20 pin BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 958 of 1002

Downloaded from www.Manualslib.com manuals search engine

721 -1 0

/Airbag System (SRS)

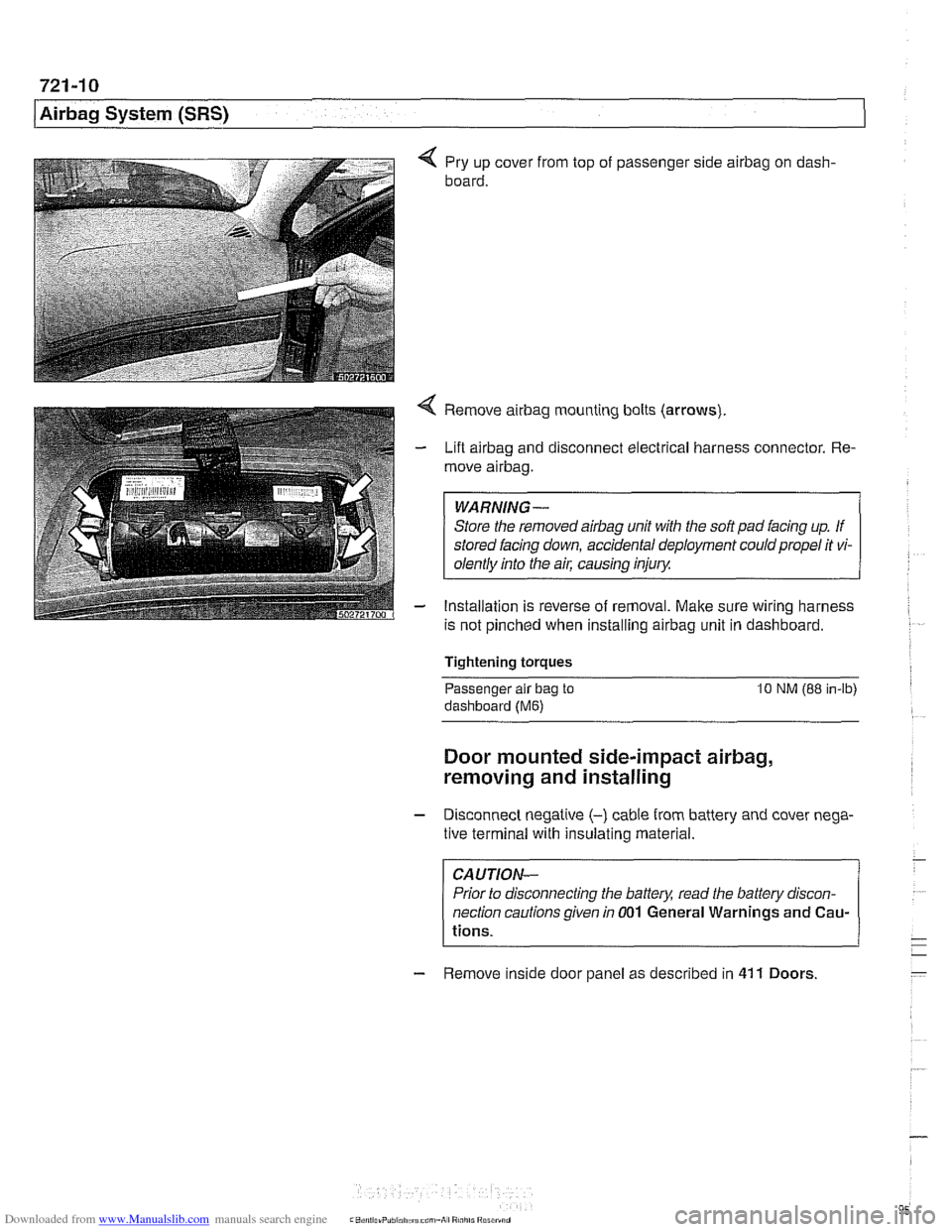

4 Pry up cover from top of passenger side airbag on dash-

board.

4 Remove airbag mounting bolts (arrows)

- Lift airbag and disconnect electrical harness connector. Re-

move

airbag.

WARNING-

Store the removed airbag unit with the soft pad facing up. If

stored facing down, accidental deployment could propel it vi-

olentlv into the

ail: causino inium

- Installation is reverse of removal. Make sure wiring harness

is not pinched when installing

airbag unit in dashboard.

Tightening torques

-

Passenger alr bag to 10 NM (88 in-lb)

dashboard (Me)

Door mounted side-impact airbag,

removing and installing

- Disconnect negatlve (-) cable from battery and cover nega-

tive terminal with insulating material.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

tions.

- Remove inside door panel as described in 41 1 Doors

Page 960 of 1002

Downloaded from www.Manualslib.com manuals search engine

721-12

Airbag System (SRS)

Head protection airbag (HPS)

4 Replacement of a head protection airbag (HPS) is an exten-

sive operation, including removal of the following:

Complete dashboard

Complete headliner

Windshield pillar (A-pillar) trim

Door pillar (B-pillar) trim

- Before starting work on the HPS airbag, disconnect negative

(-) cable from battery and cover negative terminal with insu-

lating material.

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven in001 General Warnings and Cau-

tions.

Tightening torque HPS

airbag to body 11 Nm (8 ft-lb)

HPS airbag mounting bracket

to A or B-pillar

HPS gas generator to

dashboard reinforcement

(M6

self-tapping screw) 2.5

Nm (22 in-lb)

4 Nm (35 in-lb)

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

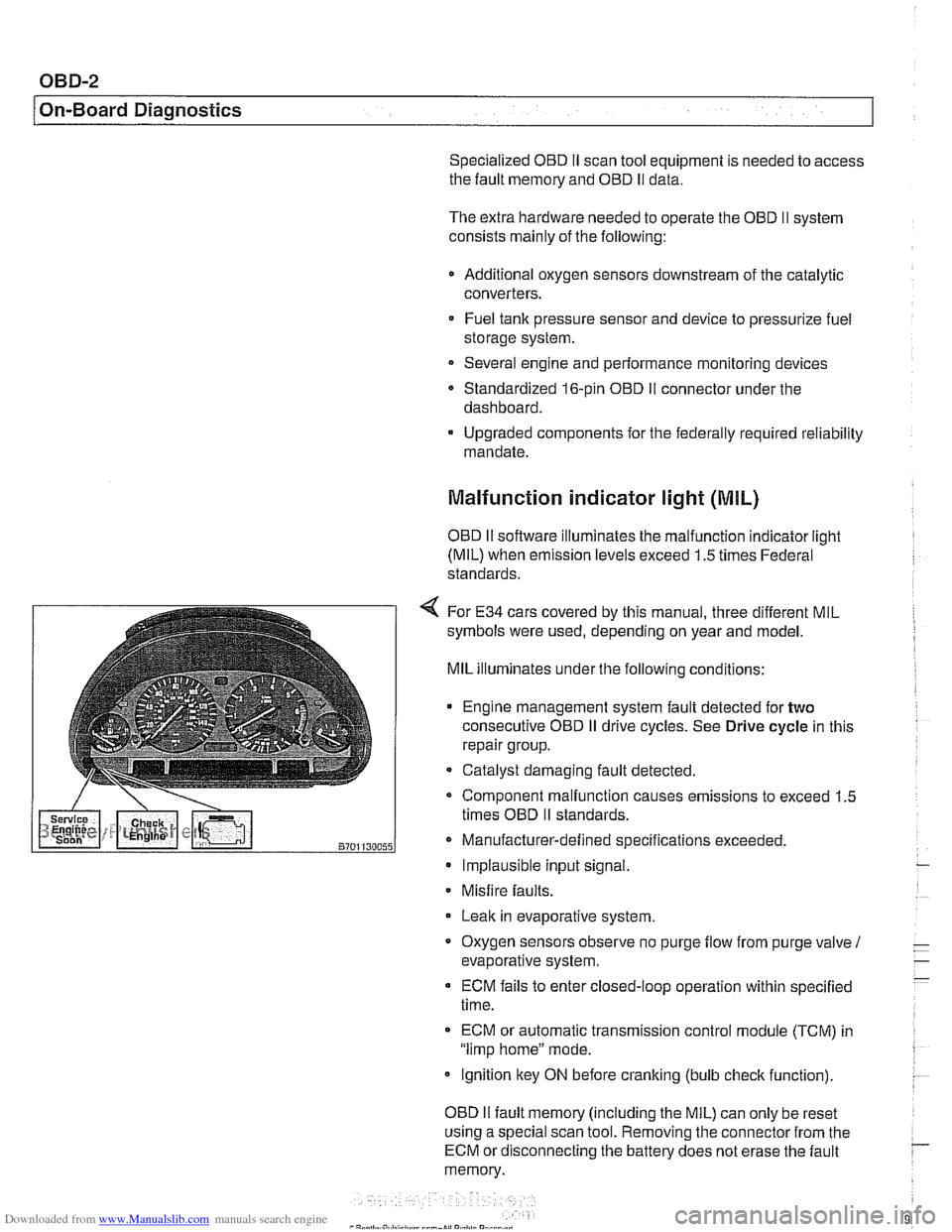

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 963 of 1002

Downloaded from www.Manualslib.com manuals search engine

OBD-3

On-Board

~iactnosticsl

Additional MIL information:

A fault code is stored within the ECM upon the first

occurrence of a fault in the system being checlted.

Two complete consecutive drive cycles with the iault

present illuminate the MIL. The exception to the two-fault

requirement is a catalyst-damaging fault, which illuminates

the MIL immediately.

If the second drive cycle was not complete and the fault

was not checked, the ECM counts the third drive cycle as

the next consecutive drive cycle. The MIL illuminates

if the

system is checked and the fault is still present.

Once the MIL is illuminated, it remains illuminated until the

vehicle completes three consecutive drive cycles without

detecting a fault.

0 An existing fault code is cleared from memory

automatically when the vehicle completes

40 consecutive

drive cycles without the fault being detected.

In order to automatically clear a catalyst-damaging fault from

memory, the condition underwhich the fault occurred must be

evaluated for 80 consecutive drive cycles without the fault

reoccurring.

A generic scan tool connected to the BMW data link

connector (DLC) or OBD

I1 plug can display diagnostic trouble

codes (DTCs), along with the conditions associated with the

illumination of the MIL. Using a more advanced or

BMW-

dedicated scan tool, additional proprietary information is

normally available.

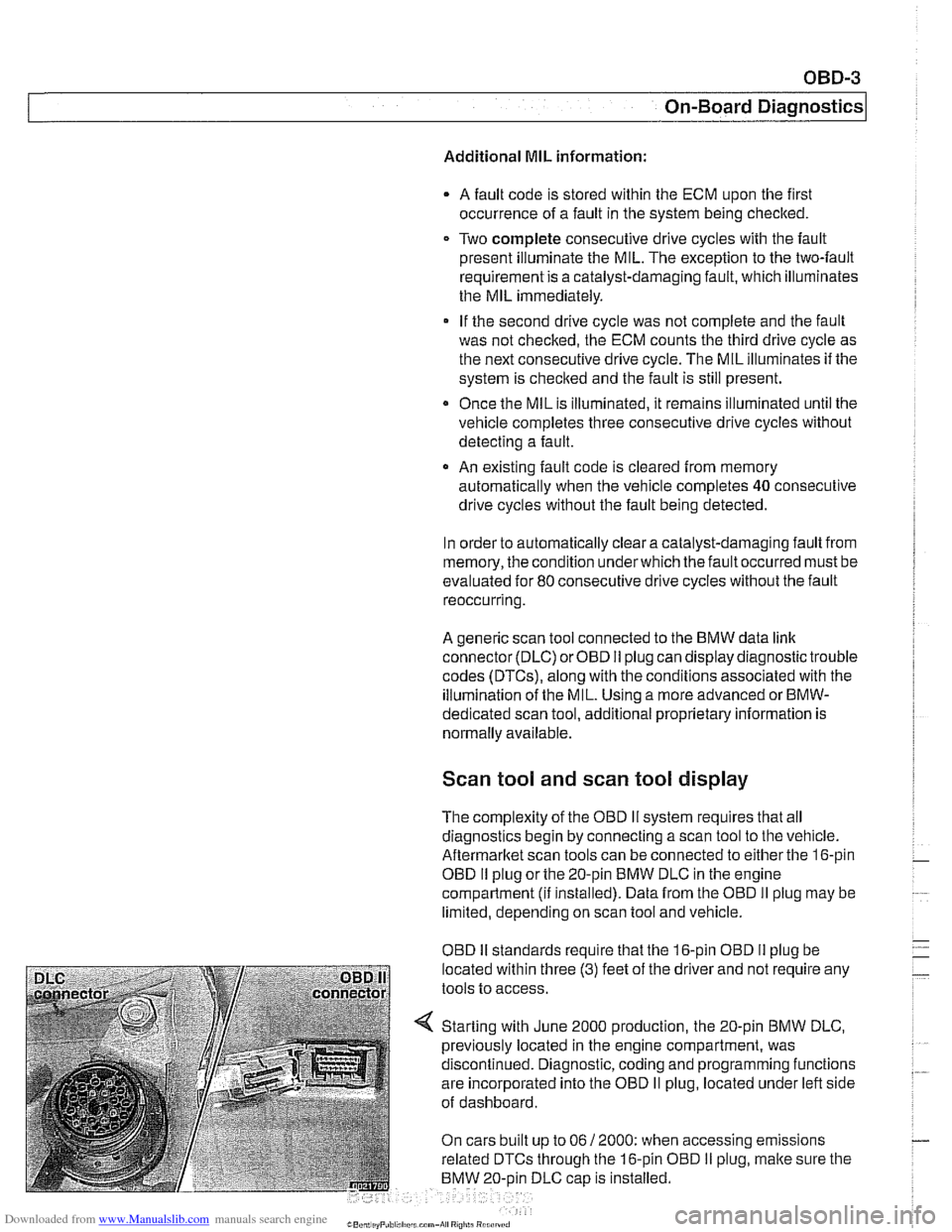

Scan tool and scan tool display

The complexity of the OBD I1 system requires that all

diagnostics begin by connecting a scan tool to the vehicle.

Aftermarltet scan tools can be connected to either the 16-pin

OBD

I1 plug or the 20-pin BMW DLC in the engine

compartment

(ii installed). Data from the OBD II plug may be

limited, depending on scan tool and vehicle.

OBD

I1 standards reouire that the 16-oin OBD I1 oluo be

located within three

(3) feet of the driier and not're&ire any

tools to access.

Starting with June 2000 production, the 20-pin BMW DLC,

previously located in the engine compartment, was

discontinued. Diagnostic, coding and programming functions

are incorporated into the OBD

II plug, located under left side

of dashboard.

On cars built up to 06

/ 2000: when accessing emissions

related DTCs through the 16-pin OBD

I1 plug, malte sure the

BMW 20-oin DLC

caD is installed.

Page 998 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual transmission

applications 200-2. 230-5

back-up light switch, replacing 230-6

gear ratios 230-6

gearshift

see Gearshiit

ID tag 200-2

fluid 020-1 0. 200-4 fluid service 230-6

oil seals

input shaft seal, replacing

230-17

output shalt seal, replacing 230-1 1

selector

shaft seal, replacing 230-8 pilot bearing 210-16

removallinstallation 230-19

see also Maintenance

Map light

see Lights, interior

Mass air flow

(MAF) sensor

see 130 under appropriate fuel

injection syslem

Master cylinder

see Brakes

see also Clutch, hydraulics

MDK

130-42

Microfilter see

NC, ventilation microfilter

see also Maintenance

Mirror see Exterior trim

Misfire see Ignition syslem, diagnosis

Motor mount

see Engine,

mounl

MRS (multiple restraint system)

see Airbag system (SRS)

Muffler

see Exhaust syslem

Neutral safety switch

see Automatic transmission, range

switch

OED II (on-board diagnostics)

OED-l

Oil change equipment 010-16

Oil level sensor

see Lubrication system

Oil pan

see Lubrication system

OH pressure

see Lubrication system

Oil pump

see Lubrication system

Oil service 020-1 1

On-Board Monitor

640-12

On-board diagnostics OED-1

Outside air temperature sensor

610-14

Outside door handle

see Door

loclc

Outside mirror switch

see Switches

Output

shaft oil seal

see Manual transmission, oil seals

Overheating

see Cooling system, troubleshooting

Overload protection

600-11

Oxygen sensors

130-72, 180-8

P codes OED-10

Panic mode operation

515-11

Parking brake

see Brakes

see also Maintenance

Parts, buying

010-11

Pedal cluster switches

see Switches

Pedal position sensor (PWG)

6-cvlinder

enqine

V-8 engine (M62 TU) 130-68

Pitman arm

see Steering

Power steering

see Steering

Power steering

fluid

see Maintenance

Power window switch

512-3 see also Switches

PWG see Pedal position sensor

(PWG)

Racic and pinion steering

see Steering

Radiator see Cooling system

Radiator cooling fan seeCooling system, cooling fan

see also Cooling system, electric fan

Radiator grill

see Exterior

trim

Radio

650-2 see also Antenna

see also Speakers

Rain sensor

611-6

Raising car safely

010-5

Readiness codes

OED-6

Rear door window

see Door window

Rear main seal

see Crankshalt oil seals

Rear parcel

sheif

513-16

Page 1000 of 1002

Downloaded from www.Manualslib.com manuals search engine

Steering description 300-10

liuid see Maintenance

gearbox

320-25

idler arm 320-30

lock 320-12

pitman arm 320-28 power steering pump 320-17

rack & pinion 320-19

steering column 320-10 motors 320-16

removinglinstalling 320-14

trim 320-10

steerino wheei 320-7 tie rods-

6-cvlinder, reelacinq 320-22

V- center tie' rod, replacing 320-32

variations 310-5

Steering box

see Steering, gearbox

Steering column switches

see Switches

Steering column

see Steering

Steering lock

see Steering

Steering

wheei switches

see Switches

Stepper motor

see

AIC

Steptronic transmission

see Gearshift

Strut see Front suspension

see also Rear suspension

Subframe see Rear suspension

Sunroof initializing

540-2

adiustinq 540-5 . . cornponents, removingiinstailing

540-9

emergency closing 540-4

Suspension, front

see Front suspension

see also

Aluminum suspension

cornponents

Suspension, rear

see Rear suspension

see also Aluminum suspension

cornponents

Swing arm

see Rear suspension, suspension

arms

Switches

ASCIDSC 612-12 back-ue

manual transmission 230-8

automatic transmission, see

Automatic transmission, range

switch

center console switches

612-11

central ioci(ing 612-1 1

hazard 612-1 I headlight 612-9

ignition cylinder 320-1 1. 612-6

outside mirror 612-11

pedal cluster switches 612-8 seat heater 612.12

steering column positioning 612-7

steering column switches 612-6 steering wheel switches 612-2

turn signaliheadlight dimmer 612-6

window 612-1 1

wipers 612-6

Tailgate

412-6 emergency release 400-4,412-6,

515-21

taiigatelrear window

loclring 515-14 see also Trunldtaiioate ioclr - see also Central ioclcing

Taillights

see Lights

Tape player

650-3

TCM (transmission control module)

see Automatic transmission

Tension strut

see Front suspension

Thermostat see Cooling system

see also Electrically heated

thermostat

Throttie body

see 130 under appropriate

fuel injection system

Throttie

cable

130-38

Throttie position sensor

see 130 under appropriate luel

injection system

Throw-out bearing

see Clutch, mechanical

Thrust arm

see Front suspension

Tie rod

see Steering

Tightening fasteners

010-8

Tilt sensor 515-24

Timing chain

see

Camshaft timing chain

Tire, changing

010-18

Tires

300-1 1

see also Maintenance

Toe

320-34

Tools

010-13