal

impeller

should

be

used

for

replacement

.

Page 207 of 759

GENERAL

.

.

.......

.

......

.

...

.

.

.

.

.

...

180-1

Exhaust

system,

removing

and

installing

.

...

.180-3

EXHAUST

SYSTEM

REPLACEMENT

.

...

180-1

Exhaust

manifolds,

removing

and

installing

.

.

.180-5

GENERAL

The

exhaust

system

is

designed

to

be

maintenance

free,

al-

though

regular

inspection

is

warranted

due

to

the

harsh

oper-

atingconditions

.

Under

normal

conditions,

the

catalytic

converter

does

not

require

replacement

unless

it

is

damaged

.

On

1996

and

later

cars,

a

pre-

and

post-catalytic

converter

oxygen

sensor

is

used

at

each

catalytic

converter

.

Be

sure

to

take

care

when

removingthe

system

not

to

damage

the

sen-

EXHAUST

SYSTEMREPLACEMENT

sors

.

See

130

Fuel

Injection

for

information

on

testing

oxygen

sensors

.

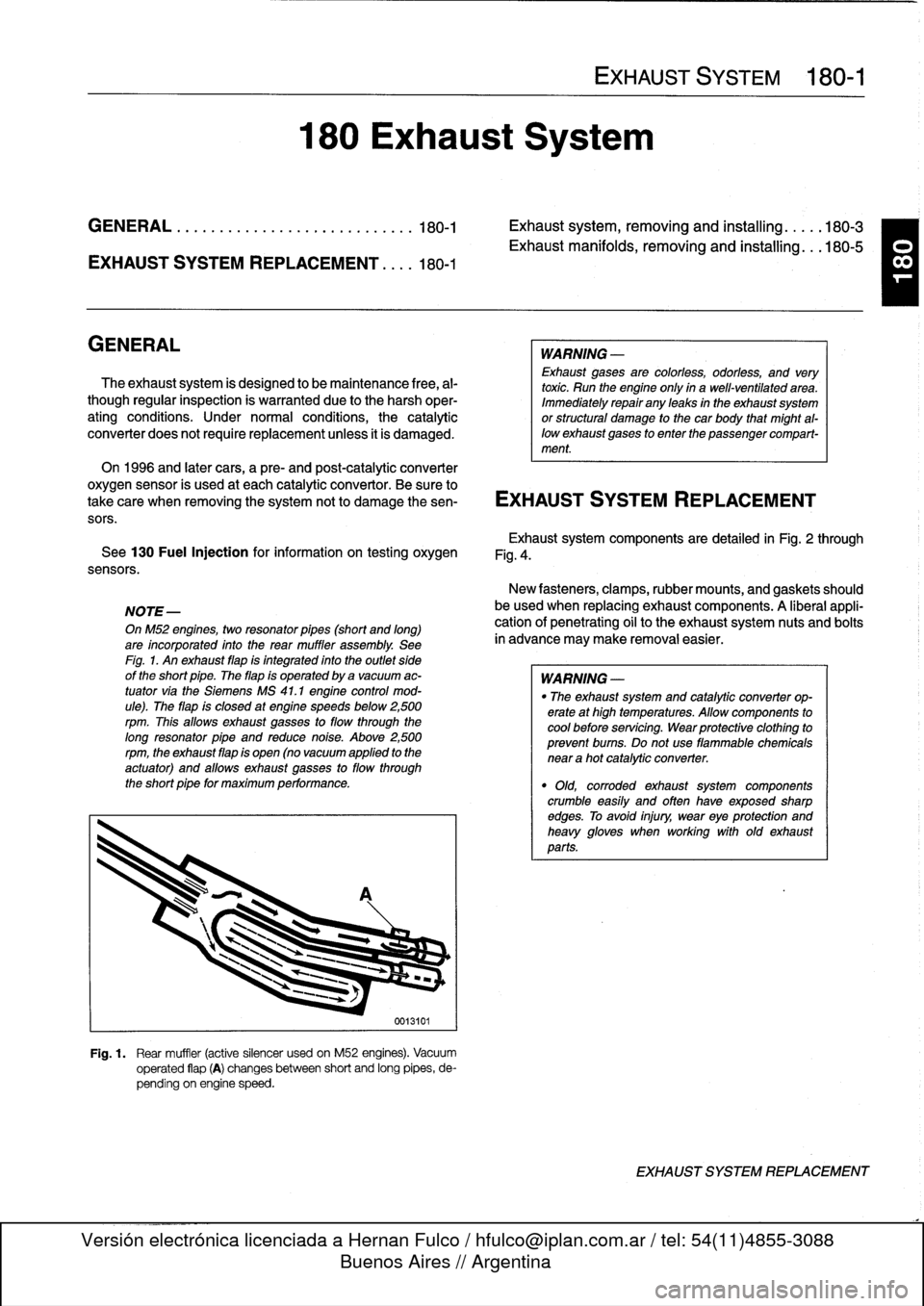

NOTE-

OnM52

engines,

two

resonator

pípes

(short

and

long)

are

incorporated

into

the

rear

muffler

assembly

.

See

Fíg

.

1

.

An

exhaust

flap

is

integrated

into

the

outlet

side

of

the

short

pipe

.

The

flap

is

operated

by

a

vacuum

ac-

tuator

via

the

Siemens

MS

41

.1

engine

control

mod-

ule)

.

The

flap

is

closed

at

engine

speeds

below

2,500

rpm

.

This

allows

exhaust

gasses

to

flow

through

the

long

resonator

pipe

and

reduce

noise

.

Above

2,500rpm,

the

exhaust

flap

is

open

(no

vacuum

applied

to

the

actuator)

and

allows

exhaust

gasses

to

flow

through

the

short

pipe

for

maximum

performance

.

180

Exhaust

System

0013101

Fig

.

1

.

Rear

muffler

(active

silencer

usedon

M52

engines)

.

Vacuum

operated

flap

(A)

changesbetween

short

and

long

pipes,

de-

pending

on

engine

speed

.

EXHAUST

SYSTEM

180-1

WARNING

-

Exhaust

gases

are

colorless,

odorless,

and

very

toxic

.

Run

the

engine

only

ín

a

well-ventilated

area

.

Immediately

repair

any

leaks

in

the

exhaust

system

or

structural

damage

to

the

car

body

that

might

al-

lowexhaust

gases

to

enter

the

passenger

compart-

ment

.

Exhaustsystem

components

are

detailed

in

Fig

.

2

through

Fig

.

4

.

New

fasteners,

clamps,rubber

mounts,

and

gaskets

should

be

used

when

replacing

exhaust

components

.

A

liberal

appli-

cationof

penetrating

oil

to

the

exhaustsystem

nuts

and

bolts

in

advance

may

make

removal

easier

.

WARNING

-

"

The

exhaust

system

and

catalytic

converter

op-

erate

at

high

temperatures

.

Allow

components

to

cool

before

servicing

.

Wear

protectíve

clothíng

to

prevent

bums

.

Do

not

use

flammable

chemicals

near

a

hot

catalytic

converter

.

"

Old,

corroded

exhaust

system

components

crumble

easíly

and

often

have

exposed

sharp

edges

.

To

avoid

injury,

wear

eye

protection

and

heavy

gloves

when

working

with

old

exhaust

parts

.

EXHAUST

SYSTEM

REPLACEMENT

T

Page 208 of 759

180-2

EXHAUST

SYSTEM

a

EXHAUST

SYSTEM

REPLACEMENT

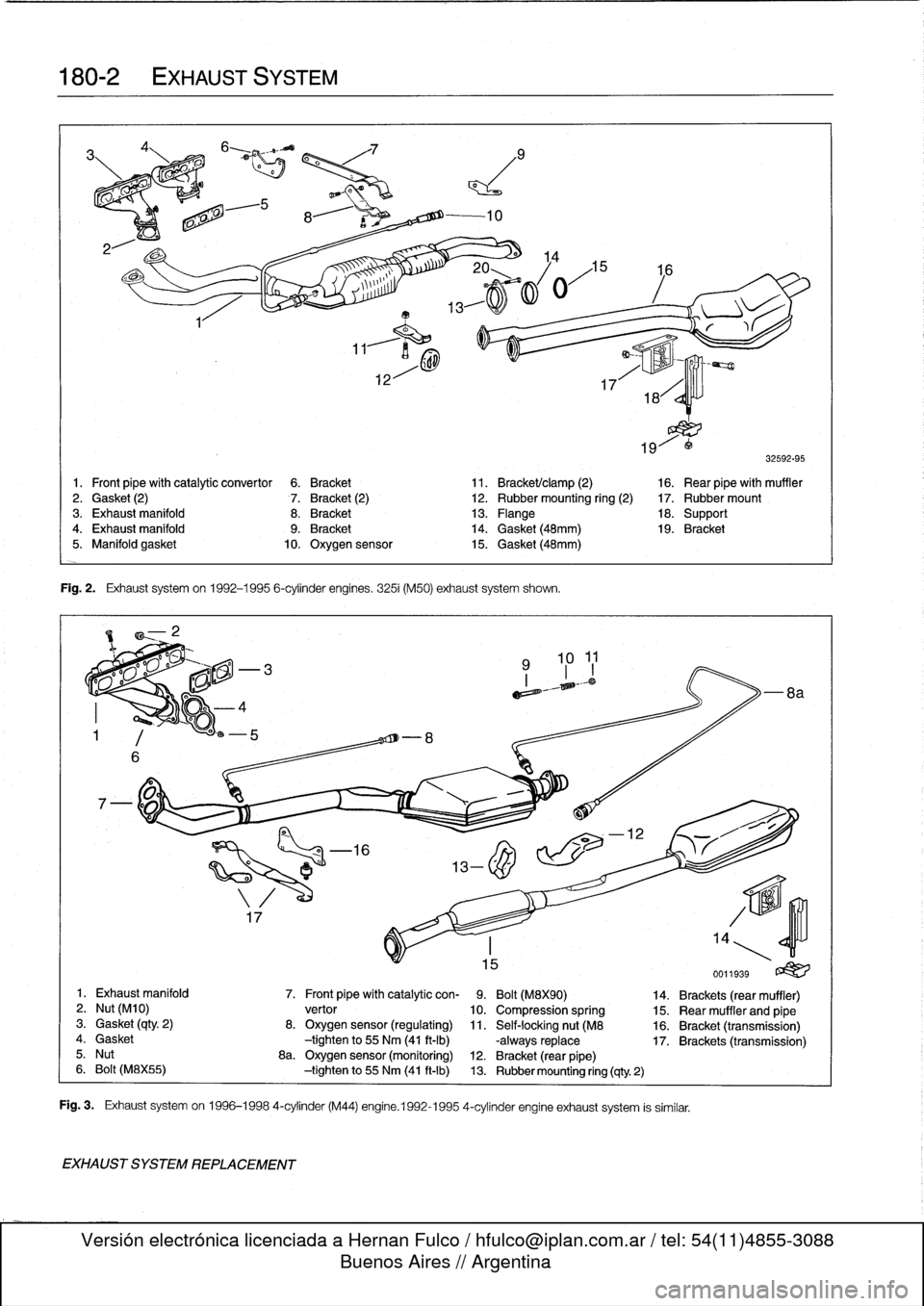

Fig

.

2

.

Exhaust

systemon

1992-1995

6-cylinder

engines

.

3251

(M50)

exhaust

system

shown

.

E~

)l-,malo

m~=

i

32592-95

1

.

Front

pipe

with

catalytic

convertor

6

.

Bracket

11

.

Bracket/clamp

(2)

16

.

Rear

pipewith

muffler

2

.

Gasket

(2)

7

.

Bracket

(2)

12

.

Rubber

mounting

ring

(2)

17

.

Rubber

mount

3

.

Exhaust

manifold

8

.

Bracket

13

.

Flange

18

.

Support4

.

Exhaust

manifold

9

.

Bracket

14

.

Gasket

(48mm)

19

.

Bracket

5

.

Manifold

gasket

10

.

Oxygen

sensor

15

.

Gasket

(48mm)

eme°"

k

:I>

-

8a

1

.

Exhaust

manifold

7

.

Front

pipe

with

catalytic

con-

9

.

Bolt

(M8X90)

14

.

Brackets

(rear

muffier)

2

.

Nut

(M10)

vertor

10

.

Compression

spring

15

.

Rear

muffler

and

pipe

3

.

Gasket

(clty

.

2)

8

.

Oxygen

sensor

(regulating)

11

.

Self-lockingnut

(M8

16

.

Bracket

(transmission)

4

.

Gasket

-tightento

55

Nm

(41

ft-Ib)

-always

replace

17

.

Brackets

(transmission)

5

.

Nut

8a

.

Oxygen

sensor

(monitoring)

12

.

Bracket

(rear

pipe)

6

.

Bolt

(M8X55)

-tightento

55

Nm

(41

ft-Ib)

13

.

Rubber

mounting

ring

(9ty

2)

Fig

.

3

.

Exhaust

systemon

1996-1998

4-cylinder

(M44)

engine

.1992-1995

4-cylinder

engine

exhaust

system

is

similar

.

Page 210 of 759

180-

4

EXHAUST

SYSTEM

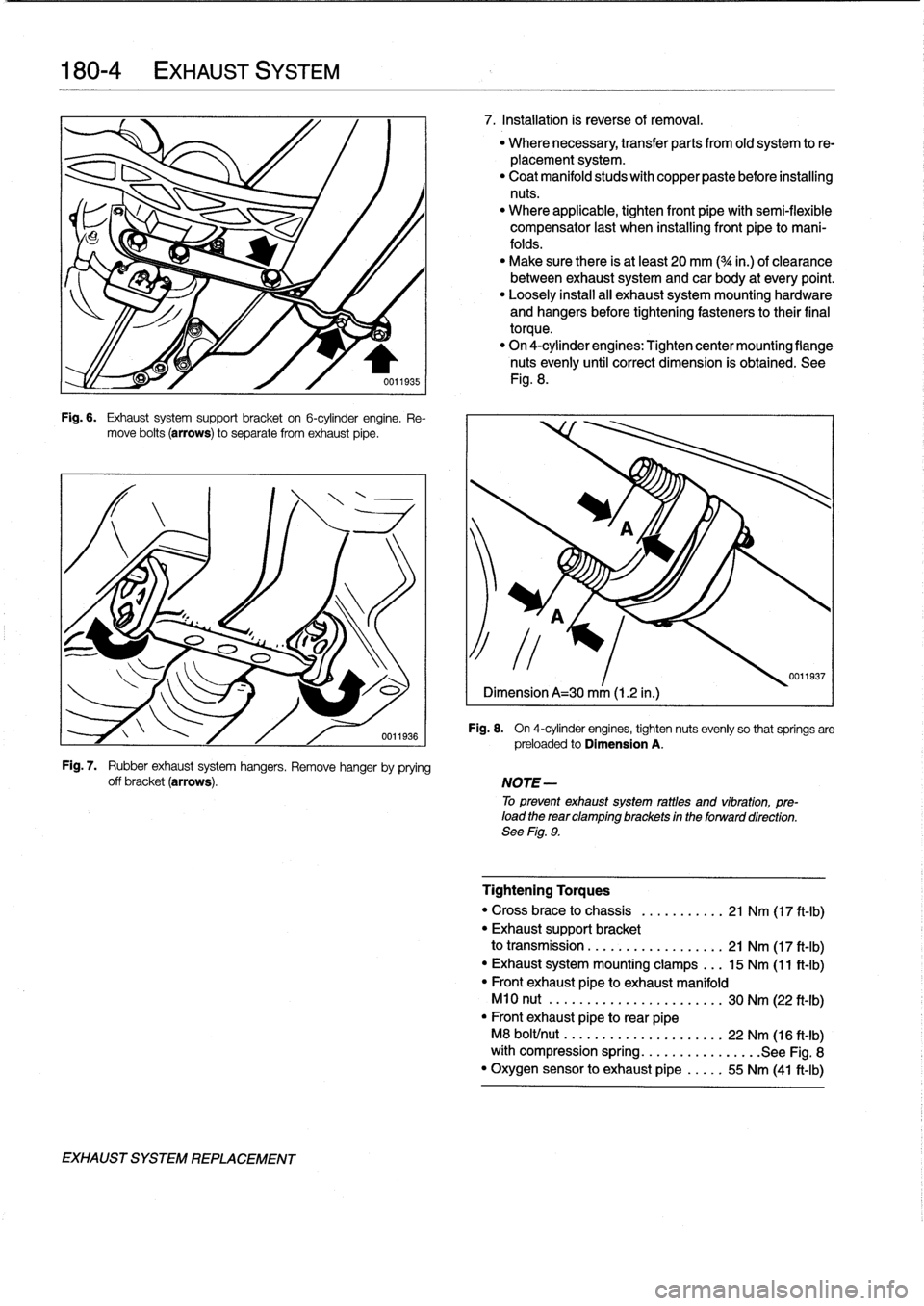

Fig

.

6

.

Exhaust

system

support

bracket

on

6-cylinder

engine

.

Re-

move

bolts

(arrows)

to

separate

from

exhaust

pipe

.

Fig

.

7

.

Rubber

exhaust

system

hangers

.

Remove

hanger

by

prying

off

bracket

(arrows)

.

EXHAUST

SYSTEM

REPLACEMENT

7

.

Installation

is

reverse

of

removal

.

"

Where

necessary,

transfer

parts

from

old

system

to

re-

placement

system

.

"

Coat

manifold

studs

with

copper

paste

before

installing

nuts

.

"

Where

applicable,

tighten

front

pípewith

semi-flexible

compensator

last

when

installing

front

pipe

to

mani-

folds

.

"

Make

sure

there

is

at

least

20

mm

(

3

/4

in

.)

of

clearance

between

exhaust

systemand

car

body

at

every

point

.

"

Loosely

install

all

exhaust

system

mountinghardware

and

hangers

before

tightening

fasteners

to

their

final

torque

.

"

On

4-cylinder

engines

:

Tighten

center

mounting

flange

nuts

evenly

until

correct

dimension

is

obtained

.

See

Fig

.

8

.

ri

J%JJ

w

~~~JJJJ

1

Fig

.

8

.

On

4-cylinder

engines,

tighten

nuts

evenly

so

that

spríngs

are

preloaded

to

Dimension

A

.

NOTE-

To

prevent

exhaust

system

rattles

and

vibration,

pre-load

the

rear

clamping

brackets

in

the

íonaard

direction

.

See

Fig

.

9

.

0011937

Tightening

Torques

"

Cross

brace

to

chassis

..

.

...

.

..

..

21

Nm

(17

ft-Ib)

"

Exhaust

support

bracket

to

transmission

.

.

.

.

.......

.....,.

21

Nm

(17

ft-Ib)

"

Exhaust

system

mounting

clamps

...

15

Nm

(11

ft-Ib)

"

Front

exhaust

pipeto

exhaust

manifold

M10

nut

.

.

.

...

.

..

..............

30

Nm

(22

ft-Ib)

"

Front

exhaust

pipe

torear

pipe

M8

bolt/nut

..

....

.

..............

22

Nm

(16

ft-Ib)

with

compression

spring

................

See

Fig

.

8

"

Oxygen

sensor

to

exhaust

pipe

.....

55

Nm

(41

ft-Ib)

Page 211 of 759

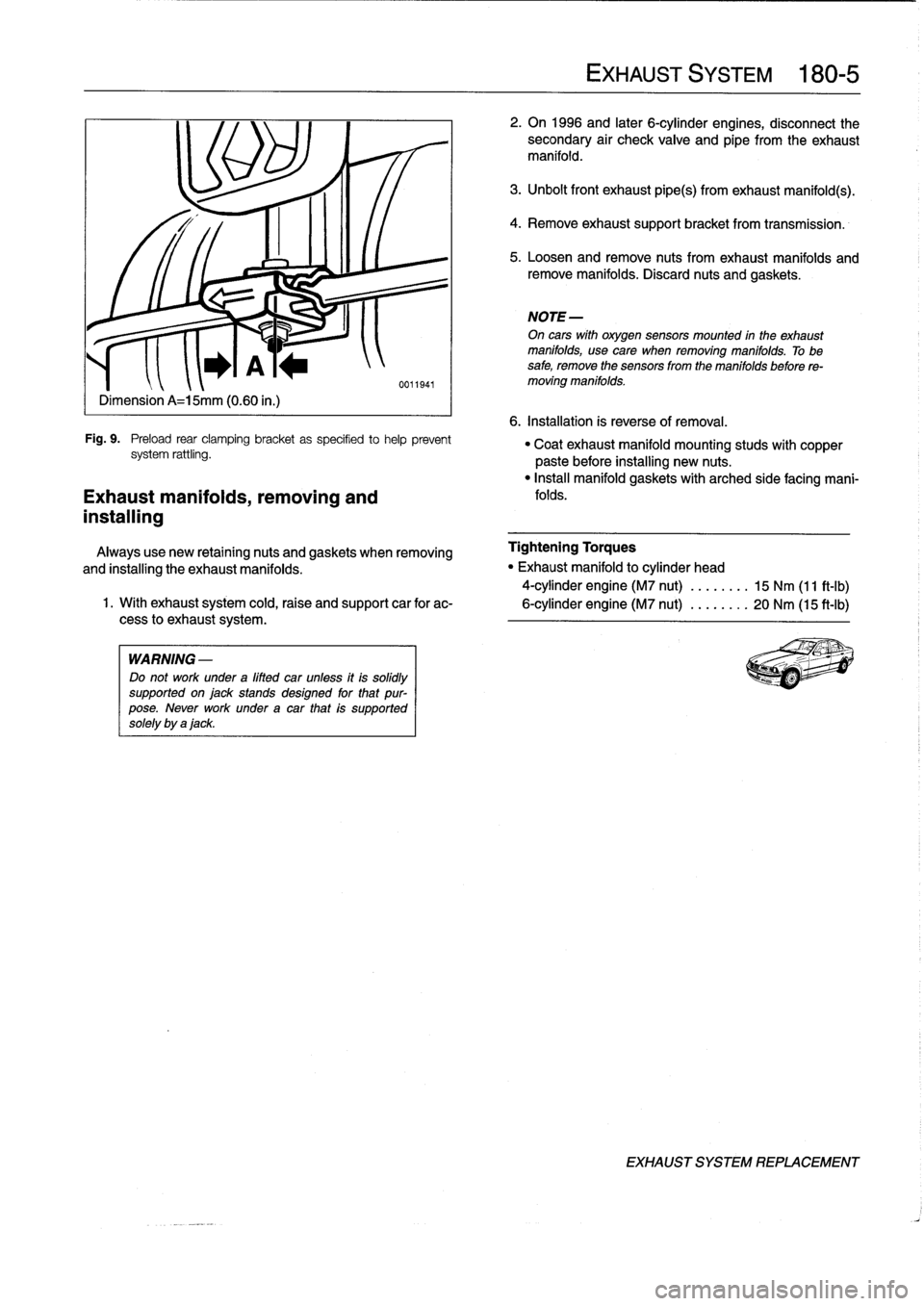

Dimension

A=15mm

(0

.60

in

.)

Fig

.

9

.

Preload

rear

clamping

bracket

as

specifíed

tohelp

prevent

system

rattling

.

Exhaust

manifolds,

removing

and

installing

WARNING

-

Do

not

work

under

a

lifted

car

unfess

itis

solidly

supportedonjackstands

designed

for

that

pur-

pose

.

Never

work

underacar

that

is

supported

solely

by

ajack

.

EXHAUST

SYSTEM

180-

5

2

.

On

1996

and

later

6-cylinder

engines,

disconnect

the

secondary

air

check

valve

and

eipe

from

the

exhaust

manifold

.

3

.

Unbolt

front

exhaust

pipe(s)

from

exhaust

manifold(s)

.

4

.

Remove

exhaustsupport

bracket

from

transmission

.

5

.

Loosen

andremove

nuts

fromexhaust

manifolds

and

remove

manifolds

.

Discard

nuts

and

gaskets

.

NOTE-

On

cars

wíth

oxygen

sensors

mounted

in

the

exhaust

manifolds,

usecare

when

removing

manifolds

.

Tobe

safe,

remove

the

sensors

from

the

manifolds

before

re-

moving

manifolds

.

6

.

Installation

is

reverse

of

removal

.

"

Coatexhaust

manifold

mounting

studs

with

copper

paste

before

installing

new

nuts

.

"

Insta¡¡

manifold

gaskets

with

arched

side

facing

mani-

folds

.

Always

use

new

retaining

nuts

and

gaskets

when

removing

Tightening

Torques

and

installing

the

exhaust

manifolds

.

"

Exhaust

manifold

to

cylinder

head

4-cylinder

engine

(M7

nut)

........

15

Nm

(11

ft-Ib)

1

.

With

exhaust

system

cold,raise

and

support

car

for

ac-

6-cylinder

engine

(M7

nut)

........

20

Nm

(15

ft-Ib)

cess

lo

exhaust

system

.

EXHAUST

SYSTEM

REPLACEMENT

Page 231 of 759

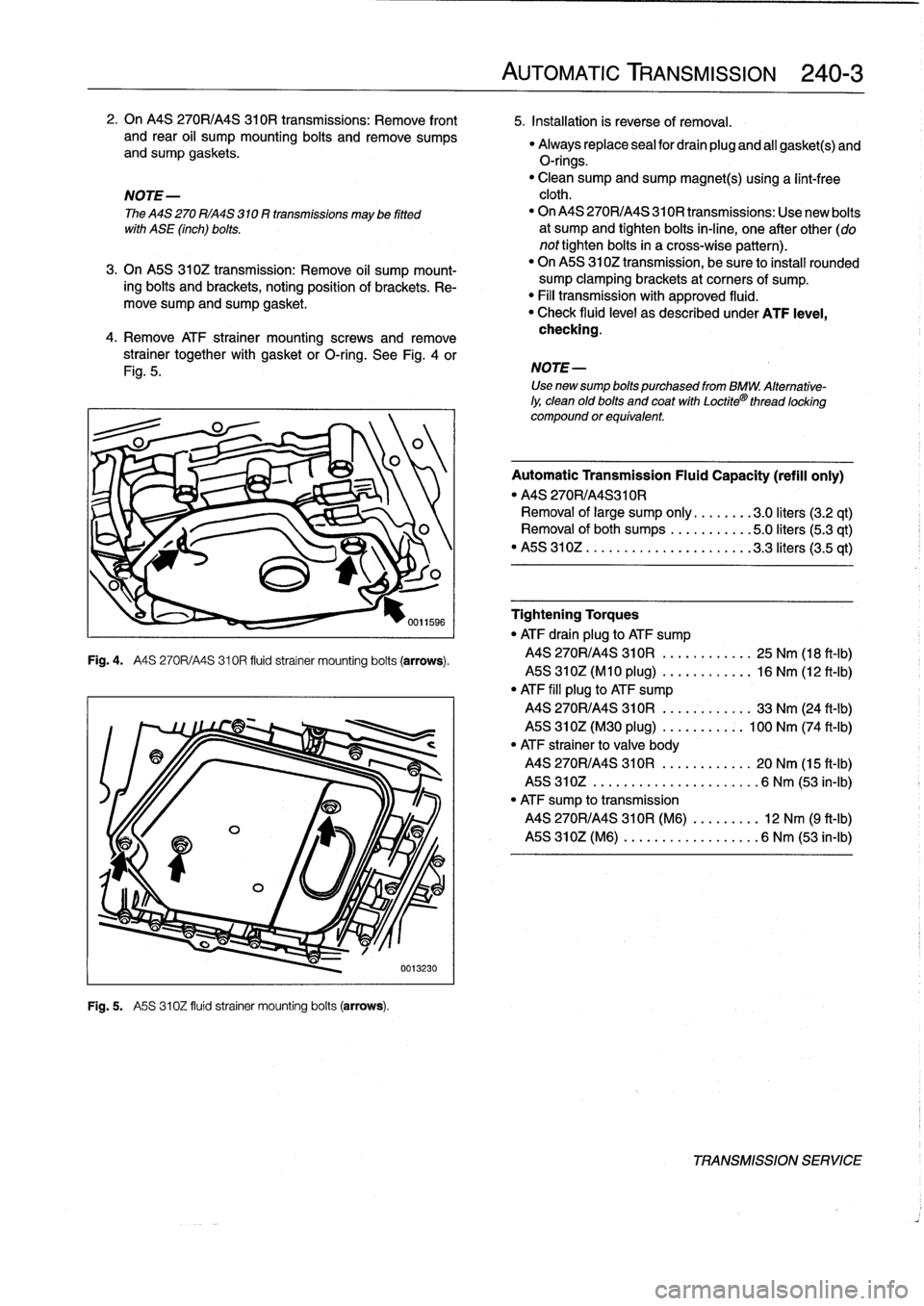

2

.

On

MS

270R/A4S

310R

transmissions

:

Remove

front

5

.

Installation

is

reverse

of

Rmoval

.

and

rear

oil

sump

mounting

bolts

andremove

sumps

"

Always

replace

sea¡

for

drain

plug

and

al¡

gasket(s)

andand

sump

gaskets

.

O-rings

.

"

Clean

sump

and

sump

magnet(s)

using

a

lint-free

NOTE-

cloth

.

The

MS

270

R/A4S

310

R

transmissions

may

be

fitted

"

On

MS

270R/A4S310R

transmissions

:

Use

new

bolts

with

ASE

(inch)

bolts

.

at

sump

and

tighten

bolts

in-line,

one

after

other

(do

nottighten

bolts

in

a

cross-wise

pattern)

.

3

.

On

A5S

310Z

transmission

:

Remove

oil

sump

mount-

"

On

MS

310Z

transmission,

be

sureto

instan

rounded

ing

bolts

and

brackets,

noting

position

of

brackets

.

Re-

sump

clamping

brackets

at

corners

of

sump

.

move

"

Fill

transmission

with

approved

fluid

.

sump

and

sump

gasket

.

"

Check

fluid

level

as

described

under

ATF

leve¡,

4

.

Remove

ATF

otra¡ner

mount¡ng

screws

and

remove

checking

.

strainer

together

with

gasket

orO-ring

.

See

Fig

.

4

or

Fig

.

5

.

Fig

.

4

.

A4S

270R/A4S310R

fluid

strainer

mounting

boits

(arrows)

.

Fig

.

5

.

A5S

310Z

fluid

strainer

mounting

boits

(arrows)

.

0013230

AUTOMATIC

TRANSMISSION

240-

3

NOTE-

Use

newsump

bolts

purchased

from

BMW

.

Alternative-

ly,

clean

old

bolts

and

coat

with

Loctite®

thread

locking

compound

or

equivalent

Automatic

Transmission

Fluid

Capacity

(refill

only)

"

MS

270R/A4S310R

Removal

of

large

sump

only

........

3

.0liters

(3.2

qt)

Removal

ofboth

sumps

...........

5

.0liters(5

.3

qt)

"

MS

310Z

..

..

..................

3

.3liters

(3.5

qt)

Tightening

Torques

"

ATF

drain

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

25

Nm

(18

ft-Ib)

MS

310Z(M10

plug)

..........

..

16

Nm

(12

ft-Ib)

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

33

Nm

(24

ft-Ib)

MS

310Z(M30

plug)

.....

..

..

:.

100

Nm

(74

ft-Ib)

"

ATF

strainer

to

valve

body

MS

270R/A4S

310R

.....

..

.

...

.

20

Nm

(15

ft-Ib)

MS

310Z

..............

..

.

...

..

6

Nm

(53

in-lb)

"

ATF

sump

to

transmission

MS

270R/A4S

310R

(M6)

.

..

.

..

...

12

Nm

(9

ft-¡b)

MS

310Z

(M6)

..........

..

.

..

...

6

Nm

(53

in-¡b)

TRANSMISSION

SERVICE

Page 241 of 759

DRIVESHAFT

SERVICE

.

...

.

.

.

...

.

..

.

.

.260-3

Driveshaft,

aligning

...............

.

...

.

.

260-3

Driveshaft,

removing

..............

.

.

.

.

.

.

260-4

260

Driveshaft

DRIVESHAFT

260-1

GENERAL

.

.

.

.

.

.

.

.....

.

.

.

........

.

...

.

260-1

Driveshaft,

installing

.

....

.

..

.

............

260-4

Flex-disc,

replacing

.....

.

.

.

.............

260-5

TROUBLESHOOTING

..

.

.

.

...

.

.........

260-1

Center

bearing

assembly,

replacing

.

......

.260-6

Frontcentering

guide,

replacing

..

.

.......

.

260-7

TABLE

a

.

Driveshaft

Troubleshooting

.

.

...

......

.

....

..

.

.

260-2

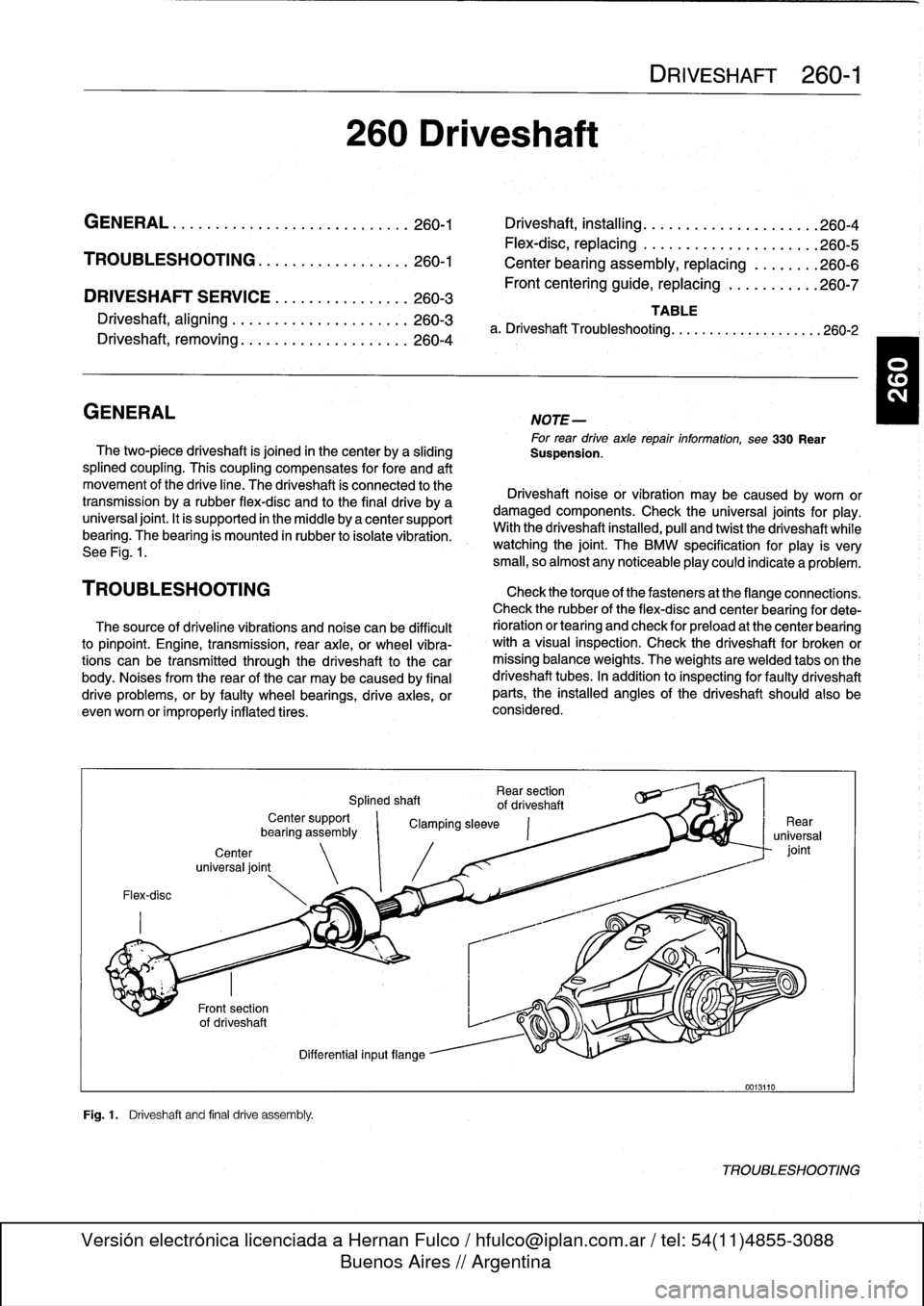

GENERAL

NOTE-

For

rear

drive

axlerepair

information,

see330

Rear

The

two-piece

driveshaft

is

joined

in

thecenter

by

a

sliding

Suspension

.

splined

coupling

.

This

coupling

compensates

for

fore

and

aft

movement

of

the

drive

line

.

The

driveshaft

ís

connected

to

the

Driveshaft

noise

or

vibration

may

be

caused

by

worn

or

transmission

bya

rubber

flex-disc

and

to

the

final

drive

by

a

damaged

components

.

Check

the

universal

joints

for

play

.

universal

joint

.

It

is

supported

in

the

micidle

by

a

center

support

With

the

driveshaft

installed,

pull

and

twist

the

driveshaft

while

bearing

.

The

bearing

is

mounted

in

rubber

to

isolate

vibration

.

watching

the

joint

.

The

BMW

specificationfor

play

is

very

See

Fig

.

1

.

small,

so

almost

any

noticeableplay

could

indicate

a

problem

.

TROU

BLESHOOTING

Check

thetorque

of

thefasteners

at

the

flange

connections

.

Check

therubber

of

the

flex-disc

and

center

bearing

for

dete

The

source

of

driveline

vibrations

and

noise

can

be

difficult

rioration

or

tearíng

and

check

for

preload

at

the

center

bearing

to

pinpoint

.

Engine,

transmission,

rear

axle,

or

wheel

vibra-

with

a

visual

inspection

.

Check

the

driveshaft

for

broken

or

tions

can

be

transmitted

through

the

driveshaft

to

the

car

missing

balance

weights

.

The

weights

are

welded

tabs

on

the

body

.

Noises

from

the

rear

of

thecar

may

be

caused

by

final

driveshaft

tubes

.

In

addition

to

inspecting

for

faulty

driveshaft

drive

problems,

orby

faulty

wheel

bearings,

drive

axies,

or

parts,

the

installed

angles

of

the

driveshaft

should

also

be

evenworn

or

improperly

inflatedtires

.

considered

.

Flex-disc

Center

universal

joint

Fig

.1

.

Driveshaft

and

final

drive

assembly

.

Rear

section

Splined

shaft

of

driveshaft

Center

support

`

Clamping

sleeve

bearíng

assembly

Differential

inputflange

0013110

TROUBLESHOOTING

Page 244 of 759

260-

4

DRIVESHAFT

CAUTION

-

The

maximum

allowable

change

in

height

of

the

center

bearing

or

transmission

support

using

shims

is

3

mm

(0

.12

in

.)

.

Driveshaft,

removing

WARNING

-

"

Be

sure

the

wheels

are

off

the

ground

before

re-

moving

the

driveshaft

.

Set

the

parking

brake

be-

fore

removing

the

driveshaft

.

"

Once

the

driveshaft

has

been

removed,

the

vehi-

cle

can

roll

regardless

of

whether

the

transmis-

sion

isin

gear

or

not

.

"

The

driveshaft

fs

mounted

to

thetransmission

and

final

drive

with

self-locking

nuts

.

These

nuts

are

designed

to

be

used

only

once

and

should

be

replaced

during

reassembly

.

1.

Disconnect

oxygen

sensor

electrical

connectors

and

remove

complete

exhaustsystem

.

See

180

Exhaust

System

.

4

.

Remove

driveshaft

mounting

bolts

.

See

Fig

.

3

.

Discard

old

nuts

.

JG

Fig

.

3

.

Front

driveshaft

totransmission

mounting

bolt

being

re-

moved

.

Note

open-end

wrench

(arrow)

being

used

to

coun-

terhold

bolt

.

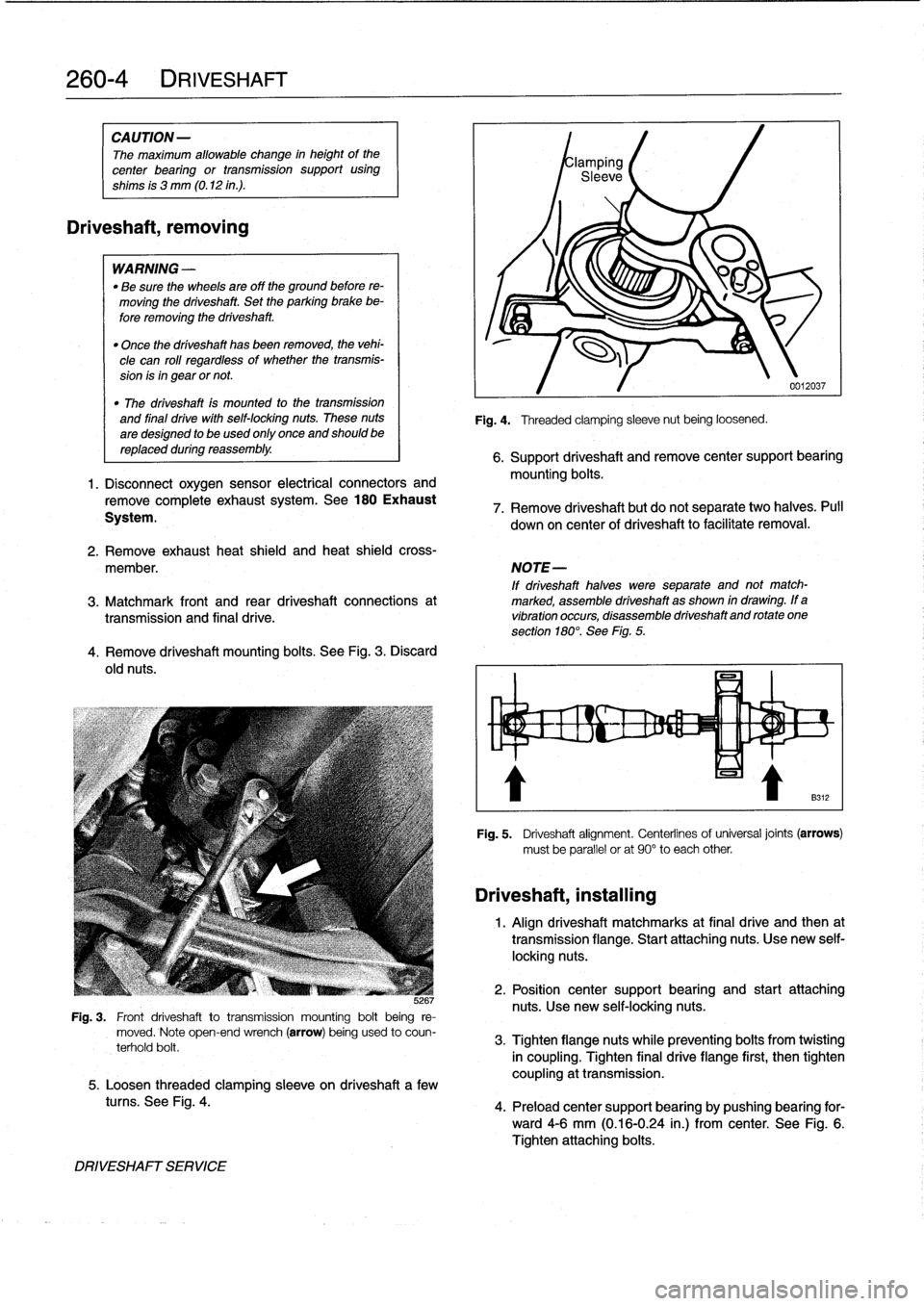

5

.

Loosen

threaded

clamping

sleeve

on

driveshaft

a

few

tucos

.

See

Fig

.

4

.

DRIVESHAFT

SERVICE

Fig

.

4

.

Threaded

clamping

sleeve

nut

being

loosened

.

0012037

6

.

Support

driveshaft

andremove

center

support

bearing

mounting

bolts

.

7

.

Remove

driveshaft

but

do

not

separate

two

halves

.

Pull

down

on

center

of

driveshaft

to

facilitate

removal

.

2

.

Remove

exhaust

heat

shield

and

heat

shieldcross-

member

.

NOTE-

If

driveshaft

halves

were

separate

and

not

match-

3

.

Matchmark

front

and

rear

driveshaft

connections

at

marked,

assemble

driveshaft

as

shown

in

drawing

.

If

a

transmissíon

and

final

drive

.

vibration

occurs,

disassemble

driveshaftand

rotate

one

section

180°

.

See

Fig

.

5

.

Driveshaft,

installing

Fig

.

5

.

Driveshaft

alignment

.

Centerlinesof

universal

joints

(arrows)

must

be

parallel

or

at

90°

to

each

other

1

.

Align

driveshaft

matchmarks

at

final

drive

and

then

at

transmission

flange

.

Start

attaching

nuts

.

Use

new

self-

locking

nuts

.

2

.

Position

center

support

bearing

and

start

attaching

nuts

.

Use

new

self-locking

nuts

.

3

.

Tighten

flangenuts

while

preventing

bolts

from

twisting

in

coupling

.

Tighten

final

drive

flange

first,

then

tighten

coupling

at

transmission

.

4

.

Preload

center

support

bearing

by

pushing

bearing

for-

ward4-6

mm

(0

.16-0

.24

in

.)

from

center

.

See

Fig

.

6

.

Tighten

attaching

bolts

.