lubrication system BMW 525i 2001 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 337 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 19-1 7

Lubrication System

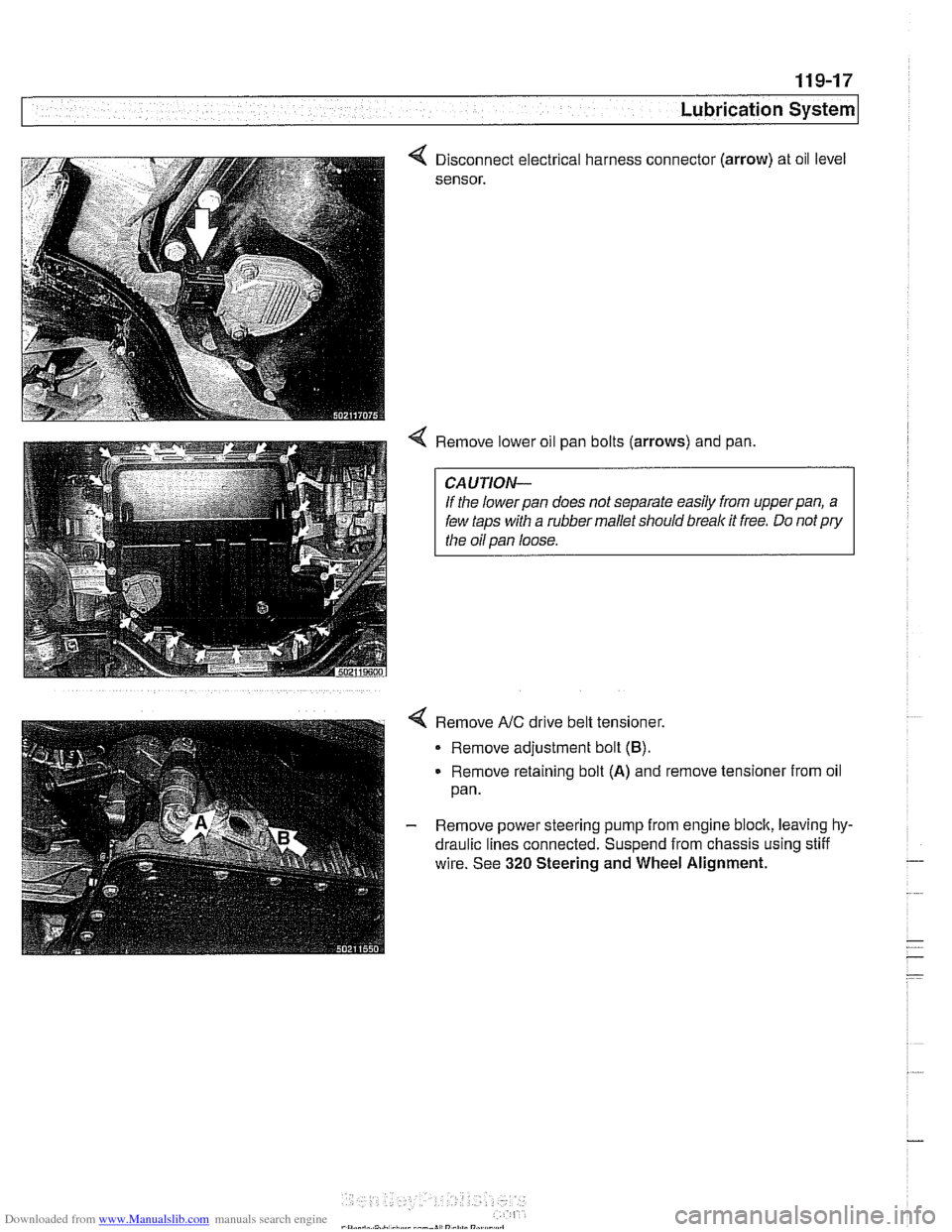

Disconnect electrical harness connect01

sensor.

. (arrow)

4 Remove lower oil pan bolts (arrows) and pan, oil

level

CAUTION-

If the lowerpan does not separate easily from upperpan, a

few taps with a rubber mallet should break it free. Do not pry

the oil pan loose.

Remove

NC drive belt tensioner.

Remove adjustment bolt

(B).

Remove retaining bolt (A) and remove tensioner from oil

pan.

- Remove power steering pump from engine block, leaving hy-

draulic lines connected. Suspend from chassis using stiff

wire. See

320 Steering and Wheel Alignment.

Page 338 of 1002

Downloaded from www.Manualslib.com manuals search engine

119-18

I Lubrication System

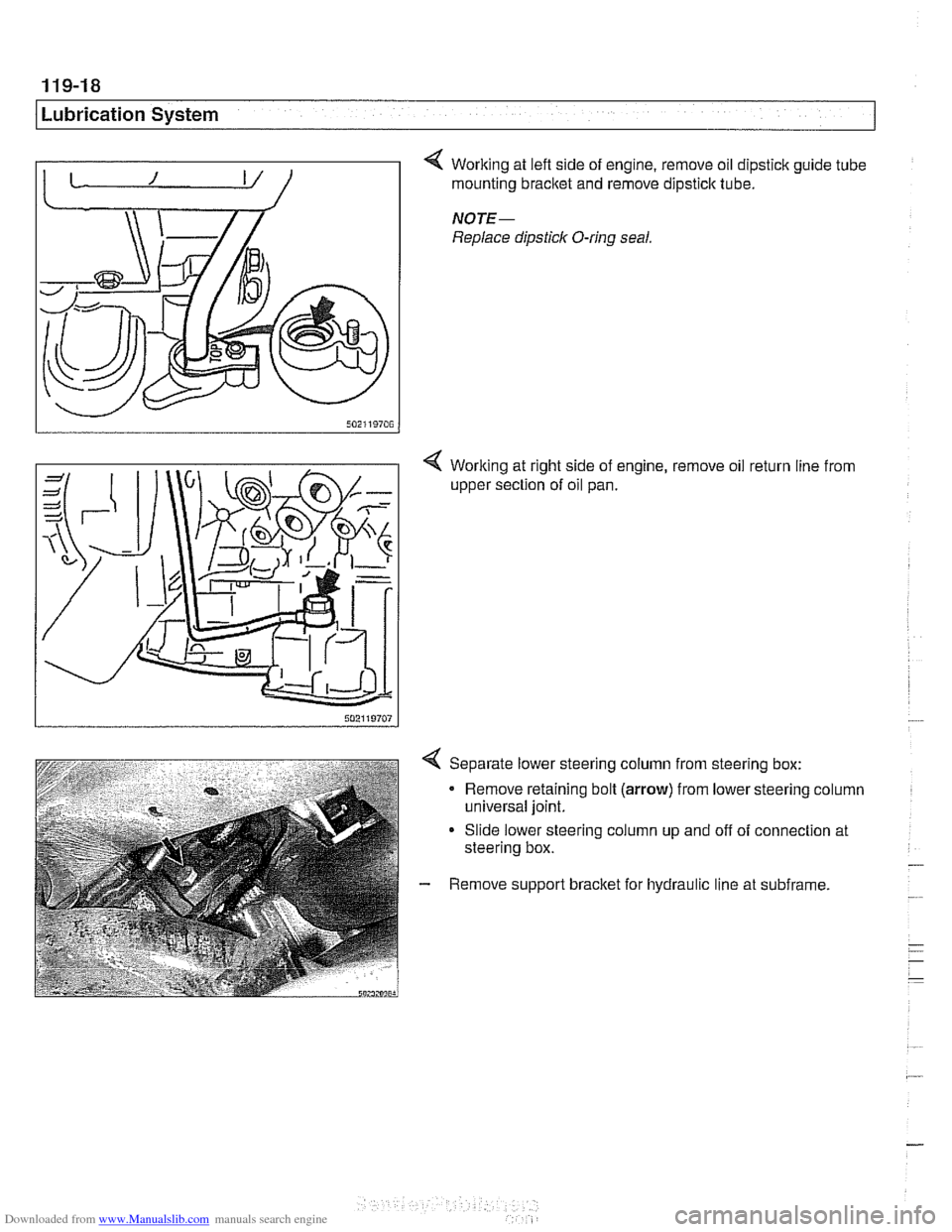

4 Working at lefl side of engine, remove oil dipstick guide tube 1 mounting bracket and remove dipstick tube.

NOTE-

Replace dipstick O-ring seal.

< Working at right side of engine, remove oil return line from

upper section of oil pan.

4 Separate lower steering column from steering box:

Remove retaining bolt

(arrow) from lower steering column

universal joint.

Slide lower steering column up and off of connection at

steering box.

- Remove support bracket for hydraulic line at subframe.

Page 342 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Lubrication System

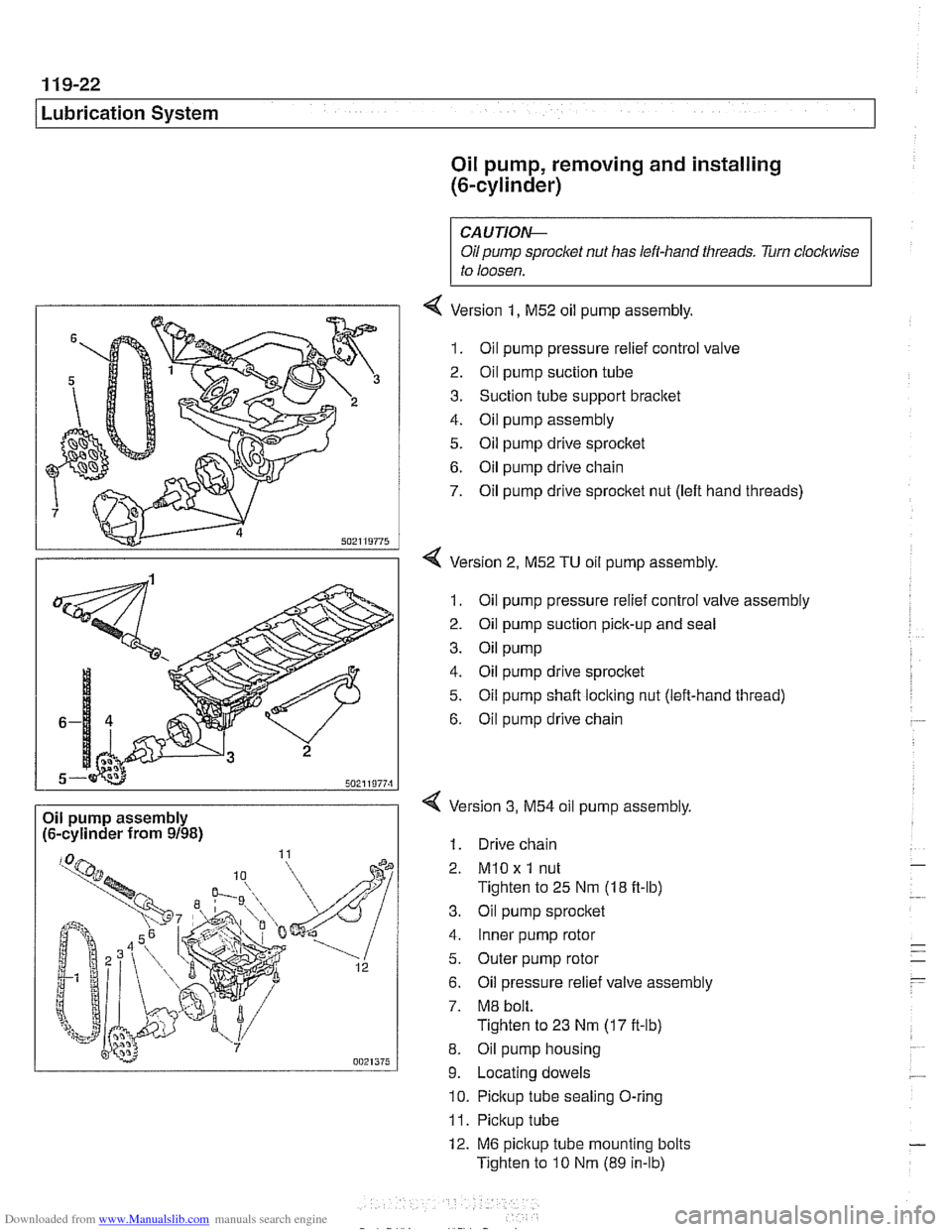

Oil pump, removing and installing

(&cylinder)

Oil pump assembly

(6-cylinder from 9/98)

CAUTIOI\C

Oil pump sproclcet nut has left-hand threads. Turn clockwise

to loosen.

4 Version 1, M52 oil pump assembly.

1. Oil pump pressure relief control valve

2. Oil pump suction tube

3. Suction tube support bracket

4. Oil pump assembly

5. Oil pump drive sprocltet

6. Oil pump drive chain

7. Oil pump drive sprocket nut (left hand threads)

4 Version 2, M52 TU oil pump assembly.

1. Oil pump pressure relief control valve assembly

2. Oil pump suction pick-up and seal

3. Oil pump

4. Oil pump drive sprocket

5. Oil pump shaft locking nut (left-hand thread)

6. Oil pump drive chain

Version

3, M54 oil pump assembly,

1. Drive chain

2.

MlO x 1 nut

Tighten to 25 Nm (18 ft-lb)

3. Oil pump sprocket

4. Inner pump rotor

5. Outer pump rotor

6. Oil pressure relief valve assembly

7. M8 bolt.

Tighten to 23 Nm

(17 it-lb)

8. Oil pump housing

9. Locating dowels

10. Pickup tube sealing O-ring

11. Pickup tube

12. M6 pickup tube mounting bolts

Tighten to

10 Nm (89 in-lb)

Page 343 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

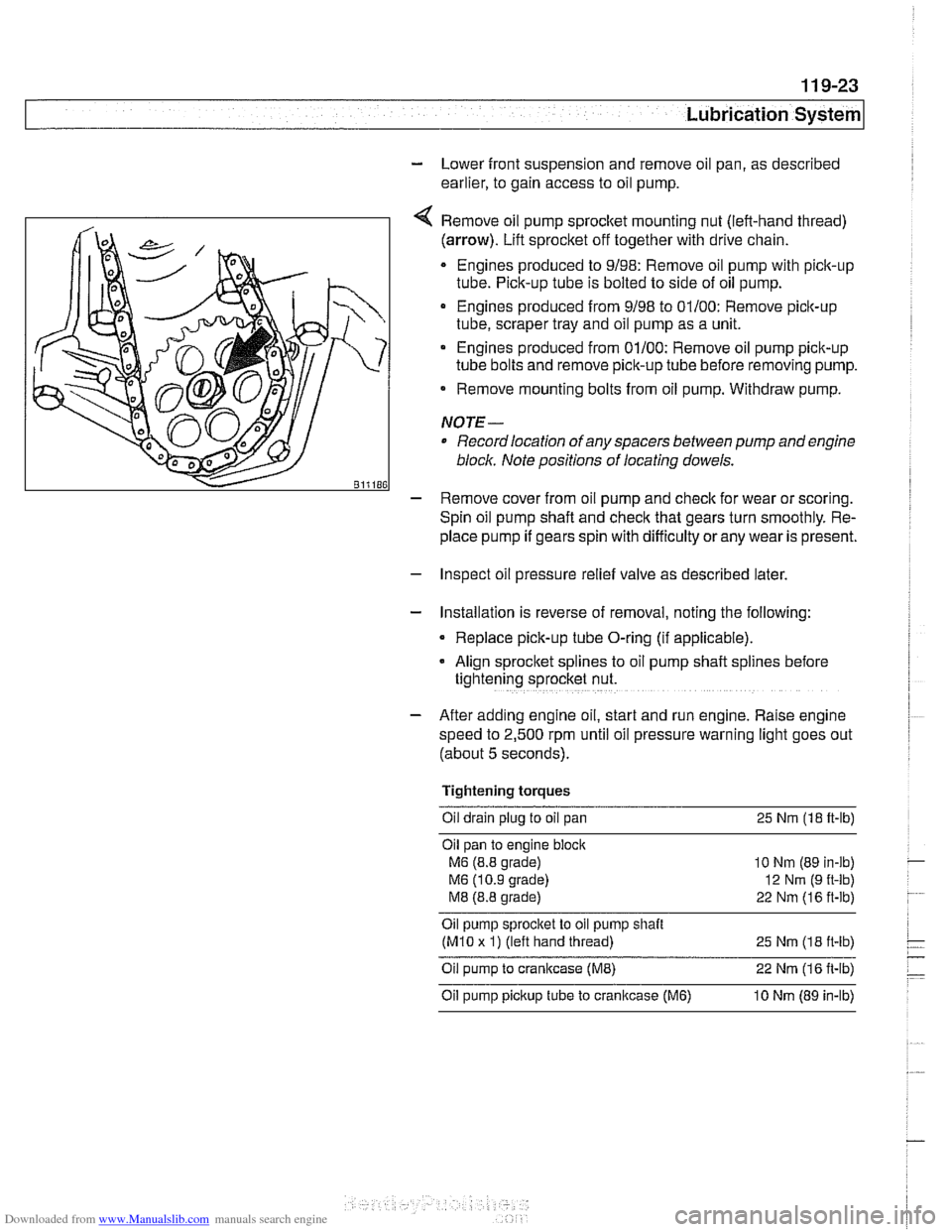

- Lower front suspension and remove oil pan, as described

earlier, to gain access to oil pump.

Remove oil pump

sprocket mounting nut (left-hand thread)

(arrow). Lift sprocket off together with drive chain.

Engines produced to 9/98: Remove oil pump with pick-up

tube. Pick-up tube is bolted to side of oil pump.

Engines produced from 9/98 to 01/00: Remove pick-up

tube, scraper tray and oil pump as a unit.

Engines produced from 01/00: Remove oil pump pick-up

tube bolts and remove pick-up tube before removing pump.

Remove mounting bolts from oil pump. Withdraw pump.

NOTE-

Record location of any spacers between pump and engine

bloclc Note positions of locating dowels.

- Remove cover from oil pump and check for wear or scoring.

Spin oil pump shaft and

check that gears turn smoothly. Re-

place pump if gears spin with difficulty

orany wear is present.

- Inspect oil pressure relief valve as described later.

- Installation is reverse of removal, noting the following:

Replace pick-up tube O-ring (if applicable).

- Align sprocket splines to oil pump shaft spl~nes before

tightening sprocket nut.

- After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

Tightening torques Oil drain plug to oil pan 25

Nm (18 ft-lb)

Oil pan to engine

bloclc

M6 (8.8 grade)

M6 (10.9 grade)

M8 (8.8 grade)

10 Nm (89 in-lb)

12

Nrn (9 ft-lb)

22 Nm (16 ft-lb)

Oil pump sprocket to oil pump shait

(M10 x 1) (left hand thread)

25 Nm (1 8 it-lb)

Oil pump to crankcase (ME) 22 Nm (1 6 it-lb)

Oil pump pickup tube to cranltcase (M6) 10 Nm (89 in-lb)

Page 344 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-24

Lubrication System

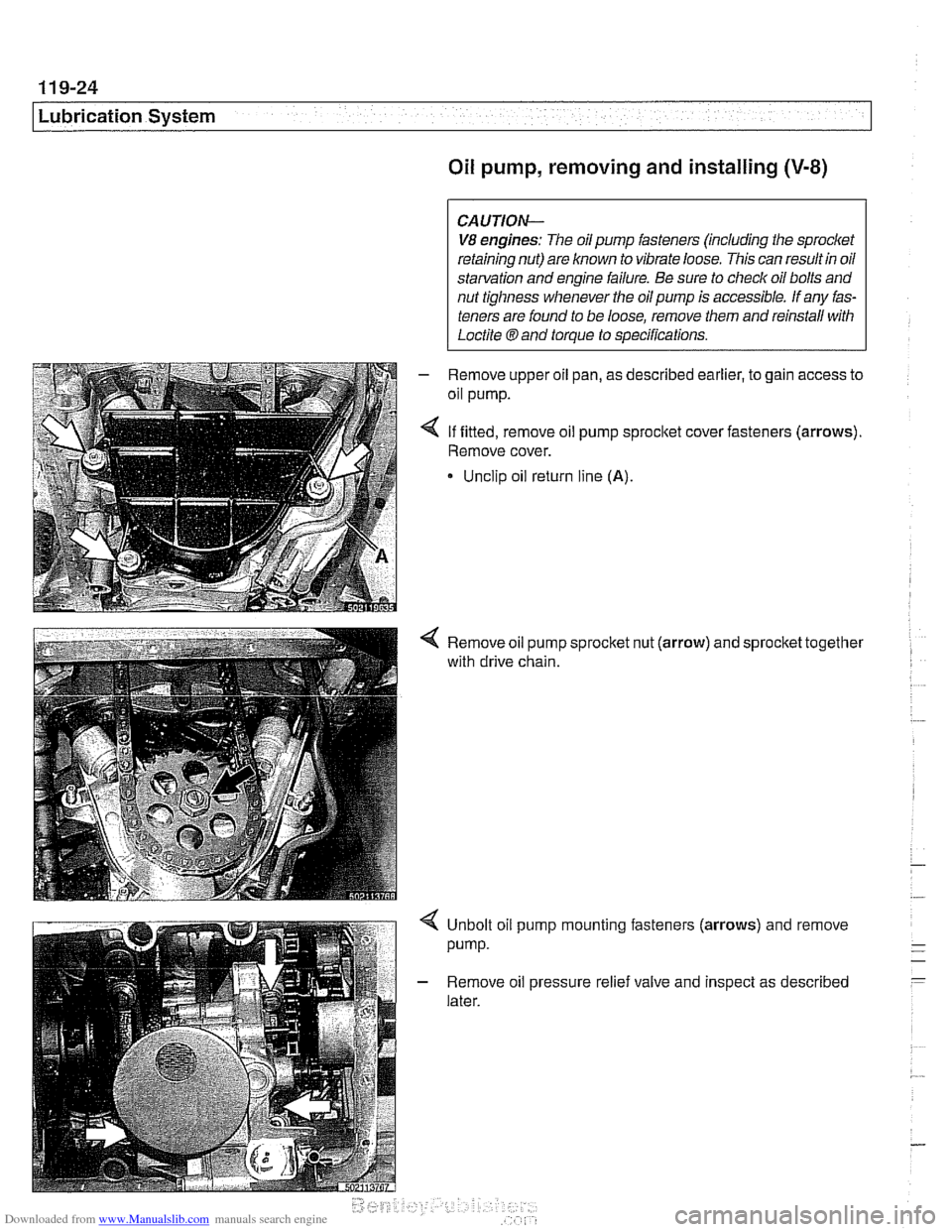

Oil pump, removing and installing (V-8)

CAUTION-

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to

checlc oil bolts and

nut tighness whenever the oil pump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

8 and torque to specifications.

- Remove upper oil pan, as described earlier, to gain access to

oil pump.

4 If fitted, remove oil pump sprocket cover fasteners (arrows).

Remove cover.

* Unclip oil return line (A).

4 Remove oil pump sprocket nut (arrow) and sprocket together

with drive chain.

Unbolt oil pump mounting fasteners (arrows) and remove

pump.

Remove oil pressure relief valve and inspect as described

later.

Page 345 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

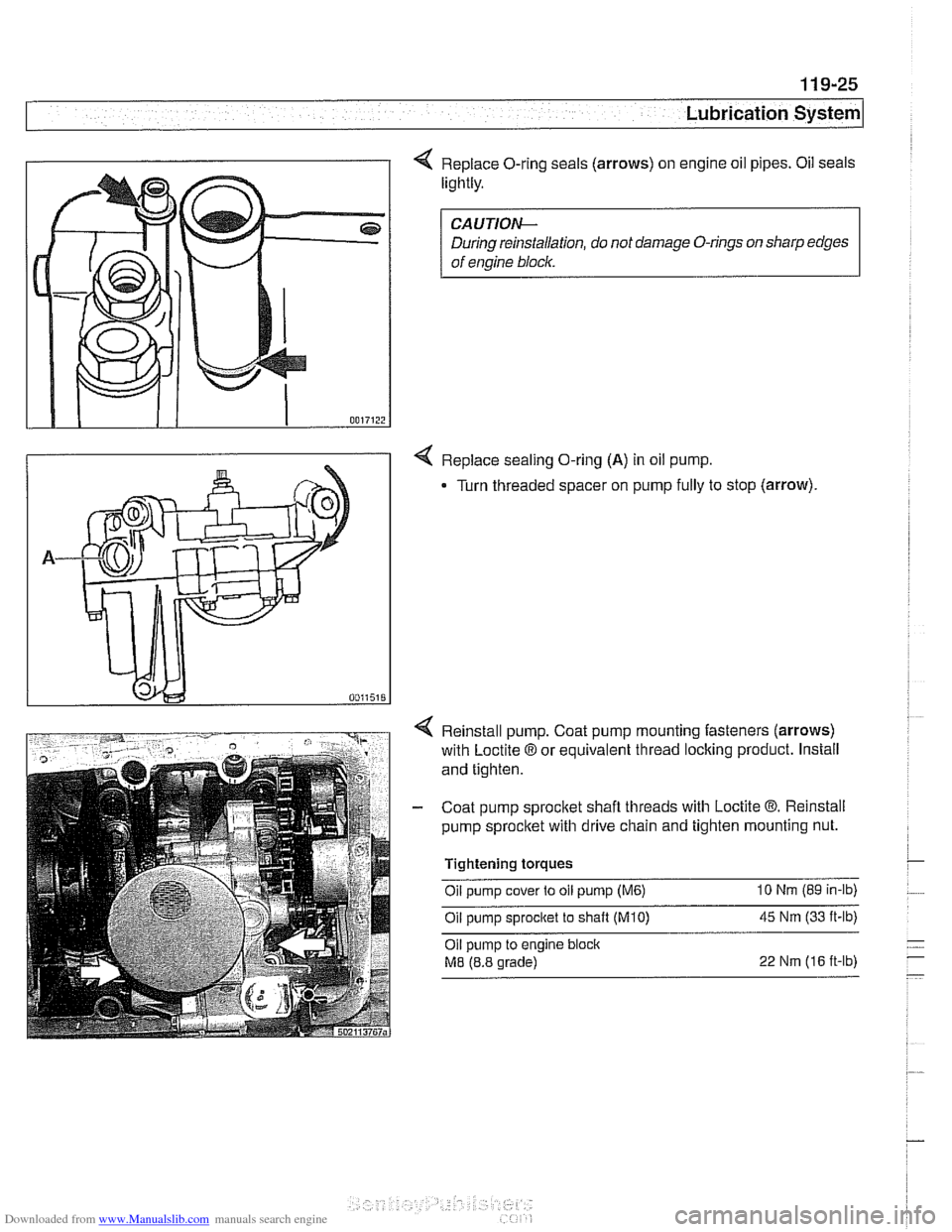

4 Replace O-ring seals (arrows) on engine oil pipes. Oil seals

lightly.

CAUTIO&

During reinstallation, do not damage O-rings on sharp edges

of engine

blocl<.

4 Replace sealing O-ring (A) in oil pump.

Turn threaded spacer on pump fully to stop

(arrow).

Reinstall pump. Coat pump mounting fasteners (arrows)

with Loctite 8 or equivalent thread locking product. Install

and tighten.

Coat pump sprocltet shafl threads with Loctite

8. Reinstall

pump sprocltet with drive chain and tighten mounting nut.

Tightening torques

Oil pump cover to oil pump (M6) 10 Nm (89 in-lb)

Oil pump sprocket to shaft

(M10) 45 Nm (33 ft-lb)

Oil pump to engine block

M8 (8.8 grade) 22 Nm (16 ft-lb)

Page 346 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-26

/Lubrication System

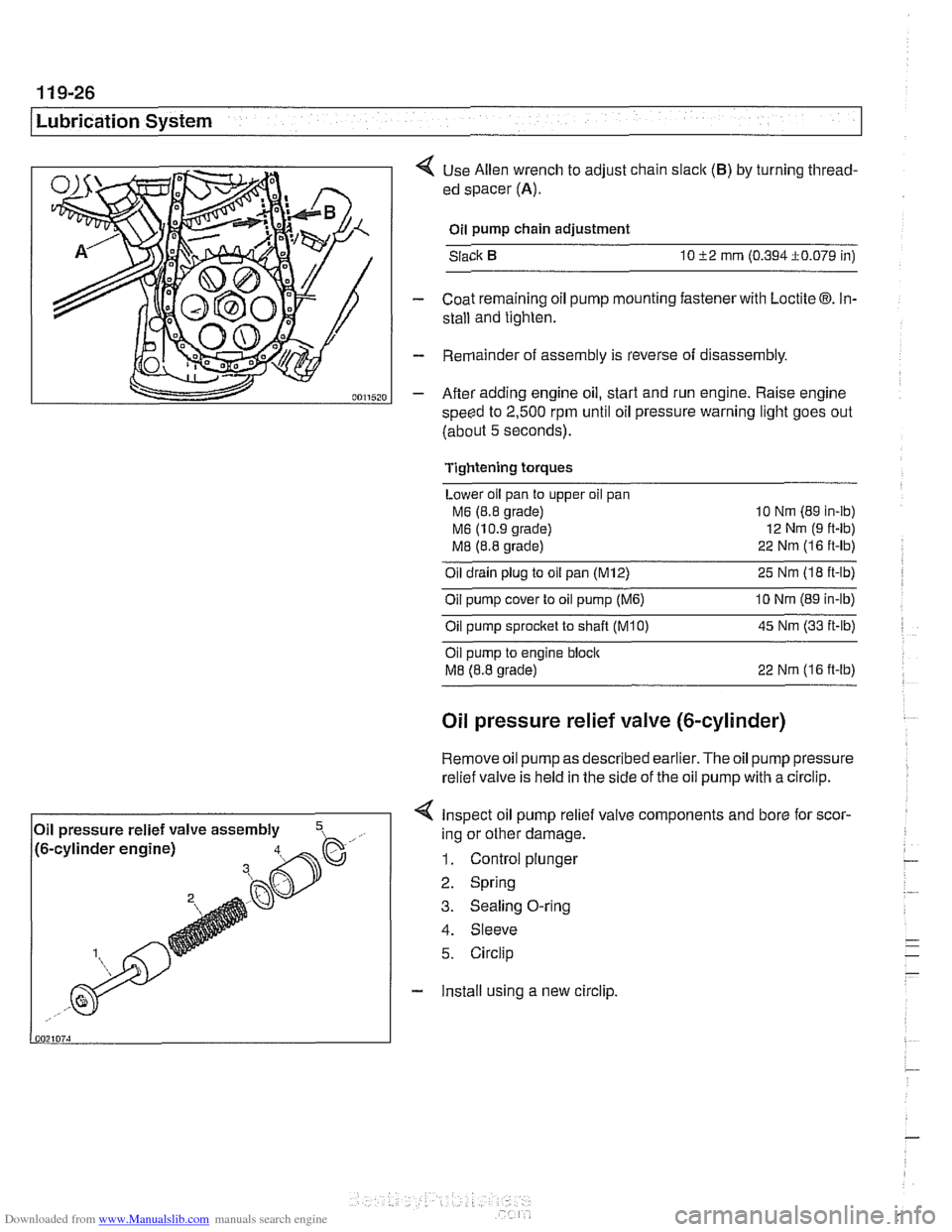

< Use Allen wrench to adjust chain slaclc (B) by turning thread-

ed spacer

(A).

Oil pump chain adjustment

Slack

10 52 mrn (0.394i0.079 in)

- Coat remaining oil pump mounting fastener with Loctite 03. In-

stall and tighten.

- Remainder of assembly is reverse of disassembly.

- After adding engine oil, start and run engine. Raise engine

speed to

2,500 rpm until oil pressure warning light goes out

(about

5 seconds).

Tightening torques

Lower oil pan to upper oil pan

M6 (8.8 grade) 10

Nm (89 in-ib)

M6 (10.9 grade) 12

Nm (9 ft-lb)

M8 (8.8 grade) 22

Nrn (1 6 ft-lb)

Oil drain plug to oil pan (M12) 25 Nm (I8 ft-lb)

Oil pump cover to oil pump

(M6) 10 Nrn (89 in-lb)

Oilpump sprocket to shaft TKO) 45 Nm (33 it-lb)

Oil pump to engine bloclc

M8 (8.8 grade) 22 Nrn (16 ft-lb)

Oil pressure relief valve (&cylinder)

Remove oil

pump as described earlier. The oil pump pressure

relief valve is held in the side of the

oil pump with a circlip.

< Inspect oil pump relief valve components and bore for scor-

4. Sleeve

5. Circlip

- Install using a new circlip.

Oil

pressure relief valve assembly

,- ..., !~. -.-~. - ~- -~!~~-% h. .- .,, /to-cy~~noer engrnej ing or other damage.

1. Control plunger

2. Spring

3. Sealing O-ring

Page 347 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-27

Lubrication System

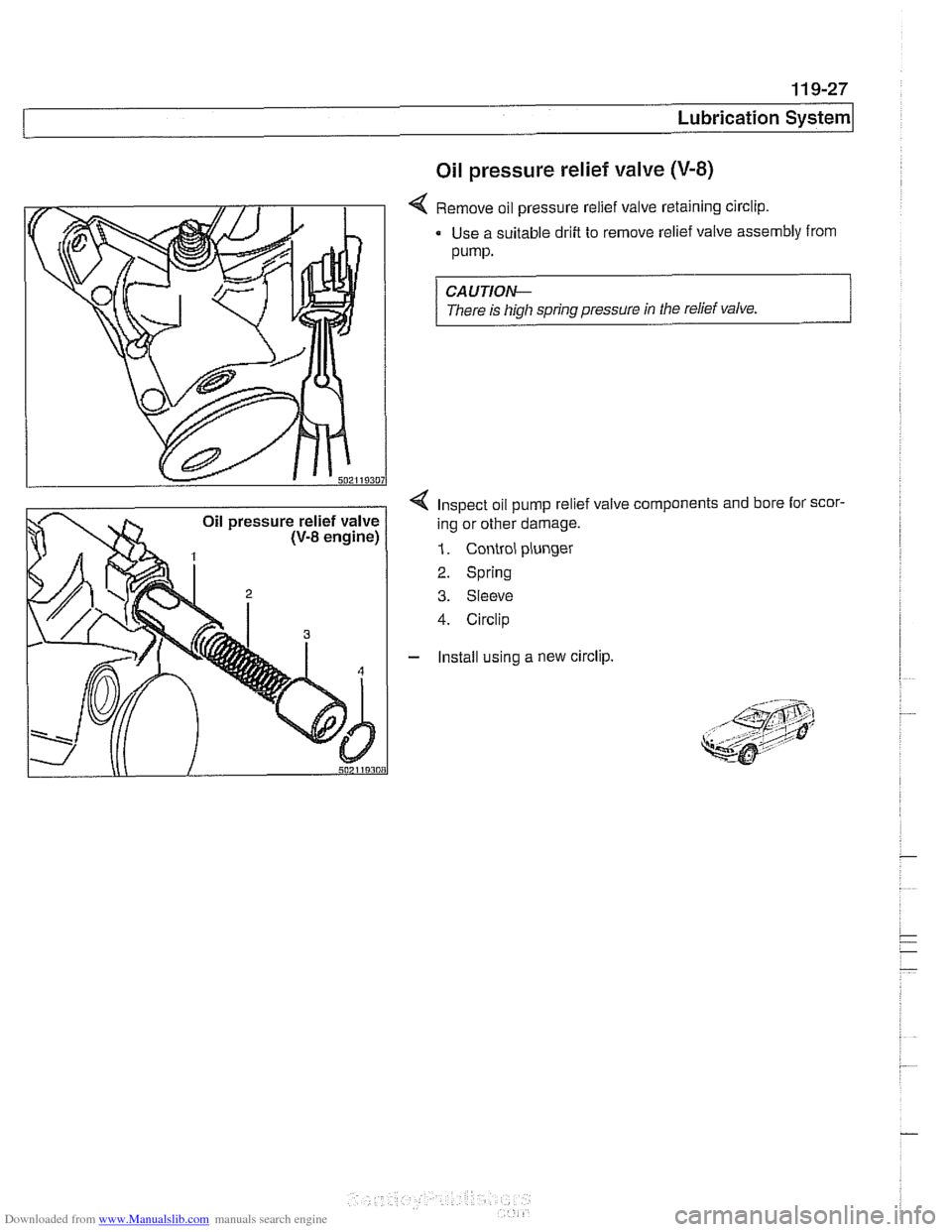

Oil pressure relief valve (V-8)

4 Remove oil pressure relief valve retaining circlip.

Use a suitable drift to remove relief valve assembly from

pump.

CAUTION--

There is high spring pressure in the relief valve.

4 Inspect oil pump relief valve components and bore lor scor-

ing or other damage.

1. Control plunger

2. Spring

3. Sleeve

4. Circlip

- Install using a new circlip.

Page 504 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-8

I Radiator and Cooling System

Common cooling system faults can be grouped into one of 4

categories:

Cooling system

lealts

Poor coolant circulation

Radiator cooling fan faults

Electrical/electronic faults

Cooling system inspection

- Check that coolant pump drive belt tensioner is functioning

properly and that belt tension is correct. Belt tensioner sys-

tems for the different models are shown in

020 Maintenance.

- Check condition of coolant pump drive belt.

- Checlc coolant hoses for cracks or softness. Checlc clamps

for looseness. Check coolant level and check for evidence of

coolant

lealts from engine.

- Check that radiator fins are not blocked with dirt or debris.

Clean radiator using low-pressure water or compressed air.

Blow outward, from engine side out.

- To check coolant pump:

Remove mechanical cooling fan. See Mechanical

(vis.

cous clutch) cooling fan, removing and installing.

Remove drive belt from coolant pump pulley. See

020

Maintenance.

Firmly grasp opposite sides of pulley and check for play in

all directions.

Spin pulley and check that shaft runs smoothly without

play.

NOTE-

The coolant provides lubrication for the pump shaft, so an oc-

casional drop of coolant

lealing from the pump is acceptable.

If coolant drips steadily from the vent hole, replace the pump.

- At normal engine operating temperature, cooling system is

pressurized. This raises boiling point of coolant.

Leaks may

prevent system from becoming pressurized. If visual evi-

dence is inconclusive, pressure test cooling system as de-

scribed later to help pinpoint hard-to-find leaks.

- If cooling system is full of coolant and holds pressure:

- Use an appropriate scan tool to interrogate engine control

module (ECM) for radiator fan or DME control circuit faults.

Checlc for loose or worn drive belt.

0 Test for failed thermostat or coolant pump impeller. Some

pumps may be fitted with plastic impellers.

Page 994 of 1002

Downloaded from www.Manualslib.com manuals search engine

4 INDEX

Door window anti-trap

512-4 convenience openinglclosing 512.4

regulator and motor 512-1 1

service

512-5 switches 512-3

see also Switches

Double

VANOS see VANOS

Drive

axle

CV joint 331-15 CV joint boot 331-15

rernovinglinstalling 331-14

Drive belt

see Maintenance

Driveabiiity troubleshooting

100-4

Driveaway protection

see EWS (eiectronic immobilization)

Driveshaft aligning

260-7

center bearing, replacing 260-12 CV joint, replacing 260-14

itex-disc, replacing 260-1 1

iront centering guide, replacing 260-13

rernovinglinstailing 260-6

lroubleshooting 260-3

U-joint 260-3

DSC

see Braires

DTC (diagnostic trouble code)

OBD-8

DWA

see Anti-theft alarm

ECM (engine control module)

see 130 under appropriate

iuei

injection system

ECT (engine coolant temperature)

sensor see 130 under appropriate

iuei

injection system

EDK adaptation

130-69

MS 43.0 130-35

EHC see Electronic iieigiit control (EHC)

Electric cooling fan

see Cooling system, cooling

fan

see also Cooiing system, eiectric fan

Electrical switches

see Switches

Electrical system abbreviations

600-14 bus System 600-4

component location table 610-3

components

photos

610-36

Sport Wagon 610-81 engine 121-2

troubleshooting 600-15

voltage and polarily 600-5 wire color codes 600-12

wiring diagrams 600-12

Electrical wiring diagrams

ELE-1

Eiectricaliy heated thermostat

(characteristic map)

170-4

Eiectronic height control (EHC)

300-8, 330-44

Eiectronic immobilization

see EWS (electronic immobilization)

Eiectronics box

(E-box)

610-37

Emergencies

010-18

Emergency brake see

BraBes, parking brake Engine

see also Cylinder head and valvetrain

applications

100-2

compression, testing 113-5

cooling see Cooiing system

crankshaft front oil seai

see Crankshaft oil seals

cyiinder leak-down test 113-8

diagnostic testing 113-1

drive belts

see Maintenance

driveability troubleshooting

100-4

engine management systems 100-2

see also Ignition

see also Fuel injection

fuel supply

130-6

ground connections 100-5

see also 61 0 identilying ieatures 100-3

lubrication svstem

see

~ubricetion system

mount

on-board diagnostics

OBD-I

oxygensensor

see Fuel injection

see also Exhaust system

Dreventive maintenance

see Maintenance

removal/installation

Engine control module (ECM)

see 130 under appropriate iuel

injection system

Engine cooiant temperature (ECT)

sensor see 130 under appropriate iuel

injection

system

Engine cooling fan

see Cooiing system, electric fan

Engine hood

41

0-6 raising to service position 410-6

Engine troubleshooting

see Engine, driveability troubleshooting

EVa~oratiVe control svstem

160-3 see also 130 under aDDroDriate iuel

injection system

Evaporator see

NC

Evaporator temperature sensor see

NC