EVAP BMW 328i 1997 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 183 of 759

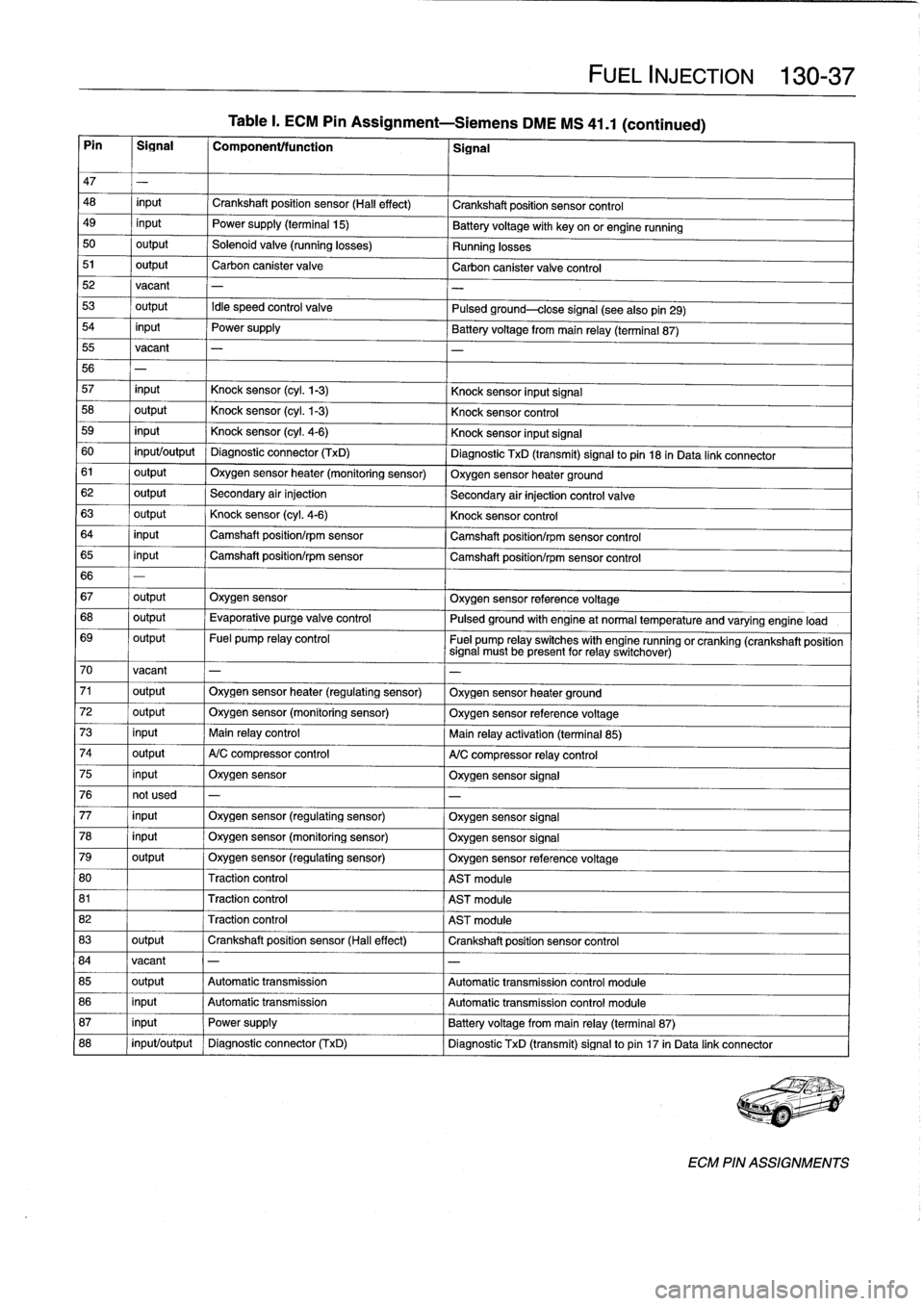

Table

I

.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

(continued)

Pin

I

Signal

I

Component/function

1

Signal

FUEL

INJECTION

130-

37

47

-

48

input

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

49

input

Power

supply

(terminal

15)

Batteryvoltage

with

key

onor

engine

running

50

output

Solenoid

valve

(running

losses)

Running

losses

51

output

Carbon

canister

valve

Carbon

canister

valve

control

52vacant

-

53

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(seealsopin29)

54

input

Power

supply

Battery

voltagefrom

main

relay

(terminal

87)

55

vacant

-

56

-

57

input

Knock

sensor

(cyl

.

1-3)

Knock

sensor

input

Signal

58

output

Knock

sensor

(cyl

.

1-3)

Knock

sensor

control

59

input

Knock

sensor

(cyl

.

4-6)

Knock

sensor

input

Signal

60

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

18

in

Data

link

connector

61

output

Oxygen

sensor

heater

(monitoring

sensor)

Oxygen

sensor

heater

ground

62

output

Secondary

air

injection

Secondary

air

injection

control

valve

63

output

Knock

sensor

(cyl

.

4-6)

Knock

sensor

control

64

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

65

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

66

-

67

output

Oxygen

sensor

Oxygen

sensor

reference

voltage

68

output

Evaporative

purge

valve

control

Pulsed

ground

with

engine

at

normal

temperature

and

varyingengine

load

69

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

runningorcranking

(crankshaft

position

signal

must

be

present

for

relay

switchover)

70

vacant

-

-

71

output

Oxygen

sensor

heater

(regulating

sensor)

Oxygen

sensor

heater

ground

72

output

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

referencevoltage

73

input

Main

relay

control

Main

relay

activation

(terminal

85)

74

output

A/C

compressor

control

A/C

compressor

relay

control

75

input

Oxygen

sensor

Oxygen

sensor

signal

76

not

used

-

-

77

input

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

signal

78

input

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

signal

79

output

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

referencevoltage

80

Traction

control

AST

module

81

Traction

control

AST

module

82

Traction

control

AST

module

83

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

84

vacant

-

-

85

output

Automatic

transmission

Automatic

transmission

control

module

86

input

Automatic

transmission

Automatic

transmissíon

control

module

87

input

Power

supply

Battery

voltage

from

main

relay

(terminal

87)

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

17

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 185 of 759

160

Fuel

Tank

and

Fuel

Pump

GENERAL

.

.

.

.

.

.

...........

.

....

.

.

.

.

.

.

160-1

Operating

fuel

pump

for

tests

.

.

.

.

.

.

.......

.160-6

Fuel

Pump

Electrical

Tests

.

.

.

.

.

.

.

...

.

.

.

.

.

160-7

FUEL

TANK

AND

LINES

..

.

.

.

..........

160-2

Fuel

pump

electrical

circuit,

testing.

...

.

.

.

.

.

160-7

Fuel

tank,

draining

..

.

.

.

.

.

.

.

.

.

..........

160-2

Fuel

pump

power

consumption,

testing

.

.

.

.

.

.

160-7

Fuel

tank,

removing

and

installing

.........

160-3

Fuel

Delivery

Tests

....

.

.

.

...

.

.....

.

.

.

..

160-8

Fuel

Tank

Evaporative

Control

System

.....

160-4

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

..

.

...........

.

.

.

..

160-8

FUEL

LEVEL

SENDERS

.

.

.

.

.

.......

.

.

.

160-4

System

pressure,

testing

.................

160-9

Fuel

level

senders,

testing

.

.

.

.

.

.......

.

.

.

160-5

Fuel

delivery

volume,

testing

.............

160-10

Fuel

leve¡

sender

and

fuel

pump

(right

side),

emoving

and

installing

.

.

.

.

.

.

160-5

TABLES

Fuel

leve¡

sender

(left

side),

a

.

FuelLeve¡

Sender

Resistances

...........

.

.

..

.160-5

removing

and

installing

.........

.

.

.

.

.

.

.

160-6

b

.

Fuel

Pump

Current

...

.................

..

...

160-8

c

.

Fuel

Pressure

Specifications

..............

.

..

160-10

FUEL

PUMP

.

.

.

................

.

.

.

.

.

.

.

160-6

d

.

Fuel

Pump

Delivery

Specifications

.........

.

..

160-10

Fuel

Pump

Fuse

and

Relay

.

.

.

....

.

.

.

.

.

.

.

160-6

GENERAL

This

repair

group

covers

service

information

specifically

for

The

cautions

and

warnings

on

this

page

should

beob

the

fuel

supply

system

.

Information

on

the

fue¡

injection

sys-

served

when

servicing

the

fuel

system

.

tem

is

covered

in

130

Fuel

Injection

.

NOTE-

Fue¡

filter

replacement

is

covered

in

020

Maintenance

Program

.

WARNING

-

"

The

fuel

system

is

designed

to

retain

pressure

even

when

the

ignition

isoff

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Before

beginning

any

work

on

the

fuel

system,

place

a

tire

extinguisher

in

the

vicinity

of

the

work

area

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

tire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

"

Do

not

use

a

work

light

near

any

fuel

.

Fuel

may

spray

onto

the

hot

bulb

causing

a

tire

.

"

Make

sure

the

work

area

is

properly

ventifated

.

FUEL

TANK

AND

FUEL

PUMP

160-1

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viü

.

"

Before

making

any

electrical

tests

with

the

ignition

tumed

on,

disable

the

ignition

system

as

de-

scribed

in

120

Ignition

System

.

Be

sure

the

bat-tery

is

disconnected

when

replacing

components

.

"

To

prevent

damage

to

the

ignition

system

or

the

electronic

fuel

system

components,

including

the

control

unit,

aiways

connect

and

disconnect

wires

and

test

equipment

with

the

ignition

off

.

"

Cleanliness

is

essential

when

working

with

the

fuel

system

.

Thoroughly

clean

the

fuel

fine

unionsbefore

disconnecting

any

of

the

fines

.

"

Use

only

clean

tools

.

Keep

removed

parts

clean

and

sealed

or

covered

with

a

clean,

lint-free

cloth,

especially

if

completion

of

the

repair

is

delayed

.

"

Do

not

move

the

car

while

the

fuel

system

is

open

.

"

Avoid

using

high

pressure

compressed

air

to

blow

out

fines

and

componente

.

High

pressure

can

rupture

infernal

seals

and

gaskets

.

"

Always

replace

seals

and

O-rings

.

GENERAL

Page 186 of 759

160-2

FUEL

TANK

AND

FUEL

PUMP

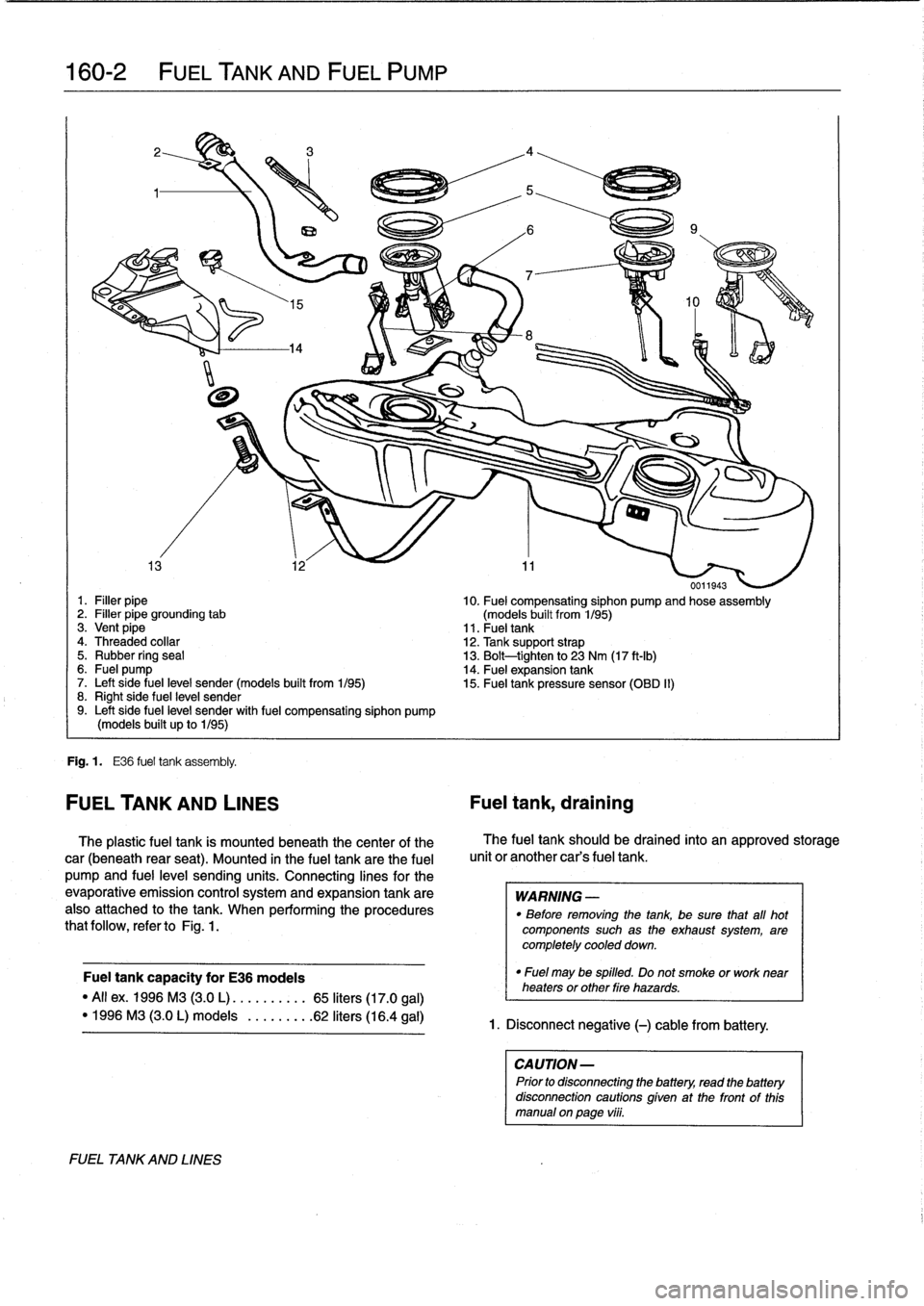

0011943

1

.

Filler

pipe

10

.

Fuel

compensating

siphon

pump

and

hose

assembly

2

.

Filler

pipe

grounding

tab

(models

built

from

1/95)

3

.

Vent

pipe

11

.

Fueltank

4

.

Threaded

collar

12

.

Tank

support

strap

5

.

Rubber

ring

seal

13

.

Bolt-tighten

to

23

Nm

(17

ft-Ib)

6

.

Fuel

pump

14

.

Fuel

expansion

tank

7

.

Left

side

fuel

leve¡

sender(models

built

from

1/95)

15

.

Fuel

tank

pressure

sensor

(OBD

II)

8

.

Right

side

fuel

leve¡

sender9

.

Left

side

fuel

leve¡

sender

with

fuel

compensating

siphon

pump

(models

built

up

to

1/95)

Fig

.

1

.

E36

fuel

tank

assembly

.

FUEL

TANK

AND

LINES

Fuel

tank,

draining

The

plastic

fuel

tank

is

mounted

beneath

the

center

of

the

car

(beneath

rear

seat)

.

Mounted

in

the

fuel

tank

are

the

fuel

pump

and

fuel

leve¡

sending

units

.

Connecting

lines

for

the

evaporative

emission

control

systemand

expansion

tank

are

also

attached

to

the

tank

.

When

performing

the

procedures

that

follow,

refer

toFig

.

1

.

Fuel

tank

capacity

for

E36

modeis

"All

ex

.

1996

M3

(3

.0

L)

.....

.

..

..

65

liters

(17

.0

gal)

"

1996

M3

(3.0L)

modeis

.

...

.

..

.

.62

liters

(16

.4

gal)

FUEL

TA

NKAND

LINES

The

fuel

tank

should

be

drained

into

an

approved

storage

unit

or

another

car's

fuel

tank

.

WARNING

-

"

Before

removing

the

tank,

be

sure

that

afl

hot

components

such

as

the

exhaust

system,

are

completely

cooled

down

.

"

Fuel

may

be

spilled

.

Do

not

smoke

or

worknear

heaters

or

other

Pire

hazards

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

paga

vi¡¡

.

Page 188 of 759

160-

4

FUEL

TANK

AND

FUEL

PUMP

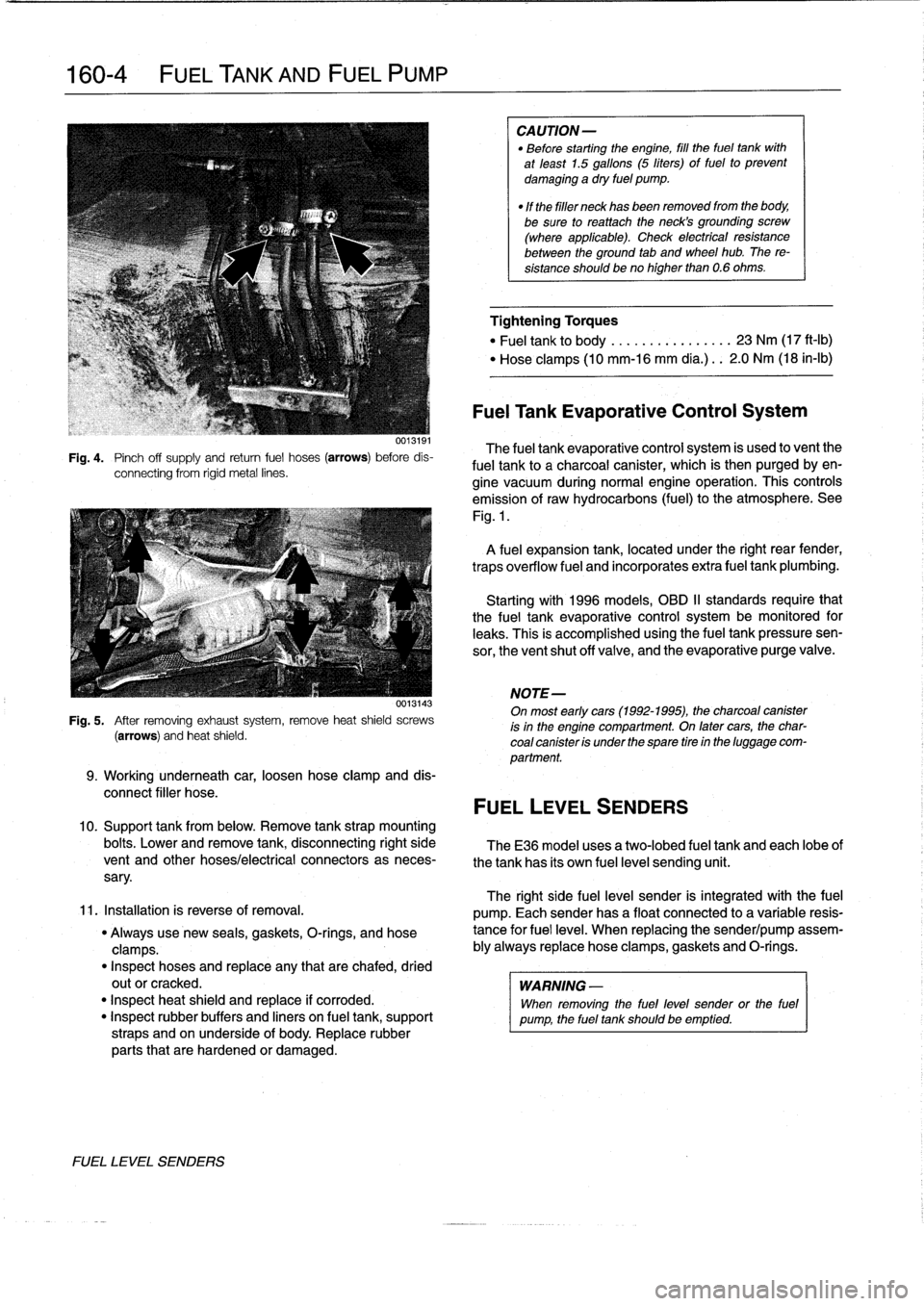

Fig

.

4

.

Pinch

off

supply

and

retum

fuel

hoses

(arrows)

before

dis-

connecting

from

rigid

metal

lines

.

0013143

Fig

.

5

.

After

removing

exhaustsystem,

remove

heat

shield

screws

(arrows)

and

heat

shield

.

9

.

Working

underneath

car,

loosen

hose

clamp

and

dis-

connect

filler

hose

.

10

.

Support

tank

from

below

.

Remove

tank

strap

mounting

bolts

.

Lower

and

remove

tank,

disconnecting

right

side

TheE36

model

uses

a

two-lobed

fuel

tank

and

each

lobeof

vent

and

other

hoses/electrical

connectors

as

neces-

the

tank

has

its

own

fuel

level

sending

unit

.

sary

.

11

.

Installation

is

reverse

of

removal

.

"

Always

use

new

seals,

gaskets,

O-rings,

and

hose

clamps

.

"

Inspect

hoses

and

replace

any

that

are

chafed,

dried

outor

cracked

.

"

Inspect

heat

shield

and

replace

if

corroded

.

"

Inspect

rubber

buffers

and

liners

on

fuel

tank,

support

straps

and

on

underside

of

body

.

Replace

rubber

parts

that

are

hardened

or

damaged

.

FUEL

LEVEL

SENDERS

CAUTION-

"

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5

liters)

of

fuel

to

prevent

damaging

a

dry

fuel

pump

.

"

If

the

filler

neck

has

been

removed

from

the

body,

be

sure

toreattach

theneck's

grounding

screw

(where

applicable)

.

Check

electrical

resistance

between

the

ground

tab

and

wheel

hub

.

The

re-

sistance

shouldbeno

higher

than

0

.6

ohms

.

Tightening

Torques

"

Fuel

tank

to

body

.............

...

23

Nm

(17

ft-Ib)

"

Hose

clamps

(10

mm-16

mm

día

.)

..

2

.0

Nm

(18

in-lb)

Fuel

Tank

Evaporative

Control

System

The

fuel

tank

evaporative

control

system

is

used

to

vent

the

fuel

tank

to

a

charcoal

canister,

which

is

then

purgedby

en-

gine

vacuum

during

normal

engine

operatíon

.

This

controls

emission

of

raw

hydrocarbons

(fuel)

to

the

atmosphere

.

See

Fig

.

1

.

A

fuel

expansion

tank,

located

under

the

right

rear

fender,

traps

overflow

fuel

and

incorporates

extra

fuel

tank

plumbing

.

Startingwith

1996

models,

OBD

II

standards

require

that

the

fuel

tank

evaporative

control

system

be

monitored

for

leaks

.

This

is

accomplished

usingthe

fuel

tankpressuresen-

sor,

the

ventshut

off

valve,

and

the

evaporative

purge

valve

.

NOTE-

On

most

early

cars(1992-1995),

the

charcoal

canister

is

in

the

engine

compartment

.

On

latercars,

the

char-

coal

canister

is

under

the

spare

tire

in

the

luggage

com-

partment

.

FUEL

LEVEL

SENDERS

The

right

side

fuel

leve¡

sender

is

integrated

with

the

fuel

pump

.

Each

senderhas

a

float

connected

to

a

variable

resis-

tance

for

fuel

leve¡

.

When

replacing

the

sender/pump

assem-

bly

always

replace

hose

clamps,gaskets

and

O-rings

.

WARNING

-

When

removing

the

fuel

level

sender

or

the

fuel

pump,

the

fuel

tank

should

be

emptied

.

Page 396 of 759

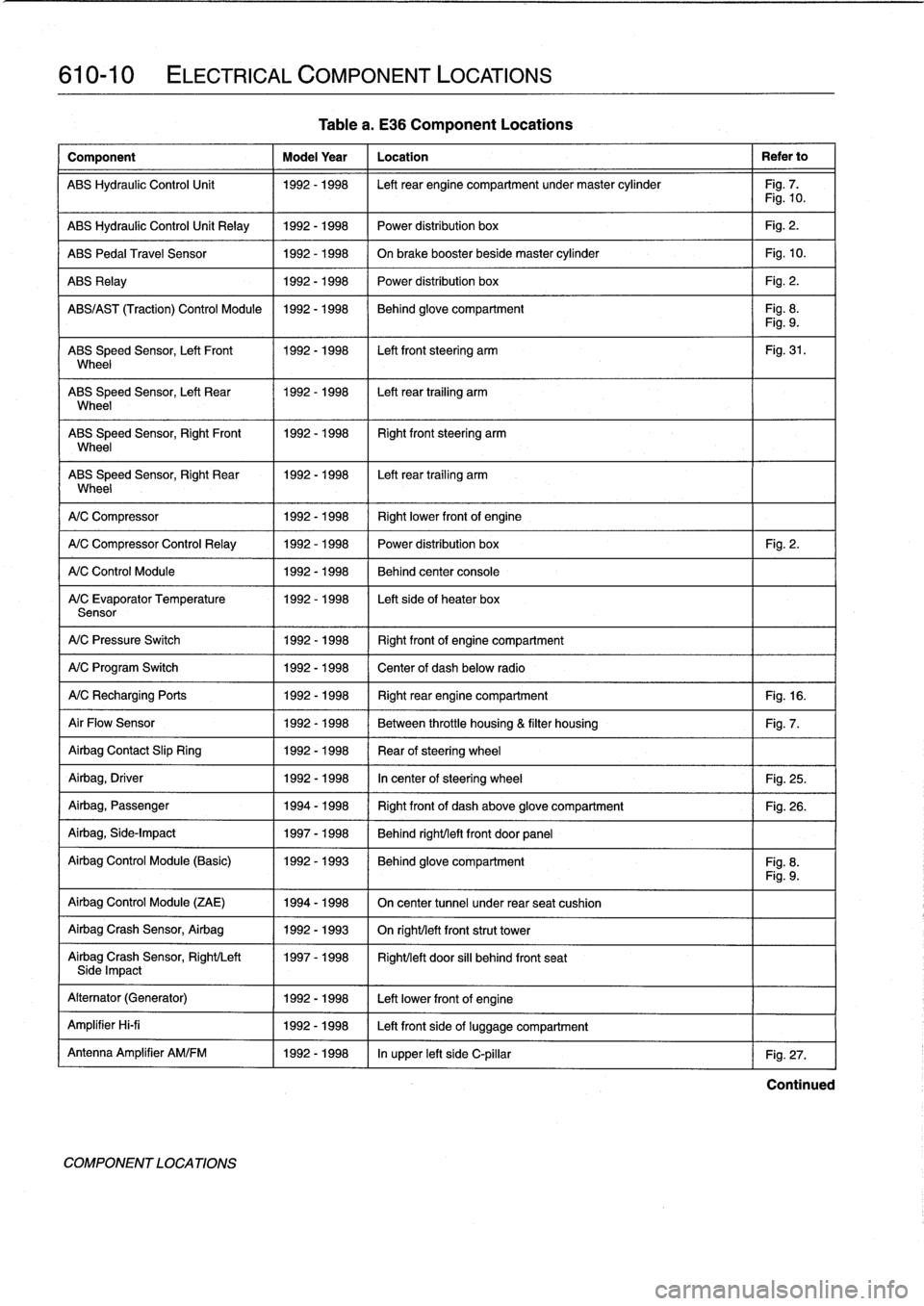

610-10

ELECTRICAL

COMPONENT

LOCATIONS

Component

Model

Year

Location

Refer

to

ABS

Hydraulic

Control

Unit

1992-1998

Left

rear

engine

compartment

undermaster

cylinder

Fig

.

7

.

Fig

.

10

.

ABS

Hydraulic

Control

Unit

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

ABS

Pedal

Travel

Sensor

1992-1998

On

brake

booster

beside

master

cylinder

Fig

.

10

.

ABS

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

ABS/AS

T

(Traction)

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

ABS

Speed

Sensor,

Left

Front

1992-1998

Left

front

steering

arm

Fig

.

31

.

Wheel

ABS

Speed

Sensor,

Left

Rear

1992-1998

Left

rear

trailing

arm

Wheel

ABS

Speed

Sensor,

RightFront

11992-1998

Right

front

steering

arm

Wheel

ABS

Speed

Sensor,

Right

Rear

1992-1998

I

Left

rear

trailing

arm

Wheel

1

A/C

Compressor

1

1992-1998

(

Rightlower

frontof

engine

A/C

Compressor

Control

Relay

1

1992-1998

1992-1998

1992-1998

A/C

Control

Module

A/C

Evaporator

Temperature

Sensor

A/C

Pressure

Switch

1992-1998

Right

frontof

engine

compartment

A/C

Program

Switch

1992-1998

Center

of

dash

below

radio

A/CRecharging

Ports

1992-1998

Right

rear

engine

compartment

Fig

.

16

.

Air

Flow

Sensor

1992-1998

Between

throttle

housing

&

filter

housing

Fig

.

7

.

Airbag

Contact

Slip

Ring

1992-1998

Rear

ofsteering

wheel

Airbag,

Driver

1992-1998

In

center

of

steering

wheel

Fig

.

25

.

Airbag,

Passenger

1994-1998

Right

front

of

dash

above

glove

compartment

Fig

.

26

.

Airbag,

Side-Impact

1997-1998

Behind

right/left

front

door

panel

Airbag

Control

Module

(Basic)

1992-1993

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Airbag

Control

Module

(ZAE)

1994-1998

On

center

tunnel

under

rear

seat

cushion

Airbag

Crash

Sensor,

Airbag

1992-1993

On

righUleft

front

strut

tower

Airbag

Crash

Sensor,

Right/Left

1997-1998

Right/left

door

si¡¡

behind

front

seatSide

Impact

Alternator

(Generator)

1992-1998

Left

lowerfront

of

engine

Amplifier

Hi-fi

1992-1998

Left

front

side

of

luggage

compartment

Antenna

Amplifier

AM/FM

1992-1998

In

upper

left

side

C-pillar

Fig

.

27

.

COMPONENT

LOCA

TIONS

Table

a

.

E36

Component

Locations

Power

distribution

box

Fig

.

2

.

Behind

center

console

Left

sideof

heater

box

Continued

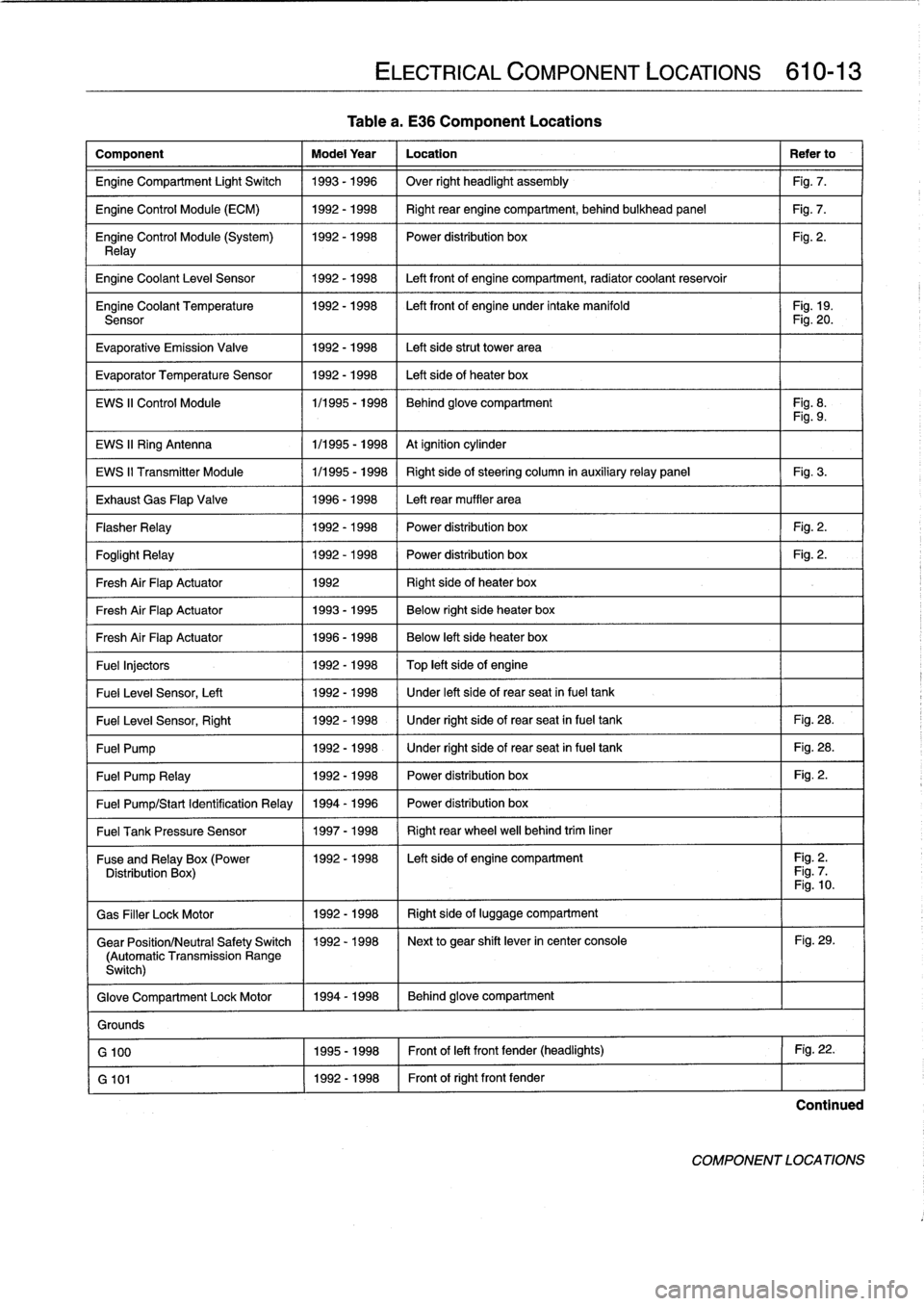

Page 399 of 759

Tablea

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Engine

Compartment

Light

Switch

1993-1996

Over

right

headlight

assembly

Fig

.

7

.

Engine

Control

Module

(ECM)

1992-1998

Right

rear

enginecompartment,

behind

bulkhead

panel

Fig

.

7

.

Engine

Control

Module

(System)

1992-1998

I

Power

distribution

box

Fig

.

2

.

Relay

Engine

Coolant

Leve¡

Sensor

1

1992-1998

1

Left

front

of

enginecompartment,

radiator

coolant

reservoir

Engine

Coolant

Temperature

1992-1998

I

Left

front

of

engine

under

intake

manifold

I

Fig

.

19

.

Sensor

Fig

.

20

.

Evaporative

Emission

Valve

1992-1998

Left

side

strut

Power

area

Evaporator

Temperature

Sensor

1992-1998

Left

side

of

heater

box

EWS

II

Control

Module

1/1995

-

1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

EWS

II

Ring

Antenna

1

1/1995

-

1998

1

At

ignition

cylinder

EWS

II

Transmitter

Module

1/1995

-

1998

Right

side

of

steering

column

in

auxiliaryrelay

panel

Fig

.

3

.

Exhaust

Gas

Flap

Valve

1996-1998

Left

rear

muffler

area

Flasher

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Foglight

Relay

1

1992-1998

1

Power

distribution

box

1

Fig

.

2

.

Fresh

Air

FlapActuator

1

1992

1

Right

side

of

heater

box

Fresh

Air

FlapActuator

1

1993-1995

1

Below

right

side

heater

box

Fresh

Air

FlapActuator

1

1996-1998

Below

left

side

heater

box

Fuel

Injectors

1992

-

1998

Top

left

side

of

engine

Fuel

Leve¡

Sensor,

Left

1

1992-1998

/

Under

left

side

of

rear

seat

infuel

tank

Fuel

Leve¡

Sensor,

Right

1

1992-1998

1

Under

right

side

of

rear

seat

in

fuel

tank

1

Fig

.

28

.

Fuel

Pump

1

1992-1998

1

Under

right

side

of

rear

seat

in

fuel

tank

1

Fig

.

28

.

Fuel

Pump

Relay

1

1992-1998

1

Power

distribution

box

1

Fig

.

2

.

Fuel

Pump/Start

Identification

Relay

1994

-

1996

Power

distribution

box

Fuel

Tank

Pressure

Sensor

1

1997-1998

1

Right

rear

wheel

well

behind

trim

liner

ELECTRICAL

COMPONENT

LOCATIONS

610-13

Fuse

andRelay

x(Power

11992-1998

I

Left

side

of

engine

compartment

I

Fig

.

2

.

Distribution

Box

Fig

.

7

Fig

.

10

.

Gas

Filler

LockMotor

1992-1998

Right

side

of

luggage

compartment

Gear

Position/Neutral

Safety

Switch

1992-1998

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

(Automatic

Transmission

Range

Switch)

Glove

Compartment

Lock

Motor

1994-1998

Behind

glove

compartment

Grounds

G

100

1995-1998

Front

of

left

front

fender

(headlights)

Fig

.

22

.

G

101

1992-1998

Front

of

right

front

fender

Continued

COMPONENT

LOCATIONS

Page 447 of 759

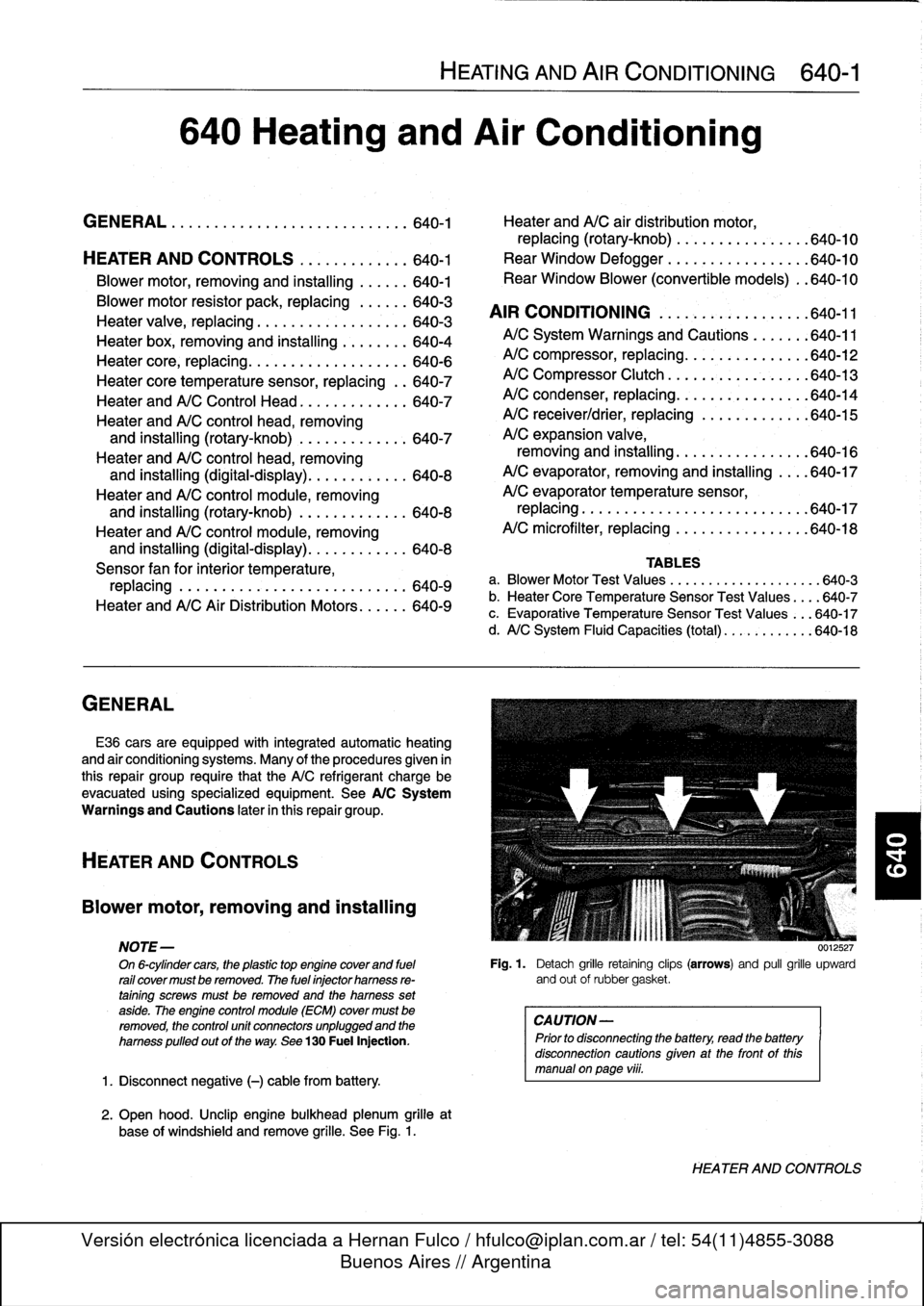

GENERAL

E36

cars

are

equipped

with

integrated

automatic

heating

and

air

conditioning

systems

.

Many

of

the

procedures

given

in

this

repair

group

require

that

the

A/C

refrigerant

charge

be

evacuated

using

specialized

equipment

.

See

A/C

System

Warningsand

Cautions

later

in

this

repair

group

.

HEATER

AND

CONTROLS

Blower

motor,

removing

and

installing

NOTE-

On

6-cylinder

cars,

the

plastic

top

enginecover

and

fuel

rail

covermustbe

removed

.

The

fuel

injectorhamess

re-

taining

screws

must

be

removed

and

the

harness

set

aside

.

The

engine

control

module

(ECM)

cover

must

be

removed,

the

control

unit

connectors

unplugged

and

the

harness

pulled

out

of

the

way

.

See

130

Fuel

Injection

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

2

.

Open

hood

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

windshíeld

and

remove

grille

.

See

Fig

.

1

.

HEATING

AND

AIR

CONDITIONING

640-1

640

Heating

and

Air

Conditioning

GENERAL

.

...

.

....

.

.

.

.

.

.

.

.

.

.......

.

.

.

640-1

Heater

andA/C

air

distribution

motor,

replacing(rotary-knob)

.

.

...

.

.

.

.......

.

640-10

HEATER

AND

CONTROLS

.

.....

.

.

.

.

.

.

.640-1

Rear

Window

Defogger

.

.

.

.

.

.

.

.

.

.

...

.

.

.

640-10

Blower

motor,

removing

and

installing

.

.

.

.

.

.

640-1

Rear

Window

Blower

(convertible

models)

.

.640-10

Blowermotor

resistor

pack,

replacing

.

.

.

.

.

.

640-3

AIR

CONDITIONING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-11

Heater

valve,

replacing

...........

.

.

.

.

.

.

.

640-3

Heater

box,

removing

and

installing

.

.

.

.

.

.

.

.

640-4

A/CSystem

Warnings

and

Cautions

.

.

.

.

.

.

:640-11

Heater

core,

replacing

.....

.

.

:

....

.

.

.

.

.

.

.

640-6

A/C

compressor,

replacing

.

.

::.

:

:

.

.

.

.

.

.

.

.640-12

Heater

core

temperature

sensor,

replacing

.

.

640-7

A/C

Compressor

Clutch

.

.

.

.

.

.

.

:

.

.

.

.

.

.

.

.

.

640-13

Heater

andA/C

Control

Head

.

.

....

.

.....

.

640-7

A/C

condenser,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-14

Heater

andA/C

control

head,

removing

A/C

receiver/drier,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

640-15

and

installing

(rotary-knob)

.

.

....

.

......

640-7

A/C

expansion

valve,

Heater

andA/C

control

head,

removing

removing

and

installing

...

.

.....

.

.

.

.

.

.

.

640-16

and

installing

(digital-display)

.

.....

.

.....

640-8

A/C

evaporator,

removing

and

installing

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

evaporator

temperature

sensor,

and

installing

(rotary-knob)

.

.

...

.

.

.

.

.

.

.

.

640-8

replacing

.

.

.

.

.

.

..............

.

.

.

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

microfilter,

replacing

......

.

....

.

.

.

..

640-18

and

installing

(digital-display)

.

...

.

.

.

.

.

...

640-8

Sensor

fan

for

interior

temperature,

TABLES

replacing

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-9

a

.

Blower

Motor

Test

Values

.........

...

.

.

......

640-3

Heater

andA/C

AirDistribution

Motors

.

.

.

.

.

.

640-9

b

.

Heater

Core

Temperature

Sensor

Test

Values

...

.640-7

c

.

Evaporative

Temperature

Sensor

Test

Values

...

640-17

d

.

A/C

System

Fluid

Capacities

(total)

..

..........

640-18

0012527

Fig

.

1

.

Detach

grille

retaining

clips

(arrows)

and

pull

grille

upward

and

out

of

rubbergasket

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

HEATER

AND

CONTROLS

Page 450 of 759

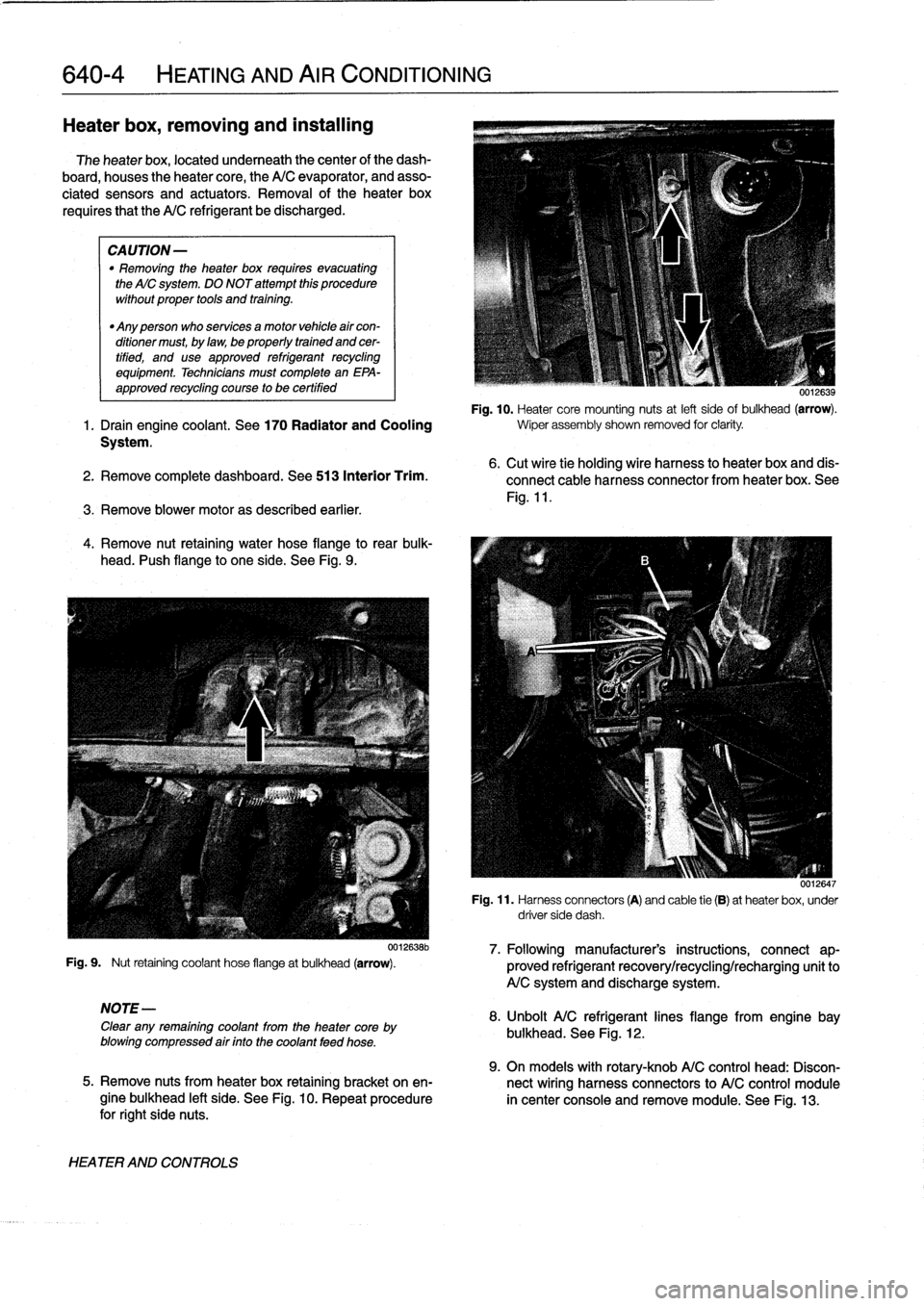

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

UU12639

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 457 of 759

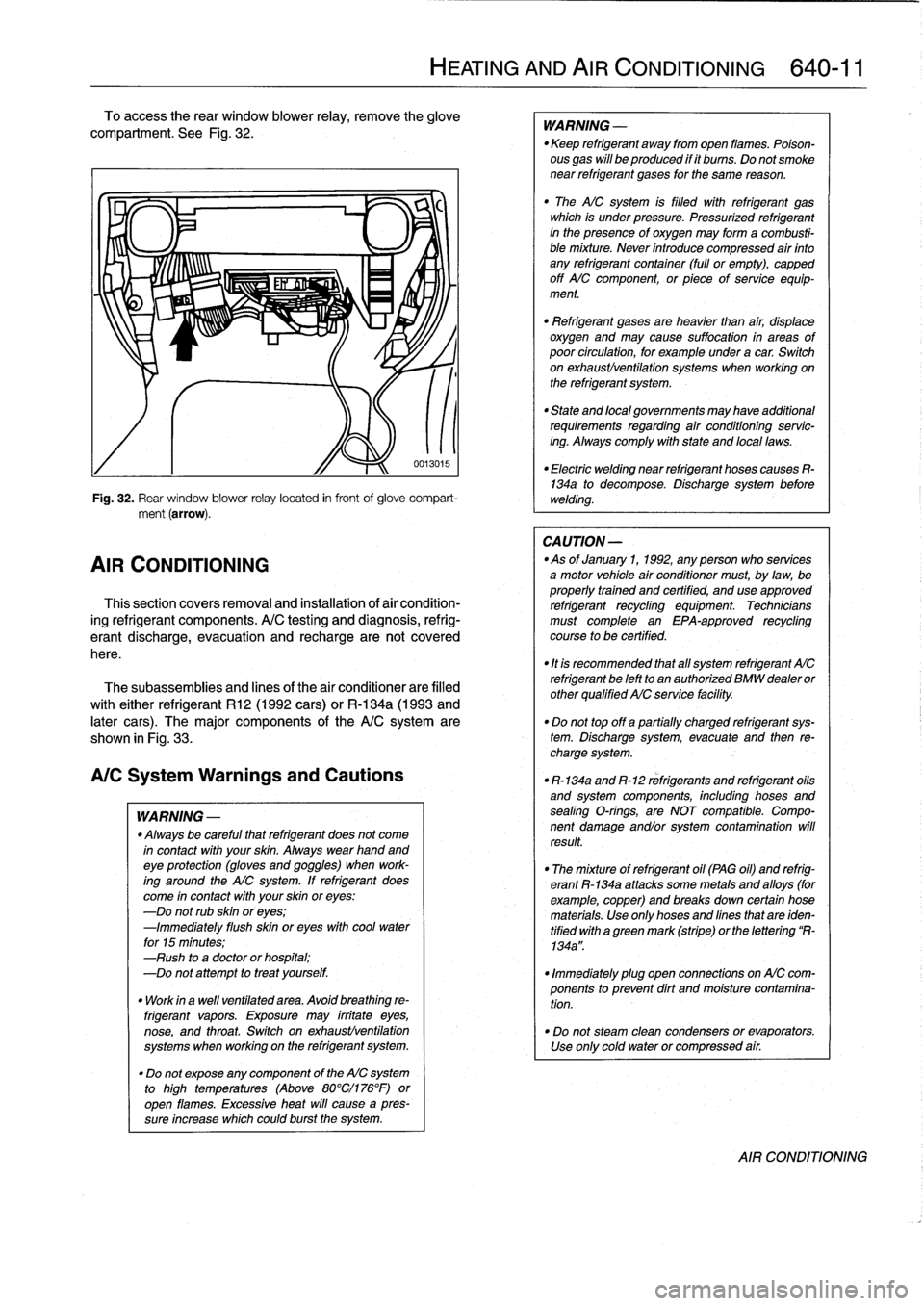

To

access

the

rear

window

blower

relay,

remove

the

glove

compariment

.

See

Fig

.

32

.

Fig

.

32

.

Rear

window

blower

relay

located

in

frontof

glove

compart-

ment

(arrow)

.

AIR

CONDITIONING

Thissection

covers

removal

and

installation

of

air

condition-

ing

refrigerant

components

.

A/C

testing

and

diagnosis,

refrig-

erantdischarge,

evacuatíon

and

recharge

are

not

covered

here

.

The

subassemblies

and

lines

of

the

air

conditionerare

filled

with

either

refrigerant

R12

(1992

cars)

or

R-134a

(1993

and

later

cars)

.

The

major

components

of

the

A/Csystem

are

shown

in

Fig

.

33

.

A/CSystem

Warnings

and

Cautions

WARNING

-

"

Always

be

careful

that

refrigerant

does

not

come

in

contact

with

your

skin

.

Always

wearhand

andeye

protection

(gloves

and

goggles)

when

work-

ing

around

the

AIC

system

.

If

refrigerant

does

come

in

contact

with

your

skin

oreyes

:

-Do

not

rub

skin

oreyes

;

-Immediately

flush

skin

oreyes

withcool

water

for

15

minutes

;

-Rush

to

a

doctor

orhospital

;

-Do

not

attempt

to

treat

yourself

.

"

Work

in

a

wefl

ventilated

area

.

Avoid

breathing

re-

frigerant

vapors

.

Exposure

may

irrítate

eyes,

nose,

and

throat

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

Do

not

expose

any

component

of

the

AIC

system

to

high

temperatures

(Above

80°Cl176°F)or

open

flames

.

Excessive

heat

will

cause

a

pres-

sureincrease

whichcould

burst

the

system

.

HEATING

AND

AIR

CONDITIONING

640-

1

1

0013015

WARNING

-

"

Keep

refrigerant

away

from

open

llames

.

Poison-

ous

gas

will

be

produced

if

it

bums

.

Do

not

smoke

near

refrigerant

gases

for

the

same

reason

.

"

The

AICsystem

is

filled

with

refrigerant

gas

which

is

under

pressure

.

Pressurized

refrigerant

in

the

presenceof

oxygen

may

forma

combusti-

ble

mixture

.

Never

introduce

compressed

air

finto

any

refrigerant

container

(full

or

empty),

capped

off

AIC

component,

or

piece

of

service

equip-

ment

.

"

Refrígerant

gases

are

heavier

than

air,

displace

oxygen

and

may

cause

suffocation

in

areas

of

poor

círculation,

for

example

under

a

car

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

State

and

local

governments

may

have

additional

requirements

regarding

air

conditioning

servic-

ing

.

Alwayscomply

with

state

and

local

laws

.

"

Electric

welding

near

refrigerant

hoses

causes

R-134a

to

decompose

.

Discharge

system

before

welding

.

CA

UTION

-

-As

of

January

1,

1992,

any

person

who

services

a

motor

vehicle

air

conditioner

must,

by

law,

be

properly

trained

and

certified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-approved

recycling

course

to

be

certified

.

"

It

is

recommended

that

al¡

system

refrigerant

AIC

refrigerant

be

left

to

an

authorized

BMW

dealer

or

other

qualified

AIC

service

facility

.

"

Do

not

top

off

a

partially

charged

refrigerant

sys-

tem

.

Dischargesystem,evacuate

and

then

re-

charge

system

.

"

R-134a

and

R-12

refrigerants

and

refrigerant

oils

and

system

components,

including

hoses

and

sealing

O-rings,

are

NOT

compatible

.

Compo-

nent

damage

andlor

system

contamination

will

result

.

"

The

mixture

of

refrigerant

oil

(PAG

oil)

and

refrig-

erant

R-134a

attacks

some

metals

and

alloys

(for

example,copper)

and

breaks

down

certain

hose

materials

.

Use

only

hoses

and

lines

that

are

iden-

tified

with

a

green

mark

(stripe)

or

the

lettering

R-

134a"

.

"

Immediately

plug

open

connections

on

AIC

com-

ponents

to

prevent

dirt

and

moisture

contamina-

tion

.

"

Do

not

steam

clean

condensers

or

evaporators

.

Use

only

cold

water

or

compressed

air

.

AIR

CONDITIONING

Page 461 of 759

Fig

.

42

.

Upper

A/C

condensermounting

bolts

(arrows)

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

A/C

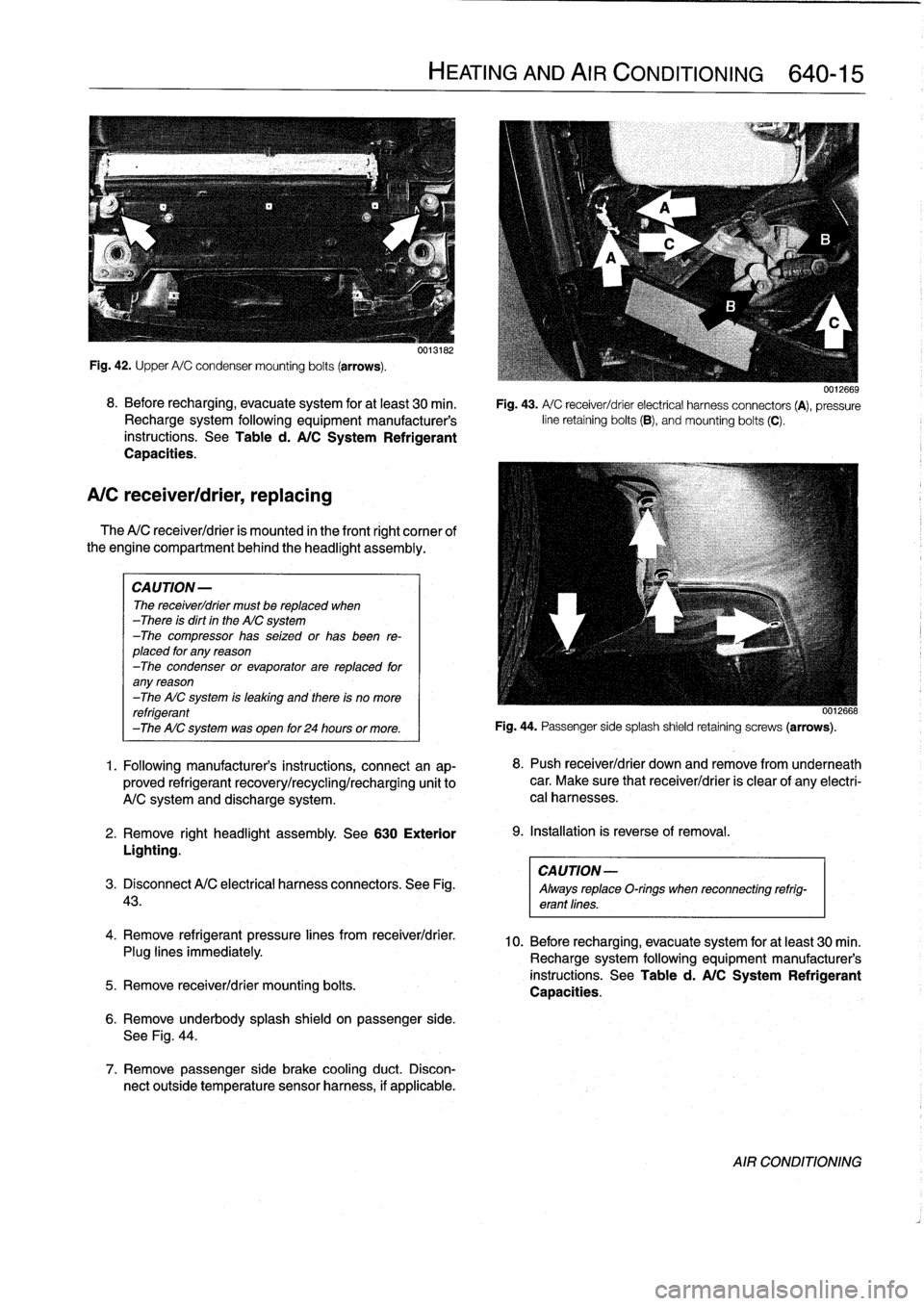

receiver/drier,

replacing

The

A/C

receiver/drier

is

mounted

in

the

front

right

cornee

of

the

engine

compartment

behind

the

headlight

assembly

.

CAUTION-

The

receiver/drier

must

be

replaced

when

-There

is

dirt

in

the

AIC

system

-The

compressor

has

seized

or

has

been

re-

placed

for

any

reason

-The

condenser

or

evaporator

are

replaced

for

any

reason

-The

AIC

system

is

leaking

and

there

is

no

more

refrigerant

-The

AIC

system

was

open

for

24

hours

or

more

.

1

.

Following

manufacturer's

instructions,

connectan

ap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

right

headlight

assembly

.

See

630

Exterior

Lighting

.

CAUTION-

3

.

Disconnect

A/C

electrical

harness

connectors

.

See

Fig

.

Always

replaceO-rings

when

reconnecting

refrig-

43

.

erant

lines

.

4

.

Remove

refrigerant

pressure

lines

from

receiver/drier

.

Plug

lines

immediately

.

5

.

Remove

receiver/drier

mounting

bolts

.

0013182

6

.

Remove

underbody

splash

shield

on

passenger

side

.

See

Fig

.

44

.

7

.

Remove

passenger

side

brake

cooling

duct

.

Discon-

nect

outside

temperature

sensor

harness,

if

applicable

.

HEATING

AND

AIR

CONDITIONING

640-15

0012669

Fig

.

43

.

A/

C

receiver/drier

electrical

harness

connectors

(A),

pressure

line

retaining

bolts

(B),

andmounting

bolts

(C)

.

0012668

Fig

.

44

.

Passenger

sidesplash

shield

retaining

screws

(arrows)

.

8

.

Push

receiver/drier

down

andremove

from

underneath

car

.

Make

sure

that

receiver/drier

is

clear

of

any

electri-

cal

harnesses

.

9

.

Installation

is

reverse

of

removal

.

10

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

AIR

CONDITIONING