clock BMW 525i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 525i, Model: BMW 525i 1998 E39Pages: 1002

Page 218 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-42

/ Cvlinder Head and Valvetrain

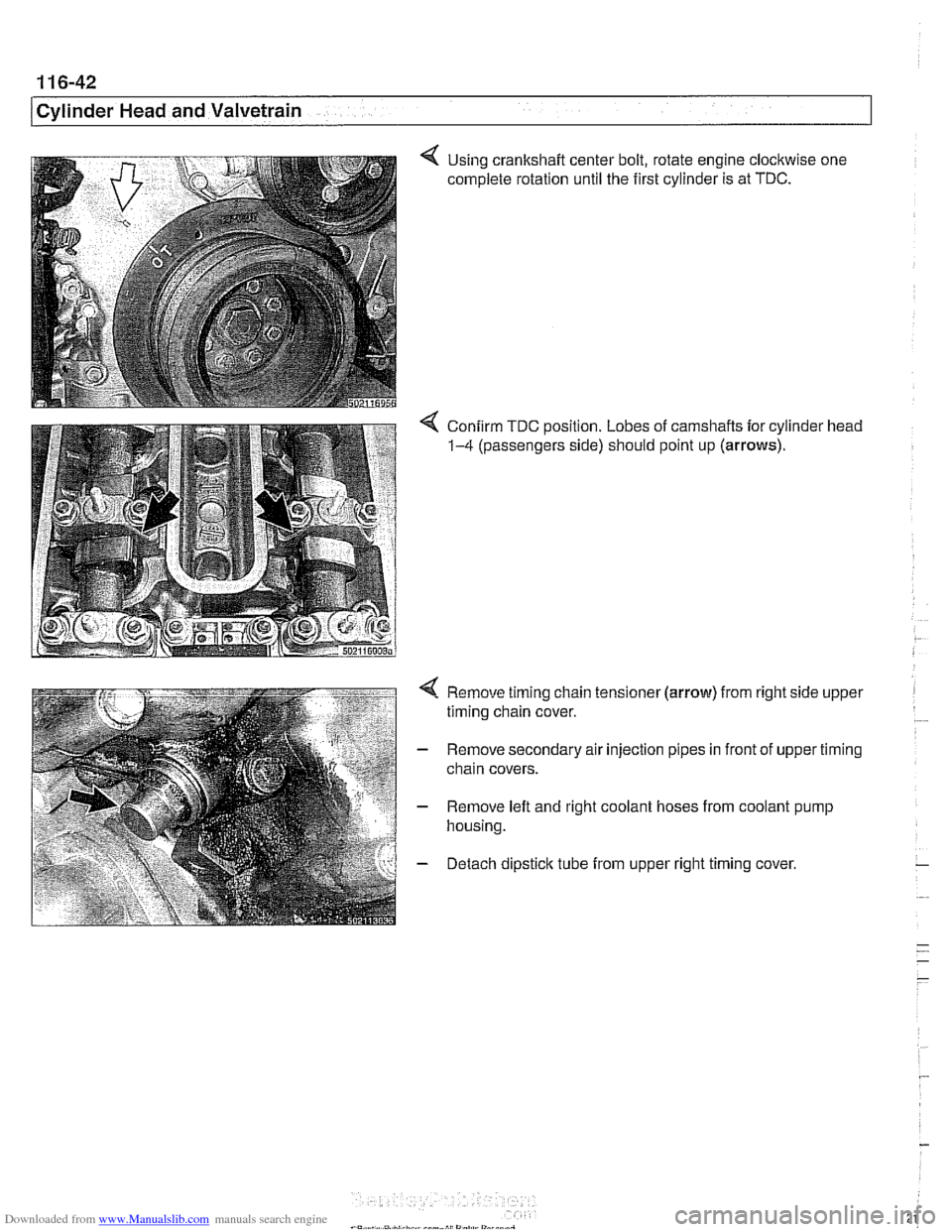

4 Using crankshaft center bolt, rotate engine clockwise one

complete rotation until the first cylinder is at TDC.

4 Confirm TDC position. Lobes of camshafts for cylinder head

1-4 (passengers side) should point up (arrows).

4 Remove timing chain tensioner (arrow) from right side upper

timing chain cover.

- Remove secondary air injection pipes in front of upper timing

chain covers.

- Remove left and right coolant hoses from coolant pump

housing.

- Detach dipsticlc tube from upper right timing cover,

Page 220 of 1002

Downloaded from www.Manualslib.com manuals search engine

..

ICylinder Head and Valvetrain -.I

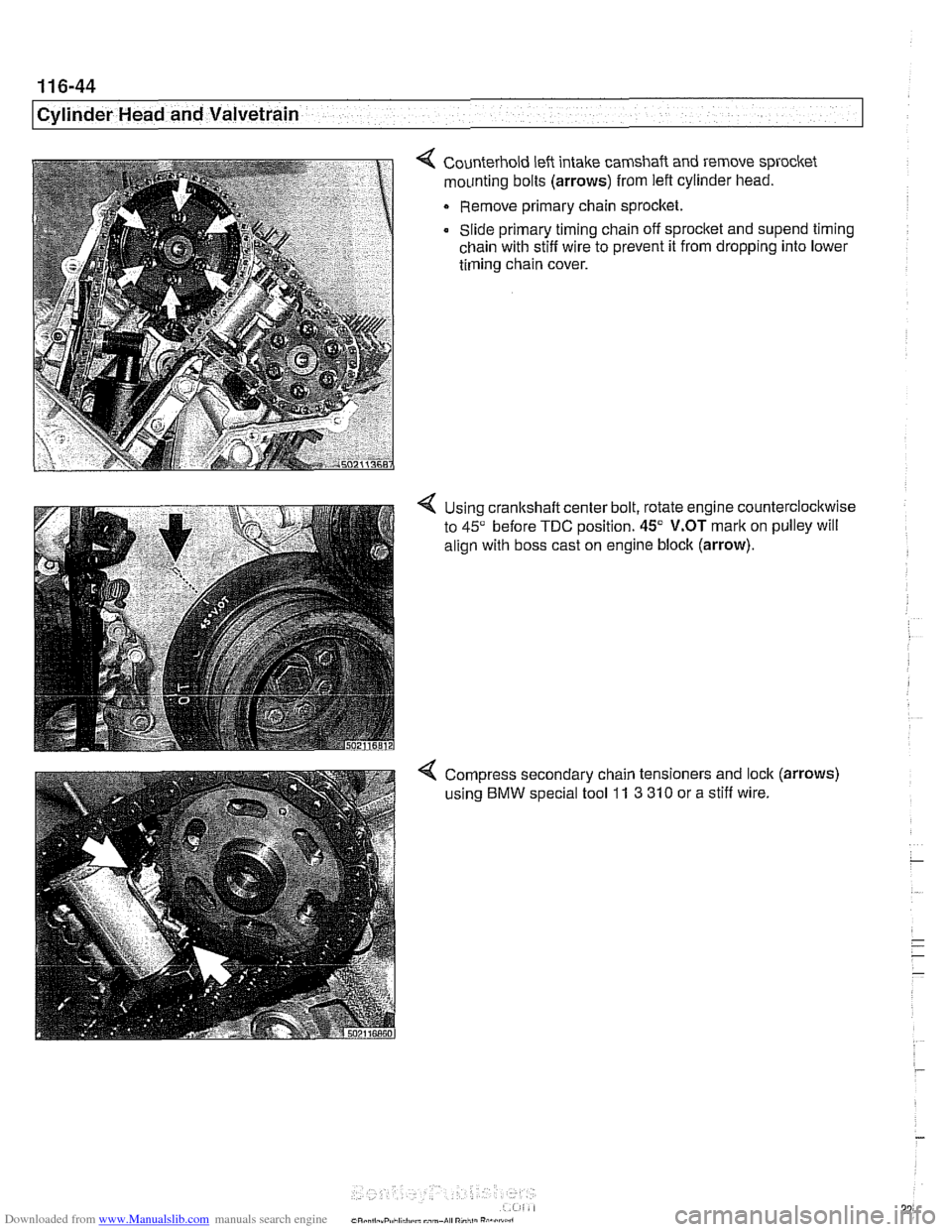

4 Counterhold left intake camshaft and remove sprocket

mounting bolts

(arrows) from left cylinder head.

Remove primary chain sprocket.

Slide primary timing chain off sprocket and

supend timing

chain with stiff wire to prevent it from dropping into lower

timing chain cover.

4 Using cranltshaft center bolt, rotate engine counterclockwise

to

45" before TDC position. 45" V.OT mark on pulley will

align with boss cast on engine block

(arrow).

4 Compress secondary chain tensioners and lock (arrows)

using BMW special tool 11 3 310 or a stiff wire.

Page 228 of 1002

Downloaded from www.Manualslib.com manuals search engine

ICylinder Head and Valvetrain -.

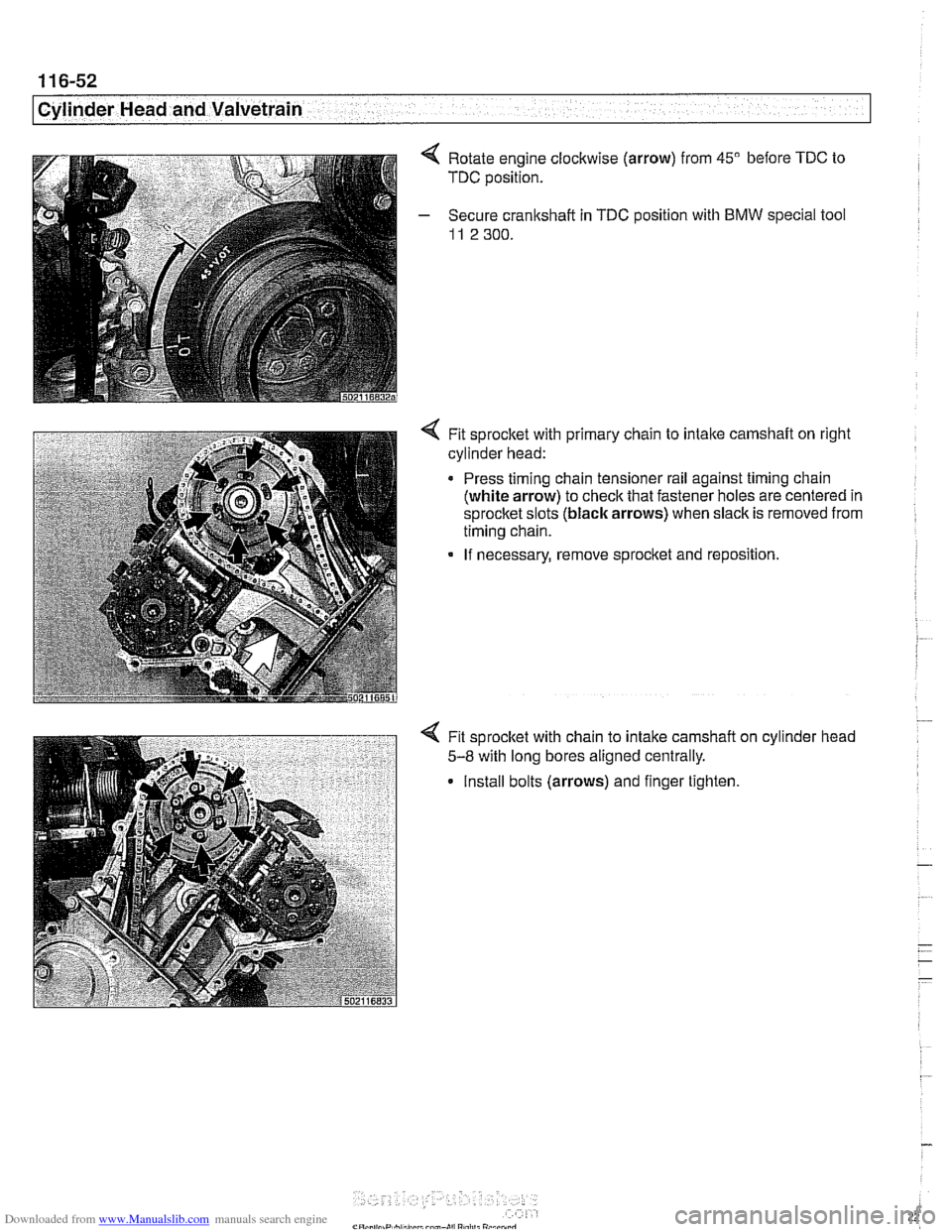

Rotate engine clockwise (arrow) from 45" before TDC to

TDC position.

Secure crankshaft in

TDC position with BMW special tool

11 2 300.

4 Fit sprocket with primary chain to intaite camshaft on right

cylinder head:

Press timing chain tensioner rail against timing chain

(white arrow) to check that fastener holes are centered in

sprocket slots (black arrows) when slack is removed from

timing chain.

If necessary, remove sprocket and reposition.

Fit sprocket with chain to intake camshaft

5-8 with long bores aligned centrally.

Install bolts (arrows) and finger tighten cylinder

head

Page 254 of 1002

Downloaded from www.Manualslib.com manuals search engine

117-18

Camshaft Timing Chain

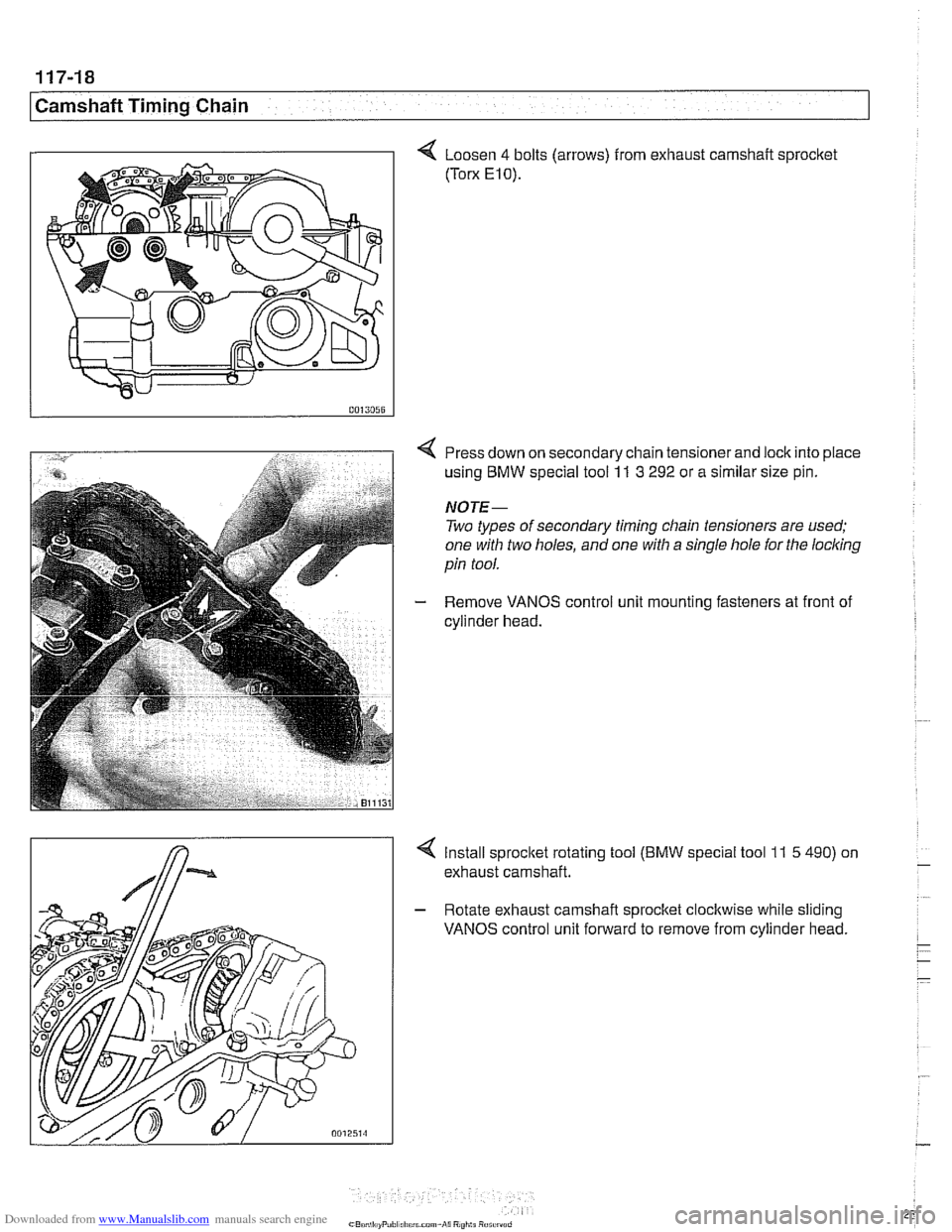

4 Loosen 4 bolts (arrows) from exhaust camshait sprocket

(Torx E10).

Press down on secondary chain tensioner and lock into place

using BMW special tool

11 3 292 or a similar size pin.

NOTE-

Two types of secondary timing chain tensioners are used;

one with two holes, and one with a single hole for the

locl

Remove VANOS control unit mounting fasteners at front of

cylinder head.

4 Install sprocltet rotating tool (BMW special tool 11 5 490) on

exhaust camshaft.

- Rotate exhaust camshaft sprocket clockwise while sliding

VANOS control unit forward to remove from cylinder head.

Page 256 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-20

Camshaft Timing Chain

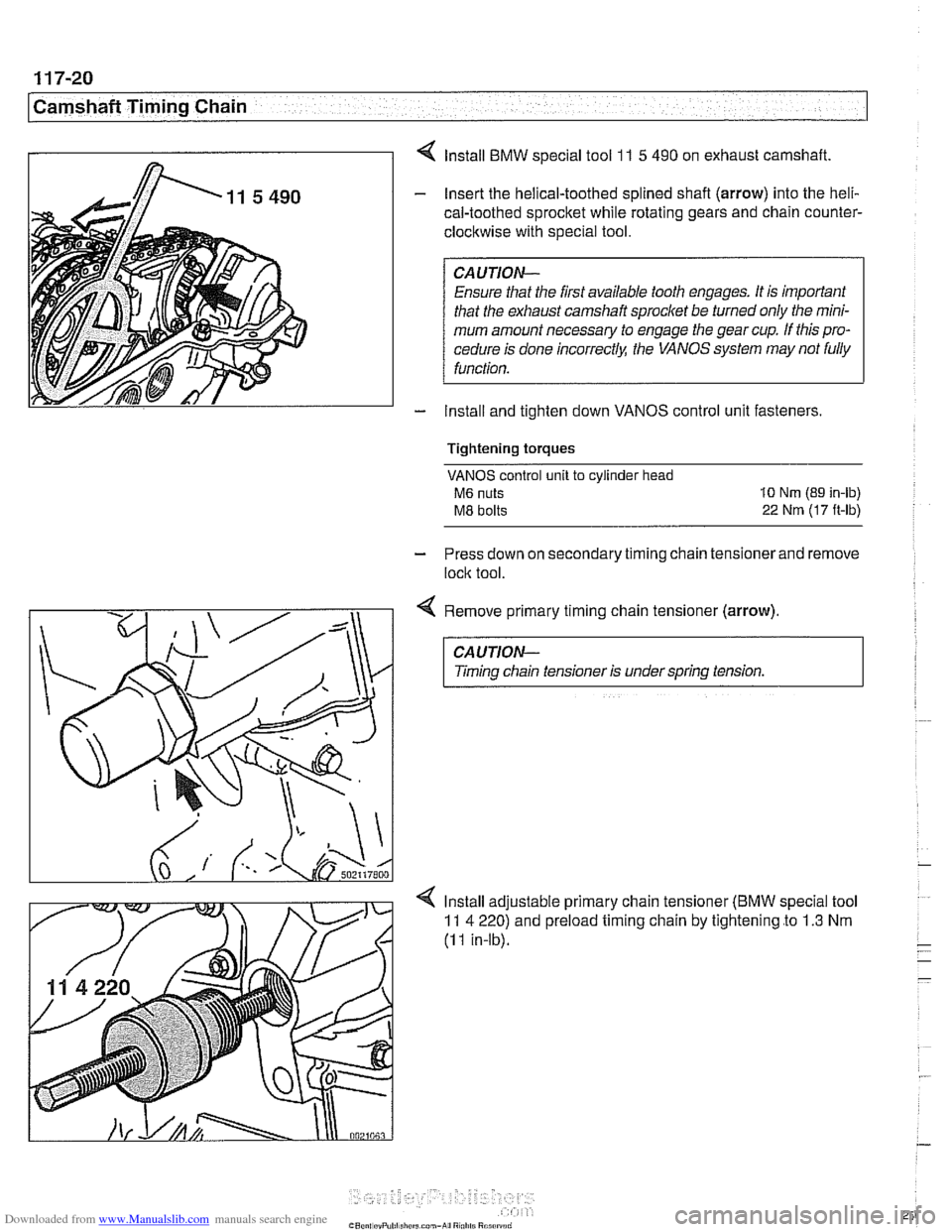

4 lnstall BMW special tool 1 I 5 490 on exhaust camshaft.

- Insert the helical-toothed splined shafl (arrow) into the heli-

cal-toothed sprocket while rotating gears and chain counter-

clockwise with special tool.

CAUTION- Ensure

that the first available tooth engages. It is important

that the exhaust camshaft sprocket be turned only the mini-

mum amount necessary to engage the gear cup. If this pro-

cedure is done

incorrectlq: the VANOS system may not fully

function.

- Install and tighten down VANOS control unit fasteners

Tightening torques

VANOS control unit to cylinder head

M6 nuts 10 Nm (89 in-lb)

M8 bolts 22 Nrn (17 ft-lbj

- Press down on secondary timing chain tensioner and remove

lock tool.

Remove primary timing chain tensioner

(arrow)

CAUTION-

Timing chain tensioner is under spring tension.

lnstall adjustable primary chain tensioner

(BMW special tool

11 4 220) and preload timing chain by tightening to 1.3 Nm

(I I in-lb).

Page 276 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .. ~-

Camshaft Timing Chain -

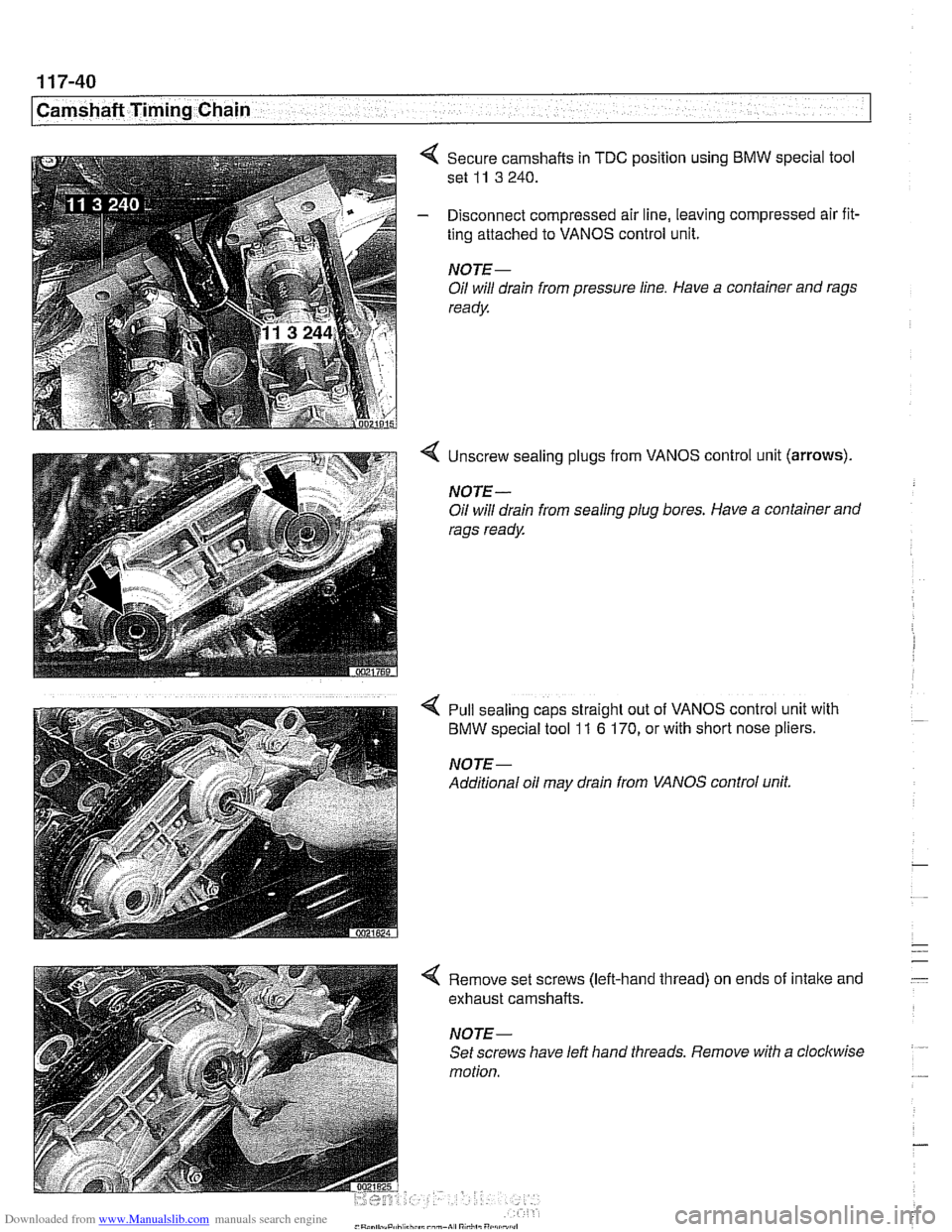

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

- Disconnect compressed air line, leaving compressed air fit-

ting attached to VANOS control unit.

NOTE -

Oil will drain from pressure line. Have a container and rags

ready

4 Unscrew sealing plugs from VANOS control unit (arrows).

NOTE-

Oil will drain from sealing plug bores. Have a container and

rags ready

4 Pull sealing caps straight out of VANOS control unit with

BMW special tool 11 6 170, or with short nose pliers.

NOTE-

Additional oil may drain from VANOS control unit.

4 Remove set screws (left-hand thread) on ends of intake and

exhaust camshafts.

NOTE-

Set screws have left hand threads. Remove with a clockwise

motion.

Page 281 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1

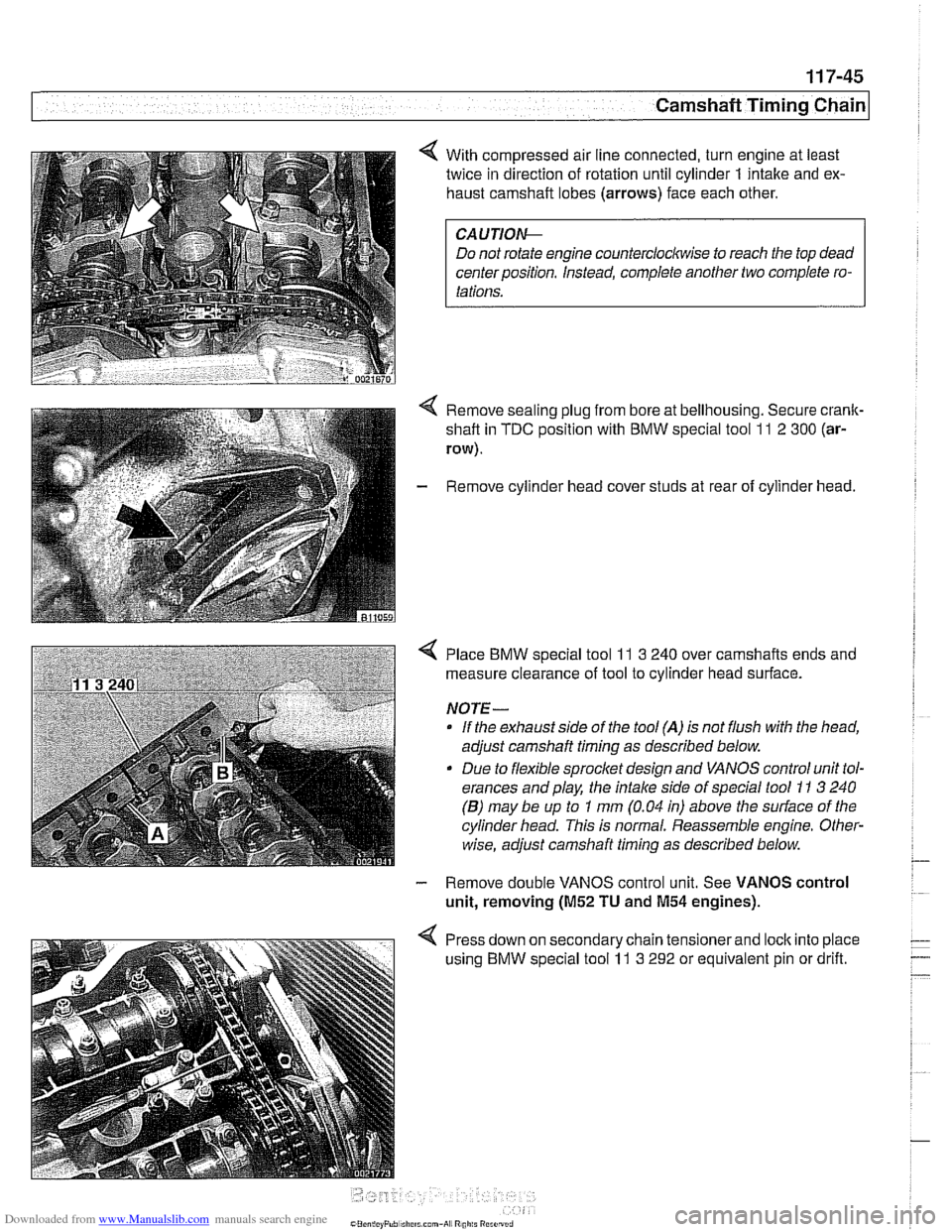

< With compressed air line connected, turn engine at least

twice in direction of rotation until cylinder

1 intake and ex-

haust camshaft lobes (arrows) face each other.

Do not rotate engine counterclockwise to reach the top dead

center position. Instead, complete another two complete ro-

Remove sealing plug from bore at bellhousing. Secure crank-

shaft in

TDC position with BMW special tool 11 2 300 (ar-

row).

- Remove cylinder head cover studs at rear of cylinder head.

< Place BMW special tool 11 3 240 over camshafts ends and

measure clearance of tool to cylinder head surface.

NOTE-

If the exhaust side of the tool (A) is not flush with the head,

adjust camshaft timing as described below.

Due to flexible sprocket design and VANOS control unit tol-

erances and play, the

intake side of special tool 11 3 240

(B) may be up to 1 mm (0.04 in) above the surface of the

cylinder head. This is normal. Reassemble engine. Other-

wise, adjust camshaft timing as described below.

- Remove double VANOS control unit. See VANOS control

unit, removing

(M52 TU and M54 engines).

< Press down on secondary chain tensionerand lock into place

using BMW special tool

11 3 292 or equivalent pin or drift.

Page 317 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain1 - -- -

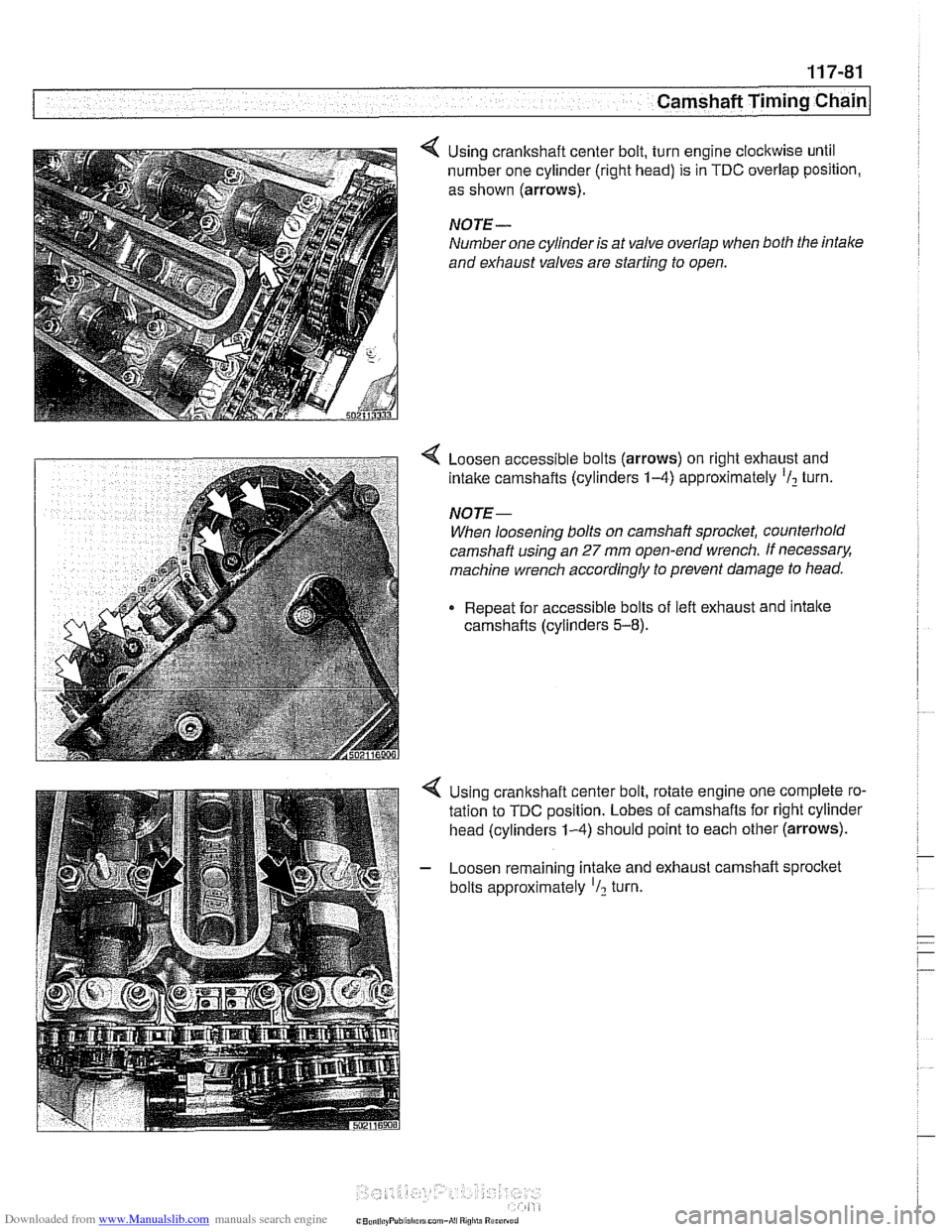

Using crankshaft center bolt, turn engine clockwise until

number one cylinder (right head) is in

TDC overlap position,

as shown

(arrows).

NOTE-

Number one cylinder is at valve overlap when both the intale

and exhaust valves are starting to open.

< Loosen accessible bolts (arrows) on right exhaust and

intake camshafts (cylinders

1-4) approximately 'I2 turn.

NOTE-

When loosening bolts on camshaft sprocket, counterhold

camshaft using an

27 mm open-end wrench. If necessary.

machine wrench accordingly to prevent damage

to head.

Repeat for accessible bolts of left exhaust and intake

camshafts (cylinders

5-8).

Using crankshaft center bolt, rotate engine one complete ro-

tation to

TDC position. Lobes of camshafts for right cylinder

head (cylinders

1-4) should point to each other (arrows).

- Loosen remaining intake and exhaust camshaft sprocltet

bolts approximately

'I2 turn.

Page 319 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing chain/

- Tighten accessible sprocket retaining bolts in the following

order:

Leit exhaust camshaft

Right exhaust

camshait

Leit intake camshaft

Right

intalte camshait

Tightening torque

Sprocket bolts to camshaft flange

15 Nm (1 1 ft-lb)

- Remove BMW special tool 11 2 300 from tool bore at bell-

housing and remove

camshaft loclting tools from cylinder

heads.

Using crankshaft center bolt, turn engine over clockwise at

least one

comolete rotation so that remainino camshaft

sprocltet

retaking bolts are accessible. -

- Tighten remaining camshait sprocket retaining bolts

Tightening torque Sprocket bolts to camshaft

flange 15 Nm (I 1 It-lb)

- Remove BMW special tool 11 3 390 from primary timing

chain tensioner bore and reinstall primary chain tensioner

- Remainder of installation is reverse or removal, noting the fol-

lowing:

Remove gasket residue from cylinder head sealing sur-

face.

Apply a thin bead of Three Bond 1209

O sealing com-

pound to joints at cylinder head cover and timing case cov-

er and at half-moon sections at rear of cylinder heads.

Replace cylinder head cover

gaskets if necessary.

Page 342 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Lubrication System

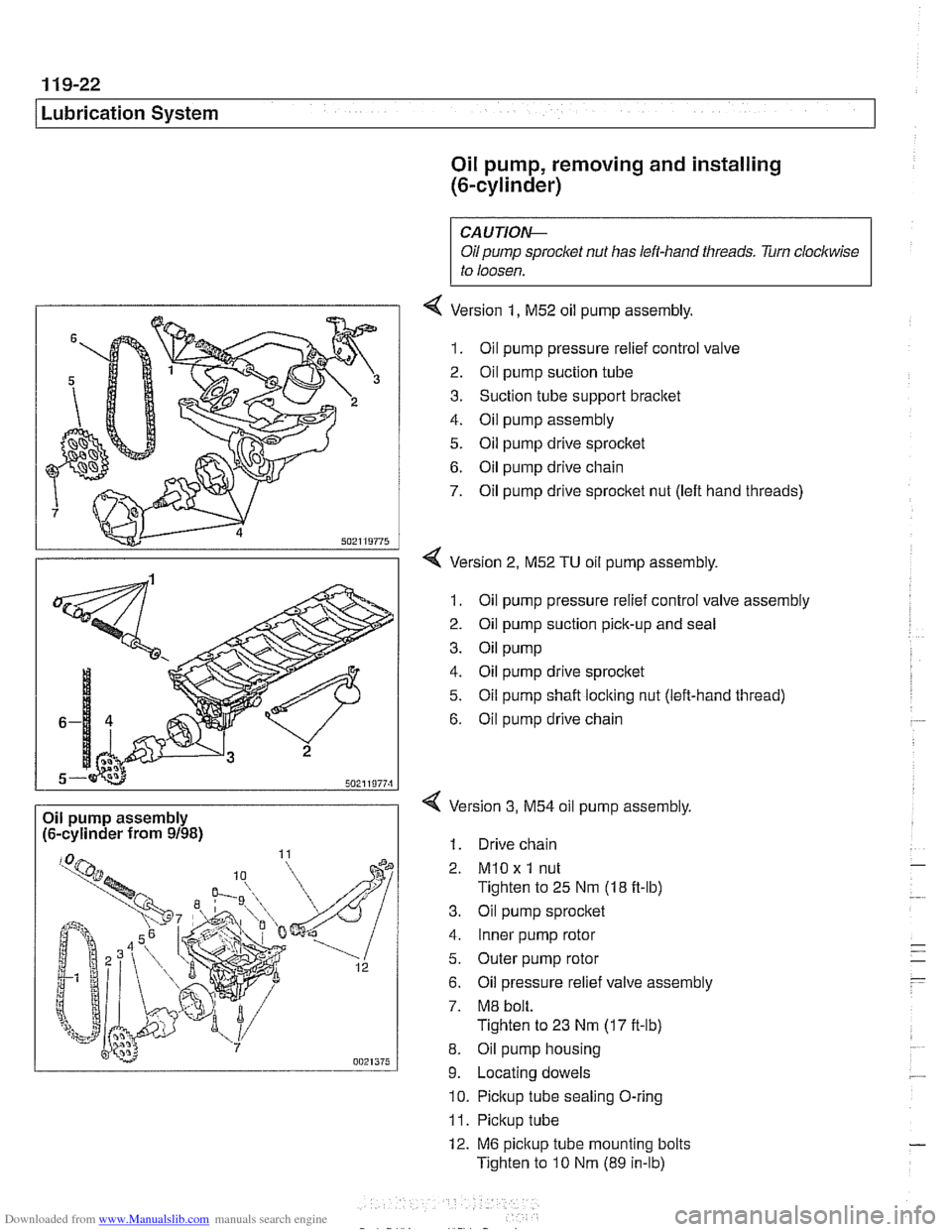

Oil pump, removing and installing

(&cylinder)

Oil pump assembly

(6-cylinder from 9/98)

CAUTIOI\C

Oil pump sproclcet nut has left-hand threads. Turn clockwise

to loosen.

4 Version 1, M52 oil pump assembly.

1. Oil pump pressure relief control valve

2. Oil pump suction tube

3. Suction tube support bracket

4. Oil pump assembly

5. Oil pump drive sprocltet

6. Oil pump drive chain

7. Oil pump drive sprocket nut (left hand threads)

4 Version 2, M52 TU oil pump assembly.

1. Oil pump pressure relief control valve assembly

2. Oil pump suction pick-up and seal

3. Oil pump

4. Oil pump drive sprocket

5. Oil pump shaft locking nut (left-hand thread)

6. Oil pump drive chain

Version

3, M54 oil pump assembly,

1. Drive chain

2.

MlO x 1 nut

Tighten to 25 Nm (18 ft-lb)

3. Oil pump sprocket

4. Inner pump rotor

5. Outer pump rotor

6. Oil pressure relief valve assembly

7. M8 bolt.

Tighten to 23 Nm

(17 it-lb)

8. Oil pump housing

9. Locating dowels

10. Pickup tube sealing O-ring

11. Pickup tube

12. M6 pickup tube mounting bolts

Tighten to

10 Nm (89 in-lb)