Seat BMW 525i 2001 E39 Service Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 560 of 1002

Downloaded from www.Manualslib.com manuals search engine

21 0-1 8

Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- Install SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques Clutch to flywheel

- M8 (8.8 grade)

MB 110.9 orade)

24 Nm (1 8 it-lb)

34 Nm (25

ft-lb)

Use 14 mm Allen wrench to unscrew (clocltwise or counter-

clockwise) lock plate in center of pressure plate.

NOTE-

The spring lockplate may make snapping noises while being

unscrewed.

Using large bolt, pull out clutch centering tool

Remove flywheel locking tool

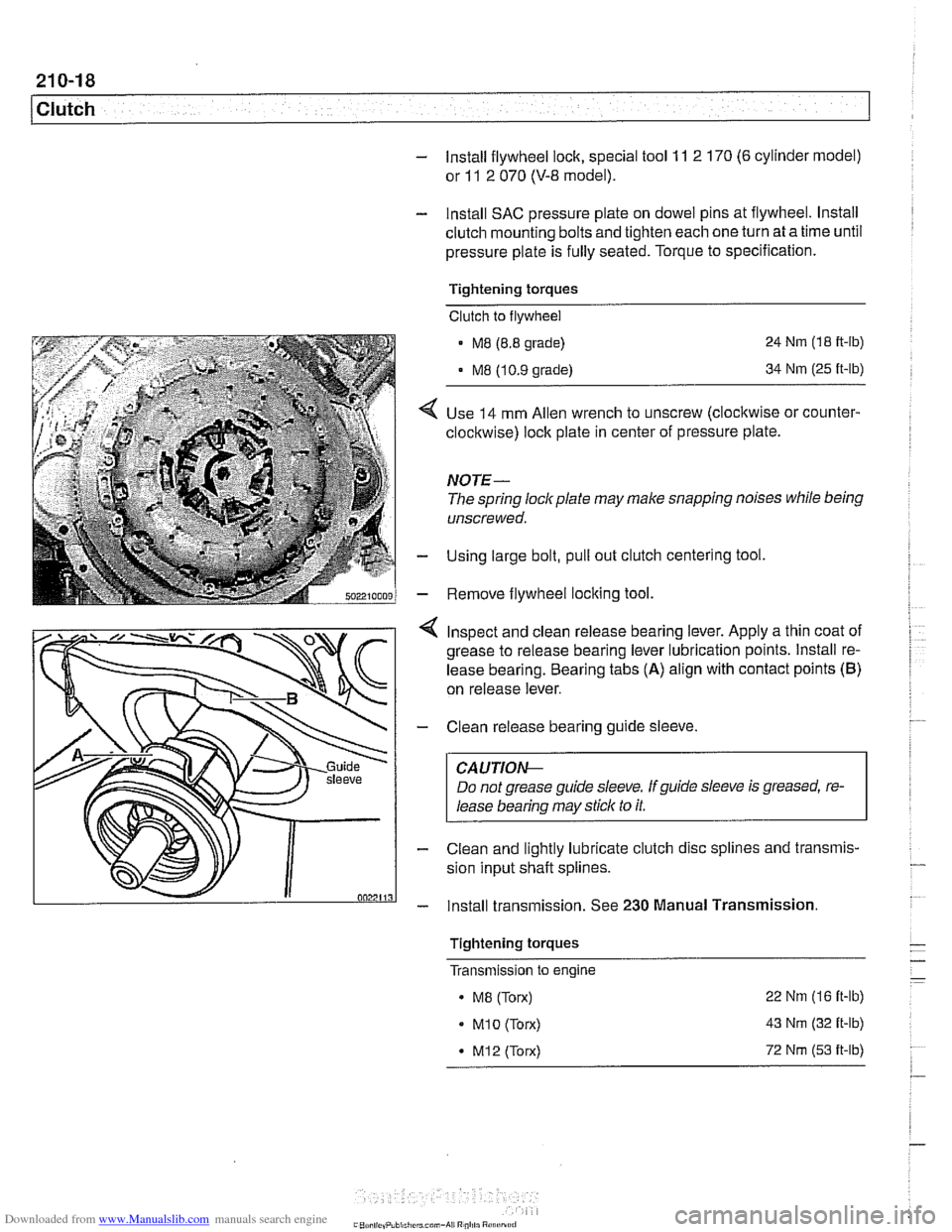

4 Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CAUTIOG

Do not grease guide sleeve. Ifguide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- lnstall transmission. See 230 Manual Transmission.

Tightening torques

- - - Transmlsslon to engine -

. MB (Torx) 22

Nm (16 it-lb)

MI0 (Torx) 43 Nm (32 it-lb)

* M12 (Torx) 72 Nm (53 it-lb)

.-

Page 562 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Clutch

- lnstall flywheel lock, special tool 11 2 170 (6 cylinder model)

or

11 2 070 (V-8 model).

- lnstall SAC pressure plate on dowel pins at flywheel. lnstall

clutch mounting bolts and tighten each one turn at a time until

pressure plate is fully seated. Torque to specification.

Tightening torques

Clutch to flywheel

- M8 (8.8 grade)

M8 (10.9 grade) 24

Nm (18

ft-ib)

34

Nm (25 ft-lb)

- Slip out clutch centering tool using large bolt.

- Remove flywheel locking tool.

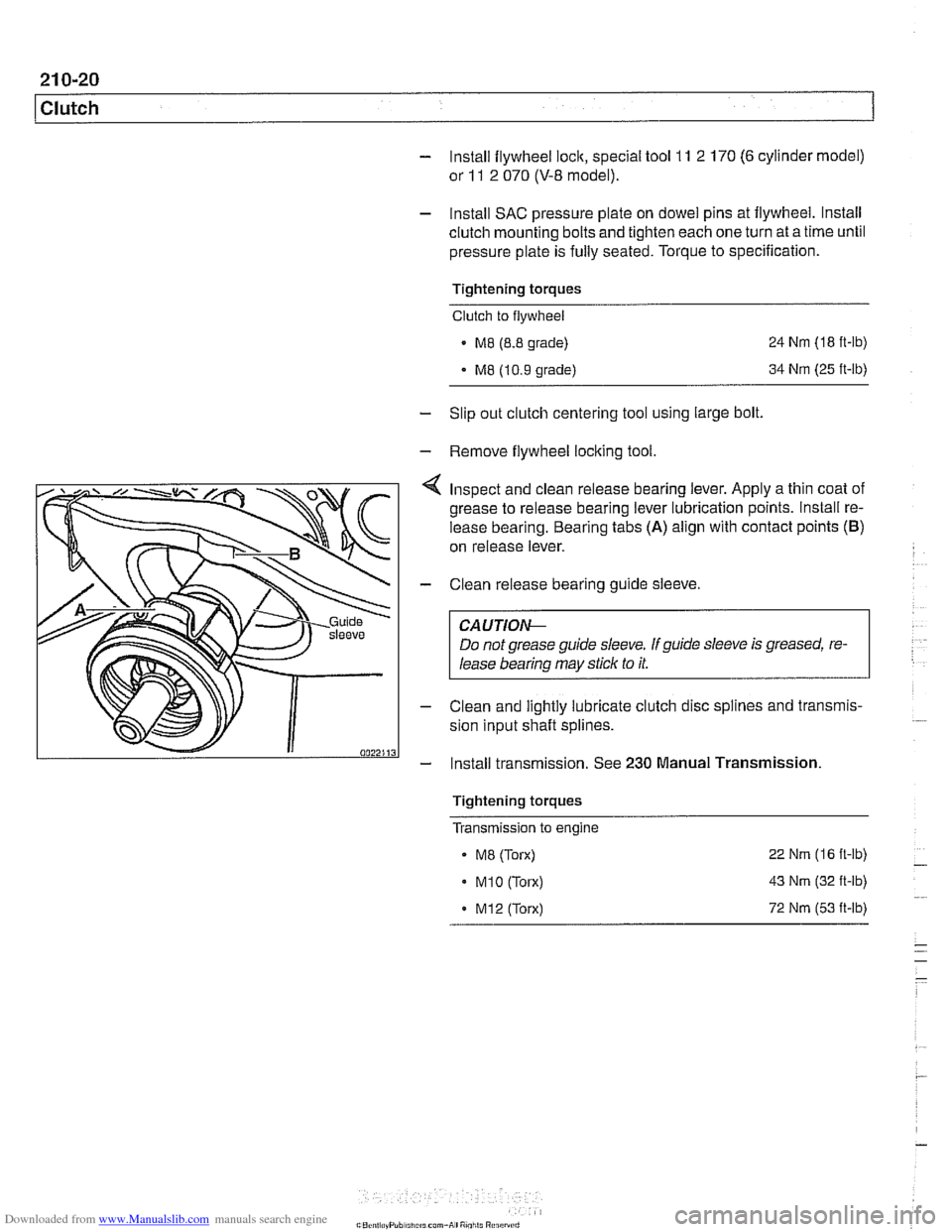

Inspect and clean release bearing lever. Apply a thin coat of

grease to release bearing lever lubrication points. lnstall re-

lease bearing. Bearing tabs

(A) align with contact points (B)

on release lever.

- Clean release bearing guide sleeve.

CA U TIOG

Do not grease guide sleeve. If guide sleeve is greased, re-

lease bearing may stick to it.

- Clean and lightly lubricate clutch disc splines and transmis-

sion input shaft splines.

- Install transmission. See 230 Manual Transmission

Tightening torques

Transmission to engine

- ME (Torx)

. M1O (Torx)

. M12 (Torx) 22

Nm (16 ft-lb)

43

Nm (32 ft-lb)

72

Nm (53 it-lb)

Page 579 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

Input shaft seal, replacing

(transmission removed)

- Remove transmission from vehicle as described later in this

group.

- Remove clutch release bearing end release bearing lever

from inside bellhousing.

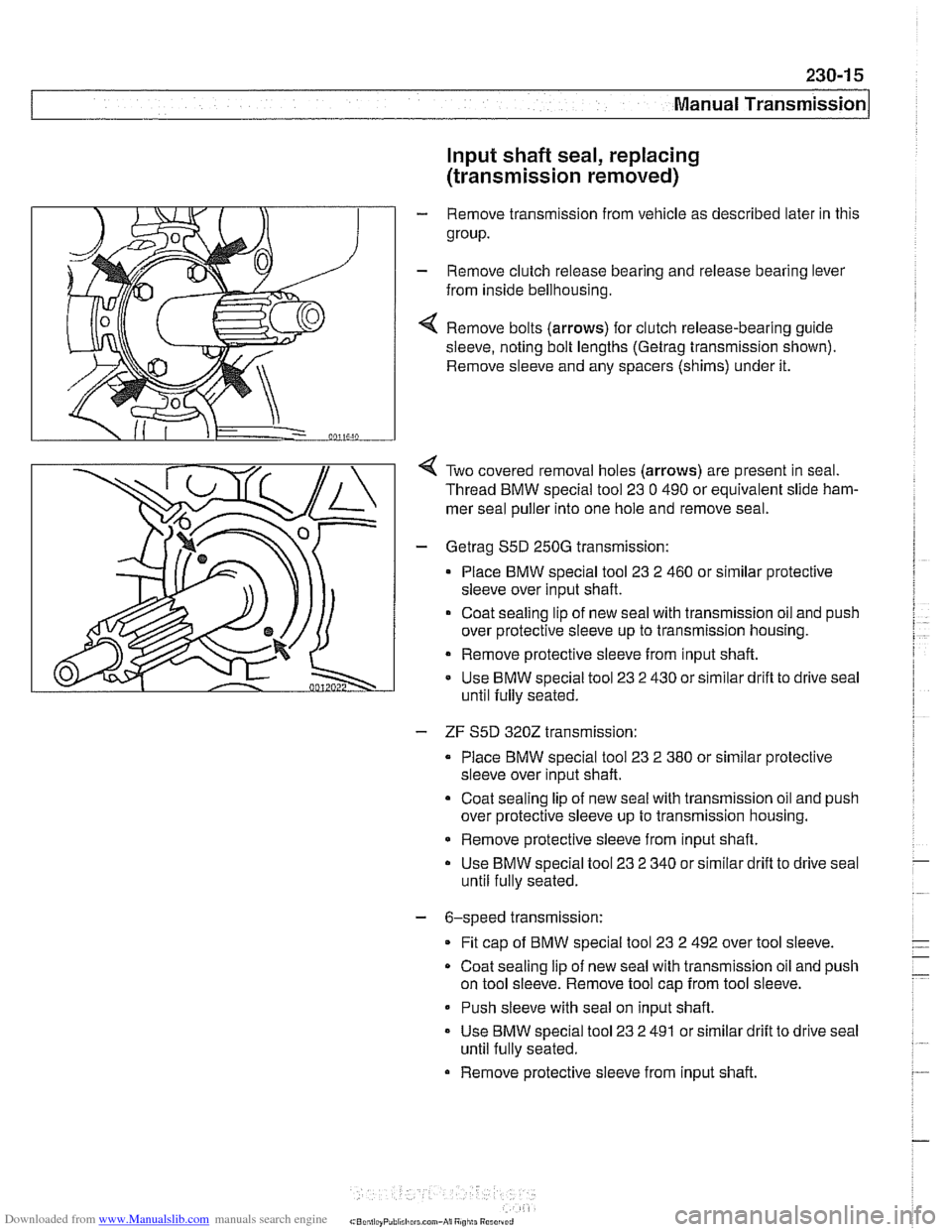

4 Remove bolts (arrows) for clutch release-bearing guide

sleeve, noting bolt lengths

(Getrag trensmission shown).

Remove sleeve and any spacers (shims) under it.

Two covered removal holes (arrows) are present in seal.

Thread BMW special tool

23 0 490 or equivalent slide ham-

mer seal puller into one hole and remove seal.

- Getreg S5D 250G transmission:

Place BMW special tool

23 2 460 or similar protective

sleeve over input shaft.

Coat sealing lip of new

seel with trensmission oil and push

over protective sleeve up to transmission housing.

Remove protective sleeve from input shaft.

Use BMW special tool

23 2 430 or similar drifl to drive seal

until fully seated.

- ZF S5D 3202 transmission:

Place BMW special tool

23 2 380 or similar protective

sleeve over input shaft.

Coat sealing lip of new seal with transmission oil and push

over protective sleeve up to transmission housing.

* Remove protective sleeve from input shaft.

Use BMW special tool

23 2 340 or similar drift to drive seal

until fully seated.

- 6-speed transmission:

Fit

cap of BMW special tool 23 2 492 over tool sleeve.

Coat sealing

lip of new seal with transmission oil and push

on tool sleeve. Remove tool cap from tool sleeve.

- Push sleeve with seal on input shaft.

- Use BMW special tool 23 2 491 or similar drift to drive seel

until fully seated.

Remove protective sleeve from input shaft.

Page 597 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 3

Automatic ~ransmissionl

- Blow out oil cooler lines with low-pressure compressed air

and flush cooler with clean ATF twice before reattaching lines

to transmission.

CA UTIOG

Wear safety glasses when worling with compressed air:

@ Do not reuse ATF used for flushing.

- Remainder of installation is reverse of removal, noting the fol-

lowing:

Reinstall driveshafl using new nuts.

Install new sealing washers on transmission cooling line

banjo bolts.

Install new O-rings on transmission cooler lines, where

applicable.

Inspect engine drive plate (flywheel) for cracks or elongat-

ed holes. Replace

if necessary.

Be sure bellhousing alignment dowel sleeves are located

correctly. Replace damaged sleeves.

Checlc to be sure torque converter is seated correctly in

transmission during final installation.

Use

BMW special tool 24 2 300 to align three mounting

tabs on torque converter with indentations on drive plate

(flywheel).

Fill transmission with clean ATF until oil level is even with

fill hole. Then check fluid level as described earlier.

Adjust gearshift mechanism. See

250 Gearshift Linkage.

NOTE-

In order to avoid difficulties in transmission removal at a fu-

ture time, use washers with Torx-head mounting bolts.

Page 616 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-1 0

/ Driveshaft

Driveshaft, installing

- Prepare CV joint for reinstallation:

Extend joint to limit.

Clean off old grease and fill with fresh grease

Install new seal.

- Bend driveshaft slightly at center universal joint to install

CAUTION-

Do not allow CVjoint seal to become displaced.

- Align matchmarlts on driveshaft to matchmarks on final drive

and transmission flanges.

- Fit constant velocity joint to final drive input flange. Alternate-

ly tighten two opposite nuts to draw constant velocity joint

evenly into the final drive input flange. Once seated, tighten

down remaining nuts.

I CAUTION-

I Do not reuse self-locking nuts. These nuts are designed to be /

I used onlv once. 1

- Insert bolts in front of driveshafl to transmission output

flange. Counterhold each bolt while tightening nut.

CAUTION-

. Do not reuse self-locking nuts. These nuts are designed to

be used only once.

Avoid stressing the flex-disc when torquing the bolts.

Do this by counterholding the bolts and turning the nuts

on the flange side.

- Position center support bearing and install mounting nuts.

Use new self-locking nuts.

- Install heat shields.

- Install rear transmission support crossmember.

- Install exhaust system. See 180 Exhaust System.

Reconnect oxygen sensor wiring harnesses and reattach

wiring harness retainers to rear transmission support

crossrnernber.

Page 634 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 4

I Susoension. Steerina and Brakes - General

DSC system I

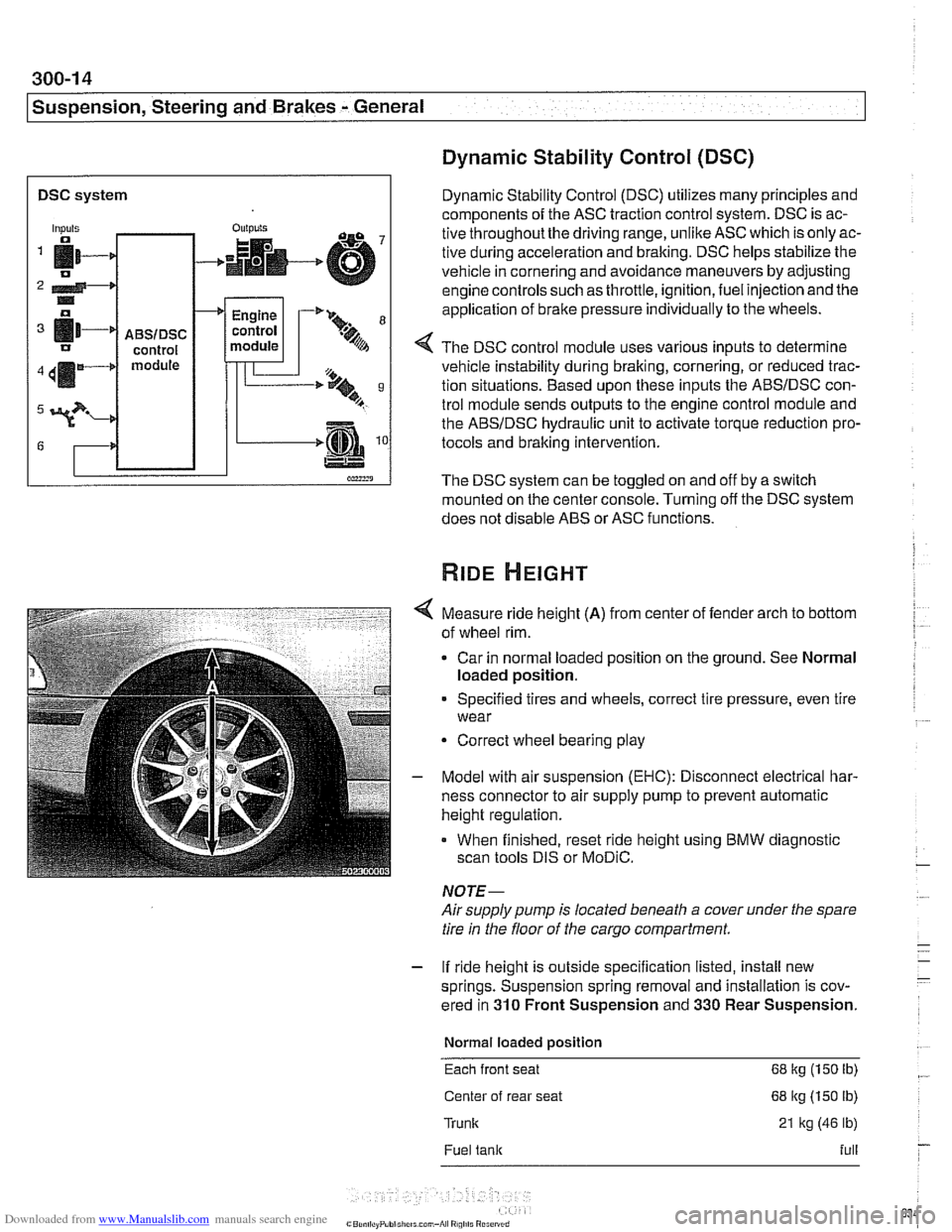

Dynamic Stability Control (DSC)

Dynamic Stability Control (DSC) utilizes many principles and

components of the ASC traction control system. DSC is ac-

tive throughoutthe driving range, unlike ASC which is only ac-

tive during acceleration and braking. DSC helps stabilize the

vehicle in cornering and avoidance maneuvers by adjusting

engine controls such as throttle, ignition, fuel injection and the

application of

brake pressure individually to the wheels.

Inputs

fi- 0

2 4-* .. o

[11-' IJ

411m4

3?-

G

4 The DSC control module uses various inputs to determine

vehicle instability during braking, cornering, or reduced trac-

tion situations. Based upon these inputs the ABSIDSC con-

trol module sends outputs to the engine control module and

the ABSIDSC hydraulic unit to activate torque reduction pro-

tocols and braking intervention.

-

ABSIDSC control module

OUI~YIS

4

The DSC system can be toggled on and off by a switch

mounted on the center console. Turning off the DSC system

does not disable ABS or ASC functions.

+

Measure ride height (A) from center of fender arch to bottom

of wheel rim.

Car in normal loaded position on the ground. See Normal

loaded position.

Engine

control

module

Specified tires and wheels, correct tire pressure, even tire

wear

-'* 9-

.%A

Correct wheel bearing play

T'== ..t, 9 B

-.m

Model with air suspension (EHC): Disconnect electrical har-

ness connector to air supply pump to prevent automatic

height regulation.

When finished, reset ride height using BMW diagnostic

scan tools DIS or

MoDiC.

NOTE-

Airsupply pump is located beneath a cover under the spare

tire in the floor of the cargo compartment.

- If ride height is outside specification listed, install new

springs. Suspension spring removal and installation is cov-

ered in

310 Front Suspension and 330 Rear Suspension.

Normal loaded position

Each front seat 68 kg (150 Ib)

Center of rear seat 68 kg (150 lb)

Trunk 21 kg (46 lb)

Fuel tank full

Page 645 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-9

Front Suspension

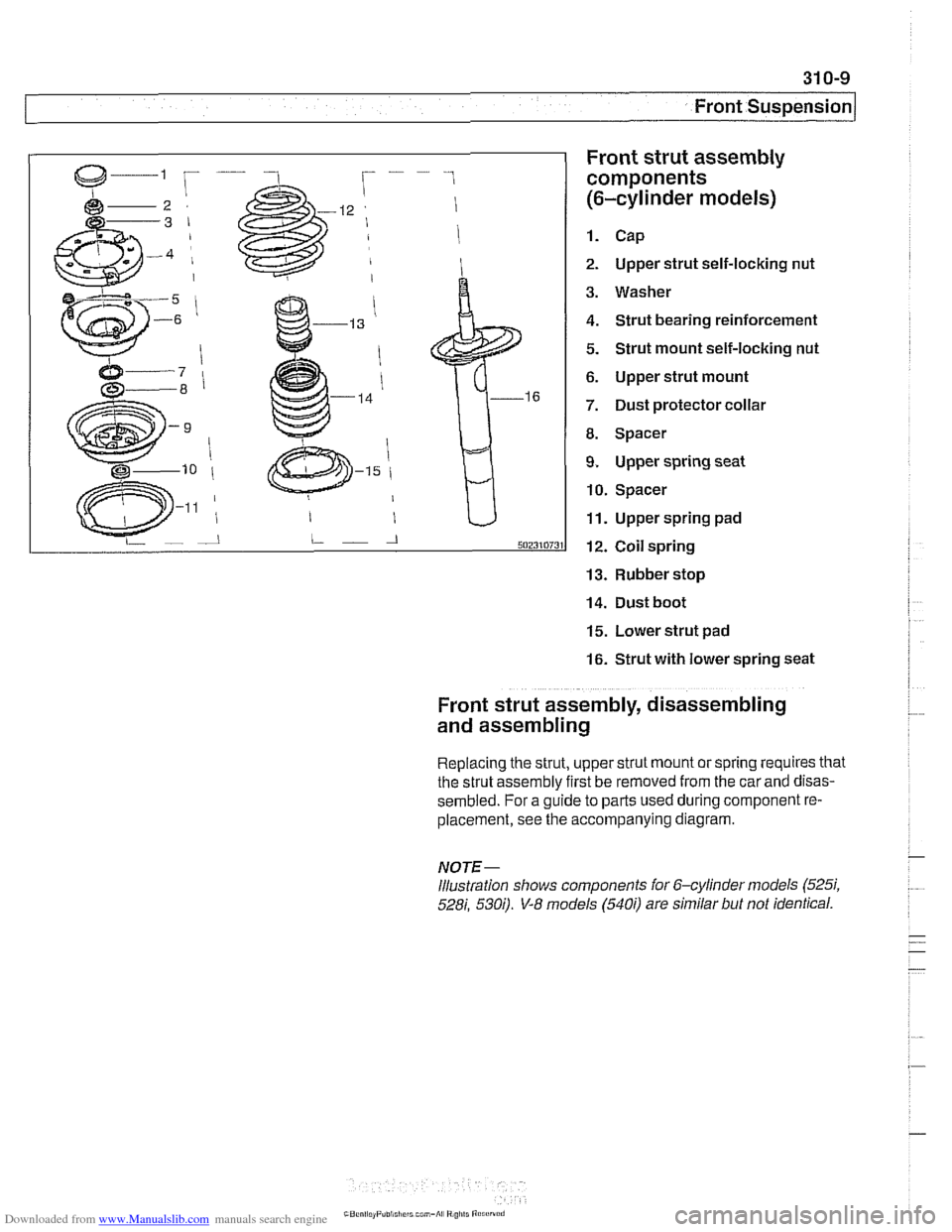

Front strut assembly

components

(6-cylinder models)

1. Cap

2. Upper strut self-locking nut

3. Washer

4. Strut bearing reinforcement

5. Strut mount self-locking nut

6. Upper strut mount

7. Dust protector collar

8. Spacer

9. Upper spring seat

10. Spacer

11. Upper spring pad

12. Coil spring

13. Rubber stop

14. Dust boot

15. Lower strut pad

16. Strut with lower spring seat

Front strut assembly, disassembling

and assembling

Replacing the strut, upper strut mount or spring requires that

the strut assembly first be removed from the car

and disas-

sembled. For a guide to parts used during component re-

placement, see the accompanying diagram.

NOTE-

Illustration shows components ior 6-cylinder models (525i,

528i, 530;). V-8 models (540i) are similar but not identical.

Page 646 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-1 0

Front Suspension

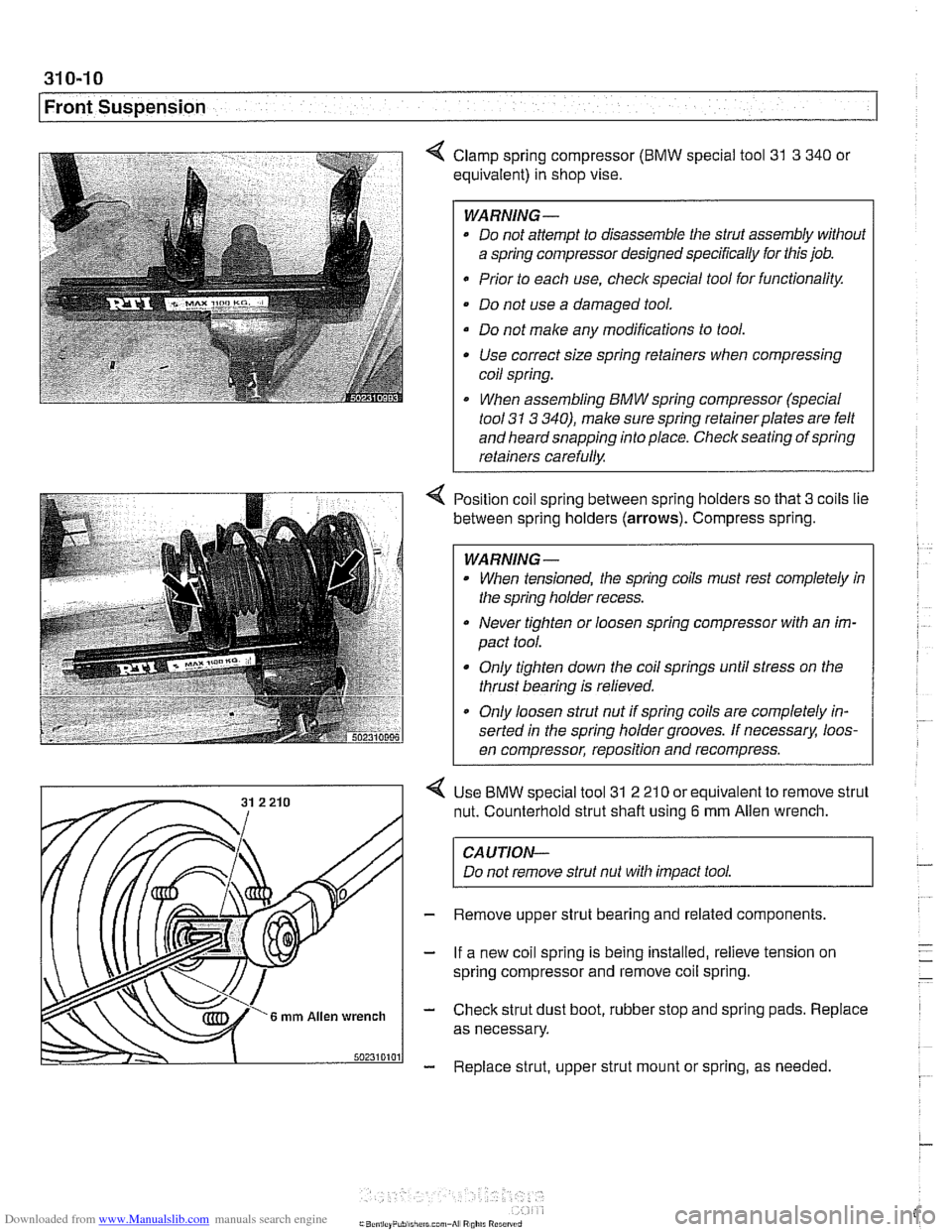

4 Clamp spring compressor (BMW special tool 31 3 340 or

equivalent) in shop vise.

WARNING-

* Do not attempt to disassemble the strut assembly without

a spring compressor designed specifically for this job.

Prior to each use,

checlc special tool for functionality.

Do not use a damaged tool.

Do not make any modifications to tool. Use correct size spring retainers when compressing

coil spring.

I When assembling BMW spring compressor (special

tool

31 3 340), make sure spring retainerplates are felt

and heard snapping into place. Check seating of spring

retainers carefully.

Position coil spring between spring holders so that

3 coils lie

between spring holders

(arrows). Compress spring.

WARNING -

When tensioned, the spring coils must rest completely in

the spring holder recess.

Never tighten or loosen spring compressor with an im-

pact tool.

Only tighten down the coil springs until stress on the

thrust bearing is relieved.

a Only loosen strut nut if spring coils are completely in-

serted in the spring holder grooves. If

necessarx loos-

en compressor, reposition and recompress.

Use

BMW special tool 31 2 21 0 or equivalent to remove strut

nut. Counterhold strut shaft using

6 mm Allen wrench.

CAUTION-

Do not remove strut nut with impact tool.

Remove upper strut bearing and related components.

If a new coil spring is being installed, relieve tension on

spring compressor and remove coil spring.

Check strut dust boot, rubber stop and spring pads. Replace

as necessary.

Replace strut, upper strut mount or spring, as needed

Page 647 of 1002

Downloaded from www.Manualslib.com manuals search engine

Front Suspension

/ Front strut top mount assembly

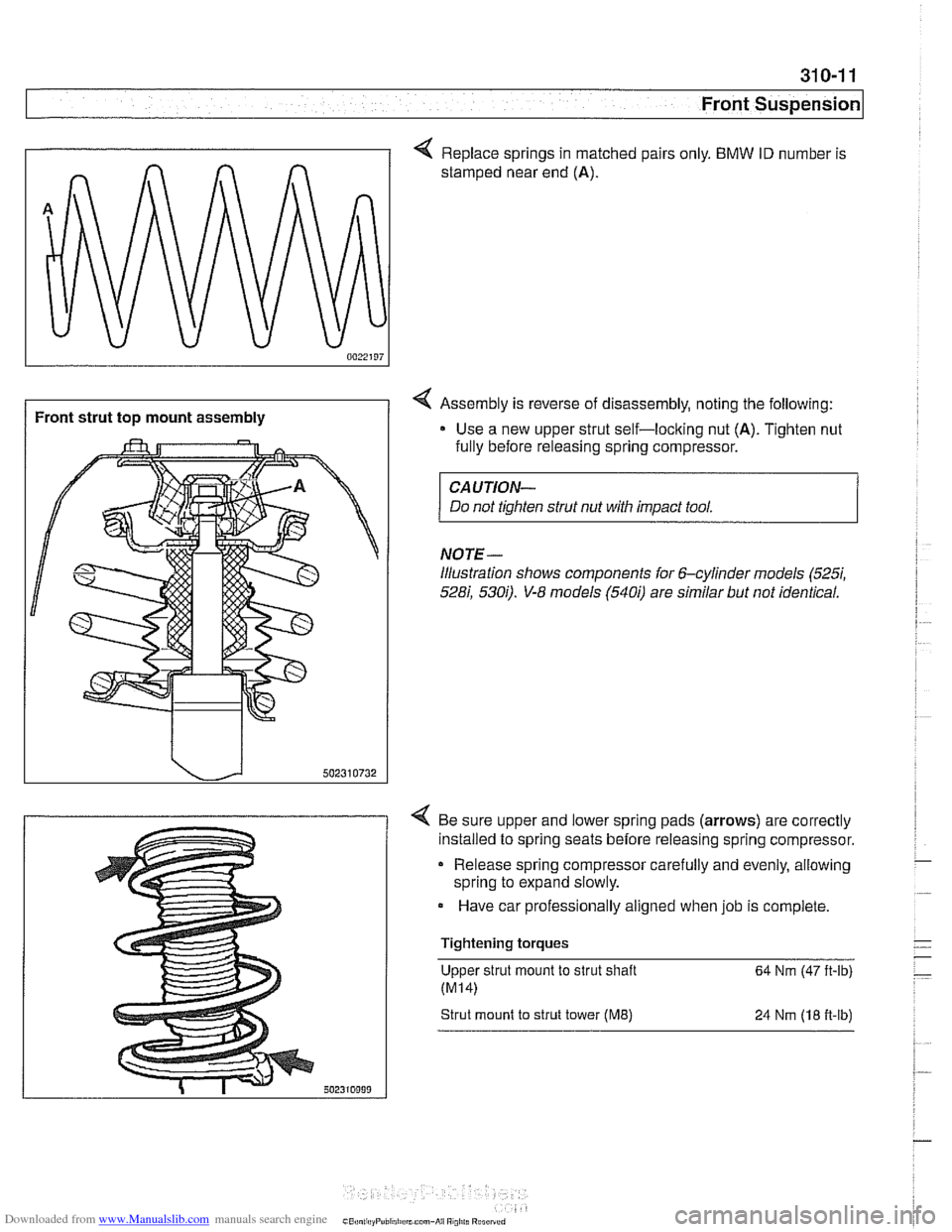

< Replace springs in matched pairs only. BMW ID number is

stamped near end

(A).

4 Assembly is reverse of disassembly, noting the following:

Use a new upper strut self-loclting nut

(A). Tighten nut

fully before releasing spring compressor.

CAUTION-

Do not tighten strut nut with impact tool.

NOTE-

illustration shows components for 6-cylinder models (5257,

528i, 5300. V-8 models (5400 are similar but not identical.

4 Be sure upper and lower spring pads (arrows) are correctly

installed to spring seats before releasing spring compressor.

Release spring compressor carefully and evenly, allowing

spring to expand slowly.

Have car professionally aligned when job is complete.

Tightening torques Upper strut mount to strut shaft

64 Nm (47 ft-lb)

Strut mount to strut tower (ME) 24 Nrn (18 fi-lb)

Page 693 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering and Wheel Alignment

- Tighten nut while counterholding adjusting bolt,

- Tighten nut only after car has been lowered to ground and

suspension has settled.

Preparing for alignment

- The following conditions are necessary prior to wheel align-

ment:

Correct wheels and tires are installed, in good condition,

and are at the correct inflation pressures.

All steering and suspension parts and bushings are un-

damaged and show no signs of abnormal wear. Wheel

bearings are in good condition.

Ride height is in accordance with specifications. See

300

Suspension, Steering and Brakes-General.

Car is in normal loaded position. See below.

* Cars with air suspension: Remove air suspension power

fuse.

Normal loaded position

Each front seat

68 Kg (I50 lb)

Center of rear seat

Trunlc

Fuel tank

68 Kg (150 lb)

21 Kg (46 lb)

Full

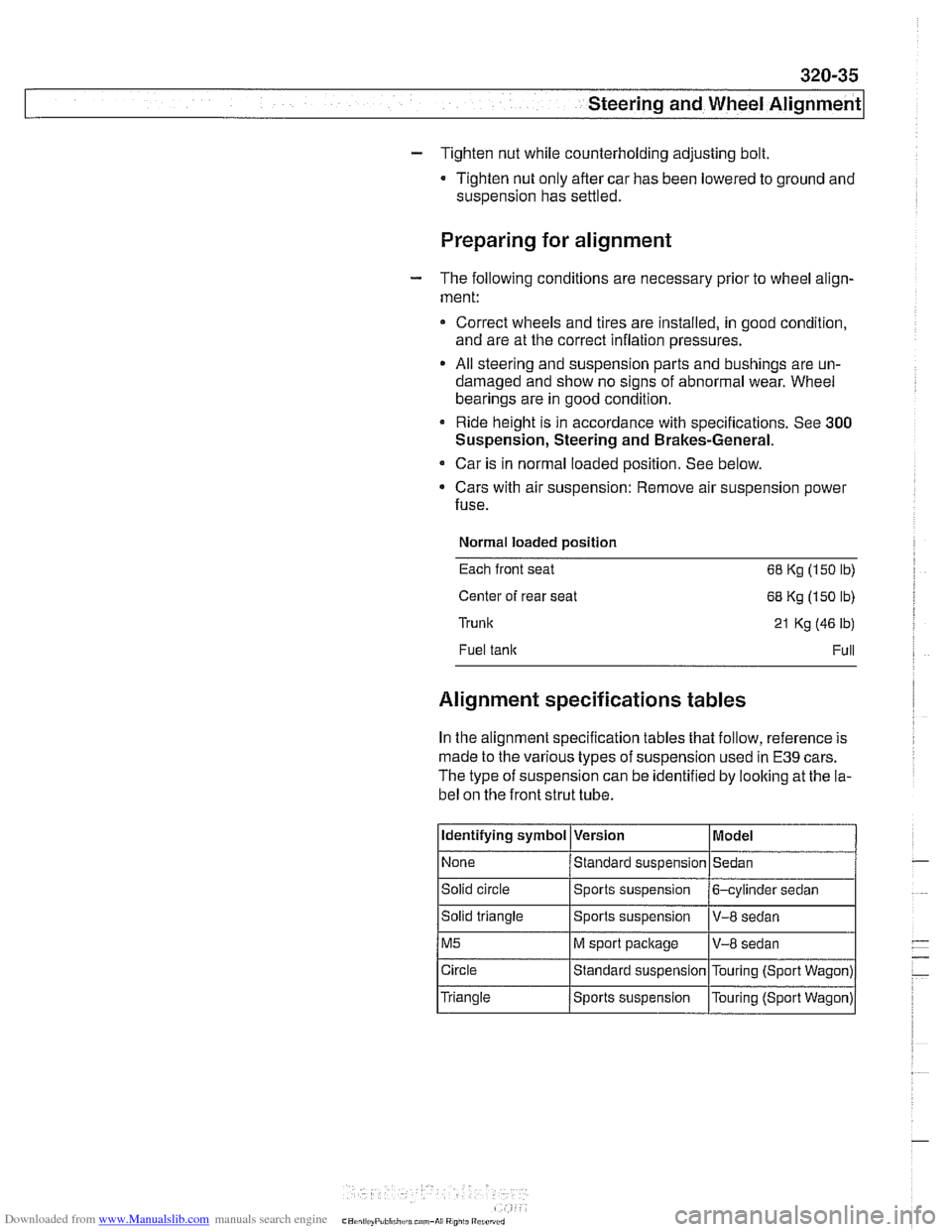

Alignment specifications tables

In the alignment specification tables that follow, reference is

made to the various types of suspension used in

E39 cars.

The type of suspension can be identified by loolting at the la-

bel on the front strut tube.

Identifying symbol

None

Solid circle

Solid triangle

M5

Circle

Triangle Version

Standard suspension

Sports

suspension

Sports suspension

M sport package

Standard suspension

Sports suspension Model

Sedan

6-cylinder sedan

V-8 sedan

V-8 sedan

Touring (Sport Wagon)

Touring (Sport Wagon)