Water BMW 325i 1998 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 325i, Model: BMW 325i 1998 E36Pages: 759

Page 367 of 759

GENERAL

...

.

.

.

.

.

................

.

.

.

.

540-1

Sunroof

panel,

emergency

closing

.......

.

.

.540-2

Sunroof

panel,

adjusting

..

.

...........

.

.

.540-2

SUDE-TILT

SUNROOF

.

.

.

.

.

.

.

.

.

......

.

.

540-2

Sunroof

motor,

removing

and

installing

...

.

.

.540-3

GENERAL

NOTE-

"

Be

sure

to

check

thedrains

in

the

front

comers

of

the

The

electrically-operated

slide-tilt

sunroof

is

controlled

by

a

sunroof

carrier

if

water

ls

entering

the

car

through

the

set

of

cables

that

move

the

sunroof

panelalongguide

rails

headliner

.

when

the

motor

is

operated

.

The

sunroof

canbe

adjusted

.

Removal

and

repairof

the

sunroof

and

other

compo-

without

removing

it

from

thecar

.

Replacement

of

the

sunroof

nents

insidethe

roof

cavity

is

beyond

the

scope

ot

this

liner

or

components

suchas

the

cable

assembly

require

that

manual

.

the

sunroof

panel

be

removed

.

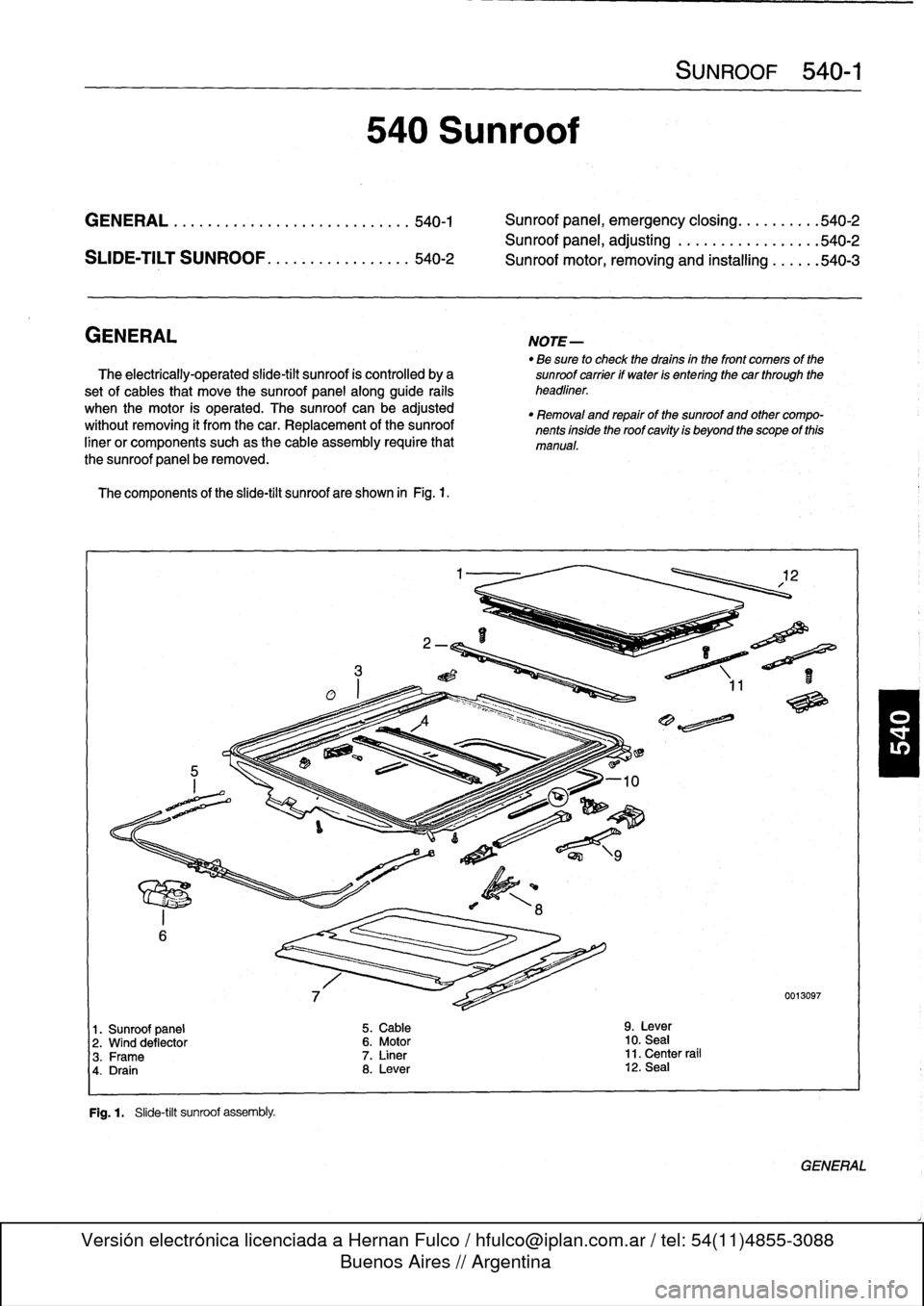

The

components

of

the

slide-tilt

sunroof

are

shown

in

Fig

.

1

.

Fig

.

1

.

Slide-tilt

sunroof

assembly

.

540

Sunroof

SUNROOF

540-1

1

.

Sunroof

panel

5

.

Cable

9

.

Lever

2

.

Wind

deflector

6

.

Motor

10

.

Sea¡

3

.

Frame

7

.

L]ner

11

.

Center

rail

4

.

Drain

8

.

Lever

12

.

Sea]

GENERAL

Page 368 of 759

540-2

SUNROOF

SLIDE-TILT

SUNROOF

Sunroof

panel,

emergency

closing

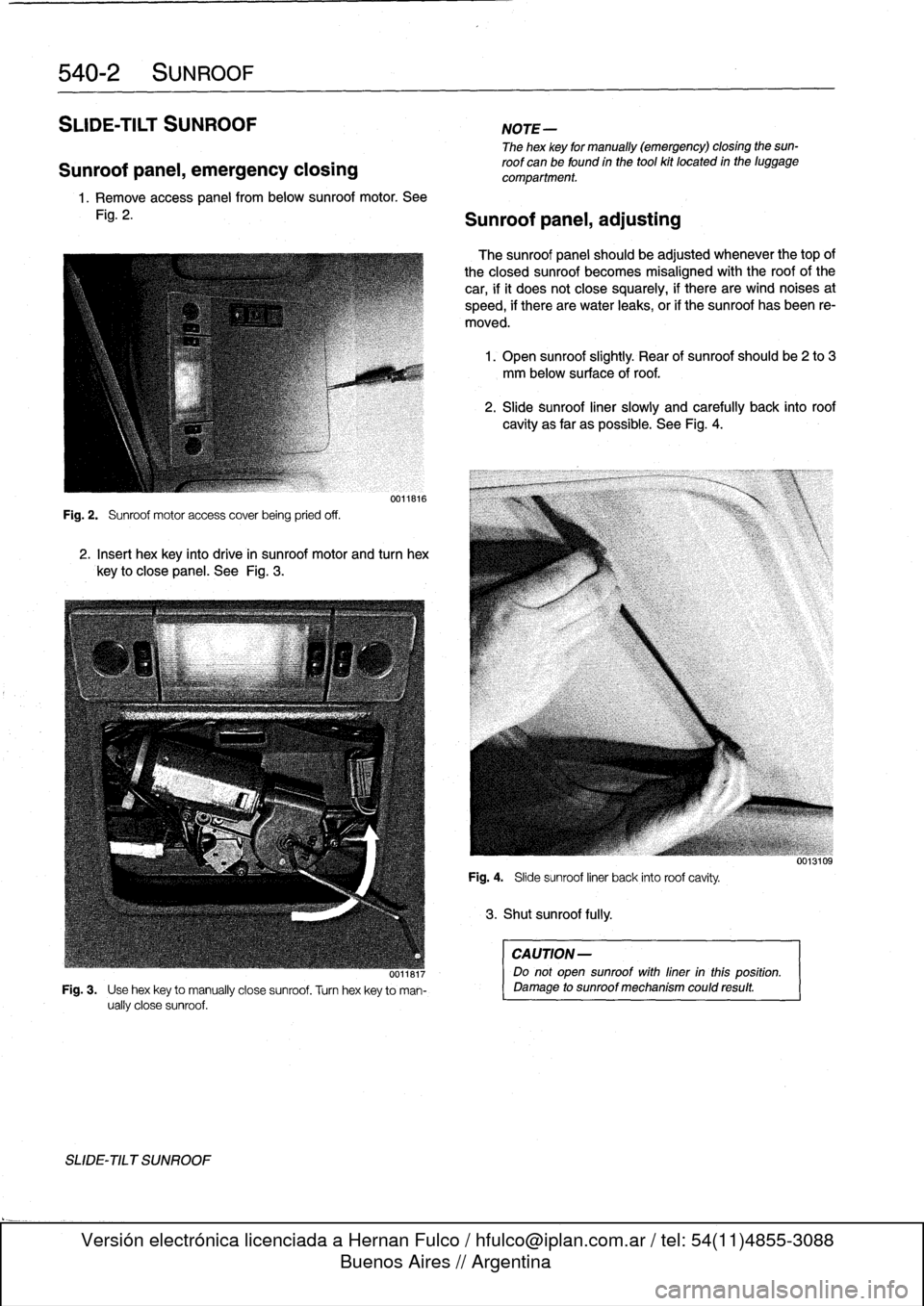

1.

Remove

access

panel

frombelow

sunroof

motor

.

See

Fig

.

2

.

Fig

.

2

.

Sunroof

motor

access

coverbeing

pried

off

.

0011816

2

.

Insert

hex

key

into

drive

in

sunroof

motor

and

turn

hex

key

to

Glosepanel

.

See

Fig

.

3

.

SLIDE-TILT

SUNROOF

0~i18r7

Fig

.

3

.

Use

hexkey

to

manually

Glose

sunroof

.

Turn

hexkey

to

mah-

ually

Glose

sunroof

.

NOTE-

The

hex

key

for

manually

(emergency)

closing

the

sun-

roof

canbe

found

in

the

tool

kit

located

in

the

luggage

compartment

.

Sunroof

panel,

adjusting

The

sunroof

panel

should

be

adjusted

whenever

thetop

of

the

closed

sunroof

becomes

misaligned

with

the

roof

of

the

car,

ifit

does

not

Glosesquarely,

if

there

arewind

noises

at

speed,

if

there

arewater

leaks,

or

if

the

sunroof

has

been

re-

moved

.

1

.

Open

sunroof

slightly

.

Rear

of

sunroof

should

be

2

to

3

mm

below

surface

of

roof

.

2

.

Slide

sunroof

liner

slowly

and

carefully

back

into

roof

cavity

as

far

as

possible

.

See

Fig

.

4

.

Fig

.

4

.

Slide

sunroof

liner

back

into

roof

cavity

.

3

.

Shut

sunroof

fully

.

CAUTION

-

Do

not

open

sunroof

with

liner

inthis

position

.

Damage

to

sunroof

mechanism

could

result

.

Page 419 of 759

611

Wipers

and

Washers

GENERAL

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.....

.

......

.

611-1

Windshield

wiper

motor,

removing

and

installing

.

...............

.611-8

WIPER

BLADES

.

.

.

.....

.

.

.

.

.

.

...

....

.611-1

Wiper

Blade

Cleaning

Problems

.

.

.

.

.

.

.....

611-1

Wiper

blades,replacing

...

.

.

.

.

.

.

.

.

.

.....

611-1

Wiper

blade

inserts,

replacing

.

.

.

.

.

.

.

.

.....

611-2

Wiper

arms,

removing

and

installing

.

.

.

.....

611-2

WINDSHIELD

WIPER

ASSEMBLY

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(4-door

models)

.

.

.

.

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(2-door

models)

.

.

.

.

.

.

.....

611-5

GENERAL

This

repair

group

covers

windshield

wiper

and

washer

sys-

tem

repair

information

.

Please

note

that

some

procedures

are

different

for

2-

and

4-door

models

.

The

windshield

wiper/washer

stalk

switch

assembly

is

cov-

ered

in

612

Switches

and

Electrical

Accessories

.

Electrical

NOTE-

wiring

diagrams

and

relays

for

the

wiper/washer

system

are

BMwhas

available

a

special

toollgauge

(BMWspecial

covered

in

Electrical

Wiring

Diagrams

.

tool

no

.

00

9210)

to

align

the

angle

of

the

wiper

arm

to

the

windshield

glass

.

WIPERBLADES

CA

UTION-

Never

turn

on

the

wiper

blades

while

the

hood

is

open

.

Damage

to

the

wiper

system

and

hood

may

occur

.

Toensure

safetyduring

wiper

biade

system

procedures,

remove

the

windshieldwiper

fuse

.

See

610

Electrical

Component

Locations

.

Wiper

Blade

Cleaning

Problems

Common

cleaning

problems

with

thewipers

includestreak-

ing

or

sheeting,

waterdrops

after

wiping,

and

blade

chatter

.

Streaking

is

usually

caused

when

wiper

blades

are

coated

with

road

film

or

car

wash

wax

.

Clean

the

blades

using

soapy

water

.

If

cleaning

does

not

cure

the

problem,

the

blades

should

be

replaced

.

BMW

recommends

replacing

the

wiper

blades

twice

a

year,

before

and

after

the

cold

season

.

WIPERS

AND

WASHERS

611-1

WINDSHIELD

CLEANING

SYSTEM

......

611-9

Windshield

spray

nozzle,

removing

and

installing

.......

.

........

.611-9

Washer

fluid

reservoir,

replacing

.........

.611-9

Windshield

washer

fluid

pump,

replacing

..

.

......

.

........

.611-9

Washer

fluid

level

sensor,

replacing

(models

with

check

control)

.

.

.

.

........

611-10

Wiper

blade

chatter

may

be

caused

by

dirty

or

worn

blades,

or

by

wiper

arms

that

areout

of

alignment

.

Clean

the

blades

and

windshield

as

described

above

.

Adjust

the

wiper

arm

so

that

there

is

even

pressure

along

the

blade,

and

so

that

the

blade

at

rest

is

perpendicular

to

the

windshield

.

If

problems

persist,

theblades

and

wiper

arms

should

be

replaced

.

The

wiper

blades

can

be

renewed

in

one

of

two

ways

:

either

by

replacing

the

complete

blade

or

by

replacing

just

therubber

insert

.

Insert

replacement

is

the

mosteconomicalmethod,

al-

though

overtime

the

wiperblade

itselfwill

become

worn

.

One

ruleof

thumb

wouldbe

to

replace

just

the

inserts

every

second

time

.

Wiper

blades,

replacing

1

.

Pivot

wiper

arm

off

windshield

.

2

.

Position

wiperblade

approximately

perpendicular

to

wiper

arm

.

3

.

Remove

wiperblade

from

wiper

arm

by

depressing

re-

taining

tab

and

sliding

blade

out

of

arm

.

See

Fig

.

1

.

Drops

that

remain

behind

after

wiping

are

usually

caused

by

NOTE-

oil,

road

film,

or

diesel

exhaust

residue

onthe

glass

.

Use

an

Some

wiperblade

versions

may

havetwo

retaining

alcohol

or

ammonia

solution

or

a

non-abrasive

cleaner

(such

tabs

.

a

s

Bon-Ami

to

clean

the

windshield

.

GENERAL

Page 439 of 759

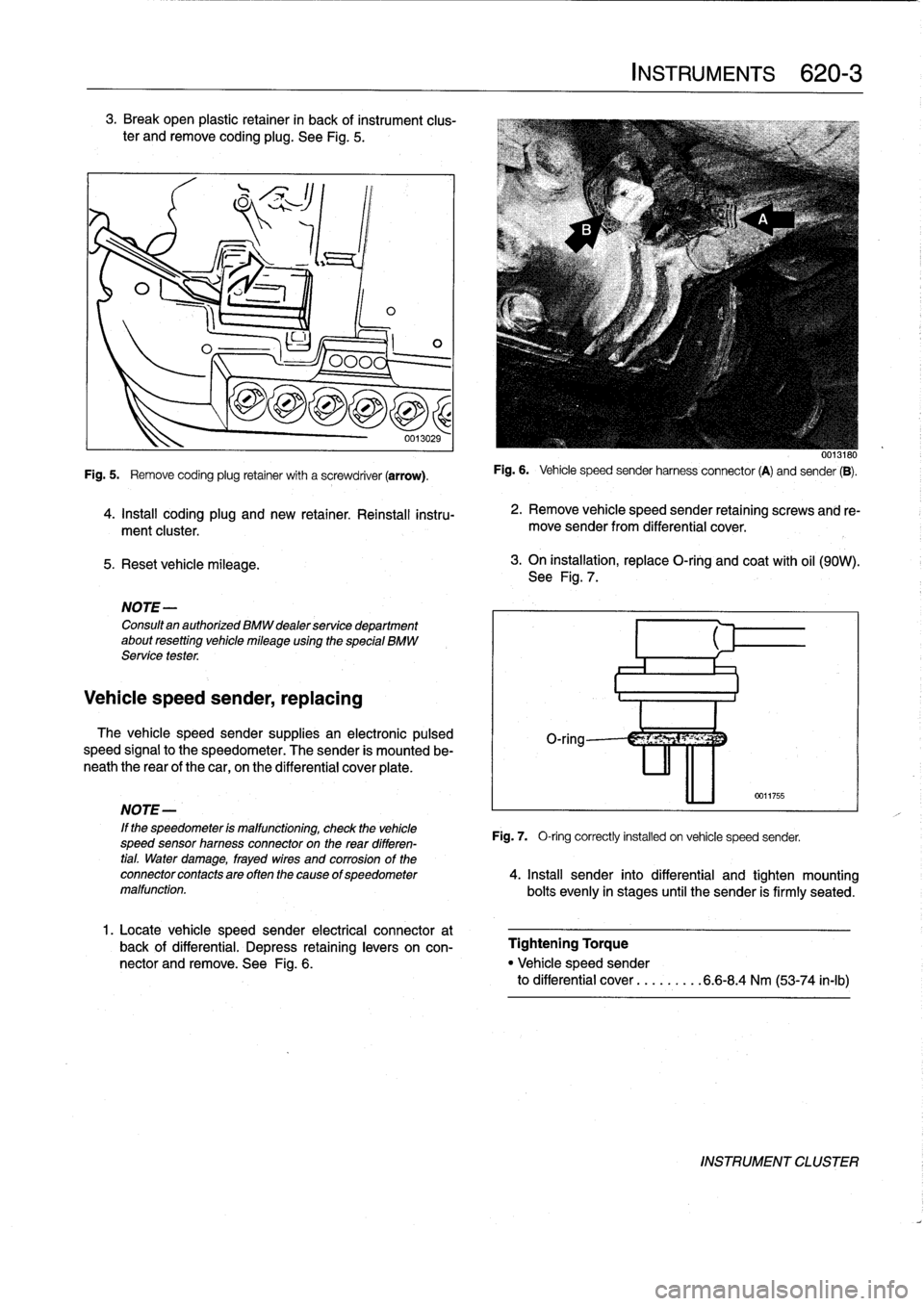

3

.

Break

open

plastic

retainer

in

back

of

instrument

clus-

ter

andremove

coding

plug

.

See

Fig

.

5

.

5

.

Reset

vehicle

mileage

.

1

ILO

NOTE-

Consultan

authorized

BMW

dealer

service

department

about

resetting

vehicle

mileage

using

the

special

BMW

Service

tester

.

Vehicle

speed

sender,

replacing

0

0013029

Fig

.

5

.

Remove

coding

plug

retainer

with

a

screwdriver

(arrow)

.

4

.

Install

coding

plug

and

new

retainer

.

Reinstall

instru-

ment

cluster

.

The

vehicle

speed

sender

supplies

an

electronic

pulsed

speed

signal

to

the

speedometer

.

The

sender

is

mounted

be-

neath

the

rear

of

the

car,

on

the

differential

cover

plate

.

1

.

Locate

vehicle

speed

sender

electrical

connector

at

back

of

differential

.

Depress

retaininglevers

on

con-

nector

and

remove

.

See

Fig

.

6

.

INSTRUMENTS

620-

3

0013180

Fig

.

6

.

Vehicle

speed

sender

harnessconnector

(A)

and

sender

(B)

.

2

.

Remove

vehicle

speed

sender

retaining

screws

and

re-

move

sender

from

differential

cover

.

3

.

On

installation,

replace

O-ring

and

coat

with

oil

(90W)

.

See

Fig

.

7

.

0011755

NOTE-

'

If

the

speedometer

is

malfunctioning,

check

the

vehicle

Fig

.

7,

O-ring

correctly

installed

on

vehicle

speed

sender,

speed

sensor

hamess

connectoron

the

rear

differen-

tial

.

Water

damage,

frayed

wires

and

corrosion

of

the

connectorcontactsareoftenthecause

ofspeedometer

4

.

Insta¡¡

sender

into

differential

and

tighten

mounting

malfunction

.

bolts

evenly

in

stages

until

the

sender

is

firmly

seated

.

Tightening

Torque

"

Vehicle

speed

sender

to

differential

cover

...

.

.....

6

.6-8

.4

Nm

(53-74

in-lb)

INSTRUMENT

CLUSTER

Page 450 of 759

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

UU12639

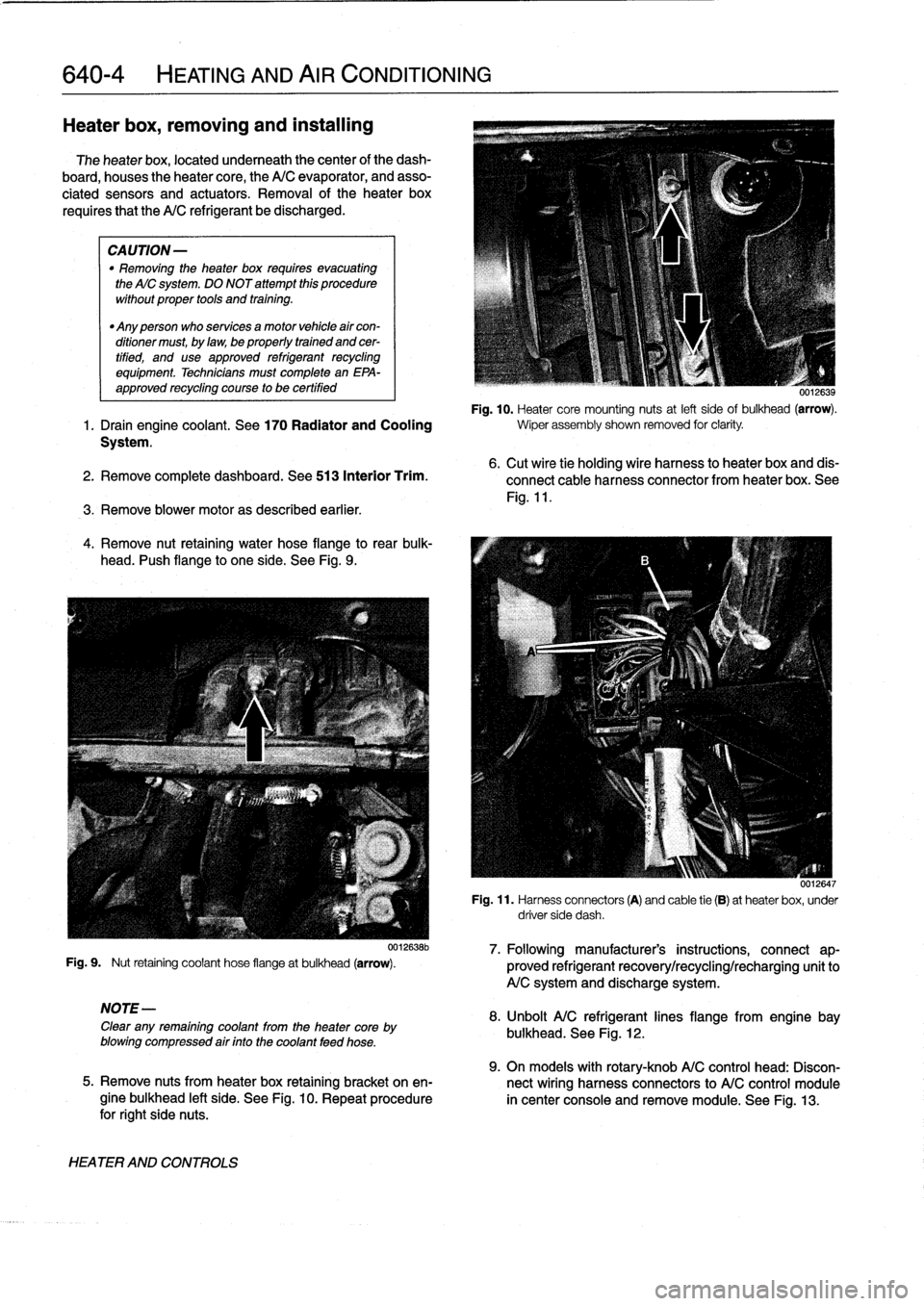

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

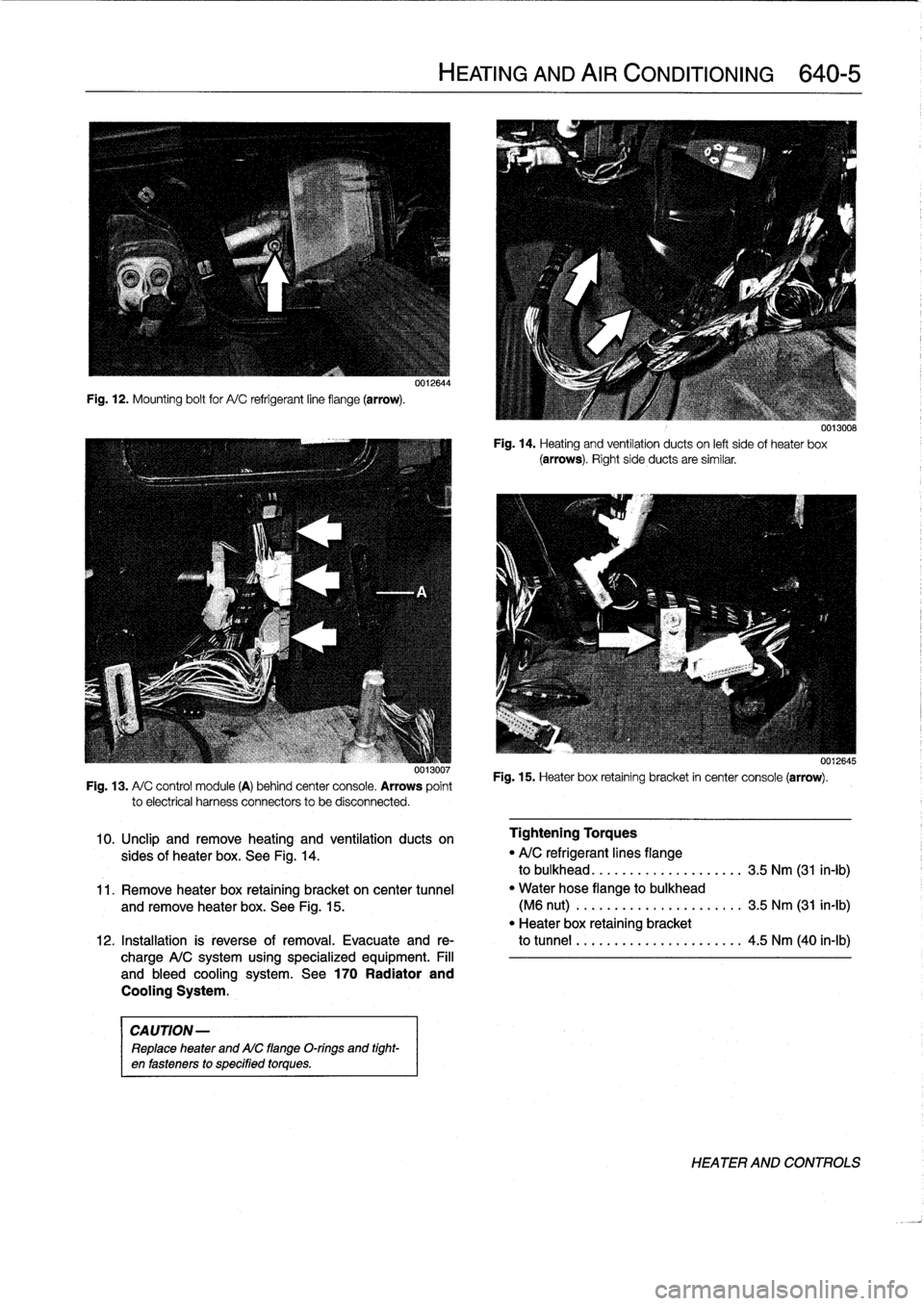

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 451 of 759

Fig

.

12

.

Mounting

bolt

for

A/C

refrigerant

line

flange

(arrow)

.

001Suu7

Fig

.

13

.

A/

C

control

module

(A)

behind

center

console

.

Arrows

pointto

electrical

harness

connectors

to

be

disconnected

.

CAUTION

-

Replace

heater

and

AIC

flange

O-rings

and

tight-

en

fasteners

to

specified

torques

.

0012644

HEATING

AND

AIR

CONDITIONING

640-5

Fig

.

14

.

Heating

and

ventilation

ducts

on

left

side

of

heater

box

(arrows)

.

Right

side

ducts

are

similar

.

Fig

.

15

.

Heater

box

retaining

bracket

in

center

console

(arrow)

.

0012645

10

.

Unclip

andremove

heating

and

ventilation

ducts

on

Tightening

Torques

sides

of

heater

box

.

See

Fig

.

14

.

"

A/C

refrigerant

lines

flange

to

bulkhead

..............

.

..

..

.

3

.5

Nm

(31

in-lb)

11

.

Remove

heater

box

retaining

bracket

on

center

tunnel

"

Water

hose

flange

to

bulkhead

and

remove

heater

box

.

See

Fig

.

15

.

(M6

nut)

................

.

...

..

3

.5

Nm

(31

in-lb)

"

Heater

box

retaining

bracket

12

.

Installation

is

reverse

of

removal

.

Evacuate

and

re-

to

tunnel

................

.

..

..

.

4

.5

Nm

(40

in-lb)

charge

A/C

system

using

specialized

equipment

.

Fill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

HEATER

AND

CONTROLS

Page 457 of 759

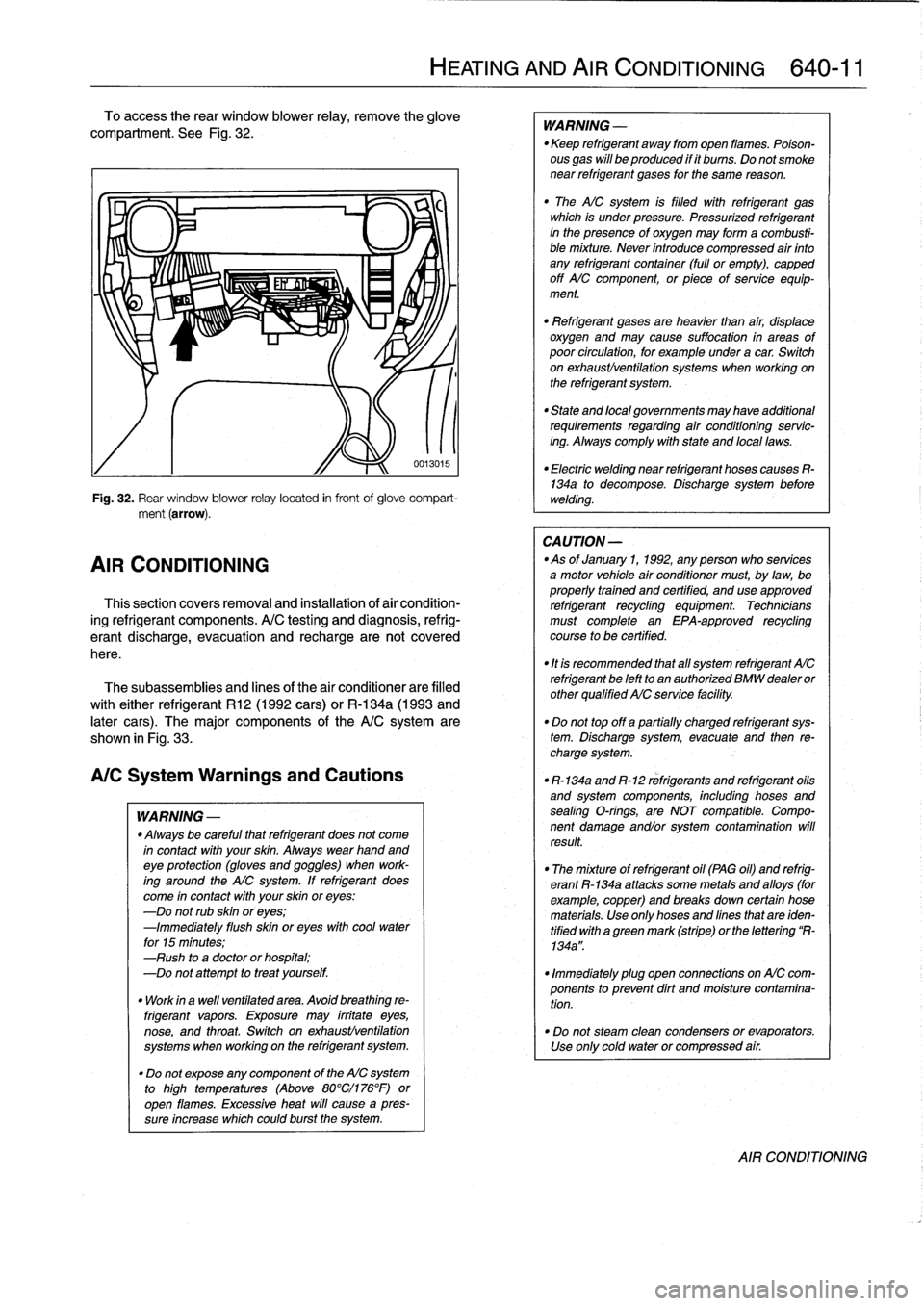

To

access

the

rear

window

blower

relay,

remove

the

glove

compariment

.

See

Fig

.

32

.

Fig

.

32

.

Rear

window

blower

relay

located

in

frontof

glove

compart-

ment

(arrow)

.

AIR

CONDITIONING

Thissection

covers

removal

and

installation

of

air

condition-

ing

refrigerant

components

.

A/C

testing

and

diagnosis,

refrig-

erantdischarge,

evacuatíon

and

recharge

are

not

covered

here

.

The

subassemblies

and

lines

of

the

air

conditionerare

filled

with

either

refrigerant

R12

(1992

cars)

or

R-134a

(1993

and

later

cars)

.

The

major

components

of

the

A/Csystem

are

shown

in

Fig

.

33

.

A/CSystem

Warnings

and

Cautions

WARNING

-

"

Always

be

careful

that

refrigerant

does

not

come

in

contact

with

your

skin

.

Always

wearhand

andeye

protection

(gloves

and

goggles)

when

work-

ing

around

the

AIC

system

.

If

refrigerant

does

come

in

contact

with

your

skin

oreyes

:

-Do

not

rub

skin

oreyes

;

-Immediately

flush

skin

oreyes

withcool

water

for

15

minutes

;

-Rush

to

a

doctor

orhospital

;

-Do

not

attempt

to

treat

yourself

.

"

Work

in

a

wefl

ventilated

area

.

Avoid

breathing

re-

frigerant

vapors

.

Exposure

may

irrítate

eyes,

nose,

and

throat

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

Do

not

expose

any

component

of

the

AIC

system

to

high

temperatures

(Above

80°Cl176°F)or

open

flames

.

Excessive

heat

will

cause

a

pres-

sureincrease

whichcould

burst

the

system

.

HEATING

AND

AIR

CONDITIONING

640-

1

1

0013015

WARNING

-

"

Keep

refrigerant

away

from

open

llames

.

Poison-

ous

gas

will

be

produced

if

it

bums

.

Do

not

smoke

near

refrigerant

gases

for

the

same

reason

.

"

The

AICsystem

is

filled

with

refrigerant

gas

which

is

under

pressure

.

Pressurized

refrigerant

in

the

presenceof

oxygen

may

forma

combusti-

ble

mixture

.

Never

introduce

compressed

air

finto

any

refrigerant

container

(full

or

empty),

capped

off

AIC

component,

or

piece

of

service

equip-

ment

.

"

Refrígerant

gases

are

heavier

than

air,

displace

oxygen

and

may

cause

suffocation

in

areas

of

poor

círculation,

for

example

under

a

car

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

State

and

local

governments

may

have

additional

requirements

regarding

air

conditioning

servic-

ing

.

Alwayscomply

with

state

and

local

laws

.

"

Electric

welding

near

refrigerant

hoses

causes

R-134a

to

decompose

.

Discharge

system

before

welding

.

CA

UTION

-

-As

of

January

1,

1992,

any

person

who

services

a

motor

vehicle

air

conditioner

must,

by

law,

be

properly

trained

and

certified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-approved

recycling

course

to

be

certified

.

"

It

is

recommended

that

al¡

system

refrigerant

AIC

refrigerant

be

left

to

an

authorized

BMW

dealer

or

other

qualified

AIC

service

facility

.

"

Do

not

top

off

a

partially

charged

refrigerant

sys-

tem

.

Dischargesystem,evacuate

and

then

re-

charge

system

.

"

R-134a

and

R-12

refrigerants

and

refrigerant

oils

and

system

components,

including

hoses

and

sealing

O-rings,

are

NOT

compatible

.

Compo-

nent

damage

andlor

system

contamination

will

result

.

"

The

mixture

of

refrigerant

oil

(PAG

oil)

and

refrig-

erant

R-134a

attacks

some

metals

and

alloys

(for

example,copper)

and

breaks

down

certain

hose

materials

.

Use

only

hoses

and

lines

that

are

iden-

tified

with

a

green

mark

(stripe)

or

the

lettering

R-

134a"

.

"

Immediately

plug

open

connections

on

AIC

com-

ponents

to

prevent

dirt

and

moisture

contamina-

tion

.

"

Do

not

steam

clean

condensers

or

evaporators

.

Use

only

cold

water

or

compressed

air

.

AIR

CONDITIONING

Page 501 of 759

88989

FROM1~

RED

FRONT

P

.

DISTRIBUTIONBO

I/

X

(DIAGRAM

2

OF

5)

B

I

I

I

I

I

I

I

I

I

I

L

-1

BLOWER

PARK

HEATING

BLOWER

RELAY

VENTILATION

RELAYRELAY

BOX

FROM

IGNITION

GRN

SWITCH

L

(DIAGRAM

30F5)

7

OR

RED/GR

.

I

.,

1997

OR

1DSSW/OPARK

11998W/PARK

VENTILATIONVENTILATION

FROM

IGNITION

K

SRN

SWITCH

(DIAGRAM

3

OF

5)

-------------

FUSE

FUSE

F20

F28

30A

5A

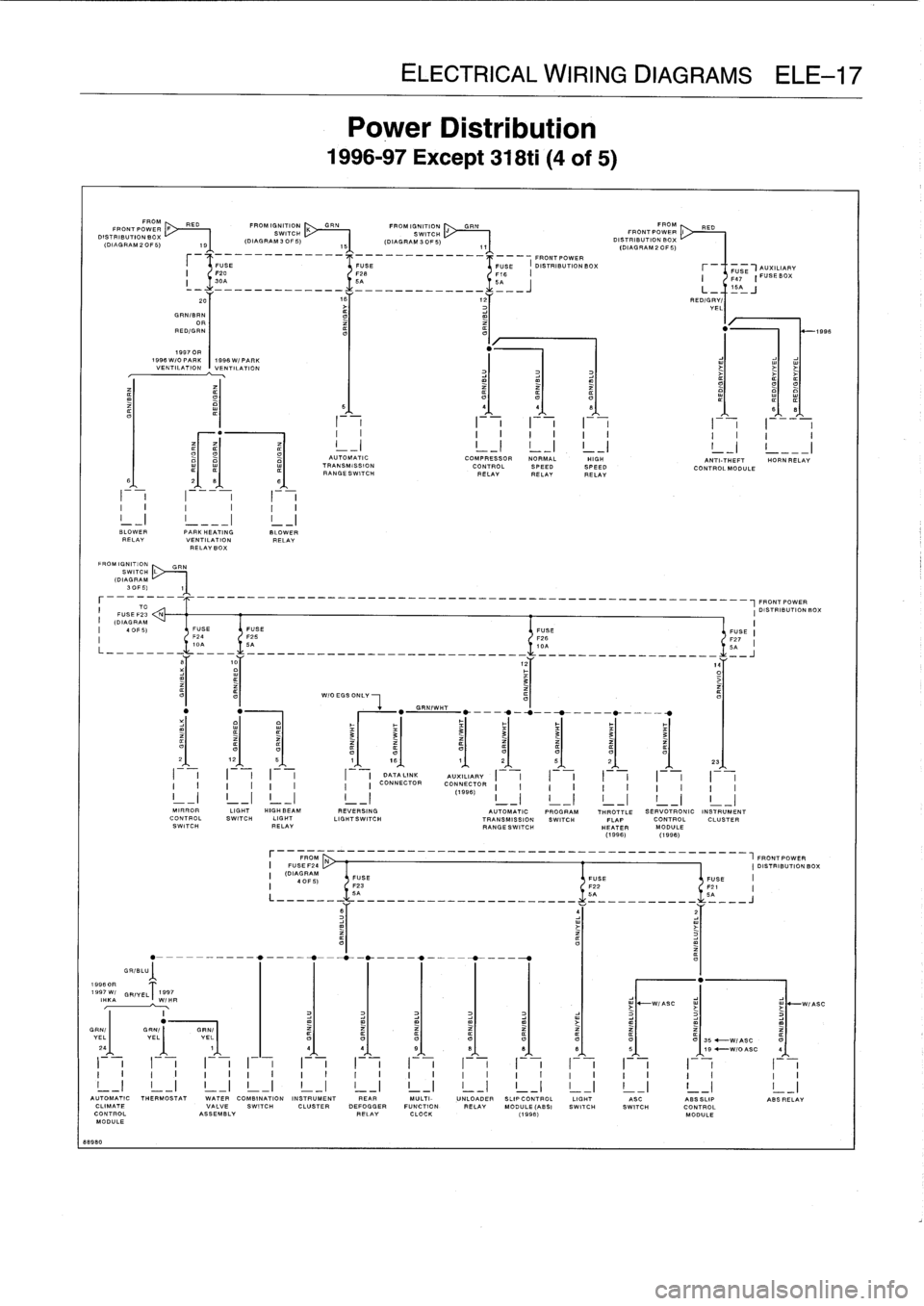

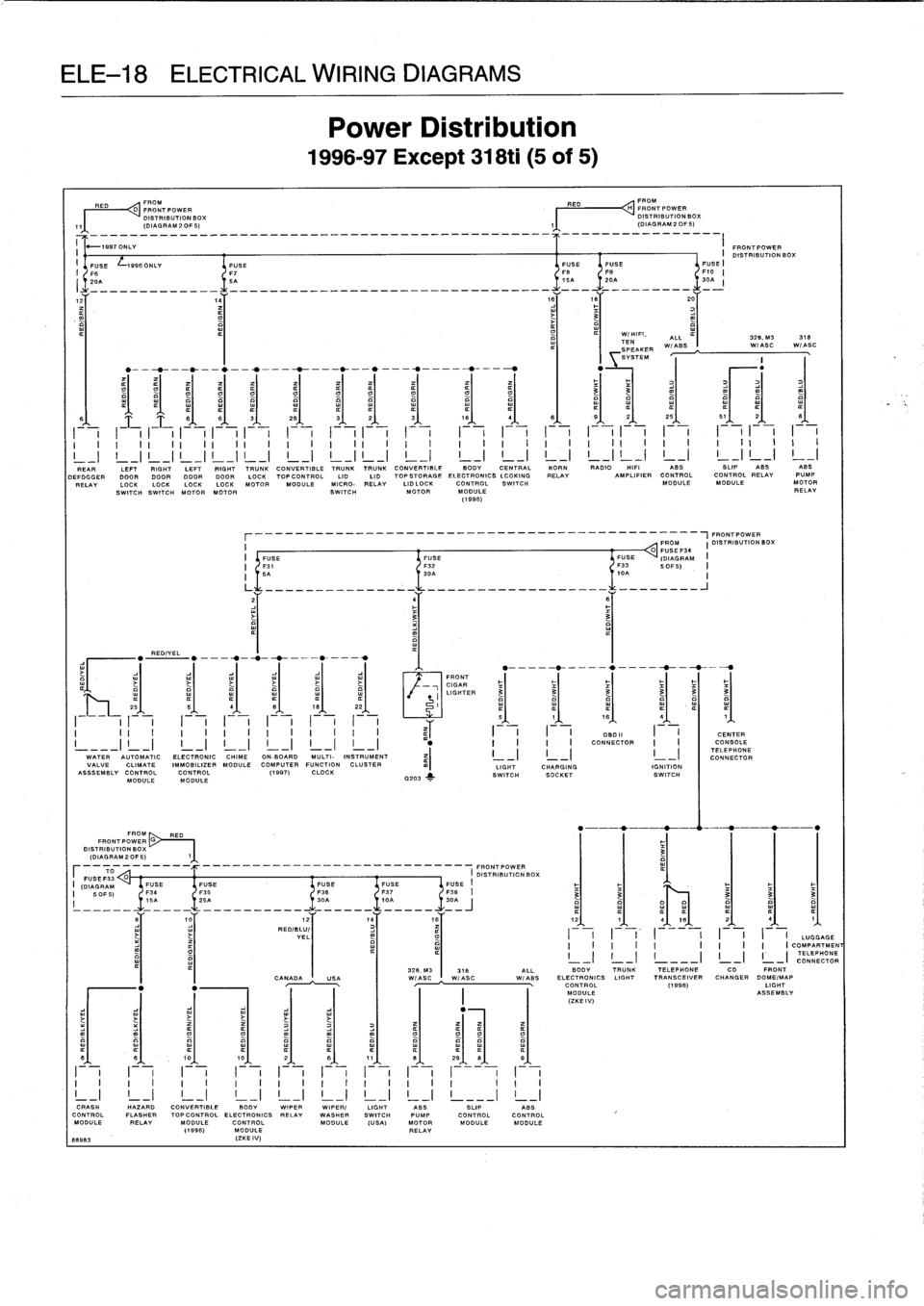

Power

Distribution

1996-97

Except

318ti

(4

of

5)

AUTOMATIC

TRANSMISSION

RANGE

S

W

ITCH

ELECTRICAL

WIRING

DIAGRAMS

ELE-17

FROM

IGNITION

~

GRN

SWITCH

(DIAGRAM

3

OF

5)

-

-

-

-

FRONTPOWER

FUSE

DISTRIBUTION

BOX

r-

_1

AUXILIARY

,IS

I

I

FE

7

E

I

FUSE

BOX

5

__~

L_

1

_

5

=J

I

-_______-___

~

--_____-___

iml

REO/GRY/

.FN/N

YEL

FROM(~

RED

FRONTPOWER

II

J-

DISTRIBUTION

BOX

(DIAGRAM

2

OF

5)

B

6B

I

I

I

I

I

I

I

I

I

I

I

II

_

1-1

I

__

I

1-1

I

__I

1____l

COMPRESSOR

NORMAL

HIGH

ANTI-THEFT

HORN

RELAY

CONTROL

SPEED

SPEED

CON

TROLMODULE

RELAYRELAYRELAY

MIRROR

LIGHT

HIGH

BEAM

REVERSING

AUTOMATIC

PROGRAM

THROTTLE

SERVOTRONIC

INSTRUMENT

CONTROL

SWITCH

LIGHT

LIGHTSWITCH

TRANSMISSION

SWITCH

FLAP

CONTROL

CLUSTER

SWITCH

RELAY

RANGESWITCH

HEATER

MODULE

(1996)(1996)

L

-I

L-1

L-1

!

_I

L-1

L

-I

L-1

L-1

L-1

L-1

!

_I

L-1

L-1

AUTOMATIC

THERMOSTAT

WATER

COMBINATION

INSTRUMENT

REAR

MULTI-

UNLOADER

SLIPCONTROL

LIGHT

AEC

ABSSLIP

ASS

RELAY

CLIMATE

VALVE

SWITCH

CLUSTER

DEFOGGER

FUNCTION

RELAY

MODULE

(ABS)

SWITCH

SWITCH

CONTROLCONTROL

ASSEMBLY

RELAYCLOCK

(1996)

MODULEMODULE

_1S96

Page 502 of 759

ELE-18

ELECTRICAL

WIRING

DIAGRAMS

RED

FROM

RED

FROM

D

FRONT

POWER

~H

FRONTPOWER

DISTRIBUTION

BOX

DISTRIBUTION

BOX

(DIAGRAM2OF5)

jl

(DIAGRAM2OF5)

-

--

I

.Sl

-

O

-

NLY

------------------------------------------

DISTRIBUTION

BOX

FUSE

F10

I

30A

I

I

FUSE

L

1995ONLY

FUSE

FUSE

FUSE

I

Ffi

F7

FB

F9

20A

SA

15A20A

'

Tw

q

RED/YEL

Power

Distribution

1996-97

Except

318ti

(5

of

5)

I

i

I

-

I

I

I

I

I

F',F',

I

i

F',F',

I

-

i

I

i

I

i

I

-

v

I

i

l

i

I

I

I

I

I

I

I

II

I

I

I

I

II

11

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

11

I

I

I

I

II

I

,

I

L-1

!

_I

!

_I

!

_l

!

_I

!

_I

L-1

!-IL-1

L-1

L-1

L-1L-1

L-1

1

-1

L-1

!-IL-1

L-1

REAR

LEFT

RIGHT

LEFT

RIGHT

TRUNK

CONVERTIBLE

TRUNK

TRUNK

CONVERTIBLE

BODY

CENTRAL

HORN

RADIO

HIFI

ASS

SLIP

ABS

ABS

DEFOGGER

DOOR

DOOR

DOOR

DOOR

LOCK

TOPCONTROL

LID

LID

TOPSTORAGE

ELECTRONICS

LCOKING

RELAY

AMPLIFIER

CONTROL

CONTROL

RELAY

PUMP

RELAY

LOCKLOCKLOCKLOCK

MOTORMODULE

MICRO-

RELAY

LIDLOCK

CONTROL

SWITCH

MODULE

MODULE

MOTOR

SWITCH

SWITCH

MOTORMOTOR

SWITCH

MOTOR

MODULE

RELAY

(1996)

_________________________________________-]PRONTPOWER

I

FROM

I

DISTRIBUTION

BOX0

FUSEF34

I

FUSE

FUSE

FUSE(DIAGRAM

II

t

J

F31

F32

133

5OF5)

II

SA

30A

t

0A

I

L

------------

__

.__

-----------

____

...

.

----------

F

-,

I

.I

F

-,

F

-,

III

I

II

I

II

I

I

I

I

I

I

I

I

I

I

I

I

___I

L-1

I-_I

L-1

L-1

L-1

L-1

WATER

AUTOMATIC

ELECTRONIC

CHIME

ON-BOARD

MULTI-

INSTRUMENTVALVE

CLIMATE

IM

MOB

ILIZER

MODULE

COMPUTER

FUNCTION

CLUSTER

AS

SSEMBLYCONTROL

CONTROL

(1997)

CLOCK

MODULEMODULE

G

FRONT

CIGAR

LIGHTER

FROM

RED

FRONTPOWER

G

DISTRIBUTIONBOX

(DIAGRAM

2

OF

5)

r

I

TO

O

I

FRONTPOWER

FUSE

F33

DISTRIBUTION

I

(DIAGRAM

FUSE

FUSE

FUSE

FUSE

FUSE

I

I

5

OF5)

F34

F35

F36

F3T

F3W

I

25----------

______

_____

328,

M3

I

315

ALL

BODY

TRUNK

TELEPHONE

CD

FRONT

CANADA

USA

WIASC

W/ASC

W/ABS

ELECTRONICS

LIGHT

TRANSCEIVER

CHANGER

DOME/MAP

I

CONTROL

(1996)

LIGHT

MODULE

ASSEMBLY

(ZKEIV)

I

-

i

I

-

i

I

I

1"!

1"!

I

I

I

-

j

1'l--I

1

-

-

i

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

_I

L-1

L-1

!

_I

1

__

j

1

__

J

1

__

j

1

__

j

1

-

1

CRASH

HAZARD

CONVERTIBLE

BOO

Y

WIPER

WIPER/

LIGHT

ABS

SLIP

ABS

CONTROL

FLASHER

TO

PCoNTROL

ELECTRONICS

RELAY

WASHER

SWITCH

PUMP

CONTROL

CONTROL

MODULE

RELAY

MODULECONTROL

MODULE

(USA)

MOTORMODULE

MODULE

(1996)

MODULE

RELAY

WW983

(ZKEIV)

W/HIFI

,

ALL

-

I

32

B,

M3

318

TEN

WIASS

I

WIASC

IN

ABC

SPEAKER

SYSTEM

'7

-

I

I

I

I

I

I

OBD11

II

II

I

II

CENTER

CONNECTOR

CONSOLE

TEL

PHONE

L-1

I

_I

L-1

CONNECTOR

LIGHT

CHARGING

IGNITION

SWITCH

SOCKET

SWITCH

Il

1

20

of

01

~

1

.1

.1

'

I

41

11

III

...

I

II

II

I

I

III

LUGGAGE

I

I

I

I

I

I

I

I

I

I

COMPARTMEN

I

-_I

ELEPHONE

CONNECTOR

Page 506 of 759

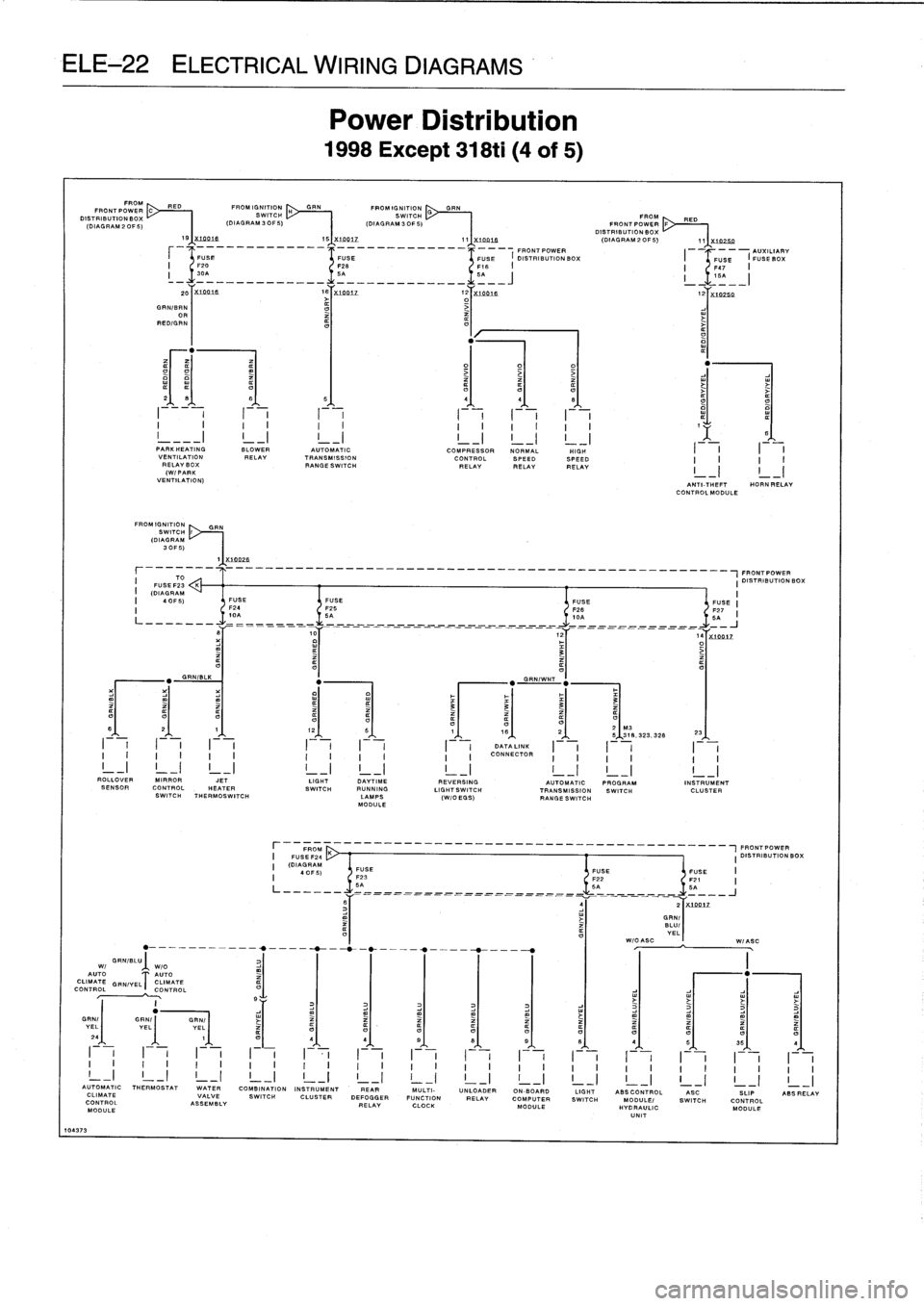

ELE-22

ELECTRICAL

WIRING

DIAGRAMS

GRNIBLU

Wl

WIO

AUTO

AUTO

CLIMATE

GEN/YELT

CLIMATE

CONTROL

CONTROL

10437

3

FP

OM~

PED

FRONTPOWER

DISTRIBUTION

BOY%

(DIAGRAM

2

OF

5)

S

FROMIGNITION

GRN

SWITCH

1

(DIAGRAM30F5)

r-______

________-IFRONTPOWER

I

FUSEF23

K

I

DISTRIBUTIONBO%

I

(DIAGRAM

I

I

40F5)

FUSE

FUSE

FUSE

FUSE

I

I

F24

F25

F2B

F27

I

I

L

5A

10A

SA

L_______

_---_--

-

y

__J

xr

10

12

141X10012

1

=1

GRN/BL

"

GRN/I

GRNI

GRNI

VEL

VELVEL

FROM

IGNITION

GRN

FPOMIGNI710N

GRN

SWITCH

H

SWITCH

G

(DIAGRAM30F5)

(DIAGRAM

OF

5)

FROM

PED

FRONTPOWER

F

DISTRIBUTION

BOX

15X

.1901Z

11IXmlfi

(DIAGRAM20F5)

11

X102s0

__

--

--

_

----

_

hRRICC

FRONT,

POWER

_

AUXILIARY

FUSE

FUSE

USE

I

DISTRIBUTION

BOX

I

FUSE

IFUSEBO%

Fzo

Fze

1J,F1s

I

(

F47

I

5A

i

5A

_

21"~e

_________

'1llZ

_________

11j

0

.X002XgOS

121K1D2=D

11

GRNIBRR

RED/GORN

i

6(

51

41

41

el

I

I

I

I

I

I

I

I

F-,

I

I

I

I

I

I

I

I

I

I

I

I

I

I

PARKHEATING

SLOWER

AUTOMATIC

COMPRESSOR

NORMAL

HIGH

VENTILATION

RELAY

TRANSMISSION

CONTROL

SPEEDSPEED

RELAYBOX

RANGESWITCH

RELAY

RELAYRELAY

(W/PARK

VENTILATION)

X7002B

Power

Distribution

1998

Except

318ti

(4

of

5)

"

_-__--_----

.

"

----+

ROLLOVER

MIRROR

JET

LIGHT

DAYTIME

REVERSING

AUTOMATIC

PROGRAM

INSTRUMENTSENSOR

CONTROL

HEATER

SWITCH

RUNNING

LIGHTSWITCH

TRANSMISSION

SWITCH

CLUSTER

SWITCH

THERMOSWITCH

LAMPS

(W/O

EGS)

RANGE

SWITCH

MODULE

61

41

zIx1oD17

ANTI-THEFT

HORNRELAY

Co

NTROLMODULE

FROM

___________________-__-_______________,FRONTPOWER

I

FUSE

F24

K

I

DISTRIBUTION

BOX

I

(DIAGRAMFUSE

USE

FUSE

I

40F5)

I

F23

F22

F21

I

5A-vvv--vv-~vv--cvvvvcv-

5-

5A___

_j

GRNI

BLU/

VEL

W/OASC

WIASC

I

I

I

I

I

I

I-I

i

I

I

I

i

I

-i

I

I

I

I

I

i

I-

i

I

i

III

I

!

_

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

!

_I

L-1

L

-I

L-1

L-1

AUTOMATIC

THERMOSTAT

WATER

COMBINATION

INSTRUMENT

REAR

MULTI-

UNLOADER

ON-BOARD

LIGHT

ABSCONTROL

AS

C

SLIP

ASS

RELAY

CLIMATE

VALVE

SWITCH

CLUSTER

DEFOGGED

FUNCTION

RELAY

COMPUTER

SWITCH

MODULE/

SWITCH

CONTROL

MODULE

L

ASSEMBLY

RELAY

CLOCK

MODULE

HYDRAULIC

MODULE

UNIT