dashboard light BMW 325i 1994 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 250 of 759

300-2

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Steering

INTEGRATED

SYSTEMS

The

steering

linkage

connects

the

rack-and-pinion

unit

through

tie

rodsto

the

steering

arms

.

The

tie

rod

ends

allow

the

wheels

to

pivot

and

react

to

suspension

travel

.

Rear

Suspension

The

rear

axle

carrier

is

the

main

mounting

point

for

the

final

drive

housing

and

the

rear

suspension

components

.

Trailing

arms

locatethe

rear

wheels

and

anchorthe

springs,

shocks

and

stabilizer

bar

.

Driveaxies

with

constant-velocity

(CV)

joints

at

both

ends

transfer

power

from

the

differential

to

the

road

wheels

.

The

differential

is

mounted

to

the

rearaxle

carrier

through

rubber

mountsand

bushings

to

hele

isolate

drivetrain

noise

and

vibration

.

Brakes

E36

cars

areequipped

with

power

disc

brakes

with

an

inte-

gral

antilock

brakes

(ABS)

.

The

parking

brake

is

a

dual-drum

system

integrated

with

the

rear

brake

rotors

.

See

Fig

.

3

.

Power

assist

is

provided

by

a

vacuum

booster

when

the

en-

gine

is

running

.

The

brakepedal

pushrod

is

connected

directly

to

the

master

cylinder,

so

failure

of

the

vacuum

booster

does

not

normally

result

in

total

brake

failure

.

0012124

Each

disc

brakeuses

a

caliper

with

a

single

hydraulic

cylin-

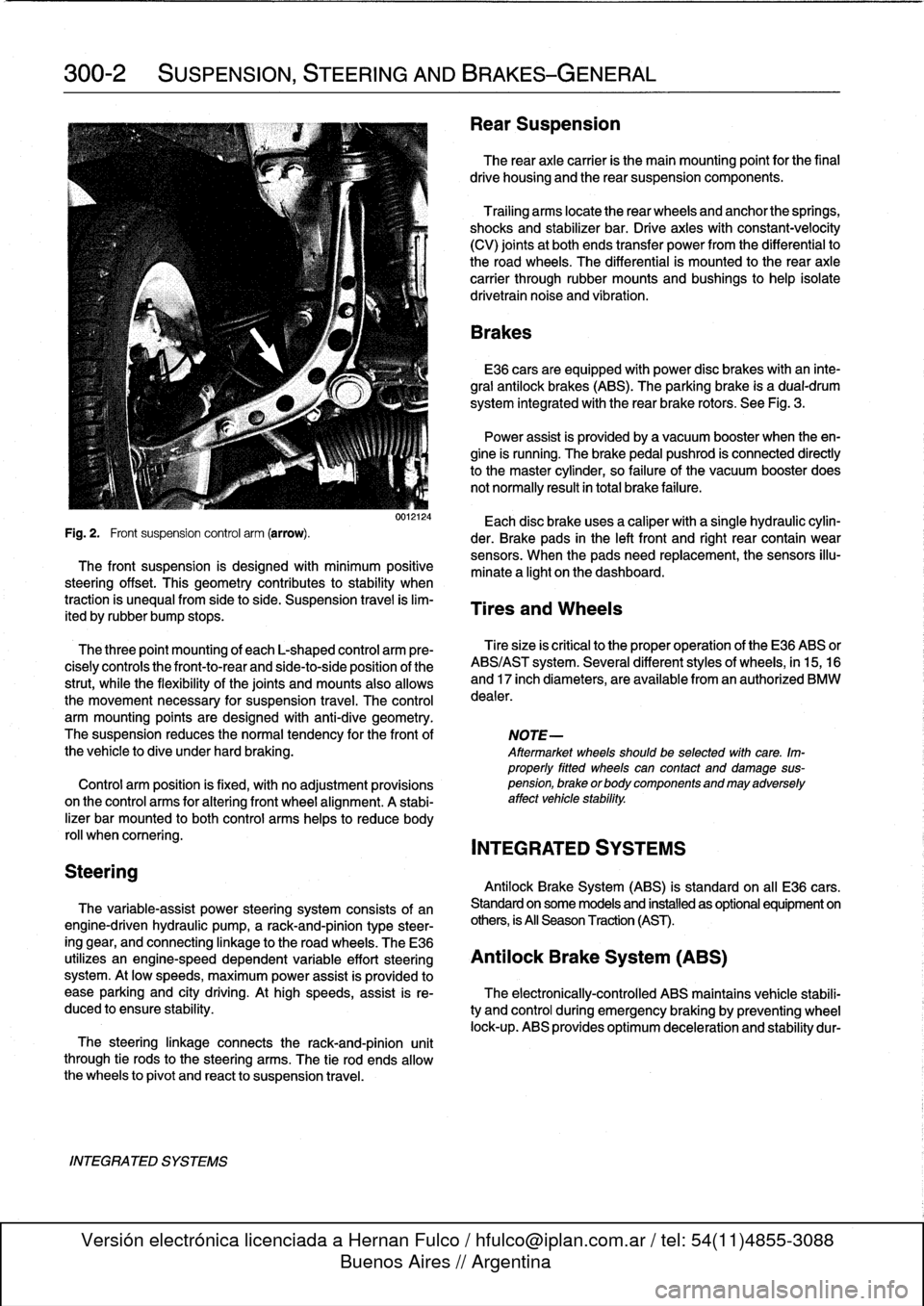

Fig

.

2

.

Front

suspension

control

arm

(arrow)

.

der

.

Brake

pads

in

the

left

front

and

right

rear

contain

wear

sensors

.

When

the

padsneed

replacement,the

sensors

illu-

The

front

suspension

is

designed

with

minimum

positive

minate

a

light

on

the

dashboard

.

steering

offset

.

This

geometry

contributes

to

stability

when

traction

is

unequalfrom

side

to

side

.

Suspension

travel

is

lim-

Tires

and

Wheels

ited

by

rubber

bump

stops

.

The

three

point

mounting

of

each

L-shaped

control

arm

ere-

Tiresize

is

critica¡

to

the

proper

operatíon

of

the

E36

ABS

or

cisely

controls

the

front-to-rear

and

side-to-side

position

of

the

ABS/AST

system

.

Severa¡

different

styles

of

wheels,

in

15,16

strut,

while

the

flexibility

of

the

joints

and

mounts

alsoallows

and

17

inch

diameters,

are

available

from

an

authorized

BMW

the

movement

necessary

for

suspension

travel

.

The

control

dealer

.

arm

mounting

points

are

designed

with

anti-dive

geometry

.

The

suspension

reduces

the

normaltendency

for

the

front

of

NOTE-

the

vehicle

to

dive

under

hard

braking

.

Aftermarket

wheelsshould

be

selected

wlth

care

.

Im-

properly

fitted

wheels

can

contact

anddamage

sus

Control

arm

position

is

fixed,

with

no

adjustment

provisions

pension,

brakeorbodycomponentsandmayadversely

on

the

control

arms

for

alter¡ng

front

wheel

al

ignment

.

A

stabi-

affect

vehicle

stability

.

lizer

bar

mounted

to

both

control

arms

heles

to

reduce

body

rol¡

whencomering

.

INTEGRATED

SYSTEMS

Antilock

Brake

System

(ABS)

is

standard

on

all

E36

cars

.

The

variable-assist

power

steering

system

consists

of

an

Standard

on

some

models

and

installed

as

optional

equipment

on

engine-driven

hydraulic

pump,

a

rack-and-pinion

type

steer-

others,

is

All

Season

Traction

(AST)

.

ing

gear,

and

connecting

linkage

to

the

road

wheels

.

TheE36

utilizes

an

engine-speed

dependent

variable

effort

steering

Antilock

Brake

System

(ABS)

system

.

At

low

speeds,

maximum

power

assist

is

provided

to

ease

parking

and

city

driving

.

Athigh

speeds,

assist

is

re-

The

electronically-controlled

ABS

maintains

vehícle

stabili

duced

to

ensure

stability

.

ty

and

control

during

emergency

braking

by

preventing

wheel

lock-up

.

ABS

provides

optimum

deceleration

and

stability

dur-

Page 302 of 759

340-

1

2

BRAKES

ABS

is

self-tested

by

the

ABS

diagnostic

unit

each

time

the

car

is

started

.

Once

the

test

is

complete,

the

ABS

dashboard

light

tucos

off

.

If

the

light

remains

lit

or

comes

on

at

any

time

during

driving,

a

system

fault

has

occurred

and

ABS

is

elec-

tronically

disabled

.

The

conventional

braking

systemremains

fully

functioning

.

ABS

Inspection

A

visual

inspection

of

the

ABS

may

help

to

locate

system

faults

.

If

no

visual

faults

can

befound

and

the

ABS

light

re-

mains

on,

have

the

system

diagnosedbyan

authorized

BMW

dealer

.

Carefully

inspect

the

entire

ABS

wiring

harness,

particularly

the

pulse

sensorharnesses

and

connectors

near

each

wheel

.

Look

for

chafing

or

damage

due

to

incorrectly

routed

wires

.

Carefully

remove

the

wheelspeed

sensors

.

Clean

the

sen-

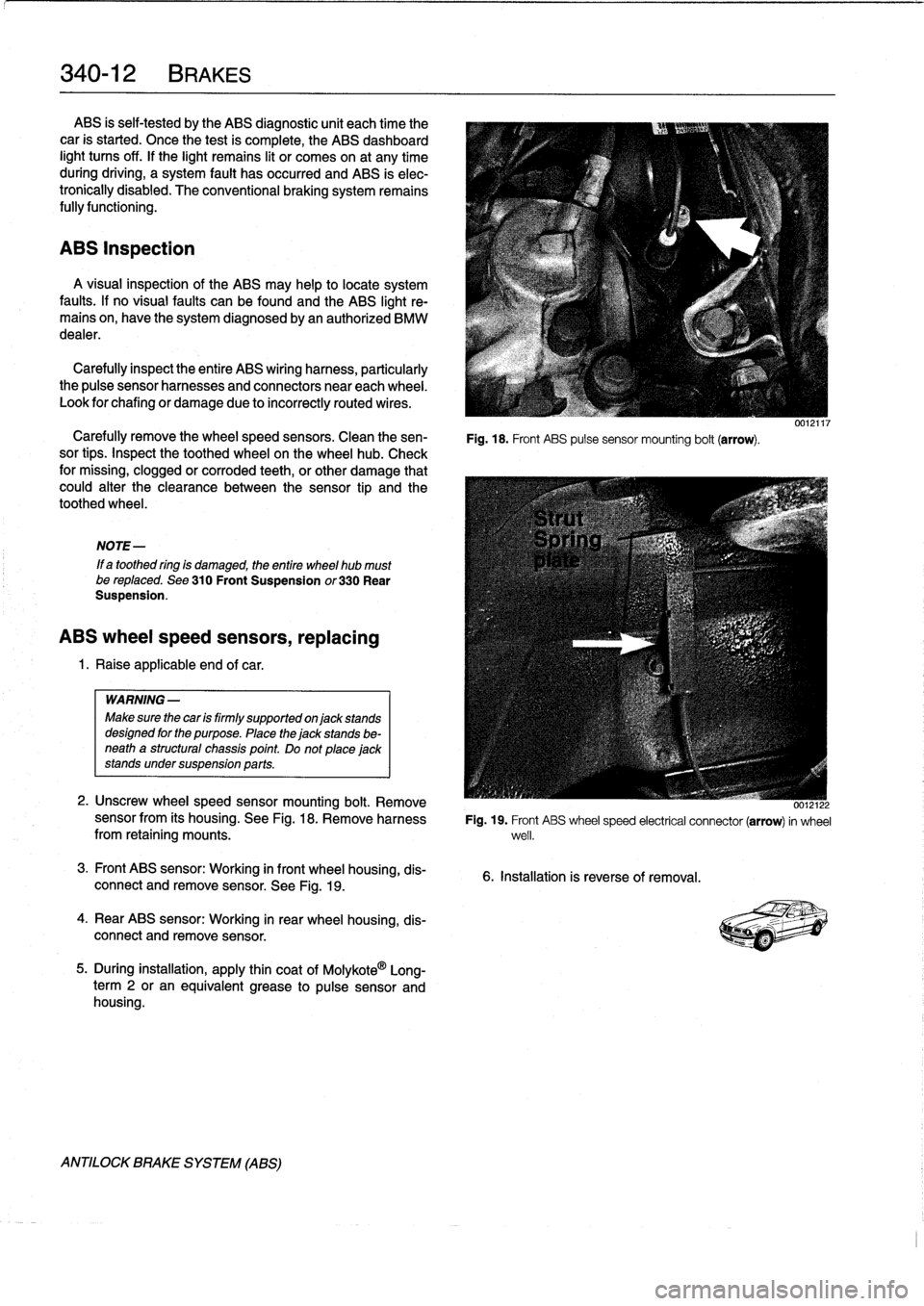

Fig

.

18

.

Front

ABS

pulse

sensor

mounting

bolt

(arrow)

.

sor

tips

.

Inspect

the

toothed

wheel

on

thewheel

hub

.

Check

for

missing,

clogged

or

corroded

teeth,

or

other

damage

that

could

alter

the

clearance

between

the

sensor

tip

and

the

toothed

wheel

.

NOTE-

If

a

toothed

ring

is

damaged,

the

entire

wheel

hub

mustbe

reptaced

.

See

310

Front

Suspension

or330

Rear

Suspension

.

ABS

wheel

speed

sensors,

replacing

1

.

Raise

applicable

end

of

car

.

WARNING

-

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Unscrew

wheelspeed

sensor

mounting

bolt

.

Remove

sensor

from

its

housing

.

See

Fig

.

18

.

Remove

harnessfrom

retaining

mounts

.

3

.

Front

ABS

sensor

:

Working

in

front

wheel

housing,

dis-

connect

and

remove

sensor

.

See

Fig

.

19

.

4

.

Rear

ABS

sensor

:

Working

in

rear

wheel

housing,

dis-

connect

andremove

sensor

.

5

.

During

installation,

apply

thin

coat

of

Molykote

0

Long-

term

2

or

an

equivalent

grease

to

pulse

sensor

and

housing

.

ANTILOCK

BRAKE

SYSTEM

(ABS)

0012122

Fig

.

19

.

Front

ABS

wheel

speed

electrical

connector

(arrow)

in

wheel

well

.

6

.

Installation

is

reverse

of

removal

.

Page 306 of 759

400-

4

BODY-GENERAL

INTERIOR

EQUIPMENT

E36

interiors

have

a

unique

character,

with

a

combínation

of

sporty

features

and

innovative

design

.

Al¡

body

versions

were

made

in

a

wide

choice

of

interior

and

exterior

colors

.

New

colors

with

matching

leather

and/or

fabric

upholstery

were

in-

troduced

for

each

model

year,

including

light-alloy

wheels

in

new

designs

.

Driving

comfort

is

enhanced

by

power

steering,

tilt

steering

wheel

(optional),

height-adjustable

front

seats,

and

electrical-

ly

adjustable

and

heated

rear-view

mirrors

.

Inside

thecar

there

are

reading

lights

at

four

seating

positions

.

Seats

and

Seat

Belts

NOTE-

Theseat

base

usedon

cars

with

pyrotechnic

seatbelt

Anatom¡cal

ly-correct

seats

are

constructed

from

polyure-

tensioners

is

not

interchangeable

with

the

earlier

seat

thane

foam

containing

areas

or

"zones"

of

different

firmness

.

base

.

The

seat

bases

have

steel

springs

for

added

support

and

strength

.

The

power

seats

are

provided

with

conveniently

lo-

Instruments

and

Controls

cated

switches

along

the

outside

edge

of

the

seat

.

Heated

seats

are

an

option

in

all

models

.

See

520

Seats

for

more

de-

Everything

in

the

interior

passenger

compartment

essential

tails

.

to

the

driver

is

logically

grouped

and

easy

to

reach

.

Al¡

instru-

ments

and

controls

havebeen

arranged

ergonomically

and

The

M3

sport

seat

is

shown

in

Fig

.

3

.

are

fully

integrated

into

the

overall

design

of

the

vehicle

.

Fig

.

3

.

M3

sport

seat

.

INTERIOR

EQUIPMENT

0013195

The

early

E36

cars

areequipped

with

a

single

(driver

side)

airbag

in

the

steering

wheel

.

Startingwith

the

1994

models,

a

dual

airbag

Supplemental

Restraint

System

has

been

stan-

dard

equipment

.

Side-impact

airbags

in

the

front

doors

are

op-

tional

in

1997

4-door

cars

and

standard

equipment

in

all

1998

models

.

Through

1996,

E36

seatbelts

were

equipped

with

BMW's

original-designspring

tensioners

.

In

1997,

the

seat

base

de-

sign

was

modified

to

accommodate

a

pyrotechnic

(explosive

charge)

seatbelt

tensioner

.

Both

types

of

tensioners

arede-

signed

to

automatically

tension

the

belts

by

about2

inches(55

mm)

in

the

event

of

a

collision

.

The

padded

dashboard

houses

the

instrument

cluster

and

the

ventilation

and

heating

system

.

The

instrument

cluster

uses

large

easy-to-read

analog

instruments

and

is

removable

as

a

unit

without

removing

the

dashboard

.

The

Service

Inter-

val

Indicator

(SII)

will

remind

the

driver

when

thecar

requires

service

.

See

620

Instruments

.

The

Multi-Information

Display

(MID)

unit

in

thecenter

of

the

dashboard

comes

in

a

variety

of

four

configurations,

the

most

advanced

being

the

On-Board

Computer

(OBC)

.

See

Fig

.

4

.

Al¡

versions

of

the

MID

have

a

clock

and

calendar

.

In

addi-

tion,

different

versions

areequipped

with

a

"check

control,"

display

for

fuel-economy

information

and

system

warnings

.

Consult

the

owner's

manual

for

fui¡

operating

instructions

.

Page 345 of 759

GENERAL

This

repair

group

covers

interior

trim

removal

and

installa-

tion

procedures

.

Forremoval

and

installation

of

interior

switches,

including

interior

lighting

equipment,

see

612

Switches

and

Electrical

Accessories

.

Most

of

the

interior

trim

and

finish

paneis

are

clipped

or

screwed

into

place

.

Many

of

the

trim

retaining

clips

arede-

signed

to

be

used

only

once

.

When

removing

trim

that

is

held

in

place

with

clips,

it

is

a

good

idea

lo

have

spareson

hand

be-

fore

beginningthejob

.

CENTER

CONSOLE

The

front

section

center

console

houses

the

Multi-Informa-

tion

Display

(MID)

module,the

front

ashtray

and

cigarette

lighter

;

shifter

lever,

power

window

switches

and

the

hazard

warning

switch

.

The

rear

center

console

section

houses

the

ashtray(s)

and

covers

the

emergency

brakecable

ends

.

Center

console,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CA

UTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

shifter

boot

or

selectorlever

cover

.

See250

Gearshift

t-inkage

.

3

.

Remove

rear

ashtray

retaining

screws

totake

out

ash-

tray

.

Remove

rear

console

retaining

screwunder

ash-

tray

.

513

Interior

Tri

m

INTERIORTRIM

513-1

GENERAL

..

.

.....

.

.

.

.

.

.

.

.

.

.

.

......

.

.

.

513-1

DASHBOARD

.....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

:

.

.513-2

Glove

compartment,removing

and

installing

.

.513-2

CENTER

CONSOLE

.

.

.

.

.

.

.

.

.

.

.........

513-1

Lower

left

dash

panel,

Center

console,

removing

and

installing

.....

513-1

removing

and

installing

.

.

.

.

.

.

.

.

.

.

.....

.

.

513-2

Dashboard,removing

and

installing

.

.

.

.

...

.

.513-3

4

.

Remove

Multi-Information

Display

module

.

See620

In-

struments

.

5

.

Remove

hazardwarning

switch

and

power

window

switches

bypushing

up

and

out

from

below

.

6

.

Remove

lower

left

dashboard

panel

and

glove

compart-

ment

as

described

later

in

this

repair

group

.

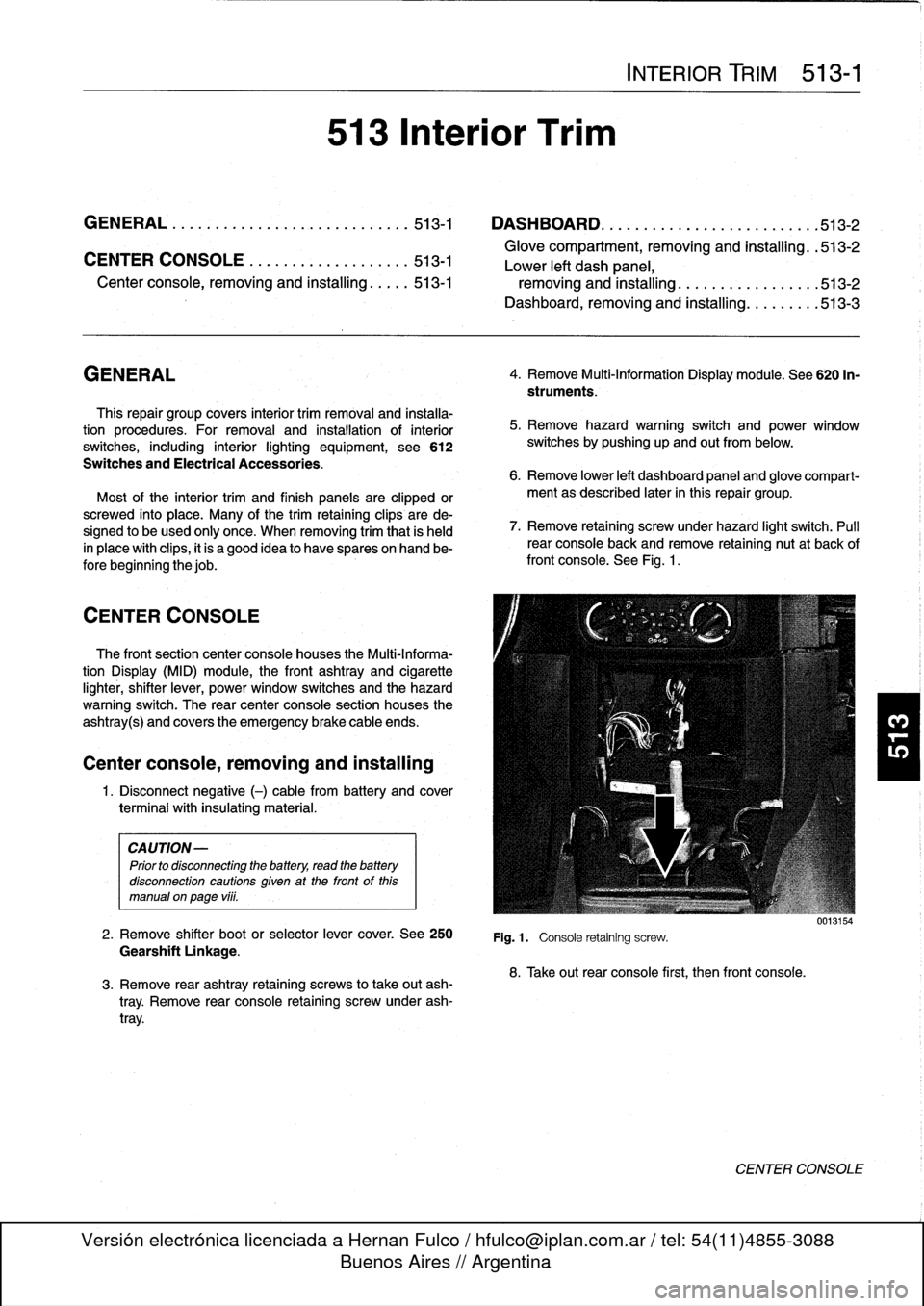

7

.

Remove

retaining

screwunder

hazard

light

switch

.

Pull

rear

console

back

and

remove

retaining

nut

at

back

of

front

console

.

See

Fig

.

1

.

Fig

.1.

Console

retaining

screw

.

8

.

Take

out

rear

console

first,

then

front

console

.

0013154

CENTER

CONSOLE

Page 347 of 759

Dashboard,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

center

console

as

described

earlier

.

3

.

Remove

glove

compartment

as

described

earlier

.

4

.

Remove

lower

left

dash

trim

piece

as

described

above

.

Remove

lower

right

dash

trim

panel

.

See

Fig

.

4

.

Fig

.

4

.

Lower

right

dash

trim

piece

retaining

screw

(arrow)

.

WARNING

-

Store

the

removed

airbags

in

a

safe

place

.

Position

the

airbags

facing

up

.

8

.

Remove

instrument

cluster

.

See

620

Instruments

.

5

.

Remove

driver

and

passenger

airbags

.

See

721

Air-

bag

System

(SRS)

.

6

.

Remove

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

INTERIOR

TRIM

513-

3

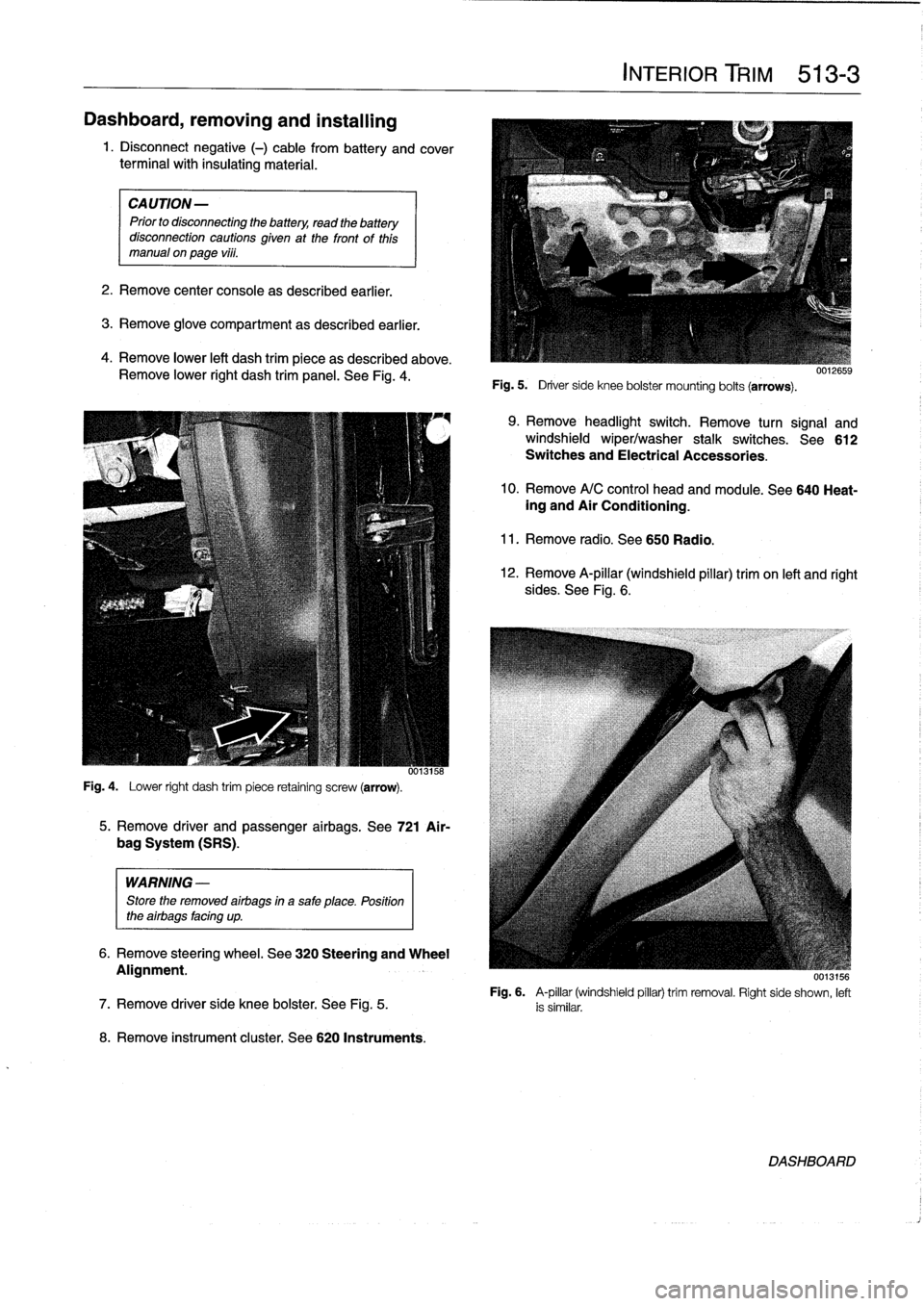

Fig

.

5

.

Driver

side

knee

bolster

mounting

bolts

(arrows)

.

9

.

Remove

headlight

switch

.

Remove

turn

signal

and

windshield

wiper/washer

stalk

switches

.

See612

Switches

and

Electrical

Accessories

.

10

.

Remove

A/C

control

head

and

module

.

See

640

Heat-ing

and

Air

Conditioning

.

11

.

Remove

radio

.

See650

Radio

.

12

.

Remove

A-pillar

(windshield

pillar)

trim

on

left

and

right

sides

.

See

Fig

.

6

.

UU13156

Fig

.

6

.

A-pillar

(windshield

pillar)

trim

removal

.

Right

side

shown,

left

7

.

Remove

driver

side

knee

bolster

.

See

Fig

.

5

.

is

similar

.

DASHBOARD

Page 348 of 759

513-

4

INTERIOR

TRIM

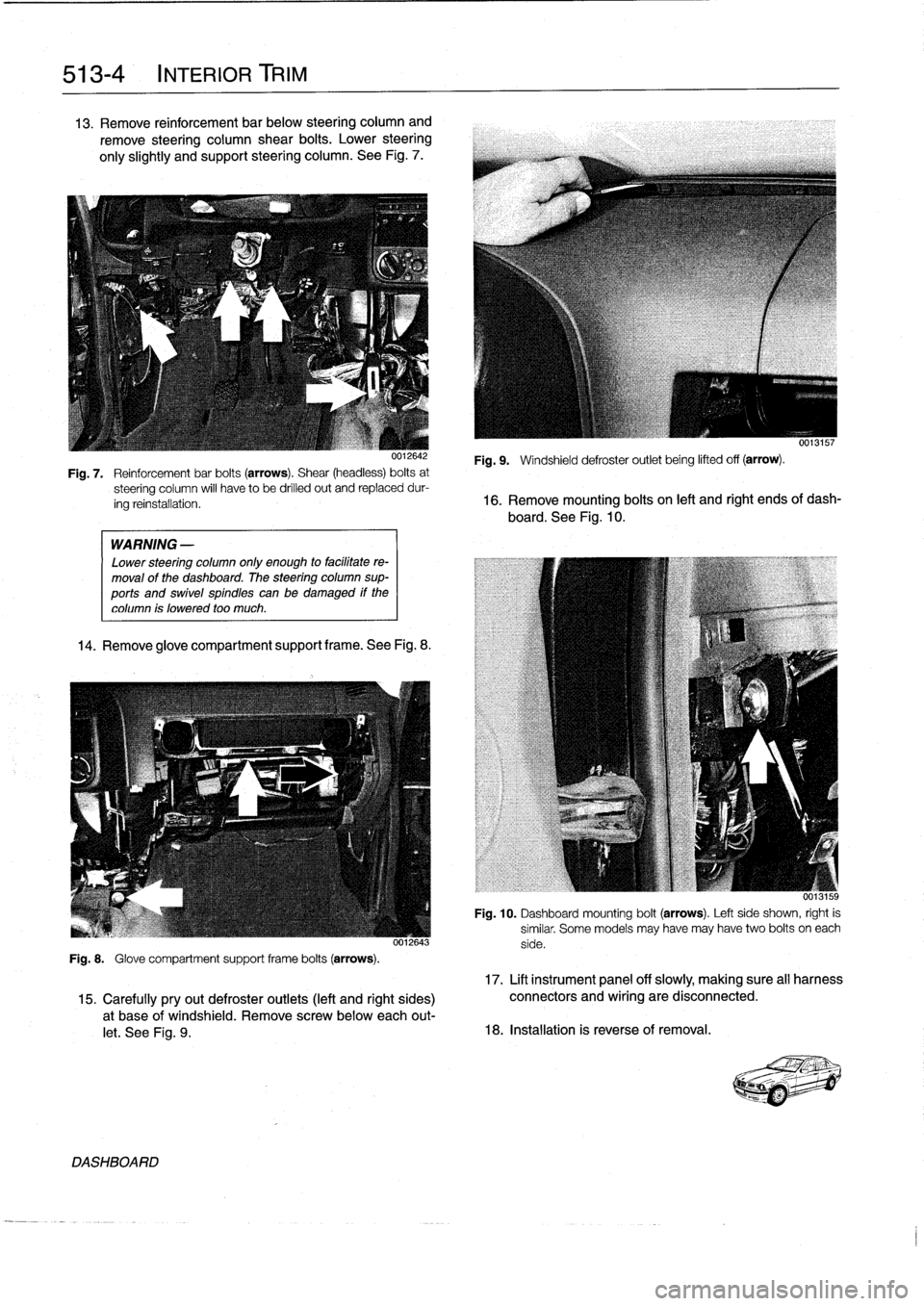

13

.

Remove

reinforcement

bar

below

steering

column

and

remove

steering

column

shear

bolts

.

Lower

steering

only

slightly

and

support

steering

column

.

See

Fig

.

7

.

WARNING

-

Lower

steering

column

only

enough

to

facilitate

re-

moval

of

the

dashboard

.

The

steering

column

sup-

ports

and

swivel

spindles

canbe

damaged

if

the

column

is

lowered

too

much

.

14

.

Remove

glove

compartment

support

frame

.See

Fig

.

8

.

0012643

Fig

.

8

.

Glove

compartment

support

frame

bolts

(arrows)

.

DASHBOARD

0013157

Fig

.

9

.

Windshield

defroster

outlet

being

lifted

off

(arrow)

.

Fig

.

7

.

Reinforcementbar

bolts

(arrows)

.

Shear

(headless)

bolts

at

steering

column

will

have

to

be

drilled

out

and

replaceddur-

ing

reinstallation

.

16

.

Remove

mounting

bolts

on

left

and

right

ends

of

dash-

board

.

See

Fig

.

10

.

Fig

.

10

.

Dashboard

mounting

bolt

(arrows)

.

Left

side

shown,

right

is

similar

.

Some

models

may

have

may

have

two

bolts

oneach

side

.

17

.

Lift

instrument

panel

off

slowly,

making

sure

all

harness

15

.

Carefullypryout

defroster

outlets

(left

and

right

sides)

connectors

and

wiring

are

disconnected

.

a

t

base

of

windshield

.

Remove

screwbelow

each

out-

let

.

See

Fig

.

9

.

18

.

Installation

is

reverse

of

removal

.

Page 379 of 759

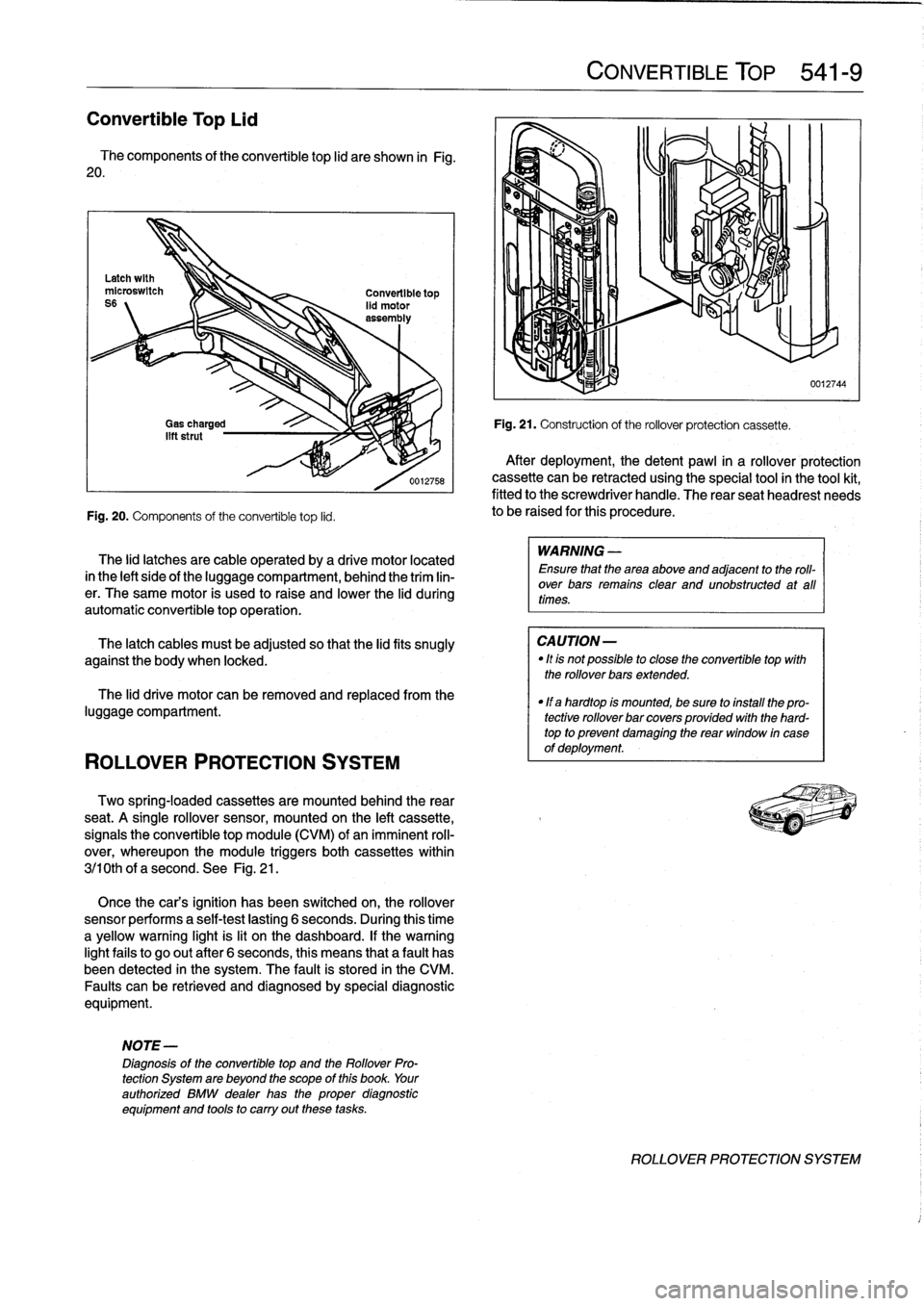

Convertible

Top

Lid

The

components

of

the

convertible

top

lid

are

shown

in

Fig

.

20

.

Fig

.

20

.

Components

of

the

convertible

top

lid

.

ROLLOVER

PROTECTION

SYSTEM

The

lid

latches

are

cable

operated

by

a

drive

motor

located

in

the

left

sideof

the

luggagecompartment,

behind

the

trim

lin-

er

.

The

same

motor

is

used

to

raise

and

lower

the

lid

during

automatic

convertible

topoperation

.

The

latch

cables

must

be

adjusted

so

that

the

lidfits

snugly

against

the

body

when

locked

.

The

lid

drive

motor

can

be

removed

and

replaced

from

the

luggage

compartment

.

Two

spring-locaed

cassettes

are

mounted

behind

the

rear

seat

.

A

single

rollover

sensor,

mounted

on

the

left

cassette,

signals

the

convertible

top

module

(CVM)

of

animminent

roll-

over,

whereupon

the

module

triggers

both

cassettes

within

3j10th

of

a

second

.

See

Fig

.

21

.

Once

the

cars

ignition

has

been

switched

on,

the

rollover

sensor

performs

a

self-test

lasting

6

seconds

.

During

this

time

a

yellow

warning

light

is

lit

on

the

dashboard

.

If

thewarning

lightfails

to

go

out

after

6

seconds,

this

means

that

a

fault

has

been

detected

in

the

system

.

The

fault

is

stored

in

the

CM

Faults

canbe

retrieved

and

diagnosedby

special

diagnostic

equipment

.

NOTE-

Diagnosis

of

the

convertible

top

and

the

Rollover

Pro-

tection

System

are

beyond

the

scope

of

this

book

.

Your

authorized

BMW

dealer

has

the

proper

diagnostic

equipment

and

tools

to

carry

out

these

tasks

.

CONVERTIBLE

TOP

541-

9

Fig

.

21

.

Construction

of

the

rollover

protection

cassette

.

After

deployment,

thedetent

pawl

in

a

rollover

protection

cassette

can

be

retracted

using

the

special

tool

in

the

tool

kit,

fitted

to

the

screwdriver

handle

.

The

rear

seatheadrest

needs

to

be

raised

for

this

procedure

.

WARNING

-

Ensure

that

the

area

above

and

adjacent

to

the

roll-

over

bars

remains

clear

and

unobstructed

at

all

times

.

CAUTION-

"

Itis

not

possible

to

close

the

convertible

top

with

the

rollover

bars

extended

.

"

If

a

hardtop

is

mounted,

be

sure

to

install

the

pro-

tective

rollover

bar

covers

provided

with

the

hard-

top

to

prevent

damaglng

the

rear

window

in

case

of

deployment

.

0012744

ROLLOVER

PROTECTION

SYSTEM

Page 388 of 759

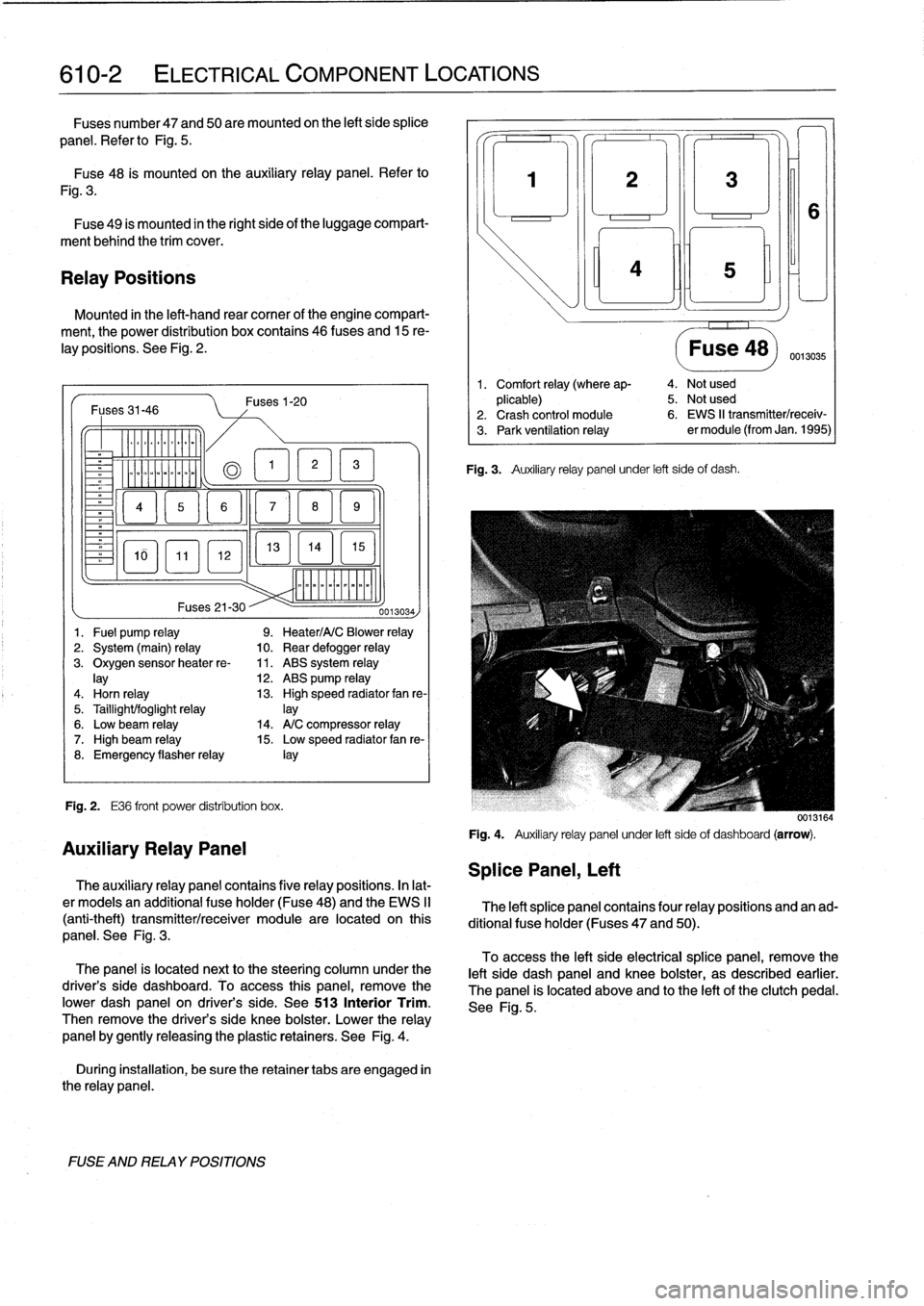

610-2

ELECTRICAL

COMPONENT

LOCATIONS

Fuses

number47

and

50are

mounted

on

the

left

side

splice

panel

.

Refer

lo

Fig

.

5

.

Fuse48

is

mounted

on

the

auxiliary

relay

panel

.

Refer

to

Fig

.

3

.

Fuse

49

is

mounted

in

the

right

side

of

the

luggage

compart-

ment

behind

the

trim

cover

.

Relay

Positions

Mounted

in

the

left-hand

rear

comer

of

the

engine

compart-

ment,

the

power

distribution

box

contains

46

(uses

and

15

re-

lay

positions

.

See

Fig

.

2

.

Fuses31-46

-

Er

a

&QT

MM

~

Fig

.

2

.

E36

front

power

distribution

box

.

FUSE

AND

RELAY

POSITIONS

Fuses1-20

13

EL1

5

]

mmmmmmmmmm

Fuses

21-30

--

0013034)

1

.

Fuel

pump

relay

9

.

Heater/A/C

Blower

relay

2

.

System

(main)

relay

10

.

Rear

defogger

relay

3

.

Oxygen

sensorheater

re-

11

.

ABS

system

relay

lay

12

.

ABS

pump

relay

4

.

Horn

relay

13

.

High

speed

radiator

fan

re-

5

.

Taillight/foglight

relay

]ay

6

.

Low

beam

relay

14

.

A/C

compressor

relay

7

.

High

beam

relay

15

.

Low

speed

radiator

fan

re-

8

.

Emergency

flasherrelay

¡ay

Auxiliary

Relay

Panel

The

auxiliary

relay

panel

contains

five

relay

positions

.

In

lat-

er

modeis

an

additional

fuse

holder

(Fuse48)

and

the

EWS

II

(anti-theft)

transmitter/receiver

module

are

located

on

this

panel

.

See

Fig

.

3

.

The

panel

is

located

nextto

the

steering

column

under

the

driver's

side

dashboard

.

To

access

this

panel,

remove

the

pwer

dash

panel

on

driver's

side

.

See513

Interior

Trim

.

Then

remove

the

driver's

side

knee

bolster

.

Lower

the

relay

panel

by

gently

releasing

the

plastic

retainers

.

See

Fig

.

4

.

During

installation,

be

sure

the

retainer

tabs

are

engaged

in

the

relay

panel

.

Splice

Panel,

Left

3

¡ni

Fig

.

3

.

Auxiliary

relay

panel

under

left

side

of

dash

.

Fuse

48)

0013035

1

.

Comfort

relay

(where

ap-

4

.

Not

used

plicable)

5

.

Not

used

2

.

Crash

control

module

6

.

EWS

II

transmitter/receiv-

3

.

Park

ventilation

relay

er

module

(from

Jan

.

1995)

0013164

Fig

.

4

.

Auxiliary

relay

panel

under

left

sideof

dashboard

(arrow)

.

The

left

splice

panel

contains

four

relay

positions

and

an

ad-

ditional

fuse

holder

(Fuses

47

and

50)

.

To

access

the

left

side

electrical

splice

panel,

remove

the

left

side

dash

panel

and

knee

bolster,

as

described

earlier

.

The

panel

is

located

above

and

lo

the

left

of

the

clutch

pedal

.

See

Fig

.

5

.

Page 432 of 759

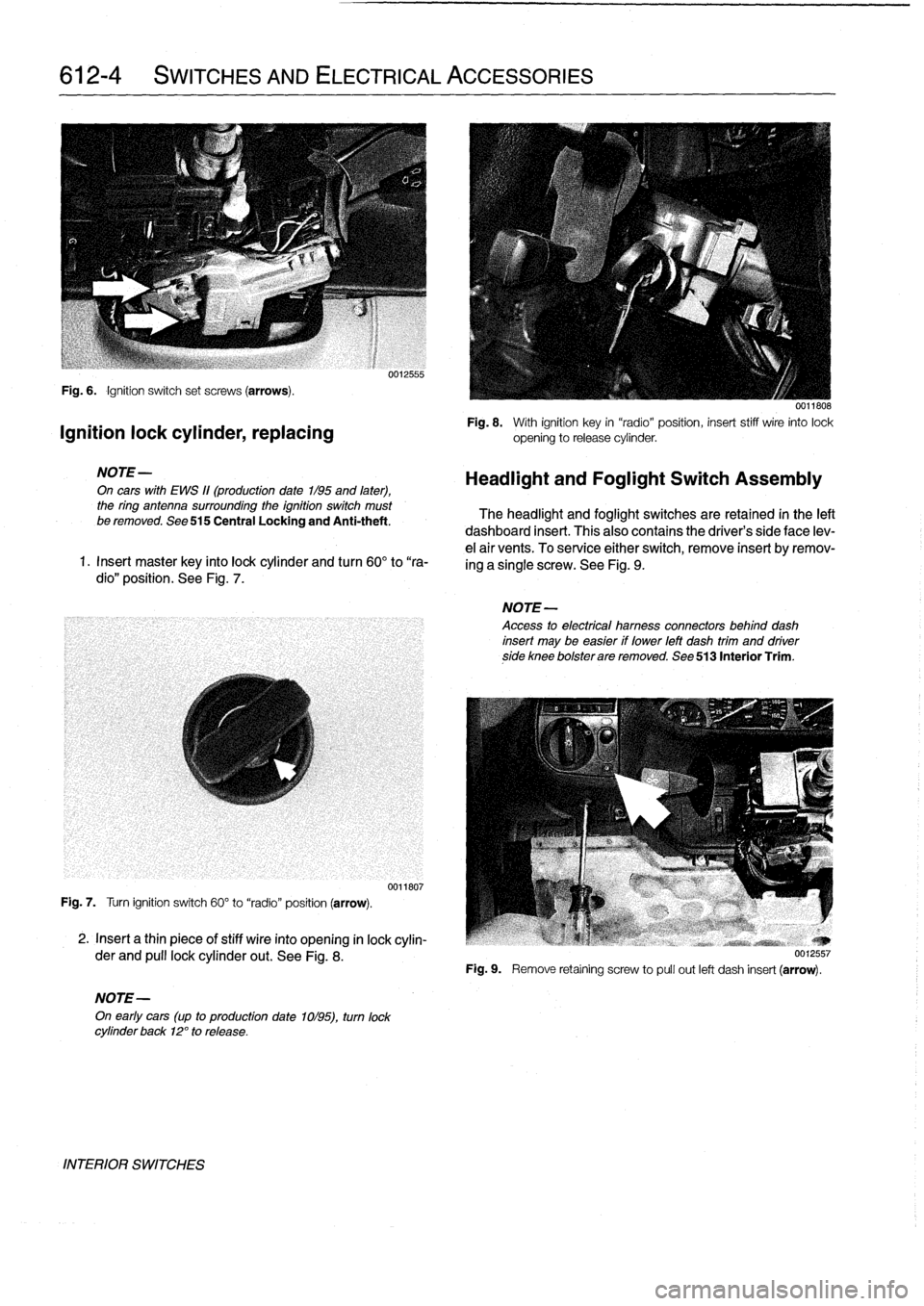

612-4

SWITCHES

AND

ELECTRICAL

ACCESSORIES

Fig

.

6

.

Ignition

switch

set

screws

(arrows)

.

Ignition

lock

cylinder,

replacing

NOTE-

On

cars

with

EWS

11(production

date

1/95

and

later),

the

ring

antenna

surrounding

the

ignition

switch

must

be

removed

.

See

515

Central

Locking

and

Anti-theft

.

1

.

Insert

master

key

finto

lock

cylinder

and

turn

60°

to

"ra-

dio"

position

.

See

Fig

.

7

.

Fig

.

7

.

Turn

ignition

switch

60°

to

"radio"

position

(arrow)

.

2

.

Insert

a

thin

piece

of

stiff

wire

into

opening

in

lock

cylin-

der

and

pull

lockcylinder

out

.

See

Fig

.

8

.

NOTE-

On

early

cars

(up

to

production

date

1ol95),

turn

lock

cylinder

back

12°

to

release

.

INTERIOR

SWITCHES

0012555

0011807

0011808

Fig

.

8

.

With

ignition

key

in

"radio"position,

insert

stiff

wire

into

lock

opening

to

release

cylinder

.

Headlight

and

Foglight

Switch

Assembly

The

headlight

and

foglight

switches

are

retained

in

the

left

dashboard

insert

.

This

alsocontains

the

driver's

side

face

lev-

e¡

air

vents

.

To

service

either

switch,

remove

insert

byremov-

ing

a

single

screw

.

See

Fig

.

9

.

NOTE-

Access

to

electrical

hamess

connectors

behind

dash

insert

may

be

easier

if

lower

left

dash

trim

and

driverside

knee

bolsterare

removed

.

See

513

Interior

Trim

.

Fig

.

9

.

Remove

retaíning

screw

to

pull

out

left

dash

insert

(arrow)

.

Page 477 of 759

721

Airbag

System

(SRS)

Airbag

Systems

.......

.

...

.

.

.

.

.

....

.

.

.

.

721-1

AIRBAG

SENSORS

AND

ELECTRONICS

721-2

SRS

Warning

Light

and

Fault

Display

.

.

.

.

.

..

721-2

Airbagcontact

ring,

replacing

........

.

.

.

.

.

721-3

Airbag

crash

sensor,replacing

..

.

....

.

...

.

721-4

ZAE

control

module,

replacing

.

.

.

.........

721-5

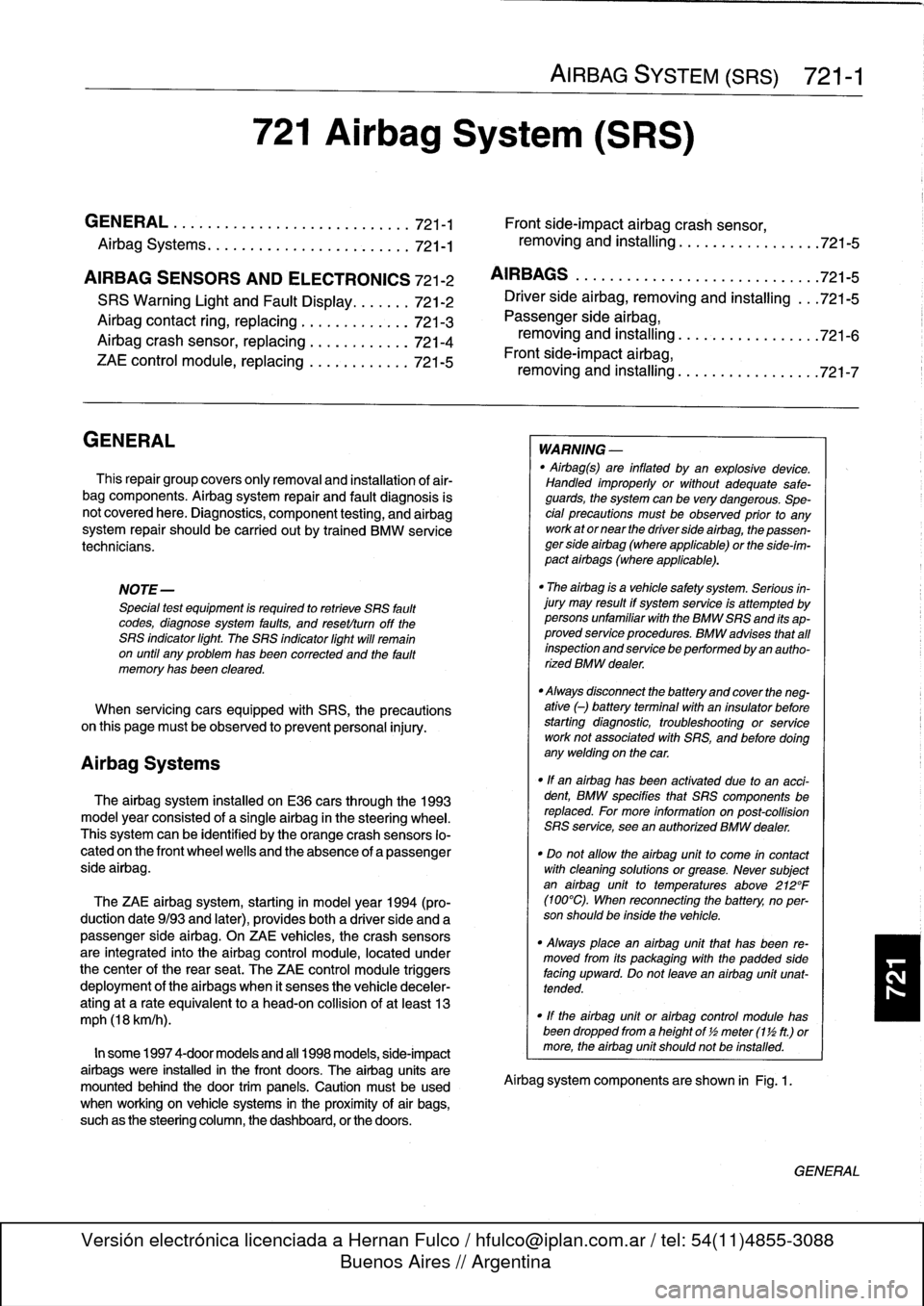

GENERAL

This

repair

group

covers

only

removal

and

installation

of

air-

bag

components

.

Airbag

system

repair

and

fault

diagnosis

is

not

covered

here

.

Diagnostics,

component

testing,

and

airbag

system

repair

should

be

carried

out

by

trained

BMW

service

technicians

.

NOTE-

Special

test

equipment

is

required

to

retrieve

SRS

fault

codes,

diagnose

system

faults,

and

resetltum

off

the

SRS

indicator

light

.

The

SRS

indicator

light

will

remain

on

until

any

problem

has

been

corrected

and

the

fault

memory

has

been

cleared

.

When

servicing

cars

equipped

with

SRS,

the

precautions

on

this

page

mustbeobserved

to

prevent

personal

injury

.

Airbag

Systems

The

airbag

system

installed

on

E36

cars

through

the

1993

model

year

consisted

of

a

single

airbag

in

the

steering

wheel

.

This

systemcan

be

identified

by

the

orange

crash

sensors

lo-

cated

on

the

front

wheel

wells

and

the

absence

of

a

passenger

side

airbag

.

The

ZAE

airbag

system,

starting

in

model

year

1994

(pro-

duction

date9/93

and

later),

provides

both

a

driver

side

and

a

passenger

sideairbag

.

On

ZAE

vehicles,

the

crash

sensorsare

integrated

into

the

airbag

control

module,

located

under

thecenter

of

the

rear

seat

.

The

ZAE

control

module

triggers

deployment

of

the

airbags

When

it

sensos

the

vehicle

deceler-

ating

at

a

rate

equivalent

to

a

head-on

collisionof

at

least

13

mph

(18

km/h)

.

In

some

1997

4-door

models

and

all

1998

models,

side-impact

airbags

were

installed

in

the

front

doors

.

The

airbag

units

are

mounted

behindthe

door

trim

panels

.

Caution

mustbeused

when

working

on

vehicle

systems

in

the

proximity

of

air

bags,

such

as

the

steering

column,

the

dashboard,

or

the

doors

.

AIRBAG

SYSTEM

(SRS)

721-1

GENERAL

.

.

.

.

.

.

.

.

.

.

.......

.

......

.

.

.

.

721-1

Front

side-impact

airbag

crash

sensor,

removing

and

installing

....

.

.....

.

.....

.

721-5

AIRBAGS

..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

721-5

Driver

side

airbag,

removing

and

installing

.

.

.

721-5

Passenger

side

airbag,

removing

and

installing

..............

.

.

.721-6

Front

side-impact

airbag,

removing

and

installing

.

.

.

.

.

.

.

.

.

.

......

.721-7

WARNING

-

"

Airbag(s)

are

inflated

byan

explosive

device

.

Handled

improperly

or

without

adequate

safe-

guards,

the

System

can

be

very

dangerous

.

Spe-

cial

precautions

must

be

observed

prior

to

any

work

ator

near

the

driverside

airbag,

the

passen-

ger

side

airbag

(where

applicable)

or

the

side-im-

pact

airbags

(where

applicable)

.

"

The

airbag

is

a

vehicle

safety

system

.

Serious

in-

jury

may

result

if

System

service

is

attempted

by

persons

unfamiliar

with

the

BMW

SRS

and

its

ap-

proved

service

procedures

.

BMW

advises

that

all

inspection

and

service

be

performed

by

an

autho-

rized

BMW

dealer

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

()

battery

terminal

with

an

insulator

before

startingdiagnostic,

troubleshooting

or

service

worknot

associated

with

SRS,

and

before

doing

any

welding

on

the

car

.

"

If

an

airbag

has

been

activated

due

to

an

acci-dent,

BMW

specifies

that

SRS

components

be

replaced

.

For

more

information

on

post-collision

SRS

service,

see

an

authorized

BMW

dealer

.

"

Do

not

allow

the

airbag

unit

to

come

in

contact

with

cleaning

solutions

orgrease

.

Never

subject

an

airbag

unit

to

temperatures

aboye

212°F

(100°C)

.

When

reconnecting

the

battery,

no

per-

son

should

be

inside

the

vehicle

.

"

Always

place

an

airbag

unitthat

has

been

re-

moved

from

its

packaging

with

the

padded

sidefacing

upward

.

Do

not

leave

an

airbag

unlt

unat-

tended

.

"

!f

the

airbag

unit

or

airbag

control

modulehas

been

dropped

froma

height

of

!

1

2

meter

(1

Y2

ft.)

ormore,

theairbag

unit

should

not

be

installed

.

Aírbag

system

components

are

shown

in

Fig

.

1.

GENERAL