brake sensor BMW 525i 2000 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 525i, Model: BMW 525i 2000 E39Pages: 1002

Page 738 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-42

/Rear Suspension

- Install ABS sensor and road wheel.

- Lower car to ground. With an assistant applying brakes, use

new axle collar nut to tighten to final torque. Stake nut.

- Remainder of installation is reverse of removal

Tightening torques ABS pulse sensor to wheel bearing carrier

8 Nm (6 ft-lb)

Brake disc to hub

16 Nm

Rear

brake pad carrier (caliper) to wheel

65 Nm (48 ft-lb)

bearing carrier

Rear axle shaft to hub

(M27) 300 Nrn (221 ft-lb)

Road wheel to hub 120F10 Nm

(89 ?7 ft-lb)

The rearstabilizer bar is mounted to the rear

subframe and at-

tached via stabilizer bar

linlts to the lower swing arms.

Stabilizer bar, removing and installing

- Raise rear end of car.

WARNING -

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points.

Do not place jack stands under

suspension parts.

- Paint mark stabilizer bar on left side for ease of assembly.

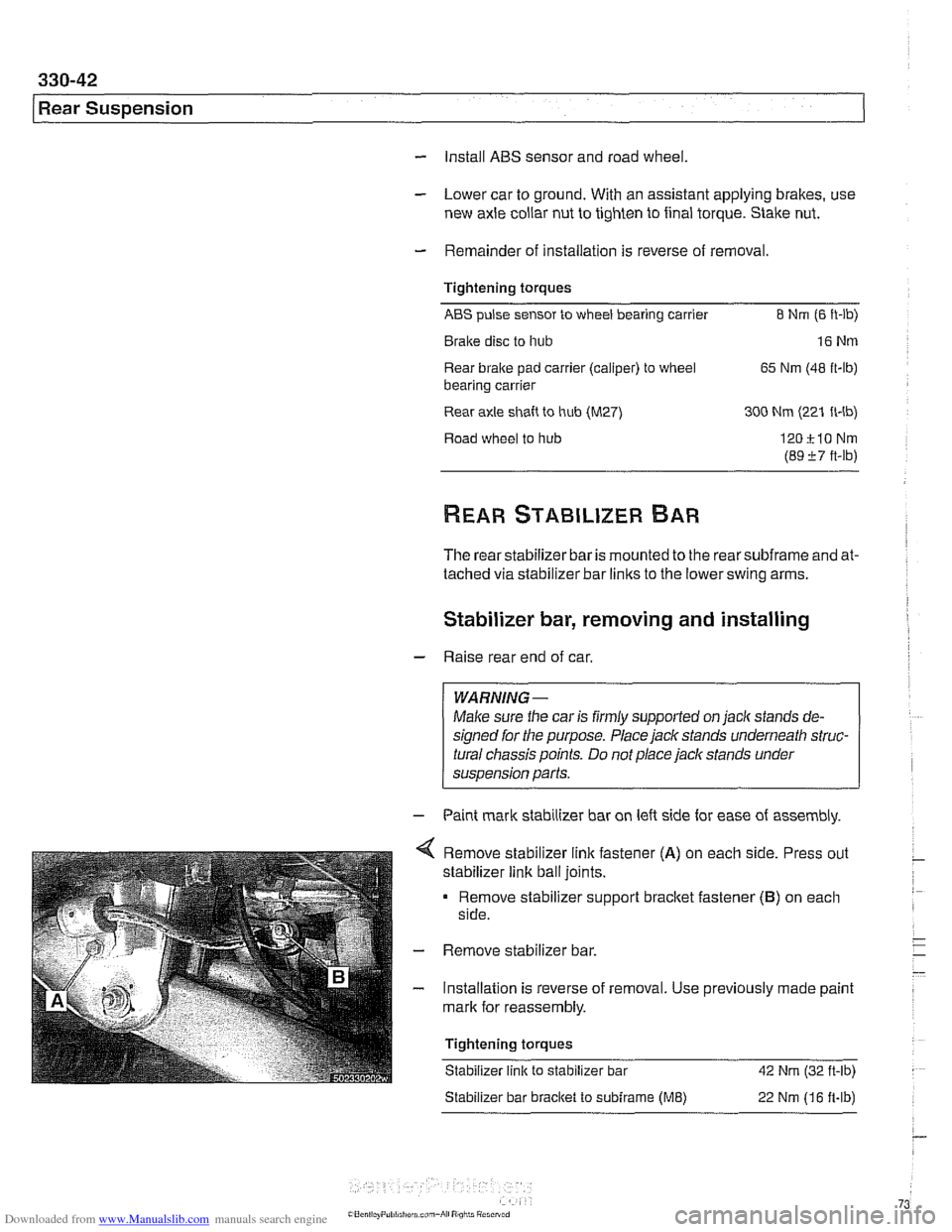

Remove stabilizer link fastener

(A) on each side. Press out

stabilizer link ball joints.

Remove stabilizer support bracket fastener

(B) on each

side.

Remove stabilizer bar.

Installation is reverse of removal. Use previously made paint

mark for reassembly.

Tightening torques Stabilizer link to stabilizer bar

42 Nm (32 ft-lb)

Stabilizer bar bracket to sublrame (ME) 22 Nm (1 6 fi-lb)

Page 740 of 1002

Downloaded from www.Manualslib.com manuals search engine

---

Rear Suspension

ELECTRONIC HEIGHT CONTROL

(EHC) COMPONENT REPLACEMENT

Sport Premium rear suspension is an option on Sport Wagon

models and standard on

1999 and later V-8 Sport Wagons.

This suspension incorporates electronic height control

(EHC)

using air springs.

With vehicle lifted off the ground,

if the rear air springs can be

compressed by hand, either the spring is defective or the sys-

tem is depressurized.

Locate

EHC faults using BMW scan tools DIS or MoDiC. EHC

description and some troubleshooting is covered in 300 Sus-

pension, Steering and Brakes-General.

Air spring replacement is covered earlier in this chapter. See

Air spring, removing and installing.

CAUTION-

Maintain high levels of cleanliness around air line connec-

tions when disassembling and assembling air suspension

components. Even

small dirt particles can cause leakage in

the pressurized system.

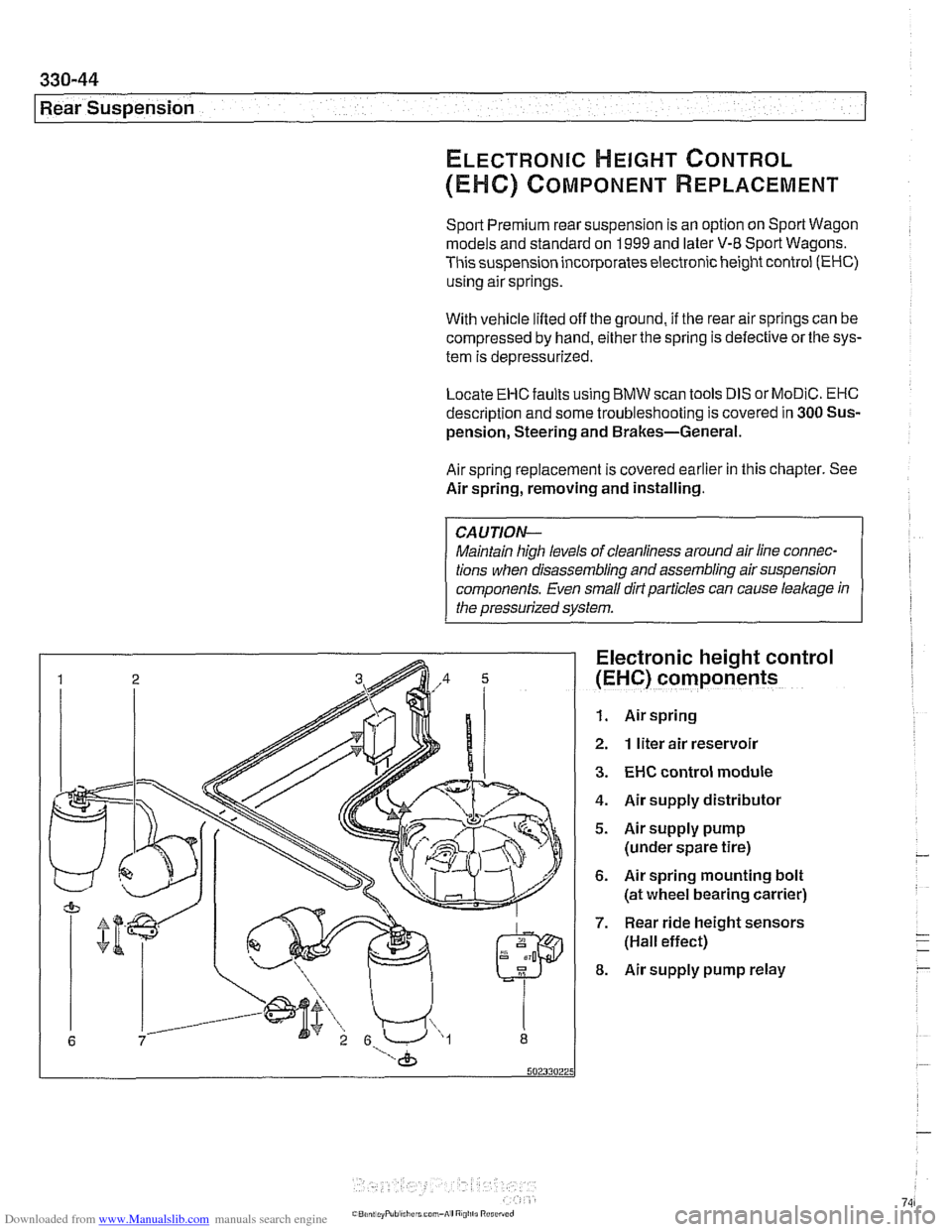

Electronic height control

(EHC) components

1. Air spring

2. 1 liter air reservoir

3. EHC control module

4. Air supply distributor

5. Airsupply pump

(under spare tire)

6. Air spring mounting bolt

(at wheel bearing carrier)

7. Rear ride height sensors

(Hall effect)

8. Air supply pump relay

Page 763 of 1002

Downloaded from www.Manualslib.com manuals search engine

General ........................... .34 0.2

Special Tools

....................... .34 0.2

E39 brake system

.................... .34 0.4

Electronic braking and stability control

.... .34 0.4

Troubleshooting

..................... .34 0.5

Warnings and cautions

................ .34 0.7

Bleeding Brakes ................... .34 0.8

Brakes, bleeding

..................... .34 0.9

Brake Pads, Calipers and Rotors ... .34 0.1 1

Braking system components .......... .34 0.11

Brake pads,

checking and replacing ..... .34 0.12

Brake rotors, removing and installing

.... .34 0.15

Master Cylinder .................. .34 0.16

Master cylinder, removing and installing

. .34 0.17

Brake Booster .................... .349 0.1

Brake booster check valve

............ .34 0.19

Brake booster, removing and installing

.. .34 0.20

Parking Brake .................... .34 0.22

Parking brake components

............ .34 0.22

Parking

brake, adjusting .............. .34 0.22

Parking bralte shoes, removing

and installing

....................... .34 0.23

Parking

brake cable, replacing ......... .34 0.24

ABS Component Replacement ..... 340-26

Wheel speed sensor. replacing

......... 340-26

ABS impulse wheel

.................. 340-27

DSC lateral acceleration or

rotational rate (yaw) sensor. replacing

... 340-27

DSC steering angle sensor.

removing and installing

............... 340-28

DSC precharge pump.

removing and installing (1998 models)

... 340-29

DSC pressure sensor

(1 999 - 2002 models) ................ 340-30

ABS /traction electronic control

module

(1 997 -1 998 models) .......... 340-31

ABS

/ DSC control module

(1 999

- 2002 models) ................ 340-31

ABS

/ traction control hydraulic unit.

removing and installing

............... 340-31

Page 765 of 1002

Downloaded from www.Manualslib.com manuals search engine

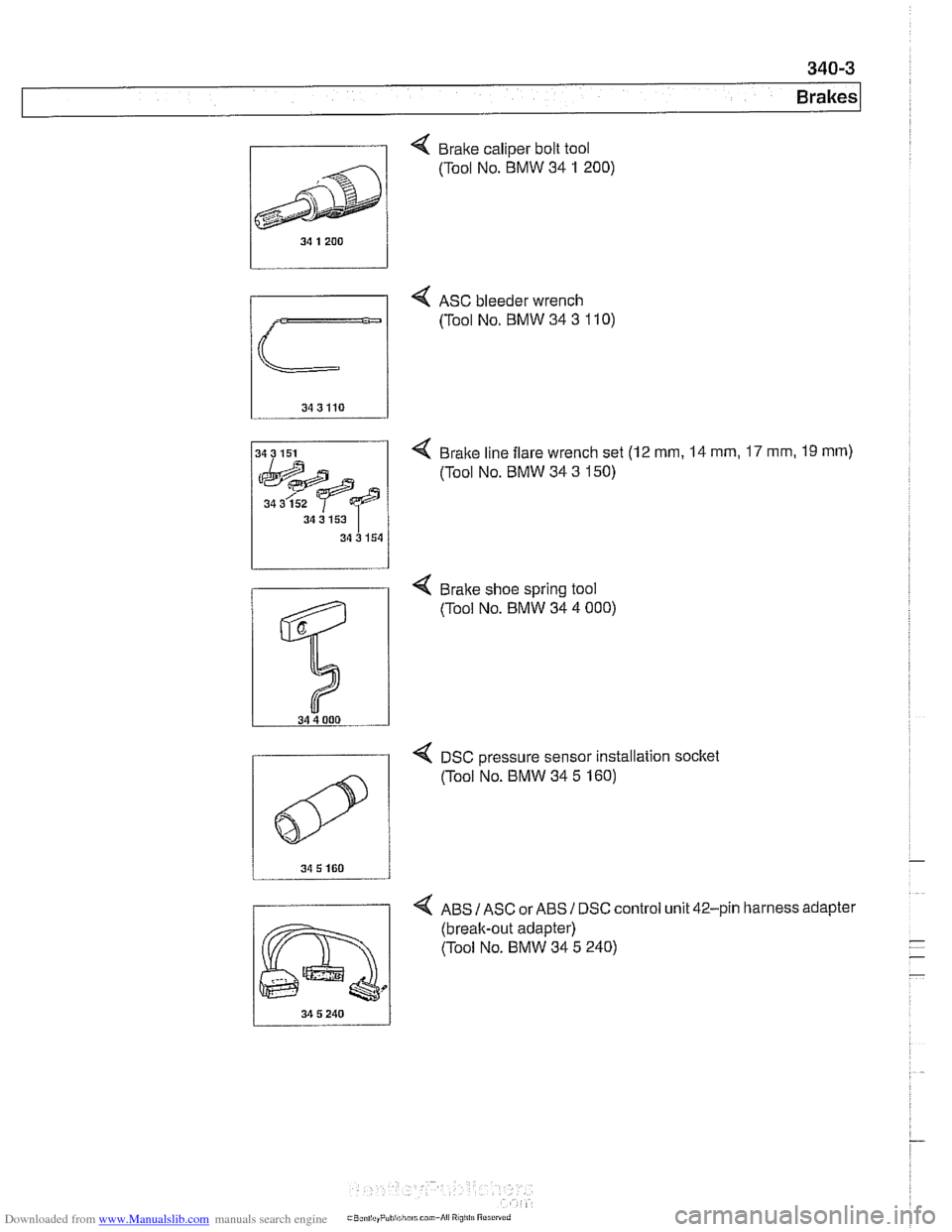

, Brake caliper bolt tool

4 ASC bleeder wrench

(Tool No. BMW 34

3 110)

4 Brake line flare wrench set (12 mm, 14 mm, 17 mm, 19 rnm)

(Tool No. BMW 34 3 150)

34 3 152

34 3 153

34 3 154

4 DSC Dressure sensor installation socltet

4 ABS IASC or ABSI DSC control unit 42-pin harness adapter

(break-out adapter)

(Tool No. BMW 34 5 240)

0

(Tool NO. BMW 34 5 160)

Page 766 of 1002

Downloaded from www.Manualslib.com manuals search engine

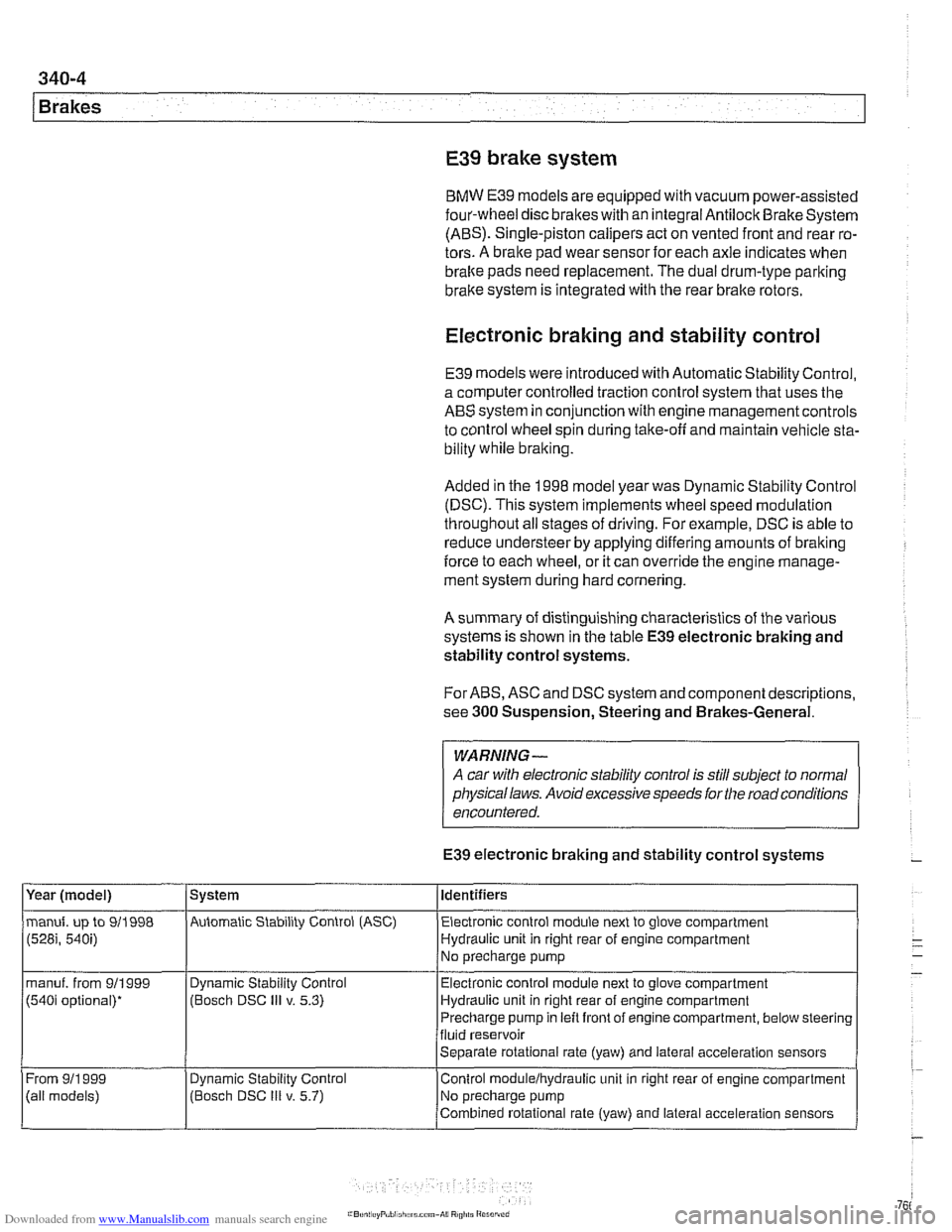

E39 brake system

BMW E39 models are equipped with vacuum power-assisted

four-wheel disc brakes with an integral

Antilock Brake System

(ABS). Single-piston calipers act on vented front and rear ro-

tors. A brake pad wear sensor for each axle indicates when

brake pads need replacement. The dual drum-type parking

brake system is integrated with the rear brake rotors.

Electronic braking and stability control

E39 models were introduced with Automatic Stability Control,

a computer controlled traction control system that uses the

AB5 system in conjunction with engine management controls

to control wheel spin during take-off and maintain vehicle sta-

bility while braking.

Added in the

1998 model year was Dynamic Stability Control

(DSC). This system implements wheel speed modulation

throughout all stages of driving. For example, DSC is able to

reduce understeer by applying differing amounts of braking

force to each wheel, or it can override the engine manage-

ment system during hard cornering.

A summary of distinguishing characteristics of the various

systems is shown in the table

E39 electronic braking and

stability control systems.

For ABS, ASC and DSC system and component descriptions,

see

300 Suspension, Steering and Brakes-General.

WARNING-

A car with electronic stability control is still subject to normal

physical laws. Avoid excessive speeds for the road conditions

encountered.

E39 electronic braking and stability control systems

Year (model)

manuf. up to 911998

(528i, 540i)

manuf. from 911999

(540i optional)*

From

911 999

(ail models) System

Automatic Stability Control (ASC) Identifiers

Electronic control module next to glove compartment

Hydraulic unit in right rear of engine compartment

No precharge pump

Dynamic Stability Control

(Bosch DSC

Ill v. 5.3)

Dynamic

Stabil~ty Control

(Bosch DSC

Ill v. 5.7) Electronic

control module next to glove compartment

Hydraulic unit in right rear of engine compartment

Precharge pump in left front of engine compartment, below steering

fluid reservoir

Separate rotational rate (yaw) and lateral acceleration sensors

Control

modulelhydraulic unit in right rear of engine compartment

No precharge pump

Combined rotational rate (yaw) and lateral acceleration sensors

Page 773 of 1002

Downloaded from www.Manualslib.com manuals search engine

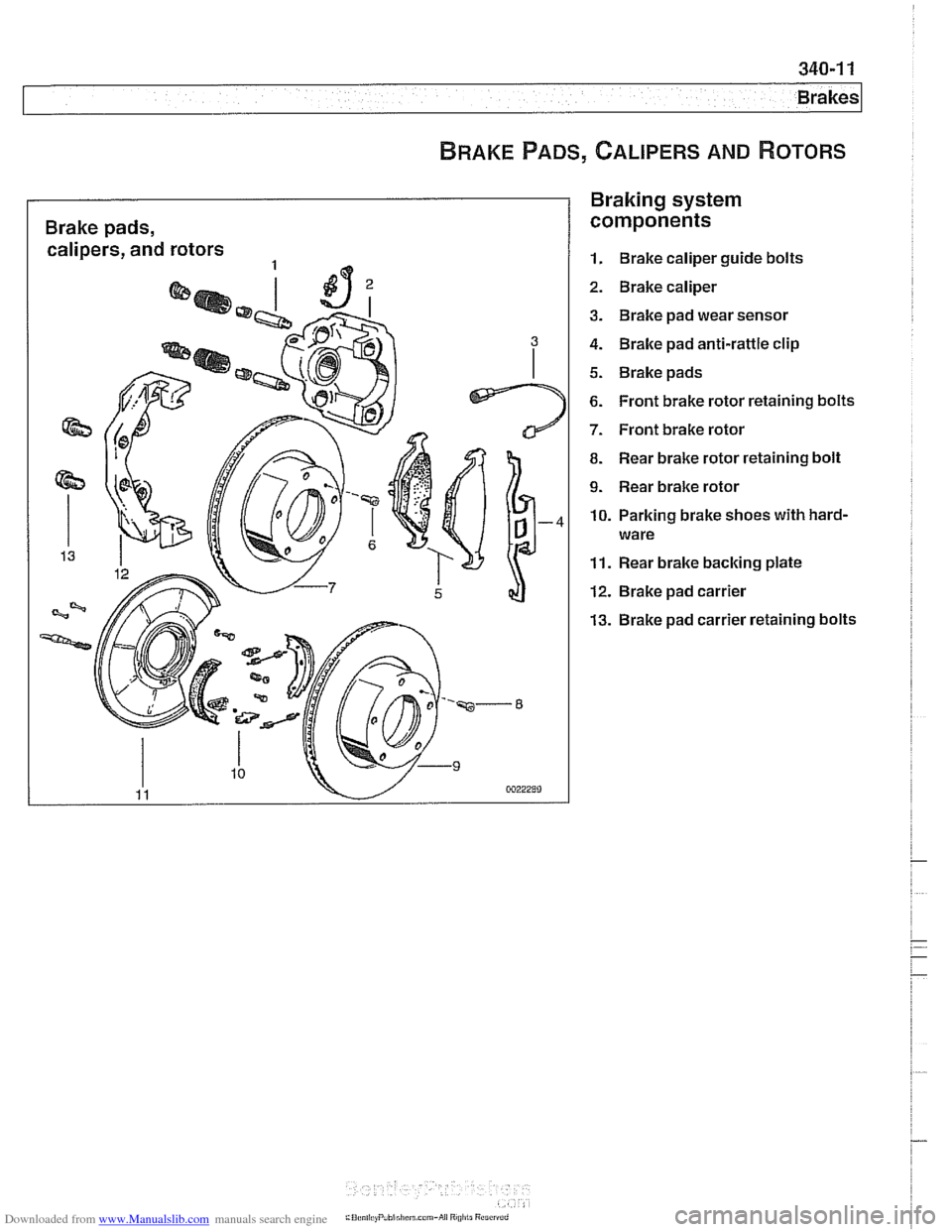

Brakes

BRAKE PADS, CALIPERS AND ROTORS

Brake pads,

calipers, and rotors

Braking system

components

1. Brake caliper guide bolts

2. Brake caliper

3. Brake pad wear sensor

4. Brake pad anti-rattle clip

5. Brake pads

6. Front brake rotor retaining bolts

7. Front brake rotor

8. Rear brake rotor retaining bolt

9. Rear brake rotor

10. Parking brake shoes with hard-

ware

11. Rear brake backing plate

12. Brake pad carrier

13. Brake pad carrier retaining bolts

Page 775 of 1002

Downloaded from www.Manualslib.com manuals search engine

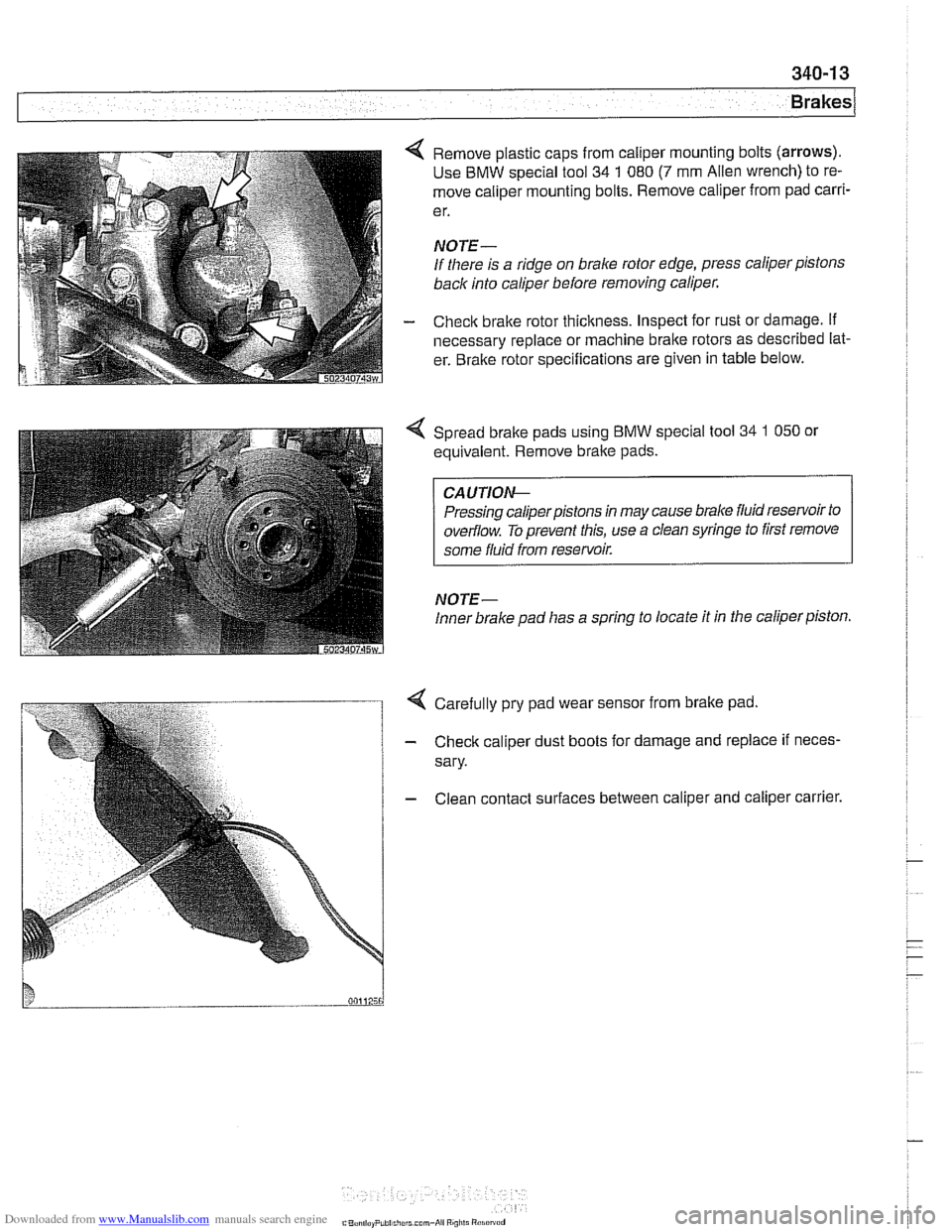

4 Remove plastic caps from caliper mounting bolts (arrows).

Use BMW special tool 34 1 080 (7 mm Alien wrench) to re-

move caliper mounting bolts. Remove caliper from pad

carri-

e r.

NOTE-

If there is a ridge on brake rotor edge, press caliper pistons

back into caliper before removing caliper.

- Check brake rotor thickness. Inspect for rust or damage. if

necessary replace or machine brake rotors as described lat-

er. Bralte rotor specifications are given in table below.

Spread bralte pads using BMW special tool

34 1 050 or

equivalent. Remove brake pads.

CA UTIOG

Pressing caliperpistons in may cause brake fluid reservoir to

overflow. To prevent this, use a clean syringe to first remove

some fluid from reservoir.

NOTE-

Inner brake pad lias a spring to locate it in the caliper piston.

4 Carefully pry pad wear sensor from brake pad

- Check caliper dust boots for damage and replace if neces-

sary.

- Clean contact surfaces between caliper and caliper carrier.

C"..., I,.. P,hi..,,,.r.. mm-*ii Ai"i,li "1.i"~"d

Page 776 of 1002

Downloaded from www.Manualslib.com manuals search engine

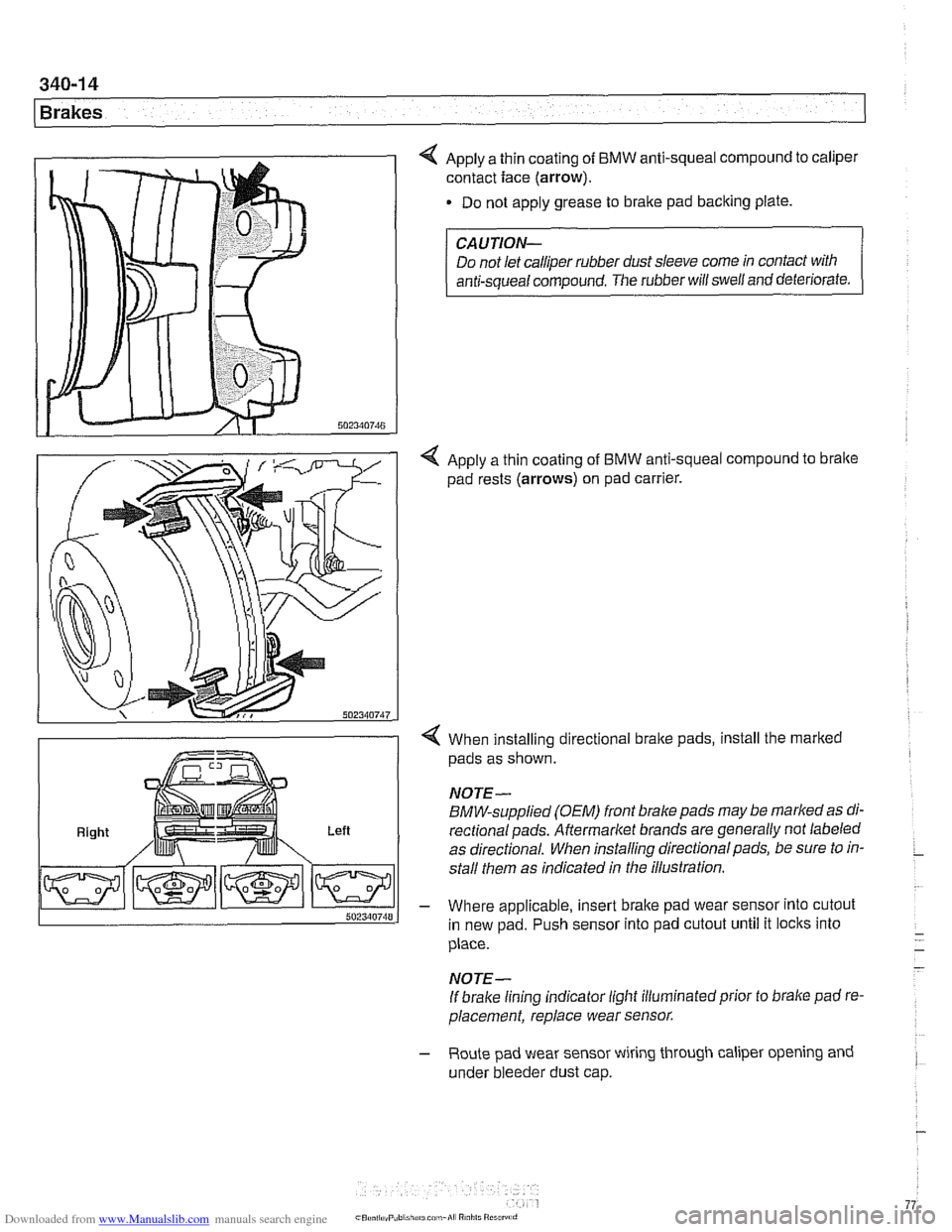

340-1 4

Brakes

4 Apply a thin coating of BMW anti-squeal compound to caliper

contact face

(arrow).

Do not apply grease to brake pad backing plate.

Right Left

CAUTION-

Do not let calliper rubber dust sleeve come in contact with

anti-squeal compound. The rubber will swell and deteriorate.

4 Apply a thin coating of BMW anti-squeal compound to bralte

pad rests (arrows) on pad carrier.

4 When installing directional brake pads, install the marked

pads as shown.

NOTE-

BMW-supplied (OEM) front brake pads may be marked as di-

rectionalpads. Aftermarket brands are generally not labeled

as directional. When installing directional pads, be sure to in-

stall them as indicated in the illustration.

- Where applicable, insert brake pad wear sensor into cutout

in new pad. Push sensor into pad cutout until it locks into

place.

- -

- NOTE-

If brake lining indicator light illuminatedprior to brake pad re-

placement, replace wear sensor.

- Route pad wear sensor wiring through caliper opening and

under bleeder dust cap.

Page 779 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

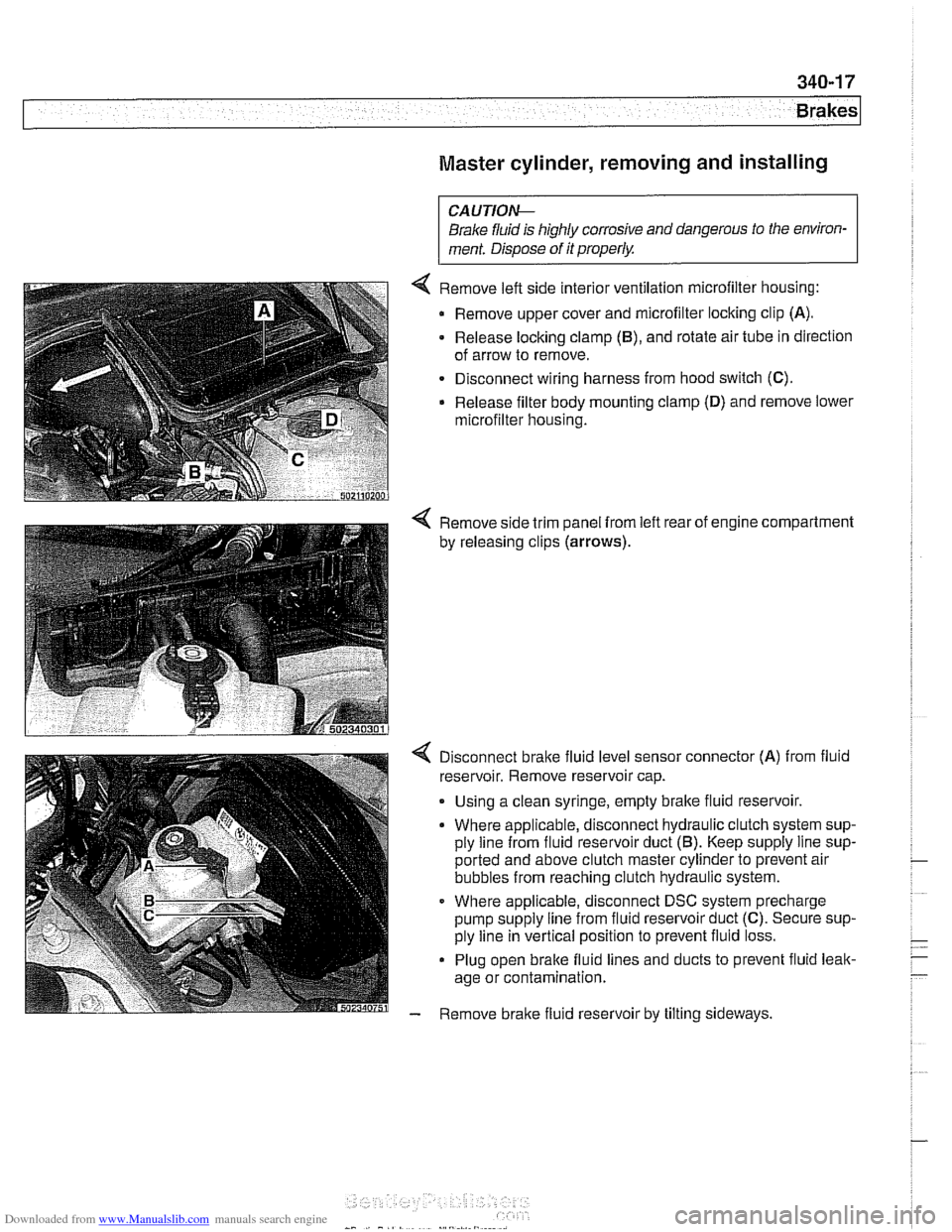

Master cylinder, removing and installing

CAUTlOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it properly.

4 Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter locking clip

(A).

- Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

4 Remove side trim panel from left rear of engine compartment

by releasing clips

(arrows).

4 Disconnect bralte fluid level sensor connector (A) from fluid

reservoir. Remove reservoir cap.

. Using a clean syringe, empty bralte fluid reservoir.

Where applicable, disconnect hydraulic clutch system sup-

ply line from fluid reservoir duct

(5). Keep supply line sup-

ported and above clutch master cylinder to prevent air

bubbles from reaching clutch hydraulic system.

Where applicable, disconnect DSC system precharge

pump supply line from fluid reservoir duct

(C). Secure sup-

ply line in vertical position to prevent fluid loss.

Plug open brake fluid lines and ducts to prevent fluid leak-

age or contamination.

- Remove brake fluid reservoir by tilting sideways.

Page 788 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

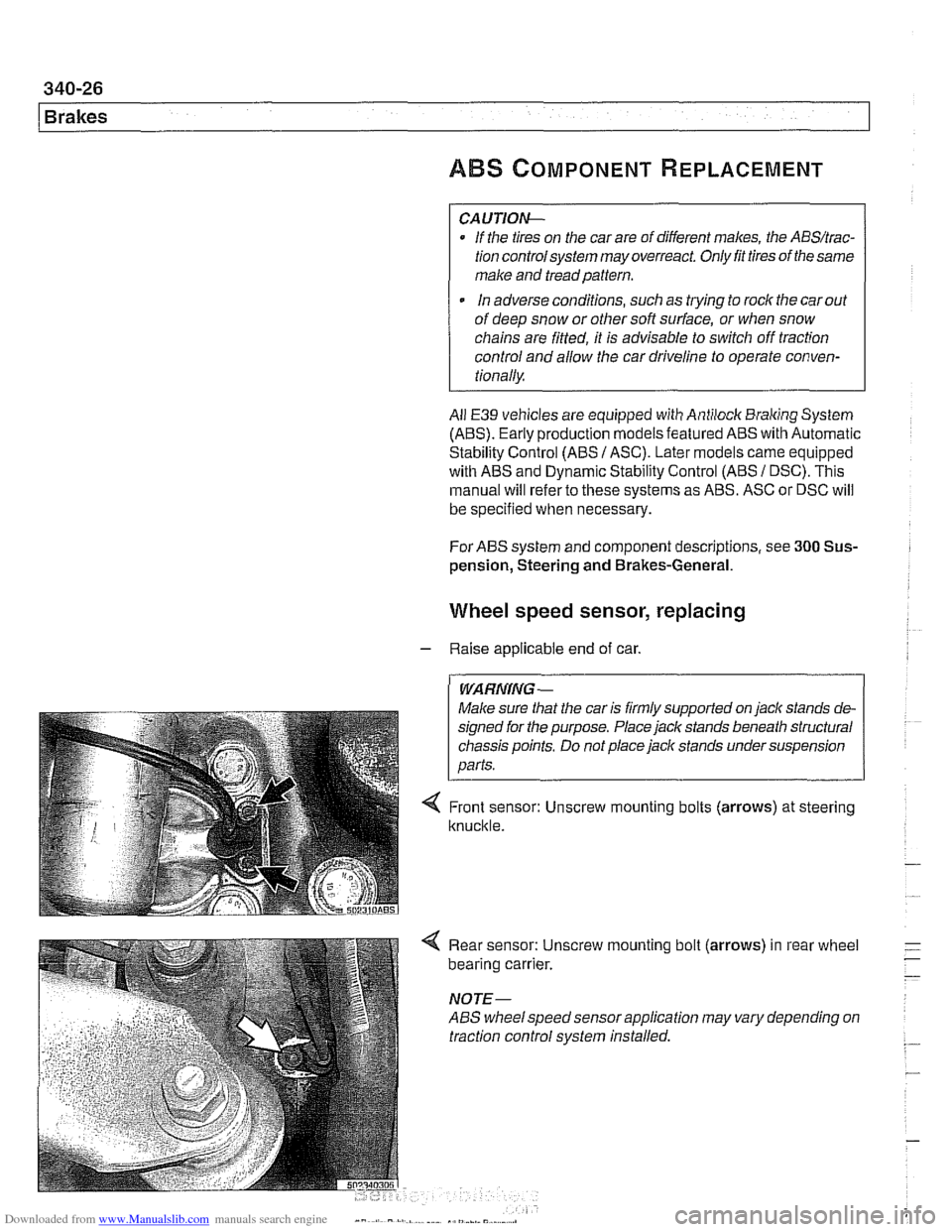

ABS COMPONENT REPLACEMENT

CA UTIOW-

If the tires on the car are of different makes, the ABS/trac-

tion controlsystem may overreact. Only fit tires of the same

make and treadpattern.

In adverse conditions, such as trying to rock the car out

of deep snow or other soft surface, or when snow

chains are fitted, it is advisable to switch off traction

control and allow

tlie car driveline to operate conven-

tionally.

All E39 vehicles are equipped with

Antilock Braking System

(ABS). Early production models featured ABS with Automatic

Stability Control (ABS

I ASC). Later models came equipped

with ABS and Dynamic Stability Control (ABS

/ DSC). This

manual will refer to these systems as ABS. ASC or DSC will

be specified when necessary.

For ABS system and component descriptions, see

300 Sus-

pension, Steering and Brakes-General.

Wheel speed sensor, replacing

- Raise applicable end of car.

Make sure that the car is firmly supported on

jack stands de-

signed for the purpose. Place

jack stands beneath structural

chassis points. Do not place jack stands under suspension

< Front sensor: Unscrew mounting bolts (arrows) at steering

knuckle.

4 Rear sensor: Unscrew mounting bolt (arrows) in rear wheel

bearing carrier.

NOTE-

ABS wheelspeed sensor application may vary depending on

traction control system installed.