set clock BMW 525i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 525i, Model: BMW 525i 2000 E39Pages: 1002

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

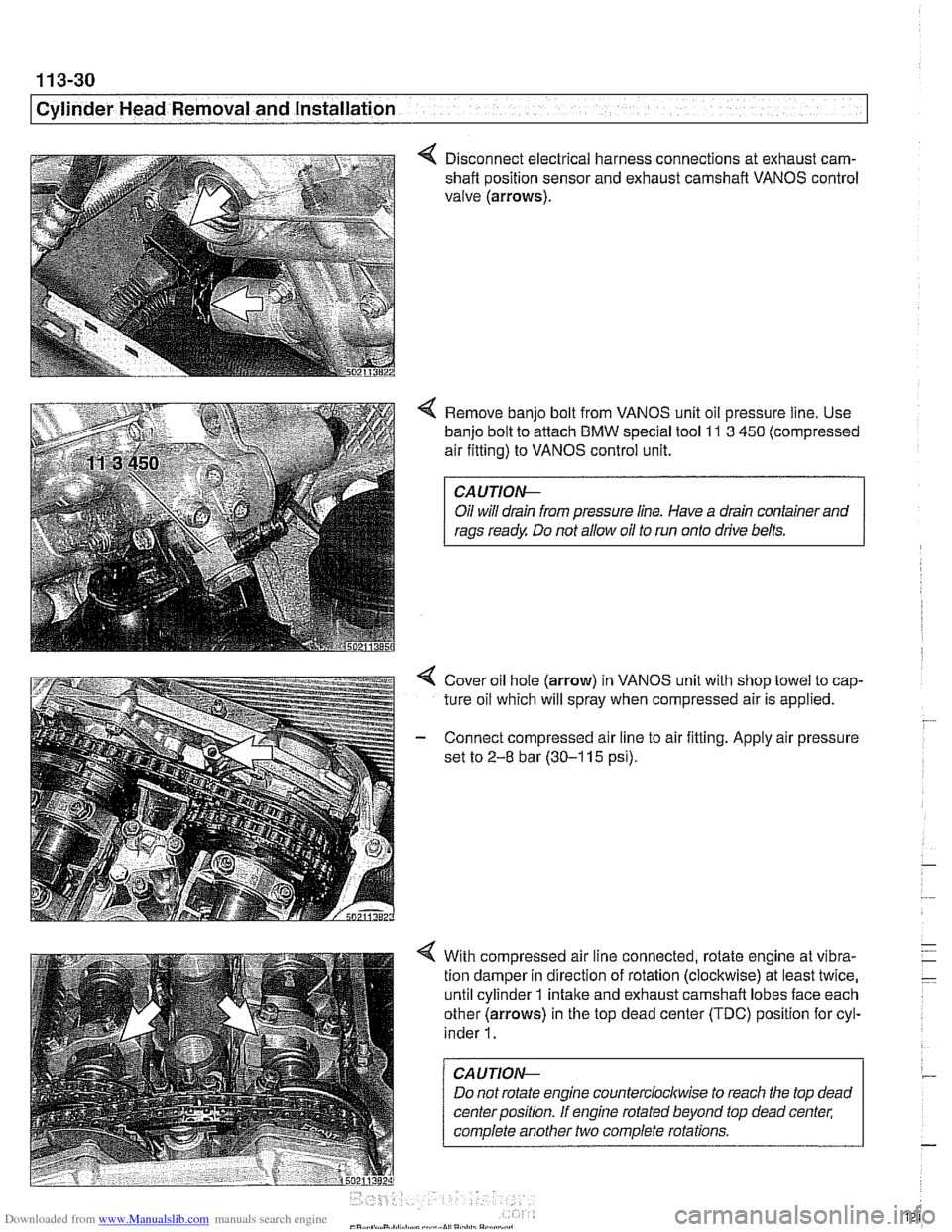

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.

Page 147 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

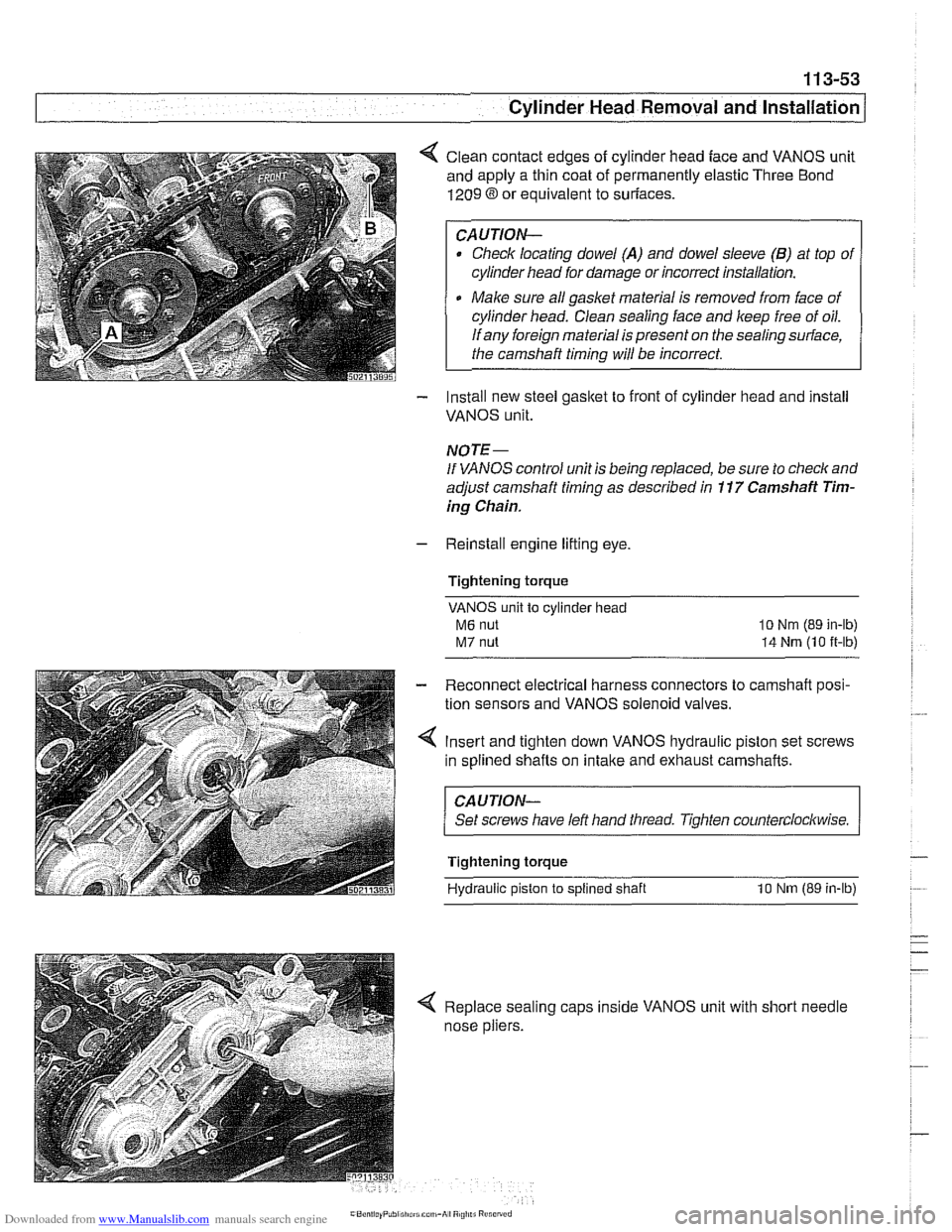

< Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of permanently elastic Three Bond

1209 8 or equivalent to suriaces.

CAUTION-

Check locating dowel (A) and dowel sleeve (B) at top of

cylinder head for damage or incorrect installation.

Make sure all gasket material is removed from face of

cylinder head. Clean sealing face and keep free of oil.

If any foreign material is present on the sealing surface,

the camshaft timing will be incorrect.

- Install new steel gasket to front of cylinder head and install

VANOS unit.

NOTE -

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in

11 7 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

Tightening torque

VANOS unit to cylinder head

M6 nut

M7 nut

lo Nm (89 in-lb)

14 Nrn (10 it-lb)

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and VANOS solenoid valves.

4 Insert and tighten down VANOS hydraulic piston set screws

in splined shafts on

intake and exhaust camshafts.

CAUJION-

Set screws have left hand tliread. Tighten counterclockwise.

Tightening torque

Hydraulic piston

to splined shaft 10 Nm (89 in-lb)

< Replace sealing caps inside VANOS unit with short needle

nose pliers.

Page 162 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-68

Cylinder Head Removal and Installation

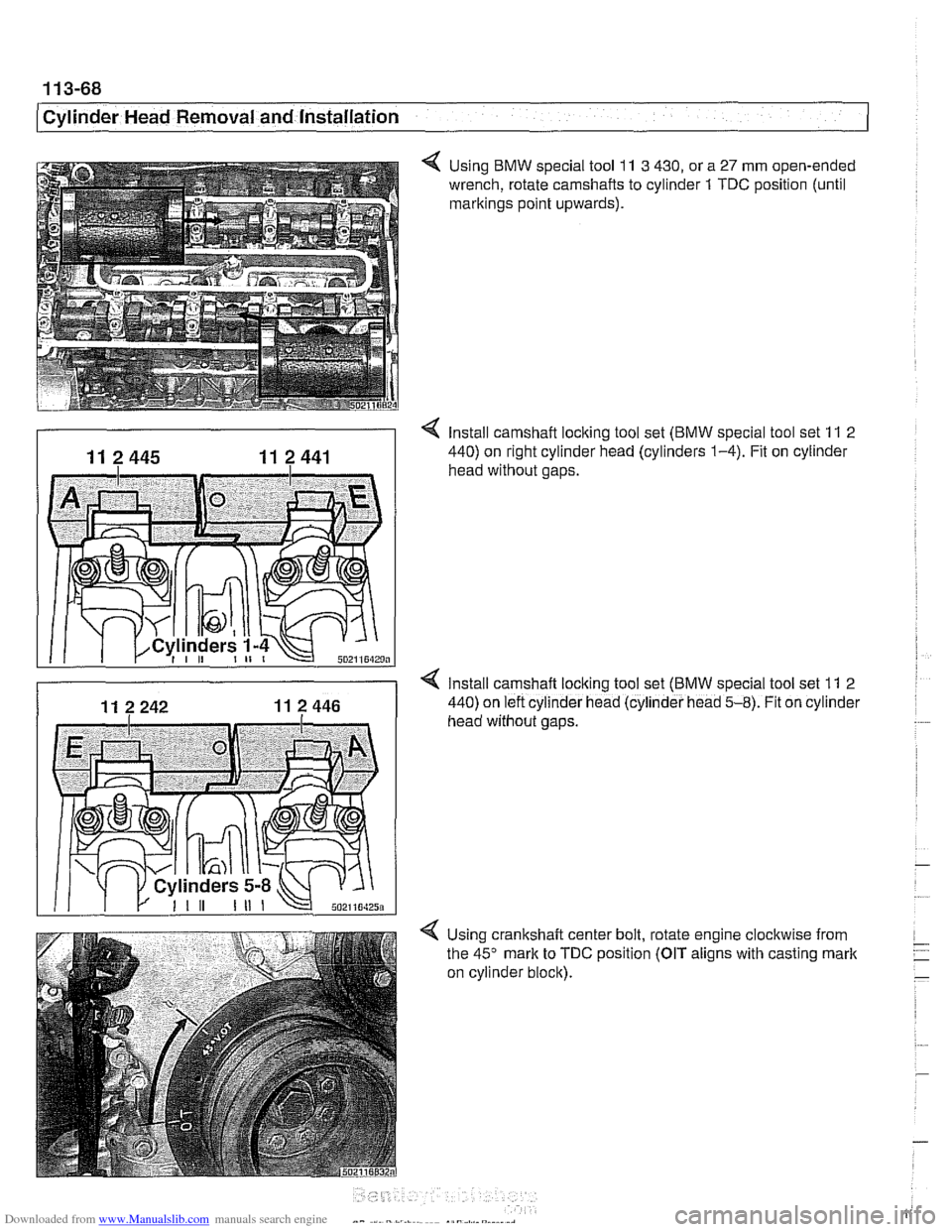

< Using BMW special tool 11 3 430, or a 27 mm open-ended

wrench, rotate camshafts to cylinder 1

TDC position (until

markings point upwards).

I I < Install camshaft locltina tool set (BMW soecial tool set 11 2

440) on right cylinder head (cylinders 1-4). Fit on cylinde~

head without gaps.

Install

camshaft locking tool set (BMW special tool set 11 2

440) on left cylinder head (cylinder head 5-8). Fit on cylinder

head without gaps.

4 Using crankshaft center bolt, rotate engine clockwise from

the

45" mark to TDC position (OIT aligns with casting mark

on cylinder block).

Page 200 of 1002

Downloaded from www.Manualslib.com manuals search engine

..--.

I Cylinder Head and Valvetrain - I

4 Lift primary chain and hold under tension, rotate engine

against direction of rotation (counterclockwise) approximate-

ly 30".

To prevent damaging valves while

worlcing on camshafts, no

aistons should be in the TDC position.

- Remove BMW special tool set 1 I 3 240 from rear of cylinder

head.

Remove retaining nuts (arrows) and bearing cap

1 of intake

camshaft.

Intake camshaft bearing cap

1 is centered with adapter

sleeves. To avoid camshaft damage, it must be removed be-

fore anv other caos.

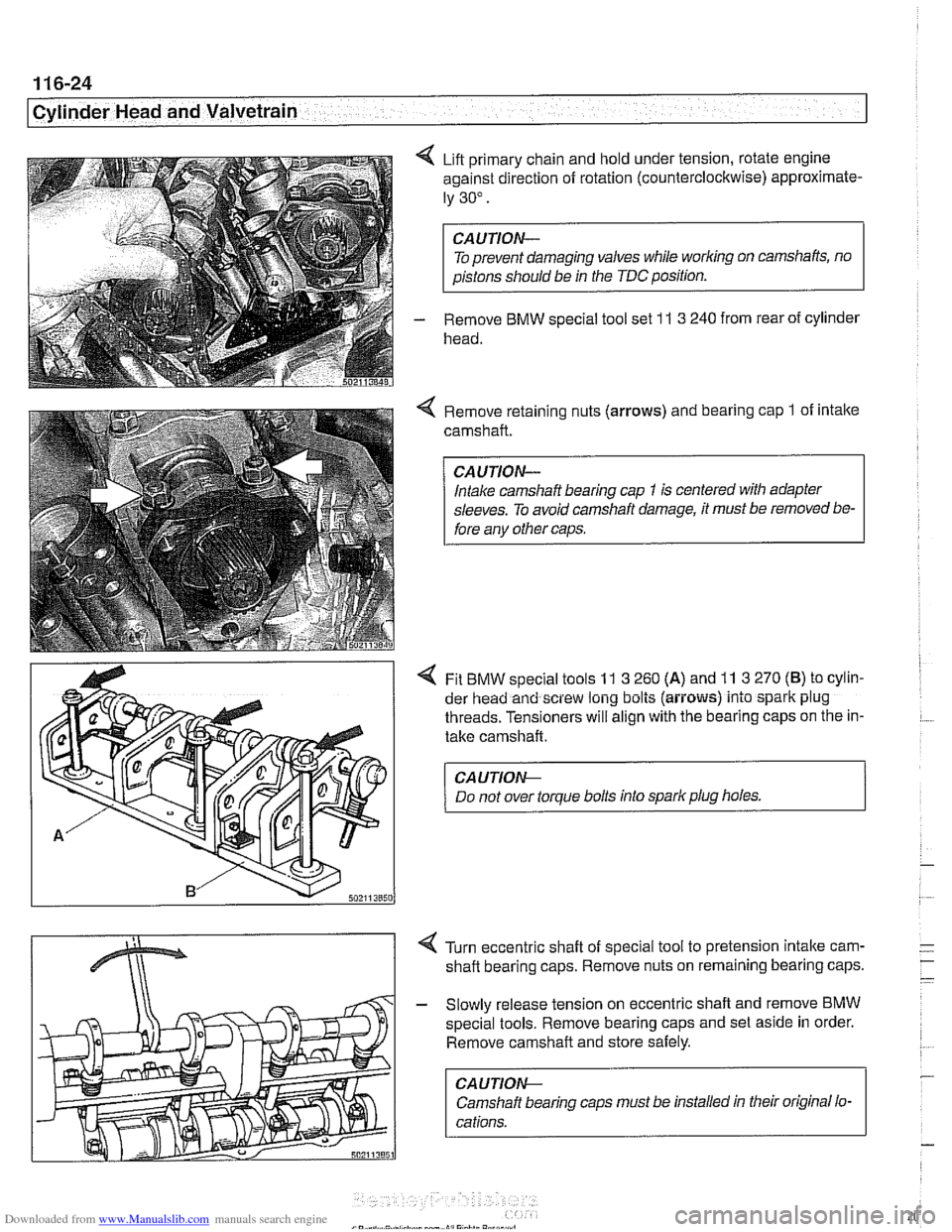

4 Fit BMW special tools 11 3 260 (A) and 11 3 270 (B) to cylin-

der head and screw long bolts (aiiows) into spark plug

threads. Tensioners will align with the bearing caps on the in-

take camshaft.

CA UTION--

Do not over torque bolts into spark plug holes. 1

4 Turn eccentric shaft of special tool to pretension intake carn-

shaft bearing caps. Remove nuts on remaining bearing caps.

- Slowly release tension on eccentric shaft and remove BMW

special tools. Remove bearing caps and set aside in order.

Remove camshaft and store safely.

CA U TIOW-

Camshaft bearing caps must be installed in their original lo-

cations.

Page 276 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .. ~-

Camshaft Timing Chain -

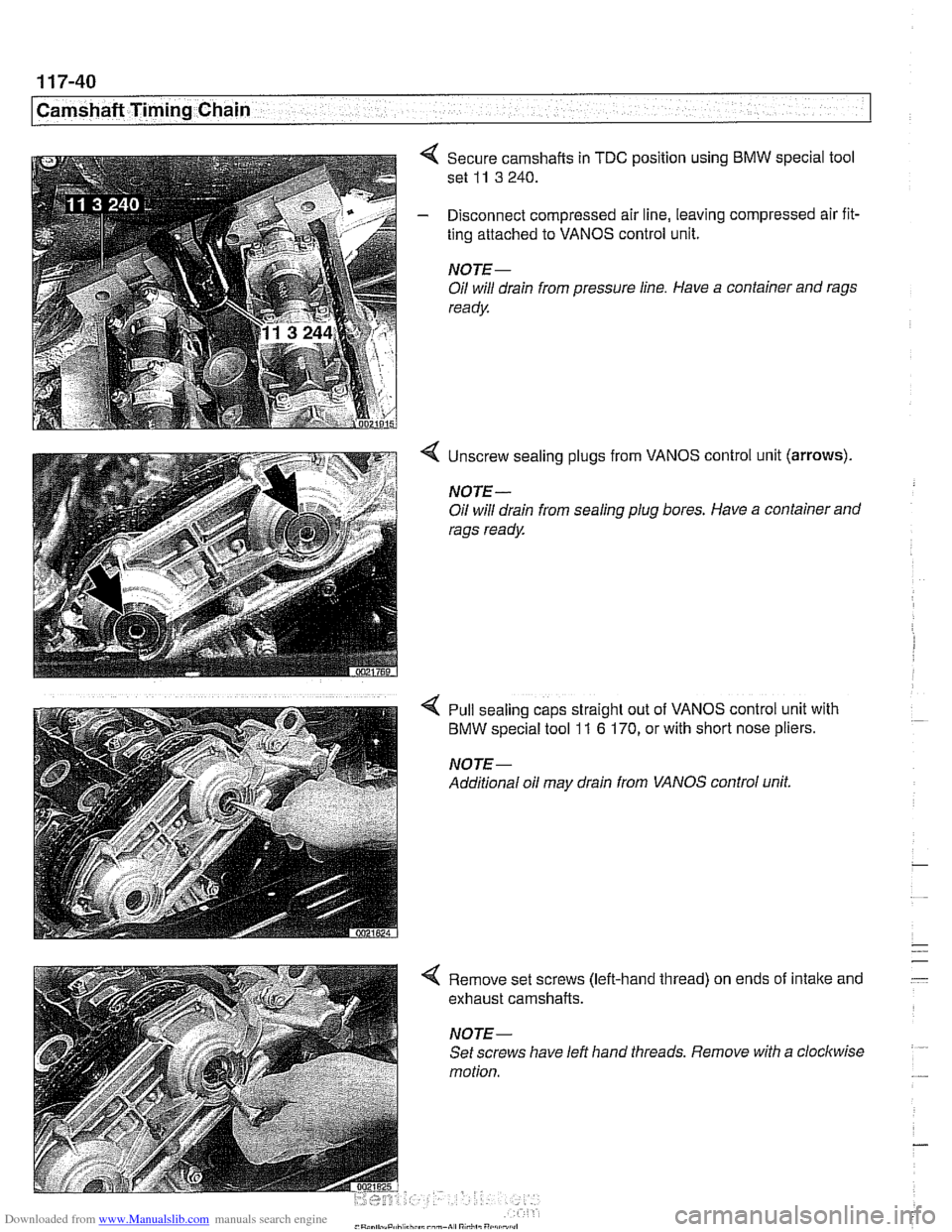

4 Secure camshafts in TDC position using BMW special tool

set

11 3 240.

- Disconnect compressed air line, leaving compressed air fit-

ting attached to VANOS control unit.

NOTE -

Oil will drain from pressure line. Have a container and rags

ready

4 Unscrew sealing plugs from VANOS control unit (arrows).

NOTE-

Oil will drain from sealing plug bores. Have a container and

rags ready

4 Pull sealing caps straight out of VANOS control unit with

BMW special tool 11 6 170, or with short nose pliers.

NOTE-

Additional oil may drain from VANOS control unit.

4 Remove set screws (left-hand thread) on ends of intake and

exhaust camshafts.

NOTE-

Set screws have left hand threads. Remove with a clockwise

motion.

Page 427 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.

Fuel Injection 1

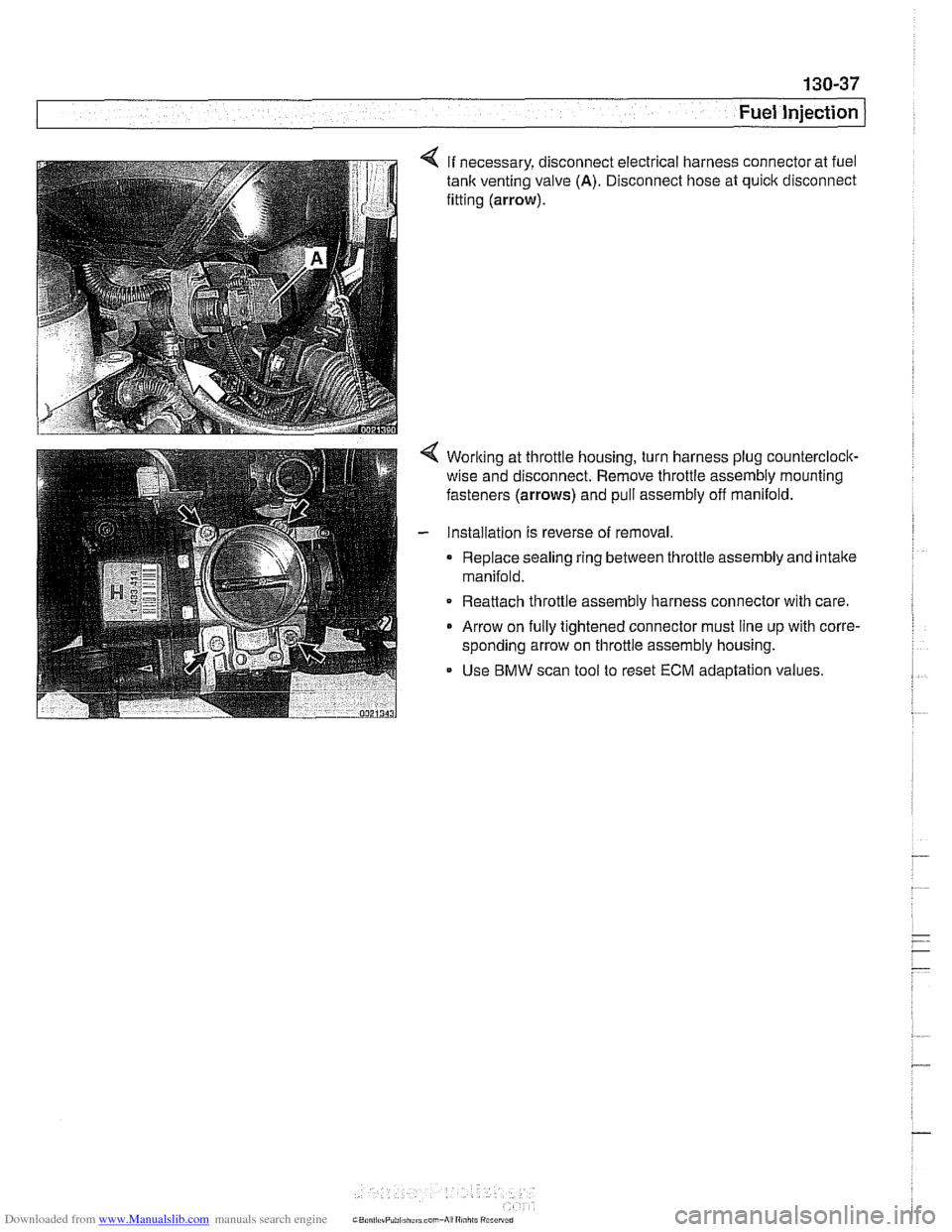

4 If necessary, disconnect electrical harness connector at fuel

tank venting valve (A). Disconnect hose at quick disconnect

fitting

(arrow).

< Worlting at throttle housing, turn harness plug counterclock-

wise and disconnect. Remove throttle assembly mounting

fasteners

(arrows) and pull assembly off manifold.

- Installation is reverse of removal.

0 Replace sealing ring between throttle assembly and intake

manifold.

Reattach throttle assembly harness connector with care.

0 Arrow on fully tightened connector must line up with corre-

sponding arrow on throttle assembly housing.

- Use BMW scan tool to reset ECM adaptation values.

Page 933 of 1002

Downloaded from www.Manualslib.com manuals search engine

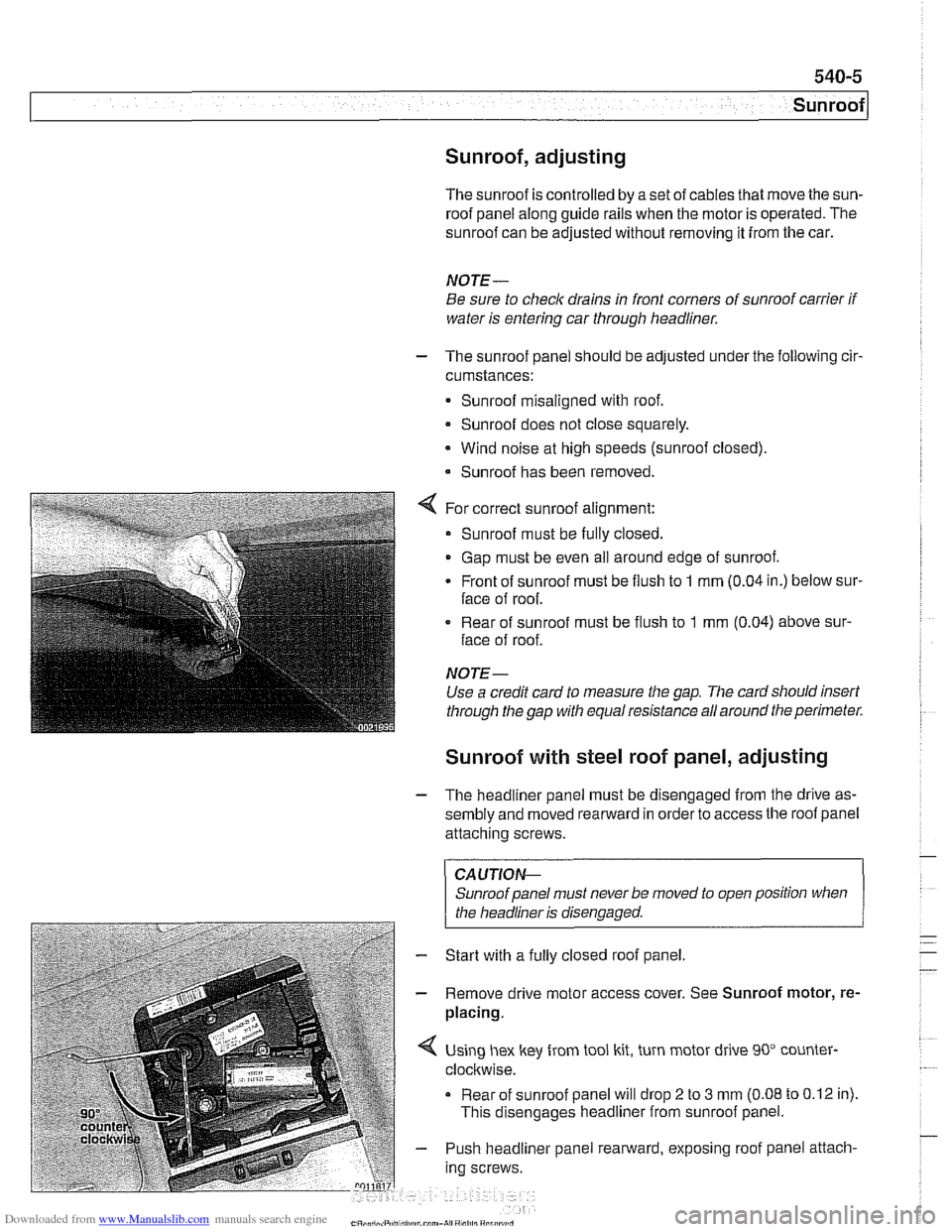

Sunroof, adjusting

The sunroof is controlled by a set of cables that move the sun-

roof panel along guide rails when the motor is operated. The

sunroof can be adjusted without removing it from the car.

NOTE-

Be sure to check drains in front corners of sunroof carrier if

water is entering car through headliner.

- The sunroof panel should be adjusted under the following cir-

cumstances:

Sunroof misaligned with roof.

Sunroof does not close squarely.

* Wind noise at high speeds (sunroof closed).

Sunroof has been removed.

For correct sunroof alignment:

Sunroof must be fully closed.

Gap must be even all around edge of sunroof.

Front of sunroof must be flush to

1 mm (0.04 in.) below sur-

face of roof.

. Rear of sunroof must be flush to 1 mm (0.04) above sur-

face of roof.

NOTE-

Use a credit card to measure the gap. The card sllould insert

through the gap with equal resistance all around the perimeter.

Sunroof with steel roof panel, adjusting

- The headliner panel must be disengaged from the drive as-

sembly and moved rearward in order to access the roof panel

attaching screws.

CAUTIOI\C

Sunroof panel must never be moved to open position when . .

I the headliner is disenaaaed. 1

- Start with a fully closed roof panel.

- Remove drive motor access cover. See Sunroof motor, re-

placing.

Using hex key from tool kit, turn motor drive 90" counter-

clockwise.

Rear of sunroof panel will drop

2 to 3 mm (0.08 to 0.12 in).

This disengages headliner from sunroof panel.

- Push headliner panel rearward, exposing roof panel attach-

ing screws.

Page 934 of 1002

Downloaded from www.Manualslib.com manuals search engine

l Sunroof

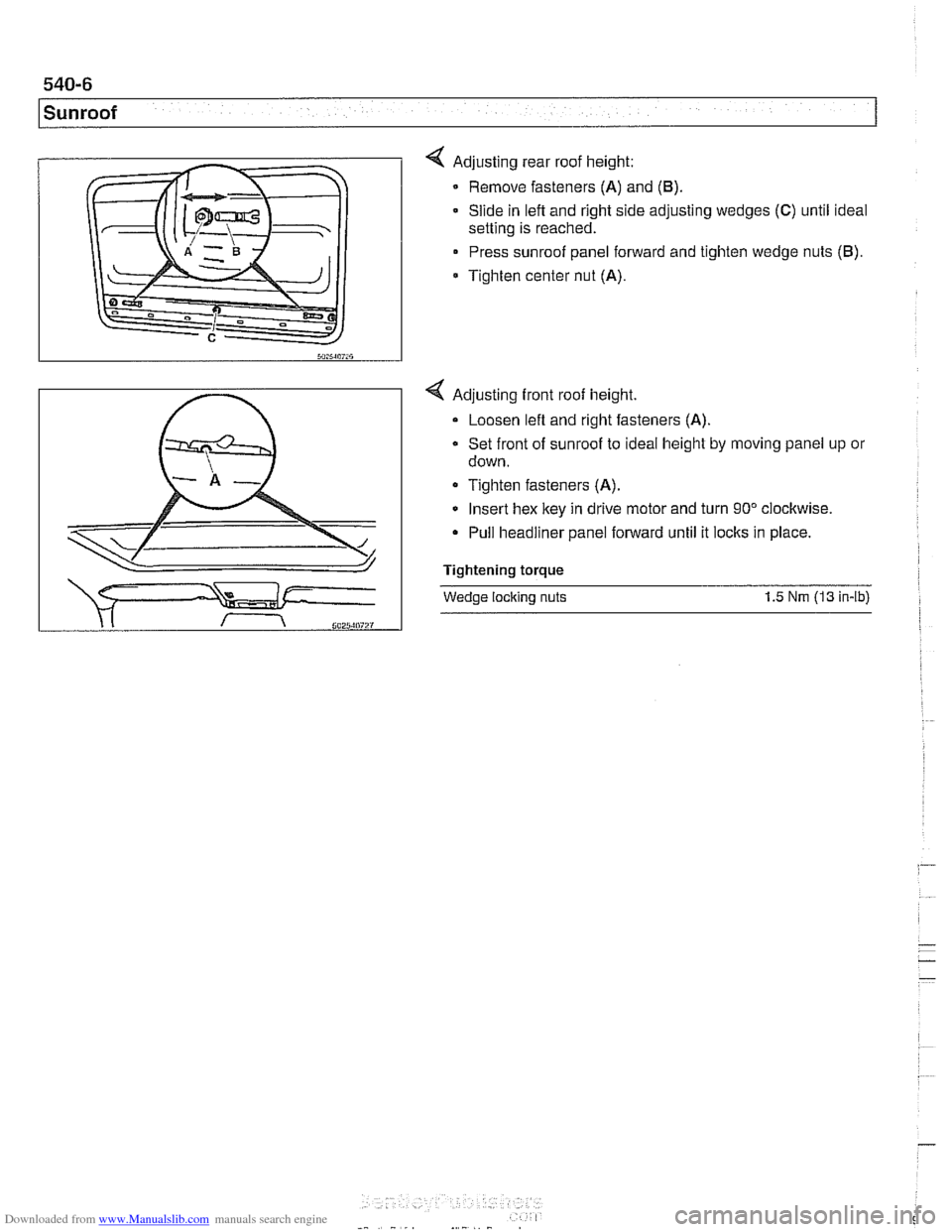

4 Adjusting rear roof height:

Remove fasteners

(A) and (6)

Slide in left and right side adjusting wedges (C) until ideal

setting is reached.

Press sunroof panel forward and tighten wedge nuts

(6).

* Tighten center nut (A).

4 Adjusting front roof height.

Loosen lefl and right fasteners

(A)

Set front of sunroof to ideal height by moving panel up or

down.

Tighten fasteners

(A).

Insert hex key in drive motor and turn 90" clockwise.

Pull headliner panel forward until it locks in place.

Tightening torque

Wedge locking nuts 1.5 Nm (1 3 in-lb)