Speed signal BMW 525i 2001 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

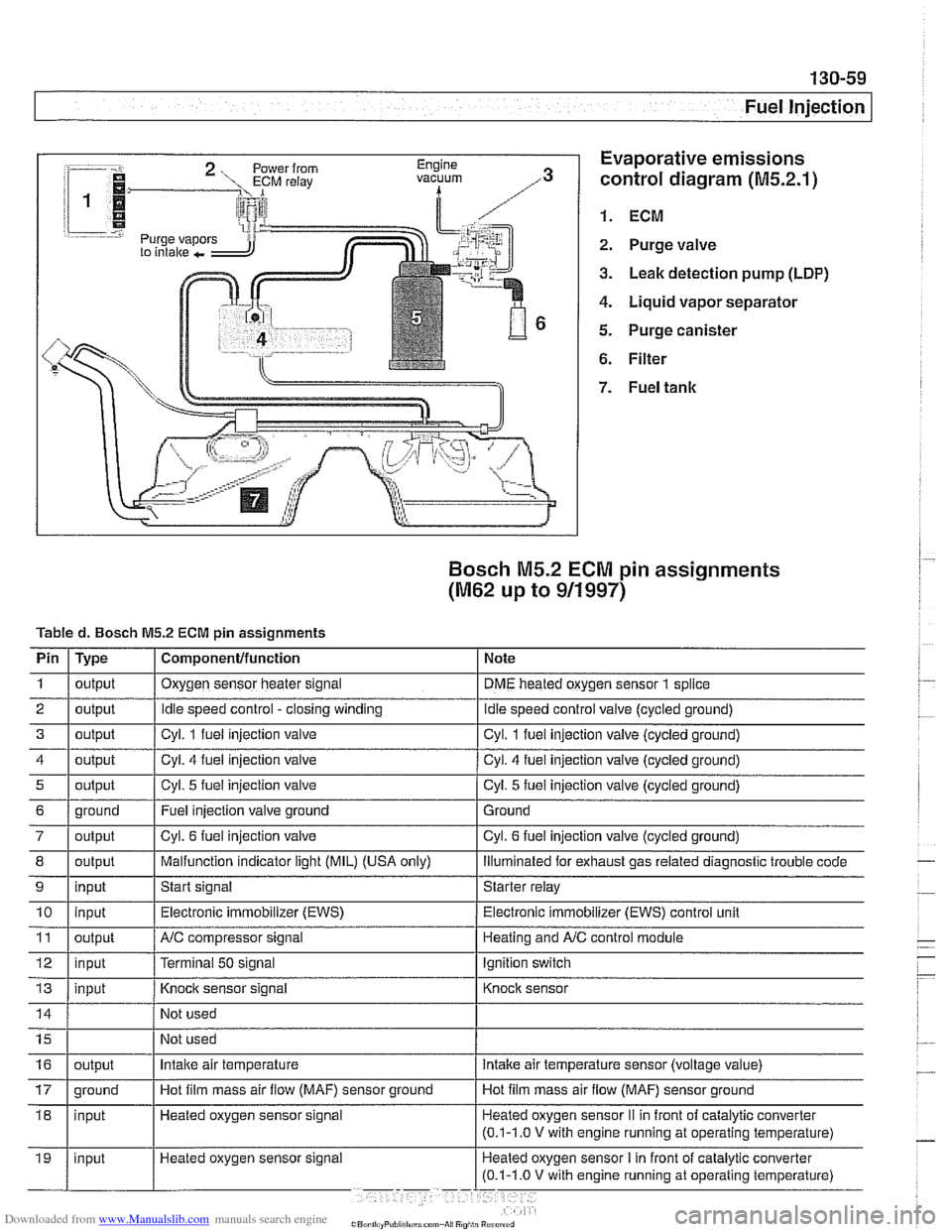

130-59

Fuel Injection

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

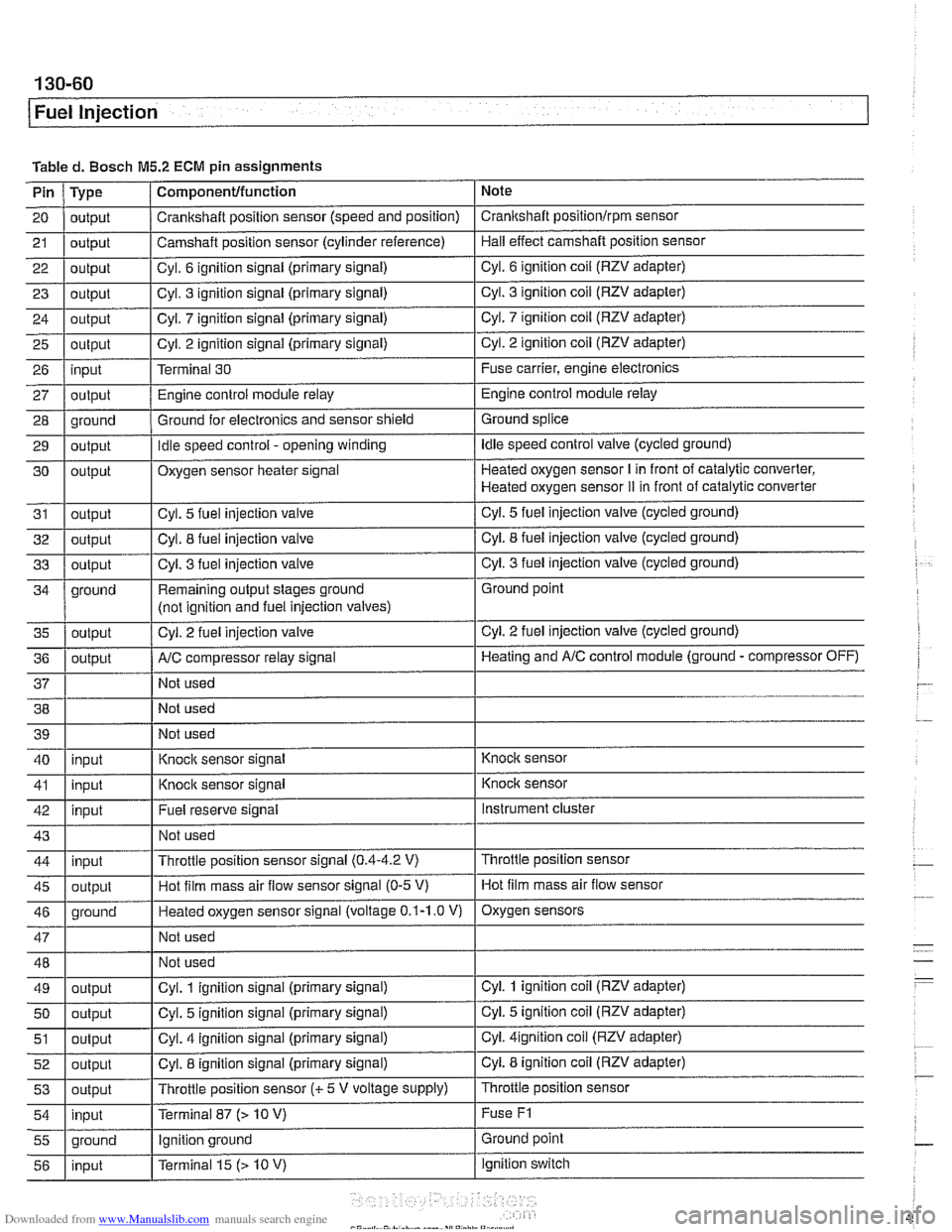

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 450 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-60

/Fuel lniection

Tabled. Bosch M5.2 ECM pin assignments

Note

Pin

21

20 I output / Crankshaft position sensor (speed and position) I Crankshaft positionlrpm sensor

23

I - I I 29 1 output I Idle speed control - opening winding I Idle speed control valve (cycled ground)

Type

22

1 output I Cvl. 6 ignition signal (primary signal) I Cyl. 6 ignition coil (RZV adapter)

output

25

26

27

28

Component/function

24 1 outout I Cvl. 7 iqnition siqnal (primary signal) I Cyl. 7 ignition coil (RZV adapter)

output

4 outbut I' I - I Cyl. 3

fuel injection valve I Cyl. 3 fuel injection valve (cycled ground)

Camshaft position

sensor (cylinder reference)

output input

output

oround

30

31

32

ground Hall effect camshaft position sensor

Cyl. 3 ignition signal (primary signal)

output

I

Cyl. 3 ignition coil (RZV adapter)

. - . .. . .

Cyl. 2 ignition signal (primary signal)

Terminal 30

Engine control module relay

Ground for electronics and sensor shield

output

output

outout

Remaining output stages ground

(not iclnition and fuel iniection valves) Cyl.

2 ignition coil (RZV adapter)

Fuse carrier, engine electronics

Engine control module relay

Ground splice ,

Cyl. 2 fuel injection valve

Oxygen sensor heater signal

Cyl. 5

fuel injection valve

Cvl. 8 fuel iniection valve

AIC comuressor relav sianal

Heated oxygen sensor I in front of catalytic converter,

Heated oxygen sensor

iI in front of catalytic converter

Cyl.

5 fuel injection valve (cycled ground)

Cvl. 8 fuel iniection valve (cycled ground)

. -

Not used Ground point

Cyl.

2 fuel injection valve (cycled ground)

Heatinq and AIC control module (ground - compressor OFF)

38 Not used

40 39

1 I Not used

I'

I . I

I' I -. I

46 1 ground I Heated oxygen sensor signal (voltage 0.1-1.0 V) I Oxygen sensors

41

1 inuut I Knock

sensor signal I Knock sensor

input

I

I I

Instrument cluster

I' I I 55 1 ground I Ignition ground I Ground point

Knock sensor signal

43

1 I Not used I

Fuel reserve signal

42

Throttle position sensor

47

48

49

50

51

52

53

54

Knoclc sensor

input

45

1 outout I Hot film mass air flow sensor signal (0-5 V) I Hot film mass air flow sensor

Throttle position sensor signal

(0.4-4.2 V) 44

input

output

output

output

output

output

inout

I - I

Not used

Not used

Cyl. 1 ignition signal (primary signal)

Cyl. 5 ignition signal (primary signal)

Cyl. 4 ignition signal (primary signal)

Cyl. 8 ignition signal (primary signal)

Throttle position sensor

(c 5 V voltage supply)

Terminal 87

f> 10 V)

ignition switch

56

Cyl. 1 ignition coil (RZV adapter)

Cyi. 5 ignition coil (RZV adapter)

Cyi.

4ignition coil (RZV adapter)

Cyl. 8 ignition coil (RZV adapter)

Throttle position sensor

Fuse

F1

input Terminal 15 (> 10 V)

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

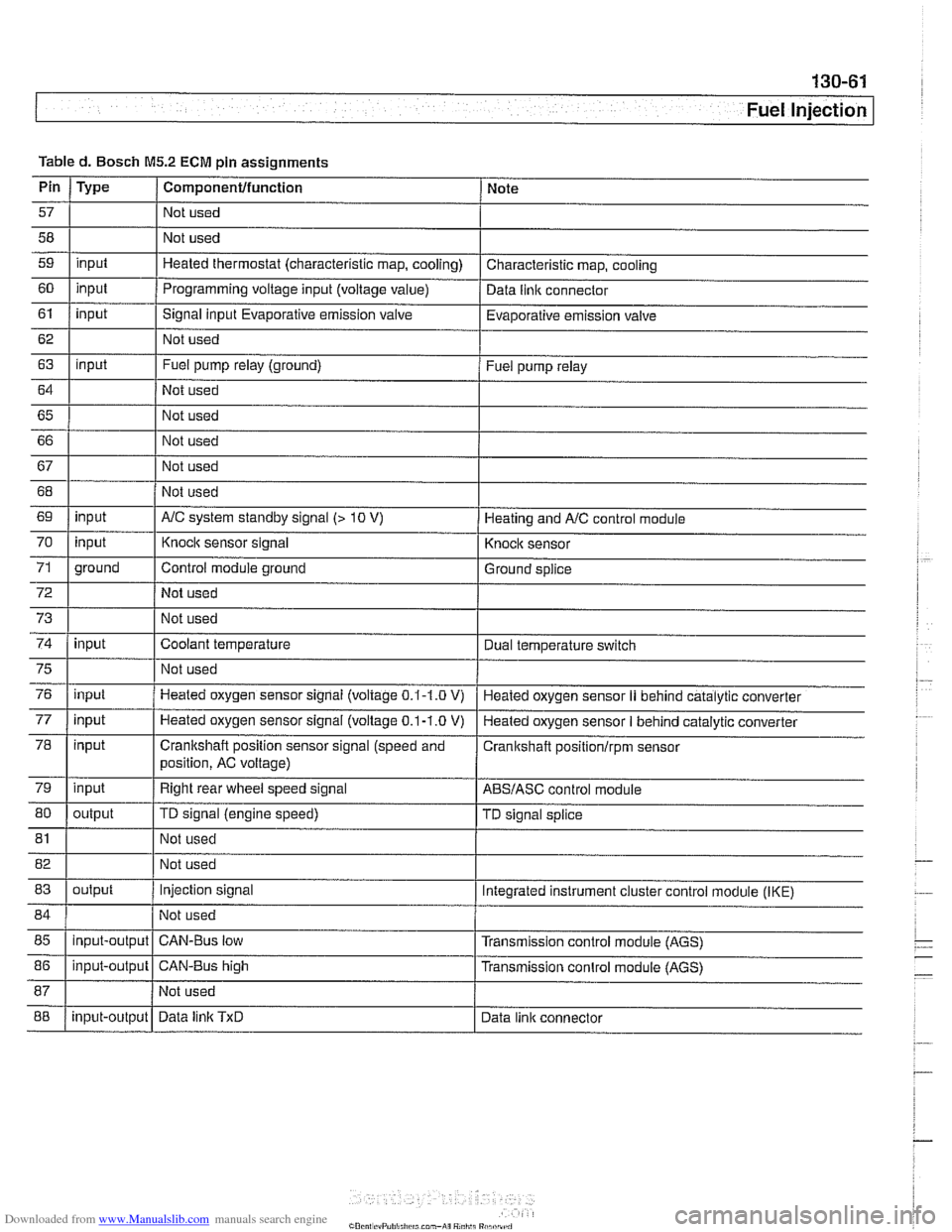

Fuel Injection

I 68 1 / Not used

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 454 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

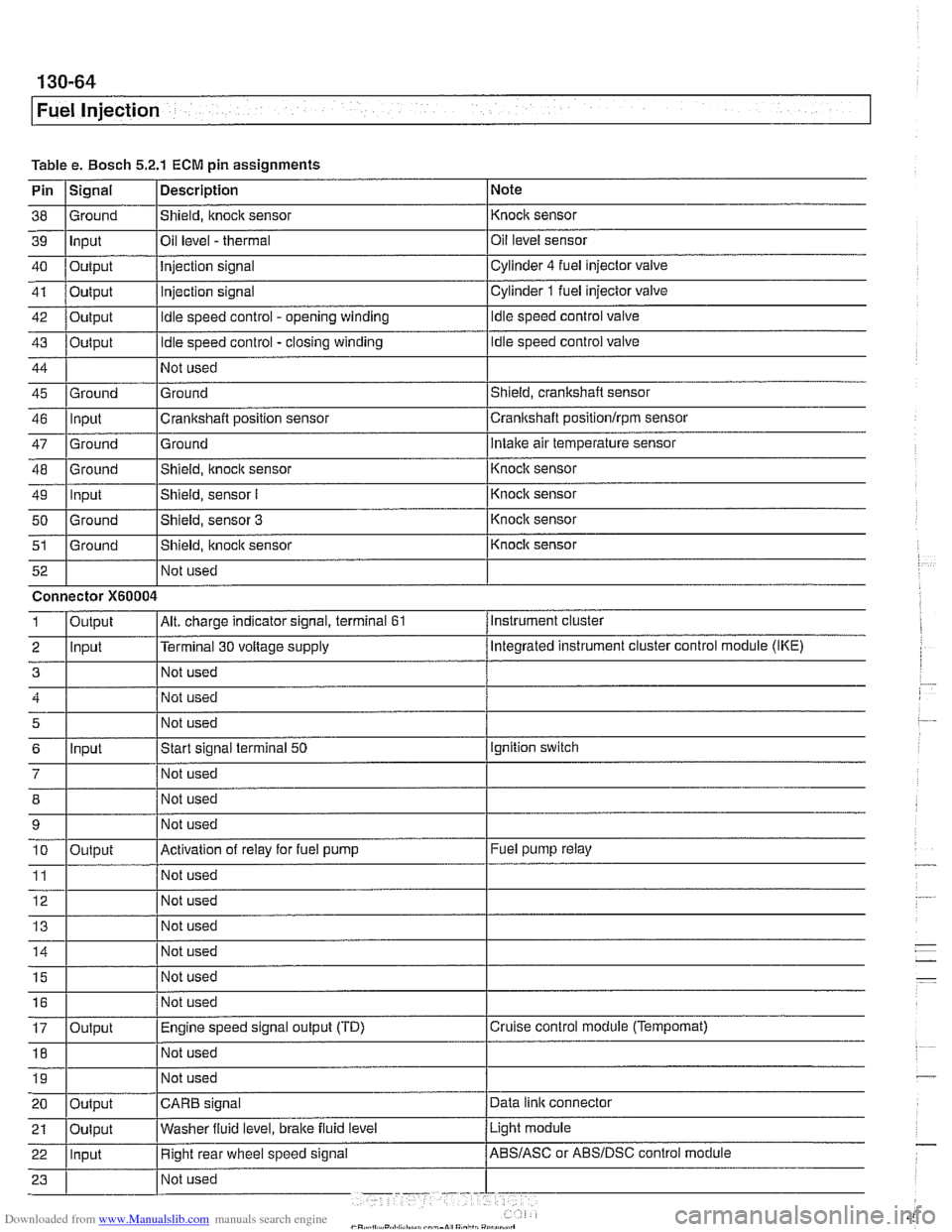

Table e. Bosch 5.2.1 ECM pin assignments

Pin

I~iqnal 1 Description 1 Note

I I I

46 llnput ICrankshaft position sensor Icrankshaft positionlrpm sensor

38

39

40

41

42

43

44

45 Ground Input

Output

Output

Output

Output

Ground

47

48

49

50

51

Not used

I Not used

52

Shield, knock sensor

Oil level

- thermal

Injection signal

injection signal

Idle speed control - opening winding

Idle speed control - closing winding

Not used

Ground

Ground

-- Ground Input

Ground

Ground Not used Knock sensor

Oil level sensor

Cylinder

4 fuel injector

valve

Cylinder

1 fuel injector valve

Idle speed control valve

Idle speed control valve

Shield, crankshaft sensor

5

6

7

12 Not used

Ground

Intake air temperature sensor

Connector

X60004

8

9 10

11

14 1 1 Not used I

Shield, knock sensor

Shield, sensor

I

Shield, sensor 3

Shield, itnock sensor

Input

- Knoclc sensor

Knock sensor

Knock sensor

Knock sensor

Instrument cluster

Output

2 llnput l~erminal 30 voltage supply /Megrated instrument cluster control module (IKE)

Alt. charge indicator signal, terminal 61 1

Not used

Start signal terminal

50

Not used

15

16

17

18

Output

Ignition switch

Not used

Not used

Activation of relay for fuel pump

Not used

19

Fuel pump relay

Output Not used

I I I 20 loutput ICARB signal /Data link connector

Not

used

Not used

Engine speed signal output (TD)

Not used

Light module

21

Cruise control module (Tempomat)

22 llnput I Right rear wheel speed signal /ABS/ASC or ABSIDSC control module

Oulput

Washer

fluid level,

brake fluid level

Page 458 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-68

Fuel Injection

0

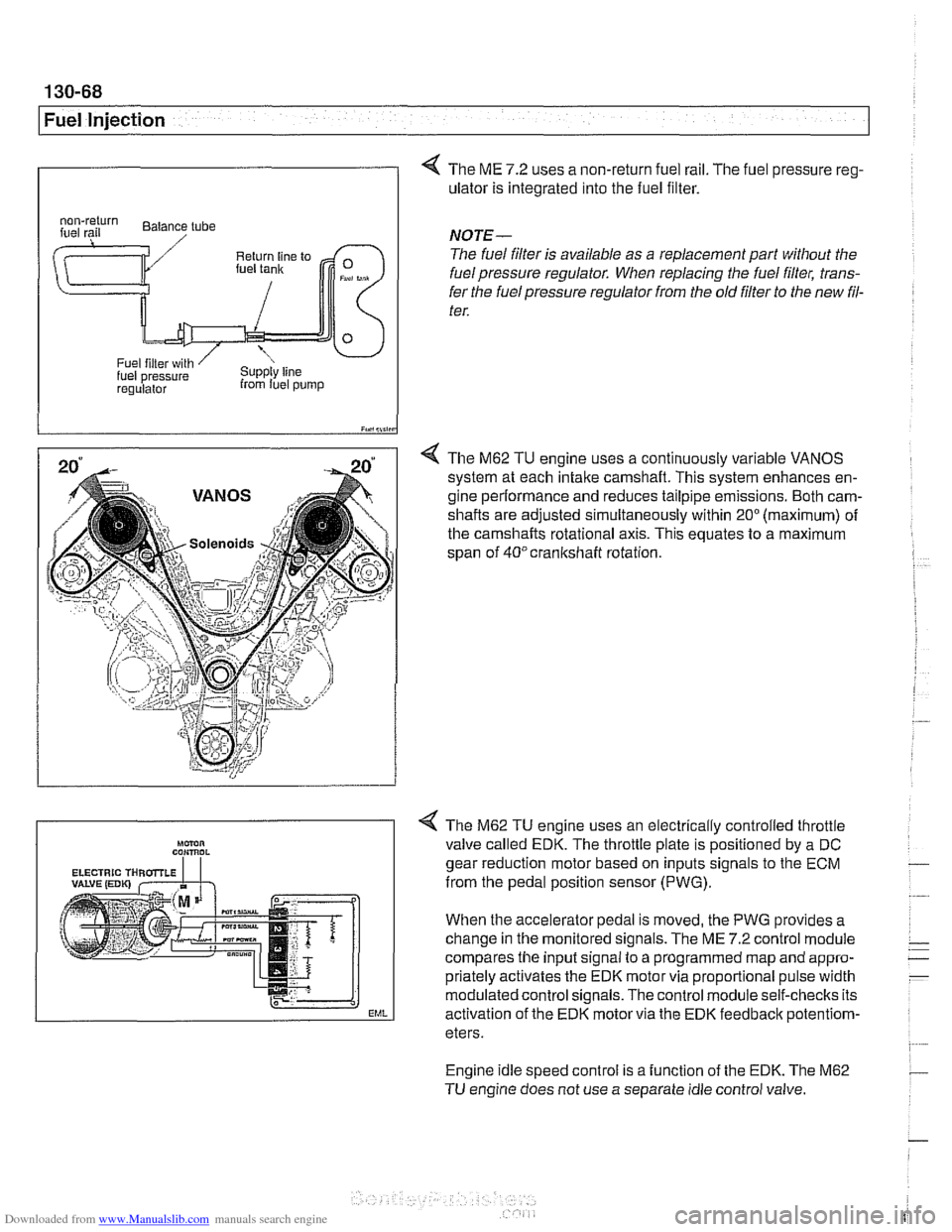

4 The ME 7.2 uses a non-return fuel rail. The fuel pressure reg-

ulator is integrated into the fuel filter.

I iY.,lii,in

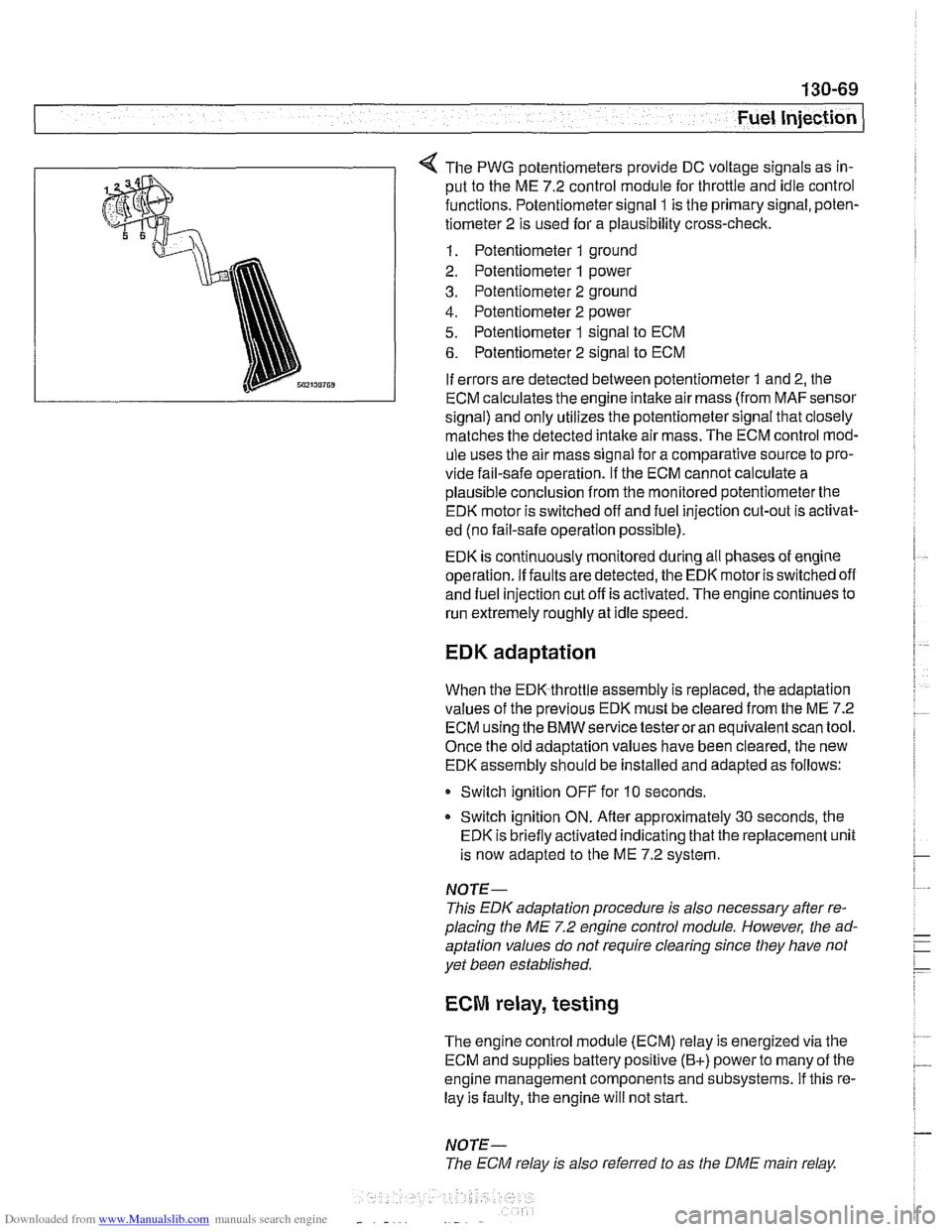

4 The M62 TU engine uses a continuously variable VANOS

system at each intake camshaft. This system enhances en-

gine performance and reduces tailpipe emissions. Both cam-

shafts are adjusted simultaneously within

20" (maximum) of

the camshafts rotational axis. This equates to a maximum

span of

40°crankshaft rotation.

regulalor from luel pump

NOTE-

The fuel filter is available as a replacement part without the

fuel pressure regulator. When replacing the fuel filter, trans-

fer the fuel pressure regulator from the old

filter to the new fil-

ter.

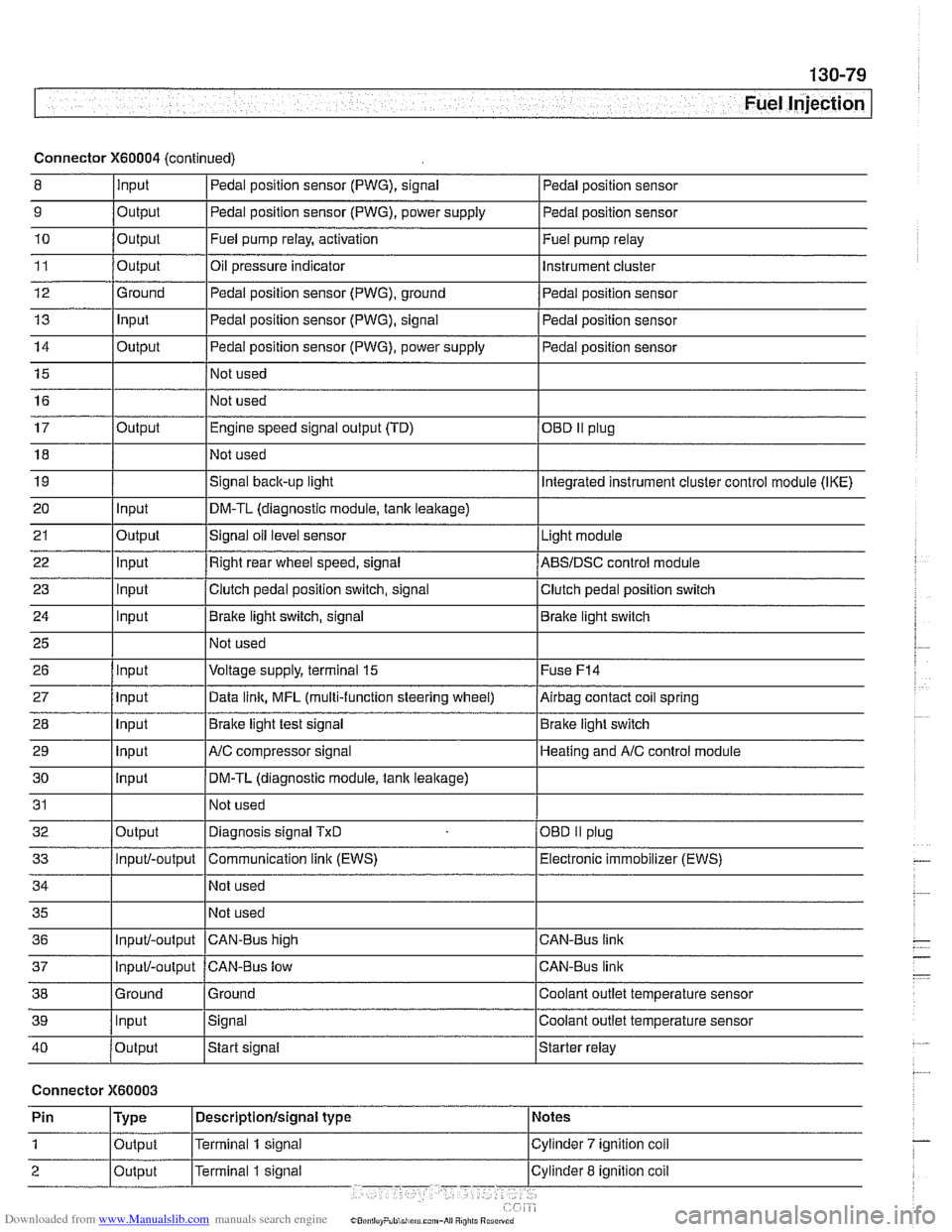

Engine idle speed control is a function of the EDK. The M62

TU engine does not use a separate idle control valve.

Mmn CON,ROL

EML

< The M62 TU engine uses an electrically controlled throttle

valve called EDK. The throttle plate is positioned by a DC

gear reduction motor based on inputs signals to the ECM

from the pedal position sensor (PWG).

When the accelerator pedal is moved, the PWG provides a

change in the monitored signals. The ME

7.2 control module

compares the input signal to a programmed map and appro-

priately activates the EDK motor via proportional pulse width

modulated control signals. The control module self-checks its

activation of the EDK motor via the EDK feedbaclc

potentiom-

eters.

Page 459 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Fuel Injection I

The PWG potentiometers provide DC voltage signals as in-

put to the ME 7.2 control module for throttle and idle control

functions. Potentiometer signal

1 is the primary signal, poten-

tiometer 2 is used for a plausibility cross-check.

1. Potentiometer 1 ground

2. Potentiometer

1 power

3. Potentiometer 2 ground

4. Potentiometer 2 power

5. Potentiometer 1 signal to ECM

6. Potentiometer 2 signal to ECM

If errors are detected between potentiometer

1 and 2, the

ECM calculates the engine intake air mass (from

MAFsensor

signal) and only utilizes the potentiometer signal that closely

matches the detected

intake air mass. The ECM control mod-

ule uses the air mass signal for a comparative source to pro-

vide fail-safe operation.

If the ECM cannot calculate a

plausible conclusion from the monitored potentiometerthe

EDK motor is switched off and fuel injection cut-out is activat-

ed (no fail-safe operation possible).

EDK is continuously monitored during all phases of engine

operation. If faults are detected, the EDK motor is switched off

and fuel injection cut off is activated. The engine continues to

run extremely roughly at idle speed.

EDK adaptation

When the EDK throttle assembly is replaced, the adaptation

values of the previous EDK must be cleared from the ME 7.2

ECM using the BMW service testeroran equivalentscan tool.

Once the old adaptation values have been cleared, the new

EDK assembly should be installed and adapted as follows:

0 Switch ignition OFF for 10 seconds.

* Switch ignition ON. Afler approximately 30 seconds, the

EDK is briefly activated indicating that the replacement unit

is now adapted to the ME 7.2 system.

NOTE-

This EDK adaptation procedure is also necessary after re-

placing the

ME 7.2 engine control module. However, the ad-

aptation values do not require clearing since they have not

yet been established.

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine management components and subsystems. If this re-

lay is faulty, the engine will not start.

NOTE-

The ECM relay is also referred to as the DME main relay

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low

Page 501 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-5

Radiator and Cooling System

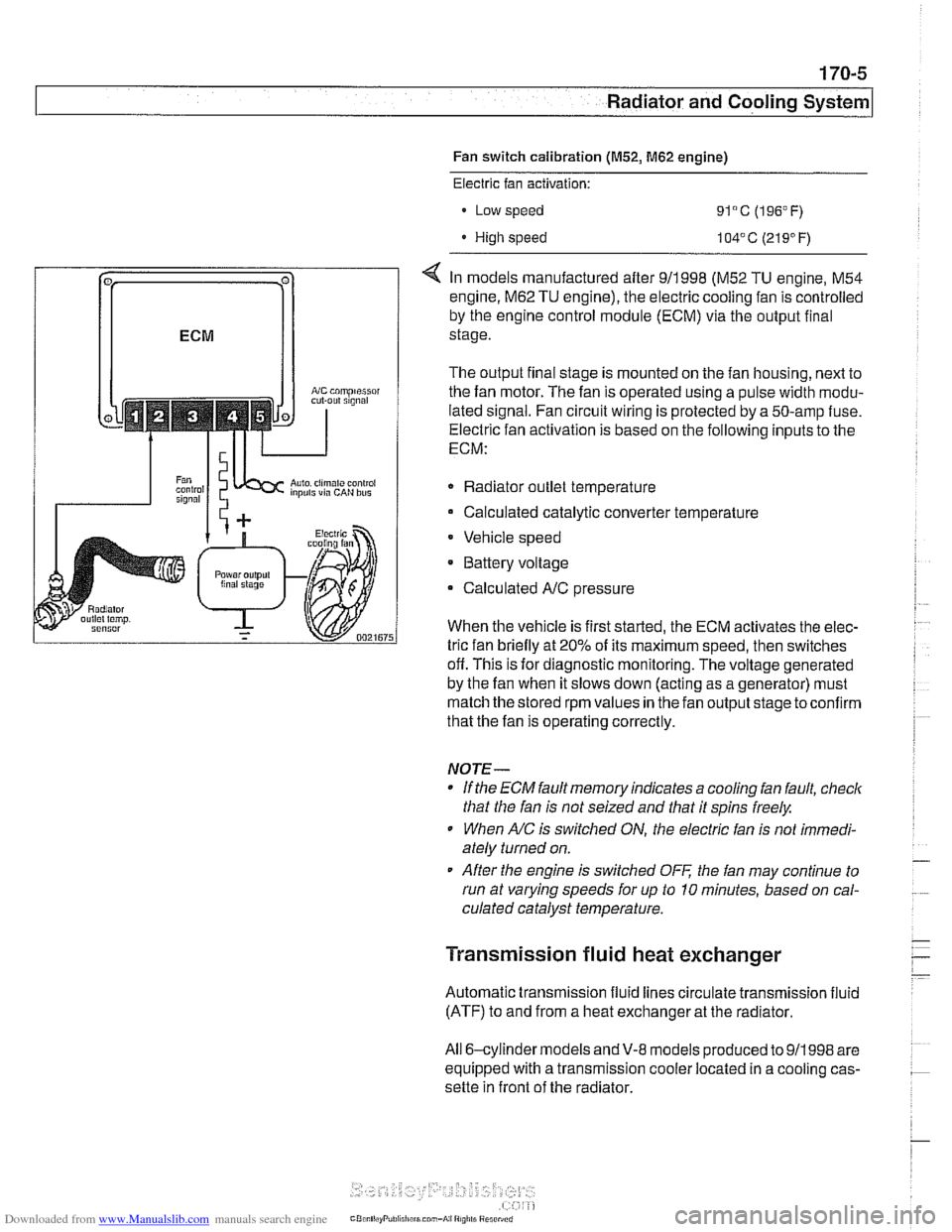

Fan switch calibration (M52, M62 engine)

coniprairoi OUt rlgnal

Auto. ciimilte ~ontioi inpuls via CAN bus

Electric fan activation:

Low speed

91°C (196°F)

High speed 104' C (21 9' F)

< In models manufactured after 911998 (M52 TU engine, M54

engine.

M62 TU engine), the electric cooling fan is controlled

by the engine control module (ECM) via the output final

stage.

The output final stage is mounted on the fan housing, next to

the fan motor. The fan is operated using a pulse width modu-

lated signal. Fan circuit wiring is protected by a 50-amp fuse.

Electric fan activation is based on the following inputs to the

ECM:

Radiator outlet temperature

Calculated catalytic converter temperature

Vehicle speed

* Battery voltage

Calculated

A/C pressure

When the vehicle is first started, the ECM activates the elec-

tric fan briefly at 20% of its maximum speed, then switches

off. This is for diagnostic monitoring. The voltage generated

by the fan when it slows down (acting as a generator) must

match the stored rpm values in the fan output stage toconfirm

that the fan is operating correctly.

NOTE-

If the ECM fault memory indicates a cooling fan fault, check

that the fan is not seized and that it spins freely.

When

A/C is switched ON, the electric fan is not immedi-

ately turned on.

After the engine is switched

OFF the fan may continue to

run at varying speeds for up to 10 minutes, based on cal-

culated catalyst temperature.

Transmission fluid heat exchanger

Automatic transmission fluid lines circulate transmission fluid

(ATF) to and from a heat exchanger at the radiator.

All 6-cylinder

models andV-8 models produced to 911998 are

equipped with a transmission cooler located in a cooling cas-

sette in front of the radiator.

Page 899 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

DWA alarm

The DWA alarm system is

armedldisarmed when thevehicle

is locked / unlocked from either the door or trunk.

Convenience closing

I opening

The windows and sun roof can be closed or opened by hold-

ing the key in the

loclc I unlock position.

Crash sensor

The crash sensor is located in the left front

kick panel. It func-

tions by unlocking all doors in the event of an accident.

NOTE-

Continuous and repeated locliing / unlocking may cause

timedarrest of

the locliing system. When activated, the timed

arrest lasts for two minutes. The timed arrest does not affect

the crash sensor

unlocliing the doors in case of an accident.

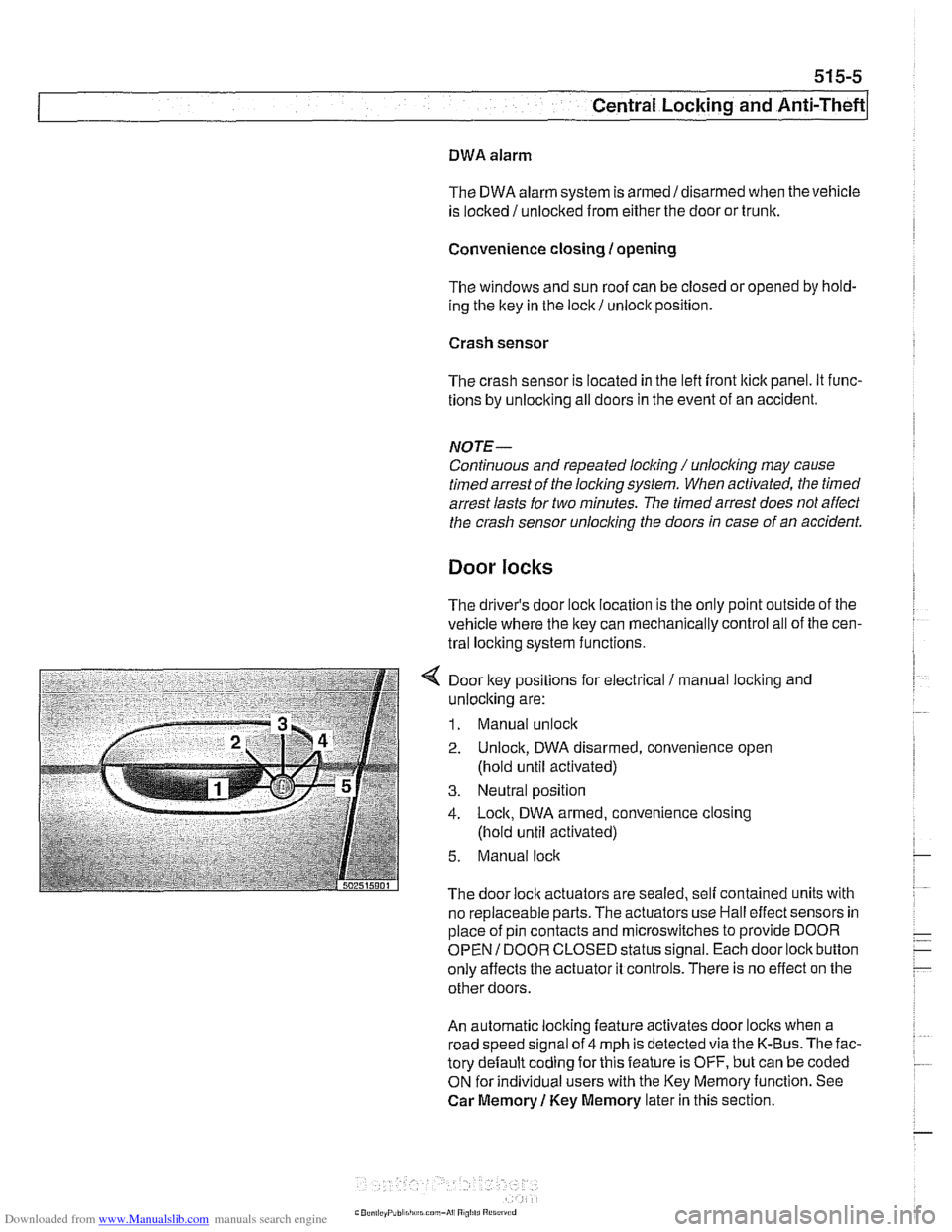

Door locks

The driver's door lock location is the only point outside of the

vehicle where the ltey can mechanically control all of the cen-

tral locking system functions.

4 Door key positions for electrical / manual loclting and

unlocking are:

1. Manual unlock

2. Unlock, DWA disarmed, convenience open

(hold until activated)

3. Neutral position

4. Lock, DWA armed, convenience closing

(hold until activated)

5. Manual lock

The door lock actuators are sealed. self contained units with

no replaceable parts. The

actuators use Hall effect sensors in

place of pin contacts and microswitches to provide DOOR

OPEN

I DOOR CLOSED status signal. Each door lock button

only affects the actuator it controls. There is no effect on the

other doors.

An automatic locking feature activates door locks when a

road speed signal of 4 mph is detected via the K-Bus. The fac-

tory default coding for this feature is OFF, but can be coded

ON for individual users with the Key Memoryfunction. See

Car Memory

1 Key Memory later in this section.

Page 901 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

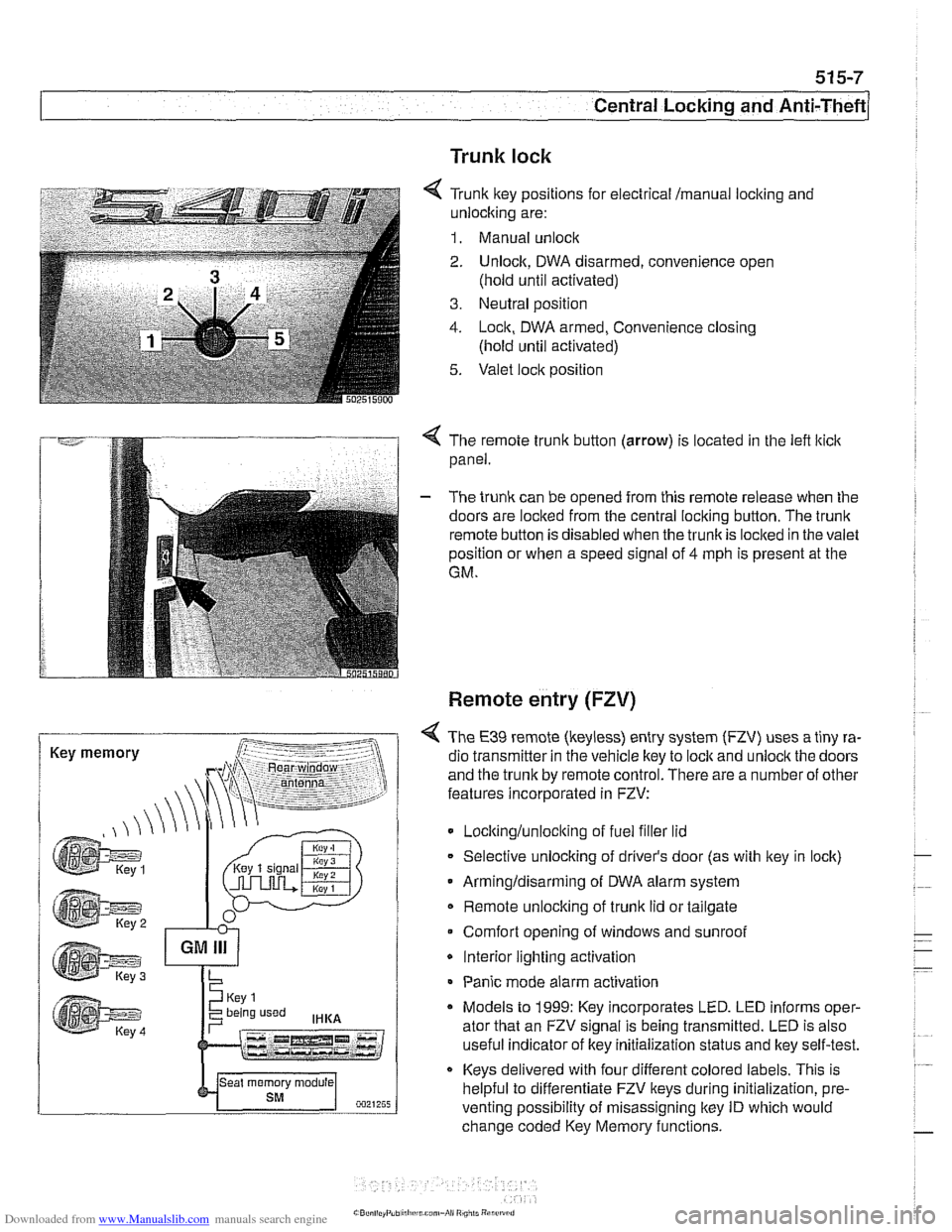

Trunk lock

6 Tr~nk ftey pos~rions for eecir'cal mama, locking and

-nlock~ng are:

1. Manual unock .. - - - ........ - ..- .- ................. s.=.=-- 2. Unlock. DWA oisarmed, conven:ence open

(nold

un1:l aclivaledj

3. Ne~tral posit'on

1. -ocn. DWA armeo, Convenience closng

(hold ~nti activated)

5. Valet .oc,t position

. -- .............-... .- . - -.....

Key memory

< The remote trunk button (arrow) is located in the lefl lticlc

panel.

- The trunk can be opened from this remote release when the

doors are locked from the central locking button. The

trunk

remote button is disabled when the trunkis loclted in the valet

position or when a speed signal of

4 mph is present at the

GM.

Remote entry (FZV)

< The €39 remote (keyless) entry system (FZV) uses a tiny ra-

dio transmitter in the vehicle key to

lock and unlock the doors

and the trunk by remote control. There are a number of other

features incorporated in FZV:

Locltinglunloclting of fuel filler lid

Selective unlocking of driver's door (as with key in lock)

Armingldisarming of DWA alarm system

Remote unlocking of

trunk lid or tailgate

Comfort opening of windows and sunroof

* Interior lighting activation

Panic mode alarm activation

* Models to 1999: Key incorporates LED. LED informs oper-

ator that an FZV signal is being transmitted. LED is also

useful indicator of key initialization status and lkey self-test.

Keys delivered with four different colored labels. This is

helpful to differentiate FZV keys during initialization,

pre.

venting possibility of misassigning key ID which would

change coded Key Memory functions.