Suspension BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

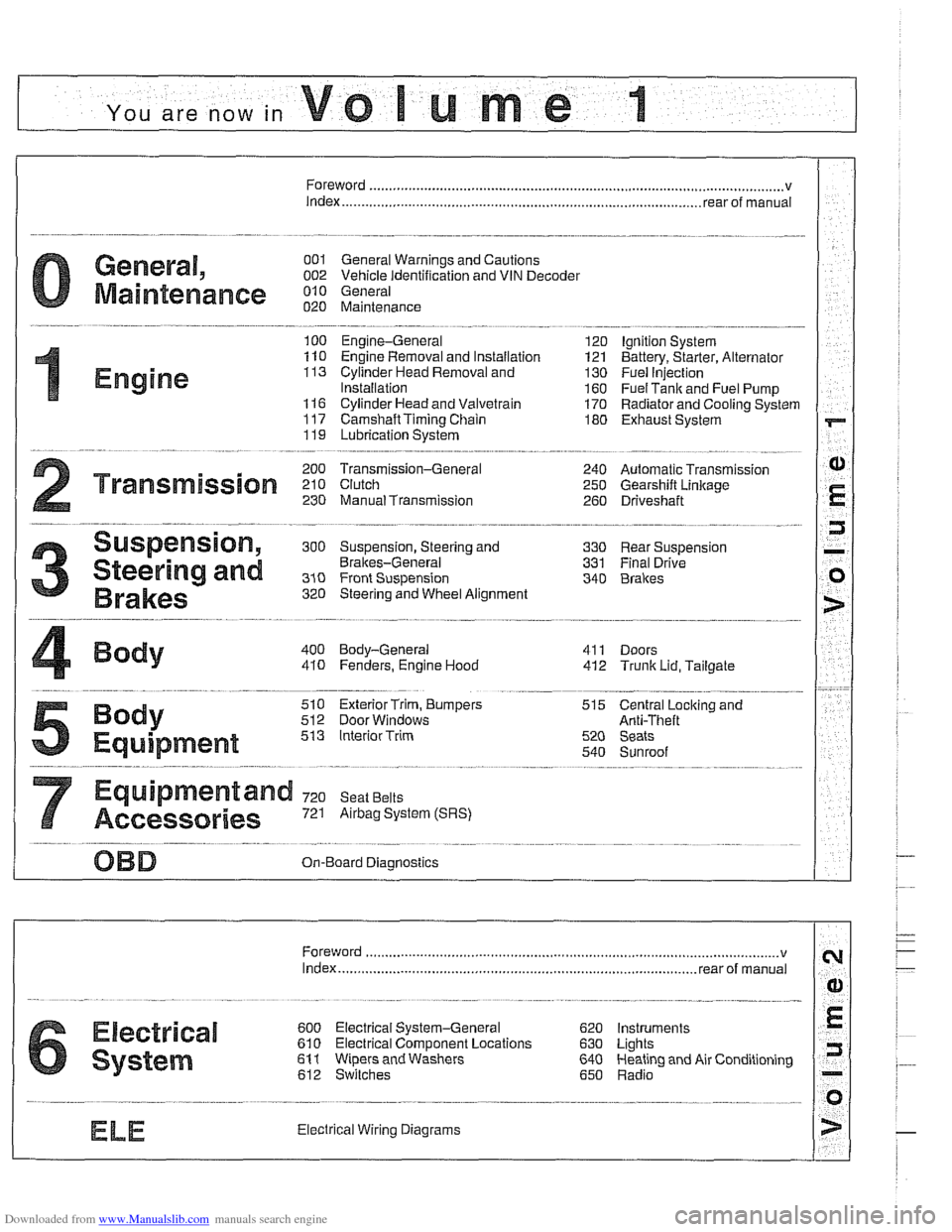

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 12 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-2

General

This section is intended to help the do-it-yourselfer get start-

ed. Tips on workshop practices, basic tools, and a quick refer-

ence guide to emergencies can be found here.

WARNING-

Do not use this manual unless you are familiar with basic

automotive repair procedures and safe workshop

practices.

0 This manual illustrates the worl

and up-to-date information from the vehicle manufac-

turer or for proper training as an automotive technician.

Note that it is not possible to anticipate all of the ways

or conditions under which vehicles may be serviced or

to provide cautions as to all of the possible hazards that

may result.

MOW TO USE THIS MANUAL

WARNING -

Your common sense and goodjudgement are crucial to safe

and successful service

work. Read procedures through be-

fore starting them. Think about whether the condition of your

cac your level of mechanical skill, or pour level of reading

comprehension might result in or contribute in some way to

an occurrence that might cause you injury, damage your car;

or result in an unsafe repair. If you have doubts for these or

other reasons about your ability to perform safe repair work

on your car; have the work done at an authorized

BMW deal-

er or other qualified shop.

The manual is divided into ten sections:

0 GENERAL, MAINTENANCE

0 I ENGINE

2 TRANSMISSION

3 SUSPENSION, STEERING AND BRAKES

4 BODY

5 BODY EQUIPMENT

6 ELECTRICAL SYSTEM

7 EQUIPMENT AND ACCESSORIES

- ELE ELECTRICAL WIRING DIAGRAMS

OBD ON-BOARD DIAGNOSTICS

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

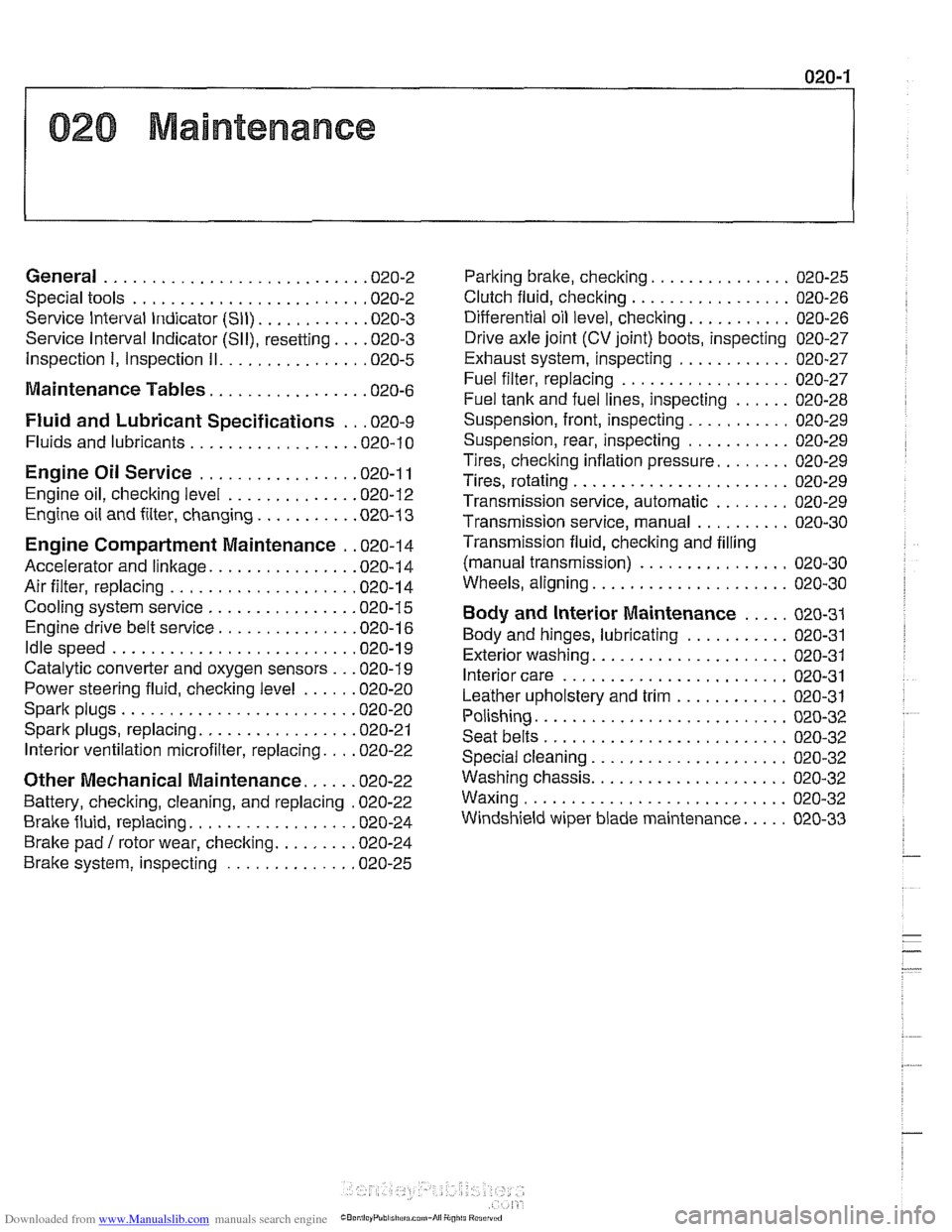

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 61 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Suspension, front, inspecting

Inspection of the front suspension and steering includes a

check of all moving parts

forwear and excessive play. Inspect

ball joint and tie-rod rubber seals and boots for cracks

ortears

that could allow the entry of dirt, water, and other

contaminants. See

310 Front Suspension.

Suspension, rear, inspecting

Differential and rear drive axle service consists of checking

and changing the gear oil, inspecting for leaks, and checking

the drive axle

CV joint boots for damage.

The areas where

lealts are most likely to occurare around the

drive shaft and drive axle mounting flanges. For more infor-

mation on identifying oil leaks and theircauses, see

330 Rear

Suspension and

331 Final Drive.

Tires, checking inflation pressure

Correct tire pressures are important to handling and stability,

fuel economy, and tire wear. Tire pressures change with tem-

perature. Pressures should be

checked oRen during season-

al temperature changes. Correct inflation pressures can be

found on the driver's door pillar and in the owner's manual.

Note that tire pressures should be higher when the car is

more heavily loaded.

WARNING-

Do not inflate any tire to a pressure higher than the tire's max-

imum inflation pressure listedon the sidewall. Use care when

adding air to warm tires. Warm tire pressures can increase as

much as

4 psi (0.3 bar) over their coldpressures.

Tires, rotating

BMW does not recommend tire rotation. Due to the car's sus-

pension design, the front tires begin to wear first at the outer

shoulder and the reartires begin to wearfirst at the middle of

the tread or inner shoulder. Rotating the tires may adversely

affect road handling and tire grip.

Transmission service, automatic

The automatic transmissions installed in E39 models are

filled with special automatic transmission fluid. The transmis-

sion lubricant type can be found on the "type-plate" on the

side of the transmission. The recommended lubricants are

listed earlier in this repair group. See Fluids and lubricants.

If in doubt, consult an authorized BMW dealer for alternate

Page 91 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-19

Engine Removal and Installation

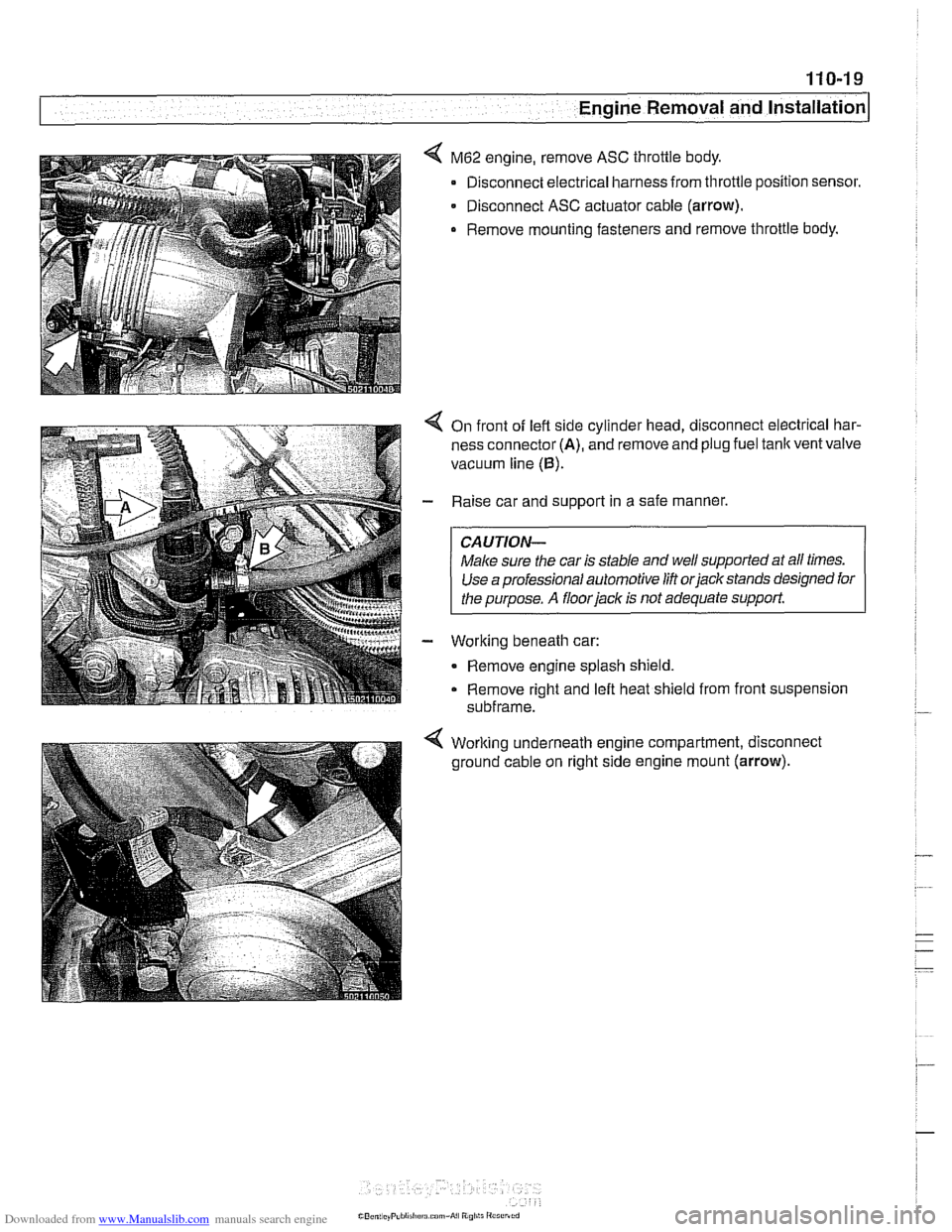

M62 engine, remove ASC throttle body.

Disconnect electrical harness from throttle position sensor.

- Disconnect ASC actuator cable (arrow).

. Remove mounting fasteners and remove throttle body.

On front of left side cylinder head, disconnect electrical har-

ness connector

(A), and remove and plug fuel tank vent valve

vacuum line

(0).

Raise car and support in a safe manner.

CAUTION-

Male sure the car is stable and well supported at aN times.

Use a professional automotive

lifi orjackstands designed for

I the ouroose. A floor jack is not adequate support.

Working beneath car:

- Remove engine splash shield.

Remove right and left heat shield from front suspension

subframe.

Working underneath engine compartment, disconnect

ground cable on right side engine mount

(arrow).

Page 322 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-2

Lubrication System

This repair group covers lubrication system troubleshooting

as well as oil pan removal and oil pump replacement.

In 6-cylinder models, removal of the oil pan requires the re-

moval of the exhaust system and some front suspension

components. Those procedures are fully covered in:

180 Exhaust System

210 Clutch

230 Manual Transmission

0 240 Automatic Transmission

310 Front Suspension

320 Steering and Wheel Alignment

NOTE-

Oil change procedure and oil filter replacement are covered

in

020 Maintenance.

CAUTIOG

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to check oil bolts and

nut tightness whenever the

oilpump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

Band torque to specifications.

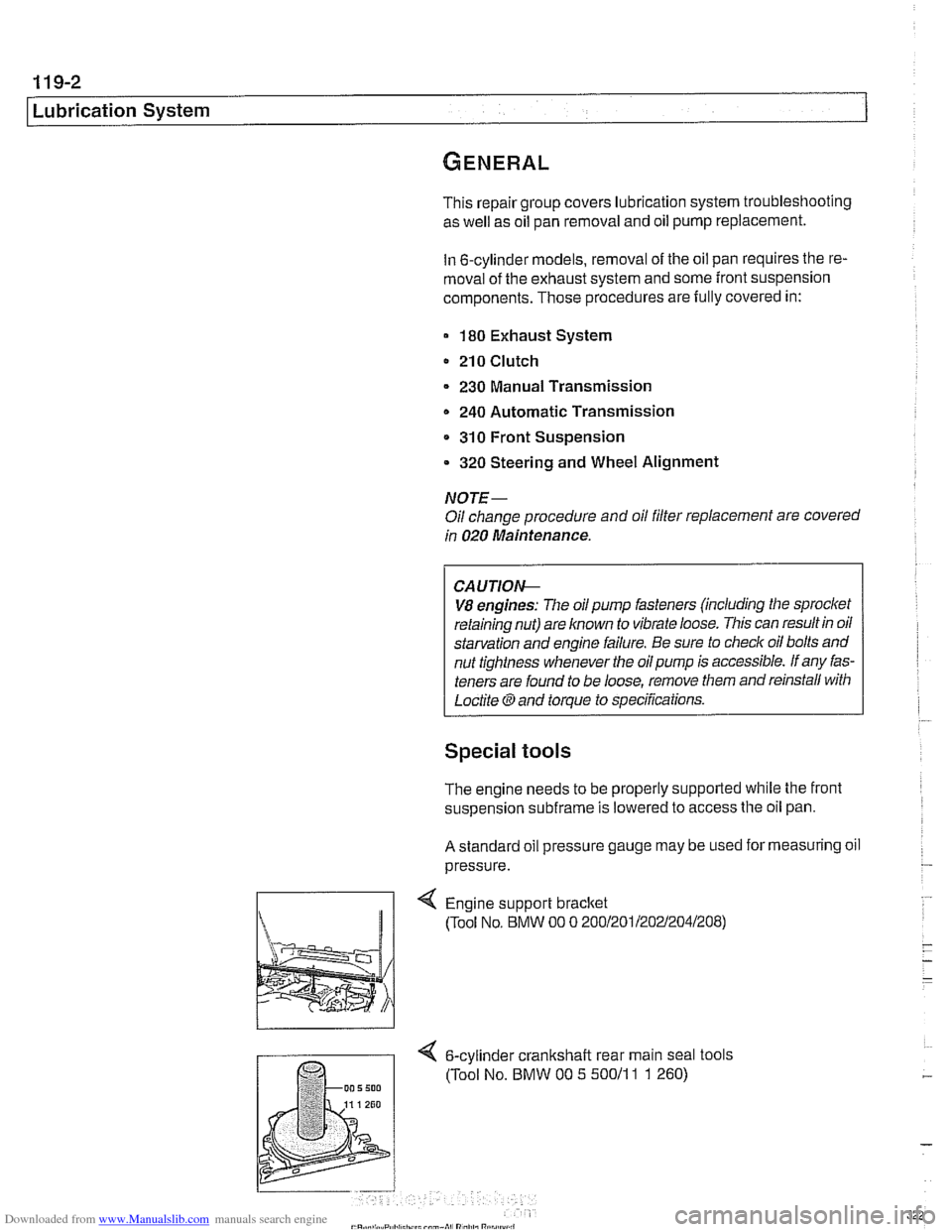

Special tools

The engine needs to be properly supported while the front

suspension

subframe is lowered to access the oil pan.

A standard oil pressure gauge may be used for measuring oil

pressure.

Engine support bracket

(Tool No, BMW 00 0 20012011202~2041208)

4 6-cylinder crankshalt rear main seal tools

(Tool No. BMW 00 5 50011

1 1 260)

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

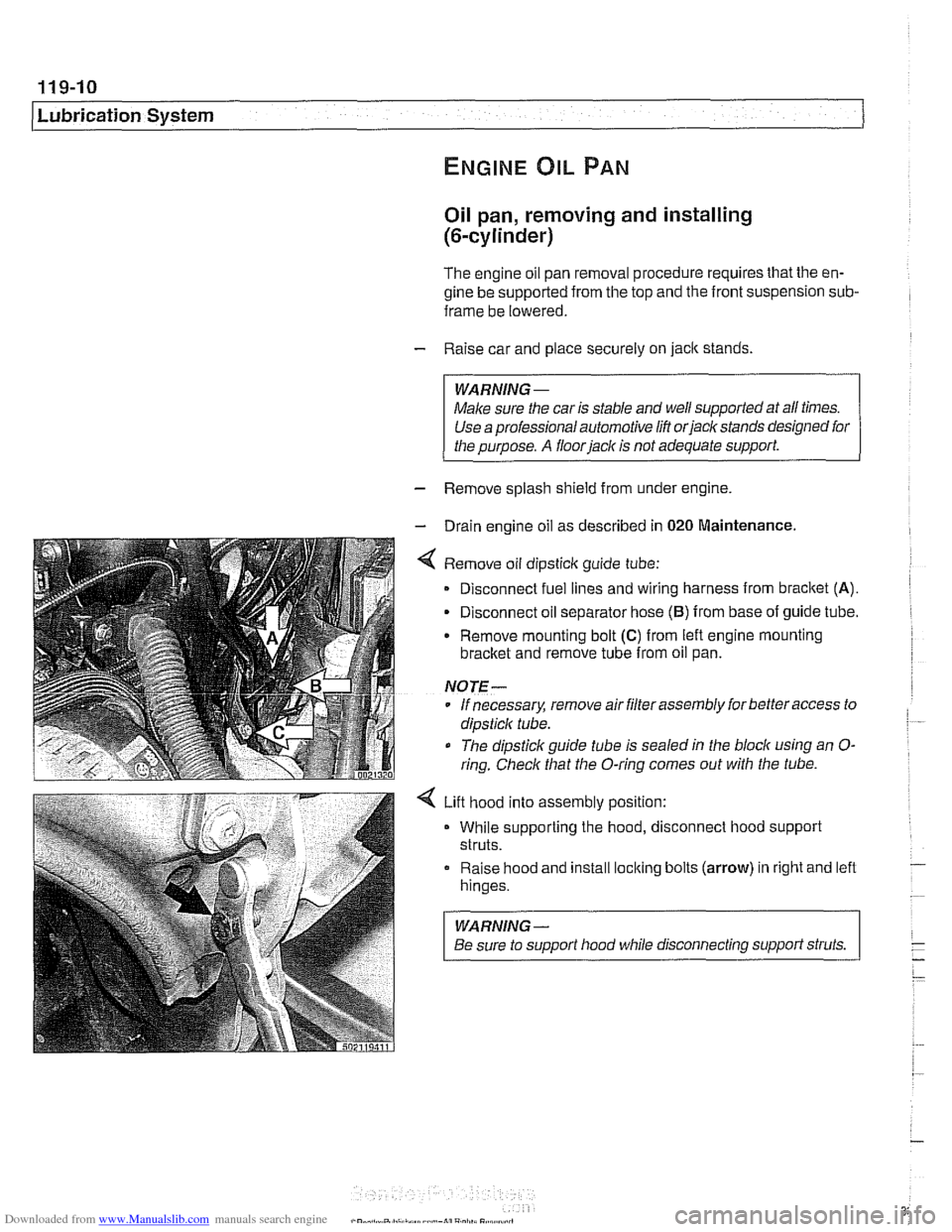

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.

Page 335 of 1002

Downloaded from www.Manualslib.com manuals search engine

... . . Lubrication sy=

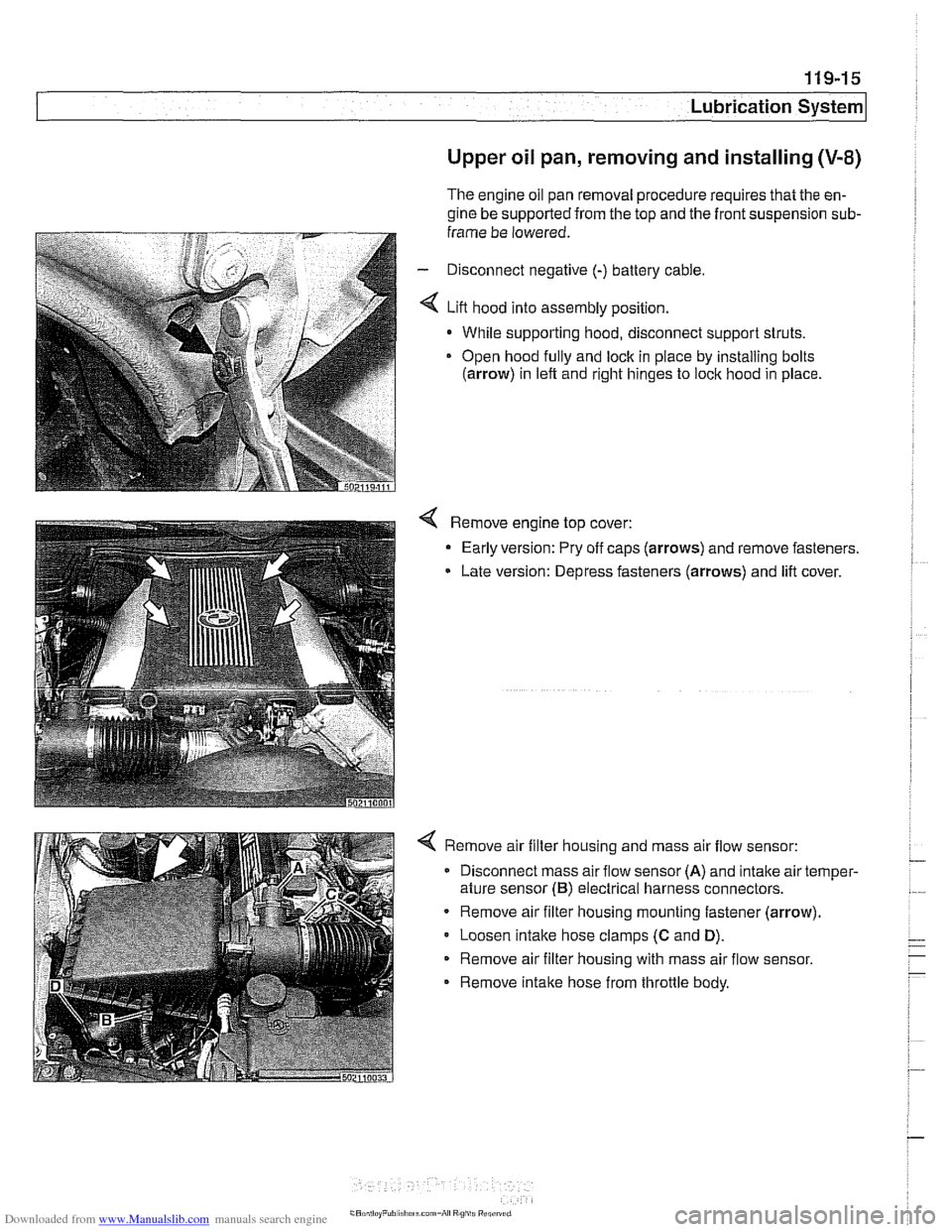

Upper oil pan, removing and installing (V-8)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Disconnect negative (-) battery cable

4 Lift hood into assembly position.

- While supporting hood, disconnect support struts.

Open hood

fully and lock in piace by installing bolts

(arrow) in left and right hinges to lock hood in place

4 Remove engine top cover:

- Early version: Pry off caps (arrows) and remove fasteners.

Late version: Depress fasteners (arrows) and lift cover.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor

(A) and intake air temper-

ature sensor

(B) electrical harness connectors.

Remove air filter housing mounting fastener (arrow)

Loosen

intake hose clamps (C and D).

Remove air filter housing with mass air flow sensor.

Remove intake hose from throttle body.

Page 343 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

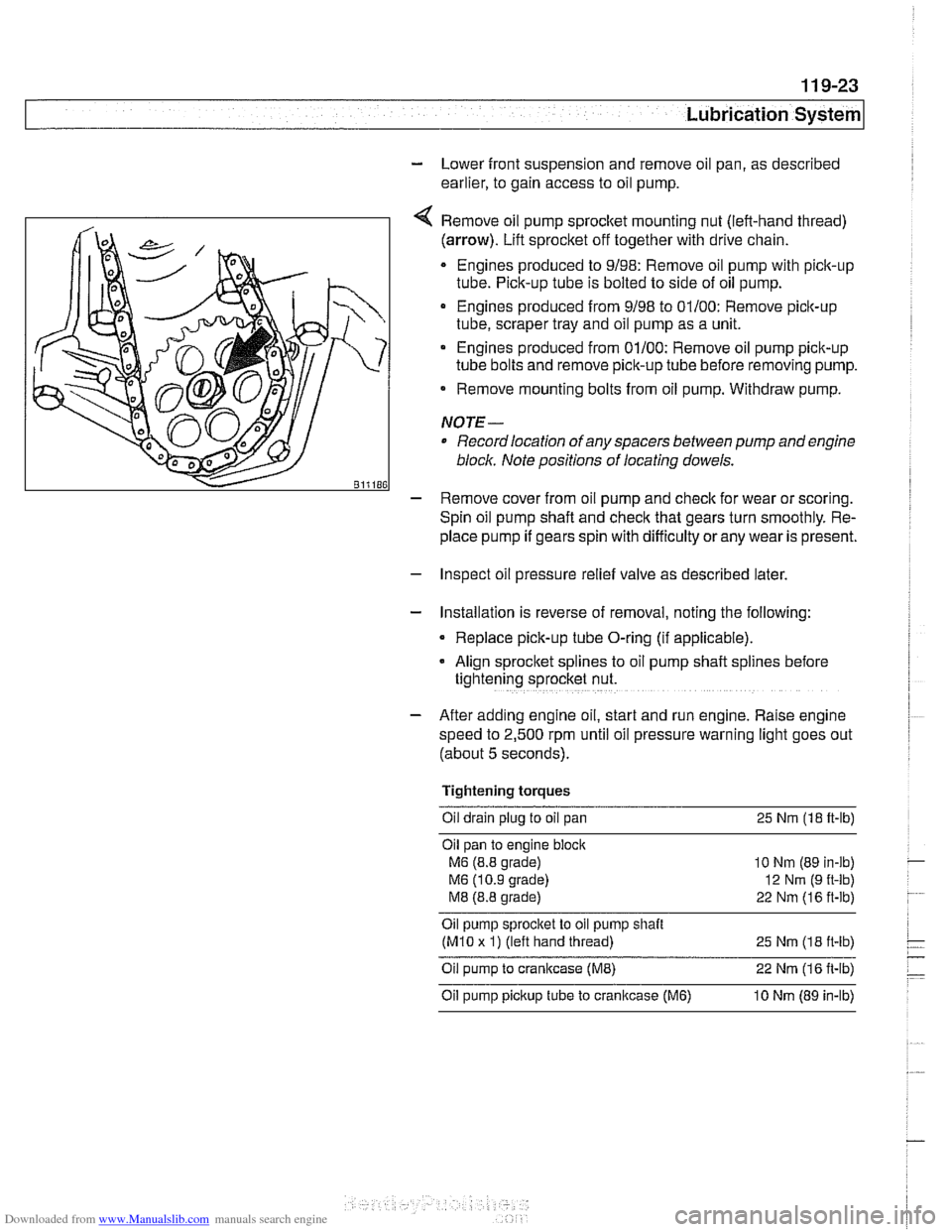

- Lower front suspension and remove oil pan, as described

earlier, to gain access to oil pump.

Remove oil pump

sprocket mounting nut (left-hand thread)

(arrow). Lift sprocket off together with drive chain.

Engines produced to 9/98: Remove oil pump with pick-up

tube. Pick-up tube is bolted to side of oil pump.

Engines produced from 9/98 to 01/00: Remove pick-up

tube, scraper tray and oil pump as a unit.

Engines produced from 01/00: Remove oil pump pick-up

tube bolts and remove pick-up tube before removing pump.

Remove mounting bolts from oil pump. Withdraw pump.

NOTE-

Record location of any spacers between pump and engine

bloclc Note positions of locating dowels.

- Remove cover from oil pump and check for wear or scoring.

Spin oil pump shaft and

check that gears turn smoothly. Re-

place pump if gears spin with difficulty

orany wear is present.

- Inspect oil pressure relief valve as described later.

- Installation is reverse of removal, noting the following:

Replace pick-up tube O-ring (if applicable).

- Align sprocket splines to oil pump shaft spl~nes before

tightening sprocket nut.

- After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

Tightening torques Oil drain plug to oil pan 25

Nm (18 ft-lb)

Oil pan to engine

bloclc

M6 (8.8 grade)

M6 (10.9 grade)

M8 (8.8 grade)

10 Nm (89 in-lb)

12

Nrn (9 ft-lb)

22 Nm (16 ft-lb)

Oil pump sprocket to oil pump shait

(M10 x 1) (left hand thread)

25 Nm (1 8 it-lb)

Oil pump to crankcase (ME) 22 Nm (1 6 it-lb)

Oil pump pickup tube to cranltcase (M6) 10 Nm (89 in-lb)

Page 530 of 1002

Downloaded from www.Manualslib.com manuals search engine

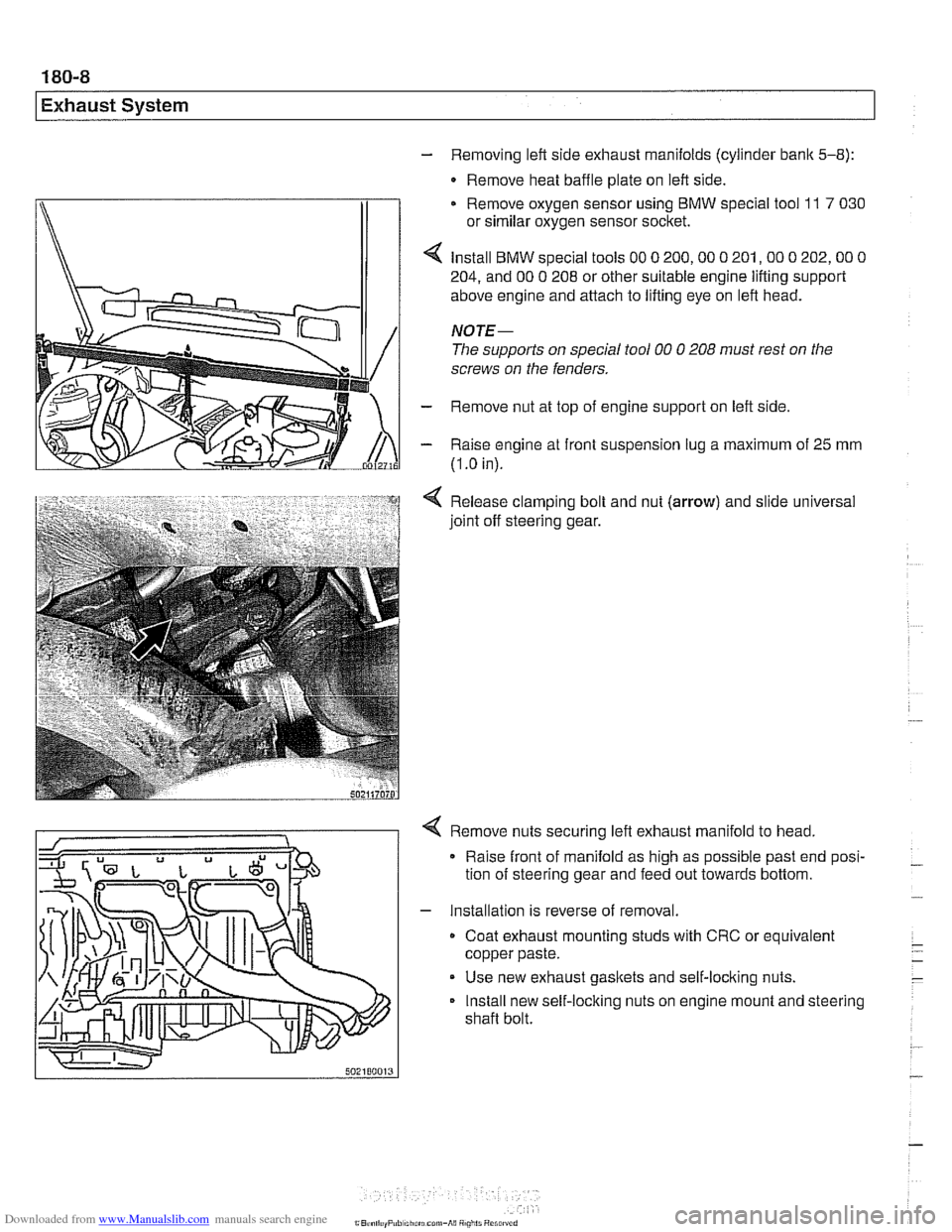

- Removing left side exhaust manifolds (cylinder bank 5-8):

- Remove heat baffle plate on left side.

Remove oxygen sensor using

BMW special tool 11 7 030

or similar oxygen sensor socket.

Install

BMW special tools 00 0 200,OO 0 201,OO 0 202,OO 0

204, and 00 0 208 or other suitable engine lifting support

above engine and attach to lifting eye on left head.

NOTE-

The supports on special tool 00 0 208 must rest on the

screws on the fenders.

- Remove nut at top of engine support on left side

- Raise engine at front suspension lug a maximum of 25 mm

(I

.O in).

Release clamping bolt and nut

(arrow) and slide universal

joint off steering gear.

4 Remove nuts securing left exhaust manifold to head,

Raise front of manifold as high as possible past end posi-

tion of steering gear and feed out towards bottom.

- Installation is reverse of removal.

Coat exhaust mounting studs with CRC or equivalent

copper paste.

Use new exhaust gaskets and self-locking nuts.

Install new self-locking nuts on engine mount and steering

shaft bolt.