Seat BMW 525i 2001 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 161 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-67

Cylinder Head Removal and lnstaKI --

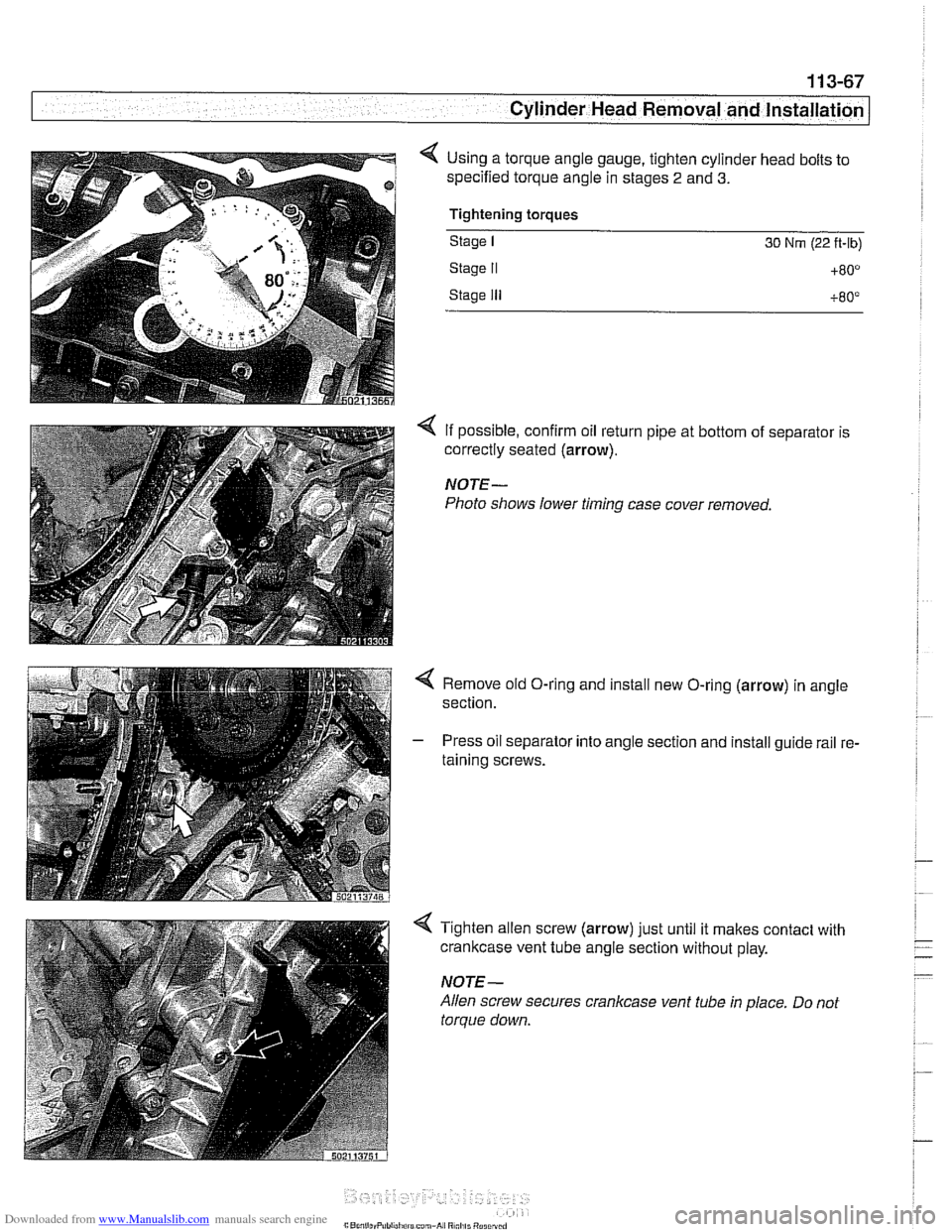

< Using a torque angle gauge, tighten cylinder head bolts to

specified torque angle in stages

2 and 3.

Tightening torques

Stage I 30 Nrn (22 ft-lb)

Stage II +80°

Stage Ill +80°

4 If possible, confirm oil return pipe at bottom of separator is

correctly seated

(arrow).

NOTE-

Photo shows lower timing case cover removed.

< Remove old O-ring and install new O-ring (arrow) in angle

section.

- Press oil separator into angle section and install guide rail re-

taining screws.

4 Tighten allen screw (arrow) just until it makes contact with

crankcase vent tube angle section without play.

NOTE-

Allen screw secures crankcase vent tube in place. Do not

torque down.

Page 165 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." . .

I - Cylinder Head Removal - and instard --

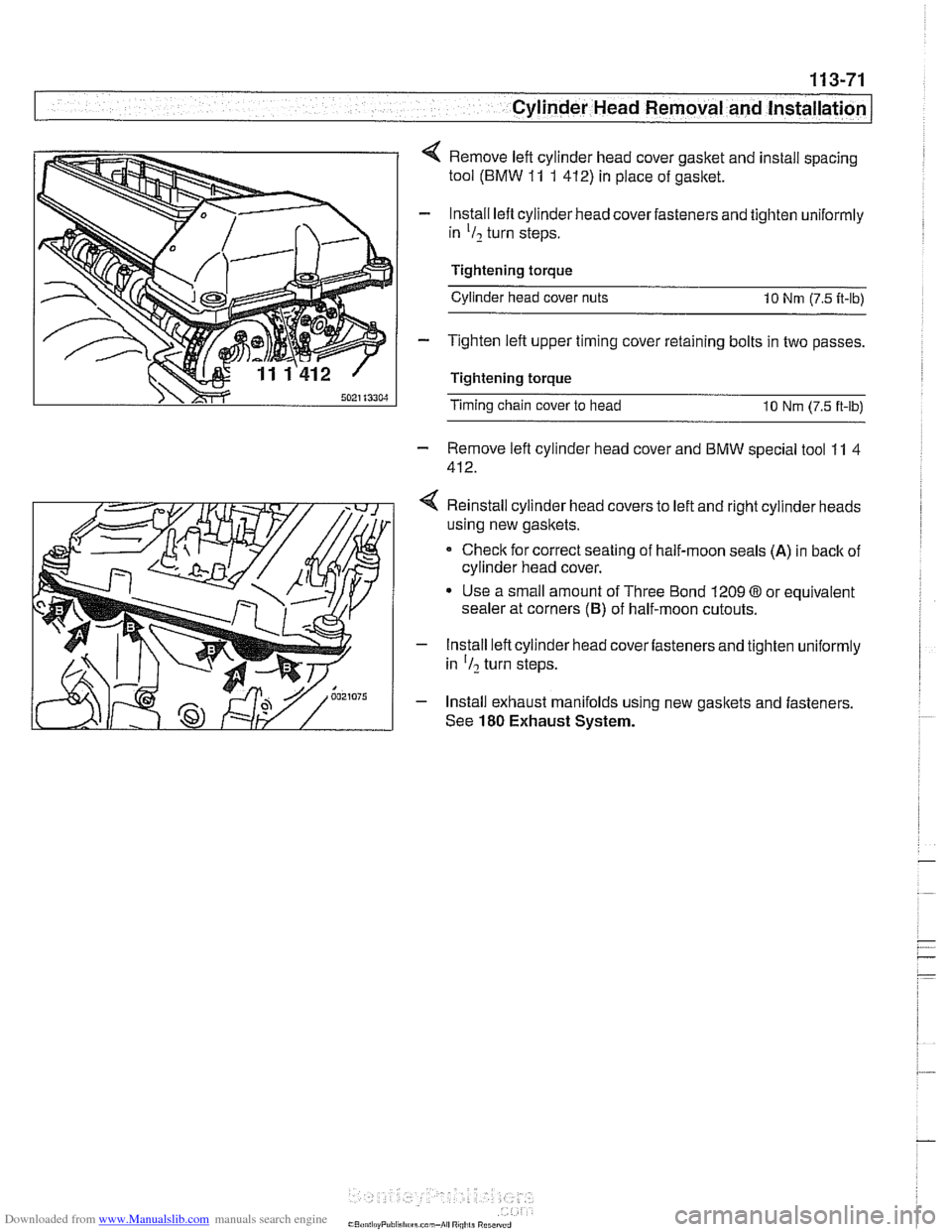

4 Remove left cylinder head cover gasket and install spacing

tool (BMW

11 1 412) in place of gasket.

- lnstall lefl cylinder head cover fasteners and tighten uniformly

in

'I2 turn steps.

Tightening torque Cylinder head cover nuts

10 Nrn (7.5 it-lb)

- Tighten left upper timing cover retaining bolts in two passes.

Tightening torque

Timing chain cover to head 10 Nrn (7.5 ft-lb)

- Remove lefl cylinder head cover and BMW special tool 11 4

412.

4 Reinstall cylinder head covers to left and right cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

03 or equivalent

sealer at corners

(6) of half-moon cutouts.

- Install left cylinder head cover fasteners and tighten uniformly

in

'I? turn steps.

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.

Page 176 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 13-82

1 Cylinder Head Removal and Installation

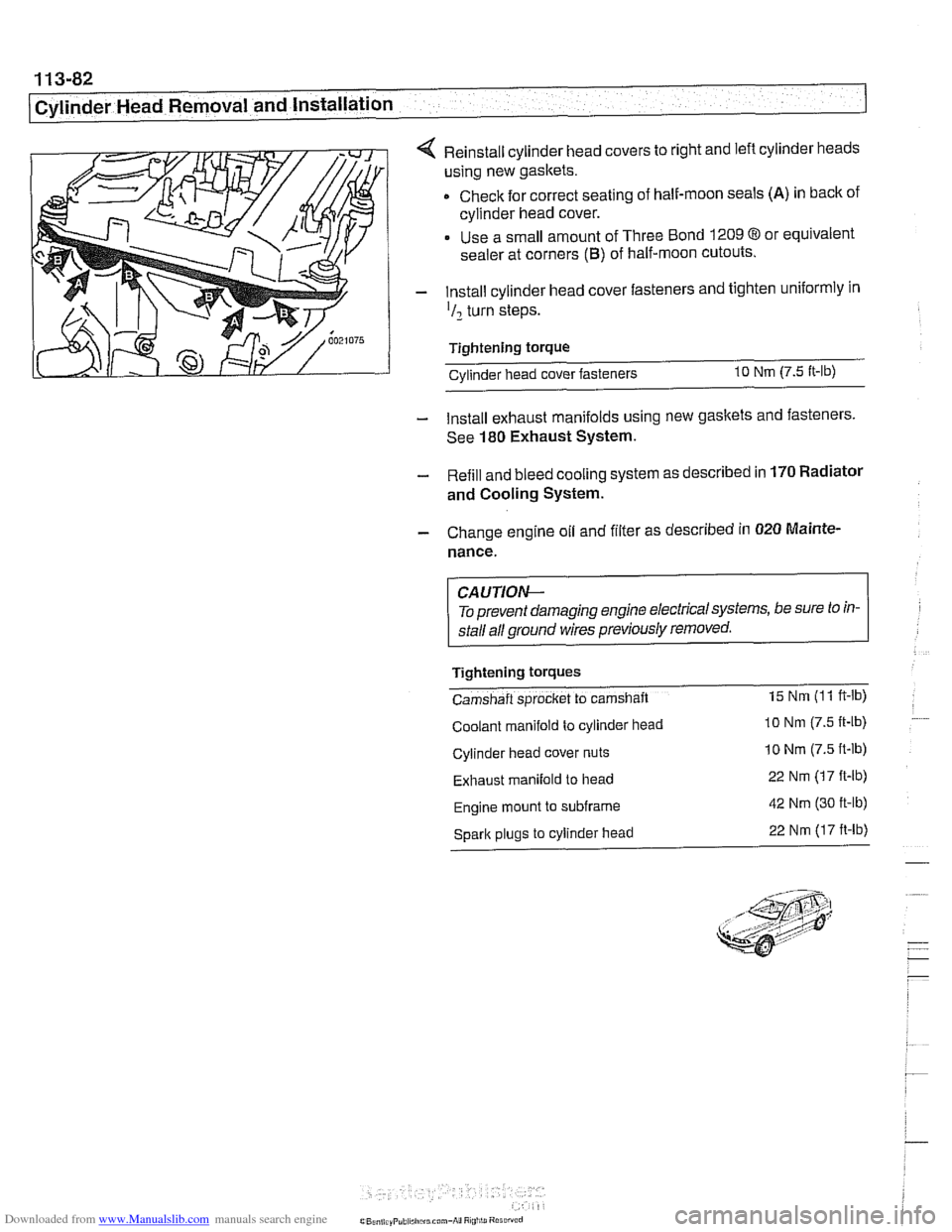

4 Reinstall cylinder head covers to right and left cylinder heads

using new gaskets.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealer at corners

(B) of half-moon cutouts.

- Install cylinder head cover fasteners and tighten uniformly in

'I2 turn steps.

Tightening torque Cvlinder head cover fasteners

10 Nm (7.5 It-lb)

- Install exhaust manifolds using new gaskets and fasteners.

See

180 Exhaust System.

- Refill and bleed cooling system as described in 170 Radiator

and Cooling System.

- Change engine oil and filter as described in 020 Mainte.

nance.

CA UTIOW-

To prevent damaging engine electricalsystems, be sure to in-

stall all ground wires previously removed.

Tightening

tOrqUeS

Camshaft sprocket to camshaft 15 Nm (1 1 ft-lb)

Coolant manifold to cylinder head lo Nm (7.5 It-lb)

Cylinder head cover nuts 10 Nm (7.5 ft-lb)

Exhaust manifold to head 22 Nm (17 ft-lb)

Engine mount to subframe 42 Nm (30 ft-lb)

Spark plugs to cylinder head 22 Nm (17 ft-lb)

Page 177 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6 Cylinder Head and Valvetrain

........................... General ............................ 1 16-2 Valves 116-56

.................... Special Tools ........................ 11 6-2 Valves. leak test 11 6-56

......... Valves. removing and installing 11 6-56 Cylinder Head ..................... .I1 6.5 ....................... Valve guides 11 6-57

Valves. leak test ...................... 11 6-6

Valve stem oil seals .................. 11 6-58 ...... ..""""."""ll 6.6 Valveseats ........................ 116-59 Hydraulic lifters, checking and replacing .. .I1 6-7 Valve ....................... 6-60 . .

Camshaft andLifter Removal

and Installation

.................... 11 6-1 1

Camshaft and lifter removal and

installation

(M52 engine) ............. .I1 6.12

Camshaft and lifter. removal and

installation (M52

TU and M54 engine) .... 11 6-1 9

Double VANOS timing chain components

. 11 6-28

Camshaft removal and installation

(M62 engine)

....................... 11 6-39

Page 181 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-5

I Cylinder Head and valvetrain1

4 Timing chain tensioner bracket (V-8)

(Tool No. BMW

11 7 380)

CYLINDER HEAD

This section provides the specifications and special recondi-

tioning information necessary to repair the cylinder heads

covered by this manual.

The disassembled cylinder head should be inspected for

warpage and cracks. Check the valve guides and valve seats

for wear before machining a warped head. Always decarbon-

ize and clean the head before inspecting it.

Visually inspect the cylinder head for craclts.

If a cracked cyl-

inder head is suspected and no

craclts are detected through

the visual Inspection, have the head further tested for cracks

by an authorized BMW dealer or an ASE certified machinist.

A cracked cylinder head must be replaced.

NOJE-

When disassembling and inspecting the cylinder head, be

sure to

checlc the camshaft carrier bearing surfaces using a

straight edge for

warpage, and check the lifter bores for wear.

A high-quality straight edge can be used to

checlc for

warpage. A warpage of 0.05 mm (0.002 in.) is acceptable

without machining. A warped cylinder head can be machined

provided no more than 0.3

mm (0.012 in.) of material is re-

moved.

If further machining is required, the head should be

replaced. Removing more than this amount will reduce the

size of the combustion chamber and adversely affect engine

performance. A 0.3 mm

thicker head gasket for machined

heads is available from an authorized BMW parts depart-

ment.

Page 187 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

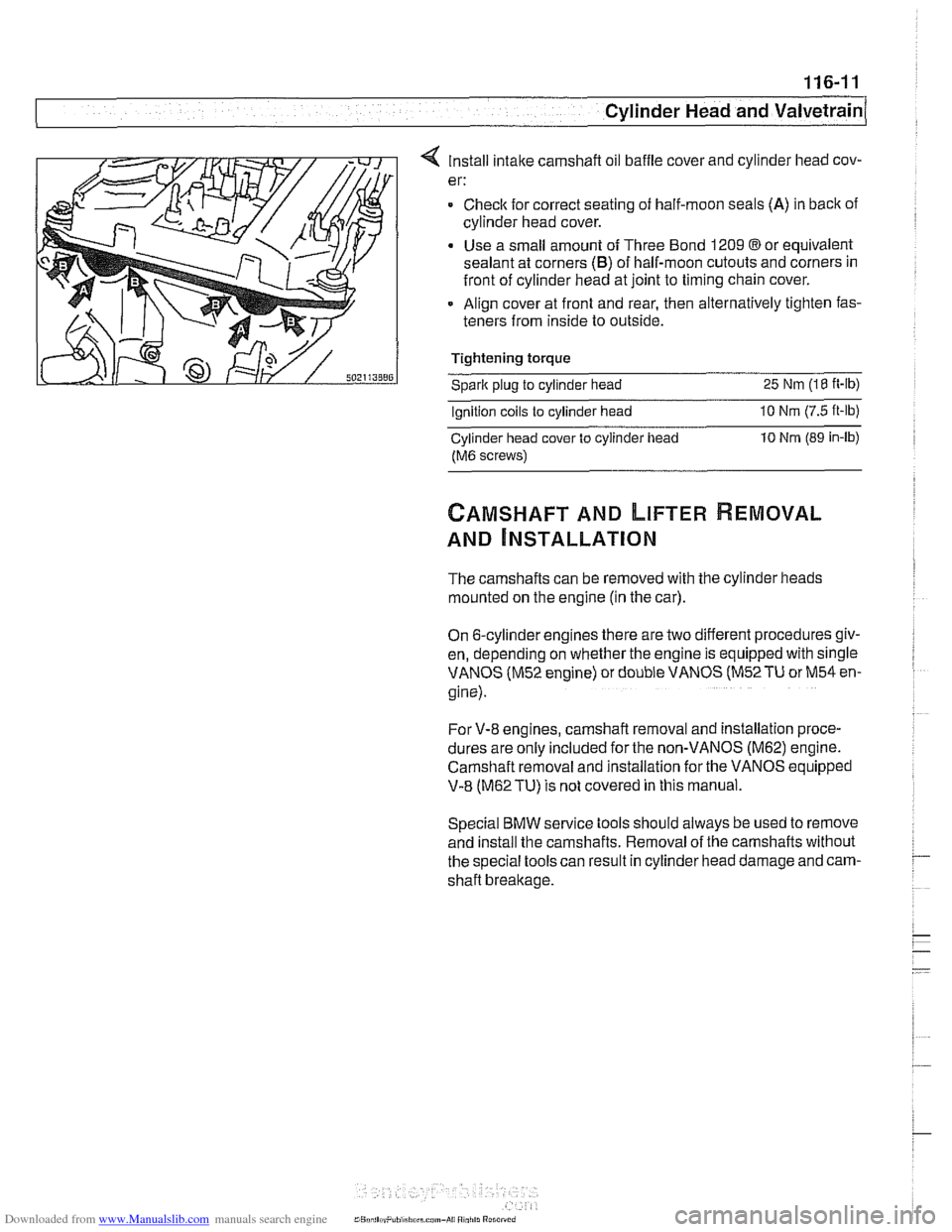

4 Install intake camshaft oil baffle cover and cylinder head cov-

er:

= Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

@or equivalent

sealant at corners

(B) of half-moon cutouts and corners in

front of cylinder head at joint to timing chain cover.

Align cover at front and rear, then alternatively tighten fas-

teners from inside to outside.

Tightening torque

Sparic plug to cylinder head 25 Nm (18 it-lb)

Ignition coils to cylinder head 10 Nrn (7.5 ft-lb)

Cylinder head cover to cylinder iiead 10 Nrn (89 in-lb)

fM6 screws)

CAMSHAFT AND LIFTER REMOVAL

AND ~NSTALLATION

The camshafts can be removed with the cylinder heads

mounted on the engine (in the car).

On 6-cylinder engines there are two different procedures giv-

en, depending on whether the engine is equipped with single

VANOS (M52 engine) or double VANOS

(M52TU or M54 en-

gine).

For V-8 engines, camshaft removal and installation proce-

dures are

only included for the non-VANOS (M62) engine.

Camshaft removal and installation for the

VANOS eq;ipped

V-8 (M62TU) is not covered in this manual.

Special BMW service tools should always be used to remove

and install the camshafts. Removal of the camshafts without

the special tools can result in cylinder head damage and cam-

shaft breakage.

Page 205 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Cylinder Head and valvetrain1

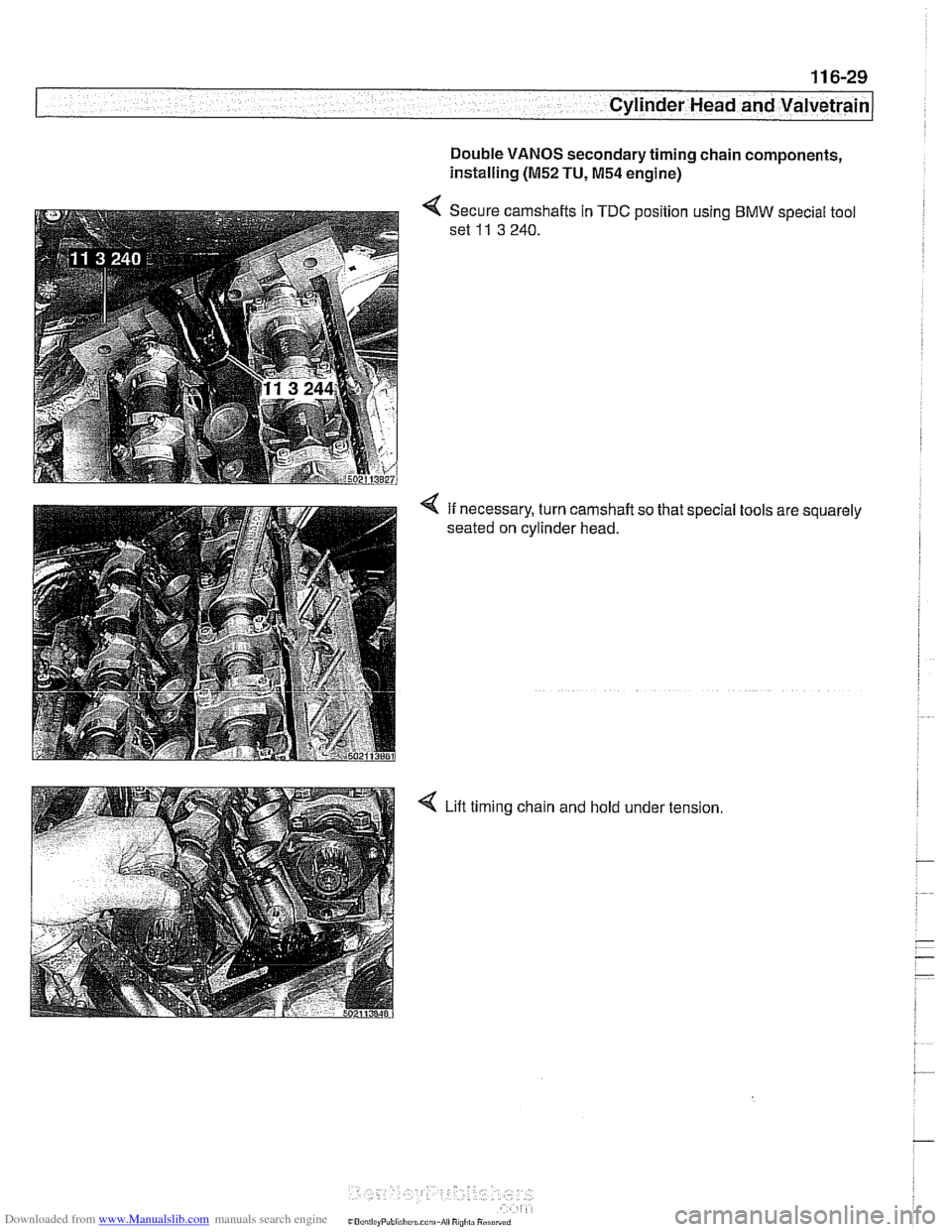

Double VANOS secondary timing chain components,

installing

(M52 TU, M54 engine)

< Secure camshafts in TDC position using BMW special tool

set

11 3 240.

4 If necessary, turn camshaft so that special tools are squarely

seated on cylinder head.

4 Lift timing chain and hold under tension

Page 214 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Cylinder Head and Valvetrain

- Remove adjustable primary timing chain tensioner tool and

reinstall primary chain tensioner cylinder to cylinder head.

Tightening torque

Primary chain tensioner cylinder

to 70 Nm (52 ft-lb)

cylinder head

- Remove flywheel locking tool from crankcase. Replace spe-

cial tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

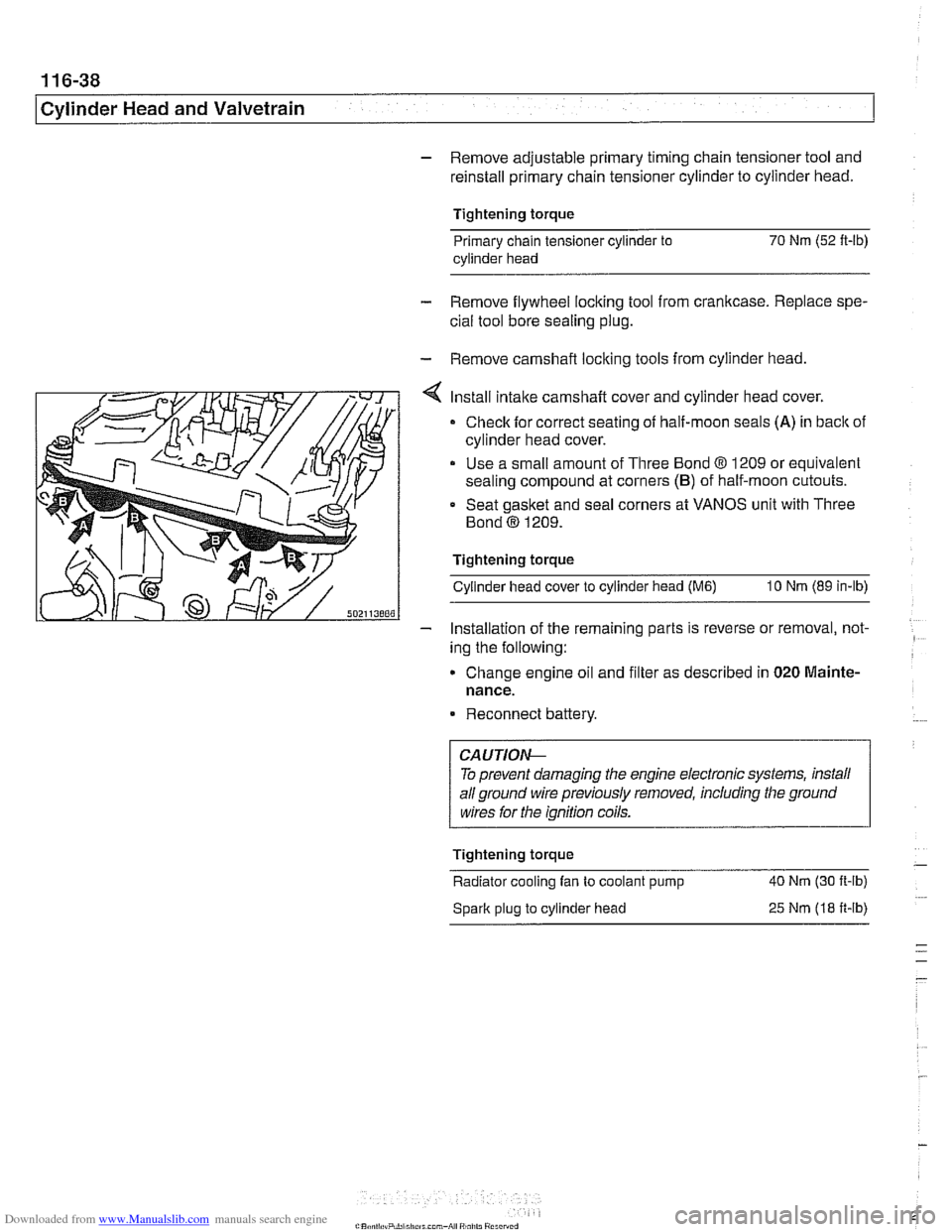

Install intake camshaft cover and cylinder head cover.

Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

8 1209 or equivalent

sealing compound at corners

(B) of half-moon cutouts.

Seat gasket and seal corners at VANOS unit with Three

Bond

@ 1209.

Tightening torque Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

- Installation of the remaininq parts is reverse or removal, not- -

ing the following:

Change engine

011 and f~lter as descr~bed in 020 Mainte-

nance.

Reconnect battery.

To prevent damaging the engine electronic systems, install

all ground wire previously removed, including the ground

wires for the ignition coils.

Tightening torque

-

Radiator cooling fan to coolant pump 40 Nm

(30 ft-ib)

Spark plug to cylinder head

25 Nm (18 ft-ib)

Page 232 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 16-56

Cylinder Head and Valvetrain

This section covers valve removal and reconditioning, includ-

ing valve guides, seats, springs, and valve stem oil seals.

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes,

check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Valves, removing and installing

- Remove cylinder head as described in 113 Cylinder Head

Removal and Installation.

CAUTIOI\C

(M52 TU/M54 engines only) Do not let the hydraulic lifters

fall out as the camshaft carrier is removed. Special suction

cups are available from

BMW to hold the hydraulic lifters in

place during carrier removal.

* Hydraulic cam lifters should be stored m an uprfght po-

sition. If necessary, use a magnetic tool to

aidin remov-

al of the lifters.

- Remove valves using a valve spring compressor.

CAUTIOI\C

Label each valve assembly as it is removed so it can be in-

stalled in its original position.

-

- Remove and discard valve stem oil seals from valve guides.

See Valve stem oil seals later in this section.

- Valve installation is reverse of removal. Remove carbon de- - -

posits from the valves using a wire brush or wire wheel. -

-

Valve specifications are listed in Table c. Valve specifica-

tions.

Page 234 of 1002

Downloaded from www.Manualslib.com manuals search engine

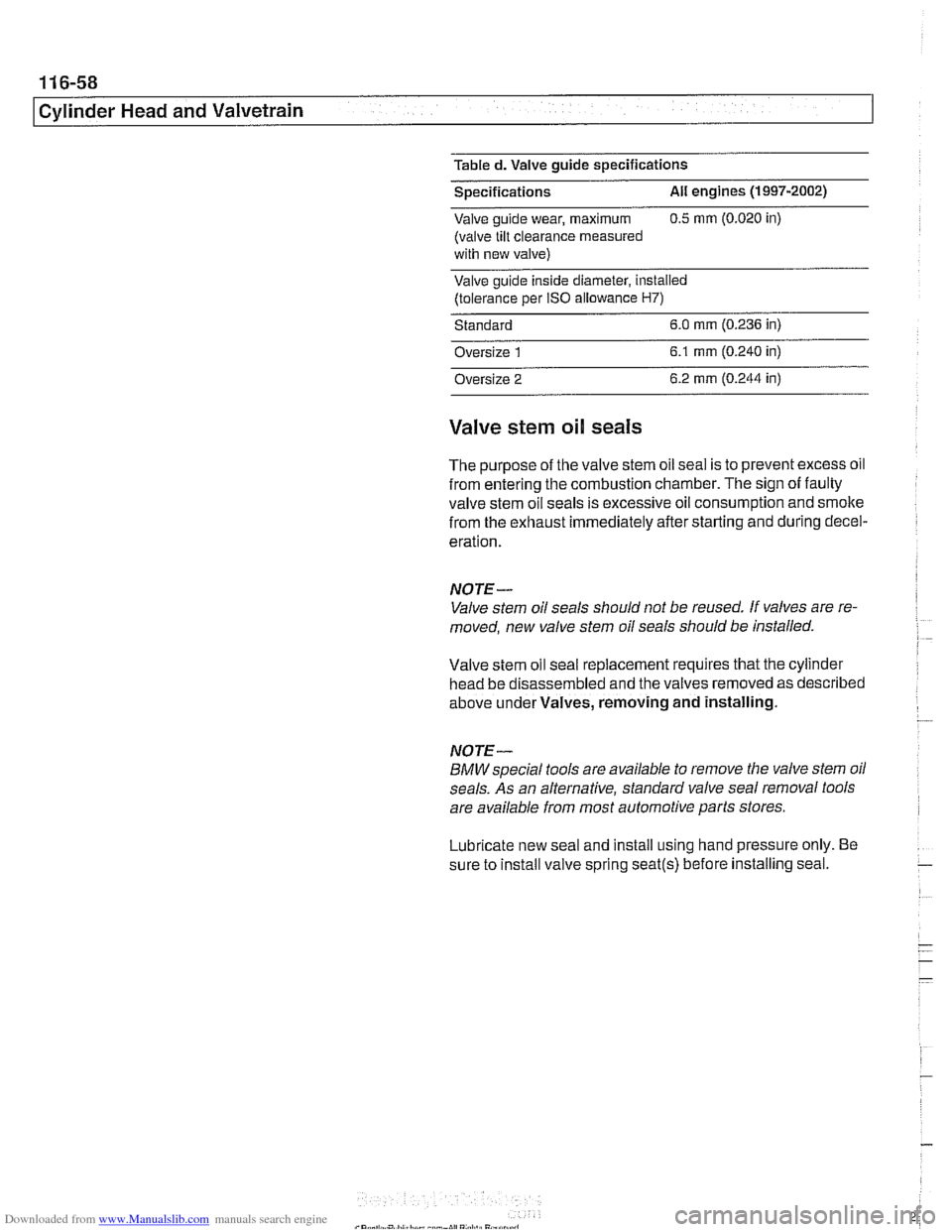

Table d. Valve guide specifications

Specifications

All engines (1997-2002)

Valve guide wear, maximum 0.5 mrn (0.020 in)

(valve tilt clearance

measured

with new valve)

Valve guide inside diameter,

installed

(tolerance per IS0 allowance H7)

Standard 6.0 mm (0.236 in)

Oversize

1 6.1 mrn (0.240 in)

Oversize 2 6.2

mm (0.244 in)

Valve stem oil seals

The purpose of the valve stem oil seal is to prevent excess oil

from entering the combustion chamber. The sign of faulty

valve stem oil seals is excessive oil consumption and smoke

from the exhaust immediately after starting and during decel-

eration.

NOTE-

Valve stem oil seals should not be reused. If valves are re-

moved, new valve stem oil seals should be installed.

Valve stem oil seal replacement requires that the cylinder

head be disassembled and the valves removed as described

above under Valves, removing and installing.

NOTE-

BMW special tools are available to remove the valve stem oil

seals. As an alternative, standard valve seal removal tools

are available from most automotive parts stores.

Lubricate new seal and install using hand pressure only. Be

sure to install valve spring

seat(s) before installing seal.