rear BMW 328i 1997 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 435 of 759

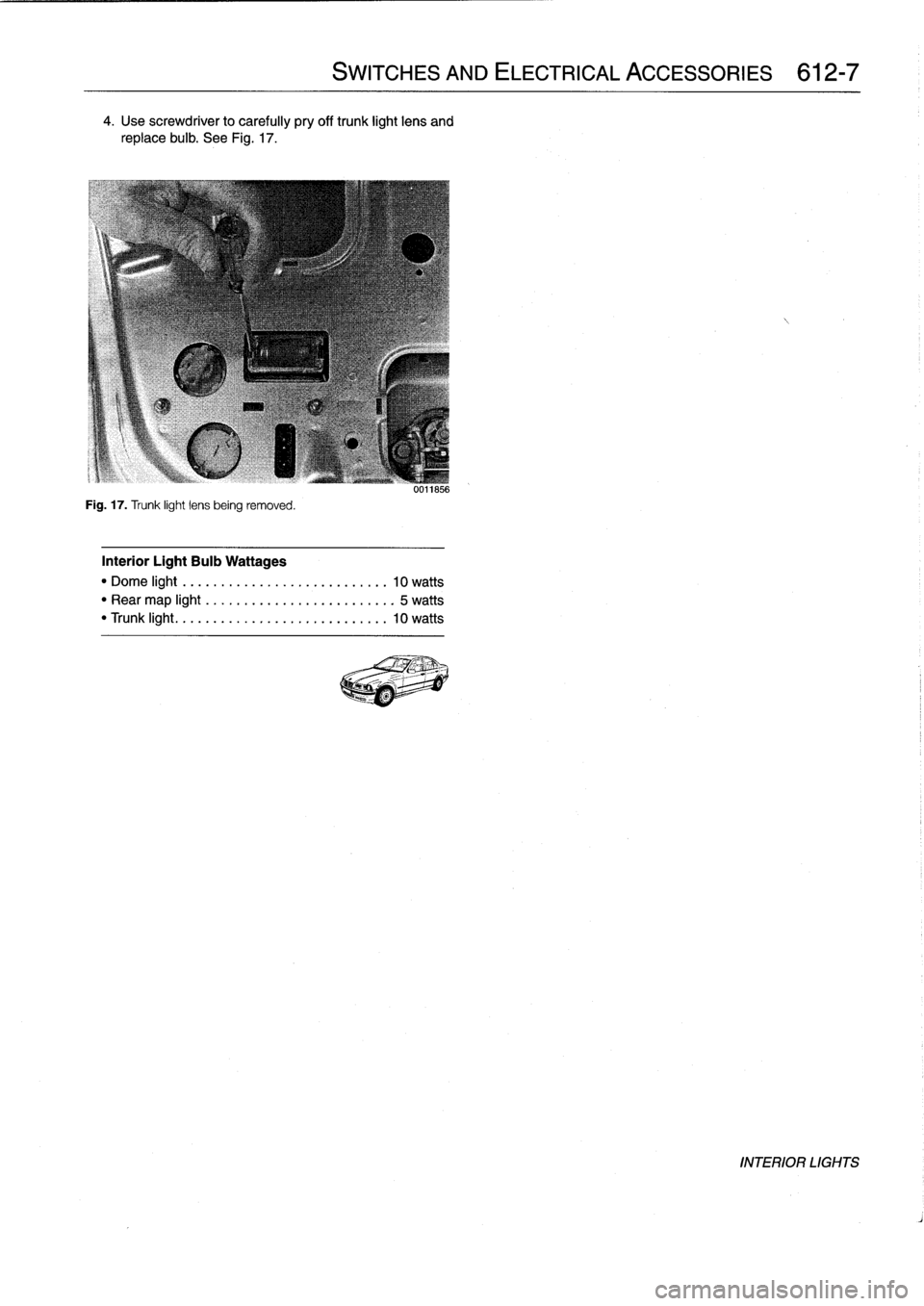

4

.

Use

screwdriver

to

carefully

pry

off

trunk

light

lens

and

replace

bulb

.

See

Fig

.

17

.

Fig

.

17

.

Trunk

light

lens

being

removed

.

Interior

Light

Bulb

Wattages

"

Dome

light

..

..

.

..

..

..................

10

watts

"

Rear

map

light

.

.

.

.

.

....................

5

watts

"

Trunk

light

...

..

.

..

....................

10

watts

SWITCHES

AND

ELECTRICAL

ACCESSORIES

612-7

uulio56

INTERIOR

LIGHTS

Page 438 of 759

620-2

INSTRUMENTS

Fig

.1.

Instrument

cluster

retaining

screws

(arrows)

.

INSTRUMENT

CLUSTER

0012562

Fig

.

3

.

Turnbulb

base

45°

in

direction

shown

(arrow)

.

l

v

w

r

v

9

10

11

12

13

14

15

16

)7

18

19

20

y

21

1

.

Temperature

warning

12

.

Brake

fluid

warning

oo13n6

2

.

Right

turn

signal

13

.

Brake

pad

wear

warning

3

.

Instrument

lighting

14

.ABS

warning

Fig

.

2

.

Instrument

cluster

connector

locking

lever

(arrow)

.

4

.

Oil

pressure

warning

15

.

Seat

belt

warning5

.

Highbeam

16

.ASTwarning

6

.

Battery

charging

lamp

17

.Check

control

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

7

.

Left

turn

signal

18

.Check

engine

"

Instrument

cluster

harness

connector

locking

levers

8

.

Low

fuel

warning

19

.

LCD

lighting

must

be

in

up

position

before

installing

connector

.

9

.

Airbag

warning

20

.

Rear

foglight

(not

used)

10

.

Catalytic

converter

warning

21

.

Front

foglights

"

Install

airbag

to

steering

wheel

as

described

in

721

11

.

Emergency

brake

Airbag

System

(SRS)

.

0012563

"

Reconnect

negative

(-)

cable

to

battery

last,

once

al¡

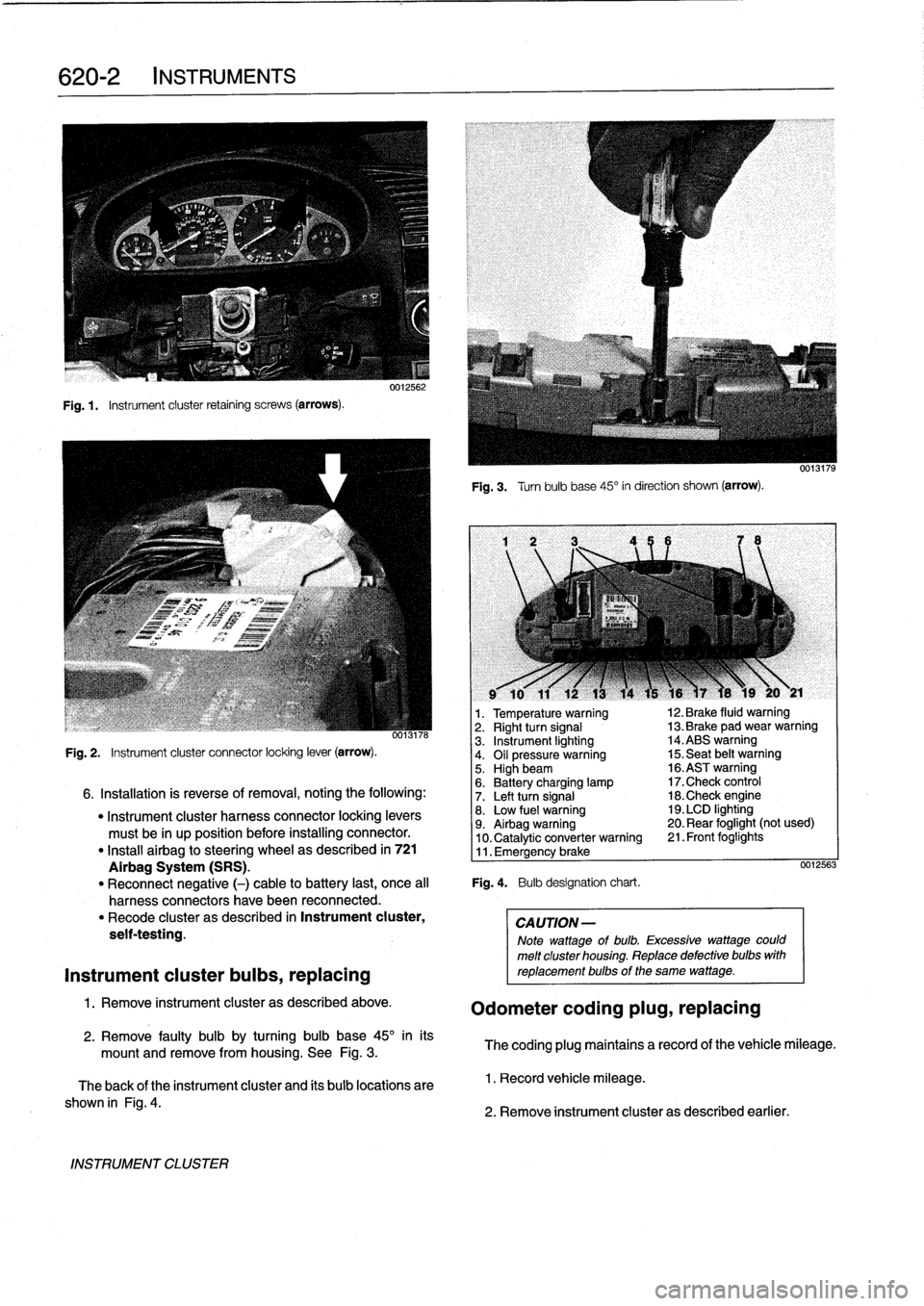

Fig

.

4

.

Bulb

designation

chart

.

harness

connectors

have

been

reconnected

.

"

Recode

cluster

as

described

in

Instrument

cluster,

CAUTION-

seif-testing

.

Note

wattage

of

bulb

.

Excessive

wattage

could

melt

cluster

housing

.

Replace

defective

bulbs

with

Instrument

cluster

bulbs,

replacing

reptacementbulbs

of

the

same

wattage

.

1

.

Remove

instrument

cluster

as

described

above

.

Odometer

coding

plug,

replacing

2

.

Remove

faulty

bulb

by

turning

bulb

base

45°

inits

mount

and

remove

from

housing

.

See

Fig

.

3

.

The

coding

plug

maintains

a

record

of

thevehicle

mileage

.

The

back

of

the

instrument

cluster

and

its

bulb

locations

are

1

.

Record

vehicle

mileage

.

shown

in

Fig

.

4

.

2

.

Remove

instrument

cluster

as

described

earlier

.

Page 439 of 759

3

.

Break

open

plastic

retainer

in

back

of

instrument

clus-

ter

andremove

coding

plug

.

See

Fig

.

5

.

5

.

Reset

vehicle

mileage

.

1

ILO

NOTE-

Consultan

authorized

BMW

dealer

service

department

about

resetting

vehicle

mileage

using

the

special

BMW

Service

tester

.

Vehicle

speed

sender,

replacing

0

0013029

Fig

.

5

.

Remove

coding

plug

retainer

with

a

screwdriver

(arrow)

.

4

.

Install

coding

plug

and

new

retainer

.

Reinstall

instru-

ment

cluster

.

The

vehicle

speed

sender

supplies

an

electronic

pulsed

speed

signal

to

the

speedometer

.

The

sender

is

mounted

be-

neath

the

rear

of

the

car,

on

the

differential

cover

plate

.

1

.

Locate

vehicle

speed

sender

electrical

connector

at

back

of

differential

.

Depress

retaininglevers

on

con-

nector

and

remove

.

See

Fig

.

6

.

INSTRUMENTS

620-

3

0013180

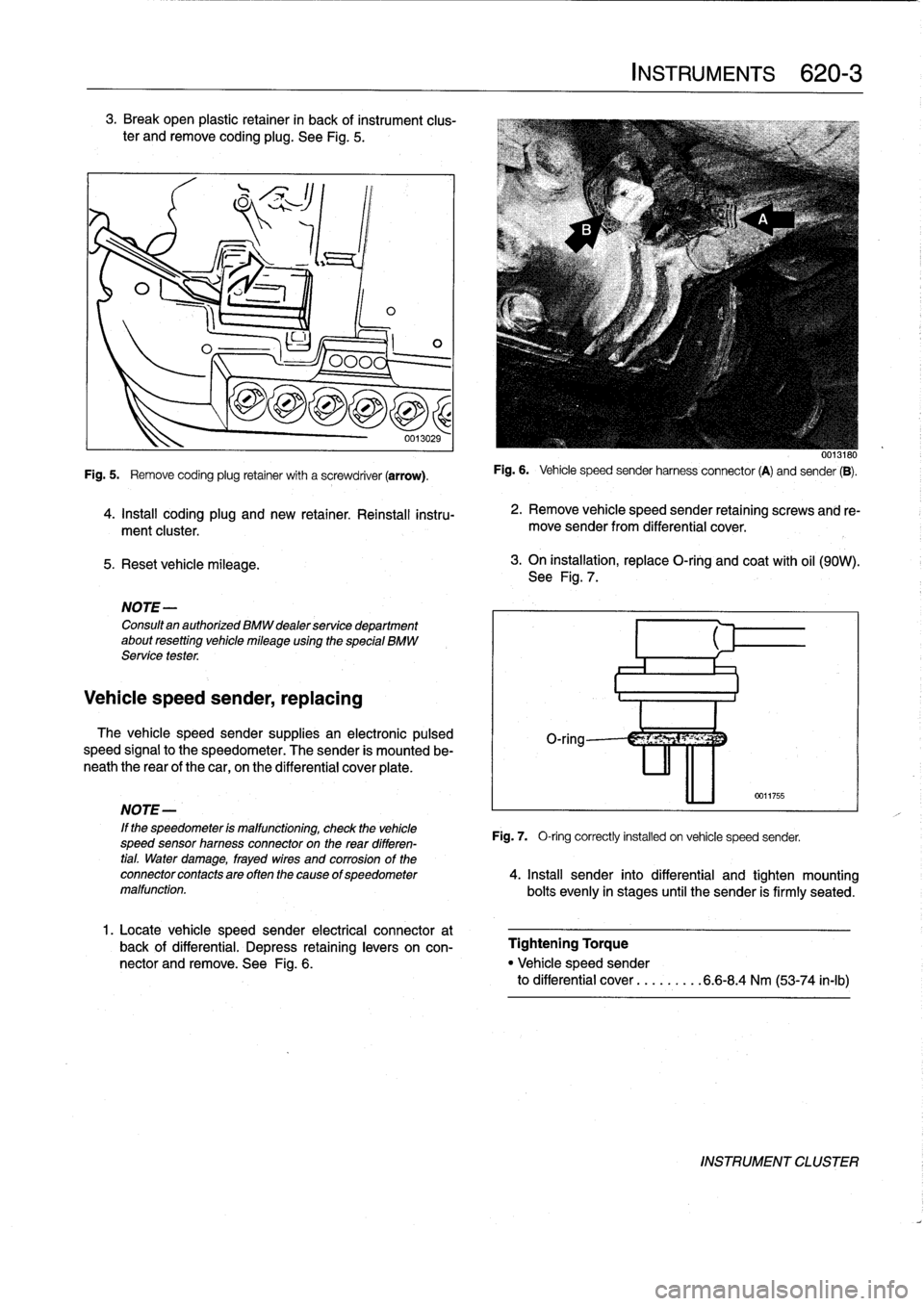

Fig

.

6

.

Vehicle

speed

sender

harnessconnector

(A)

and

sender

(B)

.

2

.

Remove

vehicle

speed

sender

retaining

screws

and

re-

move

sender

from

differential

cover

.

3

.

On

installation,

replace

O-ring

and

coat

with

oil

(90W)

.

See

Fig

.

7

.

0011755

NOTE-

'

If

the

speedometer

is

malfunctioning,

check

the

vehicle

Fig

.

7,

O-ring

correctly

installed

on

vehicle

speed

sender,

speed

sensor

hamess

connectoron

the

rear

differen-

tial

.

Water

damage,

frayed

wires

and

corrosion

of

the

connectorcontactsareoftenthecause

ofspeedometer

4

.

Insta¡¡

sender

into

differential

and

tighten

mounting

malfunction

.

bolts

evenly

in

stages

until

the

sender

is

firmly

seated

.

Tightening

Torque

"

Vehicle

speed

sender

to

differential

cover

...

.

.....

6

.6-8

.4

Nm

(53-74

in-lb)

INSTRUMENT

CLUSTER

Page 441 of 759

FRONT

LIGHTING

.

...........

.

....

.

.

.

.

630-1

Headlight

buib,

replacing

............

.

.

.

.

630-1

Headlight

assembly,

removing

and

installing

.......

.

....

.

.

.

.

630-2

Foglight

assembly,

removing

and

installing

..

630-3

Front

turn

signal

assembly,

removing

and

installing

.....

.

.

.

........

630-4

GENERAL

The

headlight

and

foglight

assemblies

usehalogen

bulbs

.

To

ensure

the

longevity

of

halogen

bulbs,

the

bulb

glass

should

not

be

handied

.

Dirt

and

skin

oíls

may

cause

a

bulbto

fail

prematurely

.

If

necessarywipe

bulb

using

a

clean

cloth

dampened

with

rubbing

alcohol

.

NOTE-

Use

only

original

equipment

replacement

bulbs

.

Non-

original

equipment

bulbs

may

cause

false

failure

read-

ings

on

the

check

control

display

(where

applicable)

.

WARNING

-

INhenworking

on

electrical

systems,

remove

the

fuse

protecting

the

circuit

under

repair

.

See

610

Electrical

Component

Locations

.

FRONT

LIGHTING

Headlight

bulb,

replacing

1

.

Open

engine

hood

.

2

.

Working

in

back

of

headlight

assembly,grasp

rear

of

bulbsocket

(harnessconnector)

and

turn

counterclock-

wise

90°

.

Pull

bulb

out

of

headlight

assembly

.

See

Fig

.

1

.

3

.

Disconnect

harness

connector

from

bulb

.

CA

UTION-

Do

not

touch

halogen

bubs

with

yourbare

hands

.

If

necessary

wipe

bulb

using

a

clean

cloth

damp-

ened

with

rubbing

alcohol

.

630

Exterior

Lighting

EXTERIOR

LIGHTING

630-1

GENERAL

.

.

.

.

...

.

................

.

.

.

.

630-1

Side

Marker

Lights

.......

.

.

.

.

.

.......

.

..

630-4

REAR

LIGHTING

.

......

.

.

.

.

.

.

.

...

.

.

.

..

630-4

Taillight

Bulbs

..........

.

.

.

.

.

.....

.

.

.

.

.

630-4

Taillight

assembly,

removing

and

installing

.

.

.

630-5

CenterBrake

Light

.......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

630-5

Center

brake

light

housing,

replacing

(4-door

and

coupe

models)

.

.

.

.

.......

.

.

.630-5

License

plate

light,

removingand

installing

.

.630-6

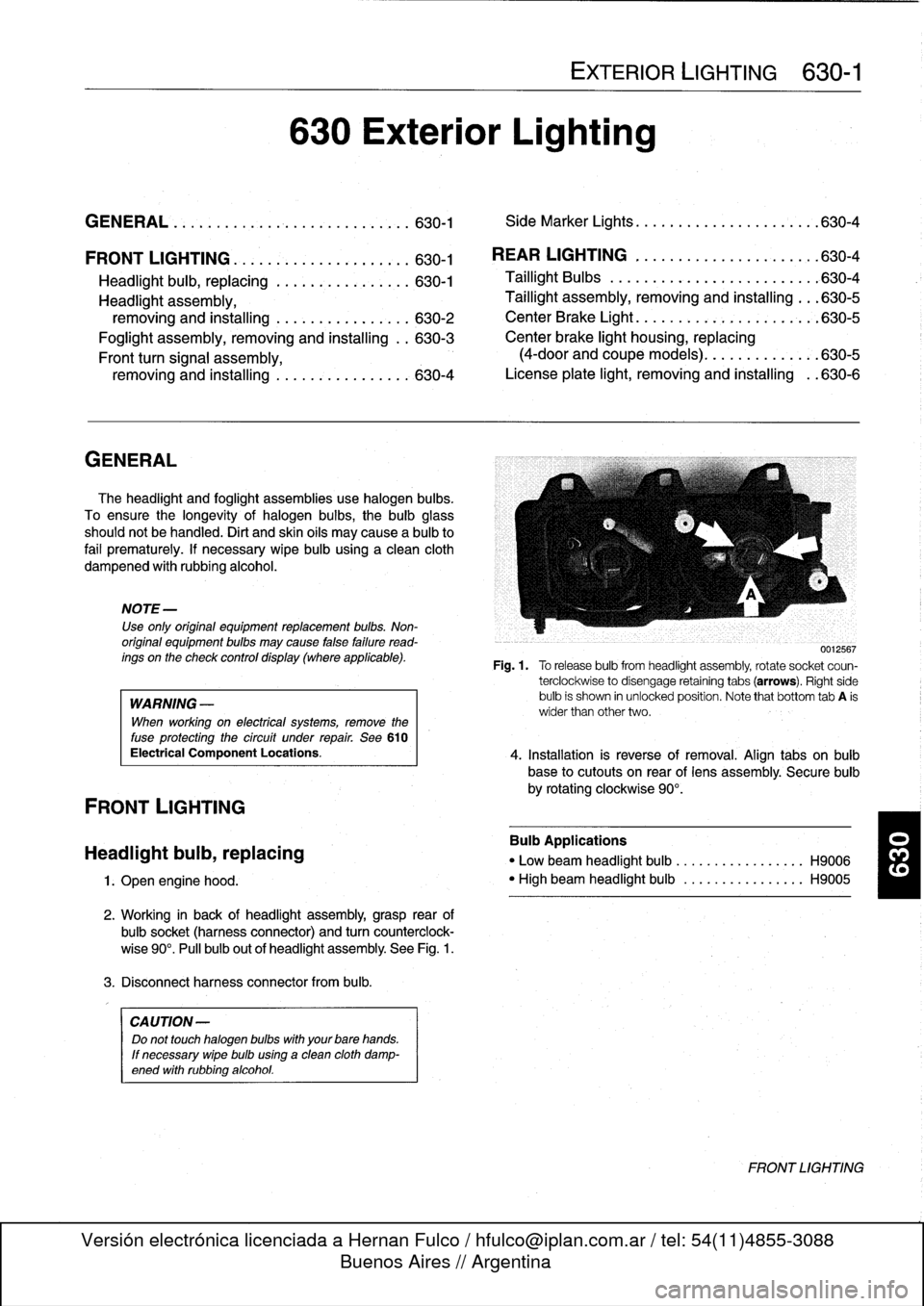

0012567

Fig

.1.

Torelease

bulbfrom

headlight

assembly,

rotate

socket

coun-

terclockwise

to

disengage

retaining

tabs

(arrows)

.

Right

side

bulb

is

shown

in

unlocked

position

.

Note

that

bottom

tab

A

is

wider

than

other

two

.

4

.

Installation

is

reverse

of

removal

.

Align

tabs

on

bulb

base

to

cutouts

on

rear

of

lens

assembly

.

Secure

bulb

by

rotating

clockwise

90°

.

Bulb

Applications

"

Low

beam

headlight

bulb

...

.

..

..

.........

H9006

"

High

beam

headlight

bulb

..

.

..

..

.........

H9005

FRONT

LIGHTING

Page 443 of 759

4

Foglight

assembly,

removing

and

installing

1

.

Foglight

lens

release

catch

2

.

Foglight

lensrear

protective

cap

3

.

Foglight

bulb

4

.

Foglight

lens

Fig

.

7

.

Foglight

assembly

(removed)

.

0012682

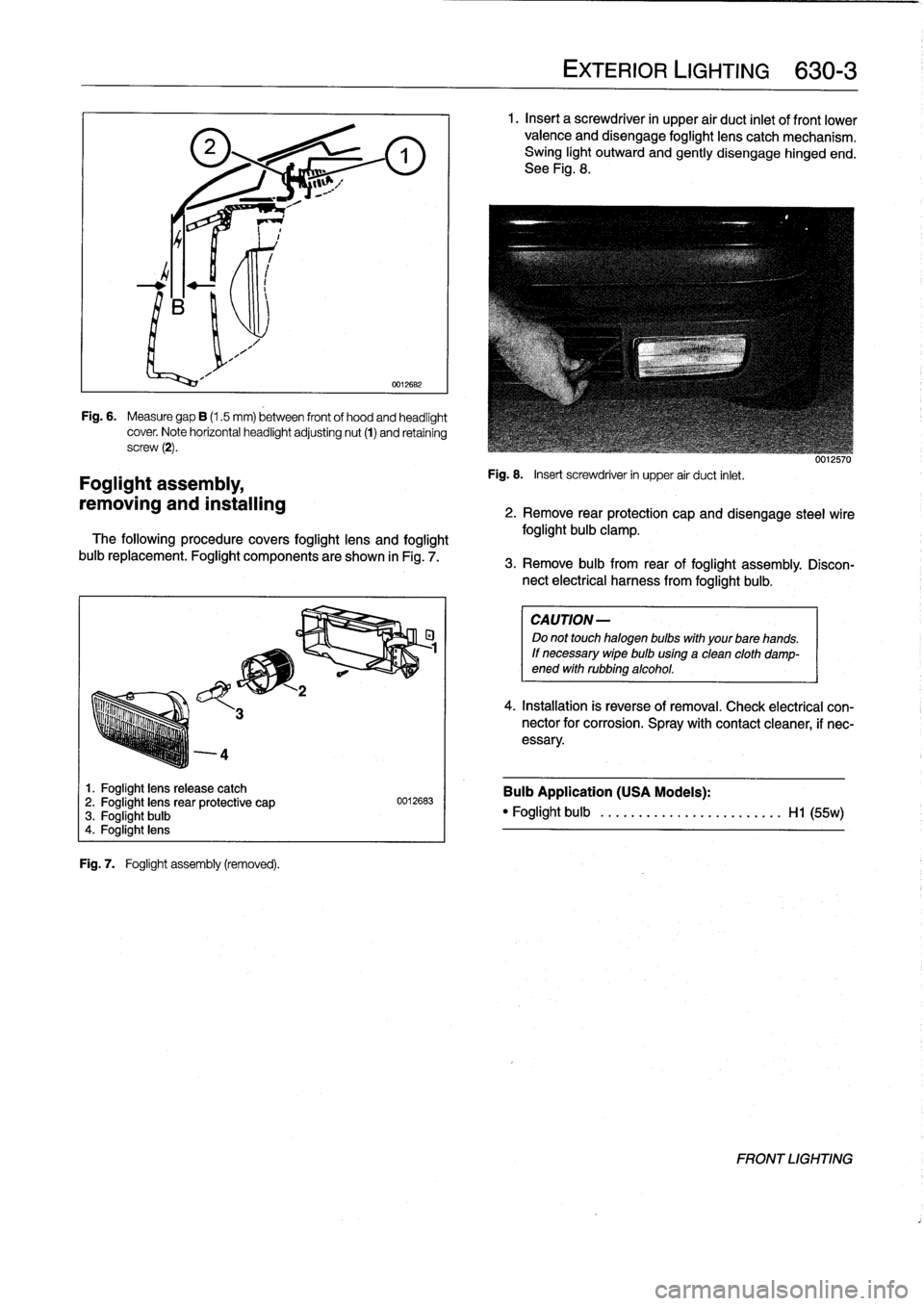

Fig

.

6

.

Measure

gap

B

(1.5

mm)

between

front

of

hood

and

headlight

cover

.

Note

horizontal

headlightadjusting

nut

(1)

and

retaining

screw

(2)

.

The

following

procedure

covers

foglight

lens

and

foglight

buib

replacement

.

Foglight

components

are

shown

in

Fig

.

7

.

0012683

EXTERIOR

LIGHTING

630-

3

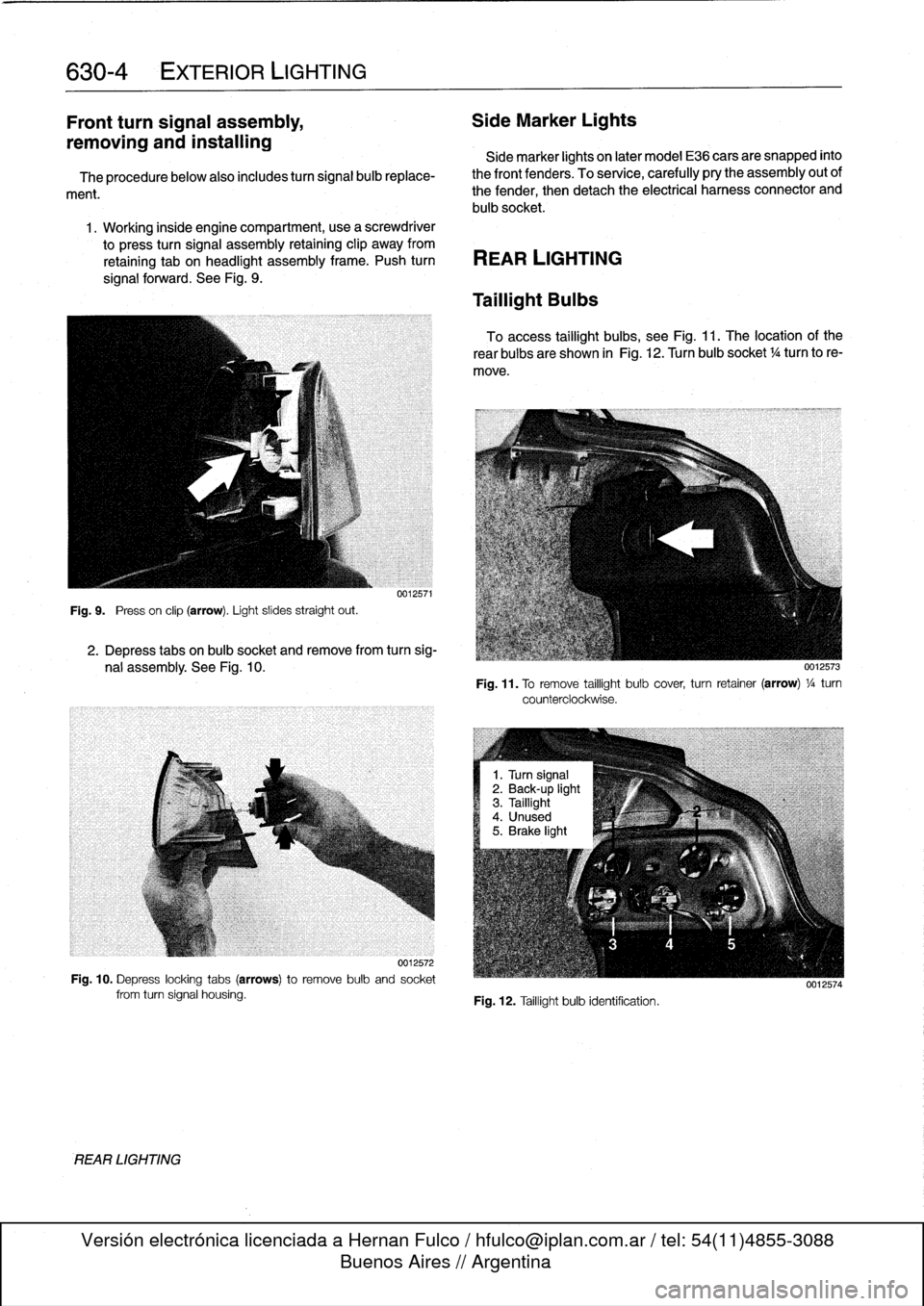

1

.

Insert

a

screwdriver

in

upper

air

duct

inlet

of

front

lower

valence

and

disengage

foglight

lens

catch

mechanism

.

Swing

light

outward

and

gently

disengage

hinged

end

.

See

Fig

.

8

.

Fig

.

8

.

Insert

screwdriver

in

upper

air

duct

inlet

.

uu¡¿biu

2

.

Remove

rear

protection

capand

disengage

steel

wire

foglight

bulb

clamp

.

3

.

Remove

bulb

from

rear

of

foglight

assembly

.

Discon-

nect

electrical

harness

from

foglight

bulb

.

CAUTION

-

Do

not

touch

halogen

bulbs

with

yourbare

hands

.

If

necessary

wipe

buib

using

a

clean

cloth

damp-ened

withrubbing

alcohol

.

4

.

Installation

is

reverse

of

removal

.

Check

electrical

con-nector

for

corrosion

.

Spray

with

contact

cleaner,

if

nec-

essary

.

Bulb

Application

(USA

Models)

:

"

Foglight

bulb

......

...

..

...

..........

Hl

(55w)

FRONT

LIGHTING

Page 444 of 759

630-

4

EXTERIOR

LIGHTING

Front

turn

signal

assembly,

Side

Marker

Lights

removing

and

installing

Side

marker

lights

on

later

model

E36

cars

are

snapped

into

The

procedurebelow

also

includes

turn

signal

bulb

replace-

the

front

fenders

.

To

service,

carefully

pry

the

assembly

out

of

ment

.

the

fender,

then

detach

the

electrical

harness

connector

and

bulb

socket

.

1

.

Working

inside

engine

compartment,usea

screwdriver

to

press

turn

signal

assembly

retaining

clip

away

from

retaining

tab

on

headlight

assembly

frame

.

Push

turn

REAR

LIGHTING

signal

forward

.

See

Fig

.

9

.

Fig

.

9

.

Press

on

clip

(arrow)

.

Light

slides

straight

out

.

REAR

LIGHTING

0012571

2

.

Depress

tabs

on

bulb

socket

and

remove

from

turn

sig-

nal

assembly

.

See

Fig

.

10

.

0012572

Fig

.

10

.

Depress

locking

tabs

(arrows)to

remove

bulb

and

socket

from

turn

signal

housing

.

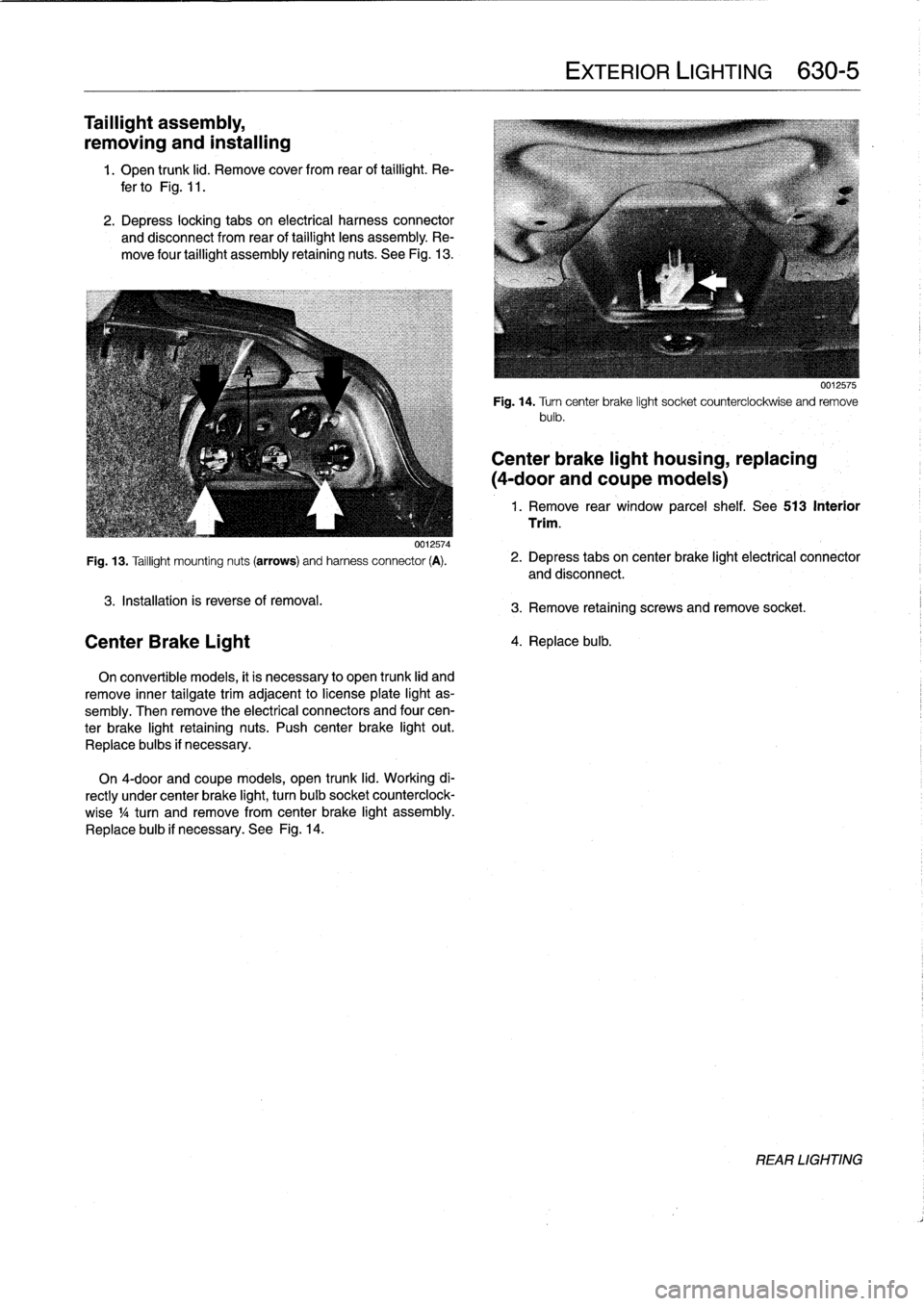

Taillight

Bulbs

To

access

taillight

bulbs,

see

Fig

.

11

.

The

location

of

the

rear

bulbs

are

shown

in

Fig

.

12

.

Turn

bulb

socket

1

/4turn

to

re-

move

.

Fig

.

11

.

To

remove

taillight

bulb

cover,

turn

retainer

(arrow)

1

/a

turn

counterclockwise

.

Fig

.

12

.

Taillight

bulb

identification

.

0012574

Page 445 of 759

Taillight

assembly,

removing

and

installing

1

.

Open

trunk

lid

.

Remove

cover

from

rear

of

taillight

.

Re-

fer

to

Fig

.

11

.

2

.

Depress

locking

tabs

on

electrical

harness

convector

and

disconnect

from

rear

of

taillight

lens

assembly

.

Re-

move

four

taillight

assembly

retaining

nuts

.

See

Fig

.

13

.

0012574

Fig

.

13

.

Taillight

mounting

nuts

(arrows)

and

harness

connector

(A)

.

3

.

Installation

is

reverse

of

removal

.

Center

Brake

Light

On

convertible

models,

it

is

necessary

to

open

trunk

lid

and

remove

inner

tailgatetrim

adjacent

to

license

plate

light

as-

sembly

.

Then

remove

the

electrical

connectors

and

four

cen-

ter

brake

light

retaining

nuts

.

Push

center

brake

light

out

.

Replace

bulbs

if

necessary

.

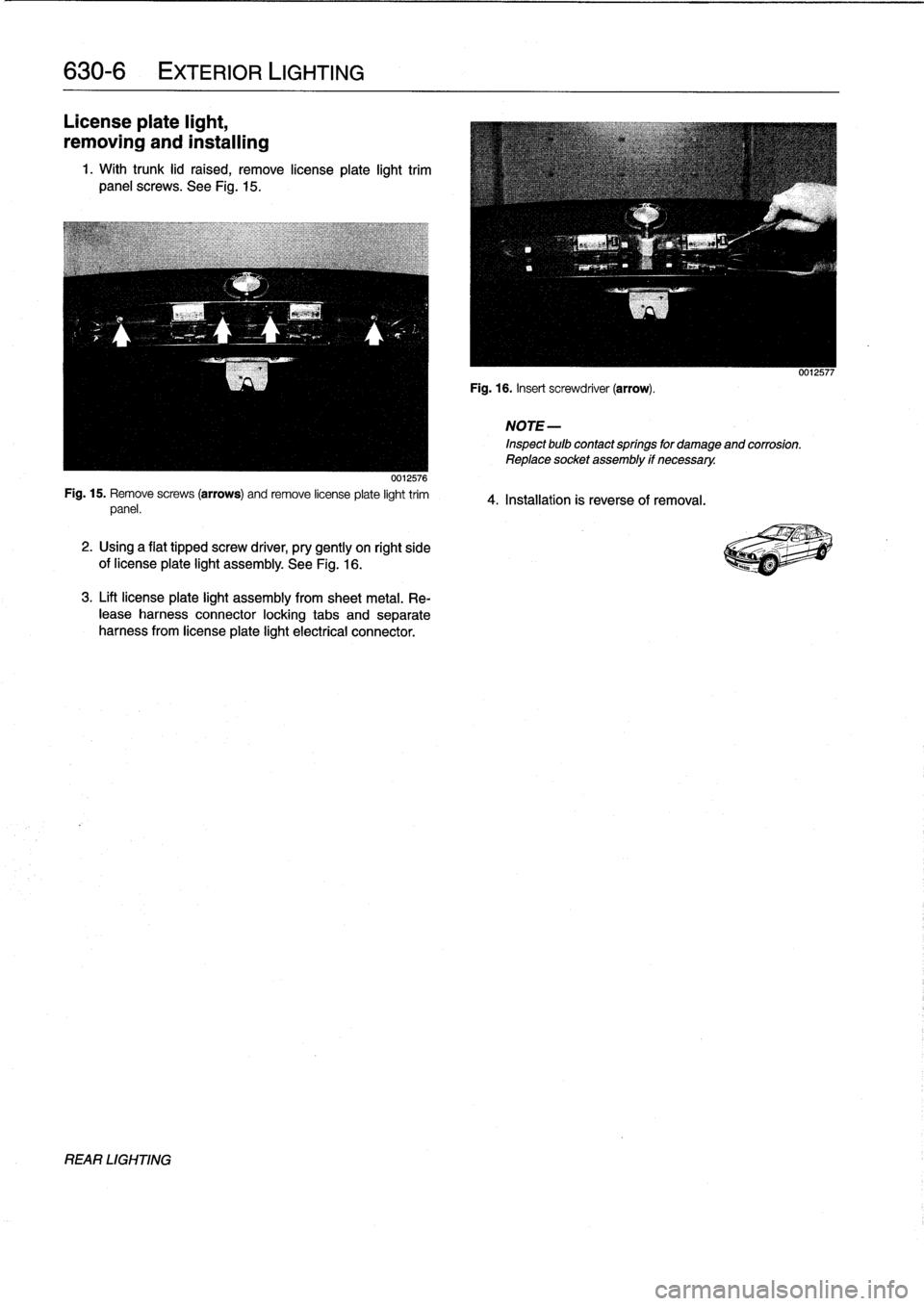

On

4-door

and

coupe

models,

open

trunk

lid

.

Working

di-

rectly

under

center

brake

light,

turn

bulb

socket

counterclock-

wise

1

/4turn

andremove

from

center

brake

light

assembly

.

Replace

bulb

if

necessary

.

See

Fig

.

14

.

EXTERIOR

LIGHTING

630-

5

0012575

Fig

.

14

.

Turncenter

brake

light

socket

counterclockwise

and

remove

bulb

.

Center

brake

light

housing,

replacing

(4-door

andcoupe

models)

1

.

Remove

rear

window

parcel

shelf

.

See513

Interior

Trim

.

2

.

Depress

tabs

on

center

brake

light

electrical

connector

and

disconnect

.

3

.

Remove

retaining

screws

and

remove

socket

.

4

.

Replace

bulb

.

REAR

LIGHTING

Page 446 of 759

630-

6

EXTERIOR

LIGHTING

License

plate

light,

removing

and

installing

1

.

With

trunk

lid

raised,

remove

lícense

plate

light

trim

panel

screws

.

See

Fig

.

15

.

0012576

Fig

.

15

.

Remove

screws

(arrows)

and

remove

license

plate

light

trim

panel

.

2

.

Using

a

flat

tipped

screw

driver,

pry

gently

on

right

side

of

license

plate

light

assembly

.

See

Fig

.

16

.

3

.

Lift

license

plate

light

assembly

from

sheetmetal

.

Re-

lease

harness

connector

locking

tabs

and

separate

harness

from

license

plate

light

electrical

connector

.

REAR

LIGHTING

Fig

.

16

.

Insert

screwdriver

(arrow)

.

NOTE

-

Inspect

bulb

contactsprings

for

damageand

corrosión

.

Reptace

socket

assembly

if

necessary

.

4

.

Installatíon

is

reverse

of

removal

.

0012577

Page 447 of 759

GENERAL

E36

cars

are

equipped

with

integrated

automatic

heating

and

air

conditioning

systems

.

Many

of

the

procedures

given

in

this

repair

group

require

that

the

A/C

refrigerant

charge

be

evacuated

using

specialized

equipment

.

See

A/C

System

Warningsand

Cautions

later

in

this

repair

group

.

HEATER

AND

CONTROLS

Blower

motor,

removing

and

installing

NOTE-

On

6-cylinder

cars,

the

plastic

top

enginecover

and

fuel

rail

covermustbe

removed

.

The

fuel

injectorhamess

re-

taining

screws

must

be

removed

and

the

harness

set

aside

.

The

engine

control

module

(ECM)

cover

must

be

removed,

the

control

unit

connectors

unplugged

and

the

harness

pulled

out

of

the

way

.

See

130

Fuel

Injection

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

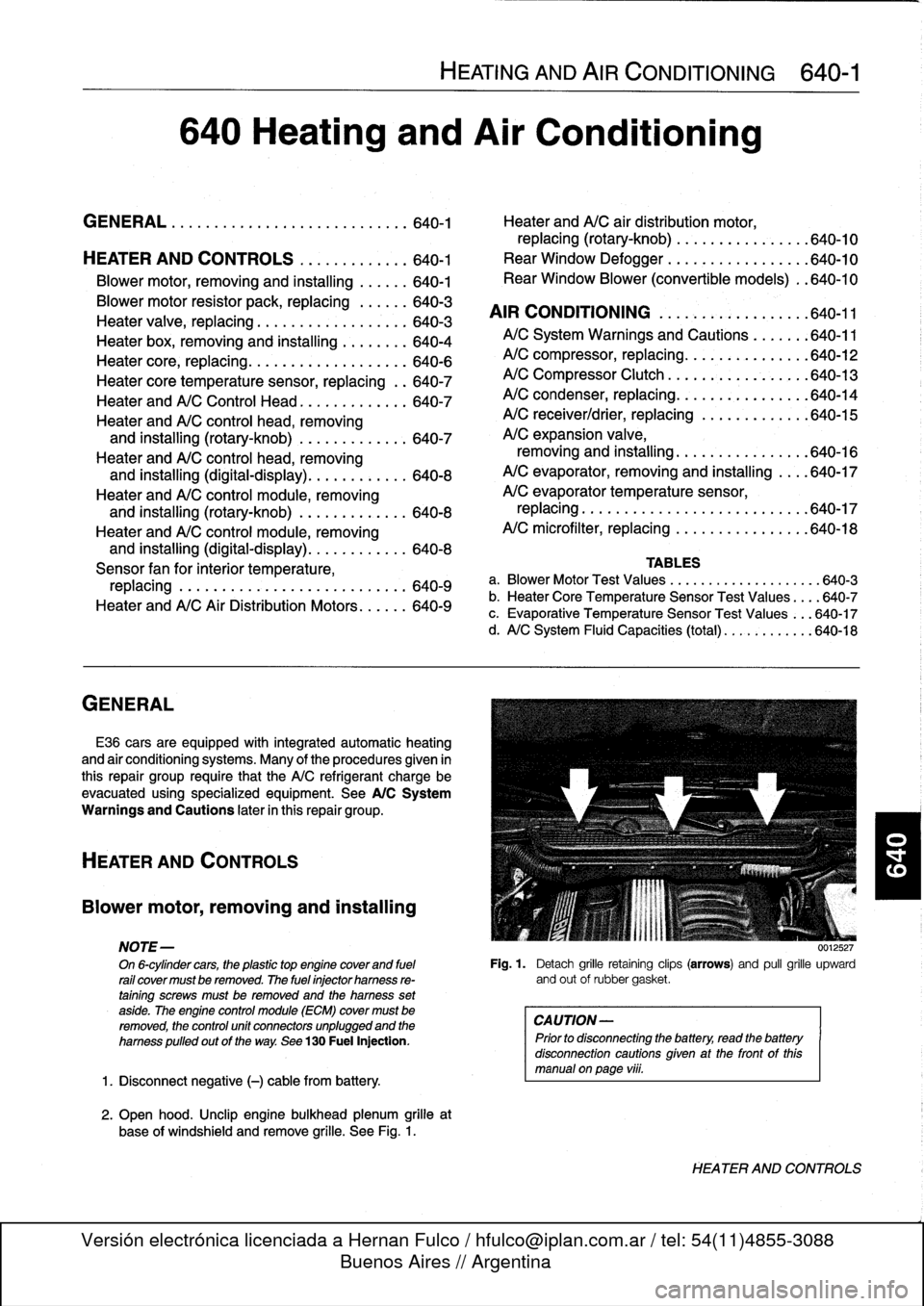

2

.

Open

hood

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

windshíeld

and

remove

grille

.

See

Fig

.

1

.

HEATING

AND

AIR

CONDITIONING

640-1

640

Heating

and

Air

Conditioning

GENERAL

.

...

.

....

.

.

.

.

.

.

.

.

.

.......

.

.

.

640-1

Heater

andA/C

air

distribution

motor,

replacing(rotary-knob)

.

.

...

.

.

.

.......

.

640-10

HEATER

AND

CONTROLS

.

.....

.

.

.

.

.

.

.640-1

Rear

Window

Defogger

.

.

.

.

.

.

.

.

.

.

...

.

.

.

640-10

Blower

motor,

removing

and

installing

.

.

.

.

.

.

640-1

Rear

Window

Blower

(convertible

models)

.

.640-10

Blowermotor

resistor

pack,

replacing

.

.

.

.

.

.

640-3

AIR

CONDITIONING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-11

Heater

valve,

replacing

...........

.

.

.

.

.

.

.

640-3

Heater

box,

removing

and

installing

.

.

.

.

.

.

.

.

640-4

A/CSystem

Warnings

and

Cautions

.

.

.

.

.

.

:640-11

Heater

core,

replacing

.....

.

.

:

....

.

.

.

.

.

.

.

640-6

A/C

compressor,

replacing

.

.

::.

:

:

.

.

.

.

.

.

.

.640-12

Heater

core

temperature

sensor,

replacing

.

.

640-7

A/C

Compressor

Clutch

.

.

.

.

.

.

.

:

.

.

.

.

.

.

.

.

.

640-13

Heater

andA/C

Control

Head

.

.

....

.

.....

.

640-7

A/C

condenser,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-14

Heater

andA/C

control

head,

removing

A/C

receiver/drier,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

640-15

and

installing

(rotary-knob)

.

.

....

.

......

640-7

A/C

expansion

valve,

Heater

andA/C

control

head,

removing

removing

and

installing

...

.

.....

.

.

.

.

.

.

.

640-16

and

installing

(digital-display)

.

.....

.

.....

640-8

A/C

evaporator,

removing

and

installing

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

evaporator

temperature

sensor,

and

installing

(rotary-knob)

.

.

...

.

.

.

.

.

.

.

.

640-8

replacing

.

.

.

.

.

.

..............

.

.

.

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

microfilter,

replacing

......

.

....

.

.

.

..

640-18

and

installing

(digital-display)

.

...

.

.

.

.

.

...

640-8

Sensor

fan

for

interior

temperature,

TABLES

replacing

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-9

a

.

Blower

Motor

Test

Values

.........

...

.

.

......

640-3

Heater

andA/C

AirDistribution

Motors

.

.

.

.

.

.

640-9

b

.

Heater

Core

Temperature

Sensor

Test

Values

...

.640-7

c

.

Evaporative

Temperature

Sensor

Test

Values

...

640-17

d

.

A/C

System

Fluid

Capacities

(total)

..

..........

640-18

0012527

Fig

.

1

.

Detach

grille

retaining

clips

(arrows)

and

pull

grille

upward

and

out

of

rubbergasket

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

HEATER

AND

CONTROLS

Page 449 of 759

9

.

Release

blower

motor

retaining

strap

andremove

blow-

er

motor

and

fans

fromcowl

opening

.

NOTE-

Twist

and

rotate

blowermotor

assembly

to

facilítate

re-

moval

from

opening

.

If

the

blower

motor

is

to

be

rein-stafled,

use

care

not

to

damage

fan

wheels

during

removal

.

ff

the

blower

motor

fs

to

be

replaced,

cut

offfan

wheels

at

center

to

aid

in

removal

.

10

.

Installation

is

reverse

of

removal

.

When

installing

a

re-

placement

blower

motor,

instan

motor

into

cowlarea

before

installing

fan

wheels

.

Blower

motor

test

specifi-

cations

are

listed

in

Table

a

.

NOTE

-

On

replacementblowermotors

from

BMW,

thefan

wheels

come

unattached

to

aid

in

installation

.

Locatearrow

on

blower

motor

and

instan

fan

wheels

atthis

po-

sition

.

Be

sure

color

coolng

matches

.

Retain

fan

wheels

using

the

new

clips

.

See

an

authorized

BMW

parts

de-

partment

for

the

latest

parts

information

.

Table

a

.

Blower

Motor

Test

Values

Testingvoltage

13

VDC

Operating

voltage

9-15

VDC

Max

.

current

consumption

(approx

.)

12

amps

Maximum

speed

3,600-4,000rpm

Axialplay

(max

.

allowable)

1

.0

mm

(0

.04

in

.)

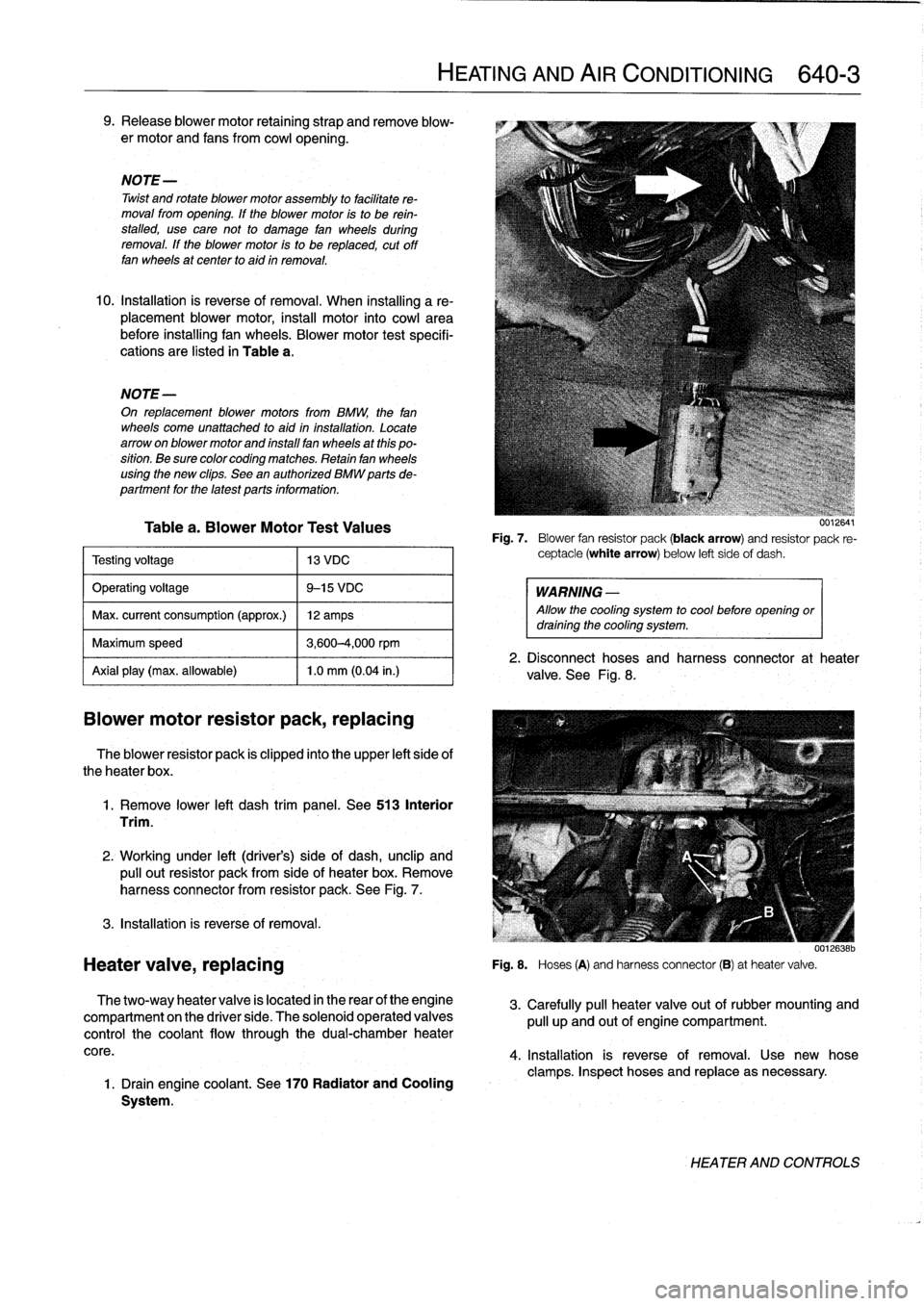

Blower

motor

resistor

pack,

replacing

The

blower

resistor

pack

is

clipped

into

the

upper

left

side

of

theheater

box

.

1

.

Remove

lower

left

dash

trim

panel

.

See513

Interior

Trim

.

2

.

Working

under

left

(driver's)

side

of

dash,

unclip

and

pulí

out

resistor

pack

from

sideof

heater

box

.

Remove

harness

connector

from

resistor

pack

.

See

Fig

.

7

.

3

.

Installation

is

reverse

of

removal

.

Heater

valve,

replacing

The

two-way

heater

valve

is

located

in

the

rear

of

the

engine

compartment

on

the

driver

side

.

The

solenoid

operated

valves

control

the

coolant

flow

through

the

dual-chamber

heater

core

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

System

.

HEATING

AND

AIR

CONDITIONING

640-

3

uuiGO4I

Fig

.

7

.

Blower

fan

resistor

pack

(black

arrow)

and

resistor

pack

re-

ceptacle

(white

arrow)

below

left

sideof

dash

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

ordraining

the

cooling

system

.

2

.

Disconnect

hoses

and

harness

connector

at

heater

valve

.

See

Fig

.

8

.

001[ó38b

Fig

.

S

.

Hoses

(A)

and

harnessconnector

(B)

at

heatervalve

.

3

.

Carefully

pull

heater

valve

out

of

rubber

mounting

and

pull

up

and

out

of

engine

compartment

.

4

.

Installation

is

reverse

of

removal

.

Use

new

hose

clamps

.

Inspect

hoses

and

replace

asnecessary

.

HEATER

AND

CONTROLS