brake sensor BMW 525i 2000 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 525i, Model: BMW 525i 2000 E39Pages: 1002

Page 790 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-28

Brakes

- Remove sensor mounting screws. Lift sensor away from

bracket.

- Installation is reverse of removal.

CAUTION-

Be sure to tighten the DSC acceleration sensor(s) and

mounting bracket, if applicable, to specified torques. The

sensor

is vibration sensitive and subject to cause DSC

malfunctions if installed improperly.

a After replacing the sensor, perform sensor adjustment

using either DIS or

MoDiC under Service Functions

menu.

Tightening

torques

Lateral acceleration I rotational rate sensor 8 Nm (6 R-ib)

to bracket

Sensor bracket to body

8 Nm (6 ft-lb)

DSC steering angle sensor, removing and

installing

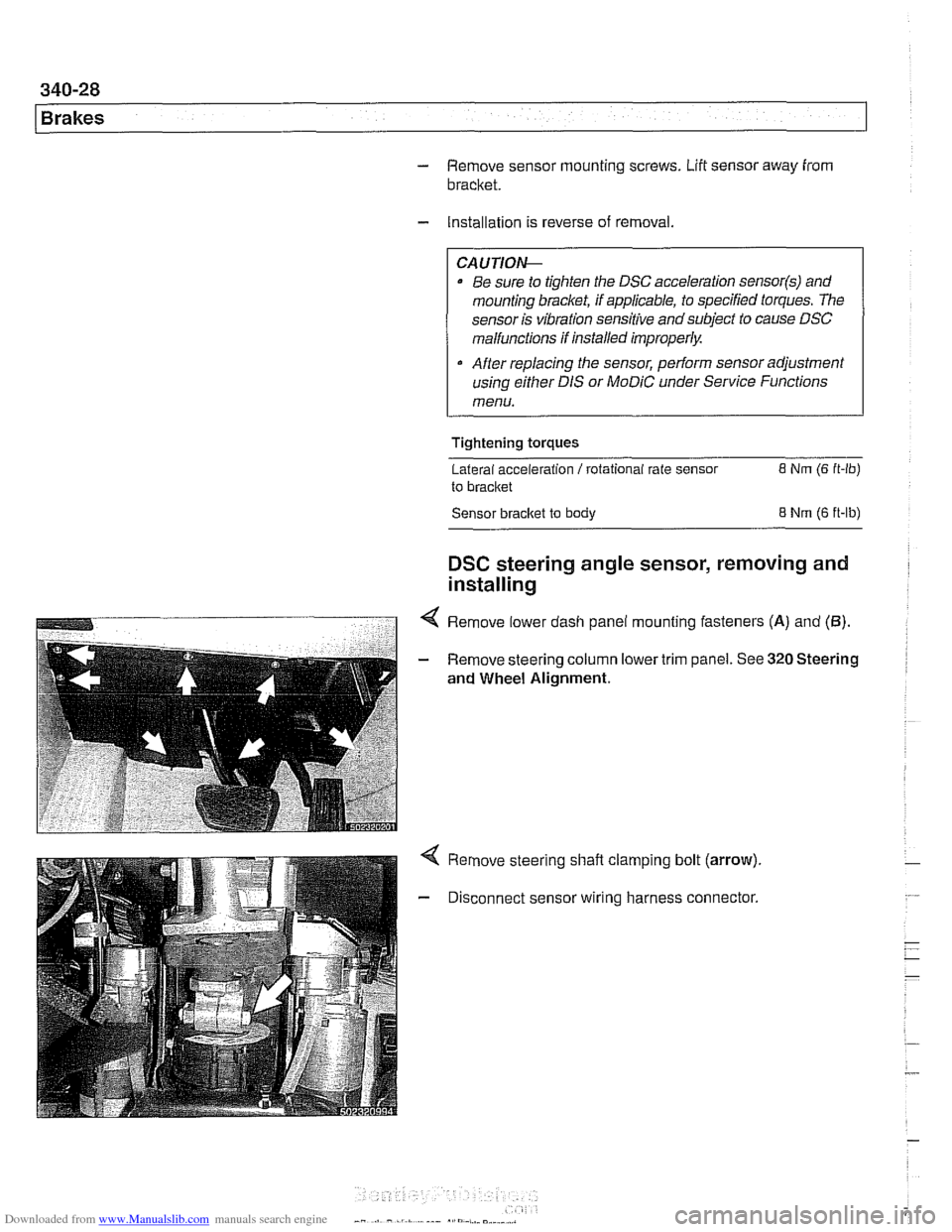

4 Remove lower dash panel mounting fasteners (A) and (5).

- Remove steering column lower trim panel. See 320 Steering

and Wheel Alignment.

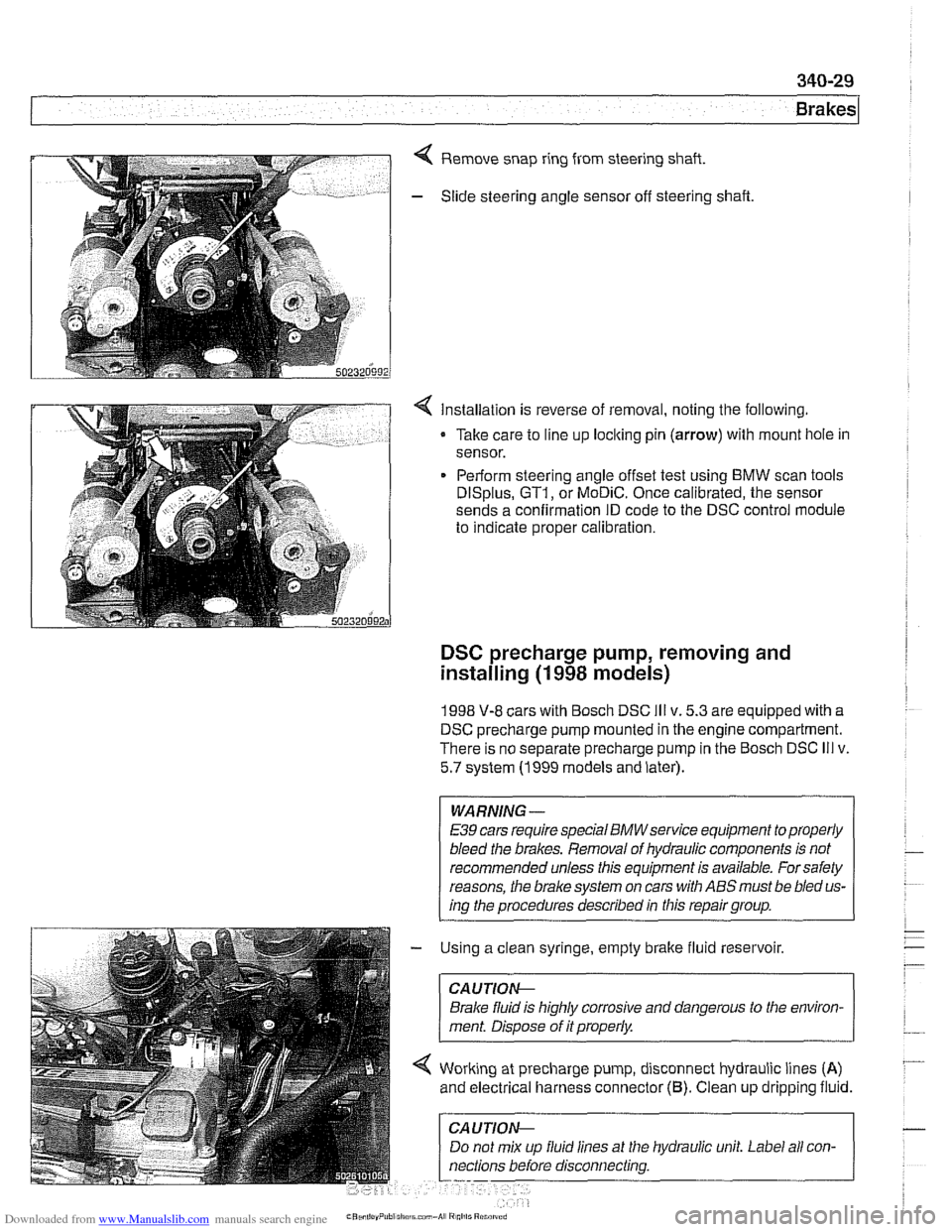

Remove steering shaft clamping bolt (arrow).

Disconnect sensor wiring harness connector.

Page 791 of 1002

Downloaded from www.Manualslib.com manuals search engine

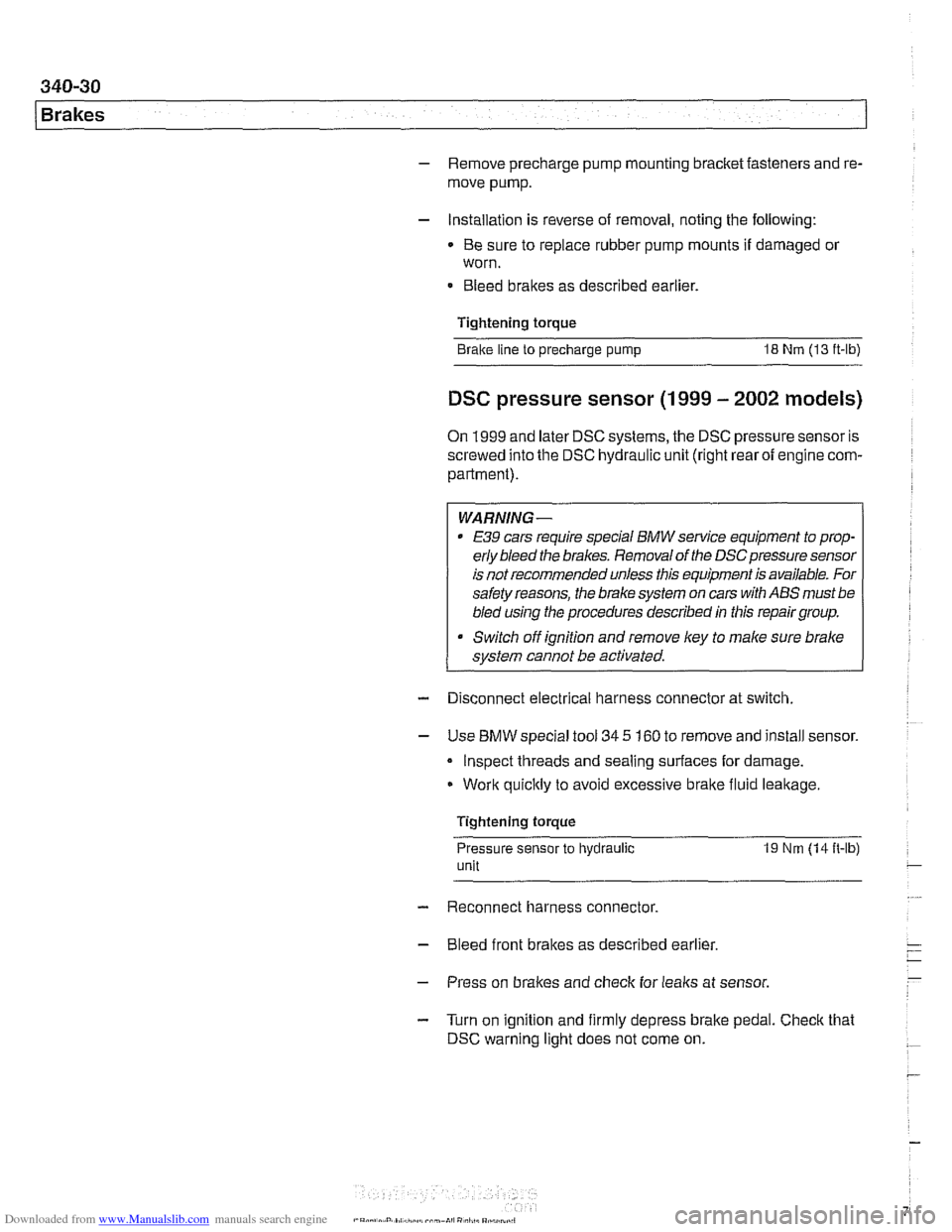

Remove snap ring from steering shaft.

- Slide steering angle sensor off steering shaft

< Installation is reverse of removal, noting the following.

Take care to line up loclting pin

(arrow) with mount hole in

sensor.

Perform steering angle offset test using BMW scan tools

DISplus, GT1, or MoDiC. Once calibrated, the sensor

sends a confirmation ID code to the DSC control module

to indicate proper calibration.

DSC precharge pump, removing and

installing

(1 998 models)

1998 V-8 cars with Bosch DSC Ill v. 5.3 are equipped with a

DSC precharge pump mounted in the engine compartment.

There is no separate precharge pump in the Bosch DSC

Ill v.

5.7 system (1999 models and later).

WARNING-

E39 cars require special BMWservice equipment to properly

bleed the brakes. Removal of hydraulic components is not

recommended unless this equipment is available. For safety

reasons, the

brake system on cars with ABS must be bled us-

ing the procedures described in this repair group.

- Using a clean syringe, empty brake fluid reservoir.

CAUTIOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Disoose of it

orooerlv.

Working at precharge pump, disconnect hydraulic lines (A)

and electrical harness connector (6). Clean up dripping fluid.

hydraulic unit. Label all

con-

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 793 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-31

Brakes

ABS 1 traction electronic control module

(1 997 -1 998 models)

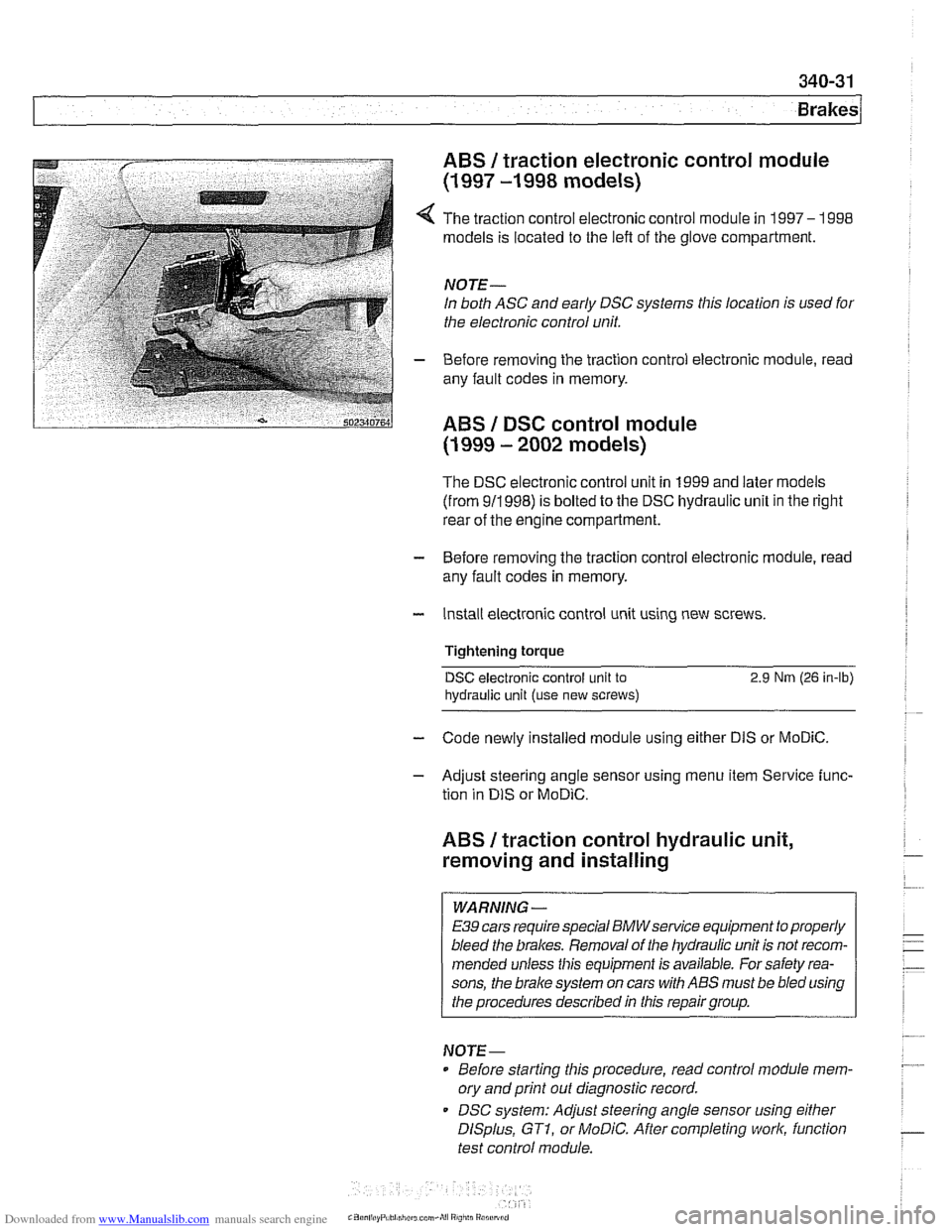

4 The traction control electronic control module in 1997- 1998

models is located to the left of the glove compartment.

NOTE-

In both ASC and early DSC systems this location is used for

the electronic control unit.

- Before removing the traction control electronic module, read

any fault codes in memory.

ABS I DSC control module

(1 999 - 2002 models)

The DSC electronic control unit in 1999 and later models

(from 911998) is bolted to the DSC hydraulic unit in the right

rear of the engine compartment.

- Before removing the traction control electronic module, read

any fault codes in memory.

- Install electronic control unit using new screws.

Tightening torque

DSC electronic control unit to 2.9 Nrn (26 in-lb)

hydraulic

unit (use new screws)

- Code newly installed module using either DIS or MoDiC.

- Adjust steering angle sensor using menu item Service func-

tion in

DIS or MoDiC.

ABS I traction control hydraulic unit,

removing and installing

WARNING -

E39 cars require special BMWsewice equipment to properly

bleed the brakes. Removal of the hydraulic unit is not recom-

mended unless this equipment is available. For safety rea-

sons, the

brake system on cars with ABS must be bled using

the procedures described in this repair group.

NOTE-

Before starting this procedure, read control module mem-

ory and print

out diagnostic record.

DSC system: Adjust steering angle sensor using

either

DISplus, GTI, or MoDiC. After completing work, function

test control module.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

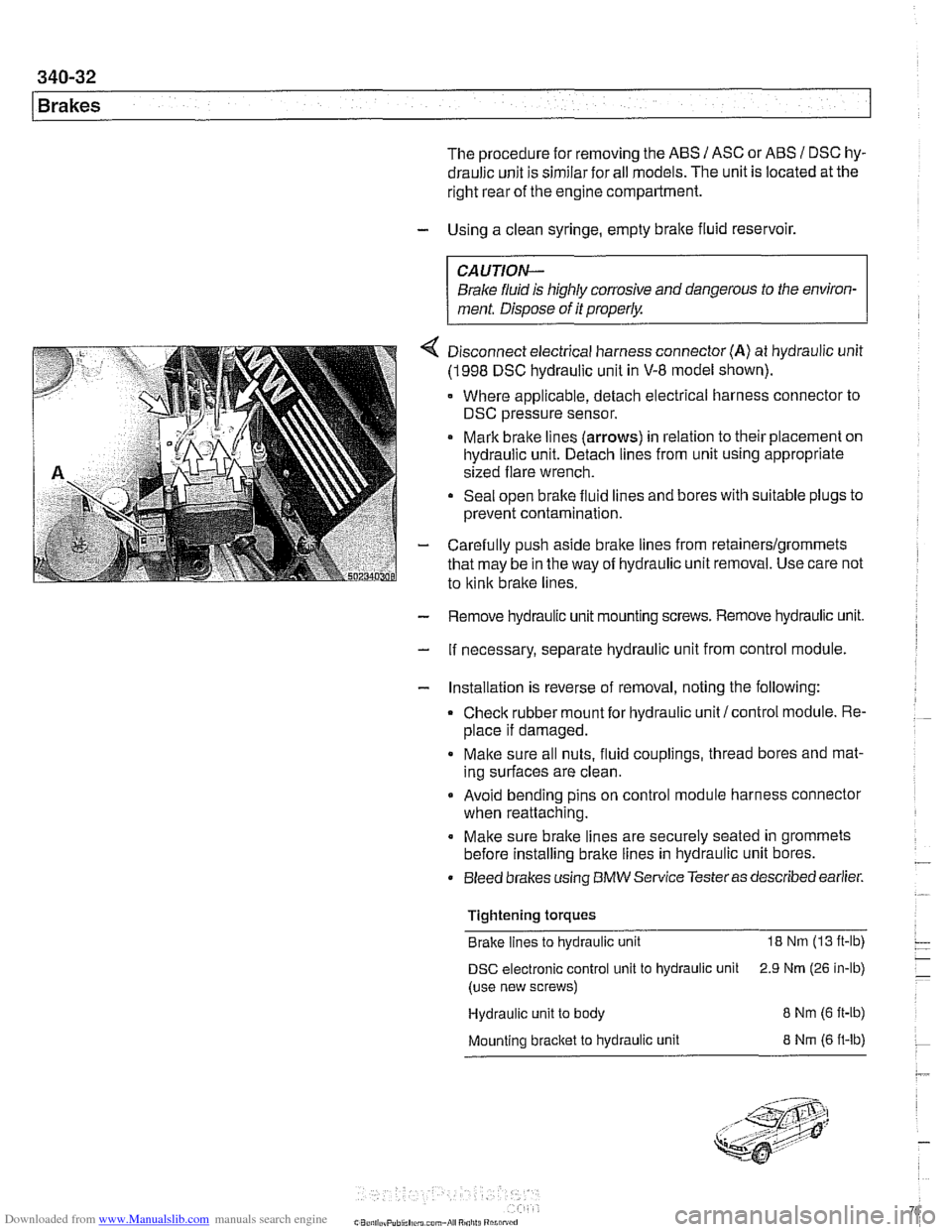

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)

Page 991 of 1002

Downloaded from www.Manualslib.com manuals search engine

INDEX 'tl

WARNING

Your common sense, good

judgemenl, and general alertness are

crucial to sale and successiul service

worlr. Belore attempting any work on

your

BMM be sure lo read 001

General Warnings and Cautions

and the

copyriglll page at the front 01

the manual. Review these warnings

and

caulions each lime you prepare

lo work on your BMW. Please also

read any warnings and cautions that

accompany

tile procedures in the

manual.

312-way valve (running losses)

see Fuel tank

Abbreviations, commonly used 600-14

ABS (antilock brake system)

see

Bral(es

A/C air distribution motors

see stepper motors (below)

blower final stage (resistor pack),

replacing

640-16

blower, removinglinslalling

640-1 5

compressor, replacing

640-24 condenser, replacing 64045

control panellmodule, removing1

installing

640-1 1

evaporakr, removinglinstalling 640-29

evaporator temperature sensor

640-12 expansion valve, removinglinstailing

640-27

IHKA/ IHKR system description 640-5

receiveridrier, replacing 640-26

stepper motors 640-1 3 ventilation microiilter, replacing

020-22. 640-17

see also Heating

Accelerator

iinlcage

see Maintenance

Activated carbon canister

see Fuel tank

ADS (auxiliary throttle valve)

130-57

Air compressor

330-44

Air conditioning

see

AIC

Air distribution (flap) motors

seeNC, stepper motors

Air filter see Maintenance

Air spring

300-6, 330-12

Airbag system (SRS)

2-stage

airbag 721-4

control module, replacing 721-7 driver airbag, removinglinstalling

721-8

iiead protection airbag 721-12 components 721-1 1

indicator

lighl721-4

passenger airbag, removinglinstalling

721-9 side-impact airbags crash sensor,

replacing

721-7

Airflow sensor see 130 under appropriate

fuel

injection system

Air pump

see 130 under appropriate fuel

injection system, secondary air

injection system

Air suspension

see Electronic height control

(EHC)

Alarm

see Anti-theft alarm

Alignment see

Wheei alignment

Aluminum suspension components

300-2

Antenna 650-6

Alternator see Battery, starter, alte rnator

Amplifier

650-4

Anti-theft alarm (DWA)

515-24 emergency disarming 515-31

Antifreeze (engine coolant)

see Maintenance

see also Cooling system

Antilock brake system (ABS) see Brakes

ASC see Brakes

ATF (automatic transmission fluid)

see Automatic transmission

see also Cooling systern

Automatic headlight adjustmenl

(LWR) see Lights

Automatic seat belt tensioner

720-4

Automatic shiftloclc

see

Gearshift

Automatic transmission

applications

200-3, 240-4

ATF 020-10, 200-4

capacity 240-8 checking 240-6

drainingifilling 240-7

heat exchanger 170-5

fluid pan and strainer 240-9 gearshift

see Gearshift

ID tag

200-3 range switch 610-6

removaliinstallation 240-10

steptronic see Gearshift

Auxiliary cooling fan

see

Coollng system, electric Ian

Auxiliary throttle valve (ADS)

130-57

Axle joint

see Drive axle

Back-up light switch

automatic transmission see Automatic transmission. range switch

- .~.~~~

manual transmission 230-8 -

- I

Page 992 of 1002

Downloaded from www.Manualslib.com manuals search engine

2 INDEX

Battery, starter, alternator

alternator (generator)

121-10

6-cylinder engine, removingi

installing 121-15

M62 engine 121-16

M62 TU engine (water cooled)

121-18

battery

121-5 charging 121-9

safety terminal 121-3

testing 121-5 charging system, troubleshooting

121-12

starter

121-1 9

6-cylinder engine, removingi instaliinq 121-20 . V-8 engine, rernovinglinsialiing

121-21

solenoid, removinglinstalling

121-23 troubleshooting 121-19

see also Maintenance

Bearing, wheel

see Front suspension

see also Rear suspension

Belts see Maintenance, drive belts

Blade, wiper

see Wipers and Washers

Blower motor see

A/C

BMW emblem

see Exterior trim

BMW special tools 010-18 see also special tools section at

beginning

of each repair group

Body dimensions 400-2

interior features

400-9 salety and security 400-7

Body side molding

see Exterior trim

Bonnet see Engine hood

Boot see Trunk

Brake fluid

020-24, 340-8

Brake fluid pressure sensor

340-30

Brakes

ABS, ASC or DSC system

300-12

component replacement 340-26

ASCIDSC switch

see Switches

bleeding

bralces 340-8

brake booster 340-1 9 bralce Dads. caiioers and rotors ,., 340-1 1

descriotion 300-10

e~ectrdnic brake & stability 300-11

light switch

see Switches

master cylinder

340-16 pariking brake 340-22

troubleshooting 340-5

Bulbs see Lights

Bumper

lront 510-6 height, adjusting 510-12

rear 510-9

Bus system

600-4

Camber

320-33

Camshaft

removingiinslaiiing

M52 engine 116-12

M52 TU

/ M54 engine 116-1 9 M62 engine 11 6-39

wear

116-6

Camshaft position sensors

see ignition system

Camshaft timing chain

adjusting M52 engine

117-22

M52 TU I M54 engine 117-43

M62 engine 117-79 removinglinstalling

M52 engine 117-26

M52TU 1 M54 engine 113-46.116-

28

M62 engine 117-66

Capacities, fluid

020.10

Car rnemorvlicev memorv . . 600-10

see also Centrai

lociking

Carbon canister, activated

see Fuel

tank

Caster

320-33

Catalytic converter and oxygen sensor 020-19

see also Exhaust system: exhaust

manilolds

Cautions

001-3

CD changer

650-4

Center bearing, driveshaft

see Driveshait

Center brake light

sedan

630-13

Center console

513-3

Centrai body electronics (ZKE 111)

600-6

Central locking

car memoryiey memory 515.12 general module iunctions 515-2

remote entry (FZV) 515-8

remote lkey initialization 515-10 single lociddouble ioclk 515-6

switch 515-4

Chain

see Camshaft liming chain

Characteristic map (electrically heated) thermostat

see Electrically heated thermostat

Charging system

see Battery, starter, alternator

Cluster see instruments

Clutch fluid see Maintenance

hydraulics

210-4

mechanical 210-9

switch

see Switches, pedal ciuster

variations

210.10

Codes, fault OED-1

Coil

see Ignition system

Coil spring

see Front suspension

see also Rear

suspe nsion

Page 994 of 1002

Downloaded from www.Manualslib.com manuals search engine

4 INDEX

Door window anti-trap

512-4 convenience openinglclosing 512.4

regulator and motor 512-1 1

service

512-5 switches 512-3

see also Switches

Double

VANOS see VANOS

Drive

axle

CV joint 331-15 CV joint boot 331-15

rernovinglinstalling 331-14

Drive belt

see Maintenance

Driveabiiity troubleshooting

100-4

Driveaway protection

see EWS (eiectronic immobilization)

Driveshaft aligning

260-7

center bearing, replacing 260-12 CV joint, replacing 260-14

itex-disc, replacing 260-1 1

iront centering guide, replacing 260-13

rernovinglinstailing 260-6

lroubleshooting 260-3

U-joint 260-3

DSC

see Braires

DTC (diagnostic trouble code)

OBD-8

DWA

see Anti-theft alarm

ECM (engine control module)

see 130 under appropriate

iuei

injection system

ECT (engine coolant temperature)

sensor see 130 under appropriate

iuei

injection system

EDK adaptation

130-69

MS 43.0 130-35

EHC see Electronic iieigiit control (EHC)

Electric cooling fan

see Cooling system, cooling

fan

see also Cooiing system, eiectric fan

Electrical switches

see Switches

Electrical system abbreviations

600-14 bus System 600-4

component location table 610-3

components

photos

610-36

Sport Wagon 610-81 engine 121-2

troubleshooting 600-15

voltage and polarily 600-5 wire color codes 600-12

wiring diagrams 600-12

Electrical wiring diagrams

ELE-1

Eiectricaliy heated thermostat

(characteristic map)

170-4

Eiectronic height control (EHC)

300-8, 330-44

Eiectronic immobilization

see EWS (electronic immobilization)

Eiectronics box

(E-box)

610-37

Emergencies

010-18

Emergency brake see

BraBes, parking brake Engine

see also Cylinder head and valvetrain

applications

100-2

compression, testing 113-5

cooling see Cooiing system

crankshaft front oil seai

see Crankshaft oil seals

cyiinder leak-down test 113-8

diagnostic testing 113-1

drive belts

see Maintenance

driveability troubleshooting

100-4

engine management systems 100-2

see also Ignition

see also Fuel injection

fuel supply

130-6

ground connections 100-5

see also 61 0 identilying ieatures 100-3

lubrication svstem

see

~ubricetion system

mount

on-board diagnostics

OBD-I

oxygensensor

see Fuel injection

see also Exhaust system

Dreventive maintenance

see Maintenance

removal/installation

Engine control module (ECM)

see 130 under appropriate iuel

injection system

Engine cooiant temperature (ECT)

sensor see 130 under appropriate iuel

injection

system

Engine cooling fan

see Cooiing system, electric fan

Engine hood

41

0-6 raising to service position 410-6

Engine troubleshooting

see Engine, driveability troubleshooting

EVa~oratiVe control svstem

160-3 see also 130 under aDDroDriate iuel

injection system

Evaporator see

NC

Evaporator temperature sensor see

NC

Page 996 of 1002

Downloaded from www.Manualslib.com manuals search engine

Gaskets and seals 01

0-9

Gearshift automatic transmission

adjusting

250-7

shift interiock. checkino function " 250-9

shiftloclc. checicino function 250-8 - manual transmission

gearshift lever, removingiinstalling

250-5

steptronic 250-7

General module (GM Ill)

600-8

see also Central locking

Generator see Battery, starter, alternator

Glass see Door window

Glove compartment

513-16

see also

Global positioning system

(GPS)

620-9

Grill

see Exterior trim

Grounds

100-5

Guide link

see Rear suspension, suspension

arms

Halogen headlight

630-5

Hand brake

see Brakes, pariring brake

Handle, door

see Door

locks

Hatch seeTailgate

Hazard warning switch

see Switches Headlight

housing trim

see Exterior trim

washer611-17 see also Lights

Headlight spray

nozzle

611-17

Headlight switch

see Switches

Heater core

see Heating

Heater valve

see Heating

Heating lieater core, replacing

640-18

lheater core temperature sensor,

removingiinstalling

640-12 heater valve, replacing 640-17

IHKA housing, removinglinstallin~

640-21

see also NC

Hood

410-6

Hood latch and release

410-10

Hydraulic valve lifters

see Cylinder head and valvetrain

IAT

(lntalce air temperature) sensor

see 130

under appropriate fuel

injection system

idle speed control valve

see 130

under appropriate fuel injection system

Idle stabilizer

see 130

under appropriate fuel

injection system, idie speed controi

valve

idler arm

320-30

lgnition coll

see lgnition system

lgnition interlock

320-13

lgnition lock cylinder

removingiinstalling

320-1 1. 612-4

lgnition switch

seeSwifches

Ignition system

diagnosis checking for

spark 120-10

disabling ignition system 120-10 misfire detection 120-6

oscilioscope diagrams 120.6

troubleshooting 120-6

camshaft position sensors 120-14 coils 120.10

crankshaft speed sensor 120-12 firing order 120-9

knoclc sensors 120-16

IHKA

see NC

IHKR see NC

Injector

see 130 under appropriate

fuel

injection system, luel injector

Input shaft

oil seal

see Manual transmission, oil seals

Inspection

see Maintenance

Instruments GPS see Global positioning system

(GPSI layout 6202

removingiinstalling 620-8 self-testing 620-6

Intake air temperature sensor (IAT)

see 130 under appropriate fuel

injection system

Intake manifold

removingiinstalling

6-cvlinder enoine 110-10. 113-8. 113-22 -

V-8 engine (M62) 113-56

Integral link

see Rear suspension, suspension

arms

lnterior lights

see Lights

lnterior protection

(FISIUIS) 515-25

lnterior trim

513-13

lnterior ventilation microfilter see

NC, ventilation microfiller

Page 997 of 1002

Downloaded from www.Manualslib.com manuals search engine

INDEX 7

WARNING

Your common sense, good

judgement, and general alertness are

crucial to safe and successful service

work. Before

attempting any work on

your BMW, be sure to read 001

General Warnings and Cautions

and the copyright page at the front of

the manual. Review these warnings

and cautions each time you prepare

to

work on your BMW. Please also

read any warnings and

caulions that

accompany

/he procedures in the

manual.

Jack stands

010-16

Jump starting 010-19

Keys

515-1 1

Knock sensor

see Ignition system

Leak detection,

fuel tanlr

see Fuel tank, leak detection unit

Leather upholstery

see Maintenance, leather

upholstery and trim

LDP

(leak detection pump)

see Fuel

tanir, leal( detection unit

Level sender

see Fuel tank

see also Fuel pump

License

plate iight

630-1 1

Lifters see Cylinder head and vaivetrain

Lifting the car

010-5 Lights

bulb applications

630-2

control module (LCM) 630-3

foglights 630-8 headiighls 630-4

automatic headlight adjustment

(LWR)

630-7

vertical aim system 630-8 interior lights 630-12

bulb applications 630-13

side turn signal 630-9

taillight 630.10 trunk light bulb 630-14

turn signals, taillights 630-12

LOClCS see Central loci(ing

see also Door loclrs

Lubrication system

oil

level warning switch, replacing

119-20

oil pan, removinglinstalling

6-cylinder 119-10

V-E lower 119-13 V-8 upper 119-15

oil pressure

checiring 11

9-4

warning system, testing 119-5 warning switch, replacing 119-20

oil pressure

reliel valve

6-cylinder 119-26

V-8 11 9-27

oil pump, removinglinstalling

6-cylinder

119-22

V-8 1 19-4

troubieshooting 119-3

Luggage compartment

seeTrunk

MAF (mass air flow) sensor

see 130 under appropriate fuel

injection system Maintenance

accelerator linkage

020-14 air filter 020-14

automatic transmission 020-29

battery 020-22

body lubrication 020-31 body and interior 020-31

braire fluid 020-24

brake padlrotor wear 020-24

brake system 020-25 clutch fluid 020-26

cooling system 020-15

CV ioint boots 020-27

differential oil level 020-26

drive bells 020-16 engine comparlmenl 020-14

engine cooling system 020-16

engine oil 020-1 1 exhaust system 020-27

exterior washing 020-31

fluid and lubricant specifications 020-9

fuel lilter 020-27 fuel lanir and fuel lines 20-28

idle speed 020-19

inspection 020-5

interior care 020-31

lealher upholslery and trim 020-31

maintenance tables 020-6

manual transmission oil 020-30

microiilter 020-22 oxygen sensors 130-72, 180-8

parlcing brake 020-25

power steering fluid level 020-20

seat belts

020-32 service indicator 020-3

spark plugs 020-20

special cleaning 020-32 suspension, front 020-29

suspension, rear 020-29

tires 020-29

washing

020-32

waxing 020-32 windshield wiper blade 020-33

wheels, aligning 020-30

Malfunction indicator iight (MIL)

OED-2

Manifold, exhaust

see Exhaust system

Manifold,

intake

see Intake maniiold