Iat BMW 325i 1993 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1993, Model line: 325i, Model: BMW 325i 1993 E36Pages: 759

Page 460 of 759

640-14

HEATING

AND

AIR

CONDITIONING

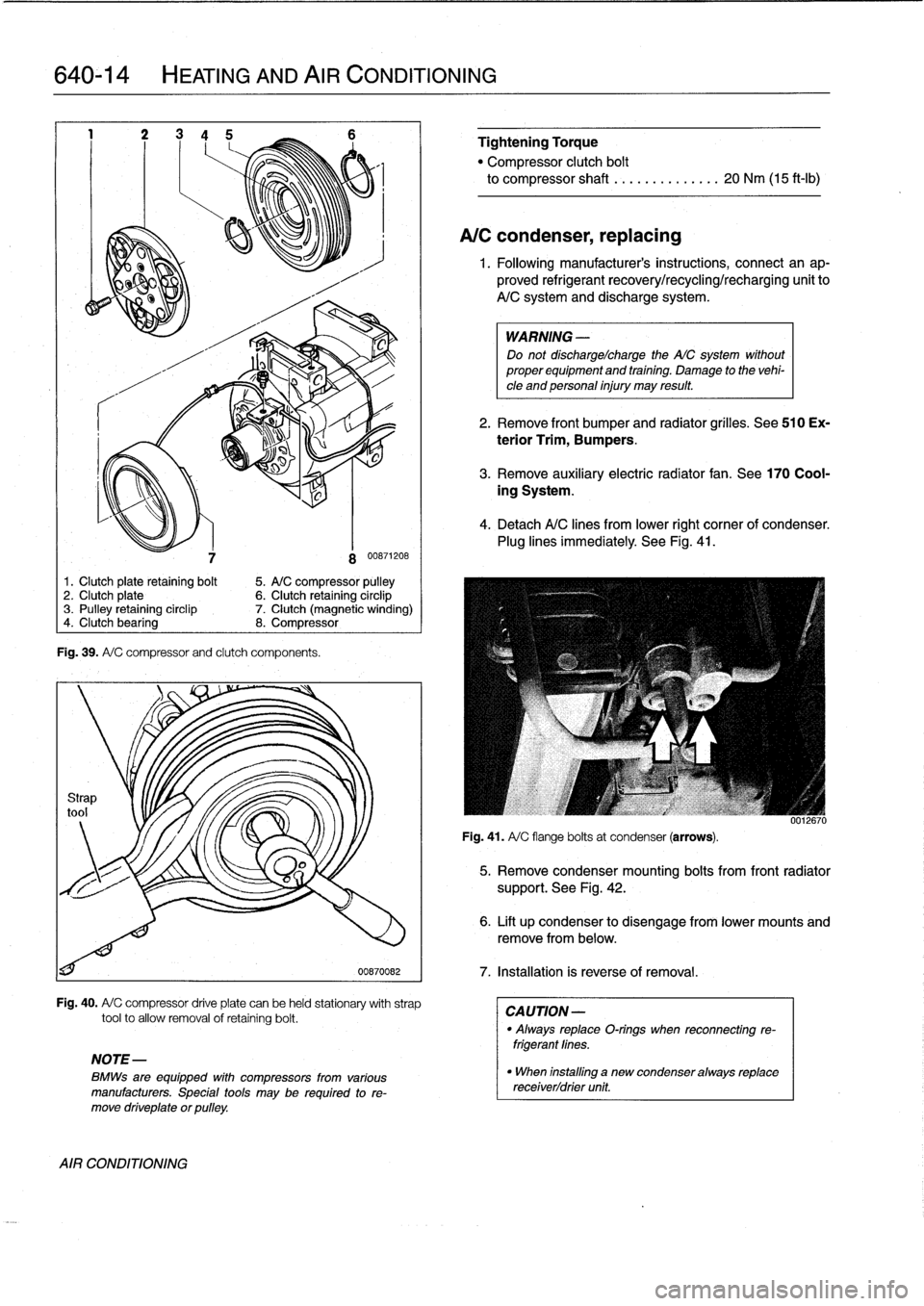

7

Fig

.

39

.

A/

C

compressorand

clutch

components

.

8

00871208

1.

Clutch

plate

retaining

bolt

5

.

A/C

compressor

pulley

2

.

Clutch

plate

6

.

Clutch

retaining

circlip

3

.

Pulley

retaining

circlip

7

.

Clutch

(magnetic

winding)

4

.

Clutch

bearing

8

.

Compressor

00870082

Fig

.

40

.

A/

C

compressor

driveplate

canbe

held

stationary

with

strap

toolto

allow

removal

of

retaining

bolt

.

NOTE-

BMWs

are

equipped

with

compressors

from

various

manufacturers

.

Special

tools

may

be

required

tore-

move

driveplate

orpulley

.

AIR

CONDITIONING

Tightening

Torque

"

Compressor

clutch

bolt

to

compressor

shaft

.....

.

....

..

.

.

20

Nm

(15

ft-Ib)

A/C

condenser,

replacing

1

.

Following

manufacturer's

instructions,

connect

an

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/Csystemand

discharge

system

.

WARNING

-

Do

not

dischargelcharge

the

AIC

system

without

proper

equipment

and

training

.

Damage

to

the

vehi-

cle

and

personal

injury

may

result

.

2

.

Remove

front

bumper

and

radiator

grilles

.

See510

Ex-

terior

Trim,

Bumpers

.

3

.

Remove

auxiliary

electric

radiator

fan

.

See

170

Cool-

ing

System

.

4

.

DetachA/C

lines

from

lower

right

corner

of

condenser

.

Plug

lines

immediately

.

See

Fig

.

41

.

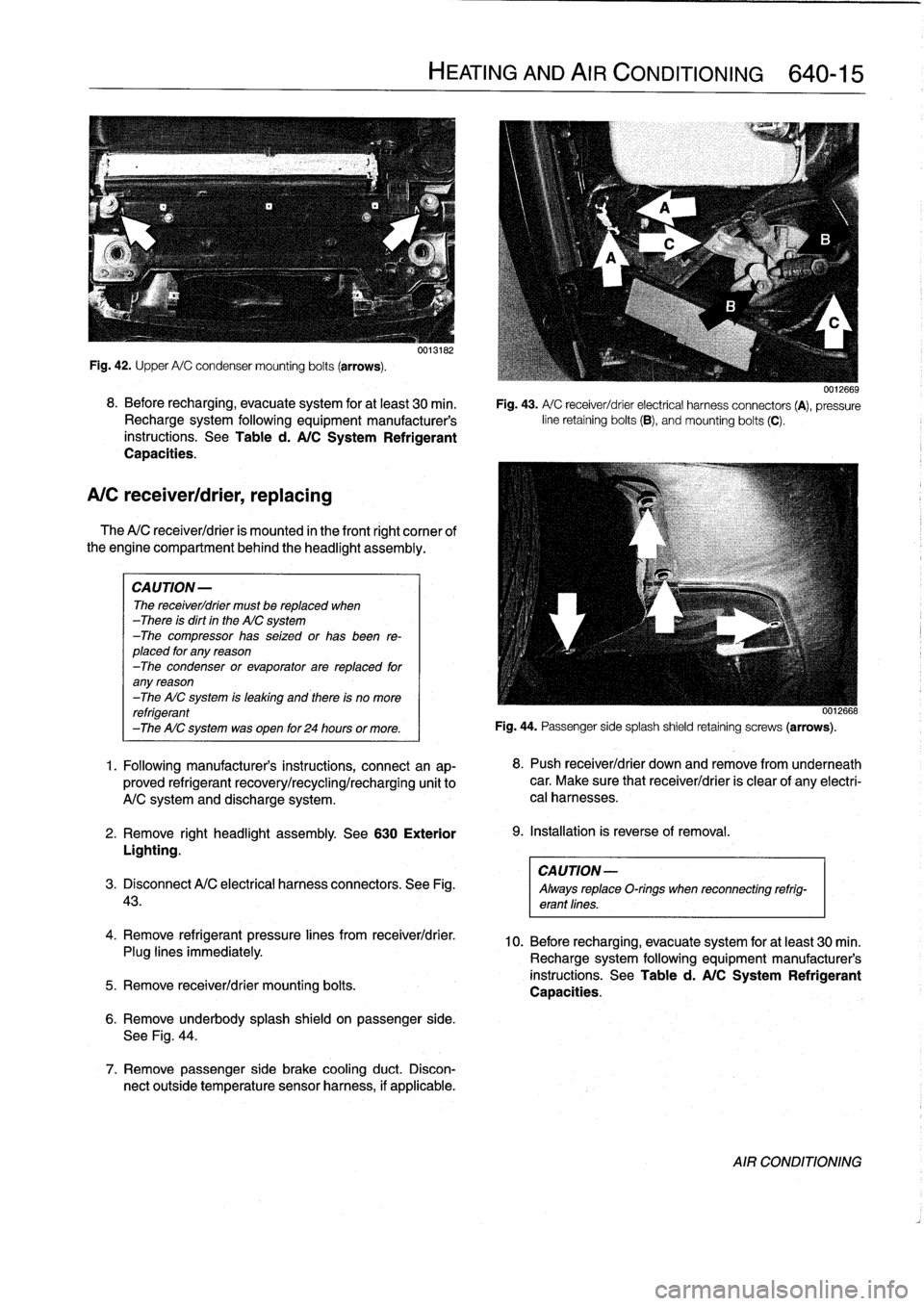

Fig

.

41

.

A/

C

flange

bolts

at

condenser

(arrows)

.

5

.

Remove

condenser

mounting

bolts

from

frontradiator

support

.

See

Fig

.

42

.

6

.

Lift

up

condenser

to

disengage

from

lower

mounts

and

remove

from

below

.

7

.

Installation

is

reverse

of

removal

.

CA

UTION-

"

Always

replace

O-rings

when

reconnecting

re-

frigerant

fines

.

"

When

installing

a

new

condenser

always

replace

receiverldrier

unit

.

Page 461 of 759

Fig

.

42

.

Upper

A/C

condensermounting

bolts

(arrows)

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

A/C

receiver/drier,

replacing

The

A/C

receiver/drier

is

mounted

in

the

front

right

cornee

of

the

engine

compartment

behind

the

headlight

assembly

.

CAUTION-

The

receiver/drier

must

be

replaced

when

-There

is

dirt

in

the

AIC

system

-The

compressor

has

seized

or

has

been

re-

placed

for

any

reason

-The

condenser

or

evaporator

are

replaced

for

any

reason

-The

AIC

system

is

leaking

and

there

is

no

more

refrigerant

-The

AIC

system

was

open

for

24

hours

or

more

.

1

.

Following

manufacturer's

instructions,

connectan

ap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

right

headlight

assembly

.

See

630

Exterior

Lighting

.

CAUTION-

3

.

Disconnect

A/C

electrical

harness

connectors

.

See

Fig

.

Always

replaceO-rings

when

reconnecting

refrig-

43

.

erant

lines

.

4

.

Remove

refrigerant

pressure

lines

from

receiver/drier

.

Plug

lines

immediately

.

5

.

Remove

receiver/drier

mounting

bolts

.

0013182

6

.

Remove

underbody

splash

shield

on

passenger

side

.

See

Fig

.

44

.

7

.

Remove

passenger

side

brake

cooling

duct

.

Discon-

nect

outside

temperature

sensor

harness,

if

applicable

.

HEATING

AND

AIR

CONDITIONING

640-15

0012669

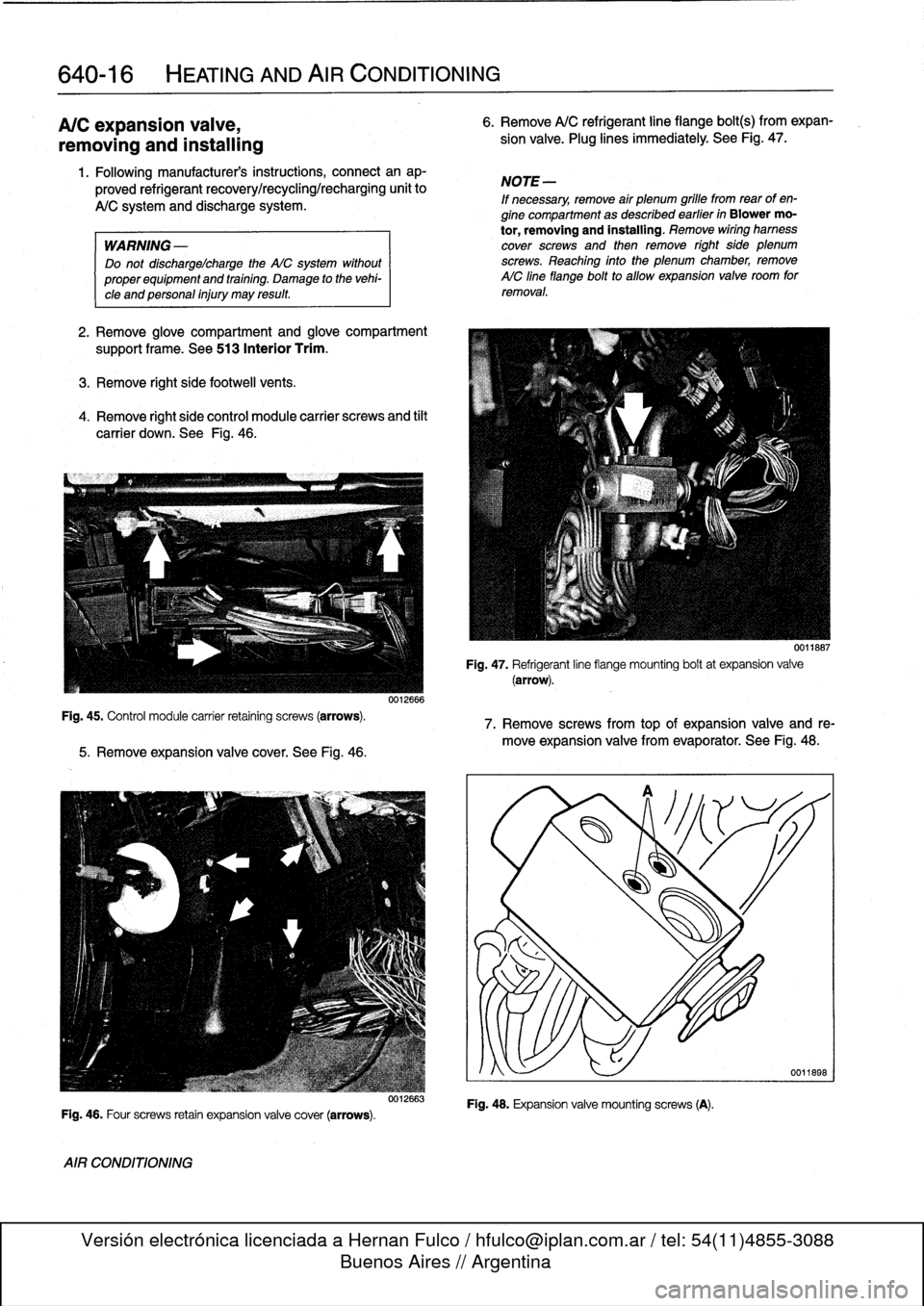

Fig

.

43

.

A/

C

receiver/drier

electrical

harness

connectors

(A),

pressure

line

retaining

bolts

(B),

andmounting

bolts

(C)

.

0012668

Fig

.

44

.

Passenger

sidesplash

shield

retaining

screws

(arrows)

.

8

.

Push

receiver/drier

down

andremove

from

underneath

car

.

Make

sure

that

receiver/drier

is

clear

of

any

electri-

cal

harnesses

.

9

.

Installation

is

reverse

of

removal

.

10

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

AIR

CONDITIONING

Page 462 of 759

640-16

HEATING

AND

AIR

CONDITIONING

A/C

expansion

valve,

removing

and

installing

Fig

.

45

.

Control

module

carrier

retaining

screws

(arrows)

.

1

.

Following

manufacturers

instructions,

connectanap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

WARNING

-

Do

not

discharge%harge

the

WC

system

without

properequipmentand

training

.

Damage

to

the

vehi-

cle

and

personal

injury

may

result

.

2

.

Remove

glove

compartment

and

glove

compartment

support

frame

.

See513

Interior

Trim

.

3

.

Remove

right

side

footwell

vents

.

4

.

Remove

right

side

control

module

carrier

screws

and

tilt

carrier

down

.

See

Fig

.

46

.

5

.

Remove

expansion

valve

cover

.

See

Fig

.

46

.

Fig

.

46

.

Four

screws

retain

expansion

valve

cover

(arrows)

.

AIR

CONDITIONING

0012666

0012663

6

.

Remove

A/C

refrigerant

line

fiange

bolt(s)

from

expan-

sion

valve

.

Plug

lines

immediately

.

See

Fig

.

47

.

NOTE

-

If

necessary,

remove

air

plenum

grille

fromrear

of

en-

gine

compartment

as

described

earlier

in

Blower

mo-

tor,

removing

and

installing

.

Remove

wiring

hamess

cover

screws

and

then

remove

right

side

plenum

screws

.

Reaching

finto

the

plenum

chamber,

remove

AIC

fine

flange

bolt

to

allow

expansion

valve

room

for

removal

.

Fig

.

47

.

Refrigerant

line

fiange

mounting

boltat

expansion

valve(arrow)

.

7

.

Remove

screws

from

top

of

expansion

valve

and

re-

move

expansion

valve

from

evaporator

.

See

Fig

.

48

.

Fig

.

48

.

Expansion

valve

mountingscrews

(A)

.

0011667

Page 477 of 759

721

Airbag

System

(SRS)

Airbag

Systems

.......

.

...

.

.

.

.

.

....

.

.

.

.

721-1

AIRBAG

SENSORS

AND

ELECTRONICS

721-2

SRS

Warning

Light

and

Fault

Display

.

.

.

.

.

..

721-2

Airbagcontact

ring,

replacing

........

.

.

.

.

.

721-3

Airbag

crash

sensor,replacing

..

.

....

.

...

.

721-4

ZAE

control

module,

replacing

.

.

.

.........

721-5

GENERAL

This

repair

group

covers

only

removal

and

installation

of

air-

bag

components

.

Airbag

system

repair

and

fault

diagnosis

is

not

covered

here

.

Diagnostics,

component

testing,

and

airbag

system

repair

should

be

carried

out

by

trained

BMW

service

technicians

.

NOTE-

Special

test

equipment

is

required

to

retrieve

SRS

fault

codes,

diagnose

system

faults,

and

resetltum

off

the

SRS

indicator

light

.

The

SRS

indicator

light

will

remain

on

until

any

problem

has

been

corrected

and

the

fault

memory

has

been

cleared

.

When

servicing

cars

equipped

with

SRS,

the

precautions

on

this

page

mustbeobserved

to

prevent

personal

injury

.

Airbag

Systems

The

airbag

system

installed

on

E36

cars

through

the

1993

model

year

consisted

of

a

single

airbag

in

the

steering

wheel

.

This

systemcan

be

identified

by

the

orange

crash

sensors

lo-

cated

on

the

front

wheel

wells

and

the

absence

of

a

passenger

side

airbag

.

The

ZAE

airbag

system,

starting

in

model

year

1994

(pro-

duction

date9/93

and

later),

provides

both

a

driver

side

and

a

passenger

sideairbag

.

On

ZAE

vehicles,

the

crash

sensorsare

integrated

into

the

airbag

control

module,

located

under

thecenter

of

the

rear

seat

.

The

ZAE

control

module

triggers

deployment

of

the

airbags

When

it

sensos

the

vehicle

deceler-

ating

at

a

rate

equivalent

to

a

head-on

collisionof

at

least

13

mph

(18

km/h)

.

In

some

1997

4-door

models

and

all

1998

models,

side-impact

airbags

were

installed

in

the

front

doors

.

The

airbag

units

are

mounted

behindthe

door

trim

panels

.

Caution

mustbeused

when

working

on

vehicle

systems

in

the

proximity

of

air

bags,

such

as

the

steering

column,

the

dashboard,

or

the

doors

.

AIRBAG

SYSTEM

(SRS)

721-1

GENERAL

.

.

.

.

.

.

.

.

.

.

.......

.

......

.

.

.

.

721-1

Front

side-impact

airbag

crash

sensor,

removing

and

installing

....

.

.....

.

.....

.

721-5

AIRBAGS

..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

721-5

Driver

side

airbag,

removing

and

installing

.

.

.

721-5

Passenger

side

airbag,

removing

and

installing

..............

.

.

.721-6

Front

side-impact

airbag,

removing

and

installing

.

.

.

.

.

.

.

.

.

.

......

.721-7

WARNING

-

"

Airbag(s)

are

inflated

byan

explosive

device

.

Handled

improperly

or

without

adequate

safe-

guards,

the

System

can

be

very

dangerous

.

Spe-

cial

precautions

must

be

observed

prior

to

any

work

ator

near

the

driverside

airbag,

the

passen-

ger

side

airbag

(where

applicable)

or

the

side-im-

pact

airbags

(where

applicable)

.

"

The

airbag

is

a

vehicle

safety

system

.

Serious

in-

jury

may

result

if

System

service

is

attempted

by

persons

unfamiliar

with

the

BMW

SRS

and

its

ap-

proved

service

procedures

.

BMW

advises

that

all

inspection

and

service

be

performed

by

an

autho-

rized

BMW

dealer

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

()

battery

terminal

with

an

insulator

before

startingdiagnostic,

troubleshooting

or

service

worknot

associated

with

SRS,

and

before

doing

any

welding

on

the

car

.

"

If

an

airbag

has

been

activated

due

to

an

acci-dent,

BMW

specifies

that

SRS

components

be

replaced

.

For

more

information

on

post-collision

SRS

service,

see

an

authorized

BMW

dealer

.

"

Do

not

allow

the

airbag

unit

to

come

in

contact

with

cleaning

solutions

orgrease

.

Never

subject

an

airbag

unit

to

temperatures

aboye

212°F

(100°C)

.

When

reconnecting

the

battery,

no

per-

son

should

be

inside

the

vehicle

.

"

Always

place

an

airbag

unitthat

has

been

re-

moved

from

its

packaging

with

the

padded

sidefacing

upward

.

Do

not

leave

an

airbag

unlt

unat-

tended

.

"

!f

the

airbag

unit

or

airbag

control

modulehas

been

dropped

froma

height

of

!

1

2

meter

(1

Y2

ft.)

ormore,

theairbag

unit

should

not

be

installed

.

Aírbag

system

components

are

shown

in

Fig

.

1.

GENERAL

Page 485 of 759

GENERAL

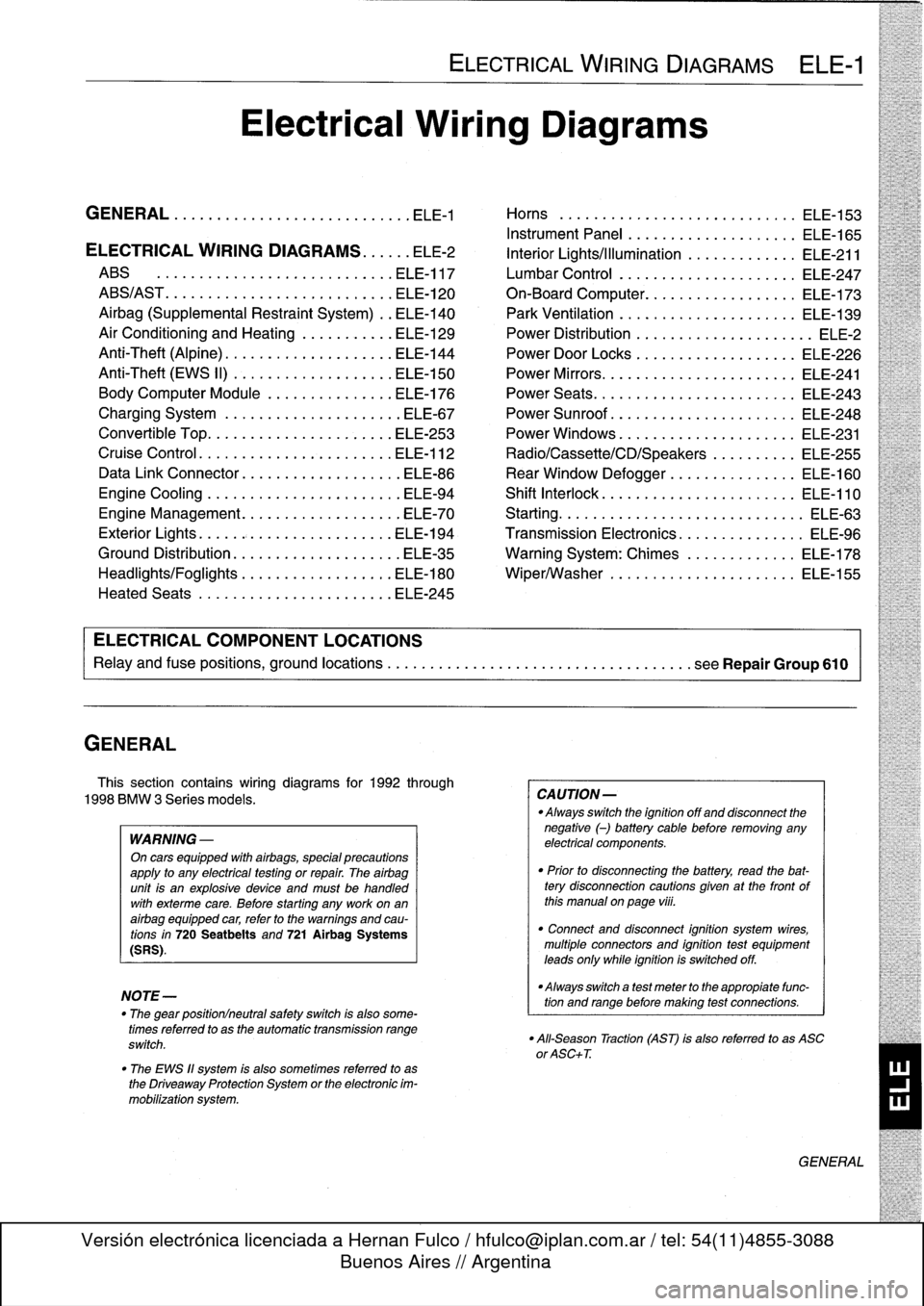

This

section

contains

wiring

diagrams

for

1992

through

1998

BMW

3

Series

models

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautions

apply

to

any

electrical

testing

or

repair

.

The

airbag

unit

is

an

explosive

device

and

must

be

handled

with

exterme

care

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

warnings

and

cau-

tions

in

720

Seatbelts

and

721

Airbag

Systems

(SRS)

.

NOTE-

The

"

gear

position/neutral

safetyswitch

is

also

some-

timesreferred

to

as

the

automatic

transmission

range

switch

.

"

The

EWS

11

system

is

also

sometimes

referred

to

as

the

Driveaway

Protection

System

or

the

electronic

im-

mobilization

system

.

ELECTRICAL

WIRING

DIAGRAMS

ELE-1

Electrical

Wiring

Diagrams

GENERAL

.

.

.

.

.

.

.

.

.

................

.

.

.

ELE-1

Horns

.....

.

.....

.

.

.

....

.

.

.

.

.

...

.

.

ELE-153

Instrument

Panel

.

.

.

.

.

.

..............

ELE-165

ELECTRICAL

WIRING

DIAGRAMS

...

.

.

.

ELE-2

Interior

Lights/Illumination

.............

ELE-211

ABS

..............

.

.

.

.....

.

.....

ELE-117

Lumbar

Control

.

....................

ELE-247

ABS/AST

.............

.

.

.

...

.

.

.

.....

ELE-120

On-Board

Computer

..................

ELE-173

Airbag

(Supplemental

Restraint

System)

..

ELE-140

Park

Ventilation

.

.

.

...........

.

...

.

..

ELE-139

Air

Conditioning

and

Heating

.

.

.

.

.

.

.....

ELE-129

Power

Distribution

......

.

...

.

.

.

.

.

.

.

...

.

ELE-2

Anti-Theft

(Alpine)

..........

.

.

.

...

.

...

ELE-144

Power

Door

Locks

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-226

Anti-Theft

(EWS

II)

.

........

.

.

.

...

.

...

ELE-150

Power

Mirrors

...

.

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-241

Body

Computer

Module

.....

.

.....

.

...

ELE-176

Power

Seats

......

.

......

.

.

.

...

.

.

.

..

ELE-243

Charging

System

.

.

................

.

.

.

ELE-67

Power

Sunroof

.

.

.

.

.

.

.

...............

ELE-248

Convertible

Top

.

.

.

.

................

.

.

ELE-253

Power

Windows

.

.

.

.

.

.

.....

.

.........

ELE-231

Cruise

Control

..

.

.

.

...........

.

....

.

.

ELE-112

Radio/Cassette/CD/Speakers

..........

ELE-255

Data

Link

Connector

................

.

.

.

ELE-86

Rear

Window

Defogger

...............

ELE-160

Engine

Cooling

.......

.

.......

.

....

.

.

.

ELE-94

Shift

Interlock

.

.

.

.

.

.

.

.

...............

ELE-110

Engine

Management

...

.

.......

.

....

.

.

.

ELE-70

Starting

....

.

.

.

.

.

...

.

................

ELE-63

Exterior

Lights

........

.

.

.

.

.

.

.

.

.

......

ELE-194

Transmission

Electronics

.

..............

ELE-96

Ground

Distribution

....

.

.

.

.

.

.

.

.

.

.......

ELE-35

Warning

System

:

Chimes

.............

ELE-178

Headlights/Foglights

...

.

.

.

.

.

.

.

.

.

......

ELE-180

Wiper/Washer

.

.....

.

...............

ELE-155

Heated

Seats

........

.

.

.

.

.

.

.

.

.

......

ELE-245

ELECTRICAL

COMPONENT

LOCATIONS

Relayand

fuse

positions,

ground

locations

...........

.

.

.

.

.

.

.

.

.

................

seeRepair

Group

610

CAUTION-

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cablebefore

removing

any

electrical

components

.

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors

and

ignition

test

equipment

leads

only

while

ignition

is

switched

off

.

-Always

switch

a

test

meter

to

the

appropiate

func-

tion

and

range

before

making

test

connections

.

"

All-Season

Traction

(AST)

is

also

referred

to

as

ASC

or

ASC+T

.

GENERAL

Page 529 of 759

890fi9

INTER-

WASHER

I

I

MEDIATE

I

I

FLUID

I

IPRESSUREI

I

-

ILEVEL

I

(SWITCH

I

-

I

SWITCH

--

(1997)

'3

HEADLIGHT/

RIGHT

I

RIGHT_

_

_

_

I

-

LEFT

I

I

I

FOG

LIGHT

I

I

I

(

)

FRONT

I

I

I

TEMPERATURE

I

(

AUXILIARY

I

'

LEFT

I

(

)

FRONT

I

I

-

I

I

RIGHT

HIGH

I

-

TURN

I

SWITCH

WASHER

i

(

LIGHT

BEAM

I

LIGHT

I

I

I

fOGH7

I

(FANMOTOR

HIGH

i

I

I

II

(

)

I

i

IBEAM

LIGHT

I

,HORN

-

LEFT

LIJ

PUMP

L-

--

---I

-

LIGHT

'~

I

I

LIGHT

1----

---1

'~

L

GHT

'

1T

1Y

T

IT

T

-T

2

WASHER

RIGHT

PRESSURE

I

(PUMP

I

(LOW

I

(

SWITCH

I

(

(1996)

I

I

I

BEAM

I

I

(

(1996)

I

-

I

(CANADA)

I

_(LIGHT

I

_I

z

T

I

_

RIGHT

I

I

)

PARK

I

I

_

PARK

I

I

-

LIGHT

I

I

-

LIGHT

I

1

G302

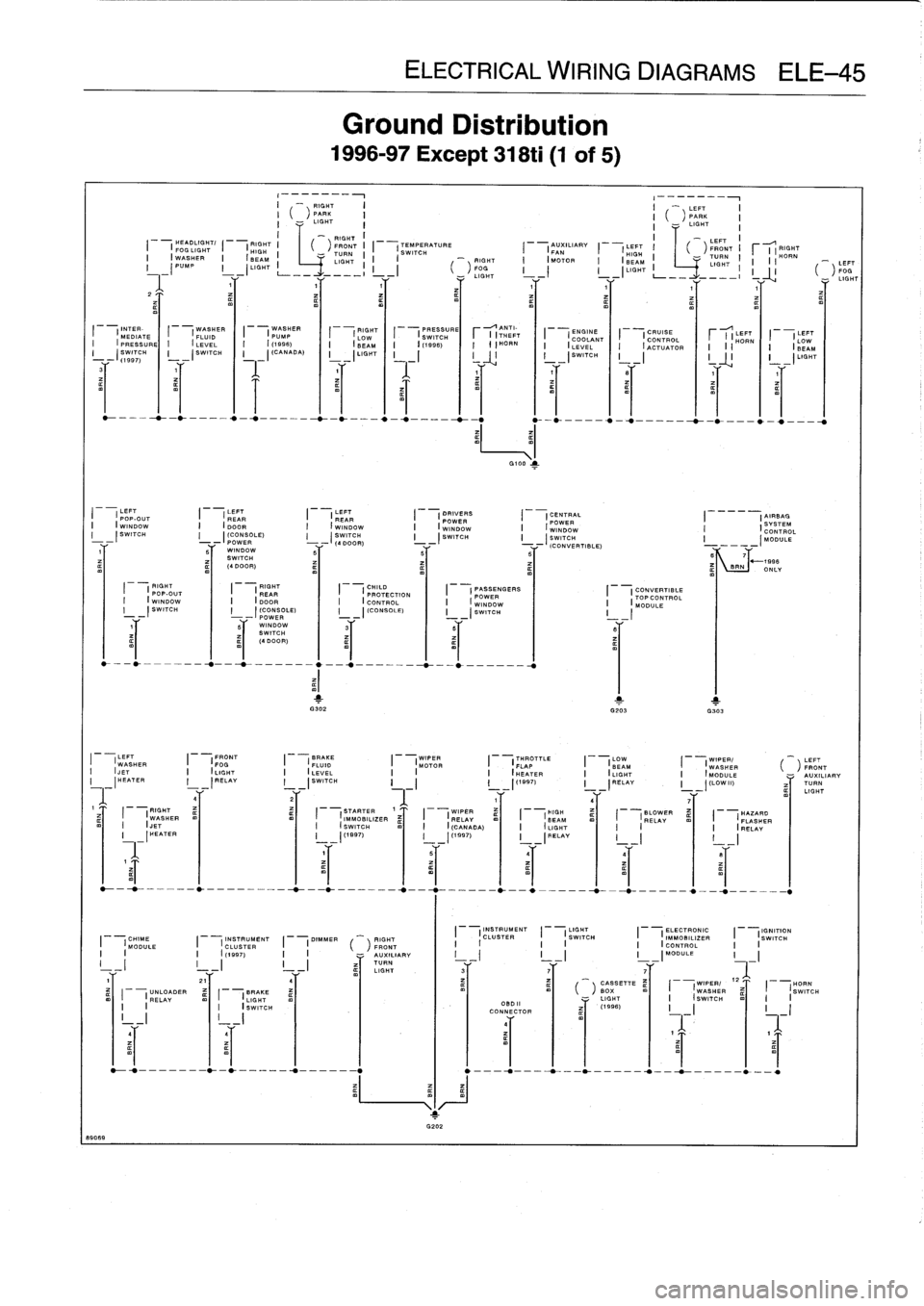

Ground

Distribution

1996-97

Except

318ti

(1

of

5)

LEFT

LEFT

LEFT

I

(

POP-OUT

I

(

REAR

I

(REAR

I

RIVERS

I

(CENTRAL

AIRBAG

I

(WINDOW

I

(DOOR

I

(WINDOW

I

(

POWER

POWER

I

(

SYSTEM

I

SWITCH

I

(CONSOLE)

SWITCH

WINDOW

I

IWINDOW

I

(CONTROL

-

POWER

I

SWITCH

v

I

v

I

I

-I(

I

-(SWITCH

-_(

(CONVERTIBLE)

I

MODULE

ELECTRICAL

WIRING

DIAGRAMS

ELE-45

WINDOW

SWITCH

T

/

6

7

f-1996

(6pDOE)

¢~

rtl

Qr

QBFN

ONLY

RIGHT

I

RIGHT

CHILD

I

(

POP-OUT

(

REAR

I

(

PROTECTION

I

-

1

PASSENGERS

I

(

CONVERTIBLE

I

(WINDOW

I

(DOOR

CONTROL'WINDOW

SWITCH

I

ITOPCONTROL

((CONSOLE)

I

_

(

(CONSOLE)

-I

-(

I

S,

To.

MODULE

I

POWER6YWINDOW

6Y

I

I

SWITCH

(4

DOOR)

'

LEFT

FRONT

BRAKE

WIPER

THROTTLE

LOW

WIPER/

LEFT

I

(

WASHER

I

(

FOG

I

(

FLUID

I

(

MOTOR

I

:THROTTLE

I

IBEAM

I

I

WgSHER

(

)

FRONT

I

_(JET

I

(LIGHT

I

ILEVEL

I

I

I

(HEATER

I

(LIGHT

I

(MODULE

AVXILIAflV

I

(HEATER

I

-

IRELAY

I

-(SWITCH_

I

_II

-((1897)

I

-IRELAY

L-1

(LOWIV

TURN

LIGHT

A

2

1

t

7I

RIGHT

STARTER

~

WIPER

HIGH

BLOWER

HAZARD

I

(WASHER

I

IIMMOBILIZER

rtI

(

RELAY

I

IBEAM

II

RELAY

I(

FLASHER

I

(JET

I

(SWITCH

I

((CANADA)

m

I

(LIGHT

II

I

IRELAY

I

(HEATER

I

-((1997)

I

_

((1997)

I

_IRELAV

I

_I

I

-I

1/

t

G202

-

ANTI-

I

(THEFT

I

(

MORN

I

ENGINECRUISE

LEFTLEFT

I

(

COOLANT

I

(CONTROL

I

-

(

MORN

I

(

LOW

I

ILEVEL

I

(ACTUATOR

I

II

I

ISEA.

I

(SWITCH

I

I

I_

_

I

(LIGHT

tY

BY

,Y

,Y

G100

1

G203

j

G303

INSTRUMENT

LIGHT

ELECTRONIC

IGNITION

CHIME

INSTRUMENT

DIMMER

RIGHT

I(

CLUSTER

I

(

SWITCH

I

I

IMMOBILI2ER

I(

SWITCH

I

(

MODULE

I

(

CLUSTER

I

I

(

_

)

FRONT

I

I

I

I

I

(CONTROL

I

II

I

I

(

(1997)

I

I

AUXILIARY

MODULE

I

II

I

I

-I_

_

_

_

III

I

I

I

I

T

Y

Y

y-

L

U

IG

R

HNT

3

7

7

CASSETTE

12

WIPER/

HORN

UNLOADER

BRAKE

BOX

I(

WASHER

I(

SWITCH

II

RELAV

I

(LIGHT

q

LIGHT

I

(SWITCH

I

I

OBDII

II

I

II

I

I

SWITCH

Do

NNNECToR(199fi)

I

,Y

I

F

Y

I

,

.~

.

,

J

.

Page 534 of 759

ELE-50

ELECTRICAL

WIRING

DIAGRAMS

I-

____RIGHT

~LEFT

I

RIGHT

(HEADLAMP

I

LEFT

,HEADLAMP

i

(

)

PARK

I

I

(

)

PARK

i

I

-

LIGHT

I

I

Y

LIGHT

I

LEFT

LEFT

DRIVER'S

CENTRAL

RIGHT

SLIP

I

REAR

I

REAR

I

(

POWER

I(

POWER

I

(

FRONT

CONTROL

I

POWER

I

,POWER

I

(WINDOW

I

(WINDOW

I

(SPEED

I

(MODULE

_

_,

WINDOW

I

_,

WINDOW

I

(

SWITCH

I

(

SWITCH

I

(

SENSOR

I

-

-

j

(WIASC)

SWITCH

SWITCH

``

77''q

(4AD00R)

0

(ATCONSOLE)

4

q

T

1

1I

I

3T

/

19T

/

-323

.328

.

M2

(AT

DOOR/

Z

3

7`

21

011

31

19/x"

318

10441

2

-

RIGHT

I

I

_

1--HEADLIGHT/

III

I

(

)FRONT

(

HIGH

I

IHORN

WASHE

HT

HIGH

SWITCH

TURN

II

,

R

I

(

BEAM

,

"-'

RIGHT

LIGHT

I

,

BEAM

I

,I

LEFT

LIGHT

I

I

(

PUMP

LIGHT_

I_

_

I

(

)

FOG

I

I

I

(

LIGHT

(

)FOG

--

_

I

T

LIGHT

L---

-I

LIGHT

1

2

1

1

1

T

I

INTER-

'

WASHER

I

RIGHT

I

MEDIATE

I

FLUID

I

LOW

IPRESSURE

I

I

LEVEL

I

I

(BEAM

I

-

,SWITCH

II

-

,SWITCH

I

J

-

(LIGHT

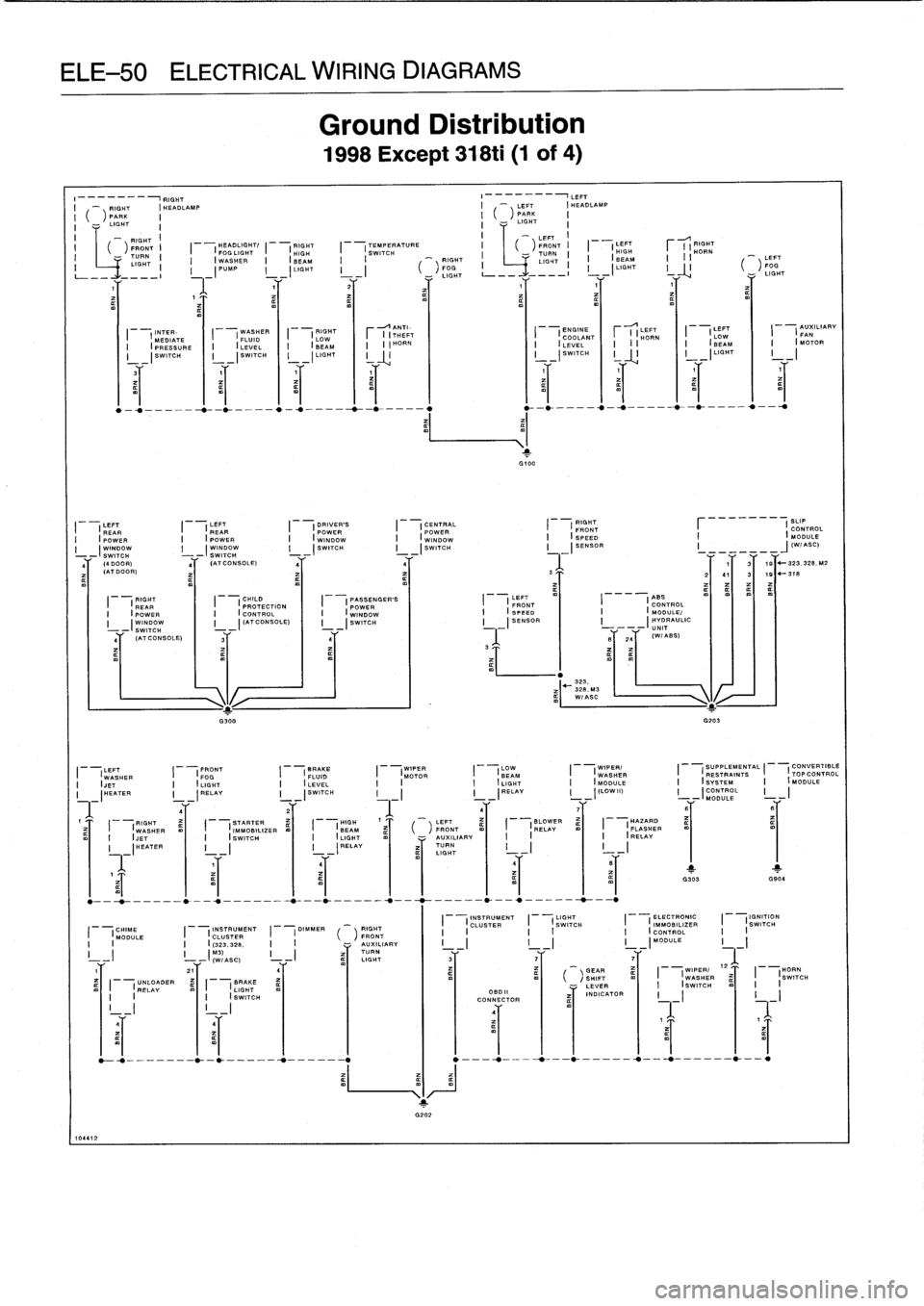

Ground

Distribution

1998Except

318ti

(1

of

4)

~

ANTI-

II

THEFT

I

I'

HORN

I

I

ENGINE

LEFT

I

COOLANTHORN

I

(

LEVEL

I

,

I

I

_I

SWITCH

I

¢t

¢~

LEFT

I

ABS

FRONT

I

CONTROL

I

I

SPEED

I

I

MODULE/

I

_

_I

SENSOR

I

I

HYDRAULIC

UNIT

(ATCONSOLE)

3'f

I

qT

2

(WIASS)

1

T

RIGHT

CHILD

I

I

REAR

I

I

PROTECTION

I

POWER

I

(CONTROL

I

,WINDOW

I

_I

(AT

CONSOLE)

--

SWITCH

G300

II

PASSENGER'S

POWER

I

I

WINDOW

I

_I

SWITCH

I

323,

1-

328,

M3

WIASC

I

I

LEFT

LO

W

I

(BEAM

I

-

(LIGHT

G203

LEFT

FRONT

BRAKE

WIPER

LOW

WIPER,

SUPPLEMENTAL

CONVERTIBLE

IWgSHER

I

FOG

,

FLUID

I

(

MOTOR

I(

BEAM

I

(WASHER

I

(

RESTRAINTS

I

ITOPCONTROL

I

,JET

I

(LIGHT

I

(LEVEL

I

I

,

(LIGHT

I

(MODULE

I

IBYSTEM

I

(MODULE

I

(HEATER__

I_

__IRELAV

I

-(SWITCH

I

I

I

-IRELAV

I

-

I(LOWIU

I

_IMODULEL

-

q

2

_

q

_

l

1

_

I

pIGHT

(STARTER

(HIGH

1

LEFT

(BLOWER

I

IHA2ARD

I

WASHER

I

IMMOBILIZER

m

I

BEAM

(

FRONT

(

RELAY

FLASHER

JET

I

SWITCH

,

,LIGHT

"'

AUXILIARY

II

I

IRELAV

I

-

,HEATER

TURN

I

-

I

I

-IRELAV

dl

IGHT

J

.

G904

INSTRUMENT

LIGHT

ELECTRONIC

IGNITION

CHIME

INSTRUMENT

DIMMER

RIGHT

I

(

CLUSTER

I

(

SWITCH

I

IIMMOaILIZER__

I(

SWITCH

I

I

MODULE

(CLUSTER

I

,

)

FRONT

I

I

I

I

I

CONTROL

I

I

II(323,328,

I

I

AUXILIARY

I

I

I

I

I

MODULE

iII

-

_

-I

I

-

-

-I

ff

TURN

(WIASC)

LIGHT

3T

7T

7

'WIPER/

12

,HORN

I

WASHER

I

--

SWITCH

,SWITCH

I

III

m

I

_I

UNLAY

OADER

I

BRAKE

I

(

REL

m

I

(

LIGHT

I

_I

I

I

SWITCH

I

_I

!

ogoHCONNECTOR

GEAR(

)

SHIFT

LEVER

INDICATOR

AU%ILIARV

I

FAN

I

I

MOTOR

Page 557 of 759

8727

6

GRN/VIO

BRNIGRN

RED/WHT

RED/WH

T

RED/WHTRED/WHT

REDRED

W/EGS

FRONT

POWER

DISTRIBUTION

BOX

I

OXYGENSENSOR

RELAY

I

HEATED

OXYGEN

CAMSHAFT

CRANKSHAFT

SENSOR

POSITION

POSITION/

SENSORRPMSENSOR

1S)

X199]9

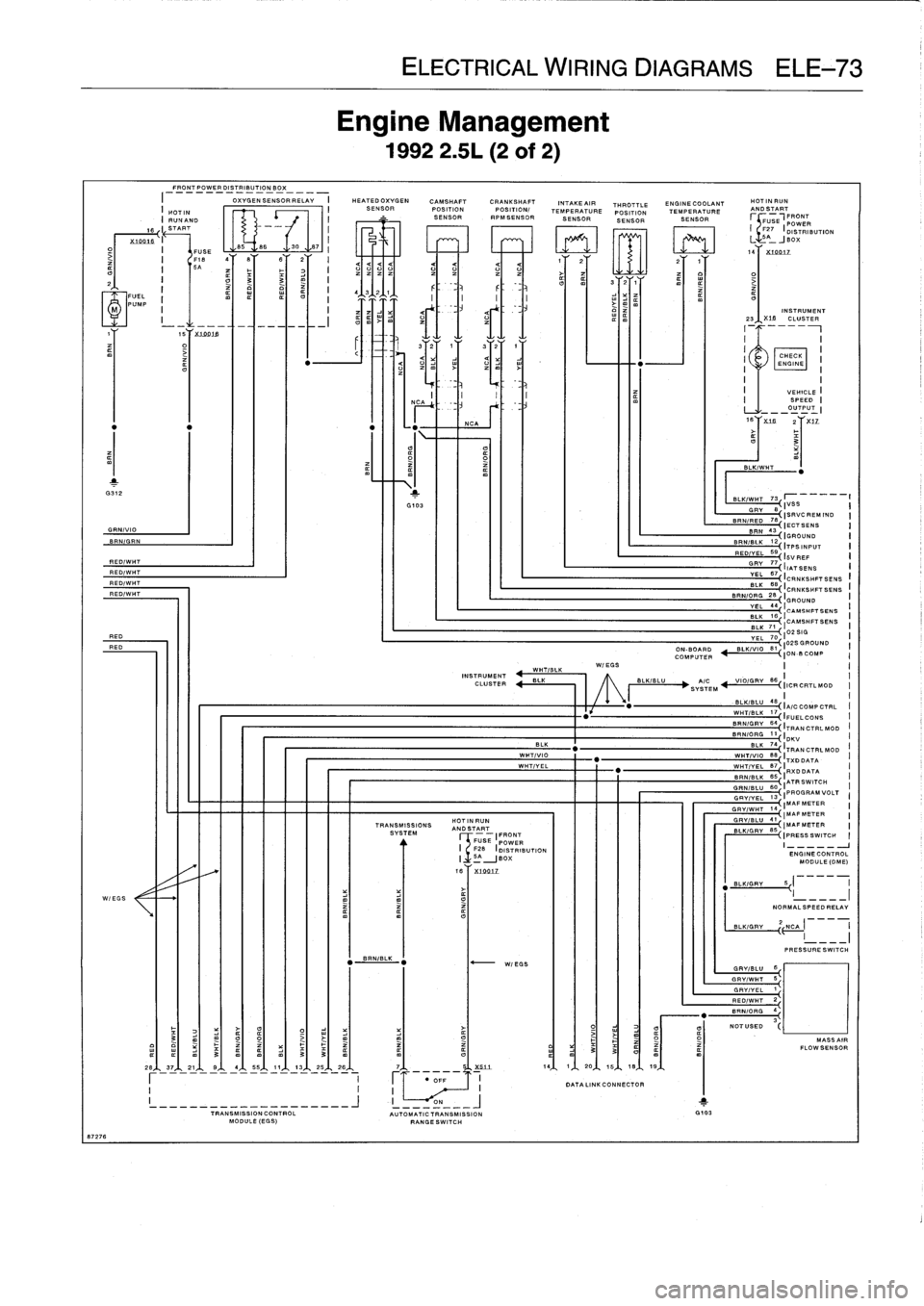

ELECTRICAL

WIRING

DIAGRAMS

ELE-73

Engine

Management

19922

.511-

(2

of

2)

86

v

30

v

87

I

_

W

[~~j

O

TRANSMISSIONS

SYSTEM

----------

---------

--------

-------

TRANSMISSIONTRANSMISSION

TRANSMISSION

CONTROL

AUTOMATIC

TRANSMISSION

MODULE

(EGS)

RANGE

SW

ITCH

HOT

IN

RUNAND

START

(FRONT

FUSE

pOYfER

I

F28

I

DISTRIBUTION

I

-AJBOX

6Y

X]4

017

INTAKEAIR

THROTTLE

ENGINECOOLANT

TEMPERATURE

POSITION

TEMPERATURE

SENSORSENSORSENSOR

O

j

1I

20j1Sj18~

10

DATA

LINK

CONNECTOR

YEL

70

I

ON-BOARD

BLK/VIO

81

1023

GROUNDCOMPUTER

4

ION-BCOMP

A/C

L~

VIO/GRY

86!

I

SYSTEM

IICRCRTLMOD

NOTUSED

HOTINRUNANOSTART

F"~

;/~

FRONT

4/F2SE

POWER

I

F7

(DISTRIBUTION

L~

-

JBOX

INSTRUMENT

23X7

.6

CLUSTER

~/

/

/p~

\

\

/

CHECK

f

\di/

ENGINE

I

BLK/WHT

GRV/BLU

B

GRV/WHT

6

GRV/YEL

1

BLK/WHT

73

r

IVSS

GRY

8

~

ED7a

ISRVCREMINO

BRN/

~JECTSENS

BRN

3

~IGROUND

BR"/81K

12

~1TPSINPUT

RED

/V

EL

59~

ISVREF

DR

IIATSENS

YEL

67

ICRNKSHFTSENS

BL

I

CRNKSHFTSENSBRN

/

RG

28

~

I

GROUND

EL

ICAMSHFTSENS

-

ICAMSHFTSENS

BL

0251G

71,

BLK/BLU

48,

I

IA/C

COMPCTRL

WHT/BLK

17

BRNI

G

R

LCONS

NIG

JV

64

~

ITRAN

CTRL

MOD

BRN/ORG

11,

I

DKV

GRV/BLU

41

-j

'

-~

.AFMETER

I

BLKKIG~y

88

IPRESSSWITCH

I

END

NE

CONTROL

MODULE

(OME)

NOFMALSPEEDRELAY

BLKBLK/GRV

z

N~I

I

I

PRESSURE

S

W

ITCH

(-__----

MASS

AIR

FLOWSENSOR

Page 641 of 759

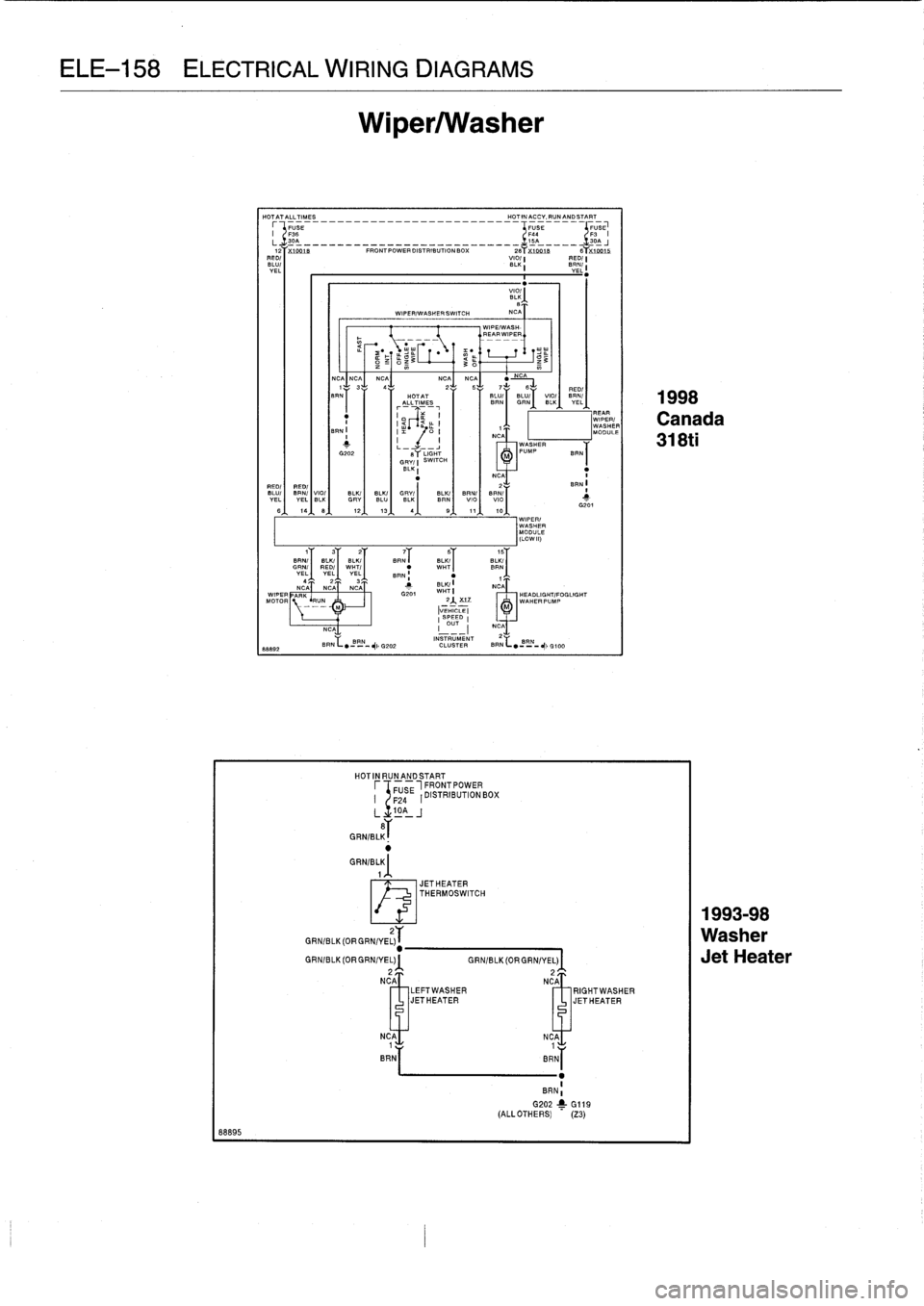

ELE-158

ELECTRICAL

WIRING

DIAGRAMS

88895

Wiper/Washer

HOTATALLTIMES

HOT

IN

ACCY,

RUNAND

START

F

~

FUSE

us....

-------

-

-

I

,

F"

-

L

,

lolA

...

.

.....

.

....

.

..

.

....

.

...

11SA

-----

-

~-

j11

1111TI-1111IT-U-N

.

.

.

~

.Y~

6y~

Of

RED/BRNI

:

YEL

Y

.L

88892

NCAINCAI

NCAI

NAl

NCA

-

S

2

7~

'

REDSRM

HOTAT

SLUI

IL

.V

-RN

I

ALLTIMES

,

RN

RN

'

t

.1,0,11

y

E

Ll

1

1998

I

I

REAR

W11-1

%

.FdF]dUd

Q

WASHER

SRM

:

'

5A

:

MODULE

1

1

1

21

Qfl

[4]WASHIR

PUM

G202

Sy

LIGHT

GR~

I

SWITCH

R'

.1

REOfBLUf

-N/

.

.

.

11

.1-K/1

-11

GRY11

.1-N/1

R

.11

R

'

N2

1t

8R'

YEL

YEL

R

--

RN

vlo

C

G2~1

D

I

"I

S

12

1S

4

11

1

.

1T

"

2

IT

1

1'Nl

LKI

K~

RN

LKT

LIQ

OR

RE

WH

I

BRN

y

I

YE

2L0

YELI

RN

:

I

NCAI

NCA

NCAI

-

BLKI

N

A

IN,

WHI

~

-

EMK

-

Ej

moT,

Sp

NCAl

i

'T

i

-

INST-RUMENT

'

L

ST'

G202

CLUSTER

RN

-

+

G

1

oo

HOT

IN

RUNAND

START

IUSE

FRONT

POWER

F24

DISTRIBUTION

BOX

L

10A

j

8

T

GRNIBLK

GRN/BLKI

1

131-~,

I

I

L-

.

H

*1

JETHEATER

THERMOSWITCH

CA

WIPERI

WASHER

MoDU

E(LCwII)

HEADLI

HTIFOGLIGHT

WAHERPUMP

vlof

PERfWASHFR

SWITCH

NCA

WIPEI

ASH

REAR

IPER

GRN[BLK(ORGRNlYEL)T

GRNIBLK(ORGRN/YELGRN/BLK(ORGRNly

2

2

N$

NIAT

RIGHTWASHER

JETHEATER

fUJETHEATER

LEFTWASHER

BRN,

G202

-97

3119

(ALLOTHERS)

(Z3)

1993-98

Washer

Jet

Heater

Page 751 of 759

2

INDEX

Brakes

(cont

.)

pressure

bleeding

brakes

(except

cars

wíth

AST)

340-3

troubleshooting

340-1

Brushes,

alternator

See

Battery,

starter,

alternator

Bulbs

See

Exterior

lighting

See

also

Instruments

Bumpers

See

Exterior

trim,

bumpers

C

CamberSee

Steering

and

wheel

alignment

Camshaft

See

Cylinder

head

and

valvetrain

Camshaft

position

sensor

See

Ignition

system

Camshaft

timing

chain

general

information

117-1

camshaft

timingchain,

4-cylinder

117-

2

camshaft

timing

chains,6-cylinder

117-6

camshaft

timing

chain,

removing

(4-cylinder

engines)

117-2

camshaft

timing

chains,

removing

(6-cylinder

engines)

117-7vanos

(variable

valve

timing)

117-14

control

unit,

removing

117-16system

operation,

testing

117-14

Caster

See

Steering

andwheel

alignment

Catalytic

convertor

See

Exhaustsystem

Cautions

viü

Center

bearing

See

Driveshaft

Center

console

See

interior

trim

Central

body

electronics

(ZKE

IV)

515-8

Central

locking

system

(ZVM)

515-7

Centrallocking

and

anti-theft

general

information

515-1

door

handles

and

Iocks

515-1

door

striker,

replacing

515-6

front

door

handle,

removing/

installing

515-3

front

door

lock,

removing/installing

515-1

rear

door

handle,

removing/installing

515-5

rear

door

lock,

removing/installing

515-4

EWS

II

control

module,

replacing

515-10

EWS

II

ring

antenna,

replacing

515-10

EWS

II

transmitter/receiver

module,

replacing

515-11

locking

system

and

electronic

immobilization

515-7

luggage

compartment

locking

actuator,

removing/installing

515-6

Clutch

general

information210-1

clutch

hydraulic

system,

bleeding

and

flushing

210-2

clutch,

inspecting

and

installing

210-5

clutch

master

cylinder,

replacing

210-2

clutch,

removing

210-4

clutch

slave

cylinder,

replacing

210-3

transmission

pilot

bearing,

replacing

210-6

Clutch

fluid

See

Maintenance

program

Coil

See

Ignition

system

Coilspring

See

Rear

suspension

Component

locations

See

Electrical

component

locations

Compressor

See

Air

conditioning

Compressor

clutch

See

Air

conditioning

Condenser

See

Air

conditioningControl

arms

See

Front

suspension

See

also

Rear

suspension

Convertible

top

general

information

541-1

manual

convertible

top

541-1

lid

release

mechanism

541-2

replacing

541-2

visor

latch

541-1

visor

latch

píate

541-1

power

convertible

top

541-2

drive

motor,

replacing

541-7

emergency

operation

541-7

front

latching

mechanism

541-4

lid

541-9

replacing

541-5

visor

latch

541-4

visor

latch

motor541-5

visor

latch

plate

541-4

rollover

protection

system

541-9

Coolant

(Anti-freeze)

See

Maintenance

program

Coolant

pump

See

Cooling

system

Cooling

system

general

information

170-1

cooling

fan,

replacing

170-8

coolant

pump,

replacing

170-10

coolant

pump

and

thermostat170-1

coolant,

draining/filling

170-5

cooling

fans

170-2

cooling

fan,

testing

170-4

cooling

system

service

170-5

cooling

system,

bleeding

(radiator

with

integral

expansion

tank)

170-6

cooling

system

pressure

test

170-3

electric

cooling

fan,

replacing

170-8

radiator,

removing/installing

170-11

Cooling

system

(cont

.)

radiator

and

expansion

tank

170-1

radiator

service

170-11

temperature

gauge

quick

check170-3

thermostat

quick

check

170-3

thermostat,

replacing

170-9

troubleshooting

170-2

warnings

and

cautions

170-2Crankshaft

position/rpm

sensor

See

Ignition

system

Crash

sensor

See

Airbag

system

(SRS)

CV

joint

See

Maintenance

program

See

also

Rear

suspension

Cylinder

head

and

valvetrain

general

information

116-1

camshaft116-7

camshafts,

removing/installing

(M42

engine)

116-1camshafts,

removing/installing

(M44

engine)

116-3

camshafts,

removing/installing

(6-cylinder

engine)

116-4

cylinder

head,

disassembly/assembly

116-1

cylinder

head

and

valvetrain,

reconditioning

116-7

cylinder

head

116-7

hydraulic

cam

followers,

checking

and

replacing

(M42

and

al]

6-cylinder

engines)

116-9

hydraulic

valve

adjusters,

checking

and

replacing

(M44

Engine)

116-8

valve

guides

116-10

valveseats

116-12

valve

springs

116-12

valve

stem

oil

seals

116-11

valves

116-11

valves,

leak

test

116-11

valves,removing/installing

116-6

Cylinder

head

removal

and

installation

general

information

113-1

cylinder

head,

removing/installing

(4-

cylinder

engine)

113-1

cylinder

head

(6-cylinder

engine),

removing/installing

113-10

Dashboard

See

Interior

trim

Deck

lid

See

Trunk

lid

Defogger

See

Heating

Differential

See

Final

drive

DISA

(dual

resonance

intake

system)

See

Fuel

injection

See

also

Engine-general

DME

(digital

motor

electronics)

See

Ignition

system

See

alsoFuel

injection