600 BMW 325i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 325i, Model: BMW 325i 1992 E36Pages: 759

Page 384 of 759

600-

4

ELECTRICAL

SYSTEM-GENERAL

Voltage

and

Voltage

Drops

The

wires,

connectors,

and

switches

that

carry

current

are

designed

with

very

low

resistance

so

that

current

flows

with

a

minimum

loss

of

voltage

.

A

voltage

drop

is

caused

by

higher

than

normal

resistance

in

a

circuit

.

This

additional

resistance

actually

decreases

or

stops

the

flow

of

current

.

A

voltage

drop

can

be

noticed

byproblems

ranging

fromdim

headlights

to

sluggish

wipers

.

Some

common

sources

of

voltage

drops

are

corroded

or

dirty

switches,

dirty

or

corroded

connections

or

contacts,

and

loose

or

corroded

ground

wires

and

ground

con-

nections

.

A

voltage

drop

test

is

a

good

test

to

make

if

current

is

flowing

through

the

circuit,

butthe

circuit

is

not

operating

correctly

.

A

voltage

drop

test

will

help

to

pinpoint

a

corroded

ground

strap

or

a

faulty

switch

.

Normally,

there

should

be

less

than

1

volt

drop

across

most

wires

or

closed

switches

.

A

voltage

drop

across

a

connector

or

short

cable

shouldnot

exceed

0

.5

volts

.

Voltage,

measuring

1

.

Connect

digital

multimeternegative

lead

to

a

reliable

ground

point

oncar

.

NOTE-

The

negative

(-)

battery

terminal

is

alwaysa

good

ground

point

.

2

.

Connect

digital

multimeter

positive

lead

to

point

incir-

cuit

you

wish

to

measure

.

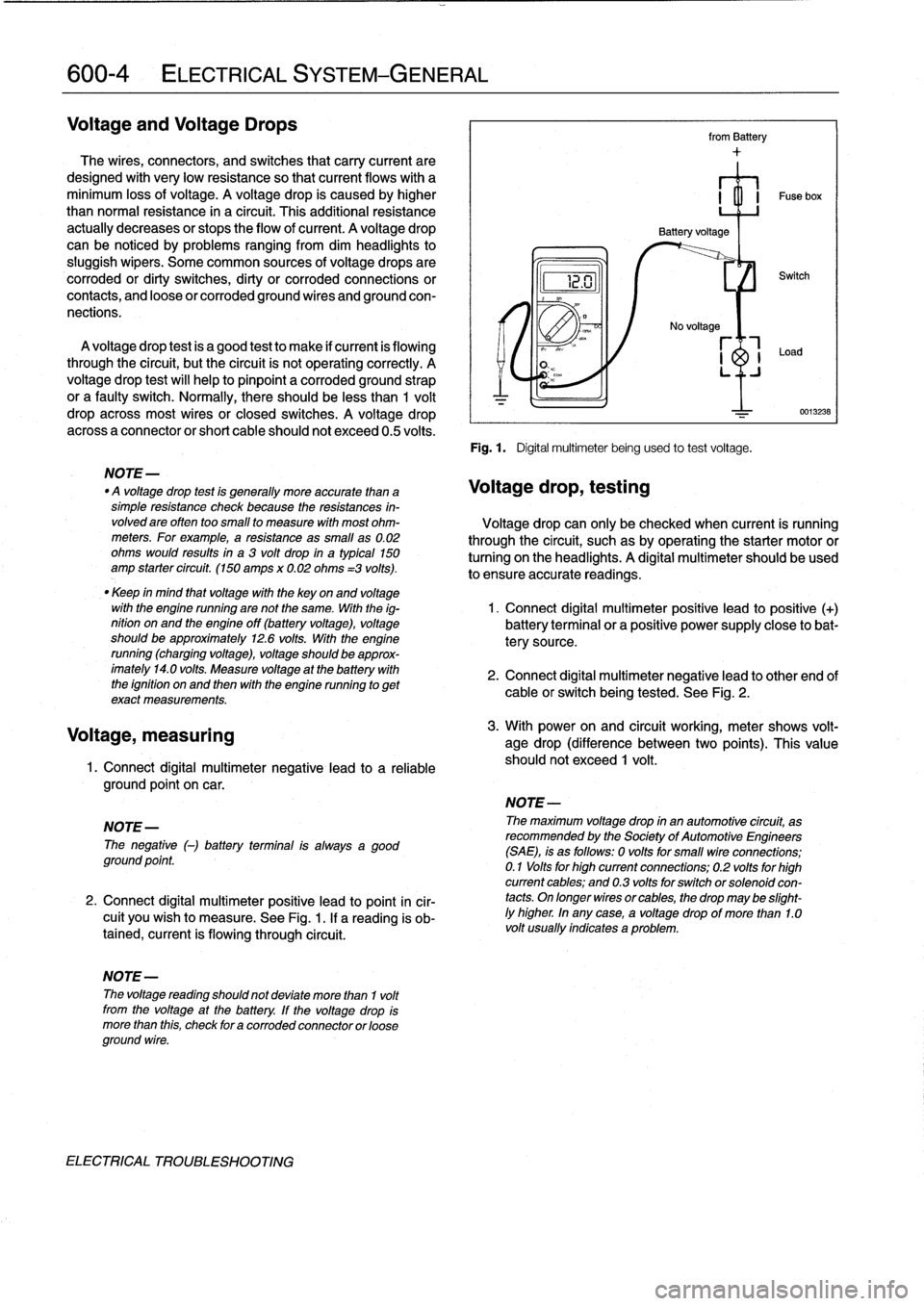

See

Fig

.

1

.

If

a

reading

is

ob-

tained,

current

is

flowing

through

circuit

.

NOTE-

The

voltage

reading

shouldnot

deviate

more

than

1

volt

from

the

voltage

at

the

battery

.

If

the

voltage

drop

is

more

than

this,

check

for

acorroded

connector

or

cose

ground

wire

.

ELECTRICAL

TROLIBLESHOOTING

from

Battery

Fig

.

1

.

Digital

multimeterbeing

used

to

test

voltage

.

No

voltage

r_l

-1

Load

LJ

Switch

NOTE-

The

maximum

voltage

drop

in

an

automotive

circuit,

as

recommended

by

the

Society

of

AutomotiveEngineers

(SAE),

is

as

follows

:

0

voltsfor

small

vire

connections

;

0

.1

Volts

for

high

current

connections

;

0

.2

volts

for

high

current

cables

;

and

0

.3volts

for

switch

or

solenoidcon-

tacts

.

On

longer

wires

or

cables,

the

drop

may

be

slight-ly

higher

.

In

any

case,

a

voltage

drop

of

more

than

1.0volt

usually

indicates

a

problem

.

0013238

NOTE-

"

A

voltage

drop

test

is

generally

more

accuratethan

a

Voltage

drop,

testing

simple

resistance

check

because

the

resistances

in-

volvedare

often

too

small

to

measure

with

most

ohm-

Voltage

drop

can

only

be

checked

when

current

is

running

meters

.

For

example,

a

resistance

as

small

as0

.02

through

the

circuit,

suchasby

operating

the

starter

motor

or

ohms

would

results

in

a

3

volt

drop

in

a

typical

150

turning

onthe

headlights

.

A

digital

multimeter

should

beused

amp

starter

circuit

.

(150

amps

x

0

.02

ohms

=3

volts)

.

lo

ensure

accurate

readings

.

"

Keep

in

mind

that

voltage

with

the

key

on

and

voltage

with

the

engine

running

arenotthe

same

.

With

the

ig-

1

.

Connect

digital

multimeter

positive

lead

to

positive

(+)

nition

on

and

the

engine

off

(battery

voltage),

voltage

battery

terminalor

a

positive

power

supply

close

lo

bat

should

be

approximately

12

.6volts

.

With

the

engine

tery

source

.

running

(charging

voltage),

voltage

should

be

approx-

imately

14

.0

volts

.

Measure

voltage

at

the

battery

with

2

.

Connect

digital

multimeter

negativelead

to

other

end

of

the

ignition

on

and

then

with

the

engine

running

to

get

cable

orswitch

being

tested

.

See

Fig

.

2

.

exact

measurements

.

3

.

With

power

on

and

circuit

working,

meter

shows

volt-

age

drop

(difference

between

two

points)

.

This

value

should

not

exceed

1

volt

.

Page 385 of 759

Continuity,

checking

Short

Circuits

from

Battery

CAUTION-

Use

only

a

high

quality

digital

ohmmeter

having

high

input

impedance

when

checking

electronic

componente

.

The

internal

power

source

used

in

most

analog

(swing-need1e)

meterscan

damage

solidstate

components

.

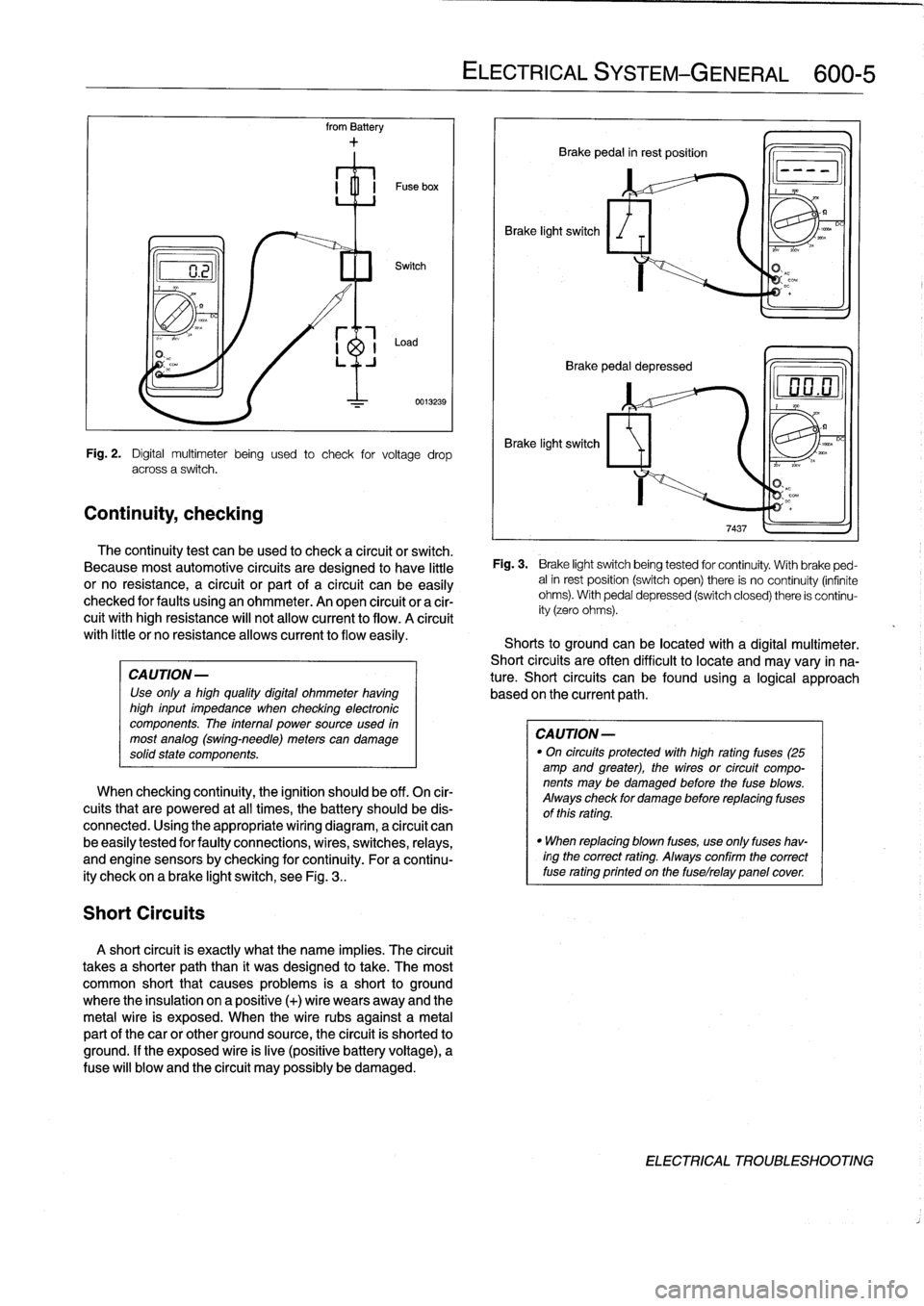

0013239

Fig

.

2

.

Digital

multimeter

being

used

to

check

for

voltage

drop

across

a

switch

.

The

continuity

test

can

beused

to

check

a

circuit

or

switch

.

Because

most

automotive

circuits

are

designed

to

have

little

or

no

resistance,

a

circuit

or

part

of

a

circuit

canbe

easily

checked

for

faults

using

an

ohmmeter

.

An

open

circuit

or

a

cir-

cuit

withhigh

resistance

will

not

allow

current

to

flow

.

A

círcuit

with

little

or

no

resistanceallows

current

to

flow

easily

.

When

checking

continuity,

the

ignition

should

be

off

.

On

cir-

cuits

that

are

powered

at

all

times,

the

battery

should

be

dis-

connected

.

Using

the

appropriate

wiring

diagram,

a

circuit

can

be

easily

tested

for

faulty

connections,

wires,

switches,

relays,

and

engine

sensorsby

checking

forcontinuity

.

For

a

continu-

ity

check

on

a

brake

light

switch,

see

Fig

.

3

..

A

short

circuit

is

exactly

what

the

narre

implies

.

The

circuit

takes

a

shorter

paththan

it

was

designed

to

take

.

The

most

common

short

that

causes

problems

is

a

short

to

ground

where

the

insulation

on

a

positive

(+)

wire

wears

away

and

the

metal

wire

is

exposed

.

When

the

wire

rubs

against

a

metal

partof

thecar

or

other

ground

source,

the

circuit

is

shorted

to

ground

.

If

the

exposed

wire

is

live

(positive

battery

voltage),

a

Puse

will

blow

and

the

circuit

may

possibly

be

damaged

.

ELECTRICAL

SYSTEM

-

GENERAL

600-

5

Brake

light

switch

Brake

pedal

in

rest

position

Q

Brake

pedal

depressed

Brake

light

switch

Fig

.

3

.

Brake

light

switchbeing

tested

for

continuity

.

With

brake

ped-

alin

rest

position

(switch

open)

there

is

no

continuity

(infinite

ohms)

.

With

pedal

depressed

(switch

closed)

there

is

continu-

ity

(zero

ohms)

.

Shorts

to

groundcanbe

located

with

a

digital

multimeter

.

Short

circuits

are

often

difficult

to

locate

and

may

vary

in

na-

ture

.

Short

circuits

can

befound

using

a

logical

approach

based

onthe

current

path

.

CAUTION

-

"

On

circuits

protected

with

high

rating

fuses

(25

amp

and

greater),

the

wires

or

circuit

compo-

nents

may

be

damaged

before

the

fuse

blows

.

Always

check

for

damage

before

replacing

fuses

of

this

rating

.

"

When

replacing

blown

fuses,

use

only

fuses

hav-

ingthe

correct

rating

.

Always

confirm

the

correct

fuse

rating

printed

on

the

fuselrelay

panelcover

DC

ELECTRICAL

TROUBLESHOOTING

Page 449 of 759

9

.

Release

blower

motor

retaining

strap

andremove

blow-

er

motor

and

fans

fromcowl

opening

.

NOTE-

Twist

and

rotate

blowermotor

assembly

to

facilítate

re-

moval

from

opening

.

If

the

blower

motor

is

to

be

rein-stafled,

use

care

not

to

damage

fan

wheels

during

removal

.

ff

the

blower

motor

fs

to

be

replaced,

cut

offfan

wheels

at

center

to

aid

in

removal

.

10

.

Installation

is

reverse

of

removal

.

When

installing

a

re-

placement

blower

motor,

instan

motor

into

cowlarea

before

installing

fan

wheels

.

Blower

motor

test

specifi-

cations

are

listed

in

Table

a

.

NOTE

-

On

replacementblowermotors

from

BMW,

thefan

wheels

come

unattached

to

aid

in

installation

.

Locatearrow

on

blower

motor

and

instan

fan

wheels

atthis

po-

sition

.

Be

sure

color

coolng

matches

.

Retain

fan

wheels

using

the

new

clips

.

See

an

authorized

BMW

parts

de-

partment

for

the

latest

parts

information

.

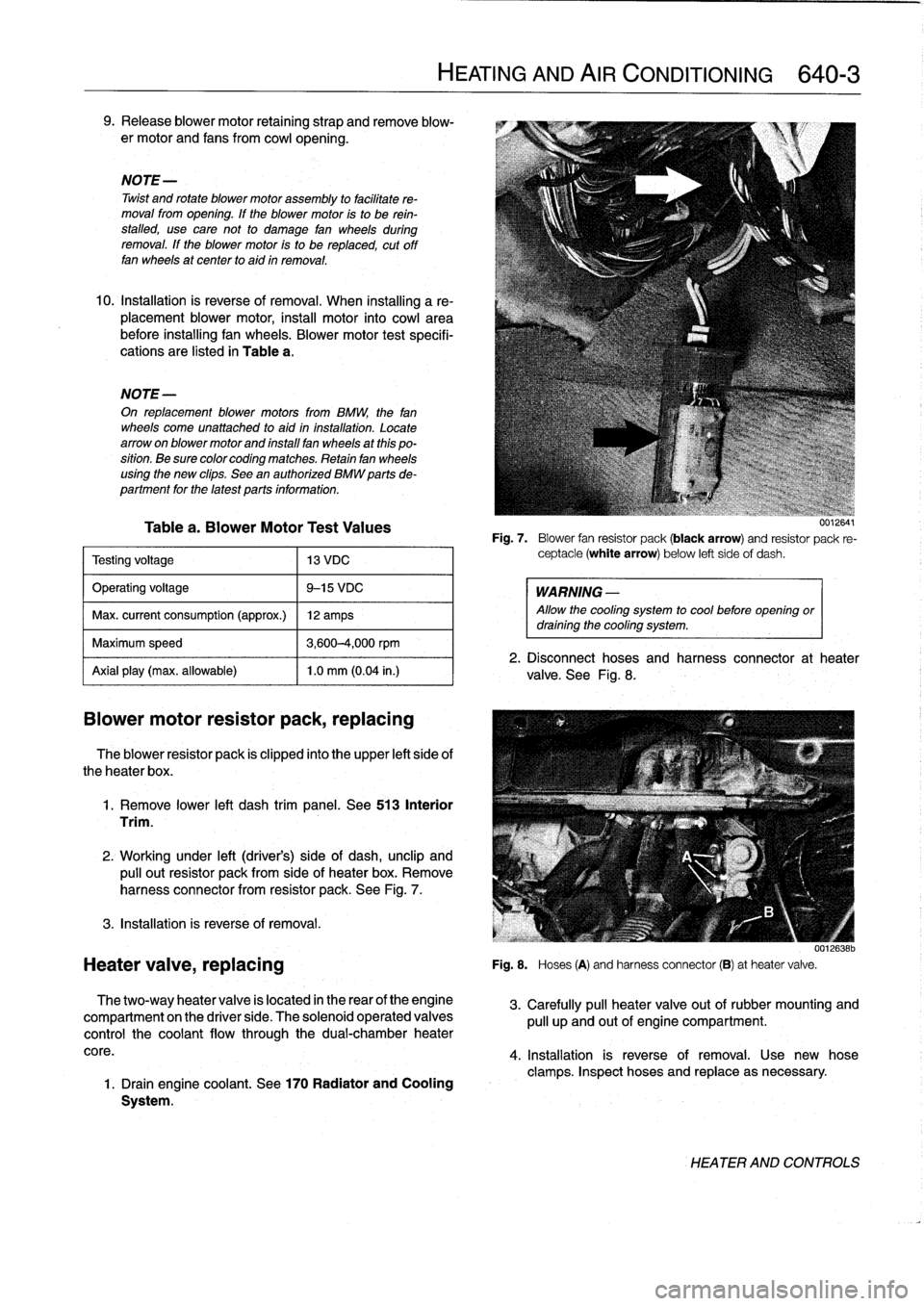

Table

a

.

Blower

Motor

Test

Values

Testingvoltage

13

VDC

Operating

voltage

9-15

VDC

Max

.

current

consumption

(approx

.)

12

amps

Maximum

speed

3,600-4,000rpm

Axialplay

(max

.

allowable)

1

.0

mm

(0

.04

in

.)

Blower

motor

resistor

pack,

replacing

The

blower

resistor

pack

is

clipped

into

the

upper

left

side

of

theheater

box

.

1

.

Remove

lower

left

dash

trim

panel

.

See513

Interior

Trim

.

2

.

Working

under

left

(driver's)

side

of

dash,

unclip

and

pulí

out

resistor

pack

from

sideof

heater

box

.

Remove

harness

connector

from

resistor

pack

.

See

Fig

.

7

.

3

.

Installation

is

reverse

of

removal

.

Heater

valve,

replacing

The

two-way

heater

valve

is

located

in

the

rear

of

the

engine

compartment

on

the

driver

side

.

The

solenoid

operated

valves

control

the

coolant

flow

through

the

dual-chamber

heater

core

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

System

.

HEATING

AND

AIR

CONDITIONING

640-

3

uuiGO4I

Fig

.

7

.

Blower

fan

resistor

pack

(black

arrow)

and

resistor

pack

re-

ceptacle

(white

arrow)

below

left

sideof

dash

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

ordraining

the

cooling

system

.

2

.

Disconnect

hoses

and

harness

connector

at

heater

valve

.

See

Fig

.

8

.

001[ó38b

Fig

.

S

.

Hoses

(A)

and

harnessconnector

(B)

at

heatervalve

.

3

.

Carefully

pull

heater

valve

out

of

rubber

mounting

and

pull

up

and

out

of

engine

compartment

.

4

.

Installation

is

reverse

of

removal

.

Use

new

hose

clamps

.

Inspect

hoses

and

replace

asnecessary

.

HEATER

AND

CONTROLS

Page 578 of 759

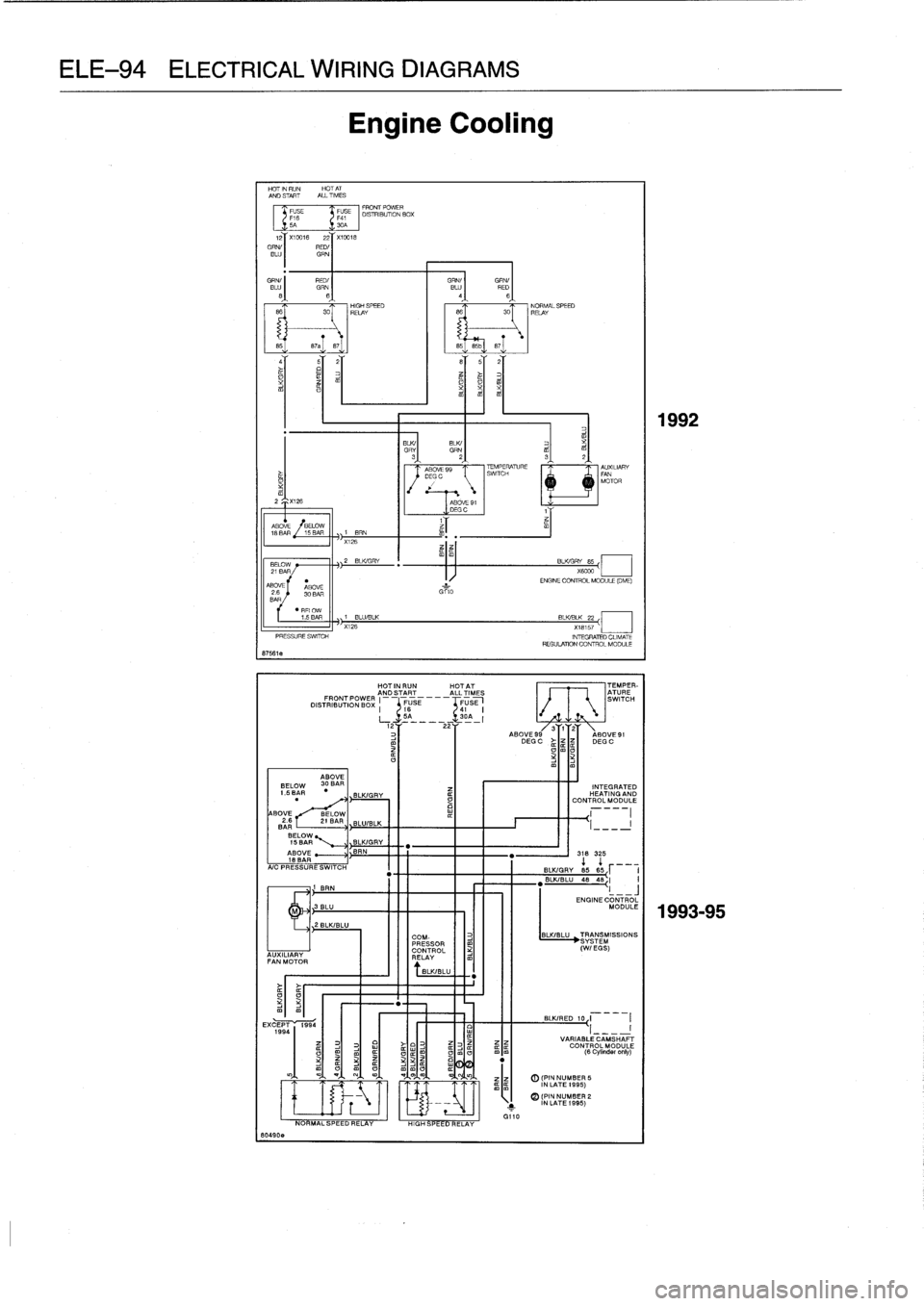

ELE-94

ELECTRICAL

WIRING

DIAGRAMS

HOT

IN

RUN

HOT

AT

AND

START

ALLTIMES

FUSE

FUSE

FRONT

POWER

F16

pq1

DISTRIBUTION

BOX

j

5A

30A

X'

W16

22

X10018

OR

RED/~

B

GRN

I

GRN/1

RED/

GRN/

GRN/~

ELL

GRN

I

BIU

I

RED

8

8

4

6

HIGH

SPEED

NORMAL

SPEED

86

30,77

RELAY

86

30

RELAY

6

87a67

85

B6b674

52

852

3

AGOlE

j

)

BELOW

18

BAR

J

15

BAR

BRN

BELOW

21

BAR

ENGINE

CONTROL

MODULE

(DME)

ABOVE

ABOVE

26

30

BAR

GfIS

BAR

BELOW

1.5

BAR

II

..1

BLU/BLK

BLWBLK

22126

X18157

PRESSURE

SWITCH

INTEGRATED

CLIMATE

REGULATION

CONTROL

MODULE

87581e

ABOVE

BELOW

30

BAR

1

.5

BAR

BLK/GRY

AUXILIARY

FAN

MOTOR

80490

.

2

BLK/BLU

Engine

Cooling

126

1

2

BLWGRY

BLWI

BLW

GRY

DUN

ASOVE99

TEMPERATURE

AUXILIARY

DEGC

SWITCH

FAN

MOTOR

ABOVE

91

DEGC

17

mlml

HOT

IN

RUN

HOTAT

TEMPER-

ANDST_AR_TA

TLL_TIMES

ATUBE

T-

7

----

-j

FUSE

FUS~

SWITCH

DISTRIBUTION

BOX

I

BOX

16

41

I

(-

SA

_-

30A-I

12Y

22Y

3'~'1

2TAS

OVE99

Y~

~ml

ABGVE91

DEGC

>

DIEGO

INTEGRATED

HEATING

ANDO

_

=

F

R

OLMODULE

a

BELOW

I

21BAR

I

BLU/BLK

BLK/GRY

BRN

318325

11

BLK/GRY

8585

r

BLK

BLK/BL48

48,

E

I

1

BRN

38LU

ENGINEC

MODU

O

LE

1993-95

G110

BLWG~~

X6000

BLK/BLU

,S

ISSIONS

YSTEM

(W/

EGS)

BLK/RED

10,

I

I

'i_--

VARIABLE

CAMSHAFTCONTROLMODULE

(B

Cylindar

only)

Q

(PIN

NUMBER

5IN

LATE

1995)

®

(PIN

NUMBER

2IN

LATE

1995)

1992

Page 752 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

to

safe

and

successful

service

work

.

Befcre

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

frontof

the

manual

.

Review

these

warnings

and

cautions

each

time

you

prepare

to

workon

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

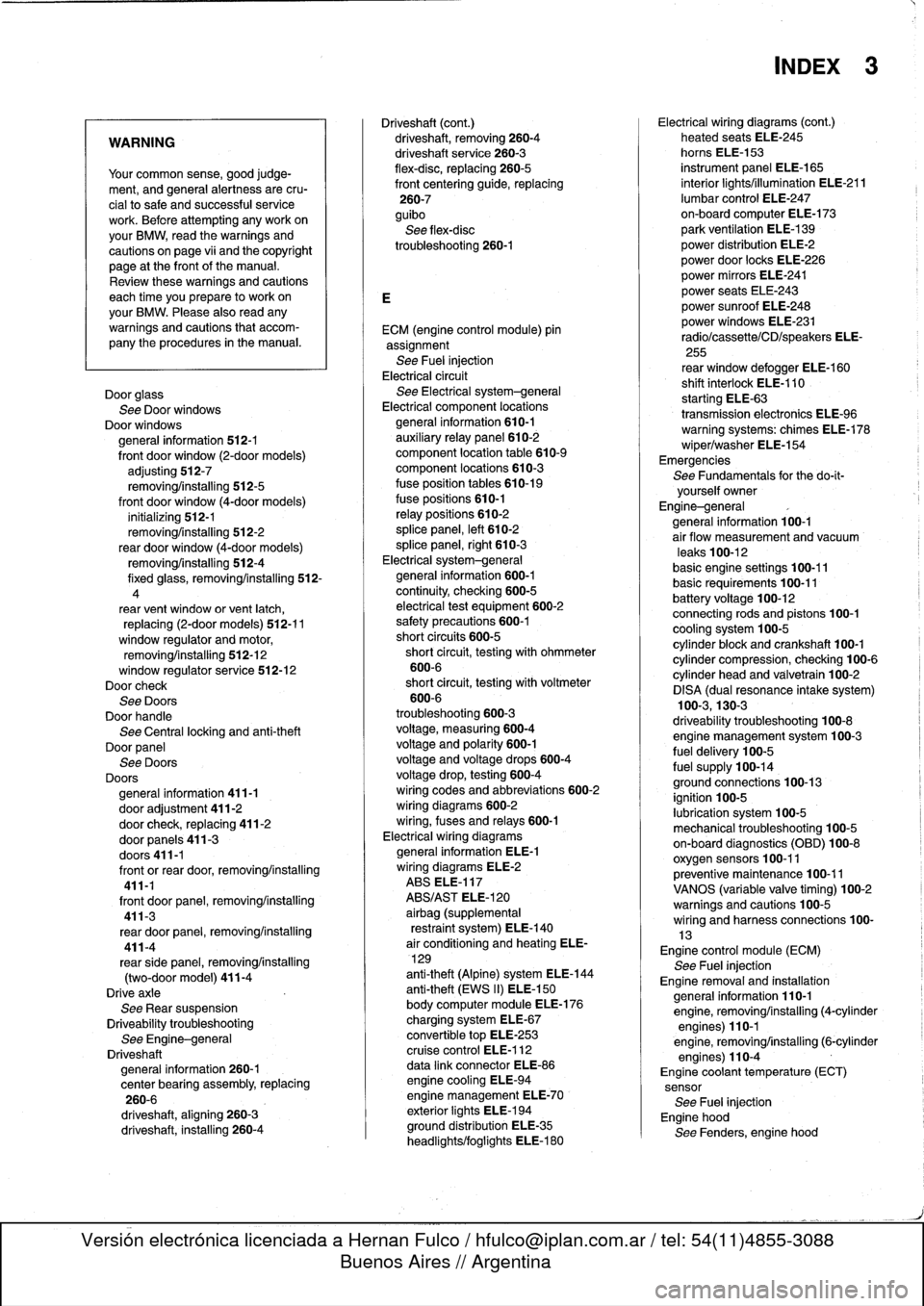

Door

glass

See

Door

windows

Door

windows

general

information

512-1

front

door

window

(2-door

models)

adjusting

512-7

removing/installing

512-5

front

door

window

(4-door

models)

initíalizing

512-1

removing/installing

512-2

rear

door

window

(4-door

models)

removing/installing

512-4

fixed

glass,

removing/installing

512-

4

rear

vent

window

or

vent

latch,

replacing

(2-door

models)

512-11

window

regulator

and

motor,

removing/installing

512-12

window

regulator

service

512-12Doorcheck

See

DoorsDoor

handle

See

Centrallocking

and

anti-theft

Door

panel

See

Doors

Doors

general

information

411-1

door

adjustment

411-2door

check,

replacing

411-2

door

panels

411-3

doors411-1

front

orrear

door,removing/installing

411-1

front

door

panel,

removing/installing

411-3

rear

door

panel,

removing/installing

411-4

rearsidepanel,

removing/installing

(two-door

model)

411-4

Drive

axle

See

Rear

suspension

Driveability

troubleshooting

See

Engine-general

Driveshaft

general

information

260-1

center

bearing

assembly,

replacing

260-6

driveshaft,

aligning

260-3

driveshaft,

installing

260-4

Driveshaft

(cont

.)

driveshaft,

removing260-4

driveshaftservice

260-3

flex-disc,

replacing

260-5

front

centering

guide,

replacing

260-7

guibo

See

flex-disc

troubleshooting260-1

ECM

(engine

control

module)

pin

assignment

See

Fuel

injection

Electrical

circuit

See

Electrical

system-general

Electrical

component

locations

general

information

610-1

auxíliary

relay

panel

610-2

component

location

table

610-9

component

locations

610-3

fuse

position

tables

610-19

fuse

positions

610-1

relay

positions

610-2

splice

panel,

left

610-2

splice

panel,

right

610-3

Electrical

system-general

general

information

600-1

continuity,

checking

600-5

electrical

test

equipment

600-2

safety

precautions

600-1

short

circuits

600-5

short

circuit,

testing

with

ohmmeter

600-6

short

circuit,

testing

with

voltmeter

600-6

troubleshooting

600-3

voltage,

measuring600-4

voltage

and

polarity

600-1

voltage

and

voltage

drops

600-4

voltage

drop,

testing

600-4

wiring

codes

and

abbreviations

600-2

wiring

diagrams

600-2

wiring,

fuses

and

relays

600-1

Electrical

wiring

diagrams

general

information

ELE-1

wiring

diagrams

ELE-2

ABS

ELE-117

ABS/AST

ELE-120

airbag

(supplemental

restraint

system)

ELE-140

air

conditioning

and

heating

ELE-

129

anti-theft

(Alpine)

system

ELE-144

anti-theft

(EWS

II)

ELE-150

body

computer

module

ELE-176

charging

system

ELE-67

convertible

top

ELE-253

cruise

control

ELE-112

data

link

connector

ELE-86

engine

cooling

ELE-94

engine

management

ELE-70

exterior

lights

ELE-194

ground

distribution

ELE-35

headlights/foglights

ELE-180

INDEX

3

Electrical

wiring

diagrams

(cont

.)

heated

seats

ELE-245

horns

ELE-153

instrument

panel

ELE-165

interior

lights/illumination

ELE-211

lumbar

control

ELE-247

on-board

computer

ELE-173

park

ventilation

ELE-139

power

distribution

ELE-2

power

door

locks

ELE-226

power

mirrors

ELE-241

power

seats

ELE-243

power

sunroof

ELE-248

power

windows

ELE-231

radio/cassette/CD/speakers

ELE-

255

rear

window

defogger

ELE-160

shift

interlock

ELE-110

starting

ELE-63

transmission

electronics

ELE-96

warning

systems`

.

chimes

ELE-178

wiper/washer

ELE-154

Emergencies

See

Fundamentals

for

the

do-it-

yourself

owner

Engine-general

general

information

100-1

air

flow

measurement

and

vacuum

leaks

100-12

basic

engine

settings

100-11

basic

requirements

100-11

battery

voltage

100-12connecting

rods

and

pistons

100-1

cooling

system

100-5

cylinder

block

and

crankshaft100-1

cylinder

compression,

checking

100-6

cylinder

head

and

valvetrain

100-2

DISA

(dual

resonance

intake

system)

100-3,130-3

driveability

troubleshooting

100-8

engine

management

system

100-3

fuel

delivery

100-5

fuel

supply

100-14ground

connections

100-13

ignition

100-5

lubrication

system100-5

mechanical

troubleshooting

100-5

on-board

diagnostics

(OBD)

100-8

oxygen

sensors

100-11

preventive

maintenance

100-11

VANOS

(variable

valve

timing)

100-2warningsand

cautions

100-5

wiring

andharness

connections100-

13Engine

control

module

(ECM)

See

Fuel

injection

Engine

removal

and

installation

general

information

110-1

engine,

removing/installing(4-cylinder

engines)

110-1

engine,

removing/installing

(6-cylinder

engines)

110-4

Engine

coolant

temperature

(ECT)

sensor

See

Fuel

injection

Engine

hood

See

Fenders,

enginehood