jack stand BMW 328i 1995 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: 328i, Model: BMW 328i 1995 E36Pages: 759

Page 265 of 759

STABILIZER

BAR

Stabilizer

bar,

removing

and

installing

Stabilizer

bar

link

arrangements

differ

slightly

among

mod-

els

.

In

most

models

the

links

attach

lo

the

control

arms

near

the

outboard

end

.

OnM3

models

the

links

attach

lo

the

strut

assemblies

.

1

.

Raise

car

and

remove

both

front

wheels

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

stands

desígned

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassís

point

.

Do

not

place

jack

stands

under

suspension

parts

.

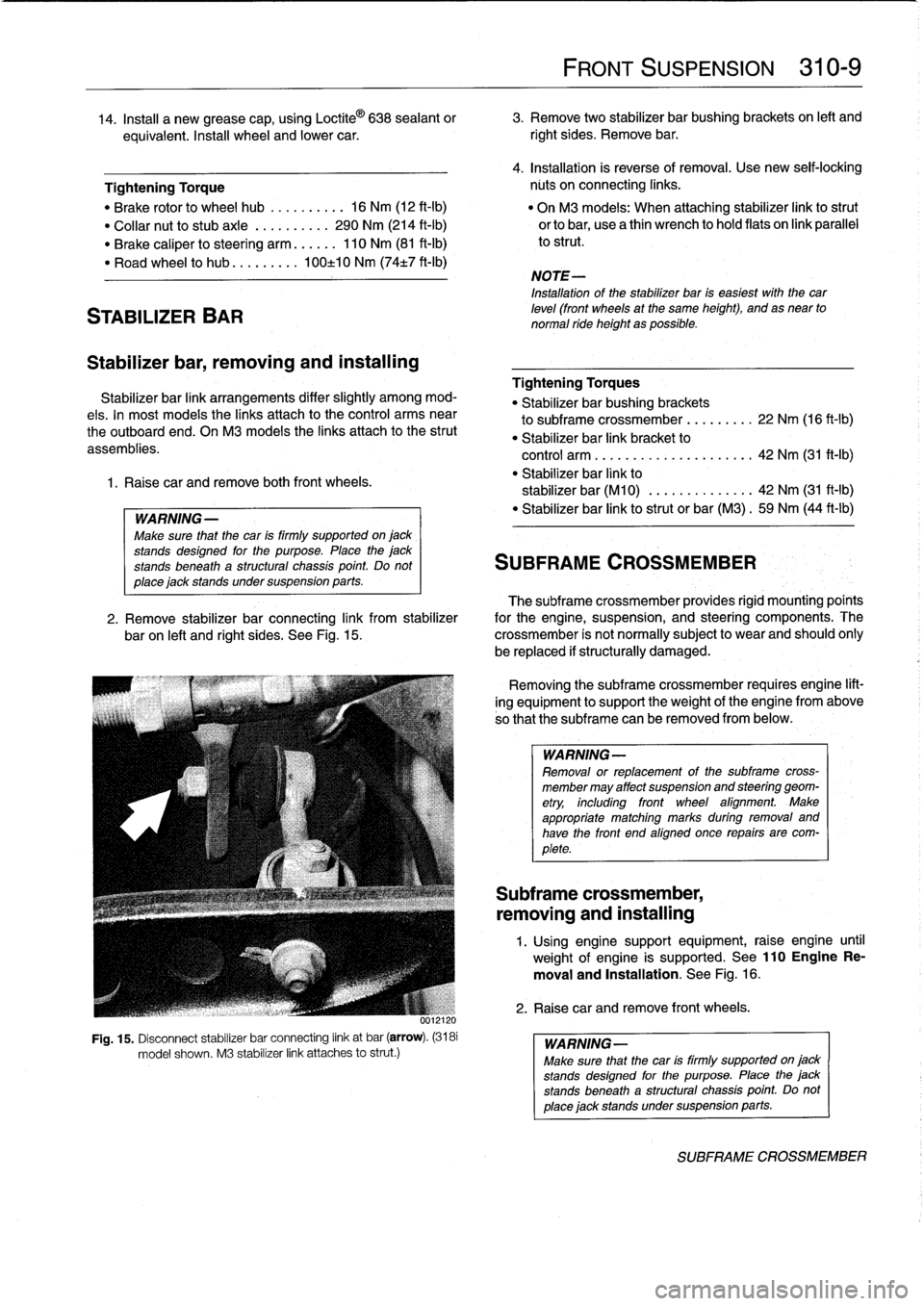

uul

Fig

.

15

.

Disconnect

stabilizer

bar

connecting

link

at

bar

(arrow)

.

(3181

model

shown

.

M3

stabilizer

link

attaches

lo

strut

.)

FRONT

SUSPENSION

310-

9

14

.

Insta¡¡

a

new

grease

cap,

using

Loctite

©

638

sealant

or

3

.

Remove

two

stabilizer

bar

bushing

brackets

on

left

and

equivalent

.

Insta¡¡

wheel

and

lower

car

.

right

sides

.

Remove

bar

.

4

.

Installation

is

reverse

of

removal

.

Use

new

seif-lockíng

Tightening

Torque

núts

on

connecting

links

.

"

Brake

rotor

lo

wheel

hub

..........

16

Nm

(12

ft-Ib)

"

On

M3

models

:

When

attaching

stabilizer

link

lostrut

"

Collar

nut

lo

stubaxle

.

.........

290

Nm

(214

ft-Ib)

orlobar,

usea

thin

wrench

lo

hold

flats

on

link

parallel

"

Brake

caliper

losteering

arm

......

110

Nm

(81

ft-Ib)

lo

strut

.

"

Road

wheel

lo

hub

...

...

.

.

.

100±10

Nm

(74t7

ft-Ib)

NOTE-

Installation

of

the

stabilizer

bar

is

easiest

with

thecar

leve¡

(front

wheels

at

the

same

height),

and

as

near

to

normal

ride

height

as

possible

.

Tightening

Torques

"

Stabilizer

bar

bushing

brackets

lo

subframe

crossmember

...

..

.

..

.

22

Nm

(16

ft-Ib)

"

Stabilizer

bar

link

bracket

lo

control

arm

................

.

.

.

.

.

42

Nm

(31

ft-1b)

"

Stabilizer

bar

link

lo

stabilizer

bar

(M10)

.............

.

42

Nm

(31

ft-Ib)

"

Stabilizer

bar

link

lostrut

or

bar

(M3)

.

59

Nm

(44

ft-Ib)

SUBFRAME

CROSSMEMBER

The

subframe

crossmember

provides

rigid

mounting'poínts

2

.

Remove

stabilizer

bar

connecting

link

from

stabilizer

for

the

engine,

suspension,

and

steering

components

.

The

baron

left

and

right

sides

.

See

Fig

.

15

.

crossmember

is

not

normally

subject

lo

wear

and

should

ohly

be

replaced

if

structurally

damaged

.

Removing

the

subframe

crossmember

requires

engine

lift-

ing

equipment

lo

support

theweight

of

tfhe

engine

from

above

so

that

the

subframe

can

be

removed

from

below

.

WARNING-

Removal

or

replacement

of

the

subframe

cross-

member

may

affect

suspension

and

steering

geom-

etry,

including

front

wheel

afignment

.

Make

appropriate

matching

marks

during

removal

and

have

the

front

end

aligned

once

repairs

are

com-

plete

.

Subframe

crossmember,

removing

and

installing

1

.

Using

enginesupport

equipment,

raise

engine

until

weight

of

engine

is

supported

.

See

110EngineRe-

moval

and

Installation

.

See

Fig

.

16

.

2

.

Raise

car

andremove

front

wheels

.

WARNING-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

desígned

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassís

point

Do

not

place

jack

standsundersuspension

parts

.

SUBFRAME

CROSSMEMBER

Page 268 of 759

320-2

STEERING

AND

WHEEL

ALIGNMENT

3

.

Carefully

remove

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

safe

place

.

WARNING-

Improper

handling

of

theaírbag

could

cause

seri-

ous

ínjury

.

Store

theaírbag

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

deployment

could

propel

it

vlolently

into

the

air,

causíng

ínjury

.

4

.

Remove

steering

wheel

center

bolt

.

Lightly

punch

mark

or

scribe

position

of

steering

wheel

to

steering

column

shaft

.

See

Fig

.

1

.

0012687

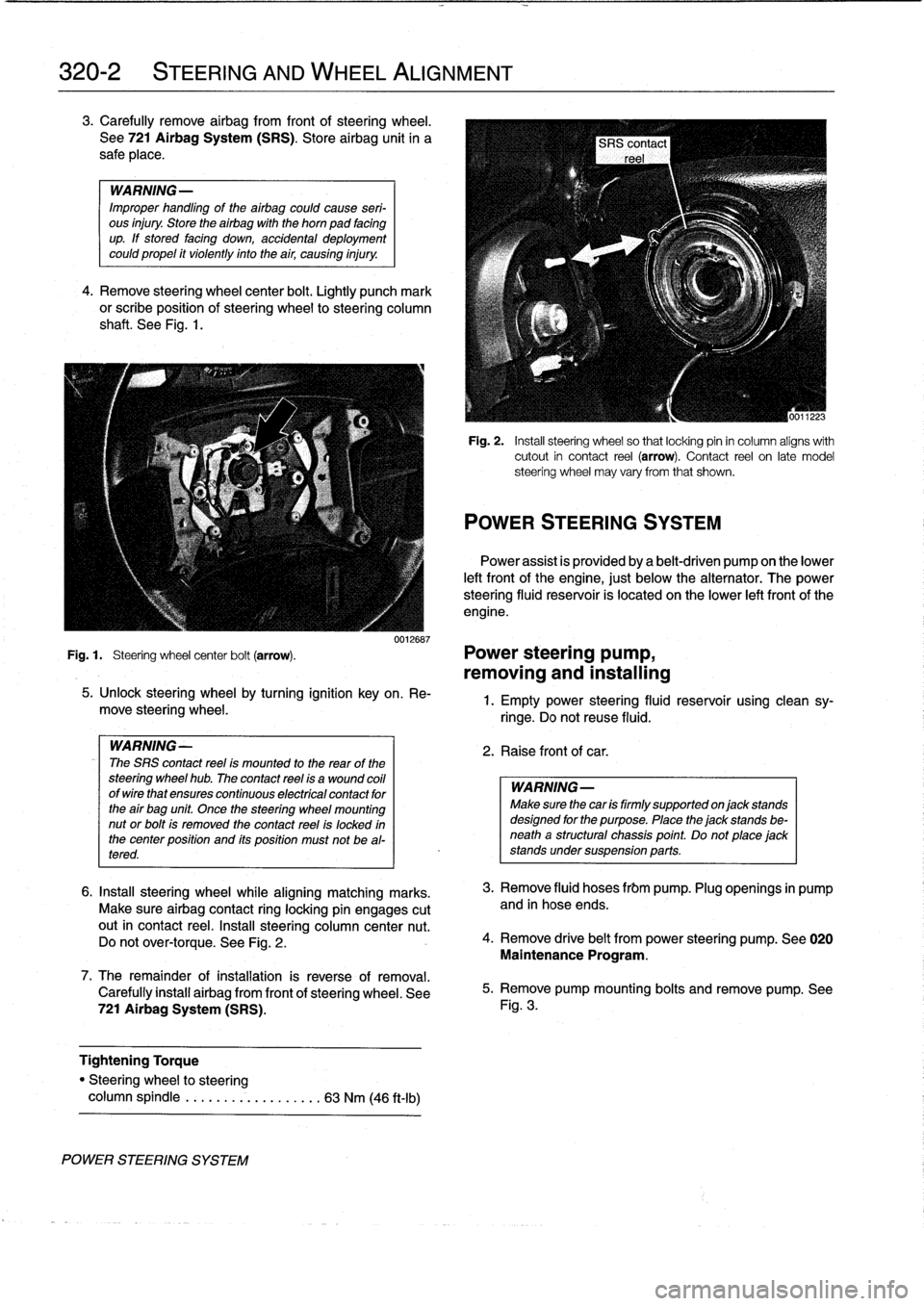

Fig

.

1

.

Steering

wheel

center

bolt

(arrow)

.

Power

steering

pump,

removing

and

installing

POWER

STEERING

SYSTEM

5

.

Unlock

steering

wheel

by

turning

ignition

key

on

.

Re-

move

steering

wheel

.

WARNING-

The

SRS

contact

reel

ís

mounted

to

the

rear

of

the

steering

wheel

hub

.

The

contact

reel

ís

a

wound

coil

ofwirethat

ensures

continuous

electrícal

contact

for

the

air

bag

unit

Once

the

steering

wheel

mounting

nut

or

bolt

is

removed

the

contact

reel

is

locked

in

the

center

position

and

its

position

must

not

be

al-

tered

.

6

.

Insta¡¡

steering

wheel

while

aligning

matching

marks

.

Make

sure

airbag

contact

ring

locking

pin

engages

cutout

in

contact

reel

.

Insta¡¡

steering

column

center

nut

.

Do

not

over-torque

.

See

Fig

.

2

.

7

.

The

remainder

ofinstallation

is

reverse

of

removal

.

Carefully

install

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Tightening

Torque

"

Steering

wheel

to

steering

column

spindle

...

..

..

.

..........

63

Nm

(46

ft-Ib)

Fig

.

2

.

Insta¡¡

steering

wheel

so

that

locking

pin

in

column

aligns

with

cutout

in

contact

reel

(arrow)

.

Contact

reel

on

late

model

steering

wheel

may

vary

from

that

shown

.

POWER

STEERING

SYSTEM

Power

assist

is

províded

by

a

belt-driven

pump

on

the

lower

left

front

of

the

engine,

just

below

the

alternator

.

The

power

steering

fluid

resenroir

is

located

on

the

lower

left

front

of

the

engine

.

1

.

Empty

power

steering

fluid

reservoir

usingclean

sy-

ringe

.

Do

not

reuse

fluid

.

2

.

Raise

front

of

car

.

WARNING

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

3

.

Remove

fluid

hoses

frbm

pump

.

Plug

openings

in

pump

and

in

hose

ends

.

4

.

Remove

drive

belt

from

power

steering

pump

.

See

020

Maintenance

Program

.

5

.

Remove

pump

mounting

bolts

and

remove

pump

.

See

Fig

.

3

.

Page 275 of 759

Rear

shock

absorber,

removing

and

installing

1.

Raisecar

and

remove

rear

wheels

.

WARNING

-

Make

sure

that

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

rear

speakers

.

See

650

Radio

.

3

.

Pryoutluggage

compartment

liner

retaining

clips

and

peel

back

liner

to

gain

access

to

upper

shock

absorber

mounting

nuts

.

See

Fig

.

3

.

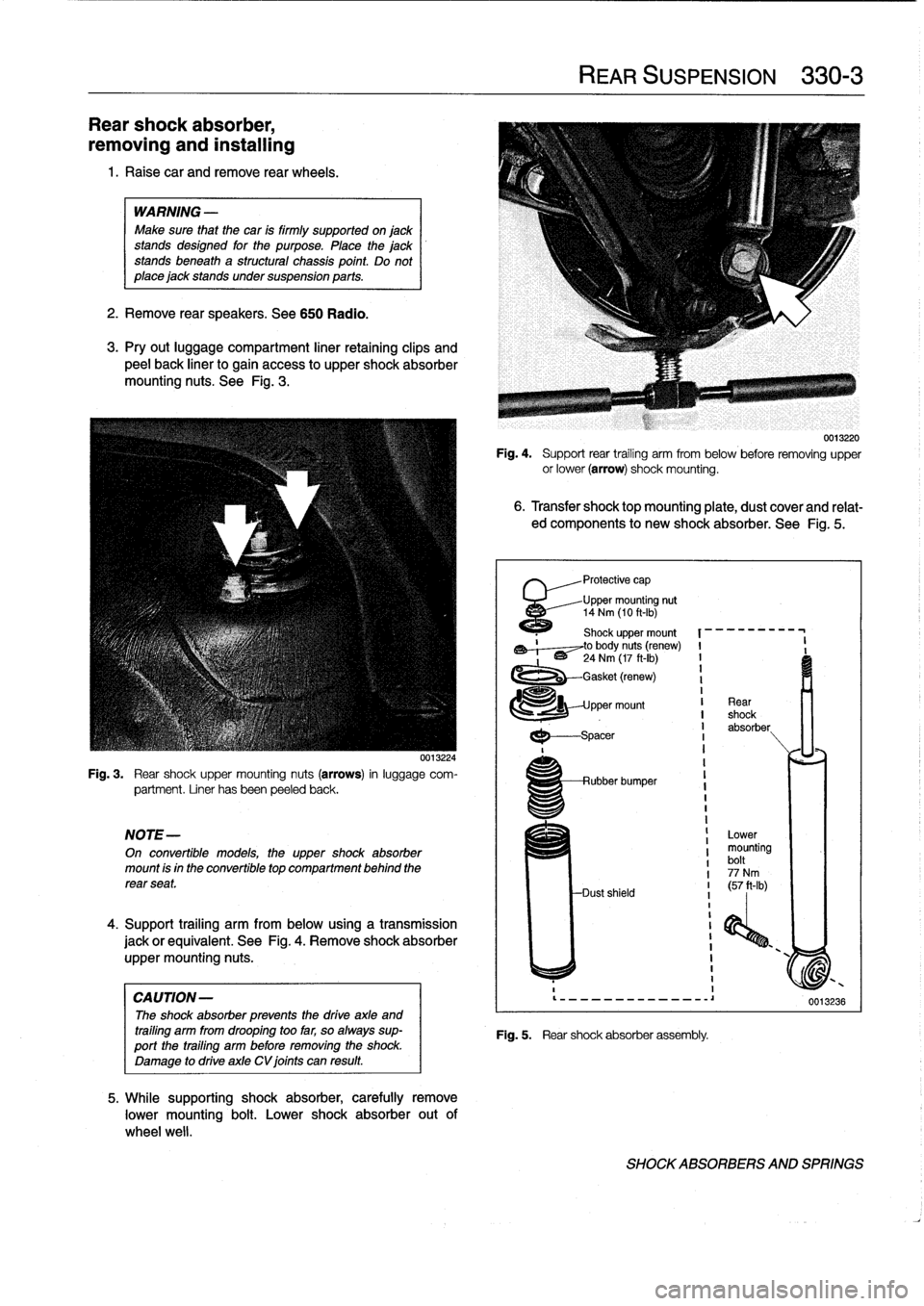

Fig

.

3

.

Rear

shock

upper

mounting

nuts

(arrows)

in

luggage

com-

partment

.

Liner

hasbeen

peeled

back

.

NOTE-

On

convertible

models,

the

uppershock

absorber

mount

is

in

the

convertible

top

compartment

behind

the

rear

seat

.

4

.

Support

trailing

arm

from

below

using

a

transmission

jack

orequivalent

.

See

Fig

.

4

.

Remove

shock

absorber

uppermounting

nuts

.

CAUTION-

The

shock

absorber

prevenís

the

drive

axle

and

trailing

arm

from

drooping

too

far,

so

always

sup-port

the

trailing

arm

before

removing

the

shock

.

Damage

to

drive

axle

CV

joints

can

result

.

0013224

5

.

While

supporting

shock

absorber,

carefully

remove

lower

mounting

bolt

.

Lower

shock

absorber

out

of

wheel

well

.

Fig

.

4

.

Support

rear

trailing

arm

from

below

before

removing

upper

or

lower

(arrow)

shock

mounting

.

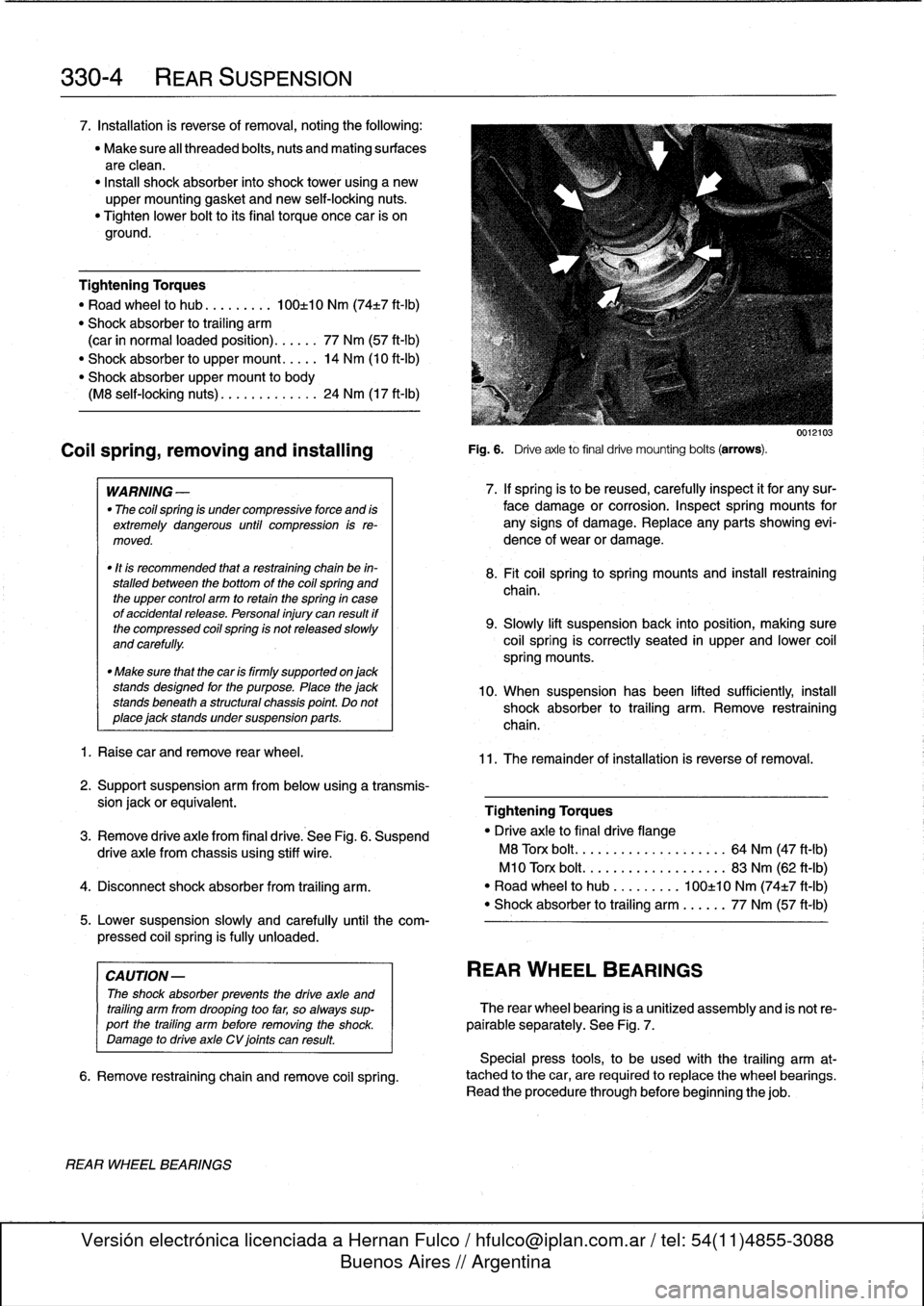

6

.

Transfer

shocktopmounting

plate,

dust

coverand

relat-

ed

components

to

new

shock

absorber

.

See

Fig

.

5

.

'

Protective

cap

Upper

mounting

nut

14

Nm

(10

ft-Ib)

1120

Shock

upper

mount

,~,--~to

body

nuts

(renew)

I

-

'

~

24

Nm

(17

ft-Ib)

I

1

-Gasket

(renew)

I

1

pper

mount

I

Rear

I

shock

I

absorber

I

I

---spacer

REAR

SUSPENSION

330-

3

Rubber

bumper

Dust

shield

Fig

.

5

.

Rear

shock

absorber

assembly

.

Lower

mounting

bolt

77

Nm

I

(57

ft-Ib)

i

I

I

1

I

0013220

0013236

SHOCKABSORBERS

AND

SPRINGS

Page 276 of 759

330-

4

REAR

SUSPENSION

7

.

Installation

is

reverse

ofremoval,

noting

the

following

:

"

Make

sure

all

threaded

bolts,

nuts

and

makng

surfaces

are

clean

.

"

Instan

shock

absorber

finto

shock

tower

using

a

new

uppermounting

gasket

and

new

self-locking

nuts

.

"

Tighten

lower

boltto

its

final

torque

oncecar

is

on

ground

.

Tightening

Torques

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

"

Shock

absorber

to

trailing

arm

(car

in

normalloaded

position)

......

77

Nm

(57

ft-Ib)

"

Shock

absorber

to

upper

mount

.....

14

Nm

(10

ft-Ib)

"

Shock

absorber

upper

mount

to

body

(M8

self-locking

nuts)

.............

24

Nm

(17

ft-Ib)

Coil

spring,

removing

and

installing

WARNING

-

"

The

coil

spring

is

undercompressive

force

and

ís

extremely

dangerous

until

compression

isre-

moved

.

"

lt

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottomof

the

coil

spring

and

the

upper

control

arm

to

retain

the

spring

in

case

of

accidental

release

.

Personal

injury

can

result

if

the

compressed

coil

spring

is

not

released

slowly

and

carefully

.

"

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

1

.

Raise

car

and

remove

rear

wheel

.

2

.

Support

suspension

arm

from

below

using

a

transmis-

sion

jack

orequívalent

.

Tightening

Torques

3

.

Remove

drive

axle

from

final

drive

.

See

Fig

.

6

.

Suspend

"

Drive

axle

to

final

drive

flange

drive

axle

from

chassis

using

stiff

wire

.

M8

Torx

bolt

.

..

...

.

.............

64

Nm

(47

ft-Ib)

M10

Torx

bolt

...................

83

Nm

(62

ft-Ib)

4

.

Disconnect

shock

absorber

from

traíling

arm

.

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

"

Shock

absorber

to

trailing

arm

......

77

Nm

(57

ft-Ib)

5

.

Lower

suspension

slowly

and

carefully

until

the

com-

pressed

coil

spring

is

fully

unloaded

.

CAUTION

-

The

shock

absorber

prevents

the

drive

axle

and

trailíng

arm

from

drooping

too

far,

so

always

sup-port

the

trailing

arm

before

removing

the

shock

.

Damage

to

drive

axle

CV

joints

can

result

.

6

.

Remove

restraining

chain

and

remove

coi¡

spring

.

REAR

WHEEL

BEARINGS

Fig

.

6

.

Driveaxle

to

final

drive

mounting

bolts

(arrows)

.

0012103

7

.

If

spring

is

to

be

reused,

carefully

inspect

it

for

any

sur-

face

damage

or

corrosion

.

Inspect

spring

mounts

for

any

signs

of

damage

.

Replace

any

parts

showing

evi-

dence

of

wear

or

damage

.

8

.

Fit

coil

springtospring

mountsand

insta¡¡

restraíning

chaina

9

.

Slowly

lift

suspensionback

into

position,

making

sure

coil

spring

is

correctly

seated

in

upper

and

lower

coil

spring

mounts

.

10

.

When

suspension

has

been

lifted

sufficiently,

instan

shock

absorber

to

trailing

arm

.

Remove

restraining

chain

.

11

.

The

remainder

of

installation

is

reverse

of

removal

.

REAR

WHEEL

BEARINGS

The

rear

wheel

bearing

is

a

unitized

assembly

and

is

not

re-

pairable

separately

.

See

Fig

.

7

.

Special

press

tools,

to

be

used

with

the

trailing

arm

at-

tached

to

the

car,

are

requiredto

replace

the

wheel

bearings

.

Read

the

procedure

through

before

beginning

thejob

.

Page 278 of 759

330-

6

REAR

SUSPENSION

12

.

Install

brake

caliper

assembly

and

rotor

as

described

in

340Brakes

.

13

.

Install

drive

axie

as

described

below

.

Tightening

Torques

"

Brake

rotor

to

drive

flange

.........

16

Nm

(12

ft-ib)

"

Brake

caliper

to

trailing

arm

........

67

Nm

(50

ft-Ib)

"

Drive

axie

collar

nut

to

drive

flange

..

.

..

..............

250

Nm

(184

ft-Ib)

M3

.....

...

..

.

.............

.

300

Nm

(221

ft-Ib)

"

Road

wheel

to

hub

.........

100±10

Nm

(74±7

ft-Ib)

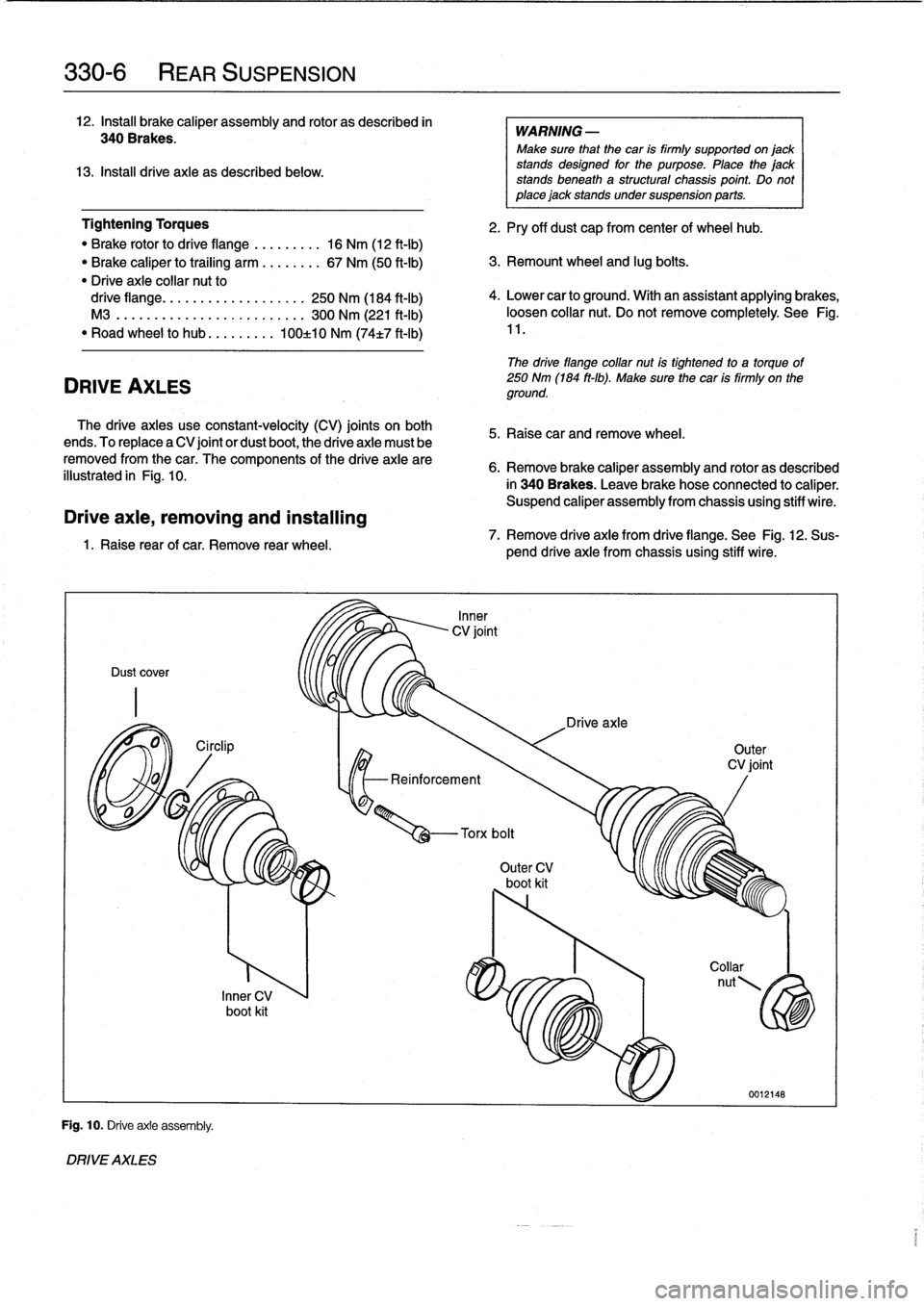

DRIVE

AXLES

The

drive

axles

use

constant-velocity

(CV)

joints

on

both

ends

.

To

replace

a

CV

joint

or

dust

boot,

the

drive

axie

must

be

removed

fromthe

car

.

The

components

of

the

drive

axie

are

illustrated

in

Fig

.

10

.

Drive

axie,

removing

and

installing

1

.

Raise

rear

of

car

.

Remove

rear

wheel

.

Dust

cover

Fig

.

10

.

Driveaxie

assembly

.

DRIVE

AXLES

Inner

CV

boot

kit

-Reinforcement

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Pry

off

dust

cap

from

center

of

wheel

hub

.

3

.

Remount

wheel

and

lug

boits

.

4

.

Lower

car

to

ground

.

With

an

assistant

applying

brakes,

loosen

collar

nut

.

Do

not

remove

completely

.

See

Fig

.

11

.

The

drive

flange

collar

nut

is

tightened

to

a

torque

of

250

Nm

(184

ft-Ib)

.

Make

sure

the

car

is

firmly

on

the

ground

.

5

.

Raisecar

andremove

wheel

.

6

.

Remove

brake

caliper

assembly

and

rotor

as

described

in

340

Brakes

.

Leave

brake

hose

connected

to

caliper

.

Suspend

caliper

assembly

from

chassis

using

stiff

wire

.

7

.

Remove

drive

axie

from

drive

flange

.

See

Fig

.

12

.

Sus-

pend

drive

axie

from

chassis

using

stiff

wire

.

Outer

CV

boot

kit

Drive

axle

Outer

CV

joint

Page 282 of 759

330-

1

0

REAR

SUSPENSION

Trailing

arm,

removing

and

installing

1

.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

brake

rotor

and

caliper

as

described

in

340

Brakes

.

Do

not

remove

brake

line

from

caliper

.

Hang

caliper

from

body

with

wire

.

4

.

Remove

parking

brakecable

frombrake

shoe

expand-

er

.

See

340

Brakes

.

5

.

Remove

rear

brake

line

bracket

from

trailing

arm

.

See

Fig

.

17

.

Fig

.

17

.

Brake

line

bracket

bolts

on

trailing

arm

(arrow)

.

WARNING

-

It

is

recommended

that

a

restraining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retainthe

spring

in

case

of

accidentalrelease

.

Personal

injury

can

re-sult

if

the

compressed

coil

spring

is

not

released

slow1y

and

carefully

.

REAR

SUSPENSION

ARMS

6

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

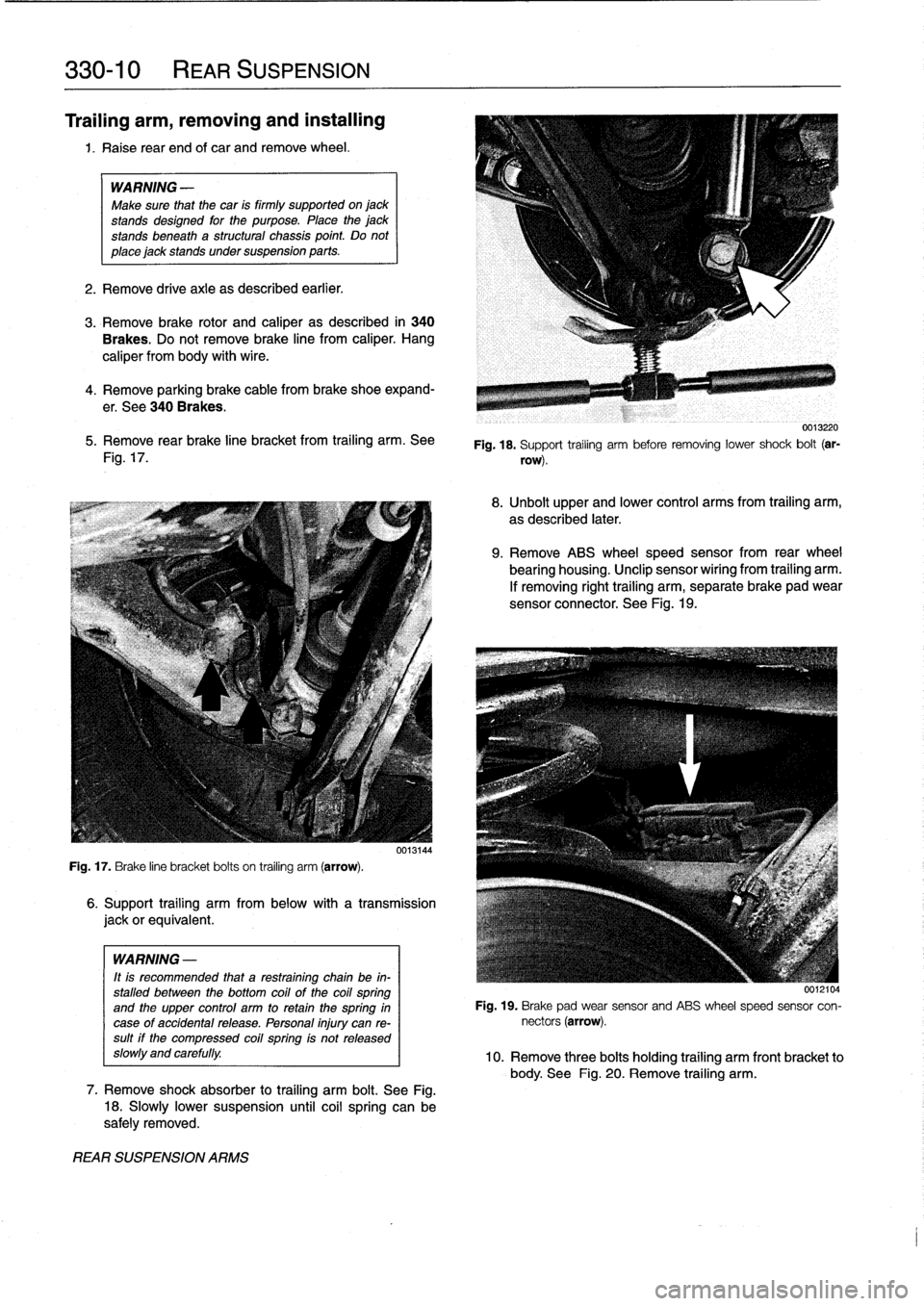

7

.

Remove

shock

absorber

to

trailing

arm

bolt

.

See

Fig

.

18

.

Slowly

lower

suspension

until

coil

spring

can

be

safely

removed

.

0013220

Fig

.

18

.

Support

trailing

arm

before

removing

lower

shock

bolt

(ar-

row)

.

8

.

Unbolt

upper

and

lower

control

arms

from

trailing

arm,

as

described

later

.

9

.

Remove

ABS

wheel

speed

sensor

from

rear

wheel

bearing

housing

.

Unclip

sensor

wiríng

from

trailing

arm

.

If

removing

right

trailing

arm,

separate

brake

pad

wear

sensor

connector

.

See

Fig

.

19

.

0012104

Fig

.

19

.

Brake

pad

wear

sensor

and

ABS

wheel

speed

sensor

con-

nectors

(arrow)

.

10

.

Remove

three

bolts

holding

trailing

arm

front

bracket

to

body

.

See

Fig

.

20

.

Remove

trailing

arm

.

Page 284 of 759

330-

1

2

REAR

SUSPENSION

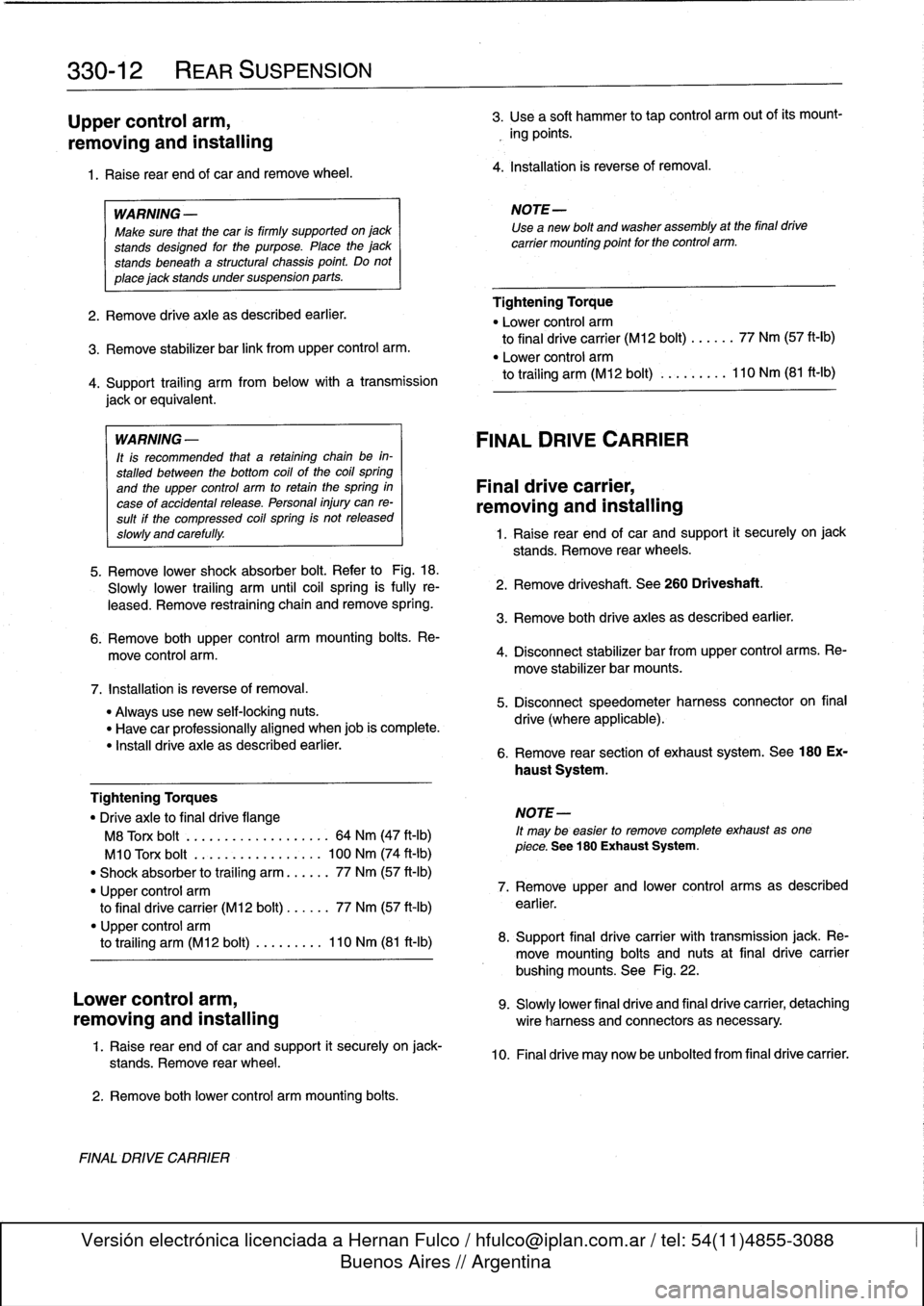

Upper

control

arm,

removing

and

installing

1.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

stabilizer

bar

link

fromupper

control

arm

.

4

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

WARNING

-

It

is

recommended

that

a

retaining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

ís

not

released

slowly

and

carefully

.

5

.

Remove

lower

shock

absorber

bolt

.

Refer

to

Fig

.

18

.

Slowly

lower

trailing

arm

until

coil

spring

is

fully

re-

leased

.

Remove

restraining

chain

and

remove

spring

.

7

.

Installation

is

reverse

of

removal

.

"

Always

use

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

"

Insta¡¡

drive

axle

as

described

earlier

.

Tightening

Torques

"

Drive

axleto

final

drive

flange

M8

Torx

bolt

..........

..

.

..

....

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.........

..

..

.

...

100

Nm

(74

ft-Ib)

"

Shock

absorber

to

trailing

arm

..

..

..

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

final

drive

carrier

(M12

bolt)

...

..

.

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

trailing

arm

(M12

bolt)

.........

110

Nm

(81

ft-Ib)

Lower

control

arm,

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack-

stands

.

Remove

rear

wheel

.

2

.

Remove

both

lower

control

arm

mounting

bolts

.

FINAL

DRIVE

CARRIER

3

.

Use

a

soft

hammer

to

tap

control

arm

out

of

its

mount-

ing

points

.

4

.

Installation

is

reverse

of

removal

.

NOTE-

Use

a

new

bolt

and

washer

assembly

at

the

final

drive

carrier

mountíng

point

forthe

control

arm

.

Tightening

Torque

"

Lower

control

arm

to

final

drive

carrier

(M12

bolt)

......

77

Nm

(57

ft-Ib)

"

Lower

control

arm

to

trailing

arm

(M12

bolt)

....

..

.

..

110

Nm

(81

ft-Ib)

FINAL

DRIVE

CARRIER

Final

drive

carrier,

removing

and

installing

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

both

drive

axles

as

described

earlier

.

6

.

Remove

both

upper

control

arm

mounting

bolts

.

Re-

move

control

arm

.

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

move

stabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Remove

rear

section

of

exhaust

system

.

See

180

Ex-

haust

System

.

NOTE-

It

may

be

easier

to

remove

complete

exhaust

asonepiece

.

See

180

Exhaust

System

.

7

.

Remove

upper

and

lower

control

arms

as

described

earlier

.

8

.

Support

final

drive

carrierwith

transmissíon

jack

.

Re-

move

mounting

bolts

and

nuts

at

final

drive

carrier

bushing

mounts

.

See

Fig

.

22

.

9

.

Slowly

lower

final

drive

and

final

drive

carrier,

detaching

removing

and

installing

wire

harness

and

connectors

as

necessary

.

10

.

Finaldrive

may

now

be

unbolted

from

final

drive

carrier

.

Page 287 of 759

GENERAL

......

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Final

Drive

Oil

Seals

.

.

...

.

.

.

.......

.

.

.

.

.

331-1

Finaldrive

flange

oil

sea¡,

replacing

....

.

.

.

..

331-2

FINAL

DRIVE

SERVICE

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

inputshaft

oil

seal,

replacing

.

.

.

.

.

331-3

Final

drive

oí¡,

draining

and

filling

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

unit,

removíng

and

installing

.

.

.

.

.

.

331-3

GENERAL

This

repa¡r

group

covers

repair

operations

that

do

not

re-

quire

complicated

disassembly

of

the

final

drive

.

Internal

re-

pairs

and

final

drive

disassembly

are

not

covered

in

this

manual

.

FINAL

DRIVE

SERVICE

Al¡

final

drive

work

requires

some

method

of

raising

thecar

and

supporting

it

securely

while

the

work

is

performed

.

Jack

stands

and

a

floor

jack

can

easily

be

used,

but

use

extreme

caution

when

working

beneath

the

car

.

See010

Fundamen-

tais

for

the

Do-It-Yourself

Owner

.

NOTE-

Removal

of

final

drive

carrier

is

covered

in

330

Rear

Suspension

.

Final

drive

oil,

draining

and

filling

1

.

Drive

car

to

warm

final

drive

fluid

.

2

.

Raise

car

and

support

safely

.

WARNING

-

Make

sure

that

thecar

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

5

.

Fill

final

drive

with

appropriate

type

and

quantity

of

lu-

bricant

.

Insta¡¡

and

tighten

fill

plug

.

331

Final

Drive

0

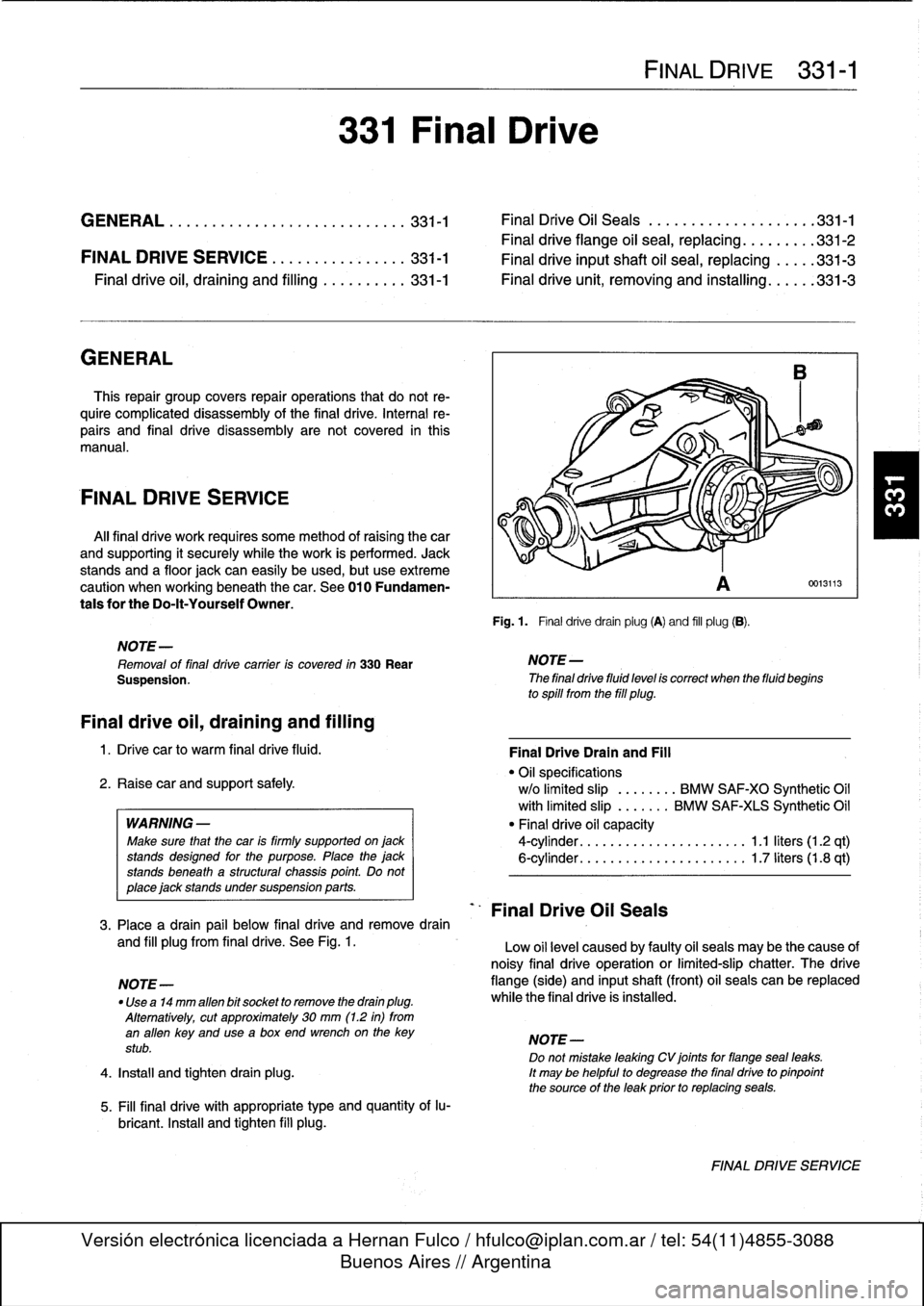

Fig

.

1

.

Final

drivedrain

plug

(A)

and

fill

plug

(B)

.

D

NOTE-

The

final

drive

fluid

level

is

correct

when

the

fluid

begins

to

spill

from

the

fill

plug

.

Final

Drive

Oil

Seals

FINAL

DRIVE

331-1

0013113

Final

DriveDrain

and

Fill

"

Oil

specifications

w/o

limited

slip

.

.......

BMW

SAF-XO

Synthetic

Oil

with

limited

slip

.

......

BMW

SAF-XIS

Synthetic

Oil

"

Final

drive

oil

capacity

4-cylinder

.

.

.

...

................

1

.1

liters

(1

.2

qt)

6-cylinder

.

.

.

...

................

1

.7liters(1.8

qt)

3

.

Place

a

drain

pail

below

final

drive

andremove

drain

and

fill

plugfrom

final

drive

.

See

Fig

.

1

.

Low

oil

level

caused

by

faulty

oil

seals

may

be

the

cause

of

noisy

final

drive

operation

or

limited-slip

chatter

.

The

drive

NOTE-

flange

(side)

and

inputshaft

(front)

oil

seals

can

be

replaced

"

Use

a14

mm

alíen

bit

socket

to

remove

the

drain

plug

.

while

the

final

drive

is

installed

.

Alternatively,

cut

approximately

30

mm

(1

.2

in)

from

an

alíen

key

and

usea

box

end

wrenchon

the

key

NOTE-

stub

.

Do

not

mistake

leaking

CV

joints

for

flangeseal

leaks

.

4

.

Install

and

tighten

drain

plug

.

It

may

be

helpful

to

degrease

the

final

drive

to

pinpoint

the

source

of

the

leak

prior

to

replacing

seals

.

FINAL

DRIVE

SERVICE

Page 289 of 759

Final

driveinputshaft

oil

sea¡,

replacing

1

.

Raise

car

and

support

safely

.

2

.

Drain

final

drive

oil

as

described

earlier

.

3

.

Remove

driveshaft

from

final

drive

inputshaft

flange

.

See

260

Driveshaft

.

4

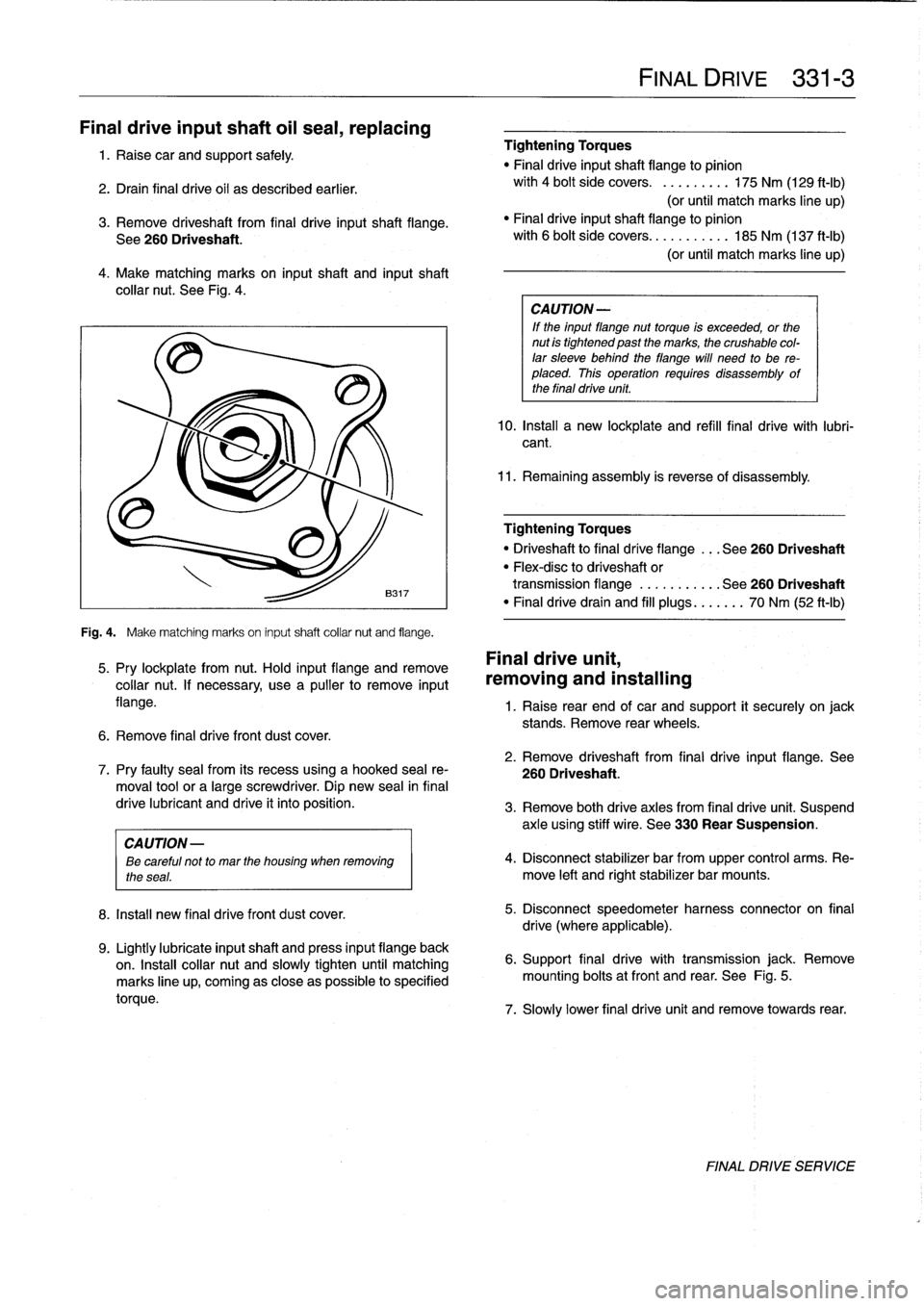

.

Make

matching

marks

on

input

shaft

and

inputshaft

collar

nut

.

See

Fig

.

4

.

Fig

.

4

.

Make

matching

marks

on

input

shaft

collar

nut

and

flange

.

5

.

Pry

lockplate

from

nut

.

Hold

input

flange

andremove

collar

nut

.

If

necessary,

usea

pullerto

remove

input

flange

.

6

.

Remove

final

drive

front

dust

cover

.

8

.

Install

new

final

drivefront

dust

cover

.

9

.

Lightly

lubricate

inputshaft

and

press

input

flange

back

on

.

Insta¡¡

collar

nut

and

slowly

tighten

until

matching

marks

line

up,

coming

as

close

aspossible

to

specified

torque

.

Tightening

Torques

"

Final

driveinputshaft

flange

to

pinion

with

4

bolt

side

covers

.

.........

175

Nm

(129

ft-Ib)

(or

until

match

marks

line

up)

"

Finaldriveinputshaft

flange

to

pinion

with

6

bolt

side

covers

...........

185

Nm

(137

ft-Ib)

(or

until

match

marks

line

up)

CA

UTION-

If

the

input

flange

nuttorque

is

exceeded,

or

the

nut

is

tightened

past

the

marks,

the

crushable

col-

lar

sleeve

behind

theflange

will

need

to

be

re-

placed

.

This

operation

requires

disassembly

of

the

final

drive

unit

.

10

.

Install

a

new

lockplate

and

refill

final

drive

with

lubri-

cant

.

11

.

Remaining

assembly

is

reverse

of

disassembly

.

Tightening

Torques

"

Driveshaftto

final

dríve

flange

...

See260

Driveshaft

"

Flex-disc

to

driveshaft

or

transmission

flange

...........

See260

Driveshaft

"

Finaldrivedrain

and

fill

plugs

...

.

..

.

70

Nm

(52

ft-Ib)

Final

drive

unit,

removing

and

installing

FINAL

DRIVE

331-

3

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

from

final

drive

input

flange

.

See

7

.

Pry

faulty

sea¡

from

its

recess

using

a

hooked

sea¡

re-

260

Driveshaft

.

moval

toolor

a

large

screwdriver

.

Dip

new

sea¡

in

final

drive

lubricant

and

drive

it

into

position

.

3

.

Remove

both

drive

axles

from

final

drive

unit

.

Suspend

axle

using

stiff

wire

.

See

330

Rear

Suspension

.

CAUTION

-

ee

careful

not

to

mar

the

housing

when

removing

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

the

seas

.

move

left

and

rightstabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Support

final

drive

with

transmission

jack

.

Remove

mounting

bolts

atfront

and

rear

.

See

Fig

.

5

.

7

.

Slowly

lower

final

drive

unit

and

remove

towards

rear

.

FINAL

DRIVE

SERVICE

Page 293 of 759

When

bleeding

the

brakes,

startat

the

wheel

farthest

from

4

.

Close

bleeder

screw

and

release

brake

pedal

.

Refill

the

master

cylinder

and

progress

in

the

following

order

:

brake

fluid

reservoir

and

proceed

to

rear

left

wheel

.

"

right

rear

brake

5

.

Proceed

with

the

remaining

wheels

using

the

order

list-

"

left

rear

brake

ed

earlier

.

"

rightfront

brake

"

left

front

brake

Pressure

bleeding

brakes

(except

carswith

AST)

1

.

Top

off

brake

fluid

in

reservoir

and

connect

pressure

bleeder

to

reservoir

.

Connect

bleeder

hose

and

bottle

to

right

rearcaliper

bleeder

screw

.

Pressurize

system

to

approximately

1

bar

(14

.5

psi)

.

BRAKES

340-

3

Tightening

Torques

"

Bleeder

screws

:

7

mm

screw

..........

..

.

.

.

.

......

5

Nm

(4

ft-Ib)

9

mm

screw

..........

..

.

..

.......

6

Nm

(5

ft-Ib)

BRAKE

PADS,

CALIPERS,

AND

ROTORS

CAUTION-

TheE36

front

brake

caliper

is

shown

in

Fig

.

2

.

The

rear

Do

not

exceed

a

pressure

of

2

bar

(29

psi)

when

brake

caliper

is

shown

in

Fig

.

7

.

pressure

bleeding

the

brake

system

.

Excessive

pressure

will

damage

the

brake

fluid

reservoir

.

Brake

pads

canbe

replaced

without

disconnecting

the

brake

fluid

hose

from

the

caliper

or

having

to

bleed

the

brakes

.

2

.

Have

a

helperhold

brake

pedal

down

.

The

rotors

can

be

replaced

without

disassembling

the

wheel

huband

bearing

.

Always

machine

or

replace

rotors

in

parts

.

3

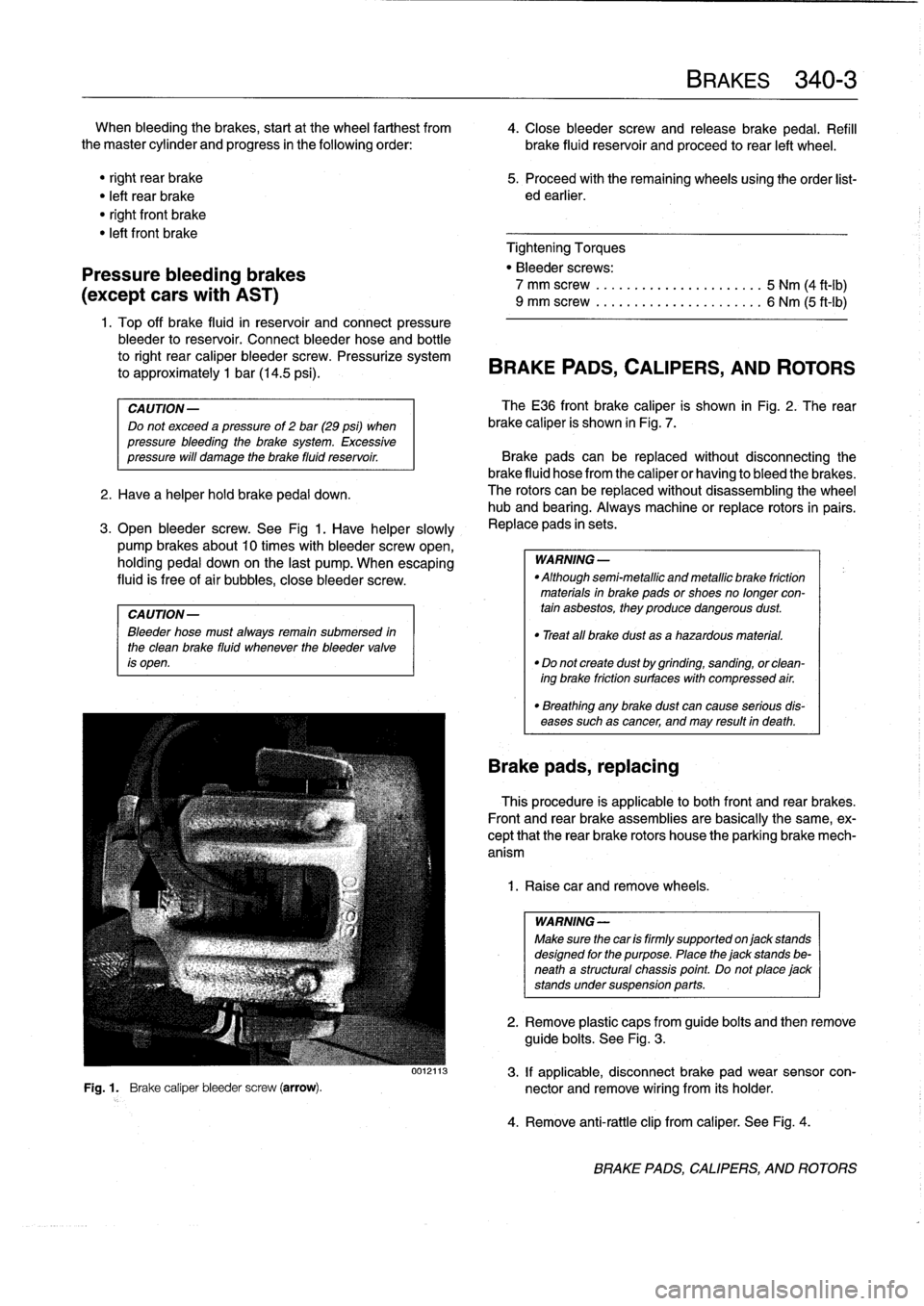

.

Open

bleeder

screw

.

See

Fig

1

.

Have

helper

slowly

,

Replace

pads

in

sets

.

pump

brakes

about10

times

with

bleeder

screw

open,

holding

pedal

down

on

the

last

pump

.

When

escaping

WARNING-

fluid

is

free

of

air

bubbles,

close

bleeder

screw

.

"

Althoughsemi-metallicandmetallicbrake

friction

materials

in

brake

pads

or

shoes

no

longer

con

CAUTION-

tain

asbestos,

they

produce

dangerous

dust

.

Bleeder

hose

must

alwaysremain

submersed

in

"

Treat

all

brake

dust

asa

hazardous

material

.

the

clean

brake

fluid

whenever

the

bleeder

valve

is

open

.

"

Do

not

create

dust

by

grinding,

sanding,

orclean-

ing

brake

friction

surfaces

with

compressed

air

.

"

Breathing

any

brake

dust

can

cause

serious

dis-

eases

such

as

cancer,

and

may

result

in

death

.

Brake

pads,

replacing

This

procedure

is

applicable

lo

both

front

and

rear

brakes

.

Front

and

rear

brake

assemblies

are

basically

the

same,

ex-

cept

that

the

rear

brake

rotors

house

the

parking

brake

mech-

anism

1

.

Raise

car

andremove

wheels

.

WARNING

-

Make

sure

thecar

is

firmly

supported

onjack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

plastic

caps

from

guide

bolts

and

then

remove

guide

bolts

.

See

Fig

.

3

.

0012113

3

.

If

applicable,

disconnect

brake

pad

wear

sensor

con-

Fig

.

1

.

Brake

caliper

bleeder

screw

(arrow)

.

nector

and

remove

wiring

from

its

holder

.

4

.

Remove

anti-rattle

clip

from

caliper

.

See

Fig

.

4

.

BRAKE

PADS,

CALIPERS,

AND

ROTORS