contact BMW 325i 1992 E36 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 325i, Model: BMW 325i 1992 E36Pages: 759

Page 266 of 759

310-

1

0

FRONT

SUSPENSION

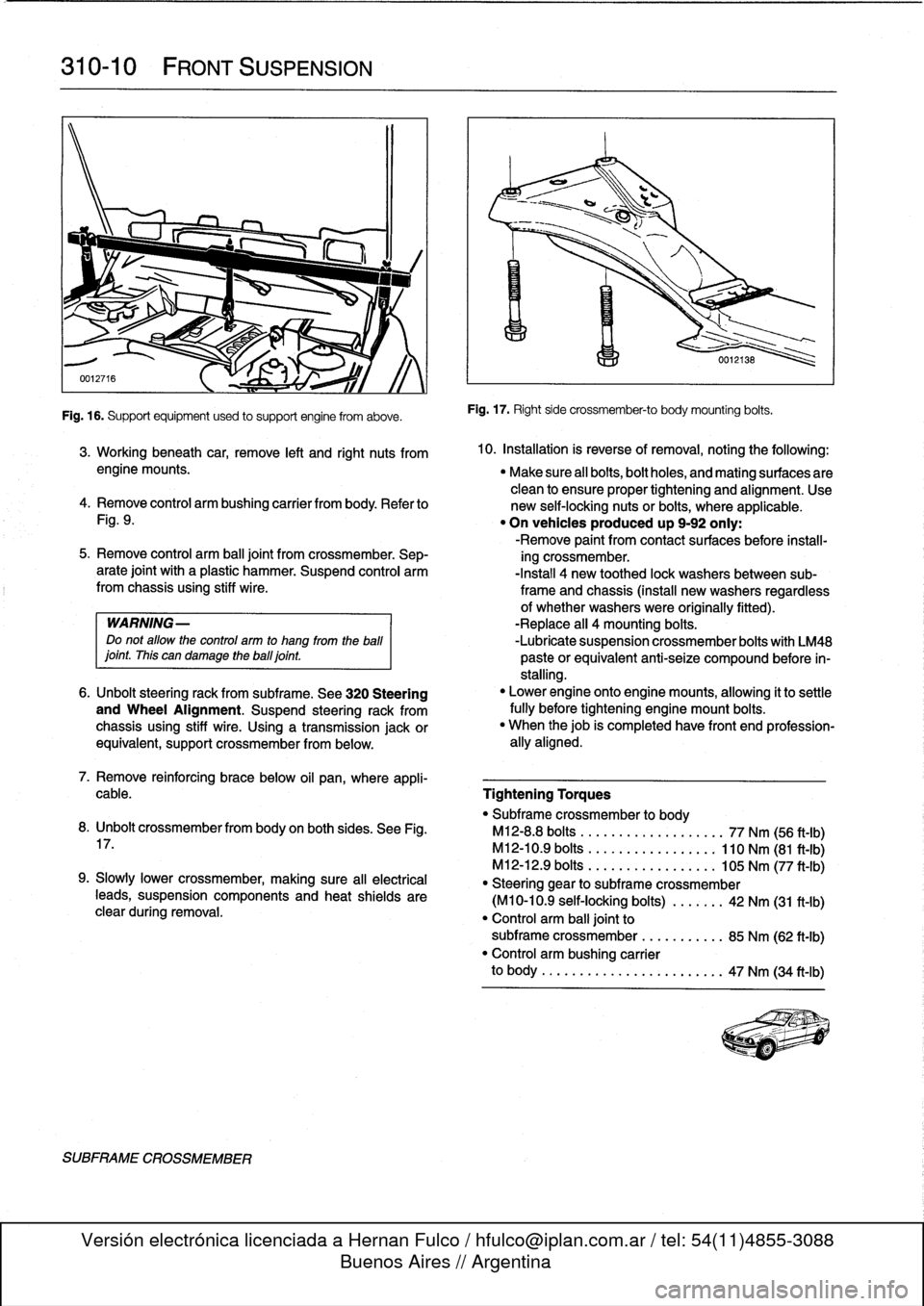

Fig

.

16

.

Supportequipment

used

to

support

engine

from

aboye

.

SUBFRAME

CROSSMEMBER

Fig

.

17

.

Right

side

crossmember-to

body

mounting

bolts

.

3

.

Working

beneath

car,

remove

left

and

right

nuts

from

10

.

Installation

is

reverse

ofremoval,

noting

the

followíng

:

engine

mounts

.

"

Make

sure

all

bolts,bolt

holes,

and

mating

surfaces

are

clean

to

ensure

proper

tightening

and

alignment

.

Use

4

.

Remove

control

arm

bushing

carrier

from

body

.

Refer

to

new

self-locking

nuts

or

bolts,

where

applicable

.

Fig

.

9

.

"

On

vehicles

produced

up

9-92

only

:

-Remove

paint

from

contact

surfaces

before

ínstall-

5

.

Remove

control

arm

ball

joint

from

crossmember

.

Sep-

ing

crossmember

.

arate

joint

with

a

plastic

hammer

.

Suspend

control

arm

-Install

4

new

toothed

lock

washersbetween

sub-from

chassis

using

stiff

wire

.

frame

and

chassis

(install

new

washers

regardless

of

whether

washers

were

originally

fitted)

.

WARNING-

-Replace

all

4

mounting

bolts

.

Do

not

allow

the

control

arm

to

hang

from

the

ball

-Lubrícate

suspension

crossmember

bolts

with

LM48

¡oint

.

This

can

damage

theball¡oint

.

paste

orequivalent

anti-seize

compound

before

ín-

stalling

.

6

.

Unbolt

steering

rack

from

subframe

.

See

320

Steering

"

Lower

engine

onto

enginemounts,

allowing

it

to

settle

and

Wheel

Alignment

.

Suspend

steering

rack

from

fully

before

tightening

engine

mount

bolts

.

chassis

using

stiff

wire

.

Using

a

transmission

jackor

"

When

thejob

is

completed

have

front

end

profession-

equivalent,

support

crossmember

from

below

.

ally

aligned

.

7

.

Remove

reinforcing

brace

below

oil

pan,

where

appli-

cable

.

Tightening

Torques

"

Subframe

crossmember

to

body

8

.

Unbolt

crossmemberfrom

body

on

both

sides

.

See

Fig

.

M12-8

.8

bolts

..................

.

77

Nm

(56

ft-Ib)

17

.

M12-10

.9

bolts

.................

110

Nm

(81

ft-Ib)

M12-12

.9

bolts

............

.

...

.

105

Nm

(77

ft-Ib)

9

.

Slowly

Lower

crossmember,

making

sure

all

electrical

"

Steering

gear

to

subframe

crossmember

teads,

suspension

components

and

heat

shields

are

(M10-10

.9

self-locking

bolts)

..

.

.

.

.

.

42

Nm

(31

ft-Ib)

clear

during

removal

.

"

Control

arm

balljoint

to

subframe

crossmember

...

.......

.

85

Nm

(62

ft-Ib)

"

Control

arm

bushing

carrier

to

body

..........

...

.

.....

.

..

..

47

Nm

(34

ft-Ib)

Page 268 of 759

320-2

STEERING

AND

WHEEL

ALIGNMENT

3

.

Carefully

remove

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

safe

place

.

WARNING-

Improper

handling

of

theaírbag

could

cause

seri-

ous

ínjury

.

Store

theaírbag

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

deployment

could

propel

it

vlolently

into

the

air,

causíng

ínjury

.

4

.

Remove

steering

wheel

center

bolt

.

Lightly

punch

mark

or

scribe

position

of

steering

wheel

to

steering

column

shaft

.

See

Fig

.

1

.

0012687

Fig

.

1

.

Steering

wheel

center

bolt

(arrow)

.

Power

steering

pump,

removing

and

installing

POWER

STEERING

SYSTEM

5

.

Unlock

steering

wheel

by

turning

ignition

key

on

.

Re-

move

steering

wheel

.

WARNING-

The

SRS

contact

reel

ís

mounted

to

the

rear

of

the

steering

wheel

hub

.

The

contact

reel

ís

a

wound

coil

ofwirethat

ensures

continuous

electrícal

contact

for

the

air

bag

unit

Once

the

steering

wheel

mounting

nut

or

bolt

is

removed

the

contact

reel

is

locked

in

the

center

position

and

its

position

must

not

be

al-

tered

.

6

.

Insta¡¡

steering

wheel

while

aligning

matching

marks

.

Make

sure

airbag

contact

ring

locking

pin

engages

cutout

in

contact

reel

.

Insta¡¡

steering

column

center

nut

.

Do

not

over-torque

.

See

Fig

.

2

.

7

.

The

remainder

ofinstallation

is

reverse

of

removal

.

Carefully

install

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Tightening

Torque

"

Steering

wheel

to

steering

column

spindle

...

..

..

.

..........

63

Nm

(46

ft-Ib)

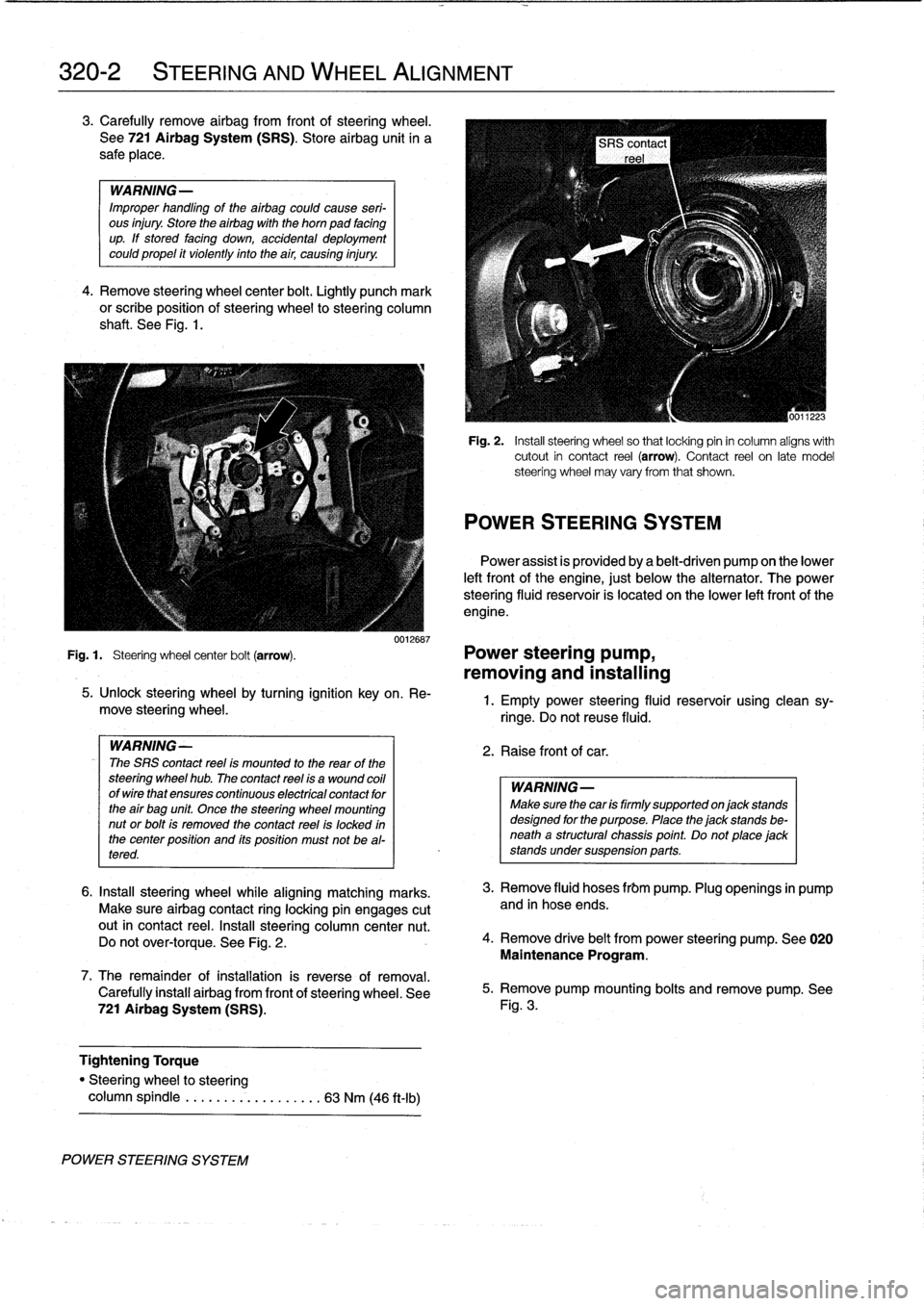

Fig

.

2

.

Insta¡¡

steering

wheel

so

that

locking

pin

in

column

aligns

with

cutout

in

contact

reel

(arrow)

.

Contact

reel

on

late

model

steering

wheel

may

vary

from

that

shown

.

POWER

STEERING

SYSTEM

Power

assist

is

províded

by

a

belt-driven

pump

on

the

lower

left

front

of

the

engine,

just

below

the

alternator

.

The

power

steering

fluid

resenroir

is

located

on

the

lower

left

front

of

the

engine

.

1

.

Empty

power

steering

fluid

reservoir

usingclean

sy-

ringe

.

Do

not

reuse

fluid

.

2

.

Raise

front

of

car

.

WARNING

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

3

.

Remove

fluid

hoses

frbm

pump

.

Plug

openings

in

pump

and

in

hose

ends

.

4

.

Remove

drive

belt

from

power

steering

pump

.

See

020

Maintenance

Program

.

5

.

Remove

pump

mounting

bolts

and

remove

pump

.

See

Fig

.

3

.

Page 277 of 759

Wheel

bearing

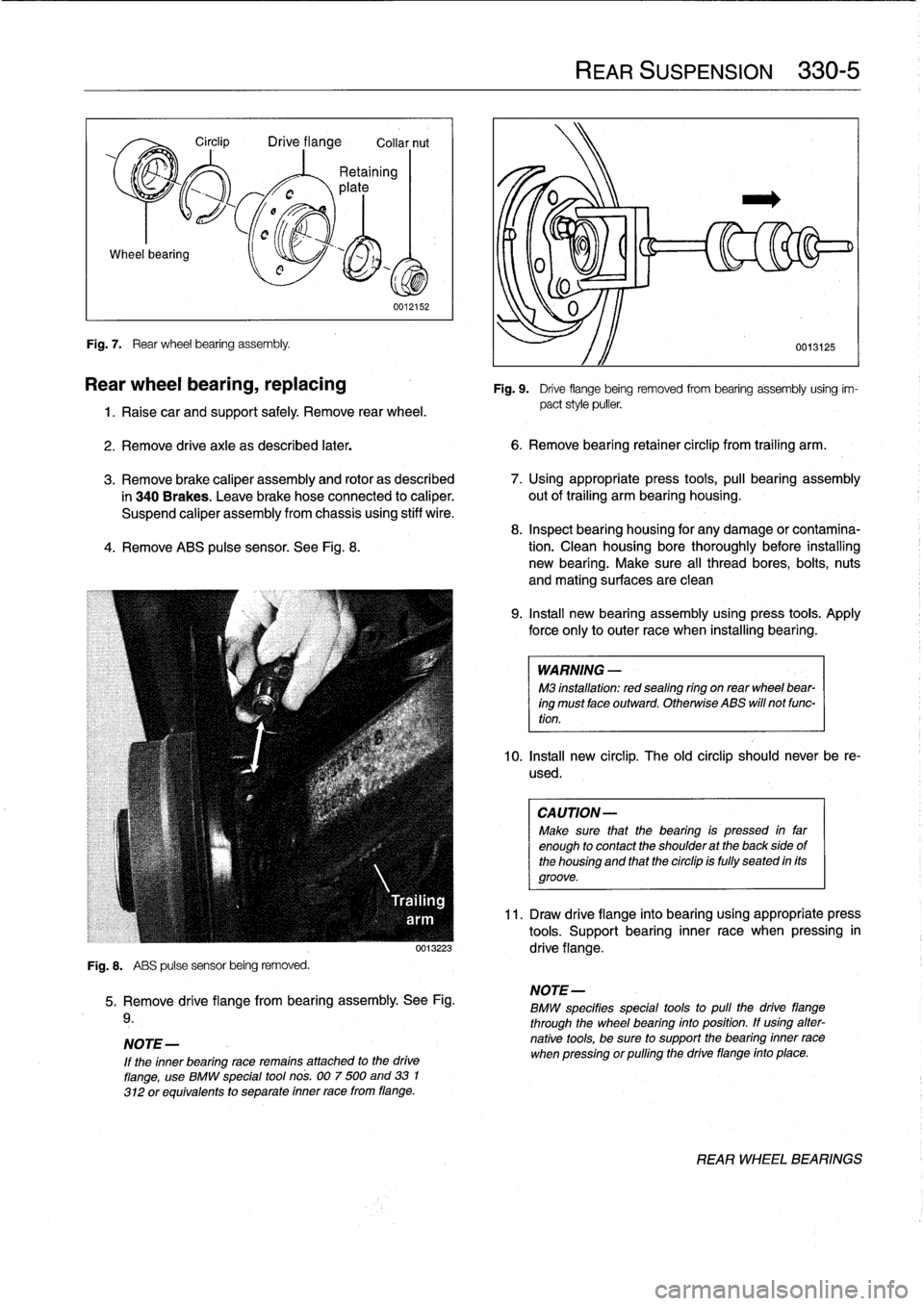

Fig

.

7

.

Rear

wheel

bearing

assembly

.

Circlip

Drive

flange

Collar

nut

0012152

Rear

wheel

bearing,

replacing

1

.

Raise

car

and

support

safely

.

Remove

rear

wheel

.

2

.

Remove

drive

axle

as

described

later

.

6

.

Remove

bearíng

retainer

circlip

from

trailing

arm

.

3

.

Remove

brake

caliper

assembly

and

rotor

as

described

7

.

Using

appropriate

press

tools,

pull

bearing

assembly

in

340

Brakes

.

Leave

brake

hose

connected

to

caliper

.

out

of

trailing

arm

bearing

housing

.

Suspend

caliper

assembly

from

chassís

using

stiff

wire

.

8

.

Inspect

bearing

housing

for

any

damage

or

contamina

4

.

Remove

ABS

pulse

sensor

.

See

Fig

.

8

.

tion

.

Clean

housing

bore

thoroughly

before

installing

new

bearing

.

Make

sure

al¡

thread

bores,

bolts,

nuts

and

mating

surfaces

are

clean

Fig

.

8

.

ABS

pulse

sensor

being

removed

.

5

.

Remove

drive

flange

from

bearing

assembly

.

See

Fig

.

9

.

NOTE-

If

the

inner

bearing

race

remains

attached

to

the

drive

flange,

use

BMW

special

tool

nos

.

007

500

and

33

1

312

or

equivalents

to

separate

inner

race

from

flange

.

REAR

SUSPENSION

330-

5

0013125

Fig

.

9

.

Drive

flange

being

removed

from

bearing

assembly

using

im-

pact

style

puller

.

9

.

Install

new

bearing

assembly

using

press

tools

.

Apply

force

only

to

outer

race

when

installing

bearing

.

WARNING

-

M3

installation

:

redsealing

ríng

on

rear

wheel

bear-

ing

must

face

outward

.

Otherwíse

ABS

will

not

func-

tion

.

10

.

Insta¡¡

new

circlip

.

The

old

circlip

should

never

be

re-

used

.

CAUTION-

Make

sure

that

the

bearing

is

pressed

in

far

enough

to

contact

the

shoulder

at

the

back

sideof

the

housing

and

that

the

circlip

is

fully

seated

in

its

groove

.

11

.

Draw

drive

flange

into

bearing

using

appropriate

press

tools

.

Support

bearing

inner

race

when

pressing

in

0013223

drive

flange

.

NOTE-

BMW

specifies

special

tools

to

pull

the

drive

fiange

through

the

wheel

bearing

into

position

.

If

using

alter-

native

tools,

be

sure

to

support

the

bearing

inner

race

when

pressing

orpulling

the

drive

flange

finto

place

.

REARWHEEL

BEARINGS

Page 279 of 759

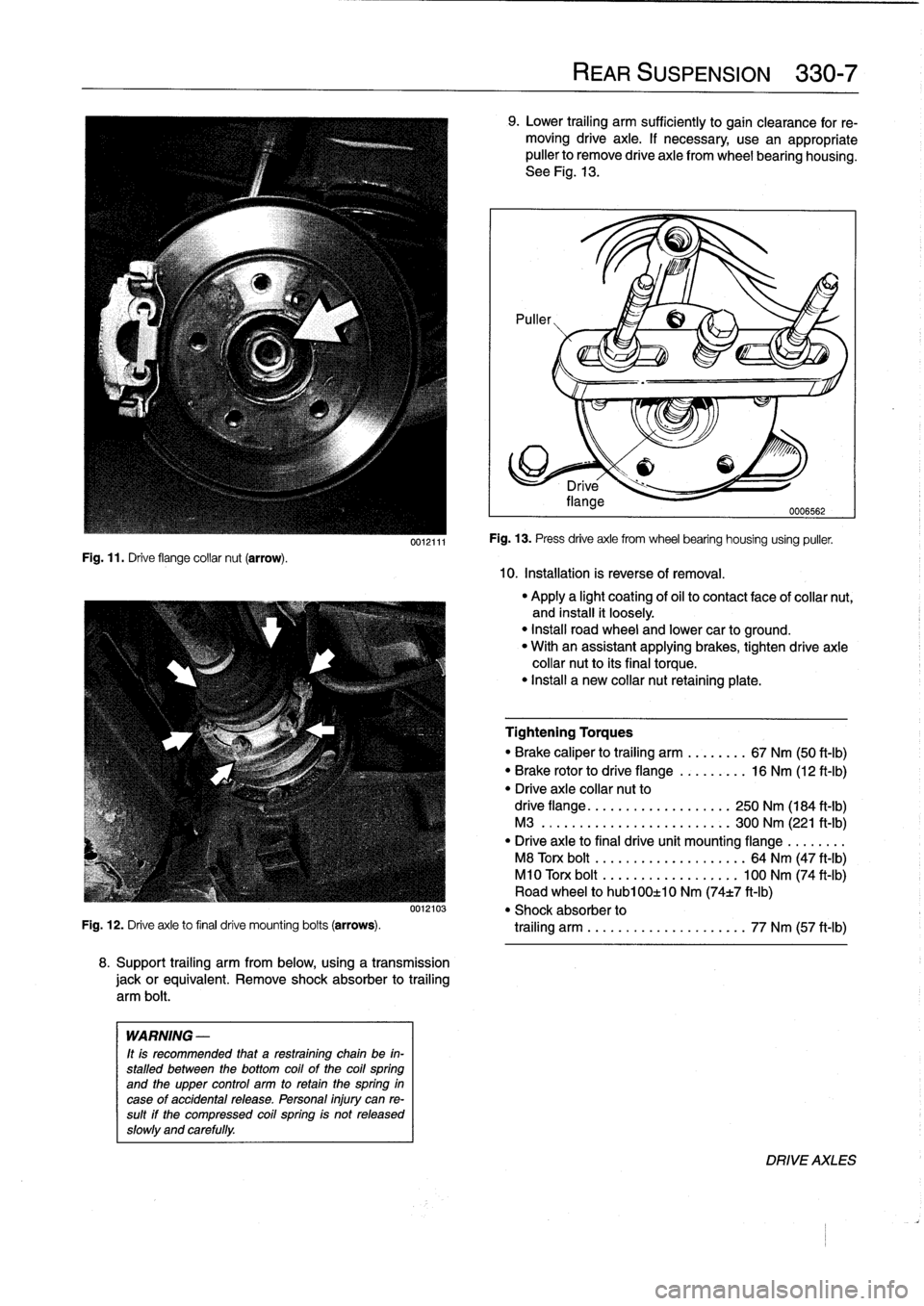

Fig

.

11

.

Drive

flange

collar

nut

(arrow)

.

0012111

8

.

Support

trailing

arm

from

below,

using

a

transmission

jackorequivalent

.

Remove

shock

absorber

to

trailing

arm

bolt

.

WARNING

-

It

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

is

not

released

slowly

and

carefully

.

REAR

SUSPENSION

330-

7

9

.

Lower

trailing

arm

sufficiently

to

gain

clearance

for

re-

moving

drive

axle

.

If

necessary

use

an

appropriate

puller

to

Rmove

drive

axle

from

wheel

bearing

housing

.

See

Fig

.

13

.

10

.

Installation

is

reverse

of

removal

.

Fig

.

13

.

Press

drive

axle

from

wheel

bearing

housing

using

puller

.

"

Apply

a

light

coating

of

oil

to

contact

face

of

collar

nut,

and

install

it

loosely

.

"

Install

road

wheel

and

lower

car

to

ground

.

"

With

an

assistant

applying

brakes,

tighten

drive

axle

collar

nut

to

its

final

torque

.

"

Install

a

new

collar

nut

retaining

plate

.

Tightening

Torques

"

Brake

caliper

to

trailing

arm

........

67

Nm

(50

ft-Ib)

"

Brake

rotor

to

drive

flange

.........

16

Nm

(12

ft-Ib)

"

Drive

axle

collar

nut

to

drive

flange

.

.

....

..

.

..........

250

Nm

(184

ft-Ib)

M3

......

.

.

.....

.

.

..........

300

Nm

(221

ft-Ib)

"

Drive

axie

to

final

drive

unit

mounting

flange

.

.

.

.....

M8

Torx

bolt

.

...

...

.

............

64

Nm

(47

ft-Ib)

M10

Torx

bolt

...

...............

100

Nm

(74

ft-Ib)

Road

wheel

to

hub100±10

Nm

(74t7

ft-Ib)

0012103

"

Shock

absorber

to

Fig

.

12

.

Drive

axle

to

final

drive

mounting

bolts

(arrows)

.

trailing

arm

.

.

...

...

.

............

77

Nm

(57

ft-Ib)

DRIVE

AXLES

Page 280 of 759

330-

8

REAR

SUSPENSION

CV

boot,

replacing

NOTE-

"

The

outer

CV

joint

cannot

be

removed

from

the

axle

shaft

.

In

order

to

replace

the

outer

CV

boot,

it

is

nec-

essary

to

remove

the

inner

joint

and

boot

first

.

"

If

the

CV

joints

are

worn

or

defective,

acomplete

re-

built

axle

shaft

is

available

from

an

authorized

BMW

dealerparts

department

.

1

.

Remove

drive

axle

from

car

as

described

above

.

2

.

Remove

inner

and

outer

CV

boot

clamping

bands

and

cut

old

boots

off

joints

and

shaft

.

Clean

grease

from

joints

.

3

.

Lift

off

dust

cover

from

inner

CV

joint

and

remove

circlip

5

.

Clean

all

old

lubricantoff

shaftsplines

and

inner

joint's

retaining

joint

inner

hub

to

axle

shaft

.

See

Fig

.

14

.

splines

.

DRIVE

AXLES

-0

1

,

1

1,1

1

L

"I

C

OYA

Drive

axle-"

e

:>,

)

0006560

CV

joint

Fig

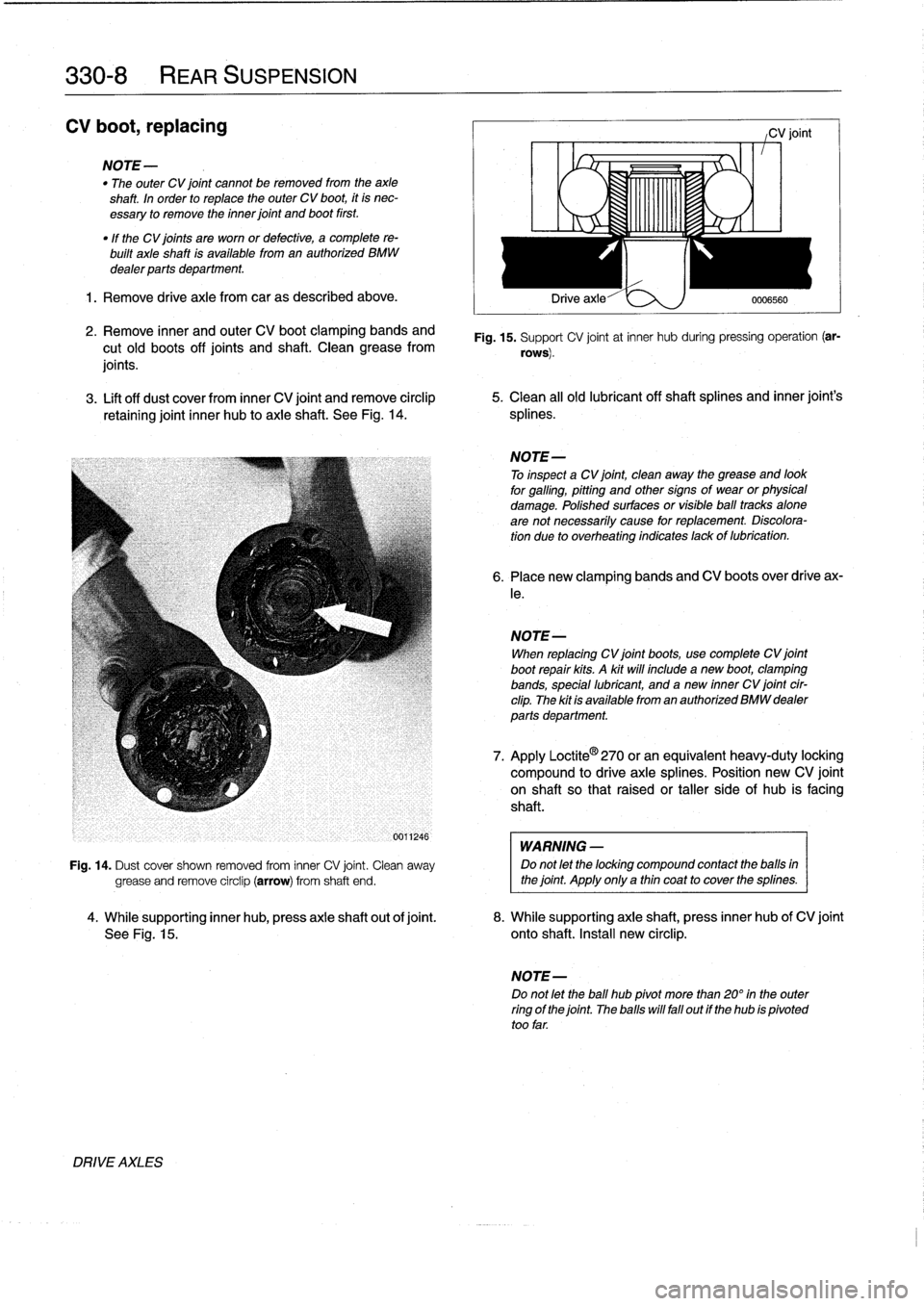

.

15

.

Support

CV

joint

at

inner

hub

duringpressing

operation

(ar-

rows)

.

NOTE-

To

inspect

a

CV

joint,

clean

away

the

grease

and

look

for

galling,pittihg

and

othersigns

of

wear

or

physical

damage

.

Polished

surfaces

or

visible

ball

tracks

alone

are

not

necessarily

cause

for

replacement

.

Discolora-

tion

due

to

overheating

indicates

lackof

lubrication

.

6

.

Place

new

clamping

bands

and

CV

boots

over

drive

ax-

le

.

NOTE-

When

replacing

CV

joint

boots,

usecomplete

CV

joint

boot

repair

kits

.

A

kit

will

include

a

new

boot,

clamping

bands,

special

lubricant,

and

anew

inner

CV

joint

cir-

clip

.

The

kit

is

available

from

an

authorized

BMW

dealer

parts

department

.

7

.

Apply

Loctite

®

270

or

an

equívalent

heavy-duty

lockíng

compound

to

drive

axlesplines

.

Position

new

CV

joint

on

shaft

so

that

raisedor

taller

side

of

hub

is

facing

shaft

.

WARNING

-

Fig

.

14

.

Dust

cover

shown

removed

from

inner

CV

joint

.

Clean

away

Do

not

let

the

locking

compound

contact

the

balls

in

grease

and

remove

circlip

(arrow)

from

shaft

end

.

the

joint

.

Apply

only

a

thin

coat

to

cover

the

splines

.

4

.

While

supporting

inner

hub,

press

axle

shaft

out

of

joint

.

8

.

While

supporting

axle

shaft,

press

inner

hub

of

CV

joint

See

Fig

.

15

.

onto

shaft

.

Install

new

circlip

.

NOTE-

Do

not

let

the

ball

hub

pivot

more

than

20°

in

the

outer

ring

of

the

joint

.

The

halls

will

fall

out

if

the

hub

ís

pivoted

too

far

.

Page 295 of 759

6

.

Remove

brake

pads

from

caliper

.

Where

applicable,

carefully

pry

pad

wear

sensor

from

pad

.

See

Fig

.

5

.

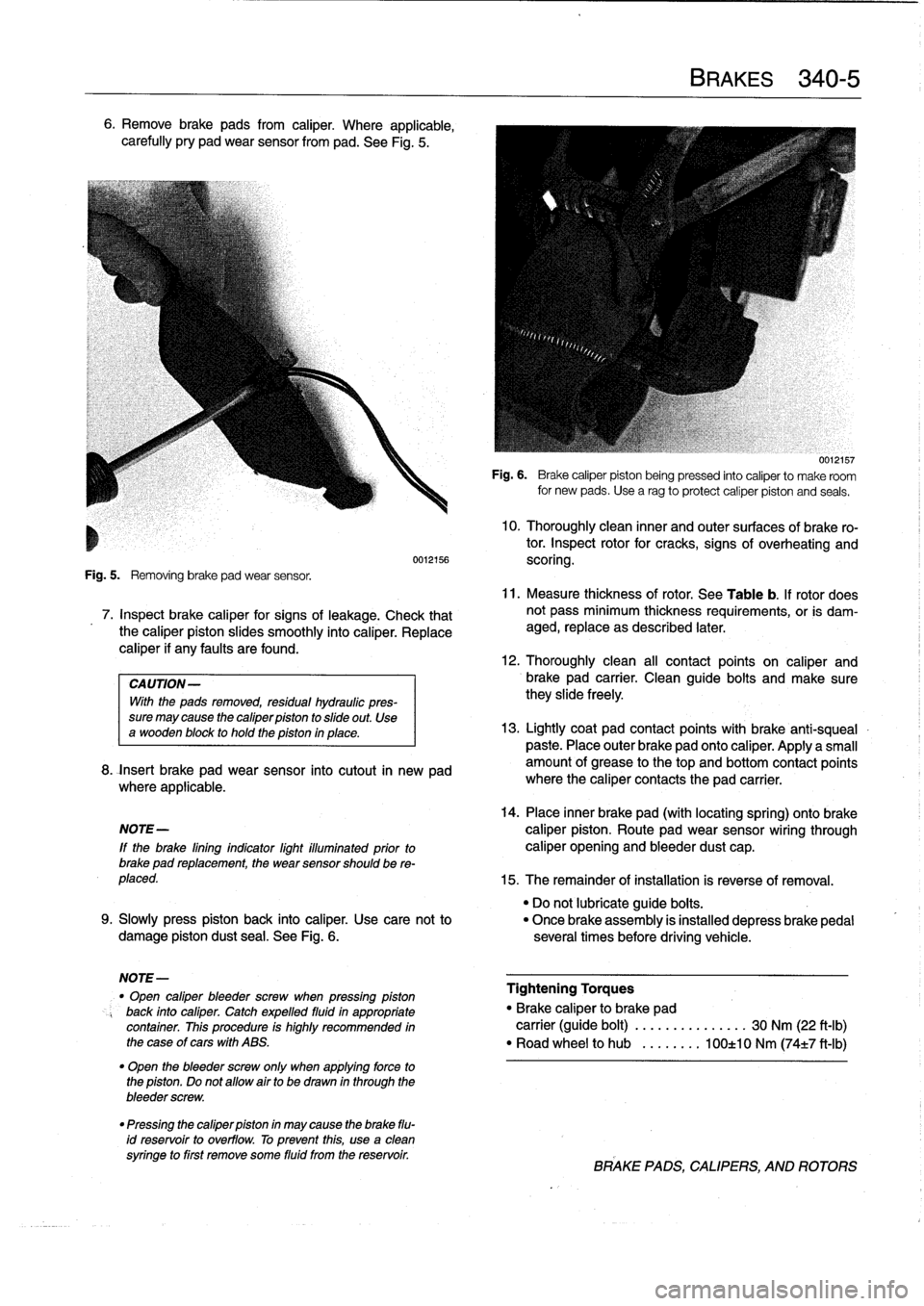

Fig

.

5

.

Removing

brake

pad

wear

sensor

.

7

.

Inspect

brake

caliper

for

signs

of

leakage

.

Check

that

the

caliper

piston

slides

smoothly

into

caliper

.

Replace

caliper

if

any

faults

are

found

.

CAUTION-

With

the

pads

removed,

residual

hydreulic

pres-

sure

may

cause

the

caliper

piston

to

slide

out

.

Use

a

wooden

block

to

hold

the

piston

in

place

.

8

.

fnsert

brake

pad

wear

sensor

into

cutout

in

new

pad

where

applicable

.

14

.

Place

inner

brake

pad

(with

locating

spring)

ontobrake

NOTE-

caliper

piston

.

Route

pad

wear

sensor

wiring

through

lf

the

brake

lining

indicator

light

illuminated

prior

to

caliper

opening

and

bleeder

dust

cap

.

brake

pad

replacement,

the

wear

sensor

should

be

re-

placed

.

15

.

The

remainder

of

installation

is

reverse

of

removal

.

"

Do

not

lubricate

guide

boits

.

9

.

Slowly

press

piston

back

into

caliper

.

Use

cace

not

to

"

Once

brake

assembly

is

installed

depress

brakepedal

damage

piston

dust

sea¡

.

See

Fig

.

6

.

severa¡

times

before

driving

vehicle

.

NOTE-

"

Open

caliper

bleeder

screw

when

pressing

piston

Tightening

Torques

back

into

caliper

.

Catch

expelled

fluidin

appropriate

"

Brake

caliper

to

brake

pad

container

.

This

procedure

is

highly

recommended

in

carrier

(guide

bolt)

..........

...

.

.

30

Nm

(22

ft-Ib)

the

case

of

cars

with

ABS

.

"

Road

wheel

to

hub

.....

.

..

100±10

Nm

(74±7

ft-Ib)

"

Open

the

bleeder

screw

only

when

applying

force

to

the

piston

.

Do

not

allow

airto

be

drawn

in

through

the

bleeder

screw

.

"

Pressing

the

caliper

piston

in

may

cause

the

brake

flu-

id

reservoir

to

overflow

.

To

prevent

this,

use

a

clean

syringe

to

first

remove

some

fluid

from

the

reservoir

.

BRAKES

340-

5

0012157

Fig

.

6

.

Brake

caliper

piston

being

pressed

into

caliper

to

make

room

for

new

pads

.

Usea

rag

toprotect

caliper

piston

and

seals

.

10

.

Thoroughly

clean

inner

and

outer

surfaces

of

brake

ro-

tor

.

Inspect

rotor

for

cracks,

signs

of

overheating

and

0012156

scoring

.

11

.

Measure

thickness

of

rotor

.

See

Table

b

.

If

rotor

does

not

pass

minimum

thickness

requirements,

or

is

dam-

aged,

replace

as

described

later

.

12

.

Thoroughly

clean

all

contact

points

on

caliper

and

brake

pad

carrier

.

Clean

guide

bolts

and

make

surethey

slide

freely

13

.

Lightly

coat

pad

contact

points

with

brake

anti-squeal

paste

.

Place

outer

brake

pad

onto

caliper

.

Applya

small

amount

of

grease

to

thetop

and

bottom

contact

points

where

the

caliper

contacts

the

pad

carrier

.

BRAKE

PADS,CALIPERS,

ANDROTORS

Page 333 of 759

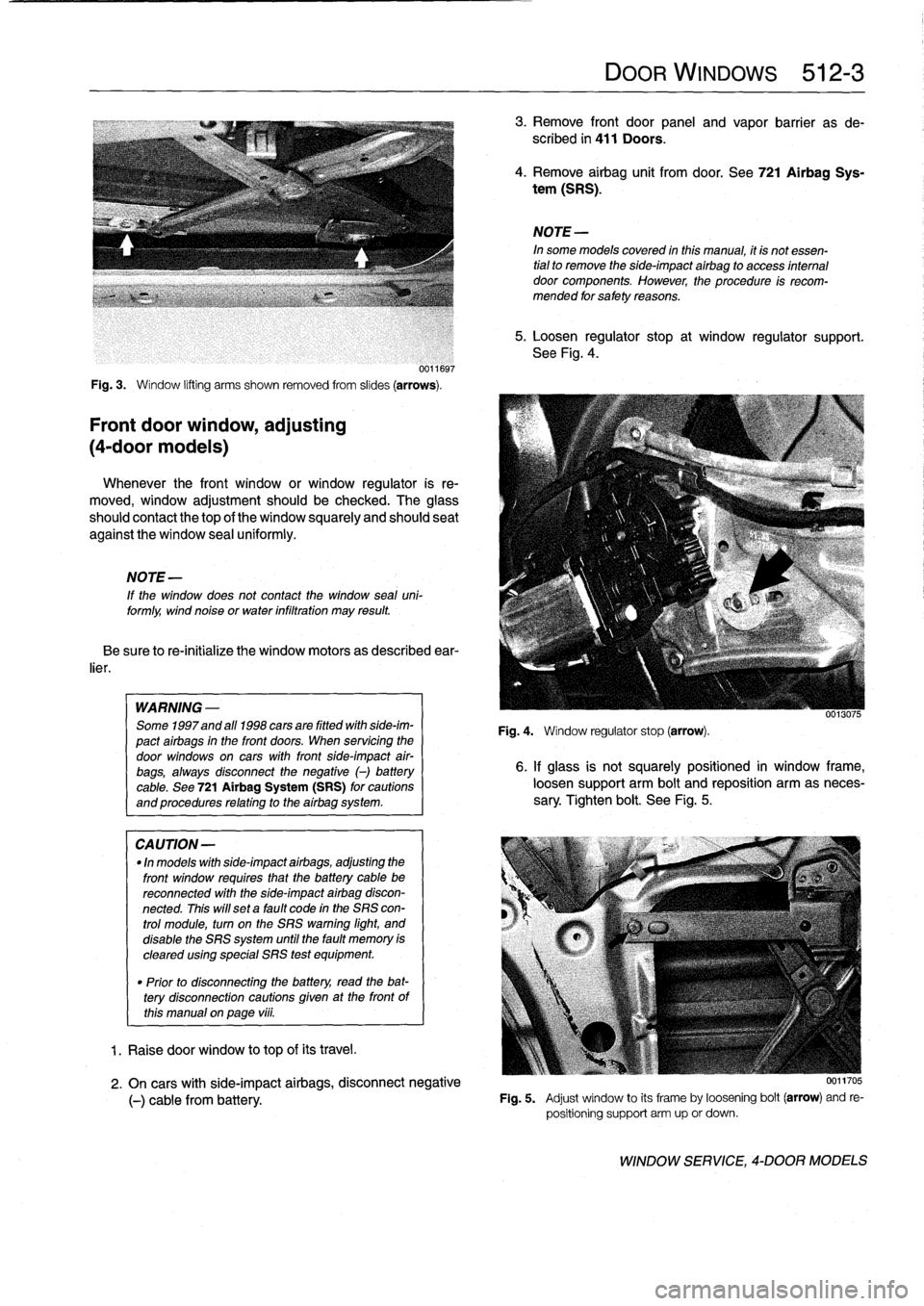

0011697

Fig

.

3

.

Window

lifting

arms

shown

removed

from

slides

(arrows)

.

Front

door

window,

adjusting

(4-door

models)

Whenever

the

front

window

or

window

regulator

is

re-

moved,

window

adjustment

should

be

checked

.

The

glass

should

contact

the

top

of

the

window

squarely

and

should

seat

against

the

window

sea¡

uniformly

.

NOTE

-

If

the

window

does

not

contact

the

window

seal

uni-formly,

wind

noise

or

water

infiltration

may

result

Be

sure

to

re-initialize

the

window

motors

as

described

ear-

lier

.

WARNING

-

Some

1997and

all

1998

cars

are

fitted

wíthside-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

windows

on

cars

with

front

side-impact

air-

bags,

always

disconnect

the

negative

()

battery

cable

.

See

721Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

CA

UTION-

"

In

models

with

side-impact

airbags,

adjusting

the

front

window

requires

that

the

battery

cable

bereconnected

with

the

side-impact

airbag

discon-

nected

.

This

will

set

a

fault

code

in

the

SRS

con-

trol

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

memory

is

cleared

using

special

SRS

test

equipment

.

"

Prior

to

disconnectiog

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

1

.

Raise

door

window

to

top

of

its

travel

.

DOOR

WINDOWS

512-

3

3

.

Remove

front

door

panel

and

vapor

barrier

as

de-

scribed

in

411

Doors

.

4

.

Remove

airbag

unit

from

door

.

See

721Airbag

Sys-

tem

(SRS)

.

NOTE-

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

interna¡

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

5

.

Loosen

regulator

stop

at

window

regulator

support

.

See

Fig

.

4

.

Fig

.

4

.

Wíndow

regulator

stop

(arrow)

.

0013075

6

.

If

glass

is

not

squarely

positioned

in

window

frame,

loosen

support

arm

bolt

and

reposition

arm

as

neces-

sary

.

Tighten

bolt

.

See

Fig

.

5

.

2

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery

.

Fig

.

5

.

Adjust

window

to

its

frameby

loosening

bolt

(arrow)

and

re-

positioning

support

arm

up

or

down

.

WINDOW

SERVICE,

4-DOOR

MODELS

Page 338 of 759

512-

8

DOOR

WINDOWS

NOTE-

To

achieve

an

accurate

window

adjustment

in

2-door

models

with

"close

with

door

shut"

feature,

simulate

a

closed

dooras

follows

:

On

early

cars,

manually

turn

the

latch

on

the

door

to

the

closed

position

.

See

Fig

.

16

.

On

latercars,

insert

a

wedge

of

wood

into

the

striker

on

the

body

to

close

the

striker

switch

.

Be

sure

to

open

thero-

tary

latch

(by

pulling

upon

the

door

handle)

or

remove

the

wedge

before

closing

the

door

.

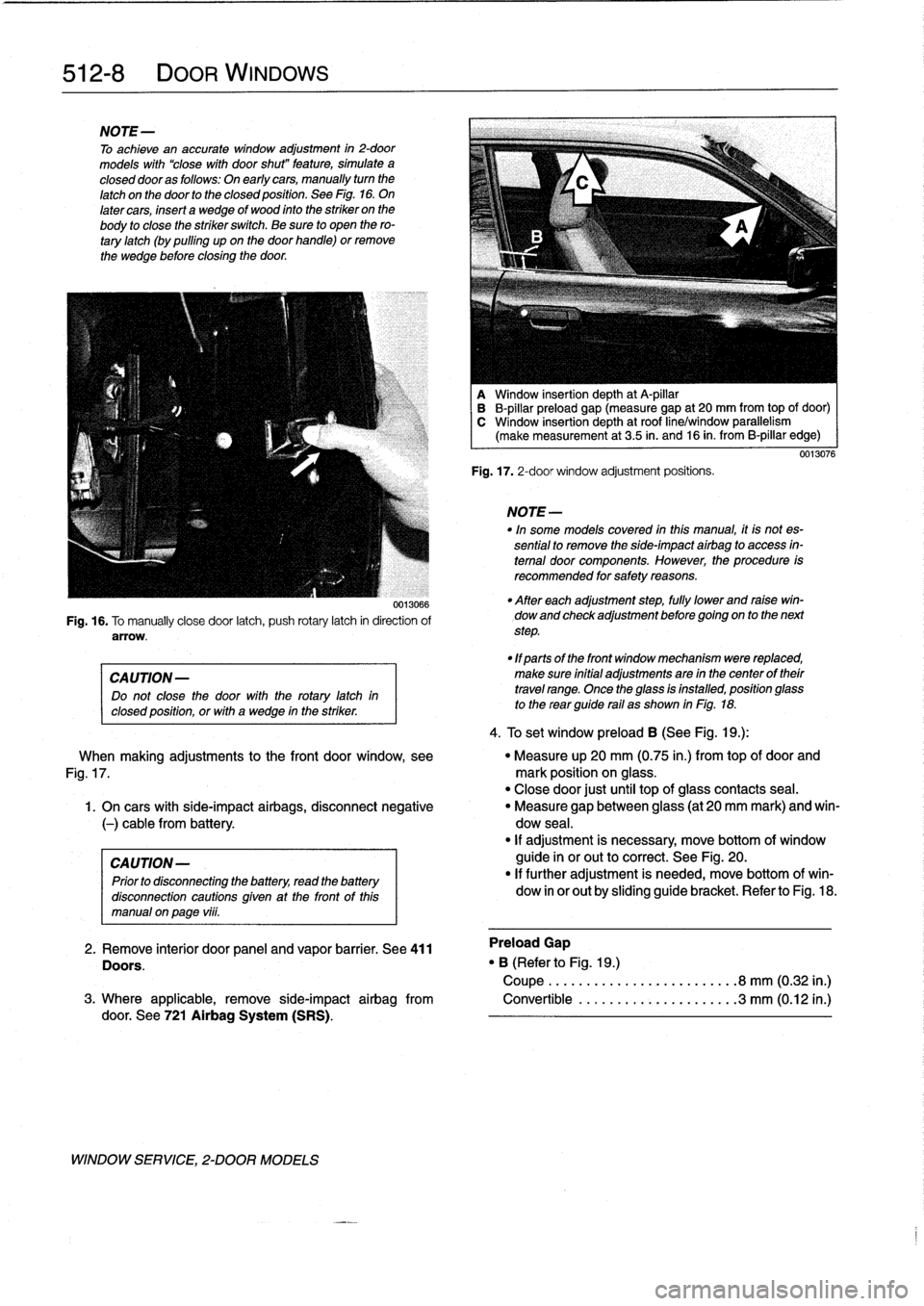

0013066

Fig

.

16

.

To

manually

close

door

latch,

push

rotary

latch

in

direction

of

arrow

.

CAUTION-

Do

not

close

the

door

with

therotary

latch

in

closed

position,

orwith

a

wedge

in

the

striker

.

WINDOW

SERVICE,

2-DOOR

MODELS

A

Window

insertion

depth

at

A-pillar

B

B-pillar

preload

gap

(measure

gap

at

20

mm

from

top

of

door)

C

Window

insertion

depth

at

roof

line/window

parallelism

(make

measurement

at

3

.5

in

.

and

16

in

.

from

B-pillar

edge)

Fig

.

17

.

2-door

window

adjustment

positions

.

NOTE-

In"

some

models

covered

inthis

manual,

it

is

not

es-

sential

to

remove

the

side-impact

airbag

to

access

in-

terna¡

door

components

.

However,

the

procedure

is

recommended

for

safety

reasons

.

"

After

each

adjustment

step,

fully

lower

and

raise

win-

dow

and

check

adjustment

before

goingon

to

the

next

step

.

"

1f

parts

of

the

front

window

mechanism

were

replaced,

make

sure

initial

adjustments

are

in

the

center

of

their

travel

range

.

Once

the

glass

isinstalled,

position

glass

to

the

rear

guide

rail

as

shown

in

Fig

.

18

.

4

.

To

set

window

preload

B

(See

Fig

.

1

g

.):

0013076

When

making

adjustments

to

the

front

door

window,

see

"

Measure

up

20

mm

(0

.75

in

.)

from

topof

door

and

Fig

.

17

.

mark

position

on

glass

.

"

Close

door

just

until

top

of

glass

contacts

seal

.

1

.

On

cars

with

side-impact

airbags,

disconnect

negative

"

Measure

gap

between

glass

(at

20

mm

mark)

and

win-

(-)

cable

from

battery

.

dow

seal

.

"

If

adjustment

is

necessary,

move

bottom

of

window

CAUTION-

guide

inor

out

to

correct

.

See

Fig

.

20

.

Prior

to

disconnecting

the

battery,

read

the

battery

"

If

further

adjustment

is

needed,

move

bottom

ofwin-

disconnection

cautionsgiven

at

the

front

of

this

dow

in

or

out

by

sliding

guide

bracket

.

Refer

to

Fig

.

18

.

manual

on

page

viii

.

2

.

Remove

interior

door

panel

and

vapor

barrier

.

See

411

Preload

Gap

Doors

.

"

B

(Referto

Fig

.

1

g

.)

Coupe

......................

.

.

.8

mm

(0

.32

in

.)

3

.

Where

applicable,

remove

side-impact

airbag

from

Convertible

..................

.

..

3

mm

(0

.12

in

.)

door

.

See

721

Airbag

System

(SRS)

.

Page 340 of 759

512-

1

0

DOOR

WINDOWS

0013078

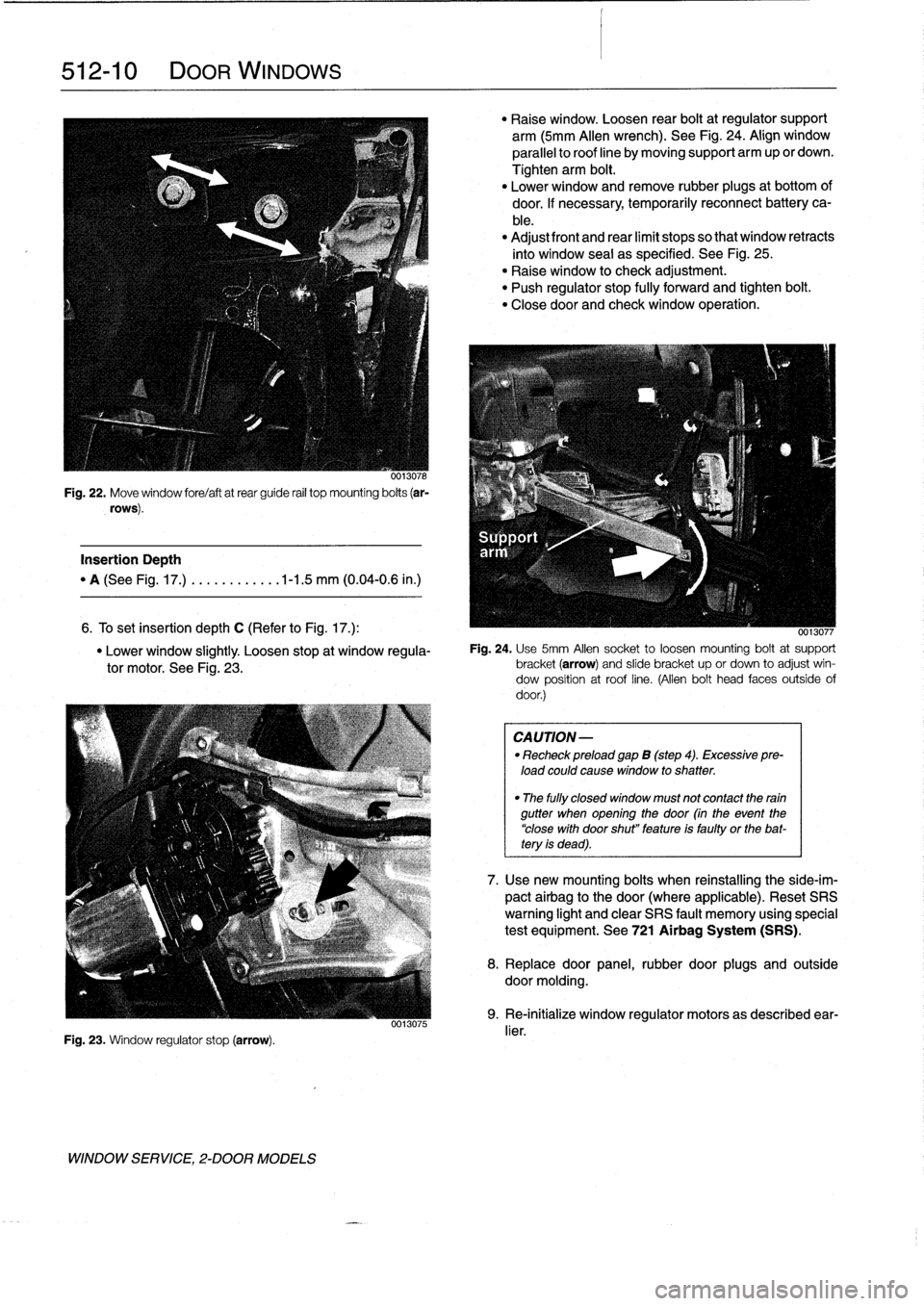

Fig

.

22

.

Move

window

fore/aftatrear

guide

rail

top

mounting

bolts

(ar-

rows)

.

Insertion

Depth

"

A

(See

Fig

.

17

.)

.

..........

.1-1

.5

mm

(0

.04-0

.6

in

.)

6

.

To

set

Insertion

depth

C

(Refer

to

Fig

.

17

.)

:

"

Lower

window

slightly

.

Loosen

stop

at

window

regula-

tor

motor

.

See

Fig

.

23

.

Fig

.

23

.

Window

regulator

stop

(arrow)

.

WINDOW

SERVICE,

2-DOOR

MODELS

0013075

"

Raise

window

.

Loosen

rear

boltat

regulator

support

arm

(5mm

Allen

wrench)

.

See

Fig

.

24

.

Align

window

parallelto

roof

line

by

moving

support

arm

up

or

clown

.

Tighten

arm

bolt

.

"

Lower

window

and

remove

rubber

plugs

at

bottom

of

door

.

If

necessary,temporarily

reconnect

battery

ca-

ble

.

"

Adjust

front

and

rear

limit

stops

so

that

window

retracts

into

window

seal

as

specified

.

See

Fig

.

25

.

"

Raise

window

to

check

adjustment

.

"

Push

regulator

stop

fully

forward

and

tighten

bolt

.

"

Closedoor

and

check

window

operation

.

0013077

Fig

.

24

.

Use

5mm

Afen

socket

to

loosen

mounting

boltat

support

bracket(arrow)

and

slide

bracket

up

or

clown

to

adjust

win-

dow

position

at

roof

line

.

(Allen

bolt

head

faces

outside

of

door

.)

CAUTION

-

"

Recheck

preload

gap

B

(step

4)

.

Excessive

pre-

load

could

cause

window

to

shatter

.

"

The

fully

closed

window

must

not

contact

the

rain

gutter

when

opening

the

door

(in

the

event

the

"close

with

door

shut"

feature

is

faulty

or

the

bat-tery

is

dead)

.

7

.

Usenew

mounting

bolts

when

reinstalling

the

side-im-

pact

airbag

to

the

door

(where

applicable)

.

Reset

SRS

warning

light

and

clear

SRS

fault

memory

using

special

test

equipment

.

See

721

Airbag

System

(SRS)

.

8

.

Replace

door

panel,

rubber

door

plugs

and

outside

doormolding

.

9

.

Re-initialize

window

regulator

motors

as

described

ear-

lier

.

Page 352 of 759

515-4

CENTRAL

LOCKING

AND

ANTI-THEFT

11

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

4

.

Remove

screws

mounting

bottom

of

window

rear

track

lowing

:

to

door

.

See

Fig

.

9

.

"

Make

sure

rubber

seal

for

handle

is

correctly

posi-

tionedbefore

tightening

mounting

fasteners

.

"

Install

exteriortrim

piece

and

then

use

a

hooked

tool

to

pull

locking

plate

into

locked

position

.

Make

sure

door

handle

trim

contacts

body

evenly

before

locking

trim

in

place

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pactairbag

to

the

door(where

applicable)

.

Reset

SRS

warning

light

and

clear

SRS

fault

memory

using

spe-

cial

test

equipment

.

See

721

Airbag

System

(SRS)

.

"

Reconnect

al¡

harness

connectors

(including

power

window

motor)before

installing

door

panel

.

"

Secure

wire

harnesses

withwire

ties

.

"

Adjust

and

reinitialize

windows

.

See

512

Door

Win-

dows

.

Tightening

Torque

"

Collar

nut

to

doorhandle

..........

10

Nm

(89

in-lb)

1.

Remove

rear

door

panel

and

vapor

barrier

as

described

in

411

Doors

.

2

.

Remove

window

from

rear

dooras

described

in

512

Door

Windows

.

3

.

Disconnect

andremove

inside

door

handle

.

See

Fig

.

8

.

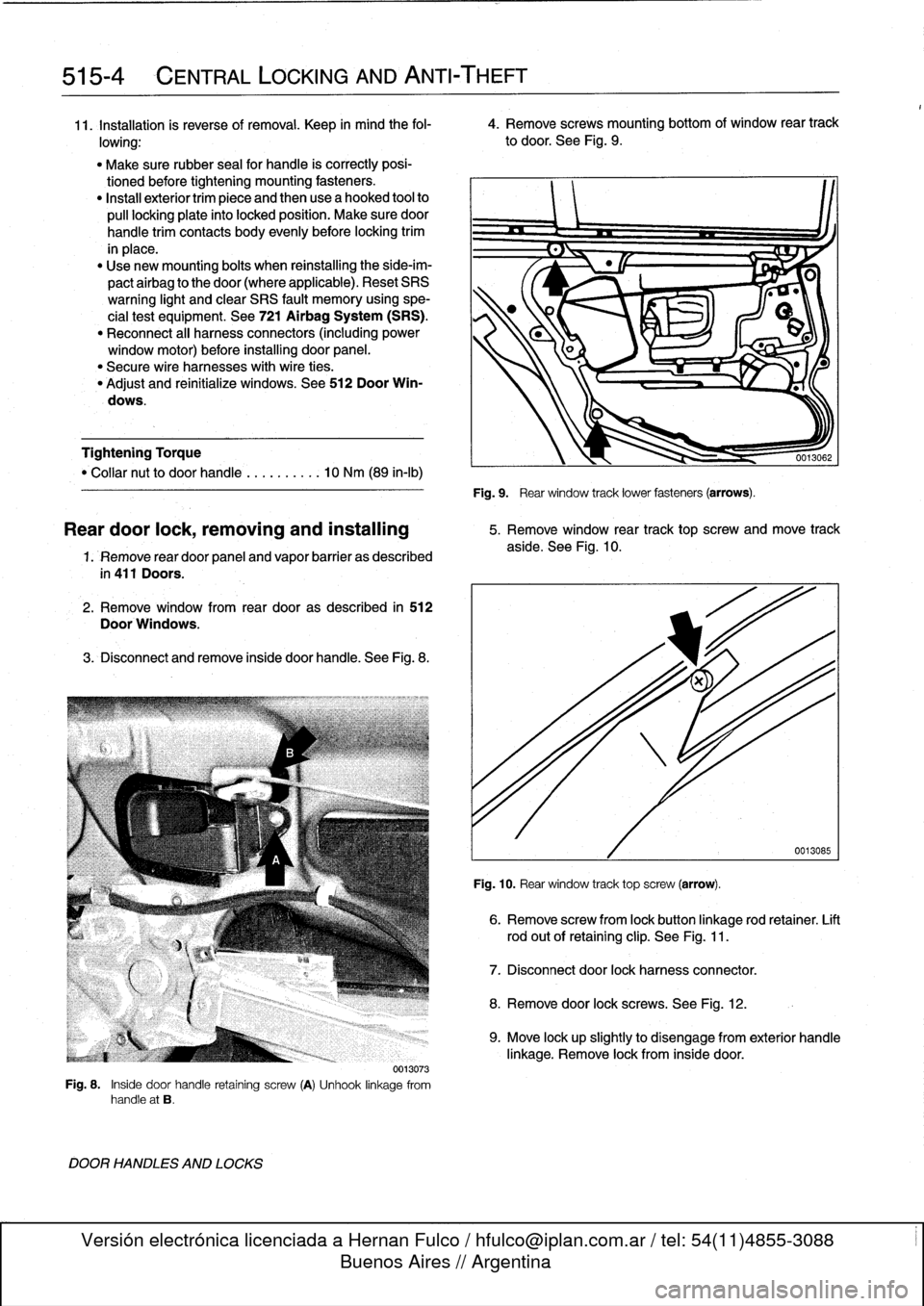

0013073

Fig

.

8

.

Inside

door

handle

retaining

screw

(A)

Unhook

linkage

from

handle

at

B

.

DOOR

HANDLES

AND

LOCKS

Fig

.

9

.

Rear

window

track

lower

fasteners

(arrows)

.

Reardoor

lock,

removing

and

installing

5

.

Remove

window

rear

track

top

screw

and

move

track

aside

.

See

Fig

.

10

.

Fig

.

10

.

Rear

window

track

top

screw

(arrow)

.

6

.

Remove

screw

from

lock

button

linkage

rod

retainer

.

Lift

rod

out

of

retaining

clip

.

See

Fig

.

11

.

7

.

Disconnect

door

lock

harnessconnector

.

8

.

Remove

door

lock

screws

.

See

Fig

.

12

.

0013085

9

.

Move

lock

upslightly

to

disengage

from

exterior

handle

linkage

.

Remove

lock

from

inside

door

.