Coolant temperature sensor BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 41 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

Table c. Inspection II Service

Additional

New parts Warm engine Dealer service repair

Tools required required required recommended information

Engine compartment maintenance

Replace air filter element. (Note: reduce

replacement intervals in dusty operating

conditions).

Replace brake

fluid every 2 years (time

interval begins from vehicle production

date).

Cooling system service

Spark plug service

Brake

system maintenance

:j:

*

Replace coolant every 3 years (time

interval begins from vehicle production

date).

Replace oxygen sensor every 160,000

itm

(1 00,000 miles).

020

FLUID AND LUBRICANT

SPECIFICATIONS

:I:

Oxygen sensor service

*

x:

Spark plugs:

M52

1 M62 engine:

Replace every 60,000 itm (48.000 miles).

M52

TU I M54 1 M62 TU engine:

Replace every 160,000

ltm (100.000

miles).

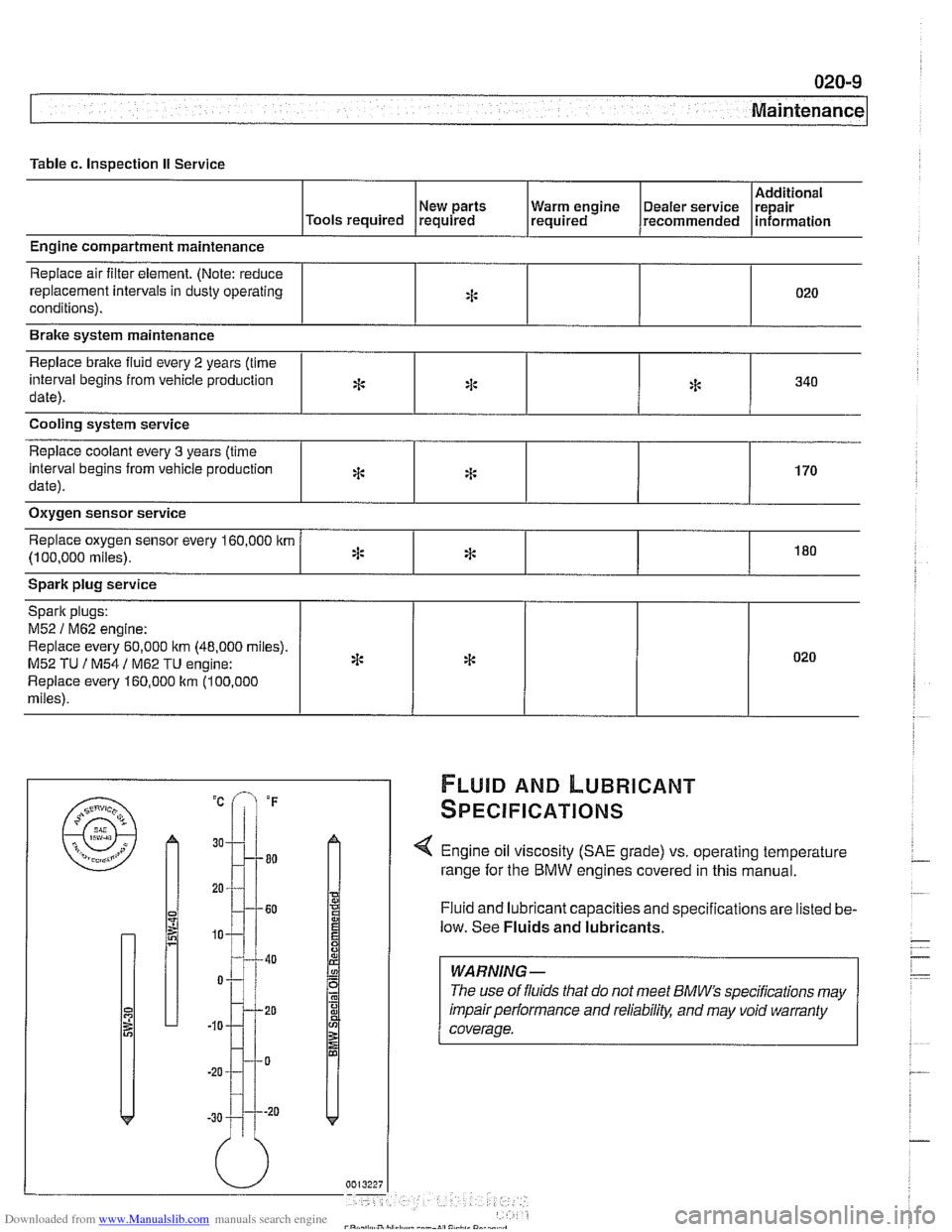

< Engine oil viscosity (SAE grade) vs. operating temperature

range for the BMW engines covered in this manual.

Fluid and lubricant capacities and specifications are listed be-

low. See

Fluids and lubricants.

:I:

*

*

*

WARNING -

The use of fluids that do not meet BMW" specifications may

impair performance and

reliabilitl: and may void warranty

coverage.

340

170

180

* 020

Page 92 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 0-20

Engine Removal and Installation

Working at right side of transmission bellhousing, disconnect

electrical harness connections (arrows) from starter. Re-

move starter retaining bolts and remove starter from trans-

mission mount.

M62 TU engine: Disconnect electrical harness connector

for right oxygen sensor from retaining clip and remove re-

taining clip from transmission.

- Working underneath engine compartment at left side:

Unclip positive battery cable from oil pan.

. Remove alternator cooling duct.

4 M62 engine: Remove fastener A and plug connector B from

alternator.

- M62 TU engine: Remove electrical harness connectors from

front of water cooled alternator.

- Remove exhaust system and transmission. See 180 Ex-

haust System and 230 Manual Transmission or 240 Auto-

matic Transmission.

- Working at front of engine:

Remove upper and lower hoses from radiator.

D~sconnect expansion tank hose from coolant pump.

- Remove belt-driven cooling fan:

Counterhold fan with special tool

11 5 050.

Turn fan mounting nut (32 mm) clockwise (left hand

threads) to loosen.

Rotate fan clockwise to remove.

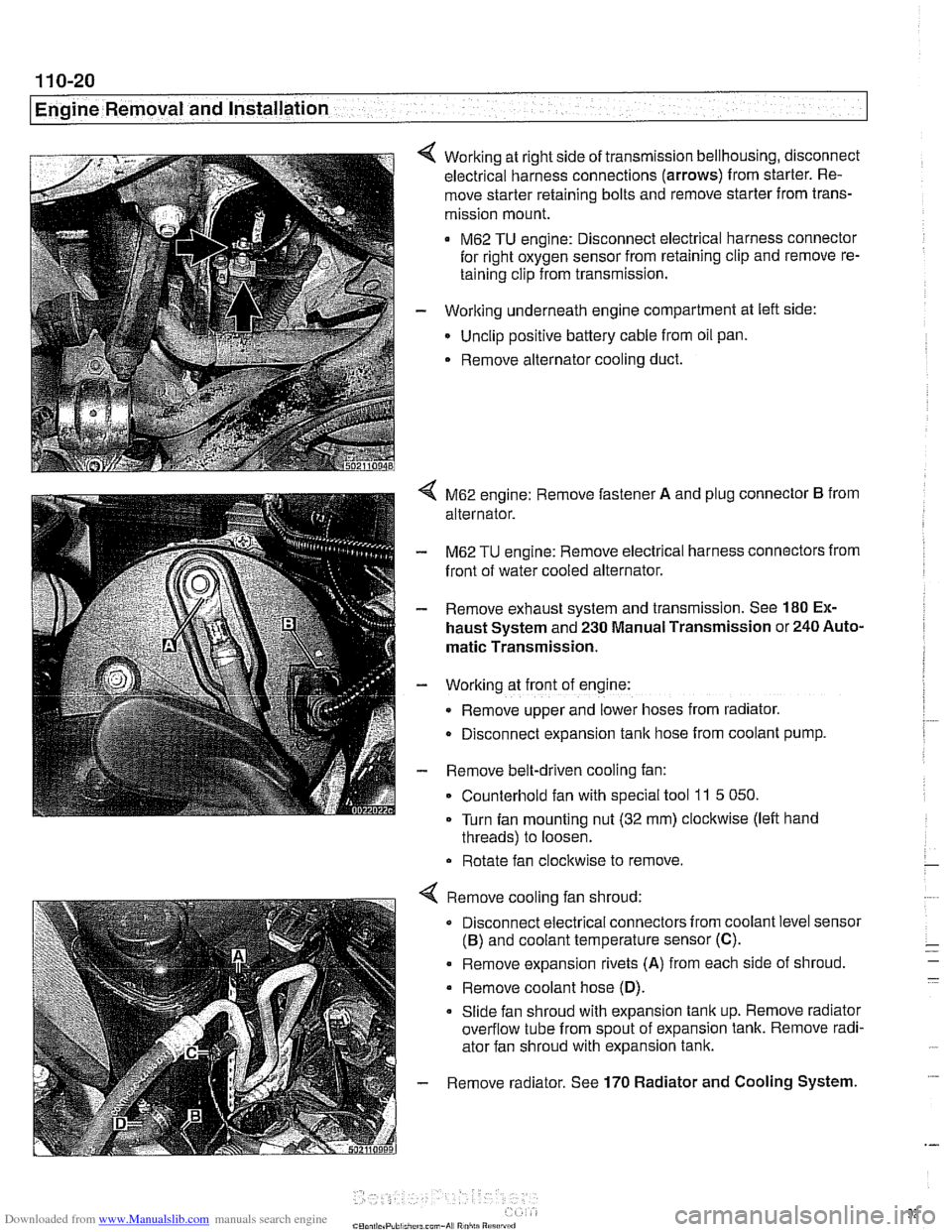

Remove cooling fan shroud:

Disconnect electrical connectors from coolant level sensor

(B) and coolant temperature sensor (C).

. Remove expansion rivets (A) from each side of shroud

Remove coolant hose

(D).

Slide fan shroud with expansion tank up. Remove radiator

overflow tube from spout of expansion tank. Remove radi-

ator fan shroud with expansion tank.

Remove radiator. See

170 Radiator and Cooling System.

Page 105 of 1002

Downloaded from www.Manualslib.com manuals search engine

..

Cylinder Head Removal and Installation 1

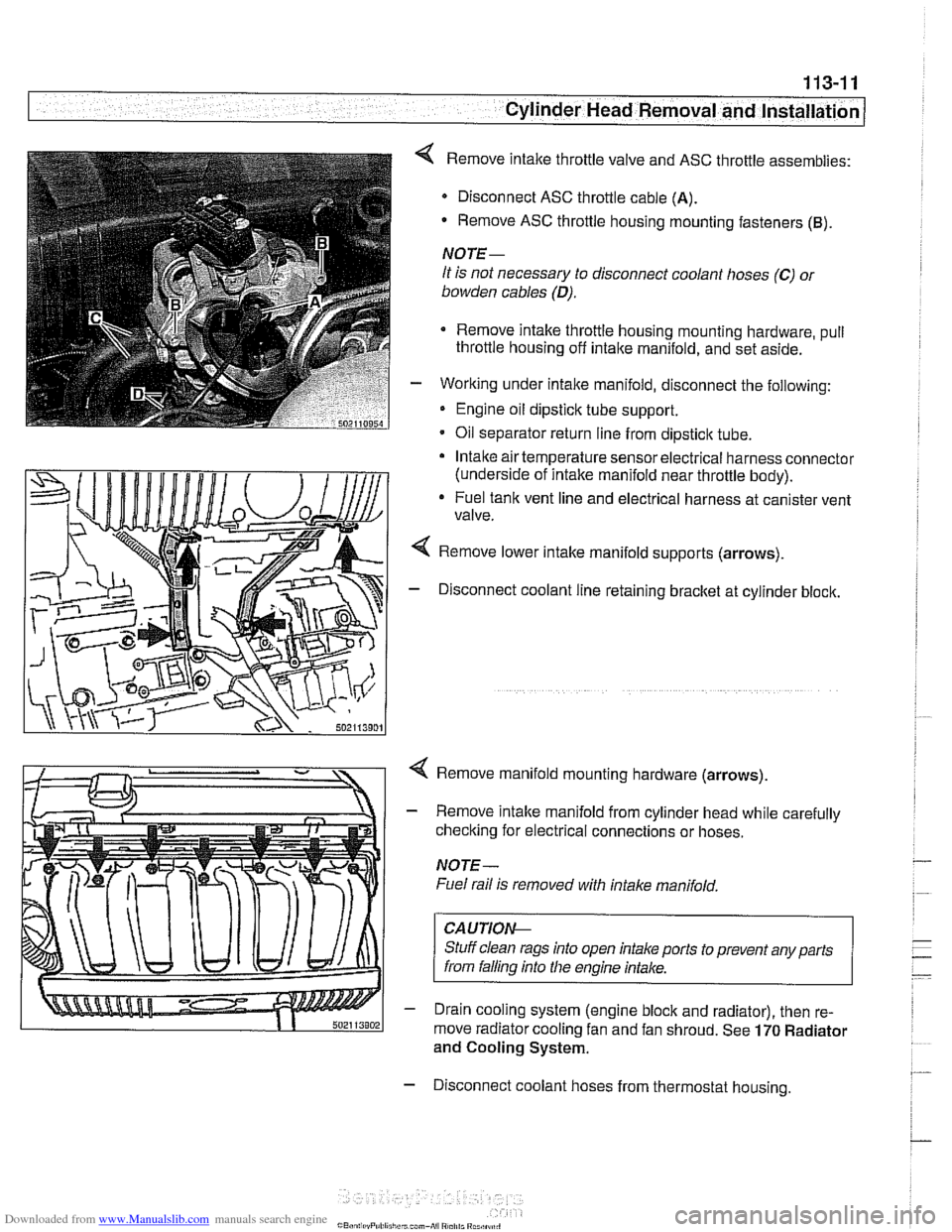

< Remove intake throttle valve and ASC throttle assemblies:

Disconnect ASC throttle cable

(A).

- Remove ASC throttle housing mounting fasteners (B).

NOTE-

It is not necessary to disconnect coolant hoses (C) 01

bowden cables (D).

Remove intake throttle housing mounting hardware, pull

throttle housing off

intake manifold, and set aside.

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from dipstick tube.

Intake air temperature sensor electrical harness connector

(underside of intake manifold near throttle body).

* Fuel tank vent line and electrical harness at canister vent

valve.

Remove lower intake manifold supports (arrows).

- Disconnect coolant line retaining bracket at cylinder block.

4 Remove manifold mounting hardware (arrows).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections or hoses.

NOTE-

Fuel rail is removed with intake manifold,

CAUTIOI\C

Stuff clean rags into open intake ports to prevent any parts

from falling into

Nie engine intake.

- Drain cooling system (engine block and radiator), then re-

move radiator cooling fan and fan shroud. See

170 Radiator

and Cooling System.

- Disconnect coolant hoses from thermostat housing.

Page 115 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Cylinder Head Removal and lnstallation

NOTE-

Be Sure the secondary timing chain tensioner is locked down

and the exhaust

camshaif mounting bolts are loose before

proceeding.

- Install VANOS control unit. See VANOS control unit, install-

ing

(M52 engine) in 117 Camshaft Timing Chain.

CAUTION--

Incorrect installation ofthe VANOS control may result in dam-

age to the engine valvefrain.

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

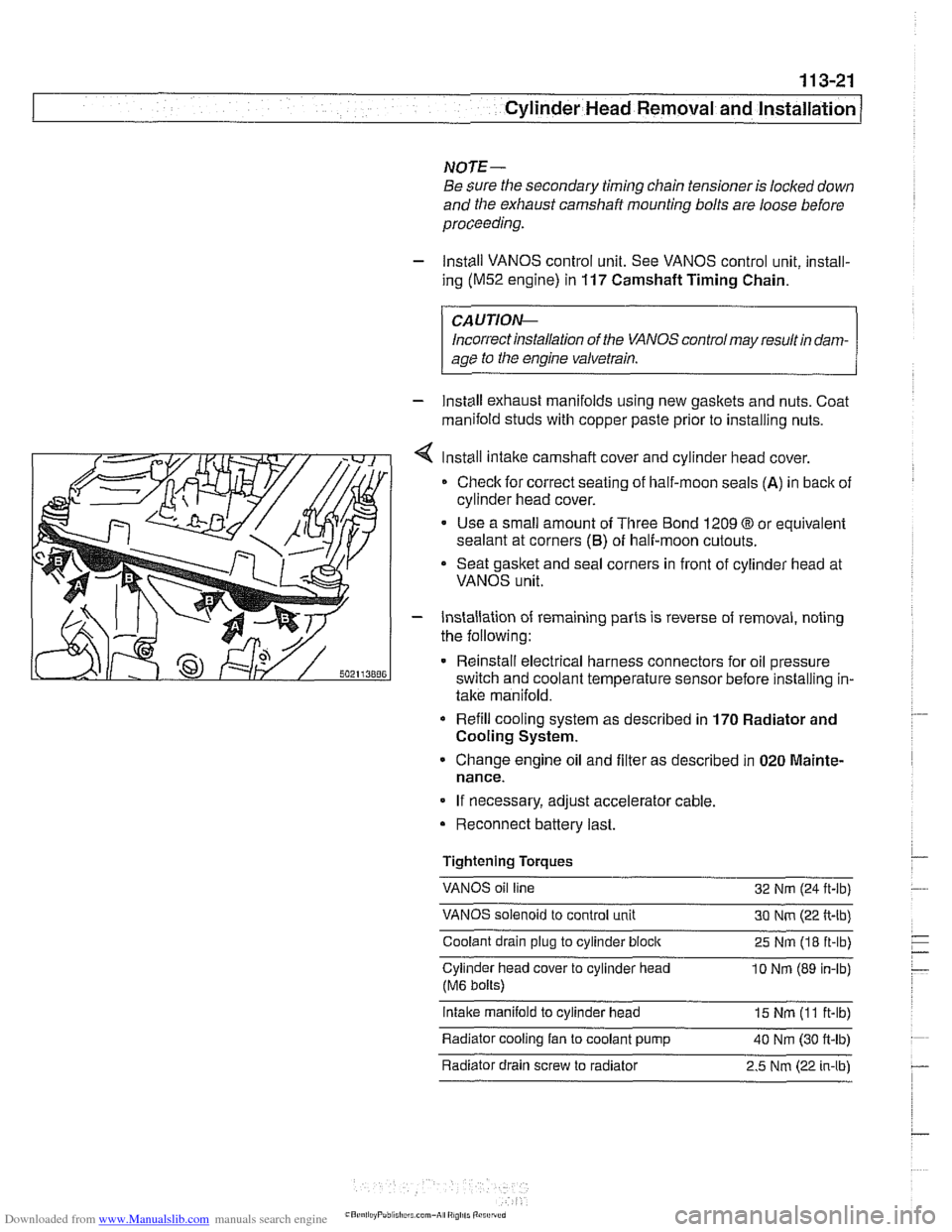

Install intake camshaft cover and cylinder

head cover.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(6) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

- Installation of remaining parts is reverse of removal, noting

the following:

Reinstall electrical harness connectors for oil pressure

switch and coolant temperature sensor before installing in-

take manifold.

Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in 020 Mainte-

nance.

If necessary, adjust accelerator cable.

Reconnect battery last.

Tightening Torques

VANOS oil line

32 Nm (24

ft-lb)

VANOS solenoid to control unit 30 Nm (22 ft-lb)

Coolant drain plug to cylinder

block 25 Nm (18 ft-lb)

Cylinder head cover to cylinder head

10 Nrn (89 in-lb)

(M6 bolts)

intake manifold to cylinder head 15 Nm (I 1 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb) - . .

Radiator drain screw to radiator 2.5 Nm (22 in-lbl

Page 149 of 1002

Downloaded from www.Manualslib.com manuals search engine

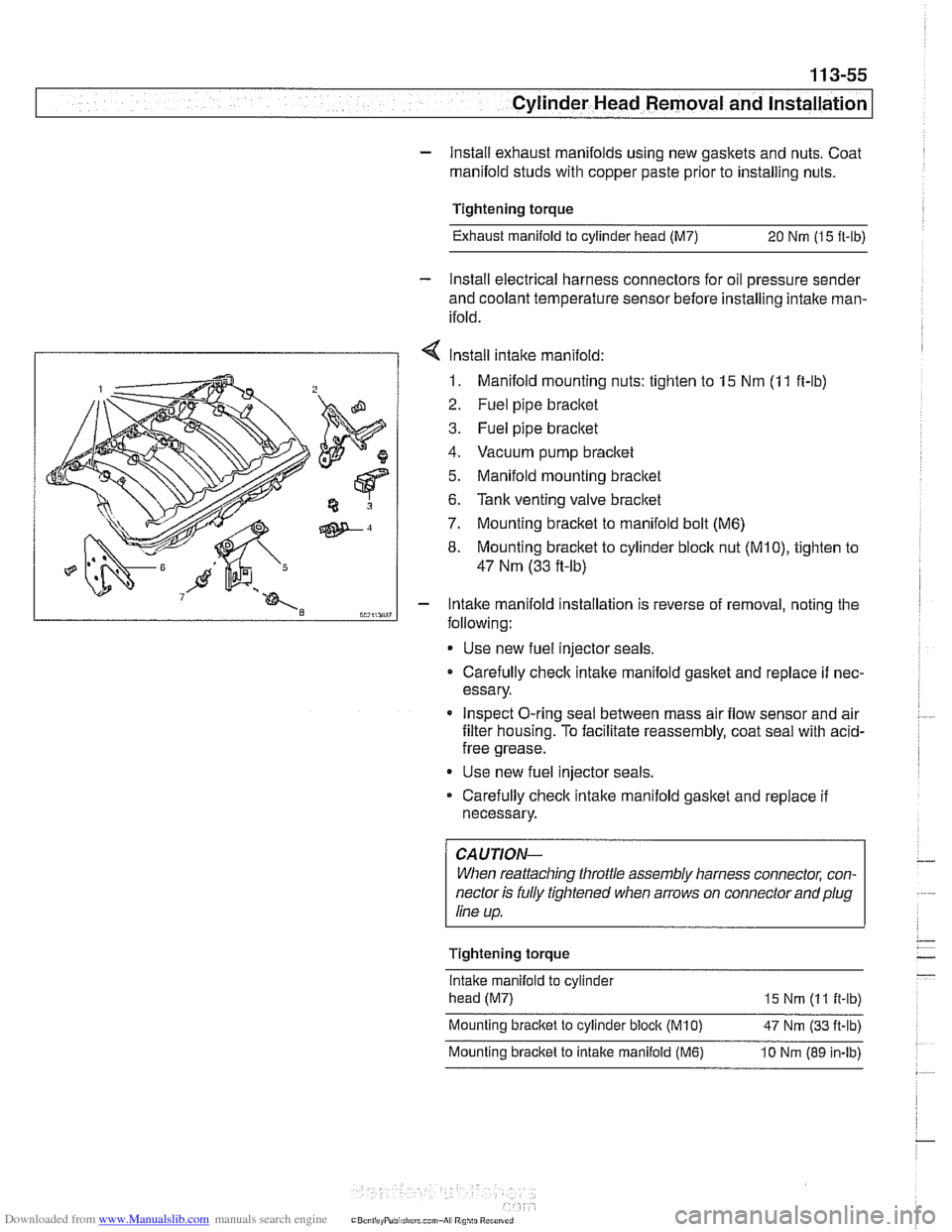

Cylinder Head Removal and Installation

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

Tightening torque Exhaust

maniiold to cylinder head (M7)

20 Nm (15 ft-lb)

- Install electrical harness connectors for oil pressure sender

and coolant temperature sensor before installing

intalte man-

ifold.

7 Install intake manifold:

1. Manifold mounting nuts: tighten to 15 Nm (1 1 ft-lb)

2. Fuel pipe bracltet

3. Fuel pipe bracltet

4. Vacuum pump bracltet

5. Manifold mounting bracltet

6.

Tank venting valve bracltet

7. Mounting bracket to manifold bolt (M6)

8. Mounting bracket to cylinder block nut (MIO), tighten to

47 Nm (33 fi-lb)

Intake manifold installation is reverse of removal, noting the

following:

* Use new fuel injector seals.

Carefully

check intake manifold gasket and replace if nec-

essary.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with

acid-

free grease.

Use new fuel injector seals.

Carefully check intake manifold gasket and replace if

necessary.

CA UTIOPI-

When reattaching throttle assembly harness connector, con-

nector is fully tightened when arrows on connector

andplug

line up.

Tightening torque

lntalte manifold to cylinder

head (M7)

15 Nm (1 1 it-lb) ~ ~- Mounting bracket to cylinder bloclt (M10) 47 Nm (33 ft-lb)

Mounting bracket to intake manifold (MI?) 10 Nm (89 in-lb)

Page 270 of 1002

Downloaded from www.Manualslib.com manuals search engine

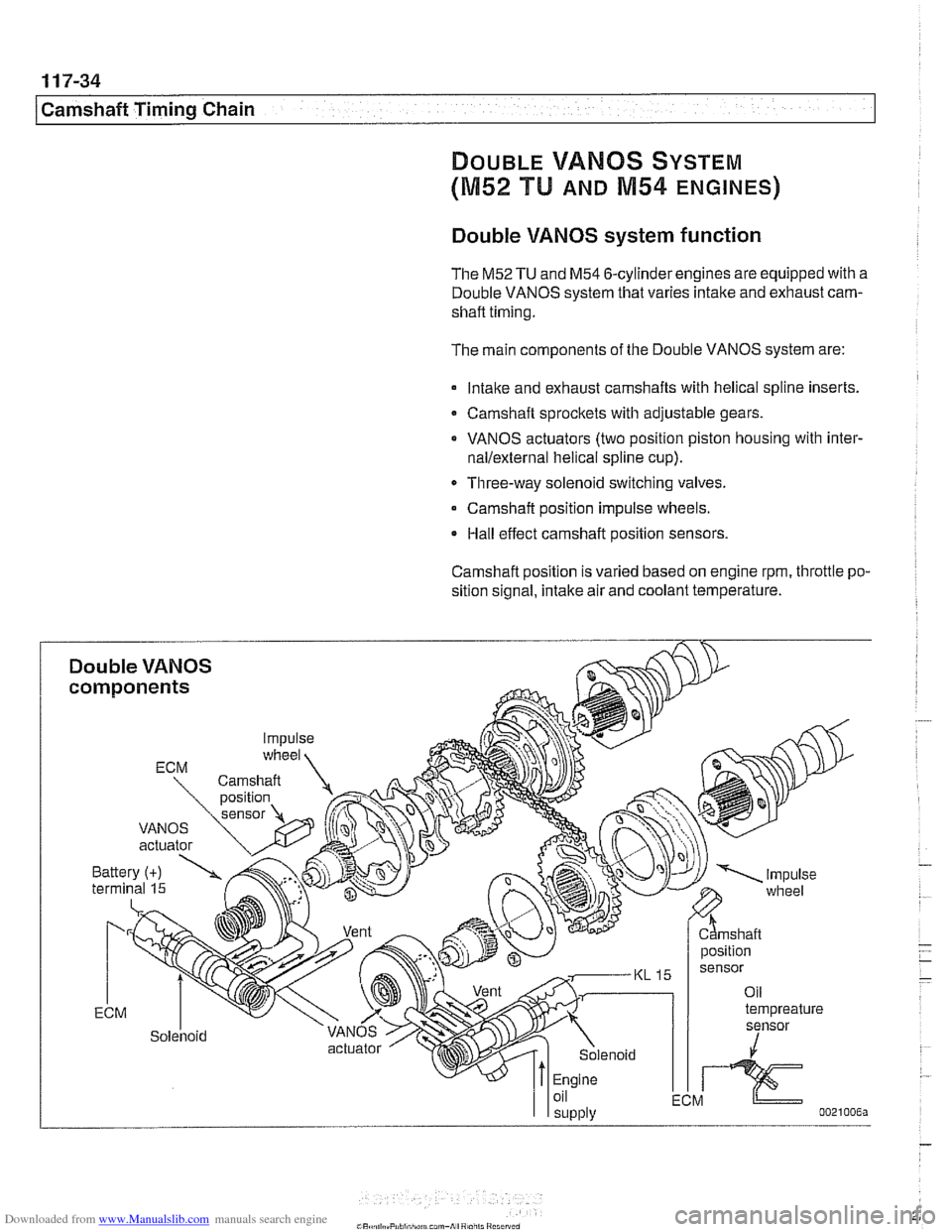

1 17-34

1 Camshaft Timing Chain

DOUBLE VAMOS SYSTEM

(M52 TU AND M54 ENGINES)

Double VANOS system function

The M52TU and M54 6-cylinder engines are equipped with a

Double VANOS system that varies intake and exhaust cam-

shaft timing.

The main components of the Double VANOS system are:

lntalte and exhaust camshafts with helical spline inserts.

Camshaft sprockets with adjustable gears.

VANOS actuators (two position piston housing with

inter-

nallexternal helical spline cup).

Three-way solenoid switching valves.

Camshaft position impulse wheels.

Hall effect camshaft position sensors.

Camshaft position

IS varied based on engine rpm, throttle po-

sition signal, intake air and coolant temperature.

Page 353 of 1002

Downloaded from www.Manualslib.com manuals search engine

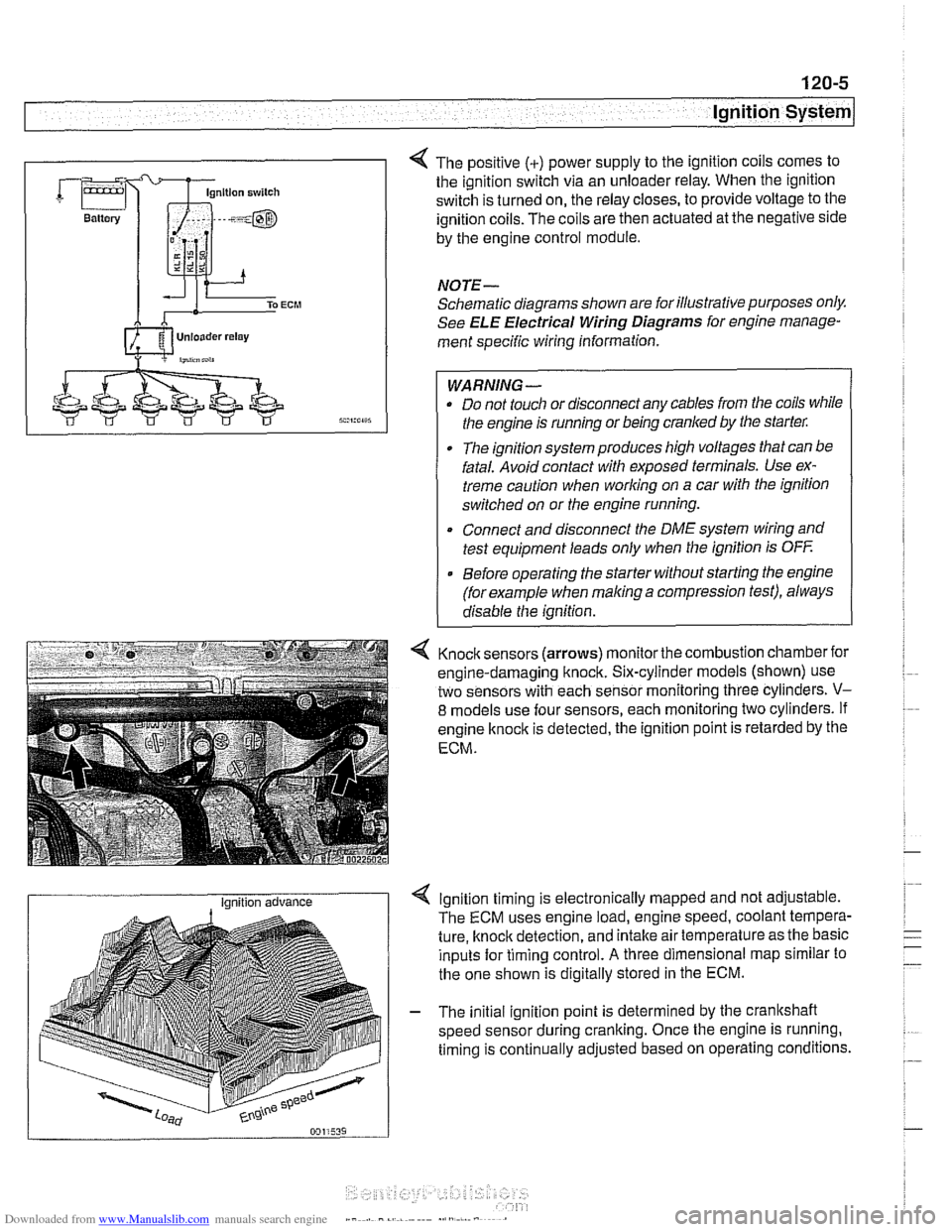

Lnition switch

4 The positive (+) power supply to the ignition coils comes to

the ignition switch via an unloader relay. When the ignition

switch is turned on, the relay closes, to provide voltage to the

ignition coils. The coils are then actuated at the negative side

by the engine control module.

NOTE-

Schematic diagrams shown are for illustrative purposes only.

See ELE Electrical Wiring Diagrams for engine manage-

ment specific wiring information.

WARNING- Do not touch or disconnect any cables from the coils while

the engine is running or being cranked by the starter:

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

* Connect and disconnect the DME system wiring and

test equipment leads only when the ignition is

OFF

Before operating the starter without starting the engine

(for example when

making a compression test), always

disable the ignition.

4 Knock sensors (arrows) monitor the combustion chamber for

engine-damaging knock. Six-cylinder models (shown) use

two sensors with each sensor monitoring three cylinders.

V-

8 models use four sensors, each monitoring two cylinders. If

engine

knock is detected, the ignition point is retarded by the

ECM.

I Ignition advance Ignition timing is electronically mapped and not adjustable.

The ECM uses engine load, engine speed, coolant tempera-

ture, knock detection, and intake air temperature as the basic

inputs for timing control.

A three dimensional map similar to

the one shown is digitally stored in the ECM.

- The initial ignition point is determined by the crankshaft

speed sensor during cranking. Once the engine is running.

timing is continually adjusted based on operating conditions.

Page 391 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1

130 Fuel injection

General ........................... .I3 0.2

Tools and test equipment .............. .I3 0.3

Warnings and cautions ................ .I3 0.5

Fuel Supply ....................... .I3 0.6

Relieving system fuel pressure .......... .I3 0.6

Siemens MS 41 . 1. ................... 1 30-7

ECM relay. testing .................... .I3 0.7

Mass air flow (MAF) sensor.

checking and replacing

................ .I3 0.9

Engine coolant temperature (ECT) sensor.

testing and replacing

.................. 130-10

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.1 1

Throttle position sensor (TPS).

testing and replacing

.................. 130-1 2

ldle speed control valve.

checking and replacing

............... .I3 0.1 3

Fuel injectors. checking and replacing .... 130-15

Evaporative emissions. overview ....... .I3 0.1 6

Secondary air injection. overview ....... .I3 0-17

Engine control module (ECM).

removing and installing

................ 130-18

Siemens MS 41.1 ECM pin assignments . .I3 0.19

Siemens MS 42.0 and MS 43.0. ..... .I3 0.23

ECM relay. testing ................... .I3 0.27

Mass air flow (MAF) sensor.

checking and replacing

............... .I3 0.28

Engine coolant temperature (ECT) sensor.

testing and replacing

................. .I3 0.30

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.31

MS 42.0 throttle valve assembly. replacing . 130-32

MS 43.0 throttle valve assembly. replacing . 130-35

Throttle cable. adjusting (MS 42.0) ...... .I3 0.38

ldle speed control valve. checking

and replacing

....................... .I3 0.38

Evaporative emissions control diagrams . . 130- 39

Evaporative emissions control.

(MS

42.0 and MS 43.0). .............. .I3 0.39

Engine control module (ECM).

removing and installing

................ 130-40

Siemens MS 42.0 and MS 43.0

ECM pin assignments ................. 130-41

Bosch M5.2 (M62 up to 911997)

BOSC~ M5.2.1 (M62 911997 to 911998) 130-46

M5.2 system features ................. 130-47

M5.2.1 system features ............... 130-47

ECM relay. testing ................... 130-49

Oxygen sensors. checking ............. 130-51

Fuel injectors. checking and replacing .... 130-52

Mass air flow (MAF) sensor. replacing .... 130-53

ldle speed control valve. testing

and replacing

....................... 130-54

Throttle position sensor (TPS).

testing and replacing

................. 130-55

Engine coolant temperature (ECT) sensor.

testing and replacing

................. 130-55

Intake air temperature (IAT) sensor.

testing and replacing

................. 130-57

Auxiliary throttle valve (ADS) (M62 and

M62 TU engine). replacing ..... 130-57

Evaporative system pressure

leak diagnosis. overview

(5.2.1 only) ..... 130-58

Bosch 5.2 ECM pin assignments

(M62 UP to 911 997) ................... 130-59

~osch 5.2.1 ECM pin assignments

(M62 911 997 to 911 998) ............... 130-62

BOSC~ ME 7.2 ..................... 1 30-66

ME 7.2 system overview ............... 130-67

EDK adaptation ..................... 130-69

ECM relay. checking .................. 130-69

Engine coolant temperature

(ECT) sensor. testing

................. 130-71

Engine coolant temperature

(ECT) sensor. replacing

............... 130-71

Oxygen sensors. replacing ............. 130-72

Fuel injectors. removing and installing .... 130-72

Mass air flow (MAF) sensor.

removing and installing

................ 130-73

Evaporative system pressure

leak diagnosis. overview

............... 130-74

Secondary air injection. overview ........ 130-75

Bosch ME 7.2 ECM pin assignments .... 130-76

Page 400 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 0

Fuel Injection

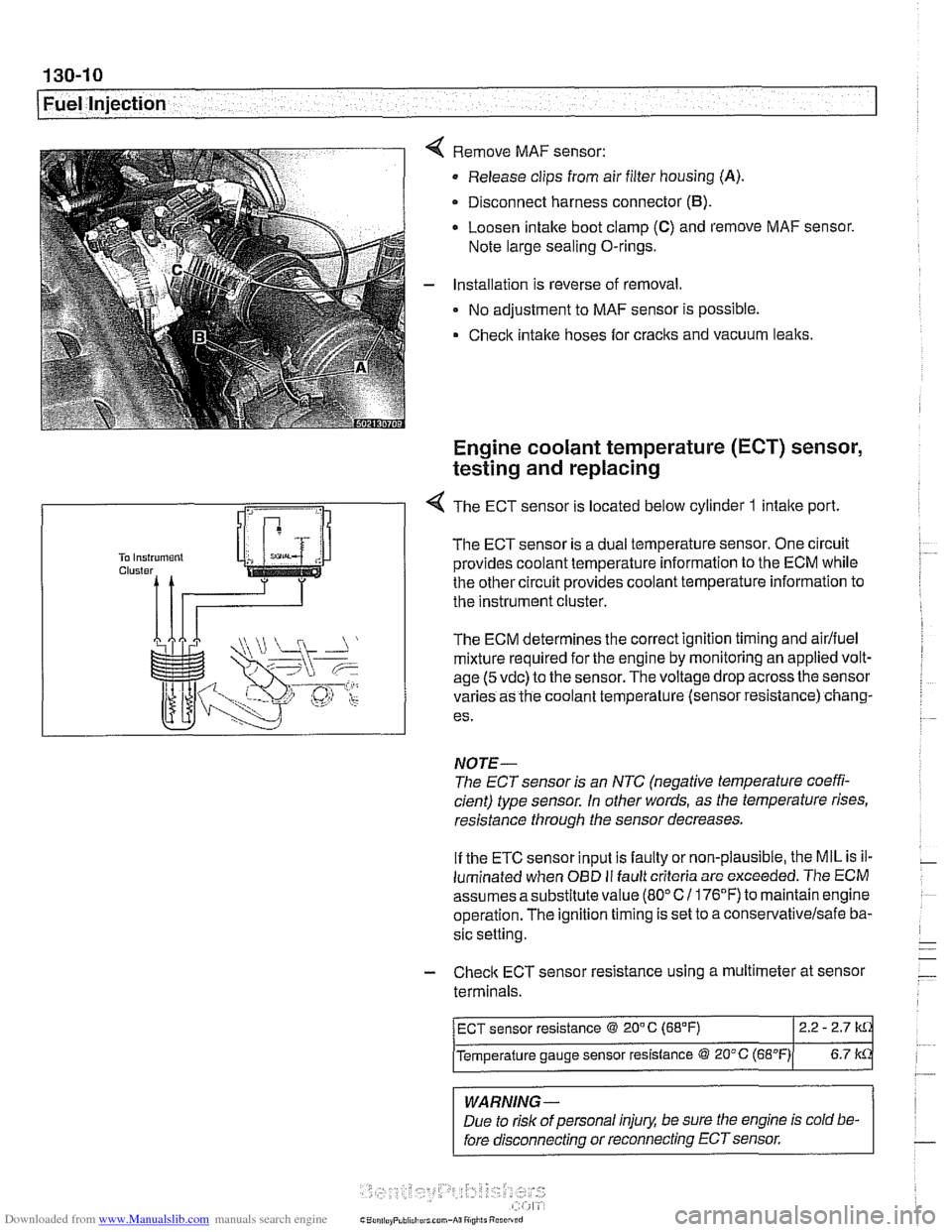

Remove MAF sensor:

Release clips from air filter housing

(A).

Disconnect harness connector (B).

Loosen intake boot clamp (C) and remove MAF sensor.

Note large sealing O-rings.

Installation is reverse of removal.

No adjustment to MAF sensor is possible.

Check intake hoses for cracks and vacuum leaks.

Engine coolant temperature (ECT) sensor,

testing and replacing

R

1 -4 The ECT sensor is located below cylinder 1 intake port

The ECT sensor is a dual temperature sensor. One circuit

provides coolant temperature information to the ECM while

the other circuit provides coolant temperature information to

the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. in other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when

OED II fault criteria are exceeded. The ECM

assumes asubstitute value

(80°C1 176°F) to maintainengine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

- Check ECT sensor resistance using a multimeter at sensor

terminals.

-

WARNING -

Due to risk of personal injury, be sure the engine is cold be-

fore disconnecting or reconnecting ECT sensor.

ECT sensor resistance @ 20" C (68°F) 2.2 - 2.7

Temperature gauge sensor resistance @ 20°C (~B"F)( 6.7 k

Page 401 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

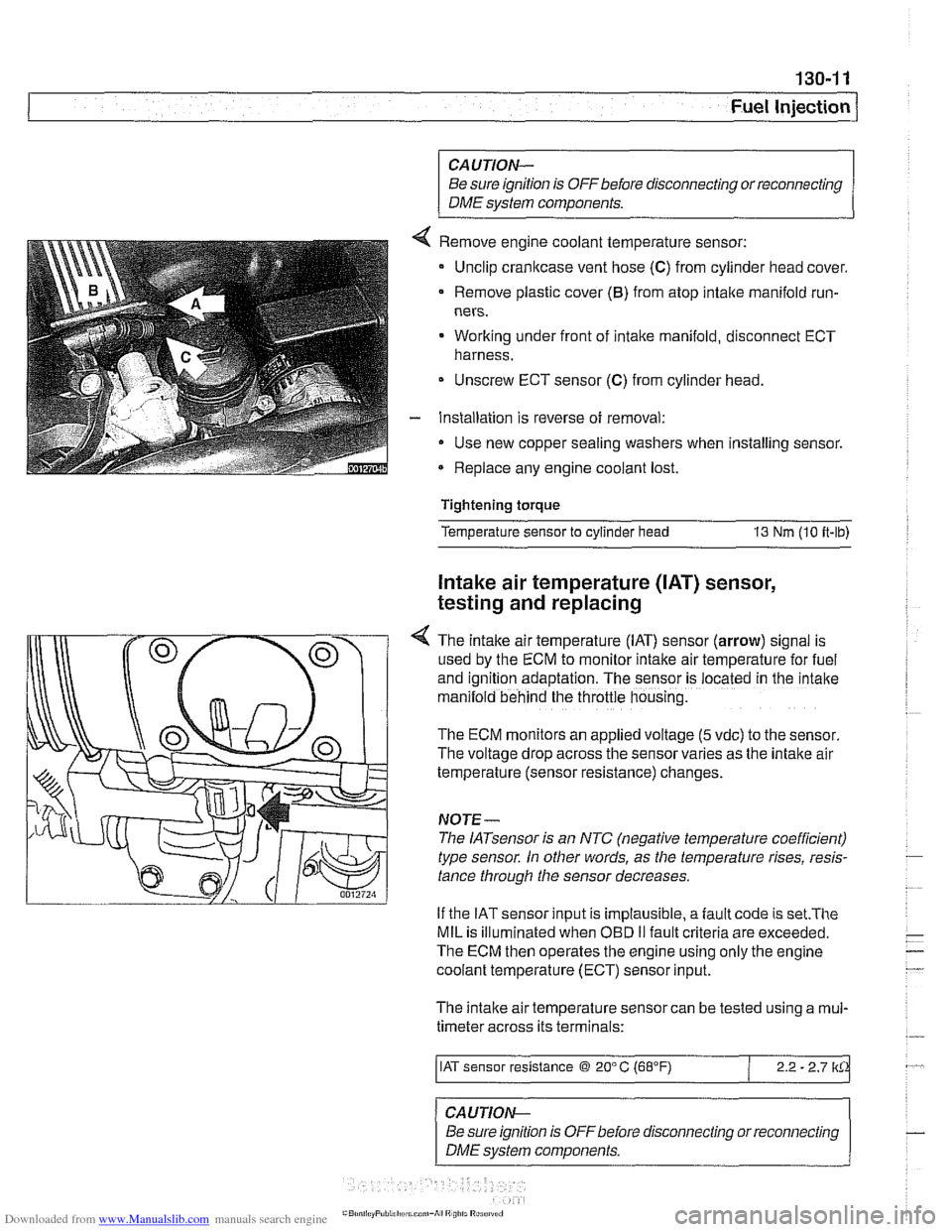

CAUTION-

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove engine coolant temperature sensor:

Unclip crankcase vent hose

(C) from cylinder head cover.

Remove plastic cover

(6) from atop intake manifold run-

ners.

Working under front of intake manifold, disconnect ECT

harness.

Unscrew ECT sensor

(C) from cylinder head.

Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any engine coolant lost.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 it-lb)

Intake air temperature ([AT) sensor,

testing and replacing

4 The intake air temperature (IAT) sensor (arrow) signal is

used by the ECM to monitor intake air temperature for fuel

and

igntion adaptation. The sensor is .ocared in rne 'ntane

man:lold behind the throttle housng.

The ECM monitors an applied voltage (5 vdc) to the sensor

The voltage drop across the sensor varies as the intake air

temperature (sensor resistance) changes.

NOJE-

The IATsensor is an NTC (negative temperature coefficient)

type sensor. In other words, as the temperature rises, resis-

tance through the sensor decreases.

If the IAT sensor input is implausible, a

fault code is set.The

MIL is illuminated when OED II fault criteria are exceeded.

The ECM then operates the engine using only the engine

coolant temperature (ECT) sensor input.

The intake air temperature sensor can be tested using a

mul-

timeter across its terminals:

/ IAT sensor resistance @ 20" C (68°F) / 2.2 - 2.7 lkCk

~ -- ~~ -

CAUTION--

Be sure ignition is

OFFbefore disconnecting or reconnecting

DME system components.