Rear seat BMW 525i 2001 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 634 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 4

I Susoension. Steerina and Brakes - General

DSC system I

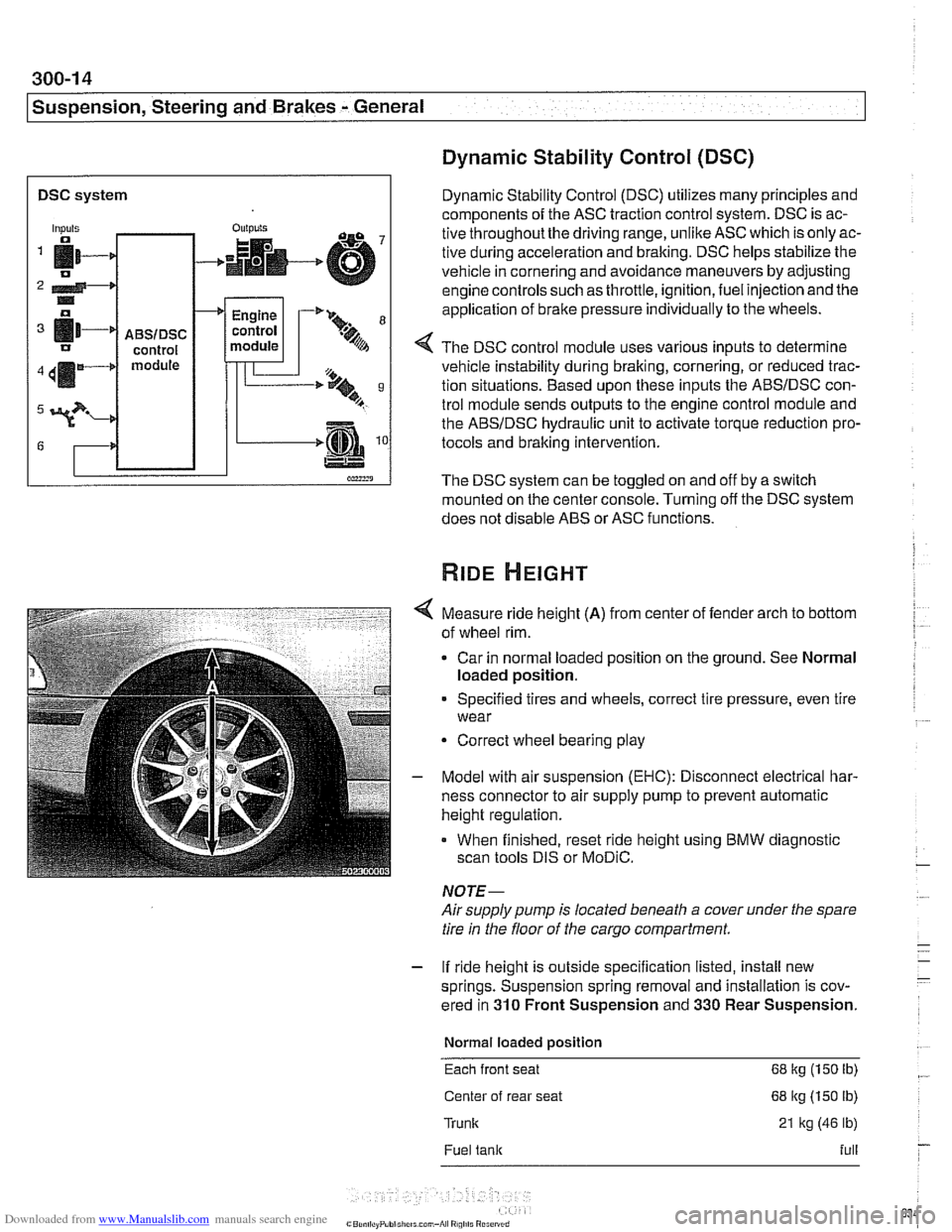

Dynamic Stability Control (DSC)

Dynamic Stability Control (DSC) utilizes many principles and

components of the ASC traction control system. DSC is ac-

tive throughoutthe driving range, unlike ASC which is only ac-

tive during acceleration and braking. DSC helps stabilize the

vehicle in cornering and avoidance maneuvers by adjusting

engine controls such as throttle, ignition, fuel injection and the

application of

brake pressure individually to the wheels.

Inputs

fi- 0

2 4-* .. o

[11-' IJ

411m4

3?-

G

4 The DSC control module uses various inputs to determine

vehicle instability during braking, cornering, or reduced trac-

tion situations. Based upon these inputs the ABSIDSC con-

trol module sends outputs to the engine control module and

the ABSIDSC hydraulic unit to activate torque reduction pro-

tocols and braking intervention.

-

ABSIDSC control module

OUI~YIS

4

The DSC system can be toggled on and off by a switch

mounted on the center console. Turning off the DSC system

does not disable ABS or ASC functions.

+

Measure ride height (A) from center of fender arch to bottom

of wheel rim.

Car in normal loaded position on the ground. See Normal

loaded position.

Engine

control

module

Specified tires and wheels, correct tire pressure, even tire

wear

-'* 9-

.%A

Correct wheel bearing play

T'== ..t, 9 B

-.m

Model with air suspension (EHC): Disconnect electrical har-

ness connector to air supply pump to prevent automatic

height regulation.

When finished, reset ride height using BMW diagnostic

scan tools DIS or

MoDiC.

NOTE-

Airsupply pump is located beneath a cover under the spare

tire in the floor of the cargo compartment.

- If ride height is outside specification listed, install new

springs. Suspension spring removal and installation is cov-

ered in

310 Front Suspension and 330 Rear Suspension.

Normal loaded position

Each front seat 68 kg (150 Ib)

Center of rear seat 68 kg (150 lb)

Trunk 21 kg (46 lb)

Fuel tank full

Page 693 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

- Tighten nut while counterholding adjusting bolt,

- Tighten nut only after car has been lowered to ground and

suspension has settled.

Preparing for alignment

- The following conditions are necessary prior to wheel align-

ment:

Correct wheels and tires are installed, in good condition,

and are at the correct inflation pressures.

All steering and suspension parts and bushings are un-

damaged and show no signs of abnormal wear. Wheel

bearings are in good condition.

Ride height is in accordance with specifications. See

300

Suspension, Steering and Brakes-General.

Car is in normal loaded position. See below.

* Cars with air suspension: Remove air suspension power

fuse.

Normal loaded position

Each front seat

68 Kg (I50 lb)

Center of rear seat

Trunlc

Fuel tank

68 Kg (150 lb)

21 Kg (46 lb)

Full

Alignment specifications tables

In the alignment specification tables that follow, reference is

made to the various types of suspension used in

E39 cars.

The type of suspension can be identified by loolting at the la-

bel on the front strut tube.

Identifying symbol

None

Solid circle

Solid triangle

M5

Circle

Triangle Version

Standard suspension

Sports

suspension

Sports suspension

M sport package

Standard suspension

Sports suspension Model

Sedan

6-cylinder sedan

V-8 sedan

V-8 sedan

Touring (Sport Wagon)

Touring (Sport Wagon)

Page 701 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-5

Rear Suspension

REAR STRUTS AND SPRINGS

(SEDAN MODELS)

Rear strut assembly, removing and

installing

Replace struts and coil springs in pairs only.

- Raise car and remove rear wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

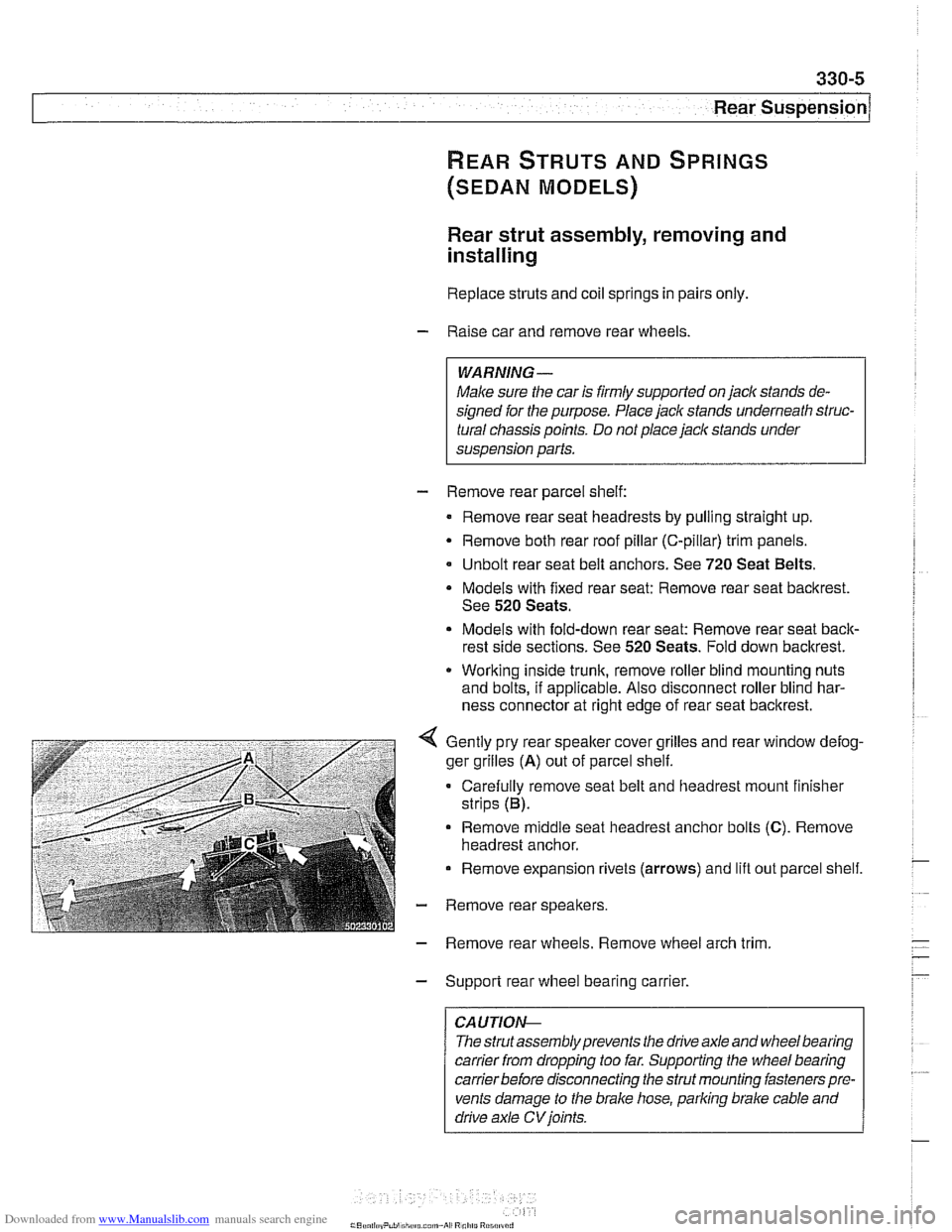

- Remove rear parcel shelf:

Remove rear seat headrests by pulling straight up.

Remove both rear roof pillar (C-pillar) trim panels.

Unbolt rear seat

belt anchors. See 720 Seat Belts.

Models with fixed rear seat: Remove rear seat backrest.

See 520 Seats.

* Models with fold-down rear seat: Remove rear seat back-

rest side sections. See 520 Seats. Fold down backrest.

* Working inside trunk, remove roller blind mounting nuts

and bolts, if applicable. Also disconnect roller blind har-

ness connector at right edge of rear seat backrest.

Gently pry rear speaker cover grilles and rear window defog-

ger grilles

(A) out of parcel shelf.

Carefully remove seat belt and headrest mount finisher

strips (B).

Remove

middle seat headrest anchor bolts (C). Remove

headrest anchor.

Remove expansion rivets (arrows) and lift out parcel shelf.

- Remove rear speakers.

- Remove rear wheels. Remove wheel arch trim

- Support rear wheel bearing carrier.

CAUTION-

The strutassembly prevents the drive axle and wheel bearing

carrier

from dropping too far. Supporting the wheel bearing

carrierbefore disconnecting the strut mounting fasteners pre-

vents damage to the brake hose, parking brake cable and

drive axle

CV joints.

Page 704 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-8

Rear Suspension

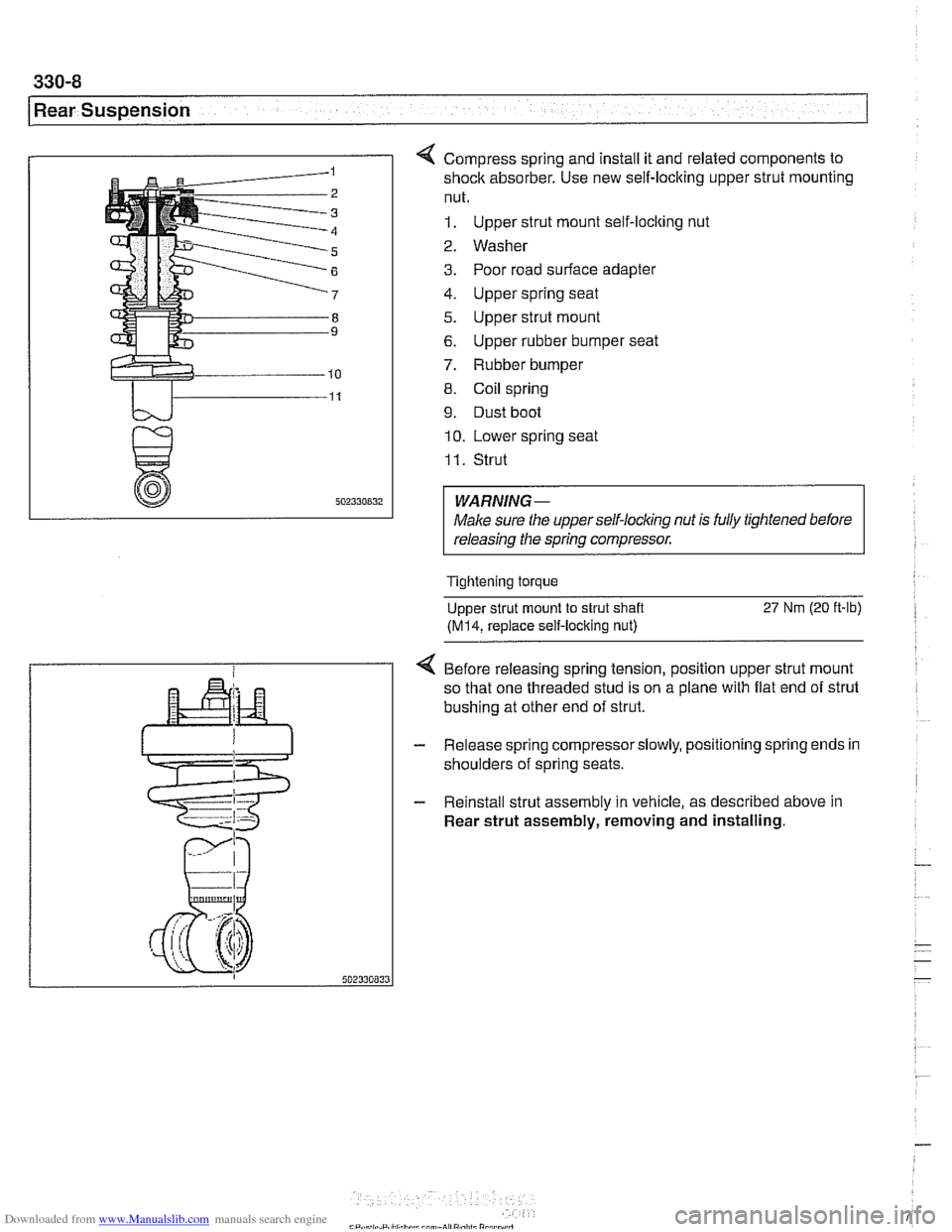

4 Compress spring and install it and related components to

shock absorber. Use new self-locking upper strut mounting

nut.

1. Upper strut mount self-locking nut

2. Washer

3. Poor road surface adapter

4. Upper spring seat

5. Upper strut mount

6. Upper rubber bumper seat

7. Rubber bumper

8. Coil spring

9. Dust boot

10. Lower spring seat

I I. Strut

WARNING-

Male sure the upperself-locking nut is fully tightened before

releasing the spring compressor.

Tightening torque

Upper strut mount to strut shaft

27 Nm (20 ft-lb)

(M14, replace self-locking nut)

4 Before releasing spring tension, position upper strut mount

so that one threaded stud is on a plane with flat end of strut

bushing at other end of strut.

- Release spring compressorslowly, positioning spring ends in

shoulders of spring seats.

- Reinstall strut assembly in vehicle, as described above in

Rear strut assembly, removing and installing.

Page 706 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 0

/Rear Suspension

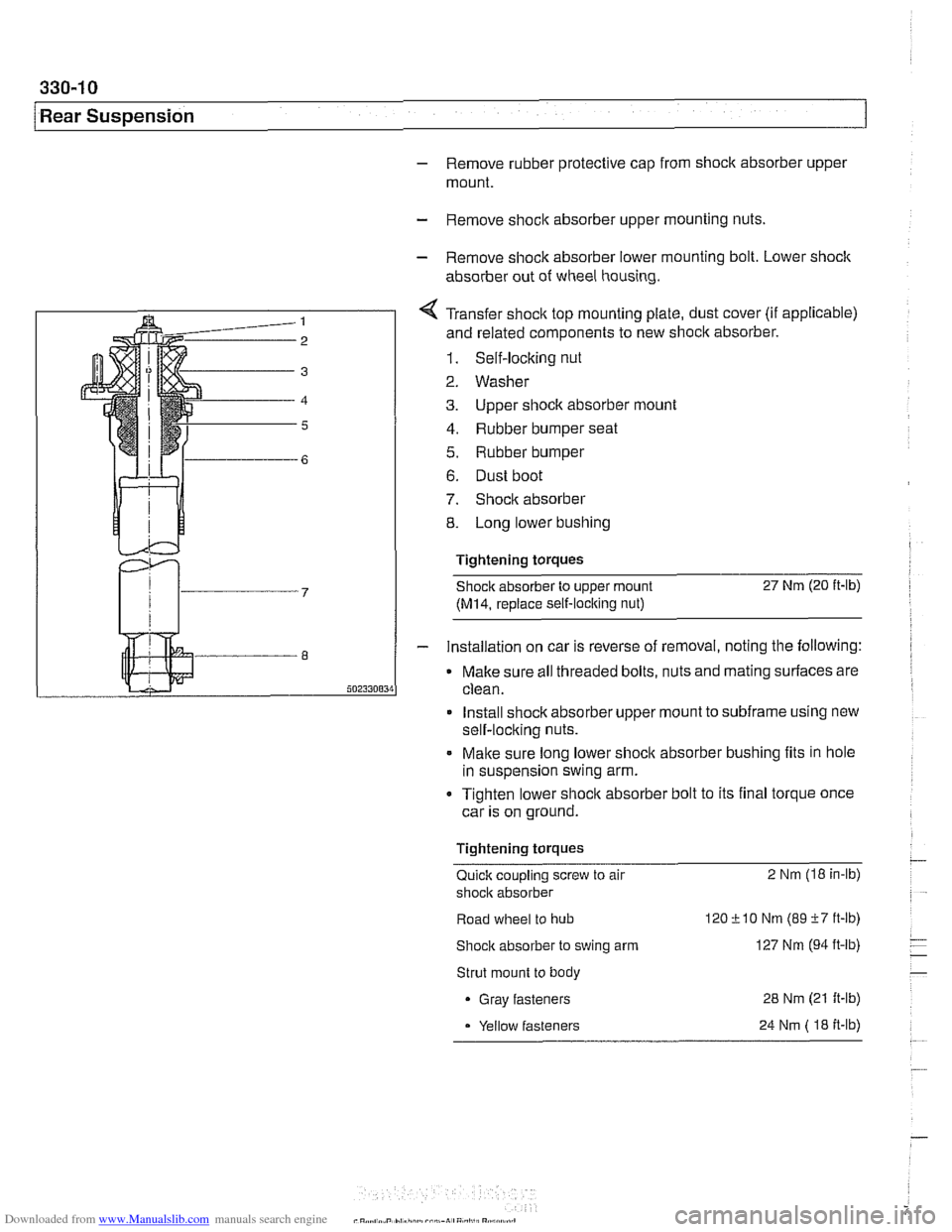

- Remove rubber protective cap from shock absorber upper

mount.

- Remove shock absorber upper mounting nuts.

- Remove shock absorber lower mounting bolt. Lower shock

absorber out of wheel housing.

< Transfer shock top mounting plate, dust cover (if applicable)

and related components to new shoclc absorber.

1. Self-locking nut

2. Washer

3. Upper siioclc absorber mount

4. Rubber bumper seat

5. Rubber bumper

6. Dust boot

7. Shock absorber

8. Long lower bushing

Tightening torques

Shock absorber to upper mount

27 Nm (20 it-lb)

(M14, replace self-locking nut)

- Installation on car is reverse of removal, noting the following:

Make sure all threaded bolts, nuts and mating surfaces are

clean.

Install shock absorber upper mount to

subframe using new

self-locking nuts.

. Make sure long lower shock absorber bushing fits in hole

in suspension swing arm.

Tighten lower shoclc absorber bolt to its final torque once

car is on ground.

Tightening torques

Quick coupling screw to air 2 Nm (18 in-lb)

shock absorber

Road wheel to

hub 120 &I0 Nm (89 -f7 ft-lb)

Shock absorber to swing arm 127 Nm (94 ft-lb)

Strut mount to body

Gray fasteners

Yellow fasteners

24 Nm ( 18 it-lb)

Page 707 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 1

Rear Suspension

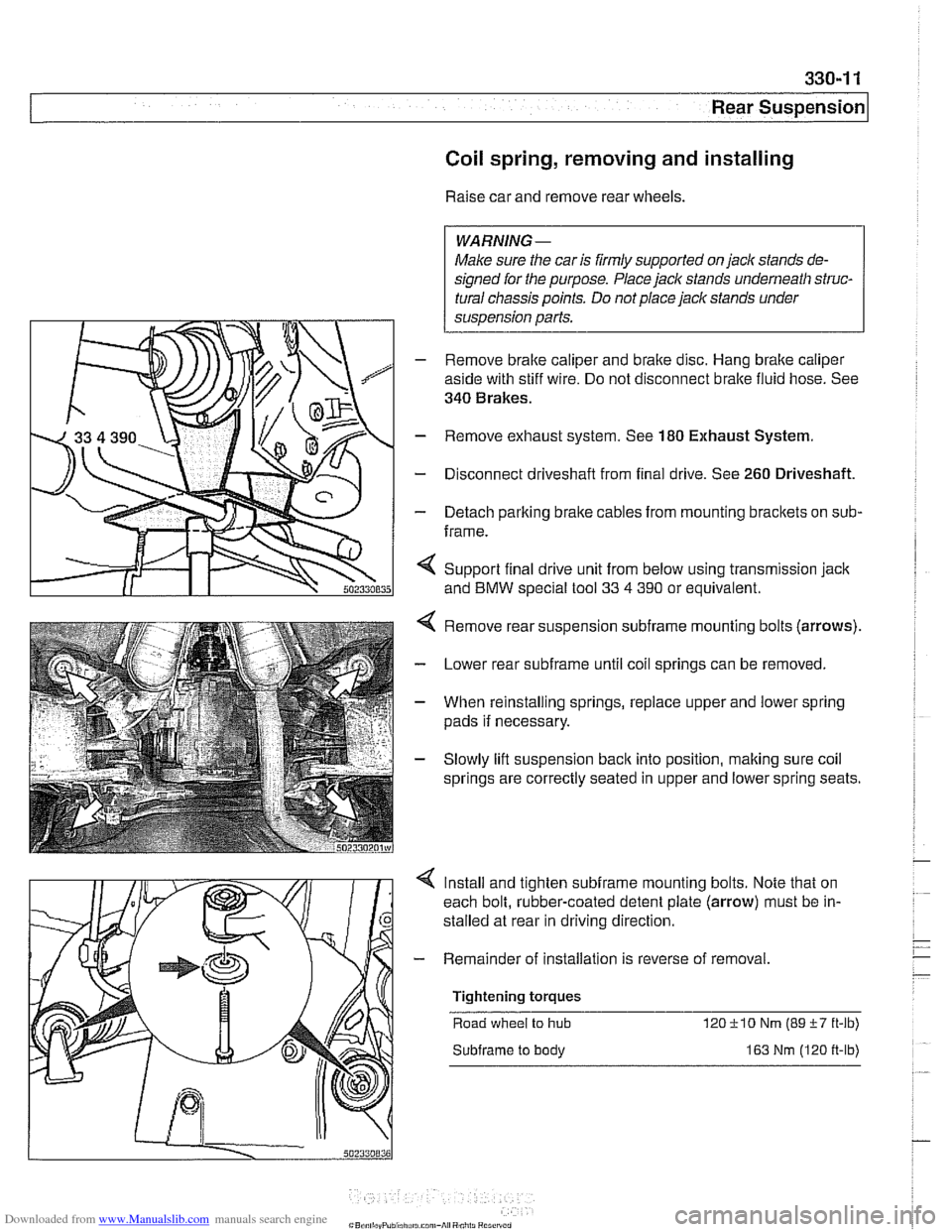

Coil spring, removing and installing

Raise car and remove rear wheels.

WARNING-

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove brake caliper and brake disc. Hang brake caliper

aside with stiff wire. Do not disconnect

bralte fluid hose. See

340 Brakes.

- Remove exhaust system. See 180 Exhaust System.

- Disconnect driveshafl from final drive. See 260 Driveshaft.

- Detach parking bralte cables from mounting bracltets on sub-

frame.

< Support final drive unit from below using transmission jack

and

BMW special tool 33 4 390 or equivalent.

Remove rear suspension

subframe mounting bolts (arrows).

Lower rear

subframe until coil springs can be removed.

When reinstalling springs, replace upper and lower spring

pads if necessary.

Slowly lift suspension

back into position, making sure coil

springs are correctly seated in upper and lower spring seats.

Install and tighten

subframe mounting bolts. Note that on

each bolt, rubber-coated detent plate (arrow) must be in-

stalled at rear in driving direction

- Remainder of installation is reverse of removal

Tightening torques Road wheel

to hub 12OilO Nm (89i-7 ft-lb)

Subframe to body 163 Nm (120 ft-lb)

Page 708 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear Suspension

Air spring, removing and installing

CAUTION-

If vehicle is driven with airspring depressurized, the airspring

will be permanently damaged and must be replaced.

An air spring is made from a flexible rubber material which

forms an airtight cavity. It is pressurized by an air supply

pump activated by an electronic control unit to provide a

vari- . . able spring rate depending on vehicle load

CAUTIOIG

Disable air supply pump by disconnecting electrical plug

before performing any repairs. Pump is located beneath a

cover under the spare tire in the floor of

the cargo compart-

ment.

When removing and installing air connections, extreme

cleanliness must be followed. Small dirt particles can

cause leakage in the system.

Remove luggage compartment floor mat.

- Working above air spring, loosen quick coupling screw con-

nection to allow

air pressure to escape.

- Once pressure has been reduced, retighten screw.

Tightening torque Quick coupling screw

to air pump 2 Nm (18 in-lb)

- Remove quick coupler. Plug openings to keep dirt out,

- Remove air spring mounting clips.

- Raise car and remove rear wheels.

Make sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place

jaclc stands under

suspension parts.

- Working underneath rear suspension, lift wheel bearing car-

rier to relieve rear spring tension. Then unbolt air spring

mounting bolt from seat on wheel bearing carrier. Remove air

spring.

NOTE-

Left and right air springs are different. The left air spring is

marked with a red identification

marl. The right air spring is

marked with a blue identification mark.

Page 709 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-1 3

Rear Suspension

1 1 4 Check roll fold of air spring (arrows). Reinstall only if roll fold

is undamaged and formed correctly.

- To install air spring:

Check sealing O-rings at air spring inlet. Replace

if dam-

aged. Do not grease O-rings. Reinstall protective plug.

* Install spring above suspension subframe. Make sure ec-

centric lug at bottom of air spring fits in recess of

subframe

spring seat.

Reattach top spring mounting clips.

- Reattach air line connections.

- Remainder of installation is reverse of removal.

Tightening torques

Air line connection

2 Nm (1 8 in-lb)

Air spring

to wheel bearing carrier 20 Nm (1 5 ft-lb)

Road

wheel to hub 120 510 Nm (89-F-7 ft-lb)

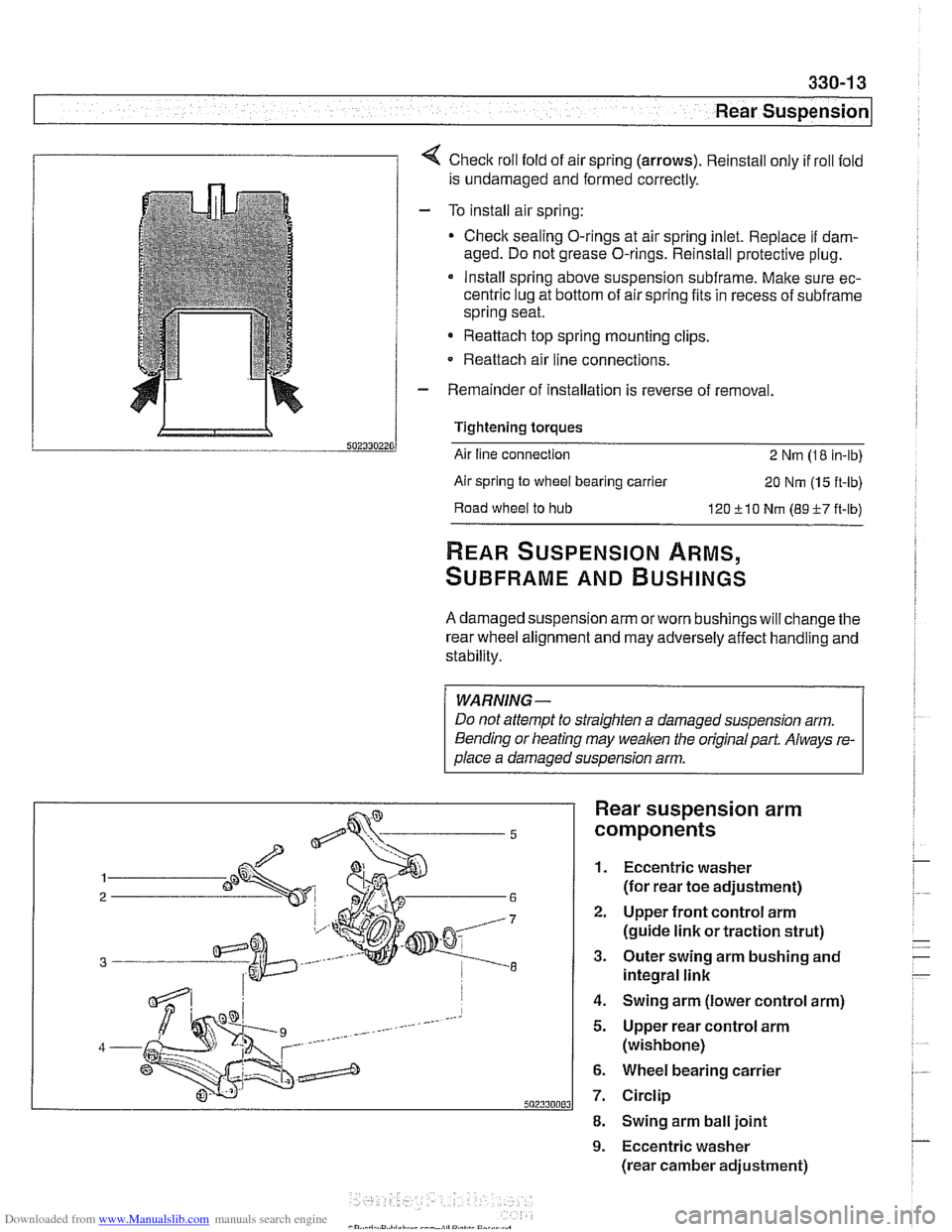

REAR SUSPENSION ARMS,

SUBFRAME AND BUSHINGS

A damaged suspension arm orworn bushings will change the

rear wheel alignment and may adversely affect handling and

stability.

WARNING-

Do not attempt to straighten a damaged suspension arm.

Bending or heating may

weaken the original part. Always re-

olace a damaoed susoension arm.

Rear suspension arm

components

1. Eccentric washer

(for rear toe adjustment)

2. Upper front control arm

(guide link or traction strut)

3. Outer swing arm bushing and

integral link

4. Swing arm (lower control arm)

5. Upper rear control arm

(wishbone)

6. Wheel bearing carrier

7. Circlip

8. Swing arm ball joint

9. Eccentric washer

(rear camber adjustment)

Page 713 of 1002

Downloaded from www.Manualslib.com manuals search engine

Rear ~us~ensionl

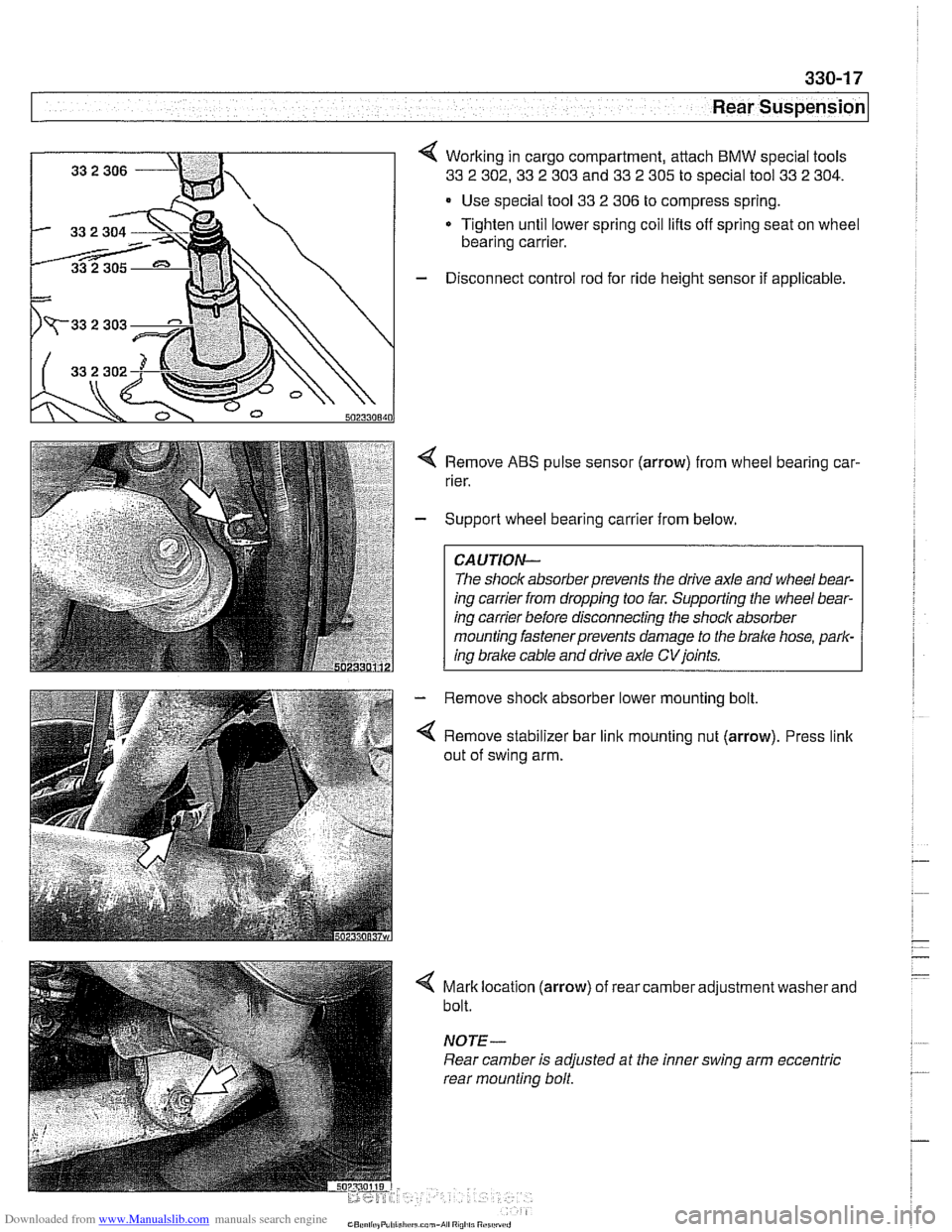

Working in cargo compartment, attach BMW special tools

33 2 302,33 2 303 and 33 2 305 to special tool 33 2 304.

Use special tool 33 2 306 to compress spring.

Tighten until lower spring coil lifts off spring seat on wheel

bearing carrier.

- Disconnect control rod for ride height sensor if applicable.

4 Remove ABS pulse sensor (arrow) from wheel bearing car-

rier.

- Support wheel bearing carrier from below.

CAUTION-

The shock absorberprevents the drive axle and wheel bear-

ing carrier from dropping too far. Supporting the wheel bear-

ing carrier before disconnecting the shock absorber

mounting fastenerprevents damage to the

brake hose, park-

ing brake cable and drive axle

CVjoints.

- Remove shock absorber lower mounting bolt

4 Remove stabilizer bar link mounting nut (arrow). Press link

out of swing arm.

4 Mark location (arrow) of rear camber adjustment washer and

bolt.

NOTE -

Rear camber is adjusted at the inner swing arm eccentric

rear mounting bolt.