contact BMW 325i 1992 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 325i, Model: BMW 325i 1992 E36Pages: 759

Page 81 of 759

NOTE-

Cylinder

head,

installing

(6-cylinder

engine)

CAUTION-

If

the

camshafts

were

removed

and

installed

while

the

cylinder

head

was

off,

a

minimum

waiting

time

is

required

after

ínstalling

the

camshafts

.

When

the

camshaftsareremoved,

the

hydraullc

lifters

can

expand

.

This

expansion

can

cause

increased

valve

lift

when

the

camshafts

are

bolted

down,

re-

sulting

in

open

valves

.

Cylinder

head

installation

waiting

times

"

68°F

(20°C)

and

higher

.

.

.

..

..........

10

minutes

"

50-68°F

(10-20°C)

........

..

.........

30

minutes

"

32-50°F

(0-10

°C)

.........

...

........

75

minutes

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-

1

5

1

.

Clean

cylinder

head

and

gasket

surfaces

of

cylinder

block

and

al¡

timing

chain

covers

.

"

Remove

all

foreign

matter

and

any

¡¡quid

from

bolt

holes,

then

clean

with

a

thread

chaser

.

CA

UTION-

Do

not

use

ametal

scraper

or

wire

brush

to

clean

the

aluminum

cylinder

head

or

pistons

.

If

neces-

sary,

use

a

hard

wooden

or

plastic

scraper

.

Also

available

are

abrasive

discs

to

be

used

in

conjunc-

tion

with

an

electric

drill

.

Be

sure

to

use

the

correct

disc

for

the

typeof

metal

being

cleaned

.

2

.

Check

gasket

surface

of

cylinder

head

and

cylinder

block

for

warpage

using

a

straight

edge

.

NOTE-

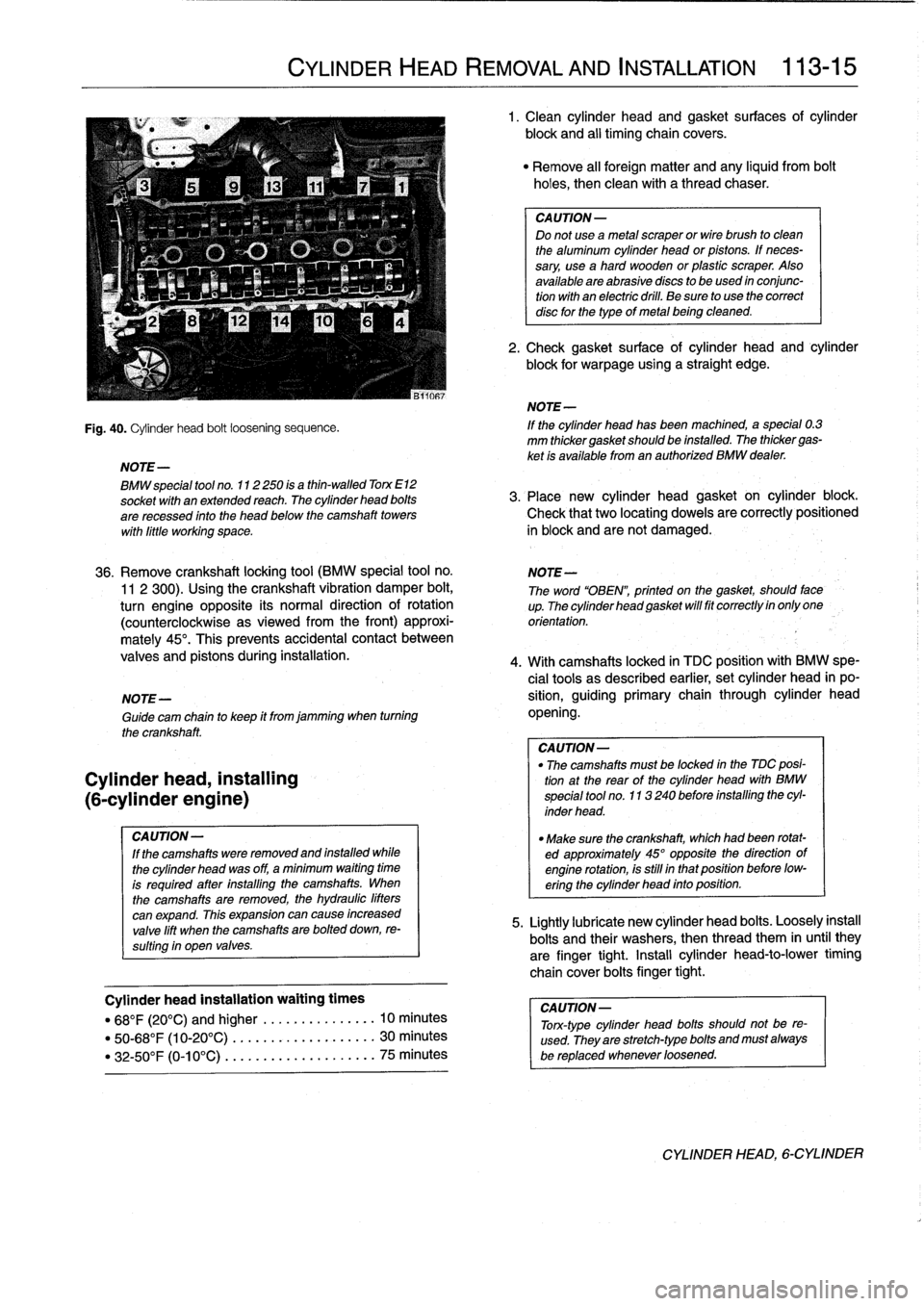

Fig

.

40

.

Cylinder

head

bolt

loosening

sequence

.

If

the

cylinder

head

has

been

machined,a

special

0

.3

mm

thickergasketshould

be

installed

.

The

thickergas-

ket

is

available

from

an

authorized

BMW

dealer

.

BMW

special

tool

no

.

112250

is

a

thin-walled

Torx

E12

socket

wíth

anextended

reach

.

The

cylinder

head

bolts

3

.

Place

new

cylinder

head

gasket

on

cylinder

block

.

are

recessed

finto

the

head

below

the

camshaft

towers

Check

that

two

locating

dowels

are

correctly

positioned

wíth

liffle

working

space

.

in

block

and

arenot

damaged

.

36

.

Remove

crankshaft

locking

tool

(BMW

special

tool

no

.

NOTE-

11

2

300)

.

Using

the

crankshaft

vibration

damper

bolt,

The

word

"OBEN",

printed

on

the

gasket,

should

face

turn

engine

opposite

its

normal

direction

of

rotation

up

.Thecylinderheadgasketwillfitcorrectlyinonlyone

(counterclockwise

asviewed

from

the

front)

approxi-

orientation

.

mately

45°

.

This

prevents

accidental

contact

between

valves

and

pistons

during

installation

.

4

.

With

camshafts

locked

in

TDC

positionwith

BMW

spe-

cial

tools

as

described

earlier,

set

cylinder

head

in

po

NOTE-

sition,

guiding

primary

chain

through

cylinder

head

Guide

cam

chain

to

keep

it

from

jamming

when

turning

opening

.

the

crankshaft

.

CA

UTION-

"

The

camshafts

must

be

locked

in

the

MC

posi-

tion

at

the

rear

of

the

cylinder

head

with

BMW

special

tool

no

.

113240

before

installing

the

cyl-

inder

head

.

"

Make

sure

the

crankshaft,

which

had

been

rotat-

ed

approximately

45°

opposite

thedirection

of

engine

rotation,is

still

in

that

position

before

low-

ering

the

cylinder

head

into

position

.

5

.

Lightly

lubricate

new

cylinder

head

bolts

.

Loosely

instan

bolts

and

their

washers,

then

thread

them

in

until

they

are

finger

tight

.

Install

cylinder

head-to-lower

timing

chaincover

boitsfinger

tight

.

CAUTION-

Tonc-type

cylinder

head

bolts

should

not

be

re-

used

.

They

are

stretch-typebolts

and

must

always

be

replaced

whenever

loosened

.

CYLINDER

HEAD,

6-CYLINDER

Page 98 of 759

117-2

CAMSHAFT

TIMING

CHAIN

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Special

BMW

service

tools

are

needed

for

timing

chain

re-

moval

and

installation

procedures

.

The

special

tools

assure

proper

timing

of

the

valvetrain

.

Precíse

marks

to

setthe

timing

on

the

camshafts

are

not

provided

for

reassembly

.

Read

the

procedures

through

before

beginning

the

job

.

CAUTION-

lf

the

camshaftsare

not

properly

timed,

the

pis-

tons

can

contact

thevalves

.

Camshaft

timing

chain,

removing

(4-cylinder

engines)

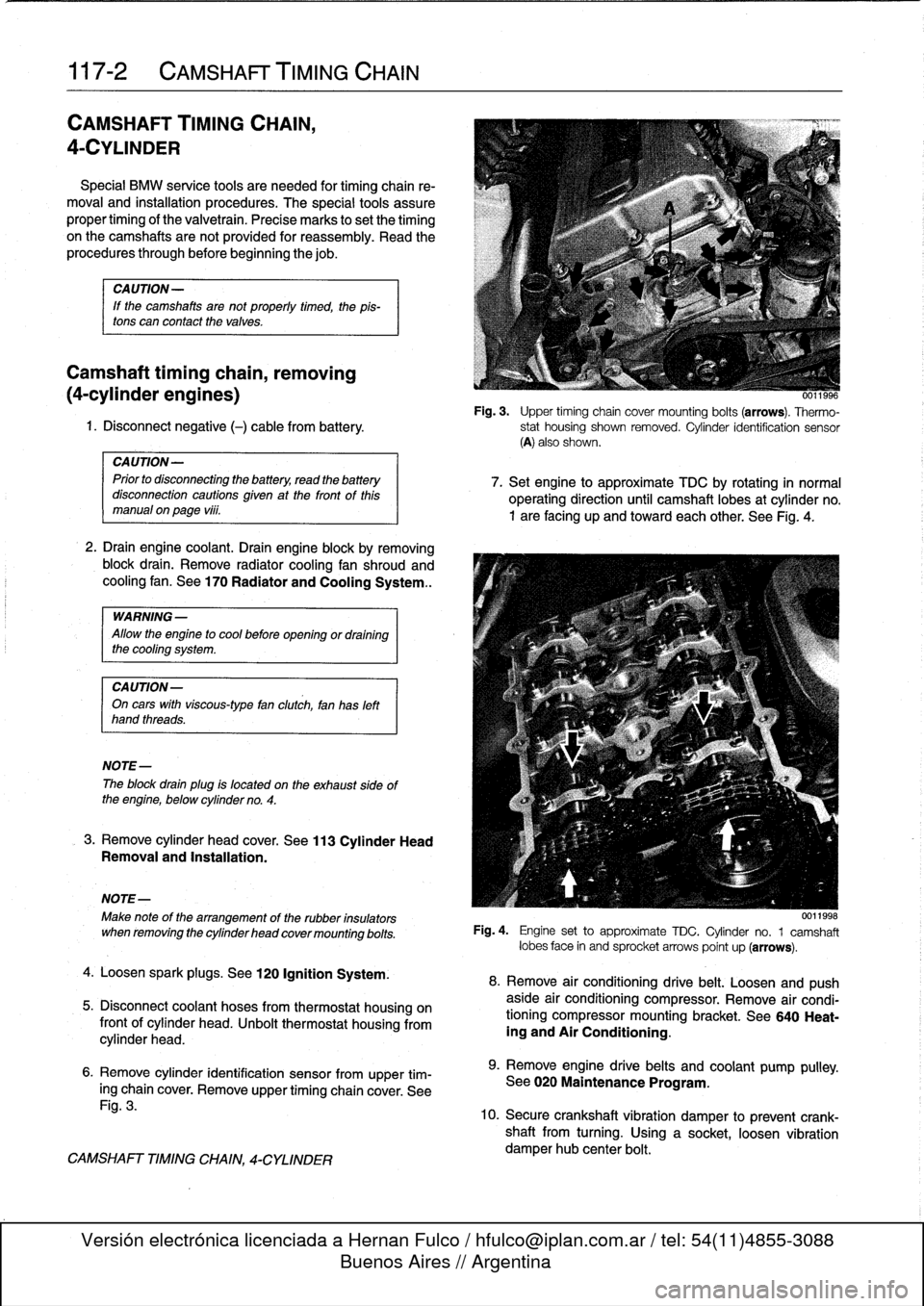

U0119-

Fig

.

3

.

Upper

timing

chain

covermounting

bolts(arrows)

.

Thermo-

1

.

Disconnect

negative

(-)cablefrom

battery

.

stat

housing

shown

removed

.

Cylinder

ídentification

sensor

(A)

also

shown

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Drain

engine

coolant

.

Drain

engine

block

byremoving

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See

170

Radiator

and

Cooling

System

..

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

cooling

system

.

CA

UTION-

On

cars

with

viscous-type

fan

clutch,

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

sideof

the

engine,

below

cylinder

no

.

4

.

3

.

Remove

cylinder

head

cover

.

See

113

Cylinder

HeadRemoval

and

Installation

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

belts

.

4

.

Loosen

sparkplugs

.

See

120

Ignition

System

.

5

.

Disconnect

coolant

hoses

from

thermostat

housingon

front

of

cylinder

head

.

Unbolt

thermostat

housing

from

cylinder

head

.

6

.

Remove

cylinder

identification

sensor

from

upper

tim-

ing

chain

cover

.

Remove

upper

timing

chain

cover

.

See

Fig

.

3

.

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

7

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

up

and

toward

each

other

.

See

Fig

.

4

.

0011998

Fig

.

4

.

Engine

set

to

approximate

TDC

.

Cylinder

no

.

1

camshaft

lobes

face

in

and

sprocket

arrows

point

up

(arrows)

.

8

.

Remove

air

conditioning

drive

belt

.

Loosenand

push

aside

air

conditioning

compressor

.

Remove

air

condi-

tioning

compressor

mounting

bracket

.

See

640

Heat-

ing

and

Air

Conditioning

.

9

.

Remove

engine

drive

belts

and

coolant

pump

pulley

.

See

020

Maintenance

Program

.

10

.

Secure

crankshaft

vibration

damper

to

prevent

crank-

shaft

from

turning

.

Using

a

socket,

loosen

vibration

damper

hub

center

bolt

.

Page 100 of 759

117-

4

CAMSHAFT

TIMING

CHAIN

15

.

Remove

mounting

bolts

from

left

and

right

camshaft

4

.

Insta¡¡

and

hand-tighten

sprocket

mounting

bolts

.

sprockets

.

16

.

On

M42

engines,

remove

upper

bolt

on

right

side

chainguide

and

unbolt

lower

timing

chainguide

below

crank-

shaft

.

17

.

Remove

camshaft

sprockets

from

camshafts

together

with

chain

and

crankshaft

sprocket

.

NoteWoodruffkey

when

removing

crankshaftsprocket

.

CA

UTION-

The

crankshaft

must

not

be

allowed

to

rotate

when

the

timing

chaín

is

removed

.

The

pistons

can

contact

the

valves

.

Camshaft

timing

chain,

installing

(4-cylinder

engines)

Inspectal¡

sprockets

for

wear

or

damage

.

Inspect

the

chain

guide

and

tensioner

rails

for

grooves

caused

by

chain

contact

.

Replace

any

partthat

is

worn

.

If

any

of

the

sprockets

are

worn,

the

chain

and

sprocketsare

replaced

asan

assembly

.

The

procedure

outlined

below

assumes

that

the

camshafts

and

the

crankshaft

arelocked

in

the

TDC

installation

positionwithspecial

tools

(shown

earlier

in

Fig

.

5

and

Fig

.

6)

.

1

.

Install

timing

chain

to

crankshaft

sprocket,

then

slide

sprocket

on

crankshaft

whílealigníng

woodruff

key

.

2

.

Place

camshaft

sprockets

on

chain,

then

place

sprock-

ets

oncamshafts

so

that

arrows

on

sprockets

point

up

and

elongatedholes

in

sprockets

are

centered

lo

tapped

holes

in

camshafts

.

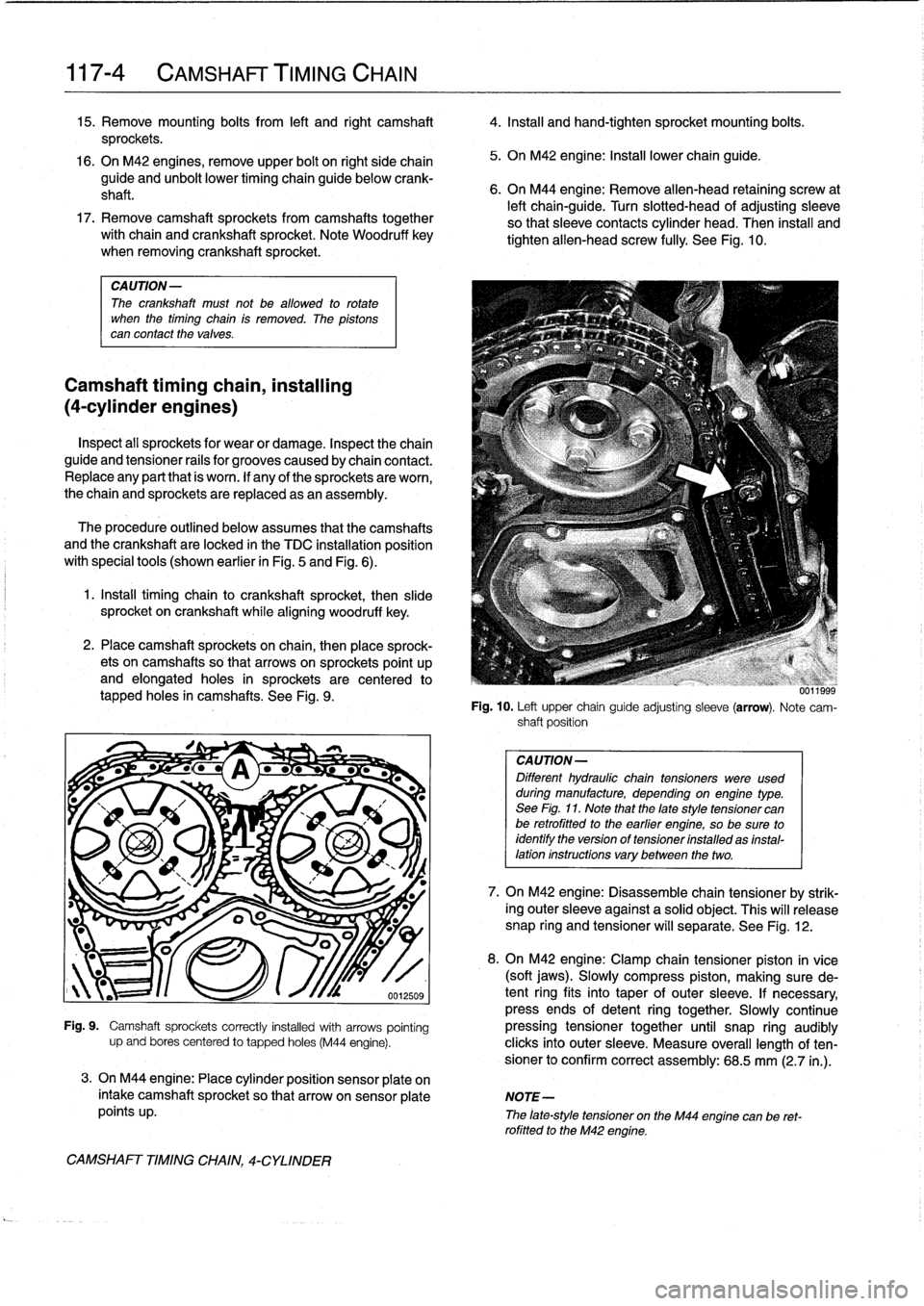

See

Fig

.

9

.

.

I

Pa

-

s

~_

a

Ge

..

.

0012509

5

.

On

M42

engine

:

Install

lowerchainguide

.

6

.

On

M44

engine

:

Remove

allen-head

retaining

screw

at

left

chain-guide

.

Turn

slotted-head

of

adjusting

sleeve

so

that

sleeve

contacts

cylinder

head

.

Then

install

and

tighten'allen-head

screw

fully

.

See

Fig

.

10

.

Fig

.

10

.

Left

upper

chain

guide

adjusting

sleeve

(arrow)

.

Note

cam-

shaft

position

CAUTION-

Different

hydraulic

chaintensioners

were

used

duringmanufacture,

depending

onengíne

type

.

See

Fig

.

11

.

Note

that

the

late

style

tensioner

canbe

retrofitted

to

the

earlier

engíne,

so

be

sure

to

identify

the

versíon

of

tensioner

ínstalled

as

ínstal-

lation

instructions

vary

between

the

two

.

7

.

On

M42

engine

:

Disassemble

chain

tensioner

by

strik-

ing

outer

sleeve

against

a

solid

object

.

This

will

release

snap

ring

and

tensioner

will

separate

.

See

Fig

.

12

.

8

.

On

M42

engine

:

Clamp

chain

tensioner

piston

in

vice

(soft

jaws)

.

Slowly

compress

piston,

making

sure

de-

tent

ring

fits

into

taper

of

outer

sleeve

.

If

necessary,

press

ends

of

detent

ring

together

.

Slowly

continueFig

.

9

.

Camshaft

sprockets

correctly

installed

with

arrows

pointing

pressing

tensioner

together

until

snap

ring

audibly

upand

bores

centered

to

tapped

holes

(M44

engine)

.

clicks

into

outer

sleeve

.

Measure

overall

length

of

ten-

sionerto

confirm

correct

assembly

:

68

.5

mm

(2

.7

in

.)

.

3

.

On

M44

engine

:

Place

cylinder

position

sensor

plate

on

intake

camshaft

sprocket

so

that

arrowonsensor

plate

NOTE-

points

up

.

The

¡ate-style

tensioner

on

the

M44

engine

can

be

ret-rofittedto

the

M42

engíne

.

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Page 102 of 759

117-

6

CAMSHAFT

TIMING

CHAIN

15

.

Insta¡¡

upper

timing

chaincover

:

17

.

Remove

crankshaft

locking

tool

from

transmission

bell-

"

Thoroughly

clean

profile

gasketgroove

and

all

sealing

housing

and

camshaft

locking

tool

from

rear

of

cylinder

surfaces

.

head

.

"

Applya

small

bead

ofsilicon

sealer

(3-Bond

1209®

or

equivalent)

to

upper

and

lower

joint

comers

where

18

.

Turn

engine

over

by

hand

in

direction

of

rotation

at

least

chaincover

meets

cylinder

head

.

two

full

rotations

.

Reinstall

camshaft

and

crankshaft

"

Insta¡¡

new

profile

gasket

to

groove

in

lowerchain

cover

.

locking

tools

to

check

engine

timing

.

Repeat

cam

timing

"

Protect

top

of

profile

gasket

using

thin

sheetmetal

procedure

if

tools

do

not

fit

easily

into

position

.

Remove

(BMW

special

tool

no

.

11

2

330

or

equivalent)

.

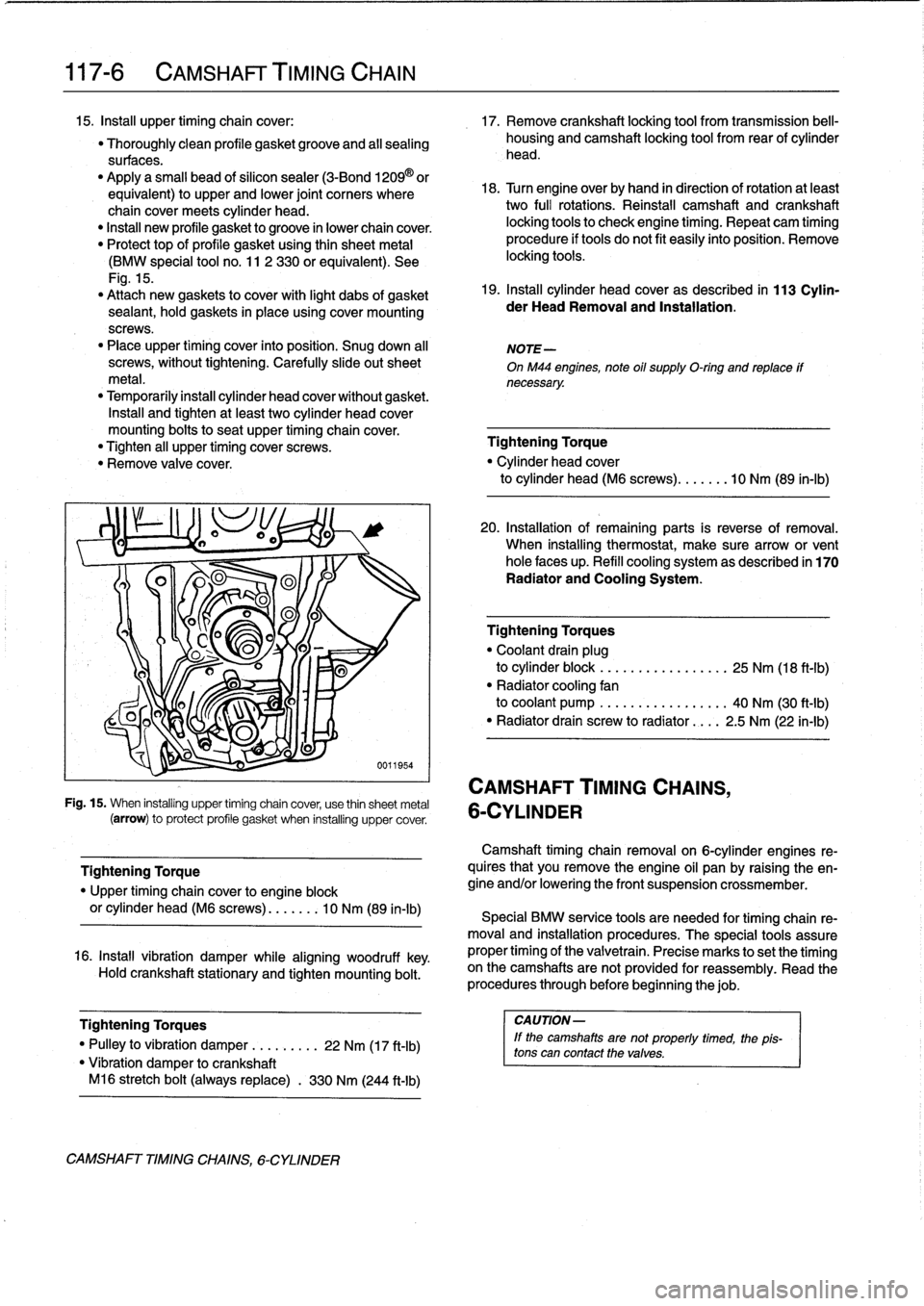

See

locking

tools

.

Fig

.

15

.

"

Attach

new

gaskets

to

cover

with

light

dabs

of

gasket

19

.

Install

cylinder

head

cover

as

described

in

113

Cylin-

sealant,

hold

gaskets

in

placeusing

cover

mounting

der

HeadRemoval

and

Installation

.

screws

.

"

Place

upper

timing

cover

into

position

.

Snug

down

al¡

NOTE-

screws,

without

tightening

.

Carefully

slide

out

sheet

OnM44

engines,

note

oil

supply

O-ring

and

replace

ff

metal

.

necessary

.

"

Temporarily

install

cylinder

head

cover

without

gasket

.

Insta¡¡

and

tighten

at

least

two

cylinder

head

cover

mounting

bolts

to

seat

upper

timing

chaincover

.

"

Tighten

all

upper

timing

cover

screws

.

Tightening

Torque

"

Remove

valve

cover

.

"

Cylinder

head

cover

to

cylinder

head

(M6

screws)

...

..

.

.

10

Nm

(89

ín-Ib)

-

CAMSHAFT

TIMING

CHAINS,

Fig

.

15

.

When

installing

upper

timing

chain

cover,

use

thin

sheetmetal

6-CYLINDER

(arrow)

to

protect

profile

gasket

when

installing

uppercover

.

Tightening

Torque

"

Upper

timing

chaincover

to

engine

block

or

cylinder

head

(M6

screws)

....

.

..

10

Nm

(89

in-lb)

16

.

Install

vibration

damper

while

aligning

woodruff

key

.

Hold

crankshaft

stationary

and

tighten

mounting

bolt

.

Tightening

Torques

I

CAUTION-

"

Pulley

to

vibration

damper

..

.

.

.

....

22

Nm

(17

ft-Ib)

lf

the

camshaftsare

not

properly

timed,

the

1

pis-

tons

can

contact

thevalves

.

"

Vibration

damper

tocrankshaft

M16

stretch

bolt

(always

replace)

.

330

Nm

(244

ft-Ib)

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

20

.

Installation

of

remaining

parts

is

reverse

of

removal

.

When

installing

thermostat,

make

sure

arrow

or

vent

hole

faces

up

.

Refill

cooling

system

as

described

in

170

Radiator

and

Cooling

System

.

Tighteníng

Torques

"

Coolant

drain

plug

to

cylinder

block

.

..

.

.

.

...

.

..

.....

25

Nm

(18

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump

.

..

.

...

...

..

.....

40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radiator

....

2

.5

Nm

(22

in-lb)

Camshaft

timing

chainremovalon

6-cylinder

engines

re-

quires

that

you

Rmove

the

engine

oil

pan

by

raising

the

en-

gine

and/or

lowering

the

front

suspension

crossmember

.

Special

BMW

service

tools

are

needed

for

timing

chain

re-

moval

and

installation

procedures

.

The

special

tools

assure

proper

timing

of

the

valvetrain

.

Precise

marks

to

setthe

timing

on

the

camshafts

arenot

provided

for

reassembly

.

Read

the

procedures

through

before

beginning

thejob

.

Page 107 of 759

9)

B11126

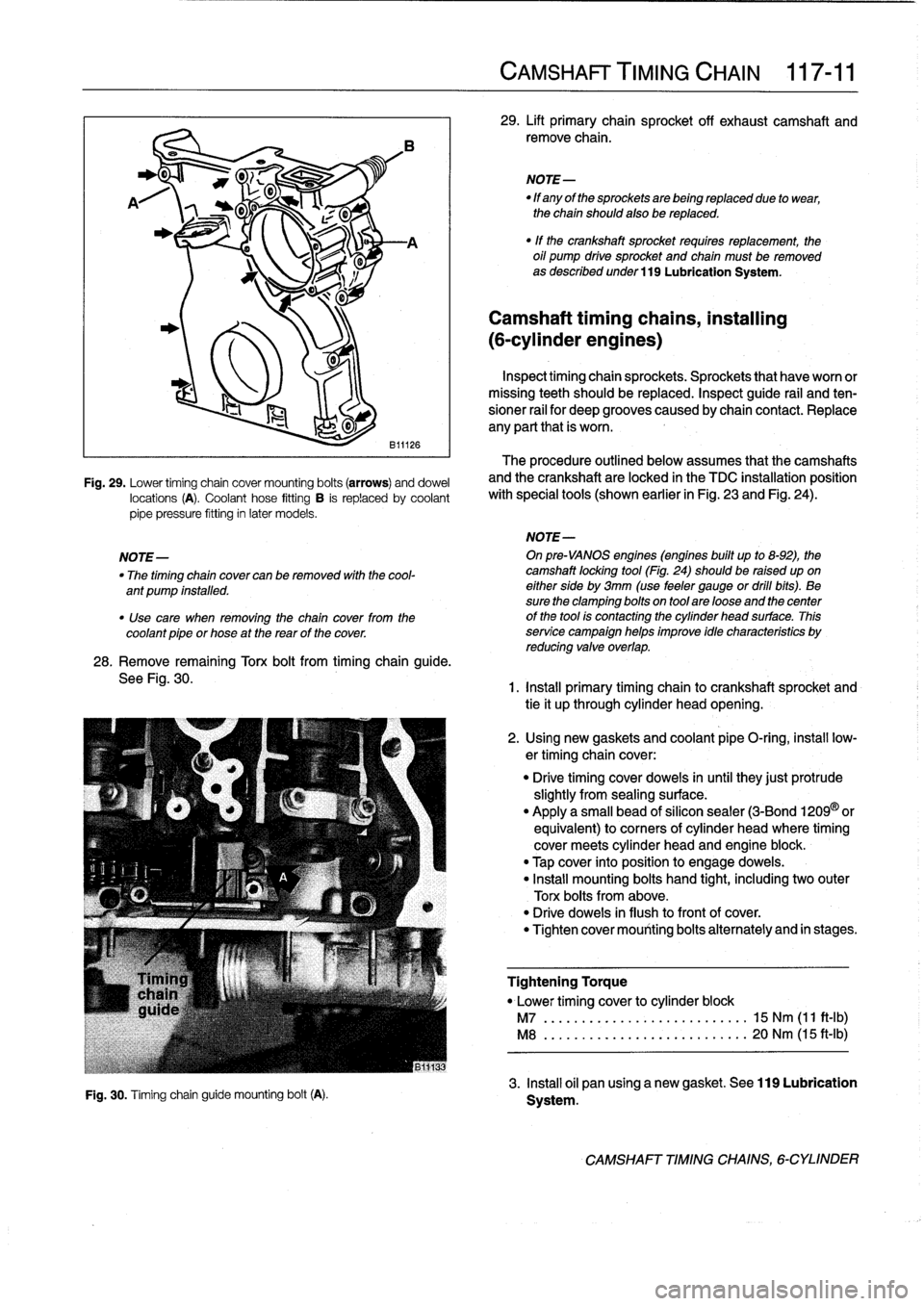

Fig

.

29

.

Lower

timing

chain

cover

mounting

bolts

(arrows)

anddowel

locations

(A)

.

Coolant

hose

fitting

B

is

replaced

by

coolant

pipe

pressure

fitting

in

later

models

.

28

.

Remove

remaining

Torx

bolt

from

timing

chain

guide

.

See

Fig

.

30

.

Fig

.

30

.

Timing

chainguide

mounting

bolt(A)

.

CAMSHAFT

TIMING

CHAIN

117-

11

29

.

Lift

primary

chain

sprocket

off

exhaust

camshaft

and

remove

chain

.

NOTE-

"

If

any

of

the

sprockets

are

being

replaced

due

to

wear,

the

chain

should

also

be

replaced

.

"

If

the

crankshaft

sprocket

requires

replacement,

the

oil

pump

drive

sprocket

and

chain

must

be

removed

as

described

under

119

Lubrication

System

.

Camshaft

timing

chains,

installing

(6-cylinder

engines)

Inspecttiming

chainsprockets

.

Sprockets

that

haveworn

or

missing

teeth

should

be

replaced

.

Inspect

guide

rail

and

ten-

sioner

rail

for

deep

grooves

caused

by

chain

contact

.

Replace

any

parí

that

is

worn

.

The

procedure

outlined

below

assumes

that

the

camshafts

and

the

crankshaft

are

locked

in

the

TDC

installation

position

with

special

tools

(shown

earlier

in

Fig

.

23

and

Fig

.

24)

.

NOTE-

NOTE-

On

pre-VANOS

engines

(engines

built

up

to

8-92),

the

"

The

timing

chain

cover

can

be

removed

with

the

cool-

camshaft

locking

tool

(Fig

.

24)should

be

raised

upon

ant

pump

installed

.

eitherside

by

3mm

(use

feeler

gauge

or

dril¡

bits)

.

Be

sure

the

clamping

bolts

on

tool

are

loose

and

thecenter

"

Use

care

when

removing

the

chain

cover

from

the

of

the

tool

is

contacting

the

cylinder

head

surface

.

This

coolant

pipe

or

hose

at

the

rearof

the

cover

.

service

campaign

helps

improve

idle

characteristics

by

reducing

valve

overlap

.

1

.

Install

primary

timing

chain

to

crankshaft

sprocket

and

tie

it

up

through

cylinder

head

opening

.

2

.

Using

new

gaskets

and

coolant

pipe

O-ring

;

insta¡¡

low-

ertiming

chain

cover

:

"

Drive

timing

cover

doweis

inuntil

they

just

protrude

slightly

from

sealing

surface

.

"

Apply

a

small

bead

of

silicon

sealer

(3-Bond

1209

©

or

equivalent)

to

corners

of

cylinder

head

where

timing

cover

meets

cylinder

head

and

engine

block

.

"

Tap

cover

into

position

to

engage

doweis

.

"

Install

mounting

bolts

hand

tight,

including

two

outer

Torx

bolts

from

above

.

"

Drive

doweis

in

flush

to

front

of

cover

.

"

Tighten

cover

mounting

bolts

alternately

and

in

stages

.

Tightening

Torque

"

Lower

timing

cover

to

cylinder

block

M7

................

...

..

.

.....

15

Nm

(11

ft-Ib)

M8

.............

.

.

...

.........

20

Nm

(15

ft-Ib)

3

.

Insta¡¡

oil

pan

using

a

new

gasket

.

See

119

Lubrication

Systern

.

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

Page 113 of 759

10

.

On

cars

built

up

to

3/95

:

Slide

control

unit

off

front

of

cylinder

head,

hand

turning

the

exhaust

sprocket

clock-

wise

(as

viewedfrom

front)

as

the

unit

is

removed

.

11

.

On

cars

built

3/95

and

latee

:

Use

a

spanner

toolto

ro-

tate

exhaust

sprocket

until

stop

on'

intake

sprocket

is

contacted

.

See

Fig

.

39

.

Then

slide

control

unit

off

front

of

cylinder

head

.

EMAÑ

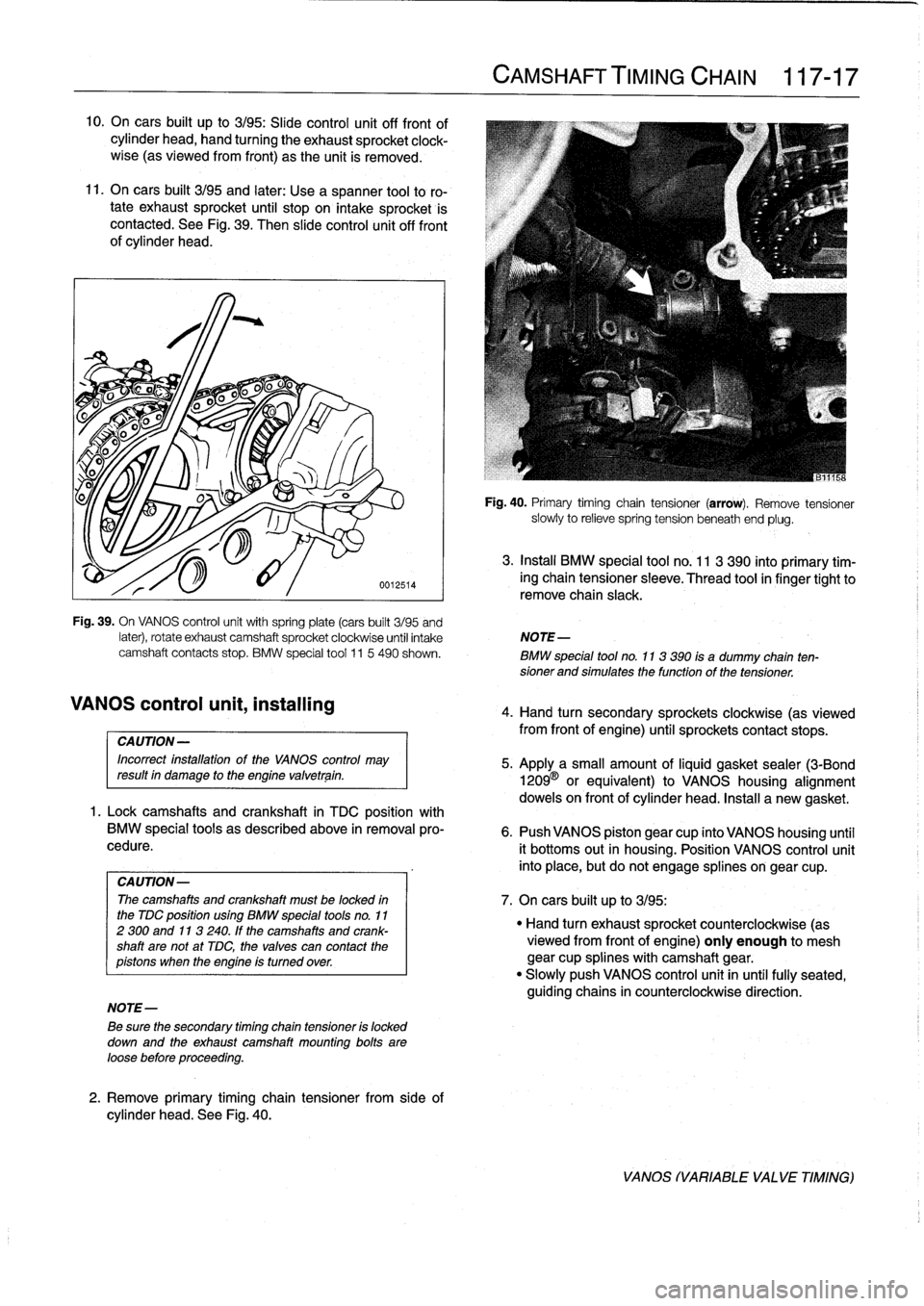

0012514

Fig

.

39

.

On

VANOS

control

unit

withspringplate

(cars

built

3/95

and

later),

rotate

exhaust

camshaft

sprocket

clockwise

until

intake

NOTE-

camshaft

contacts

stop

.

BMW

special

tool11

5490shown

.

BMW

special

tool

no

.

113

'390

is

a

dummy

chain

ten-

sioner

and

simulates

the

function

of

thetensioner

.

VANOS

control

unit,

installing

CAUTION

-

Incorrect

installation

of

the

VANOS

control

may

result

in

damage

to

the

engine

valvetráin

.

1

.

Lock

camshafts

and

crankshaft

in

TDC

positionwith

BMW

special

tools

as

described

above

in

removal

pro-

cedure

.

CA

UTION-

The

camshafts

and

crankshaft

mustbe

locked

in

the

TDC

position

using

BMW

special

tools

no

.

11

2

300and

113

240

.

If

the

camshafts

and

crank-

shaft

are

not

at

TDC,

the

valves

can

contact

the

pistons

when

the

engine

is

turned

over

.

NOTE-

Be

sure

the

secondary

timing

chain

tensioner

is

locked

down

and

the

exhaustcamshaft

mounting

bolts

are

loosebefore

proceeding

.

2

.

Remove

primary

timing

chain

tensioner

from

side

of

cylinder

head

.

See

Fig

.

40

.

CAMSHAFT

TIMING

CHAIN

117-

1

7

Fig

.

40

.

Primary

timing

chain

tensioner

(arrow)

.

Remove

tensioner

slowlyto

relieve

spring

tension

beneath

end

plug

.

3

.

Install

BMW

special

tool

no

.

11

3

390

into

primary

tim-

ing

chain

tensionersleeve

.

Thread

tool

in

finger

tight

to

remove

chain

slack

.

4

.

Hand

turn

secondary

sprocketsclockwise

(as

viewed

from

front

of

engine)

until

sprockets

contact

stops

.

5

.

Apply

a

small

amount

of

¡¡quid

gasketsealer

(3-Bond

1209

®

or

equivalent)

to

VANOS

housing

alignment

doweis

on

front

of

cylinder

head

.

lnstall

a

new

gasket

.

6

.

Push

VANOS

piston

gear

cup

finto

VANOS

housing

until

it

bottoms

out

in

housing

.

Position

VANOS

control

unitinto

place,

but

do

not

engage

splines

on

gear

cup

.

7

.

On

cars

built

up

to

3/95

:

"

Hand

turn

exhaust

sprocketcounterclockwise

(as

viewedfrom

front

of

engine)

only

enough

to

mesh

gear

cup

splines

with

camshaft

gear

:

"

Slowly

push

VANOS

control

unit

in

untilfully

seated,

guiding

chains

in

counterclockwise

direction

.

VANOS

(VARIABLE

VALVE

TIMING)

Page 131 of 759

Camshaft

position

(CMP)

sensor,

replacing

(6-cylinder

engine)

1

.

Remove

plastic

cover

from

above

fuel

injectors

.

2

.

Disconnect

harness

connector

from

VANOS

solenoid

and

unscrew

solenoid

from

VANOS

control

unit

.

Re-

"

Clean

contactsurface

on

engine

block

before

fnstall

move

oil

supply

line

from

VANOS

control

unit

.

See

117

ing

knock

sensors

.

Camshaft

Timing

Chain

.

3

.

Remove

camshaft

position

(CMP)

sensor

from

left

frontof

cylinder

head,

next

to

top

of

oil

filter

housing

.

"

Knock

sensor

to

cylinder

block

....

20

Nm

(15

ft

.

lbs

.)

4

.

Disconnect

CMP

sensor

harnessfrom

under

intake

manifold

.

5

.

Installation

is

reverse

of

removal

.

Use

a

new

O-ring

when

installing

sensor

.

Be

sure

wiring

is

rerouted

in

same

orientation

.

Tightening

Torques

"

CMP

sensor

to

cylinder

head

....

.

.

..

5

Nm

(3

.5

ft-Ib)

"

VANOS

oil

supply

pipe

to

VANOS

control

unit

...........

.

..

32

Nm

(24

ft-Ib)

"

VANOS

solenoid

to

VANOS

control

unit

...

.

.................

30

Nm

(22

ft-Ib)

Knock

sensors,

replacing

Knock

sensors

are

usedon

engines

with

Bosch

DME

M1

.7,

Bosch

DME

M3

.3

.1,

Bosch

DME

M5

.2,

and

Siemens

MS

41

.1

engine

management

systems

.

The

knocksensors

are

bolted

to

the

left

sideof

the

cylinder

block

and

monitor

the

combus-

tion

chamber

for

engine-damaging

knock

.

If

engine

knock

is

detected,

the

ignition

point

is

retarded

accordingly

via

the

en-

gine

control

module

.

CA

UTION-

"

Label

knock

sensorharness

connectors

before

disconnecting

them

.

The

connectors

must

not

be

interchanged

.

Engine

damage

may

result

if

the

sensors

are

monitoring

the

wrong

cytinders

.

"

Note

the

installed

angle

of

the

knock

sensoron

the

block

before

removing

it

.

Reinstall

the

sensor

in

the

same

position

.

Be

sure

to

usea

torque

wrench

when

tightening

the

sensormounting

bola

NOTE

-

"

On

M52

engines,

a

single

harness

connects

the

twosensors

to

the

main

harness

connector

.

The

shorter

cable

lead

fs

for

the

knock

sensor

for

cytinders

4,

5,

and

6

.

Tightening

Torque

IGNITION

SYSTEM

120-

7

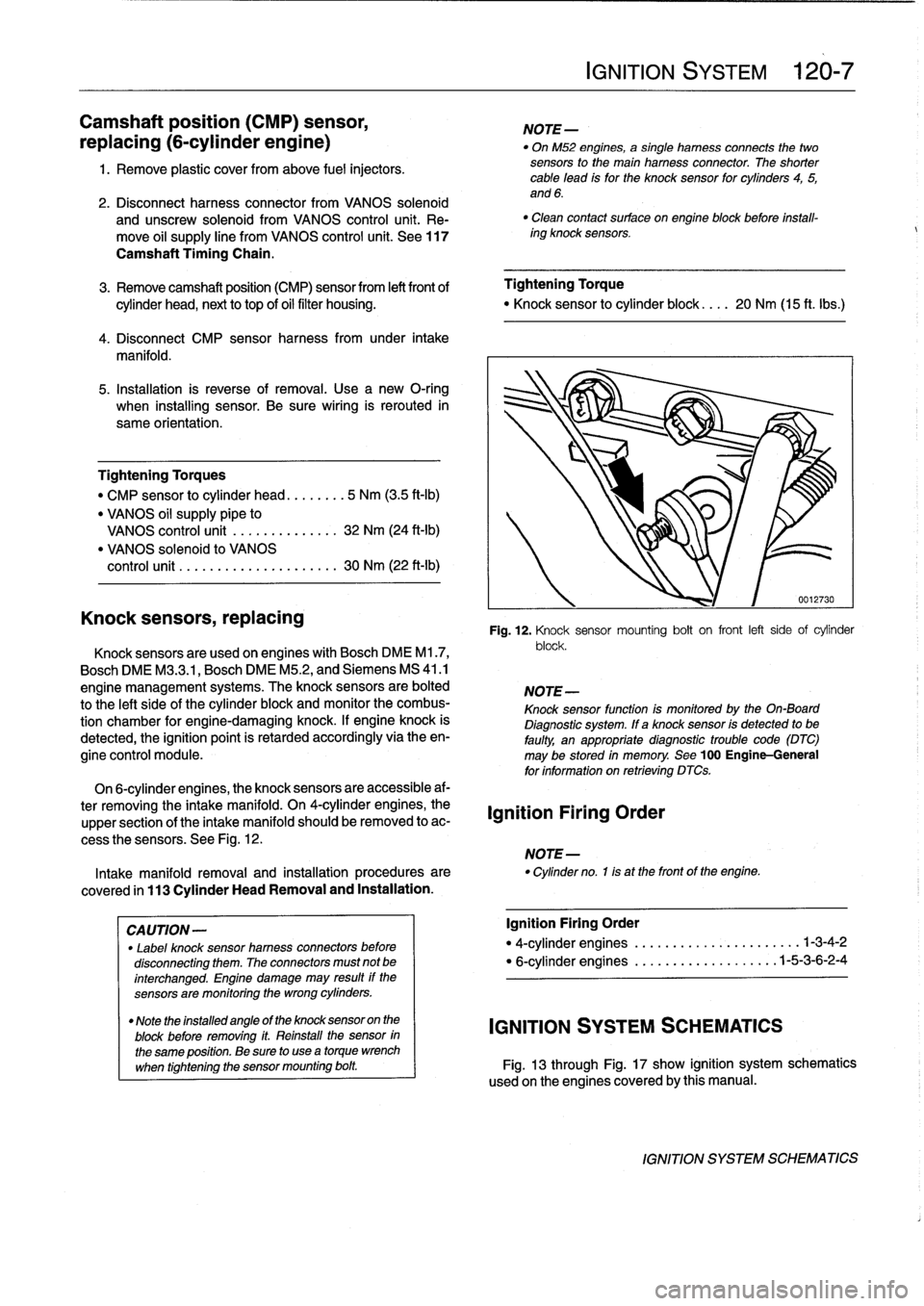

0012730

Fig

.

12

.

Knock

sensor

mounting

bolt

on

front

left

side

of

cylinder

block

.

NOTE-

Knock

sensor

function

Is

monitoredby

the

On-Board

Diagnostic

system

.

If

a

knock

sensor

is

detected

to

be

faulty,

an

appropriatediagnostic

trouble

code

(DTC)

may

be

stored

in

memory

.

See

100

Engine-General

for

information

on

retrieving

DTCs

.

On

6-cylinder

engines,

the

knock

sensors

are

accessible

af-

ter

removing

the

intake

manifold

.

On

4-cylinder

engines,

the

upper

section

of

the

intake

manifold

should

be

removed

to

ac-

cess

the

sensors

.

See

Fig

.

12

.

NOTE-

Intakemanifold

removal

and

installation

procedures

are

"

Cylinder

no

.

1is

at

the

front

of

the

engine

.

covered

in

113

Cylinder

HeadRemoval

and

Installation

.

Ignition

Firing

Order

Ignition

Firing

Order

"

4-cylinder

engines

.....

..

...

.

..........

.1-3-4-2

"

6-cylinder

engines

...........

..

.

.

..

..

1-5-3-6-2-4

IGNITION

SYSTEM

SCHEMATICS

Fig

.

13

through

Fig

.

17

show

ignition

system

schematics

usedon

the

enginescoveredby

this

manual

.

IGNITION

SYSTEM

SCHEMATICS

Page 142 of 759

121-

6

BATTERY

STARTER,

ALTERNATOR

Alternator,

removing

and

installing

(6-cylinder

engine)

A

replacement

alternator

should

have

the

same

rating

as

the

original

.

Alternator

manufacturer

and

ampere

rating

are

normally

marked

on

the

alternator

housing

.

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

alternator

cooling

duct

and

air

filter

housing

assembly

from

car

.

Disconnect

wiring

from

rear

of

alter-

nator

.

3

.

Remove

radiator

cooling

fan

and

fan

shroud

.

See

170

Radiator

and

Cooling

System

.

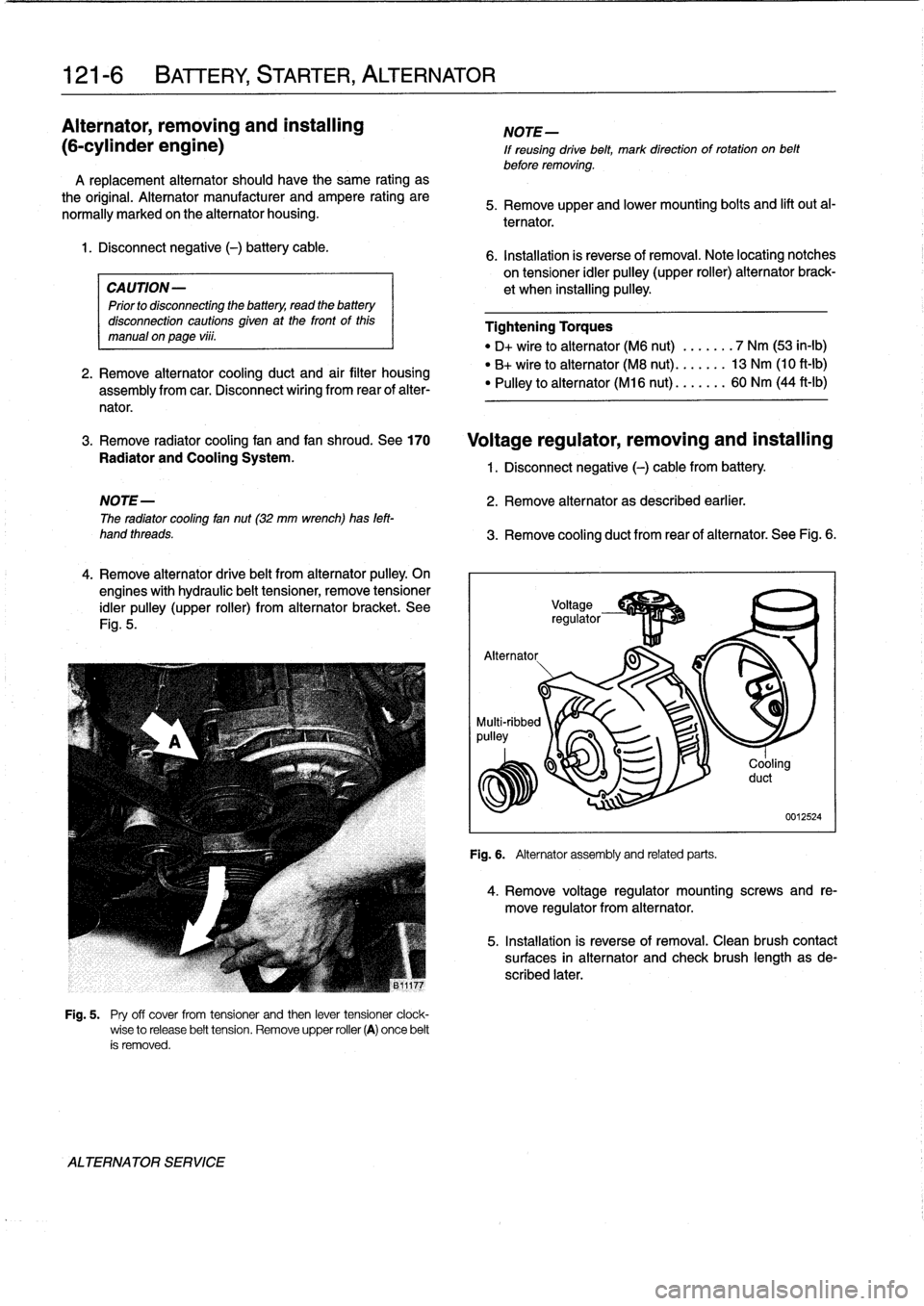

4

.

Remove

alternator

drive

belt

from

alternator

pulley

.

On

engines

with

hydraulic

belt

tensioner,

remove

tensioner

idler

pulley

(upper

roller)

from

alternator

bracket

.

See

Fig

.

5

.

ALTERNATOR

SERVICE

Fig

.

5

.

Pry

off

cover

from

tensioner

and

then

lever

tensioner

clock-

wise

to

release

belt

tension

.

Remove

upper

roller

(A)

once

belt

ís

removed

.

NOTE-

If

reusing

drive

belt,

mark

direction

of

rotation

on

belt

before

removing

.

5

.

Remove

upper

and

lower

mounting

bolts

and

lift

out

al-

ternator

.

6

.

Installation

is

reverse

of

removal

.

Note

locating

notches

on

tensioner

idler

pulley

(upper

roller)

alternator

brack-

et

when

installing

pulley

.

Tightening

Torques

"

D+

wire

to

alternator

(M6

nut)

.......

7

Nm

(53

in-lb)

"

B+

wireto

alternator

(M8

nut)

.......

13

Nm

(10

ft-Ib)

"

Pulley

to

alternator

(M16

nut)

.......

60

Nm

(44

ft-Ib)

Voltage

regulator,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

.

NOTE-

2

.

Remove

alternator

as

described

earlier

.

The

radiator

cooling

fan

nut

(32

mm

wrench)has

left-

hand

threads

.

3

.

Remove

cooling

duct

from

rear

of

alternator

.

See

Fig

.

6

.

Alternator

.

.g-

p~

J

-..

.

Fig

.

6

.

Alternator

assemblyand

related

parts

.

Cooling

duct

0012524

4

.

Remove

voltage

regulator

mounting

screws

and

re-

move

regulator

from

alternator

.

5

.

Installation

is

reverse

of

removal

.

Clean

brush

contact

surfaces

in

alternator

and

check

brush

length

asde-

scribed

later

.

Page 143 of 759

Alternator

brushes,

STARTER

SERVICE

inspecting

and

replacing

Regulator

brushesarenot

available

as

replacement

parts

from

BMW

.

Replacement

brushes

may

be

available

from

af-

termarket

sources,

however

.

1

.

Remove

voltage

regulator

as

described

above

.

2

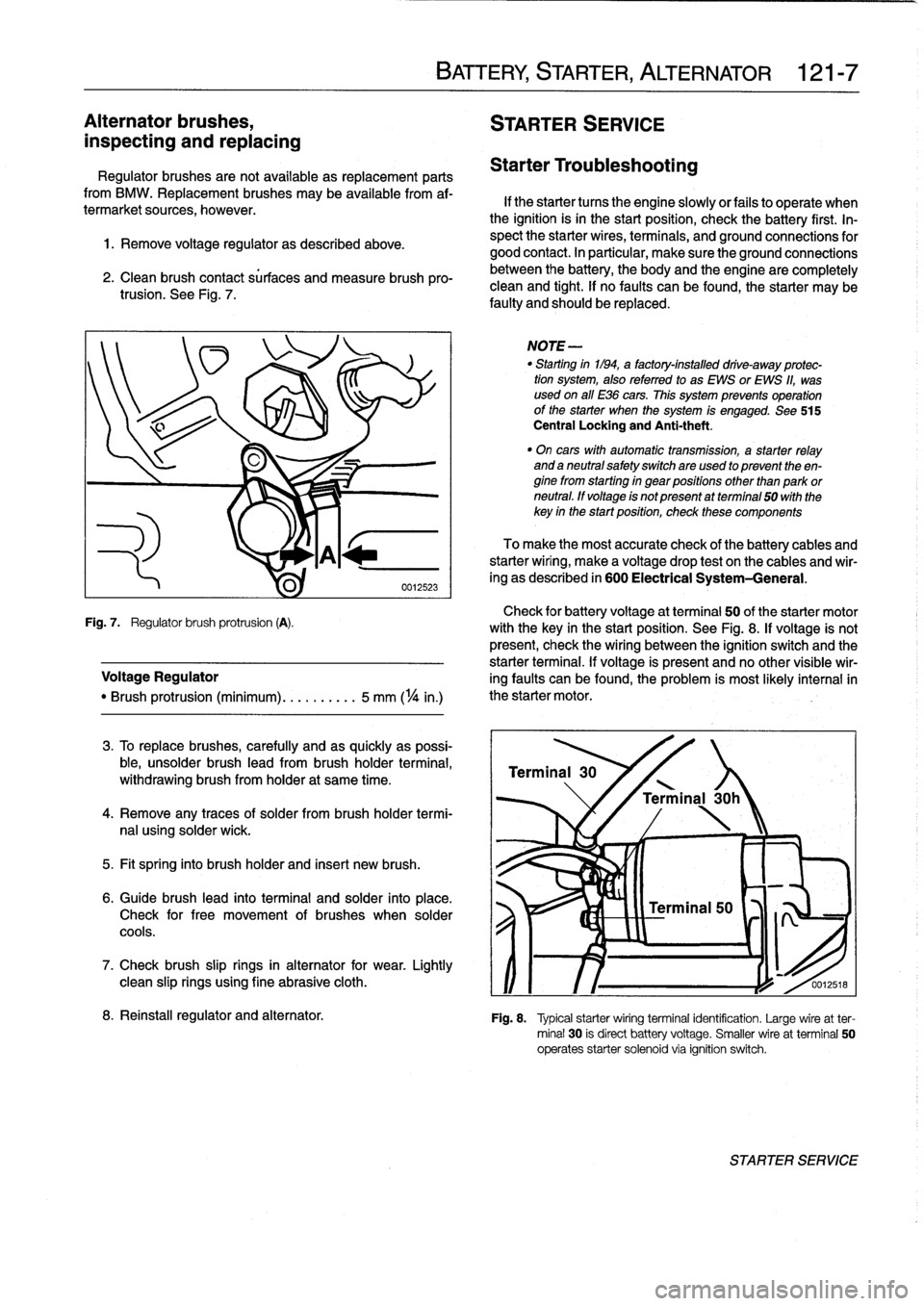

.

Clean

brush

contact

sürfaces

and

measure

brush

pro-trusion

.

See

Fig

.

7

.

Check

for

battery

voltage

at

terminal

50

of

the

starter

motor

Fig

.

7

.

Regulator

brush

protrusion

(A)

.

with

the

key

in

the

start

position

.

See

Fig

.

8

.

If

voltage

is

not

present,

check

the

wiring

between

the

ignition

switch

and

the

starter

terminal

.

If

voltage

is

present

and

no

other

visible

wir

Voltage

Regulator

ing

faults

can

be

found,

the

problem

is

most

likely

interna¡in

"

Brush

protrusion

(minimum)

.......

.

..

5

mm

(

1

/4

in

.)

the

starter

motor

.

3

.

To

replace

brushes,

carefully

and

as

quickly

as

possi-

ble,

unsolder

brush

lead

from

brush

holder

termina¡,

withdrawing

brush

from

holder

at

same

time

.

4

.

Remove

any

traces

of

solder

frombrush

holder

termi-

nal

using

solder

wick

.

5

.

Fit

spring

into

brush

holder

and

inserí

new

brush

.

6

.

Guide

brush

lead

into

terminal

and

solder

into

place

.

Check

for

free

movement

of

brushes

when

solder

cools

.

7

.

Check

brush

slip

rings

in

alternator

for

wear

.

Lightly

clean

slip

rings

using

fine

abrasive

cloth

.

BATTERY,

STARTER,

ALTERNATOR

121-

7

Starter

Troubleshooting

If

the

starter

tucos

the

engine

slowlyor

fails

to

operate

when

the

ignition

isin

the

start

position,

check

the

battery

first

.

In-

spect

the

starter

wires,

terminals,

and

ground

connections

for

good

contact

.

In

particular,

make

sure

the

ground

connections

between

the

battery,

the

body

and

the

engine

are

completely

clean

and

tight

.

If

no

faults

can

be

found,

the

starter

may

be

faulty

and

should

be

replaced

.

NOTE

-

"

Starting

in1194,

a

factory-installed

drive-away

protec-

tion

system,

alsoreferred

to

as

EWS

or

EWS

11,

was

used

on

all

E36

cars

.

This

system

prevenís

operation

of

the

starter

when

the

system

is

engaged

.

See

515

Central

Locking

and

Anti-theft

.

"

On

cars

with

automatic

transmission,

a

starter

relay

and

a

neutral

safetyswitchare

used

to

present

theen-

ginefrom

starting

in

gear

positions

other

than

park

or

neutral

.

ff

voltage

is

not

present

atterminal

50

with

the

key

in

the

startposition,

check

these

components

To

make

the

most

accurate

check

of

the

battery

cables

and

starterwiring,

make

a

voltage

drop

test

on

the

cables

and

wir-

ing

as

described

in

600

Electrical

System-General

.

Terminal

30

'

\

/

Terminal

30h

0012518

8

.

Reinstall

regulator

and

alternator

.

Fig

.

8

.

Typical

starterwiring

terminal

identification

.

Large

wireat

ter-

minal

30

is

direct

battery

voltage

.

Smaller

wire

at

terminal

50

operates

starter

solenoid

via

ignition

switch

.

STARTER

SERVICE

Page 146 of 759

121-1

O

BATTERY,

STARTER,

ALTERNATOR

9

.

Remove

starter

from

above

.

10

.

Check

starter

pinion

gear

and

flywheel

teeth

for

dam-

age

.

11

.

Installation

is

reverse

of

removal

.

Tightening

Torques

"

tntakemanifold

to

cylinder

head

M7

nut

...

.

................

...

.

15

Nm

(11

ft-Ib)

M8

nut/bolt

.............

.

.

..

...

22

Nm

(16

ft-Ib)

"

Starter

to

engine

block

(M10

bolt)

...

50

Nm

(37

ft-Ib)

"

Support

bracket

to

starter

(M5

nut)

...

5

Nm

(44

in-lb)

"

Support

bracket

to

engine

block

(M10

bolt)

.

.

..

..

...

47

Nm

(35

ft-Ib)

"

Wire

toterminal

50

(M6

nut)

.

..

.....

6

Nm

(53

in-lb)

"

Wire

toterminal

30

(M8

nut)

...

.....

12

Nm

(9

ft-Ib)

Solenoid

switch,

removing

and

installing

1

.

Remove

starter

as

described

above

.

Tightening

Torque

2

.

Remove

cover

from

solenoid

switch

.

"

Field

winding

strap

to

starter

(M8)

...

.

12

Nm

(9

ft-Ib)

3

.

Disconnect

fieid

winding

strap

between

starter

motor

and

solenoid

switch

.

NOTE-

The

condition

of

the

field

winding

strap

is

critical

.

If

it

is

damaged,

bumed

or

partially

melted

through,

a

new

or

rebuilt

starter

motor

is

needed

.

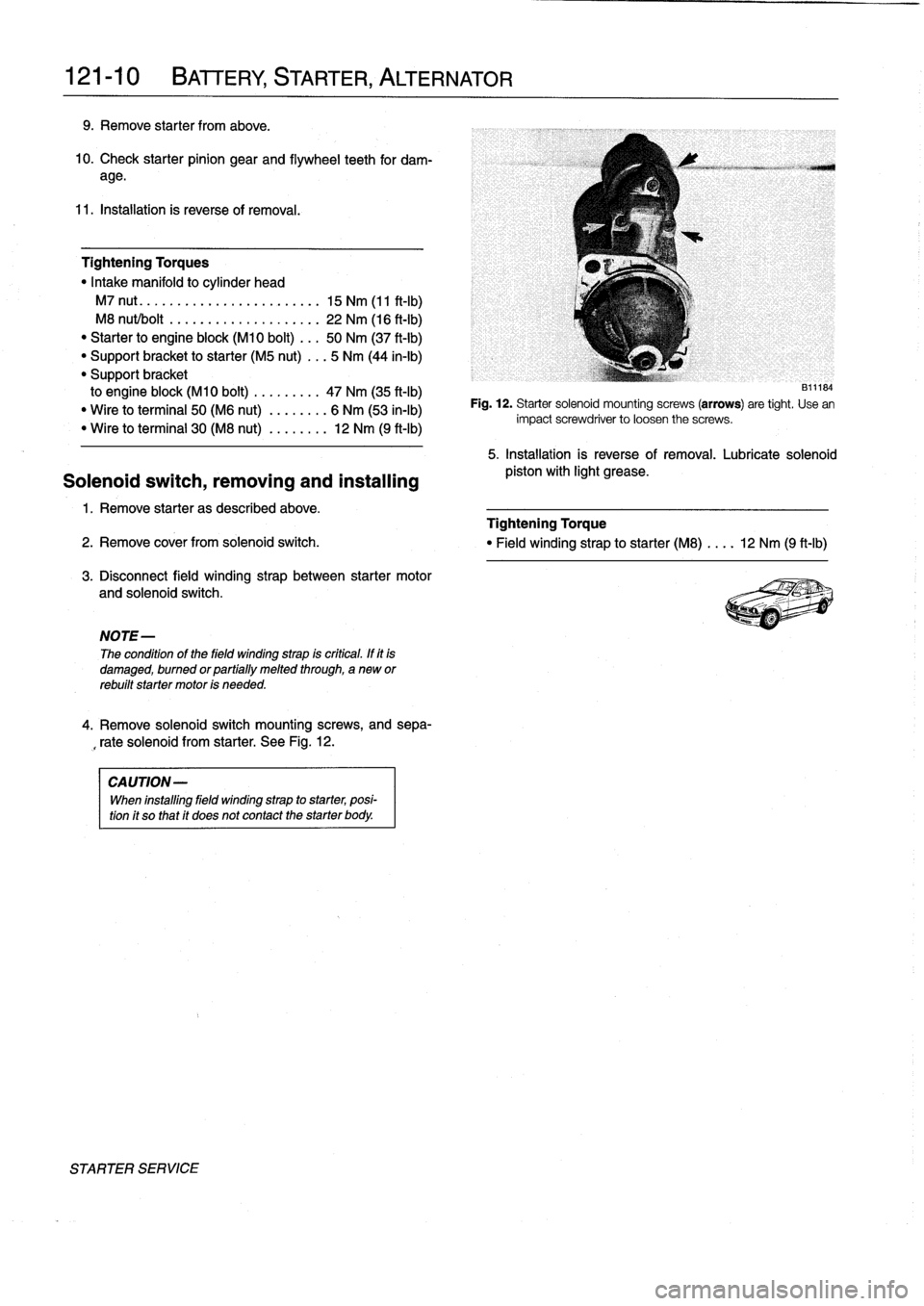

4

.

Remove

solenoidswitch

mounting

screws,

and

sepa-

,

rate

solenoid

from

starter

.

See

Fig

.

12

.

CAUTION-

When

installing

fieid

winding

strap

to

starter,

posi-

tion

it

so

that

it

does

not

contact

the

starter

body

.

STARTER

SERVICE

131~184

Fig

.

12

.

Starter

solenoid

mounting

screws

(arrows)

are

tight

.

Use

en

impact

screwdriver

to

loosen

the

screws

.

5

.

Installation

is

reverse

of

removal

.

Lubricate

solenoid

pistos

with

light

grease

.