Coolant temperature sensor BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 410 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

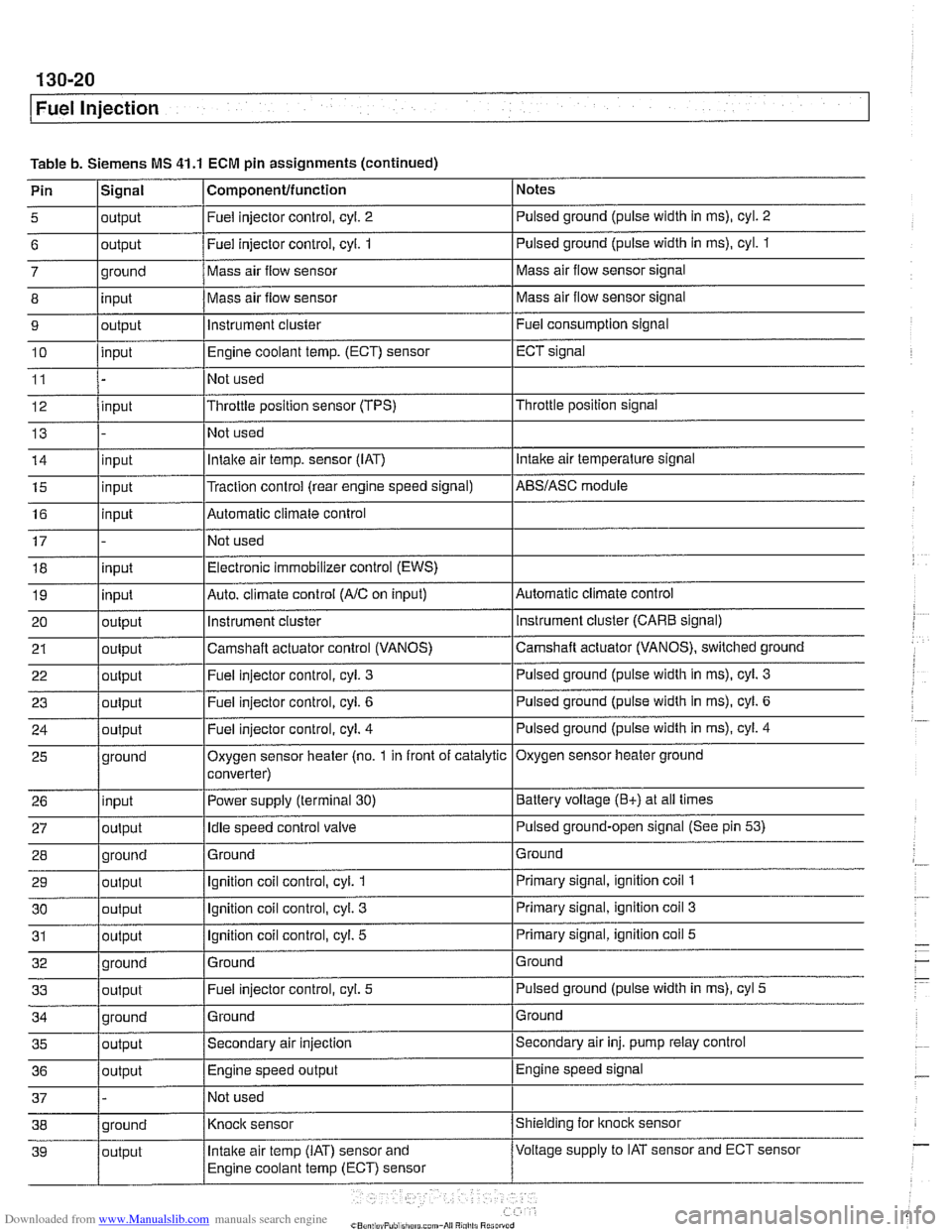

Table b. Siemens MS 41.1 ECM pin assignments (continued)

Pin

l~iqnal I Componentlfunction 1 Notes I - I I

5 loutput I Fuel injector control, cyl. 2 I Pulsed ground (pulse width in ms), cyl. 2 I I I

6 loutput /Fuel injector control, cyi. 1 I Pulsed ground (pulse width in ms), cyl. 1

I I I

14 linput I Intake air temp. sensor (IAT) I Intake air temperature signal

- 7

8

9

10

11

12

13

ground

input

output

input

input

15

16

17 18

19

20

21

22

I - I I

35 loutput /Secondary air injection ISecondary air inj. pump relay control

25

26

27

28

29

30

31

32

33

36

/output I Engine speed output IEngine speed signal

Mass air flow sensor

Mass air flow sensor

instrument cluster

Engine coolant

temp.

(ECT) sensor

Not used

Throttle position sensor (TPS)

Not used

input

input

input

input

output

output

out~ut

37 1 - /Not used I

Mass air flow sensor signal

Mass air flow sensor signal

Fuel consumption signal

ECT signal

Throttle position signal

ground

input

output

ground

output

output

output

ground

output

Traction control (rear engine speed signal) Automatic climate control

Not used Electronic immobilizer control (EWS)

Auto. climate control

(AIC on input)

instrument

cluster

Camshaft actuator control (VANOS)

Fuel iniector control, cvl.

3

AES/ASC module

Automatic climate control instrument cluster (CARE signal)

Camshaft actuator (VANOS), switched ground

Pulsed ground (pulse width in

ms), cyl. 3

Oxygen sensor heater (no. 1 in front of catalytic

converter)

Power supply (terminal

30)

Idle speed control valve

Ground

Ignition coil control, cyl.

1

Ignition coil control, cyl. 3

Ignition coil control, cyl. 5

Ground Fuel injector control, cyl.

5

Oxygen sensor heater ground

Battery voltage

(E+) at all times

Pulsed ground-open signal (See pin

53)

Ground

Primary signal, ignition coil

1

Primary signal, ignition coil 3

Primary signal, ignition coil 5

Ground

Pulsed ground (pulse width in ms), cyl

5

Page 420 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

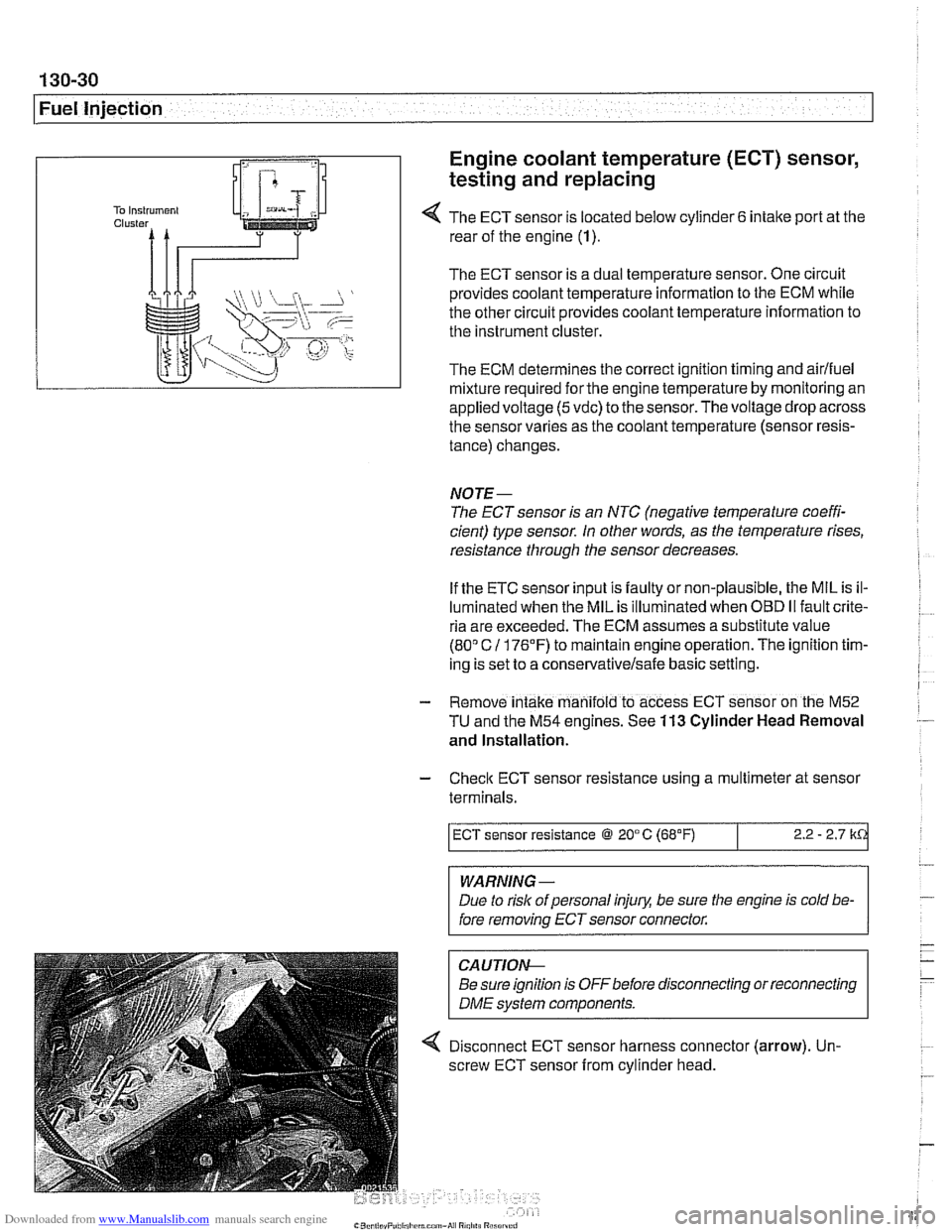

Engine coolant temperature

(ECT) sensor,

testing and replacing

4 The ECT sensor is located below cylinder 6 intake port at the

rear of the engine (1).

The ECT sensor is a dual temperature sensor. One circuit

provides coolant temperature information to the ECM while

the other circuit provides coolant temperature information to

the instrument cluster.

The ECM determines the correct ignition timing and airlfuel

mixture required

forthe engine temperature by monitoring an

appliedvoltage

(5vdc) to the sensor.Thevoltage drop across

the sensor varies as the coolant temperature (sensor resis-

tance) changes.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when the MIL is illuminated when

OED II fault crite-

ria are exceeded. The ECM assumes a substitute value

(80" C 11 76'F) to maintain engine operation. The ignition tim-

ing is set to a

conservativelsafe basic setting.

- Remove intake manifold to access ECT sensor on the M52

TU and the M54 engines. See 113 Cylinder Head Removal

and Installation.

- Check ECT sensor resistance using a multimeter at sensor

terminals.

WARNING -

Due to rislc of personal injury, be sure the engine is cold be-

fore removing ECT sensor connector.

ECT sensor resistance @ 20°C (68°F)

CAUTIOI\C

Be sure ignition is OFFbefore disconnecting or reconnecting

DME svstem components.

2.2 - 2.7 k

4 Disconnect ECT sensor harness connector (arrow). Un-

screw ECT sensor from cylinder head.

Page 421 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Installation is reverse of removal:

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

Temperature sensor to cylinder head

13 Nm (10 ft-lb)

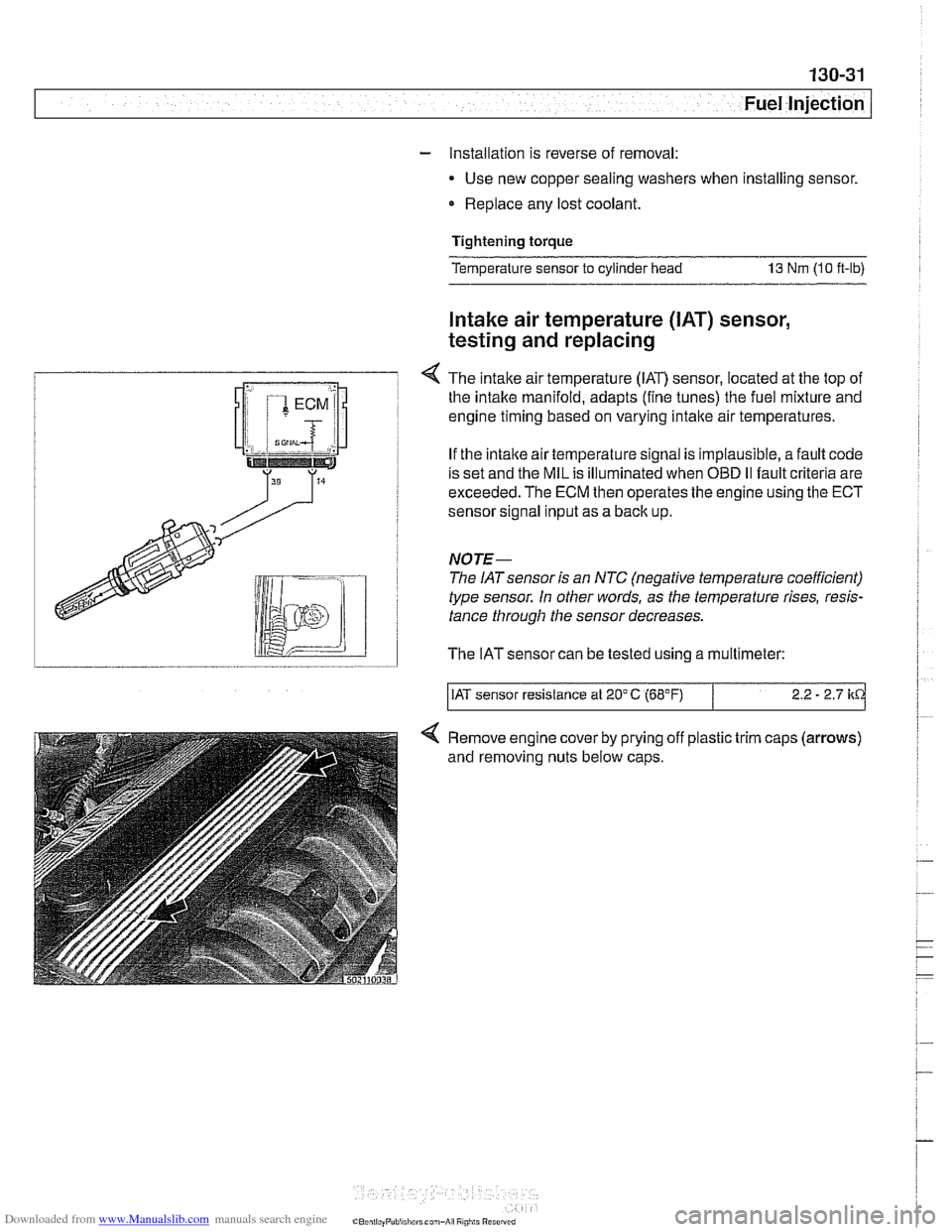

Intake air temperature (IAT) sensor,

testing and replacing

4 The intake airtemperature (IAT) sensor, located at the top of

I the intake manifold, adapts (fine tunes) the fuel mixture and i

T engine timing based on varying intake air temperatures.

i If the intaite air temperature signal is implausible, a fault code

! is set and the MIL is illuminated when OBD I1 fault criteria are

I exceeded. The ECM then operates the engine using the ECT

i sensor sional inout as a back uo.

type sensor. In other words,

a> the temperature rises, resis-

tance through the sensor decreases.

lid I The IATsensor can be tested using a multimeter:

/IAT sensor resistance at 20'C (68°F) 2.2 - 2.7 kd

Remove engine cover by prying off plastic trim caps (arrows)

and removing nuts below caps.

Page 433 of 1002

![BMW 528i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments BMW 528i 1997 E39 User Guide Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments](/img/1/2822/w960_2822-432.png)

Downloaded from www.Manualslib.com manuals search engine

130-43

Fuel Injection ]

I I I

12 llnput IFeedback signal, engine start /Starter

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments (continued)

I I - I

13 Input /I Alternator (generator) Notes

Throttle

valve

Crankshaft position sensor

Throttle valve (MS

42.0)

Throttle valve

Pin

6

7

8

9

10

11

14

15

16

17

18

19

20

I 1- I

23 l~round I~round, intaite air temperature sensor /Intake air temperature sensor

Signal

Output

Input

Input

Input

I I I

Component/function

Not used

Throttle valve supply potentiometer

2

Signal, crankshaft position sensor

Signal,

pedal position sensor 2 (MS 42.0)

Signal, throttle position sensor 1

Not used

Ground

Ground

Input

Ground

Ground

Input

Ground Cranltshaft position sensor

21

24

25

26

27

28

29

30

I 1- I

33 1 input ISignal, cylinder 1 fuel injector /cylinder 1 fuel injector

Ground, throttle position sensor (MS

42.0)

Ground, exhaust camshaftsensor I

Signal, pedal position sensor 1 (MS 42.0)

Ground, mass air flow sensor

Ground, intake camshaft sensor

1

Signal, throttle potentiometer 1

Ground, throttle position sensor

22 loutput I~ignal, intake air temperature Ilntake air temperature sensor

I I - I

Throttle

valve (MS 42.0)

Camshaft position sensor I

Throttle valve (MS

42.0)

Hot film mass air flow sensor

Camshaft position sensor i

Throttle valve

Throttle valve

Ground

Output

Ground Input

Output

Ground

Output

Out~ut

Ground, crankshaft position sensor

Knoclt sensor

31

34

35

36

37

38

39

Signal, coolant temperature sensor

Ground, coolant temperature sensor

Signal,

oil pressure

Signal, engine

oil temperature sensor

Ground, engine oil temperature sensor

Signal, knock sensor

Signal, knock sensor

32 loutput ISignal, ltnock sensor l~nock sensor

40

41

Coolant temperature sensor

Coolant temperature sensor

Oil pressure switch

Oil temperature sensor

Oil temperature sensor

Knoclt sensor

I

Input

input

Input

Input

Input

Inout

Signal, knock sensor

Input

Input Signal, cylinder

2 fuel injector

Signal, cylinder

3 fuel injector

Signal, cylinder

4 fuel injector

Signal, cylinder

5 fuel injector

Signal, cylinder

6 fuel injector

Sianai, oil level sensor Cylinder

2 fuel

injector

Cylinder

3 fuel injector

Cylinder

4 fuel injector

Cylinder

5 fuel injector

Cylinder

6 fuel injector

Oil level sensor

-

Signal. VANOS inlet valve

Signal. VANOS outlet valve VANOS

inlet valve

VANOS outlet valve

Page 445 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- If voltage is present as described above, check wiring be-

tween ECM and valve. If no wiring faults are found, check

ECM signal to valve.

- When replacing idle speed control valve, clean and inspect

all sealing areas.

. Inspect sealing ring in throttle body and replace if neces-

sary.

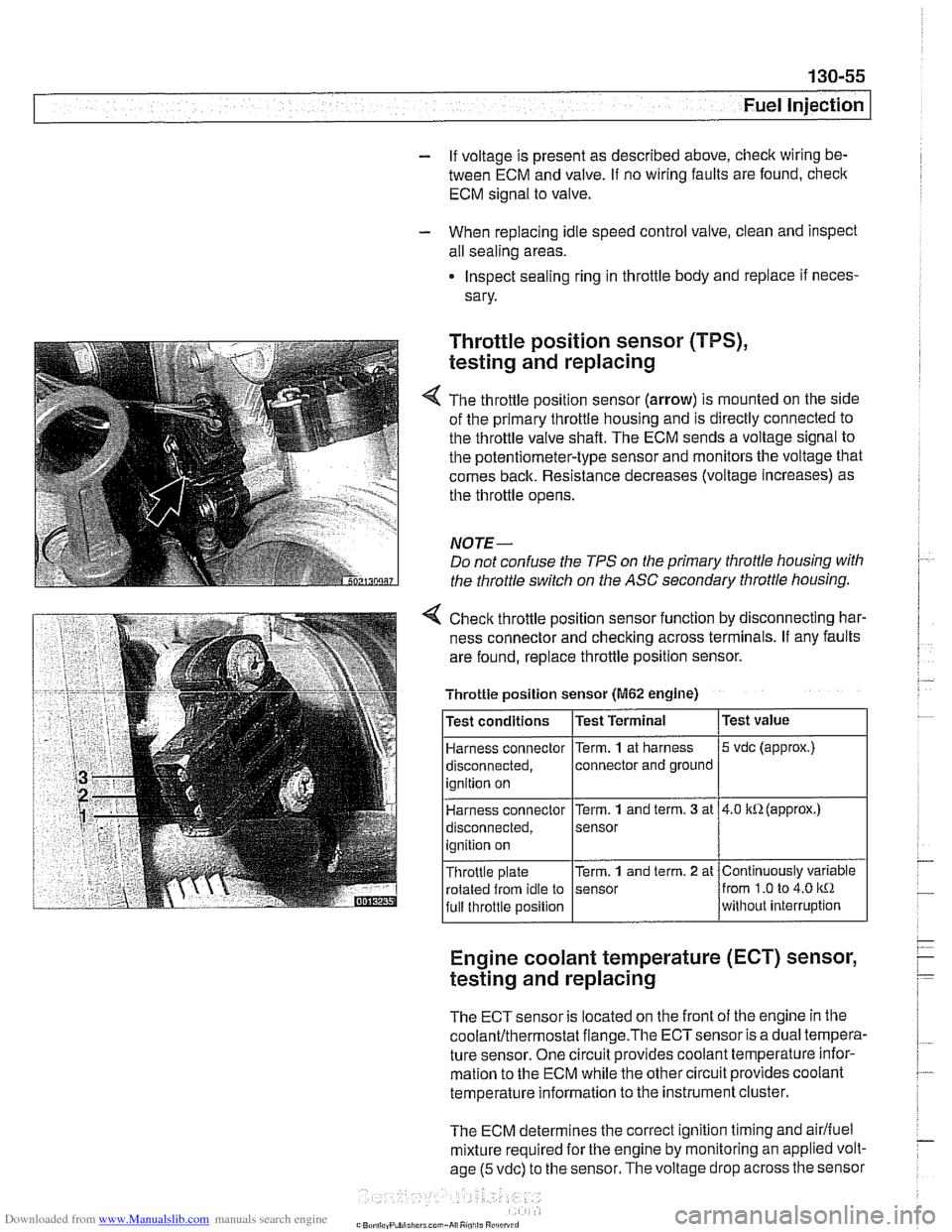

Throttle position sensor (TPS),

testing and replacing

The throttle position sensor (arrow) is mounted on the side

of the primary throttle housing and is directly connected to

the throttle valve shaft. The ECM sends a voltage signal to

the potentiometer-type sensor and monitors the voltage that

comes back. Resistance decreases (voltage increases) as

the throttle opens.

NOTE-

Do not confuse the TPS on the primary throttle housing with

the throttle switch on the

ASC secondary throttle housing.

4 Check throttle position sensor function by disconnecting har-

ness connector and checking across terminals. If any faults

are found, replace throttle position sensor.

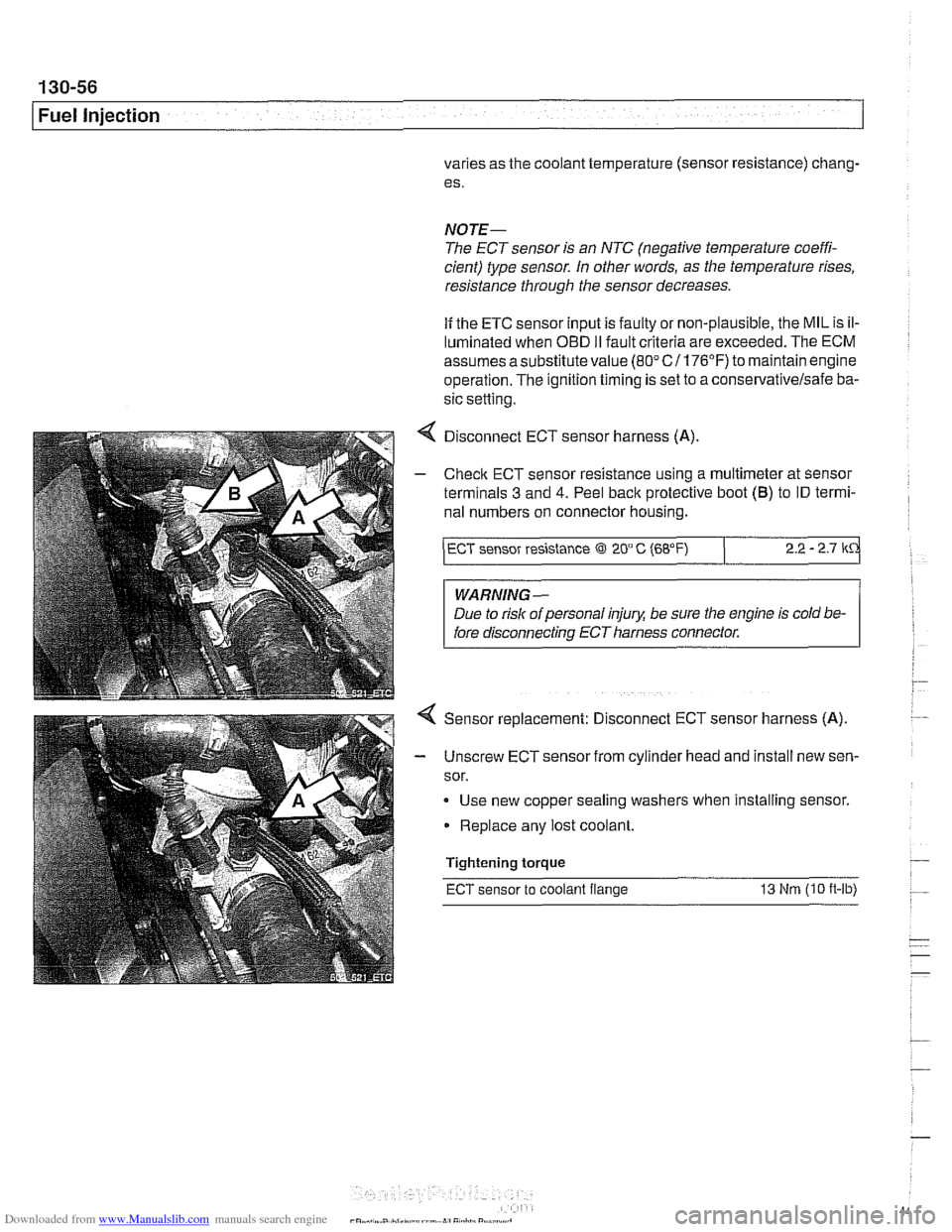

Engine coolant temperature (ECT) sensor,

testing and replacing

Throttle position sensor (M62 engine)

The ECT sensor is located on the front of the engine in the

coolanVthermostat flange.The ECTsensor is a dual tempera-

ture sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

Test

value

5 vdc (approx.)

4.0 kR(approx.)

Continuously variable

from

1.0 to 4.0 kR

without interruption

Test

conditions

Harness connector

disconnected, ignition on

Harness connector

disconnected,

ignition on

Throttle plate rotated from idle to

full throttle position Test Terminal

Term.

1 at

harness

connector and ground

Term.

1 and term. 3 at

sensor

Term.

1 and term. 2 at

sensor

Page 446 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel lniection

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeff-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MILis il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(8OoC/176"F) to maintain engine

operation. The ignition timing is set to a

conservativelsafe ba-

sic setting.

4 Disconnect ECT sensor harness (A)

- Checlc ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

/ ECT sensor resistance @l 2O" C (68°F) 2.2 - 2.7 kd

WARNING -

Due to risk of personal injug be sure the engine is cold be-

fore disconnecting ECT harness connector.

Sensor replacement: Disconnect ECT sensor harness (A).

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers

when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (I0 it-lb)

Page 451 of 1002

Downloaded from www.Manualslib.com manuals search engine

-. -

Fuel Injection

I 68 1 / Not used

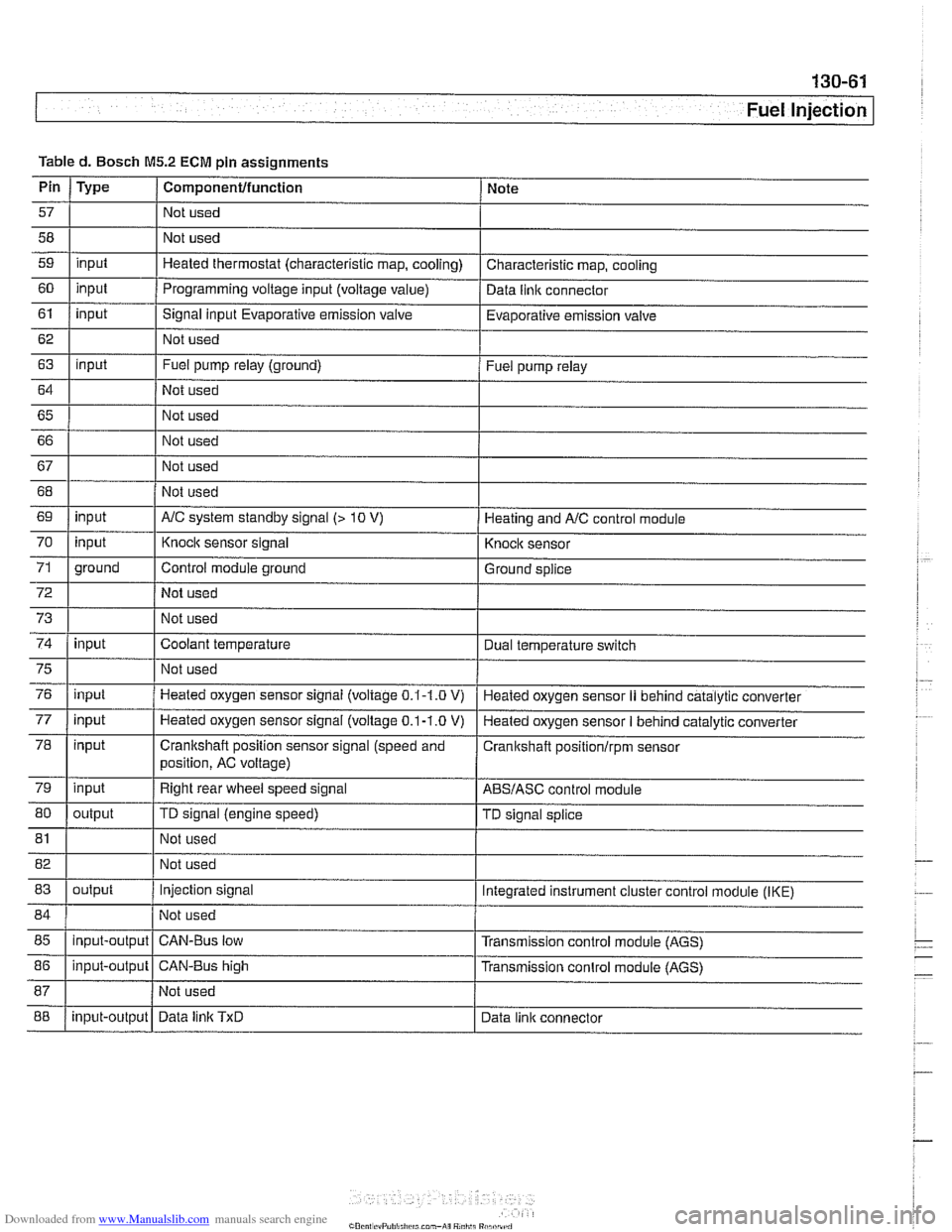

Table

d. Bosch

M5.2 ECM pin assignments

I I I

69 1 input I AIC system standby signal (> 10 V) 1 Heating and AIC control module

Pin

57

58

59

60

61

62

63

64

65 66

67

Type

input

input

input

input

I 70

72

73

74

Componentlfunction

Not used

Not used

Heated thermostat (characteristic map, cooling)

Programming voltage input (voltage

value)

Signal input Evaporative emission valve

Not used

Fuel pump relay (ground)

Not used

Not used

Not used

Not used

75

76

77

78

79

80

Note

Characteristic map, cooling

Data

llnlc connector

Evaporative emission valve

Fuel pump relay

71 1 ground I Control module ground I Ground splice

input

input

81

input input

input

input

output Not used

I

Knock sensor signal

Not used

Not used

Coolant temperature

82 1 I Not used

83

I I

Knock sensor

Dual temperature

swltch

Not used

Heated oxygen sensor signal (voltage

0.1-1.0 V)

Heated oxygen sensor

signal (voltage 0.1-1.0 V)

Crankshaft position sensor signal (speed and

position, AC voltage)

Right rear wheel speed signal

TD signal (engine speed)

85

I I I

Heated oxygen sensor II behind catalytic converter

Heated oxygen sensor

I behind catalytic converter

Cranitshaft positionlrpm sensor

ABSIASC control module

TD signal splice

84 1 / Not used 1

output

88

86

1 input-output 1 CAN-Bus high I Transmission conlrol module (AGS)

input-output

Injection signal

input-output Integrated instrument cluster control

module (IKE)

CAN-Bus low Transmission control module (AGS)

Data

linlc TxD Data link connector

Page 453 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel lnjection

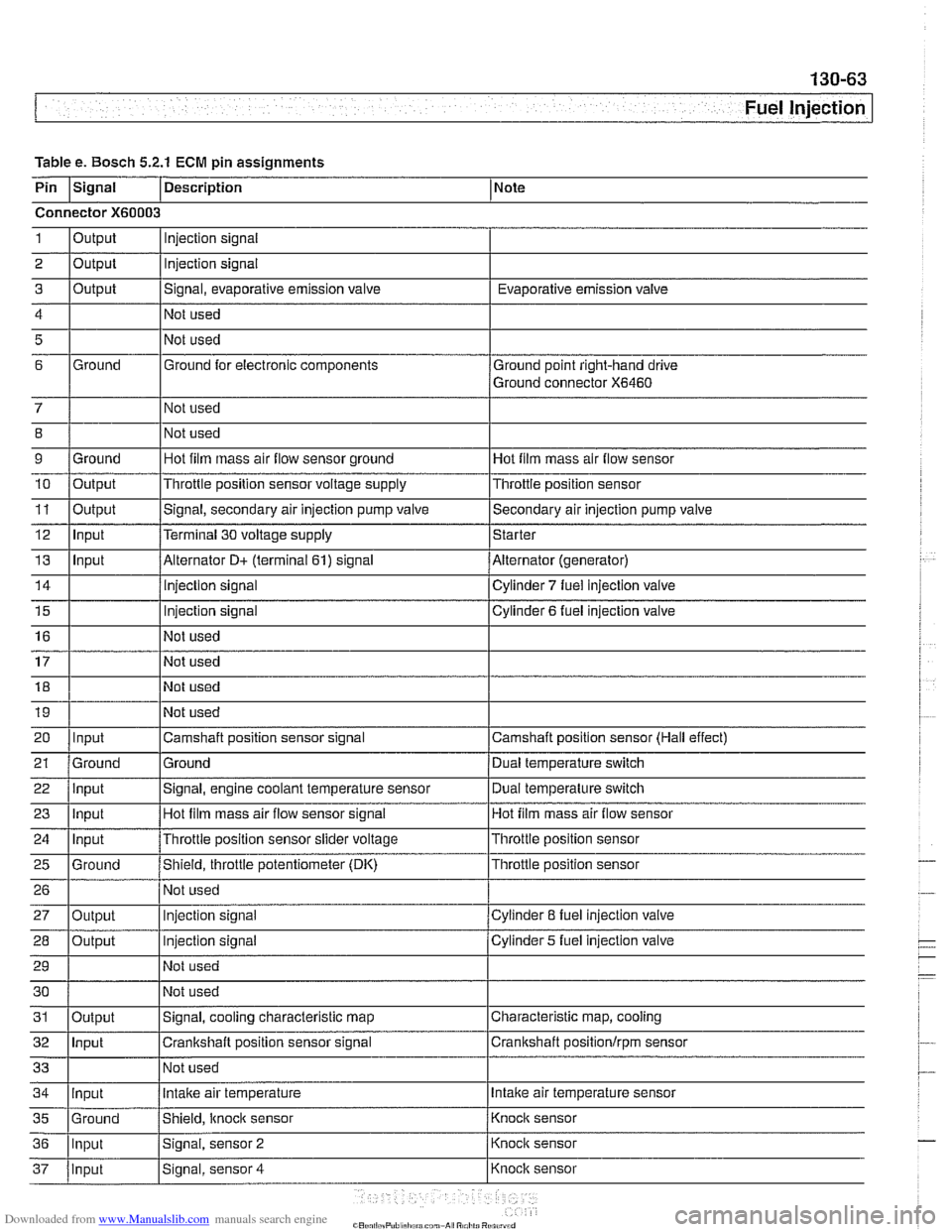

Table e. Bosch 5.2.1 ECM pin assignments

Pin

Isignal 1 Description 1 Note

Connector

X60003

1

2

3

4

5

6

7 8

9 10

11

12

13

14

15

16

17

18

19

20

21

ate alr empe

Output

Output

Output

Ground

Ground

Output

Output Input

Input

Input

Ground

22

23

24

25

26

27

28

29

30

Injection signal

Injection signal

Signal, evaporative emission valve

Not used

Not used

Ground for electronic components

Not used

Not used

Hot film mass air flow sensor ground

Throttle position sensor voltage supply

Signal, engine coolant temperature sensor

Hot

film mass air flow sensor signal

Throttle position sensor slider voltage

Shield, throttle potentiometer (DK) Not used

Injection signal

Injection signal

Not used

Not used

Input

Input

Input

Ground

Output

Output Evaporative emission

valve

Ground point right-hand drive

Ground connector

X6460

Hot film mass air flow sensor

Throttle position sensor

Signal, secondary air injection pump valve

Terminal

30 voltage supply

Alternator

D+ (terminal 61) signal

injection signal

Injection

signal

Not used

Not used

Not used

Not used

Camshaft position sensor signal

Ground Dual temperature switch

Hot film mass air flow sensor

Throttle position sensor

Throttle position sensor

Cylinder

8 fuel injection valve

Cylinder

5 fuel injection valve

Secondary air injection pump

valve

Starter

Alternator (generator)

Cylinder

7 fuel injection valve

Cylinder 6 fuel injection valve

Camshaft position sensor (Hall effect) Dual temperature

switch

Page 461 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

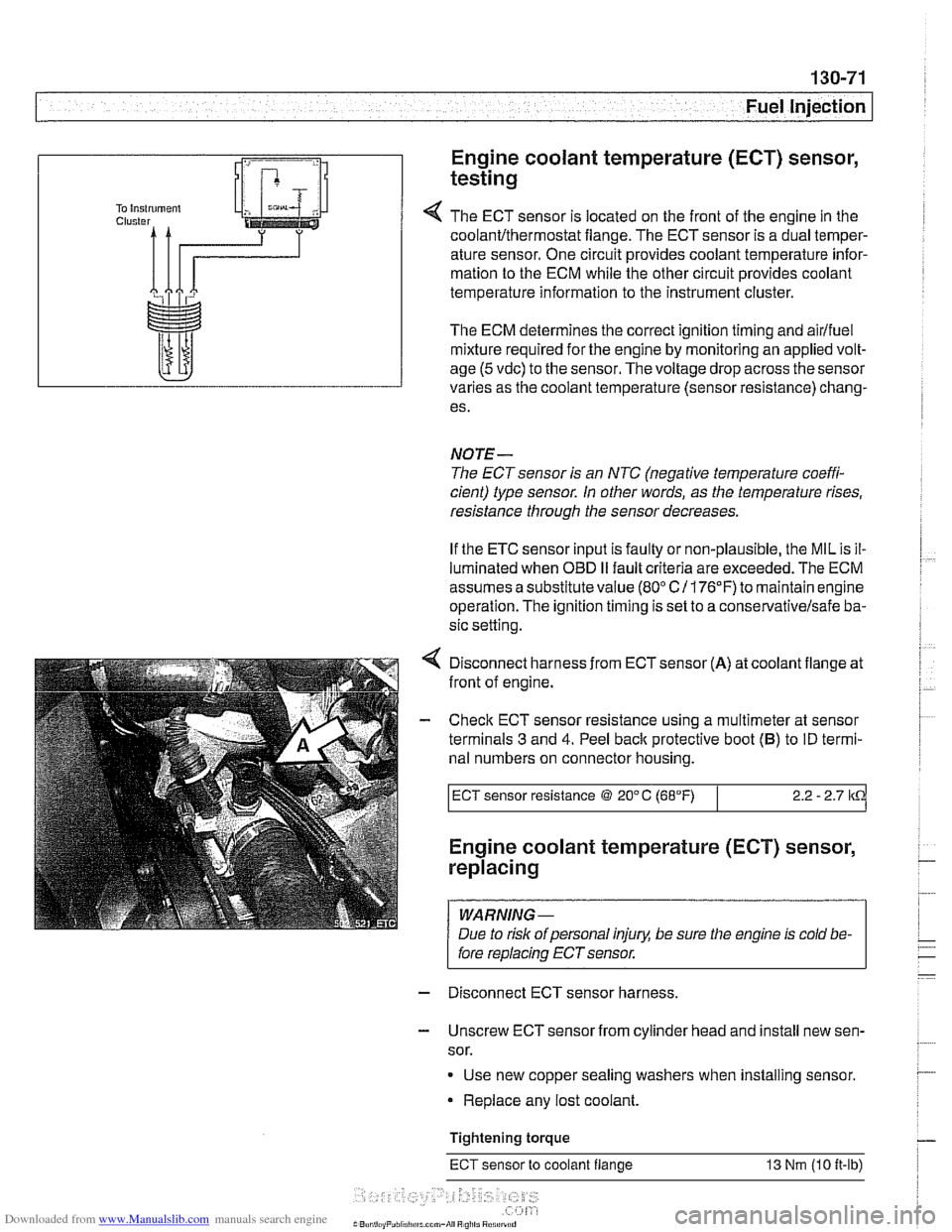

Engine coolant temperature (ECT) sensor,

testing

The ECT sensor is located on the front of the engine in the

coolant~thermostat flange. The ECT sensor is a dual temper-

ature sensor. One circuit provides coolant temperature infor-

mation to the ECM while the other circuit provides coolant

temperature information to the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. Thevoltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when OBD

II fault criteria are exceeded. The ECM

assumes a substitute value

(80" C/ 176°F) to maintain engine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

Disconnect harness from

ECTsensor (A) at coolant flange at

front of engine.

- Check ECT sensor resistance using a multimeter at sensor

terminals

3 and 4. Peel back protective boot (B) to ID termi-

nal numbers on connector housing.

I ECT sensor resistance @ 20" C (68°F) I 2.2 - 2.7 lkCi

Engine coolant temperature (ECT) sensor,

replacing

I WARNING-

/ Due to risk ofpersonal injury, be sure the engine is cold be- I

I fore replacin~~~~sensor. -

-

I

- Disconnect ECT sensor harness.

- Unscrew ECT sensor from cylinder head and install new sen-

sor.

Use new copper sealing washers when installing sensor.

Replace any lost coolant.

Tightening torque

ECT sensor to coolant flange 13 Nm (10 it-lb)

Page 469 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection I

Connector X60004 (continued)

8 10

11

12

13

14

15

16

9

Output 0

Input

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

39

llnput lsignal l~oolant outlet temperature sensor

Output

Output

Ground

Input

Output

I I - I

40 /output Istart signal Istarter relay

Pedal position sensor (PWG), signal

Output Input

Output

input

Input

Input

Input

Input

Input

input

Input

Output

Input/-output

Input/-output

37

Connector X60003

Pedal position sensor

Fuel pump relay, activation

Oil pressure indicator Pedal position sensor (PWG), ground

Pedal position sensor (PWG), signal

Pedal position sensor (PWG), power supply

Not used

Not used Fuel

pump relay

Instrument cluster

Pedal position sensor

Pedal position sensor

Pedal position sensor

Engine speed signal output (TD)

Not used

Signal

back-up light

DM-TL (diagnostic module,

tank leakage)

Signal oil level sensor

Right rear wheel speed, signal

Clutch pedal position switch, signal

Brake light switch, signal

Not used

Voltage supply, terminal

15

Data link, MFL (multi-function steering wheel)

Brake light test signal

AJC compressor signal

DM-TL (diagnostic module, tank

leakage)

Not used

Diagnosis signal

TxD

Communication link (EWS)

Not used

Not used

CAN-BUS hiqh

38 1 Ground l~round I Coolant outlet temperature sensor

OED II plug

Integrated instrument cluster control module (IKE)

Light module

ABSIDSC control module

Clutch pedal position switch

Brake light switch

Fuse

F14

Airbag contact coil spring

Brake light switch

Heating and

A/C control module

OBD

II plug

Electronic immobilizer (EWS)

CAN-Bus link

CAN-Bus link

Input/-output CAN-Bus low