Steer BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

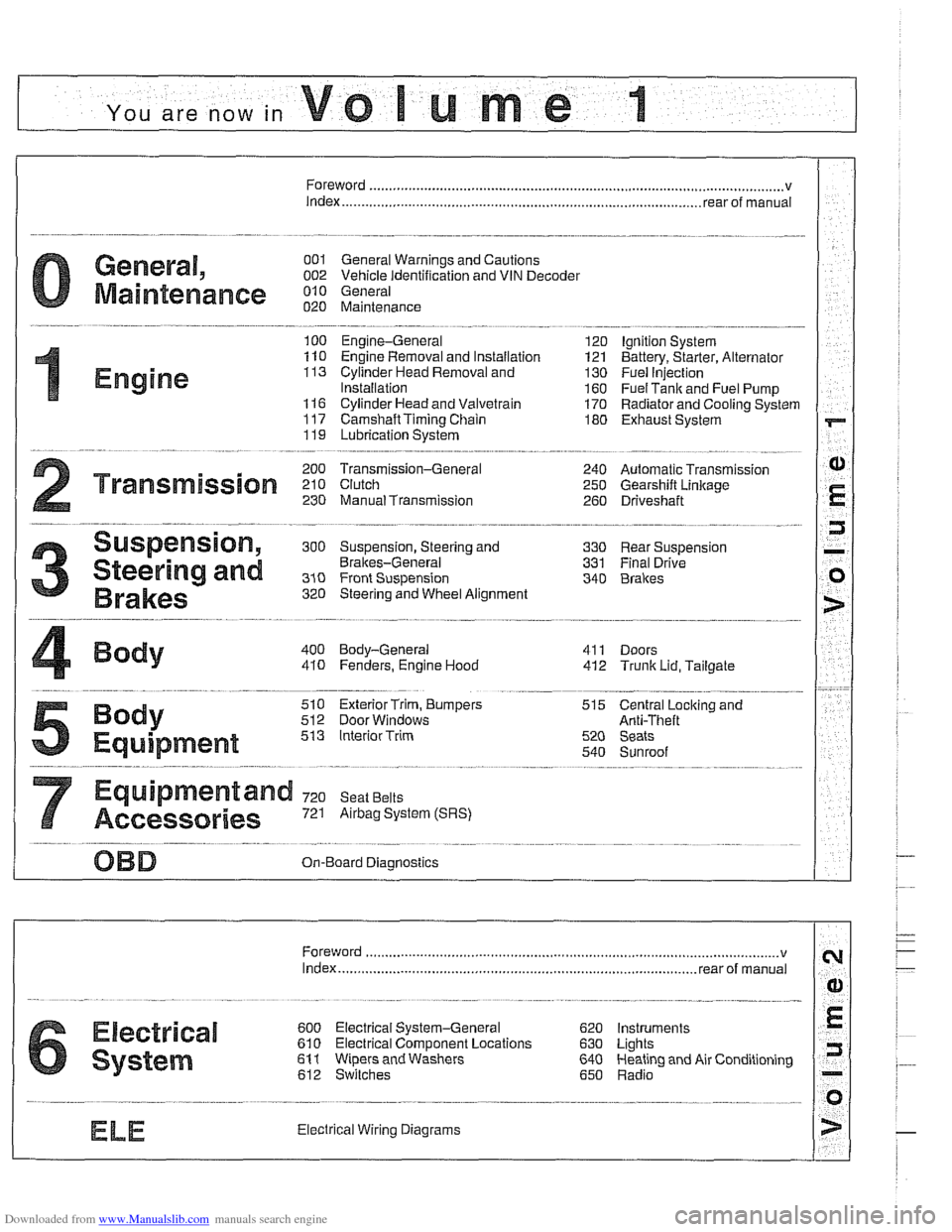

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 12 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-2

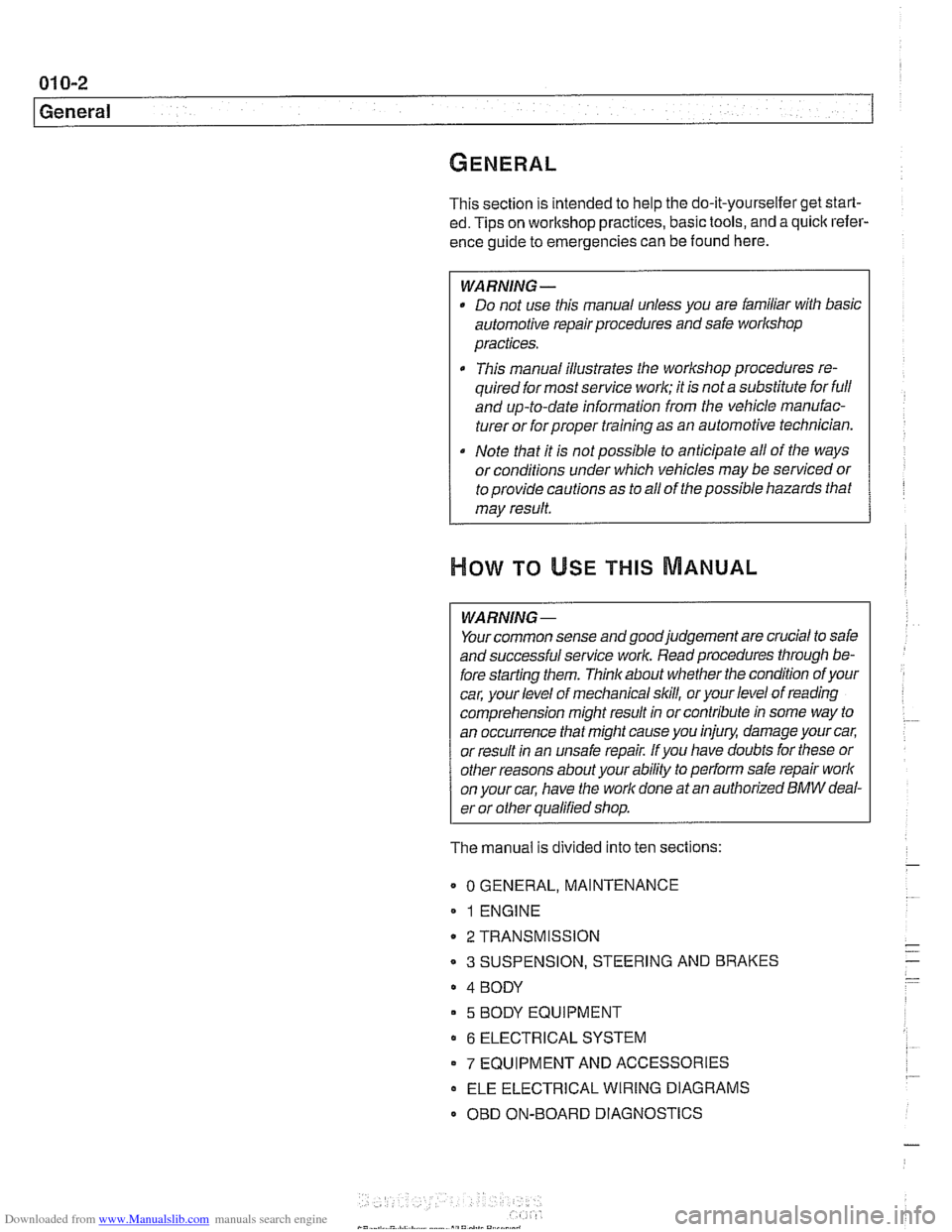

General

This section is intended to help the do-it-yourselfer get start-

ed. Tips on workshop practices, basic tools, and a quick refer-

ence guide to emergencies can be found here.

WARNING-

Do not use this manual unless you are familiar with basic

automotive repair procedures and safe workshop

practices.

0 This manual illustrates the worl

and up-to-date information from the vehicle manufac-

turer or for proper training as an automotive technician.

Note that it is not possible to anticipate all of the ways

or conditions under which vehicles may be serviced or

to provide cautions as to all of the possible hazards that

may result.

MOW TO USE THIS MANUAL

WARNING -

Your common sense and goodjudgement are crucial to safe

and successful service

work. Read procedures through be-

fore starting them. Think about whether the condition of your

cac your level of mechanical skill, or pour level of reading

comprehension might result in or contribute in some way to

an occurrence that might cause you injury, damage your car;

or result in an unsafe repair. If you have doubts for these or

other reasons about your ability to perform safe repair work

on your car; have the work done at an authorized

BMW deal-

er or other qualified shop.

The manual is divided into ten sections:

0 GENERAL, MAINTENANCE

0 I ENGINE

2 TRANSMISSION

3 SUSPENSION, STEERING AND BRAKES

4 BODY

5 BODY EQUIPMENT

6 ELECTRICAL SYSTEM

7 EQUIPMENT AND ACCESSORIES

- ELE ELECTRICAL WIRING DIAGRAMS

OBD ON-BOARD DIAGNOSTICS

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

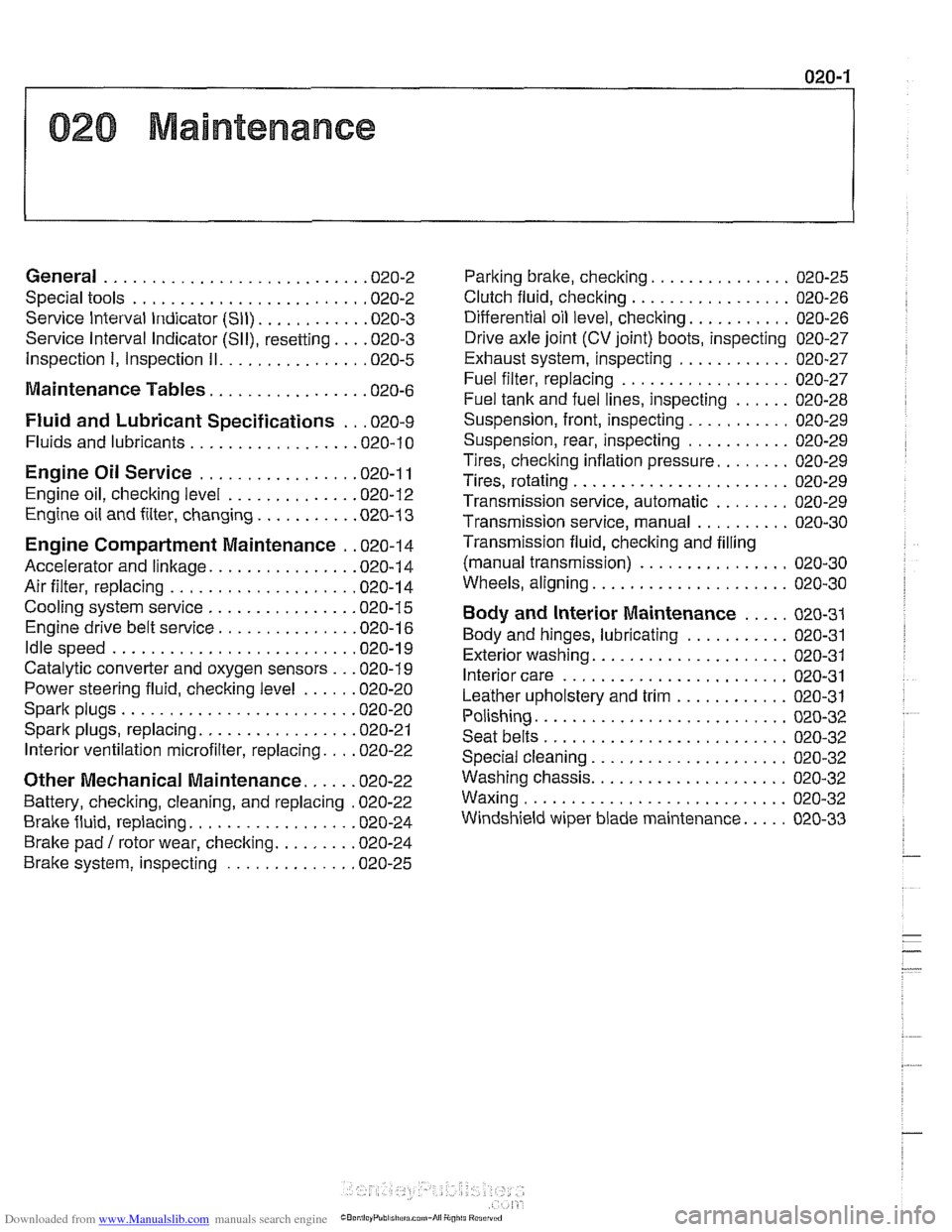

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 39 of 1002

Downloaded from www.Manualslib.com manuals search engine

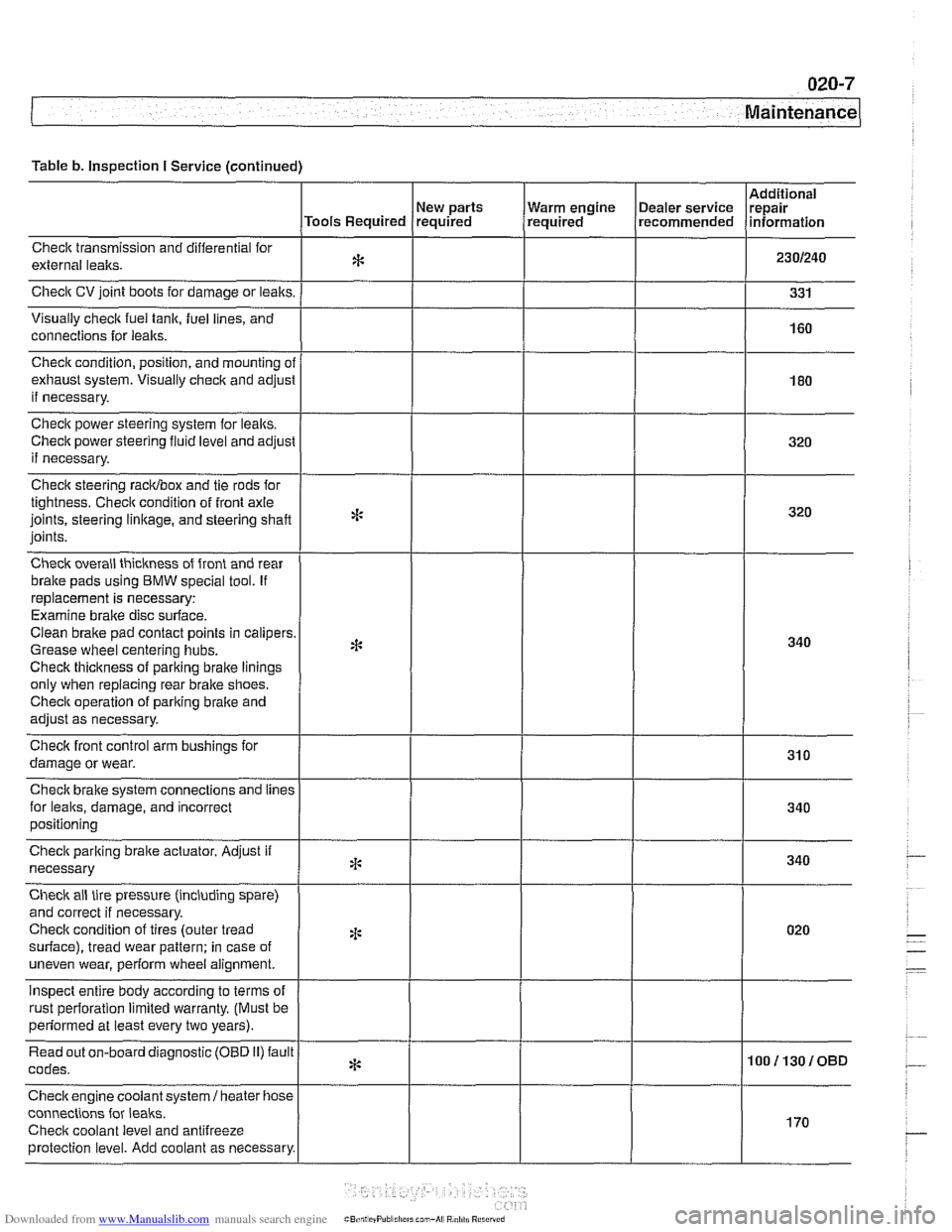

Table b. Inspection I Service (continued)

Checlt transmission and differential for

external lealts.

Check CV joint boots for damage or leaks.

Visually

check fuel tank, fuel lines, and

connections for

leaks.

New parts

Tools Required required

Check condition, position, and mounting

ol

exhaust system. Visually check and adjusl

if necessary.

Check power steering system for lealts.

Check power steering

fluid level and adjust

if necessary.

Check steering racidbox and tie rods for

tightness. Checit condition of front axle

joints, steering

linkage, and steering shaft

joints.

Check overall thickness of front and rear

bralte pads using

BMW special tool. If

replacement is necessary:

Examine brake disc surface.

Clean brake pad contact points in calipers

Grease wheel centering hubs.

Checlt thickness of parking brake linings

only when replacing rear brake shoes.

Checit operation of pariting brake and

adjust as necessary.

Checlt front control arm bushings for

damage or wear.

Check brake system connections and

lines

for leaks, damage, and incorrect

positioning Warm

engine

(~ealer service Irepair , required recommended lnformat~on

Check parking braite actuator. Adjust if

necessary

Check ail tire pressure (including spare)

and correct if necessary.

Checlt condition of tires (outer tread

surface), tread wear pattern: in case of

uneven wear, perform wheel alignment.

inspect entire body according to terms of

rust oerforation limited warrantv. (Must be

*:

4:

2 ~ perfdrmed at least every two years). I

Read out on-board diagnostic (OBD 11) fault

codes.

Checkengine coolant

system1 heater hose

connections for

leaks.

Checit coolant level and antifreeze

protection level. Add coolant as necessary.

* 100113010BD

I

170

Page 40 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

Table b. Inspection I Service (continued)

I I I I

Warm engine Dealer service

required recommended

Check windshield

washer fluid level and

antifreeze protection.

Add washer fluid as necessary.

Replace ventilation

microfilter. (Note:

reduce replacement intervals in dusty

operation conditions)

Reset Service interval Indicator

(Sil).

Additional

repair

information

Tools Required

*

eck aim of washer jets and adjust if

necessary.

covers, obvious damage or attachment o

s or accessories.

Road test

Check braking performance, steering,

heating and air conditioner operation.

Check manual transmission and clutch

operation or automatic transmission

operation. New

parts

required

*

Bodylelectrical

121

630

630

Checic battery state of charge

Check operation of:

headlights,

parking iights, back-up lights.

license plate lights, interior lights,

glove box

illumination, engine compartment light,

trunk light, turn signals, emergency

flashers, stop iights.

Check operation of horn and headlight

dimmer switch

:i:

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 6

Maintenance

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

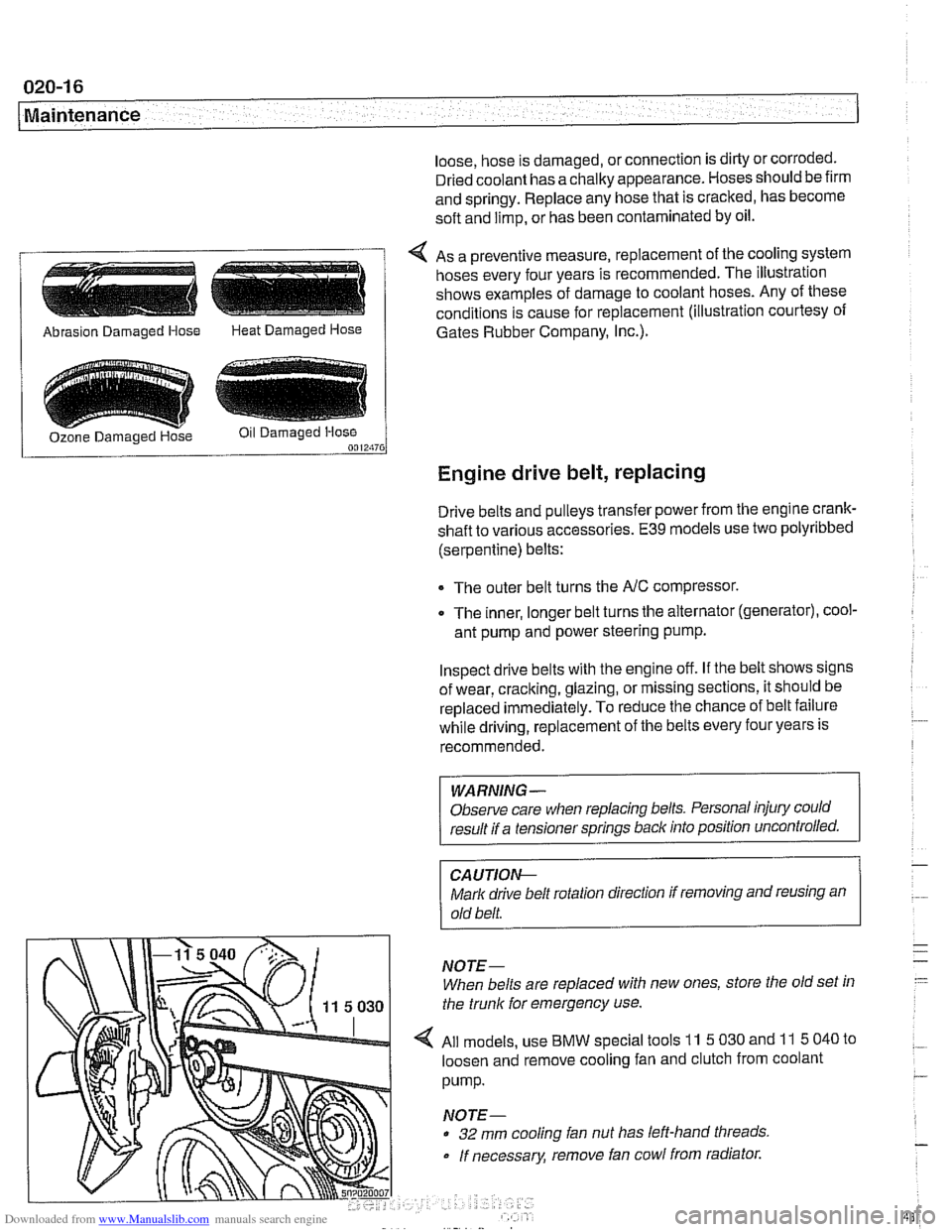

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 52 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

continue to operate as designed. Extending the replacement

interval may void the emission control warranty coverage.

See

180 Exhaust System for information on replacing the

oxygen sensors.

Tightening torque

Oxvoen sensor to exhaust

manifold 50 Nrn (37 ft-lb)

NOTE-

A special soclet for replacing the oxygen sensor is available

from most automotive parts stores. The soclet has

a groove

cut down one side to allow the sensor to be installed without

damaging the wire harness.

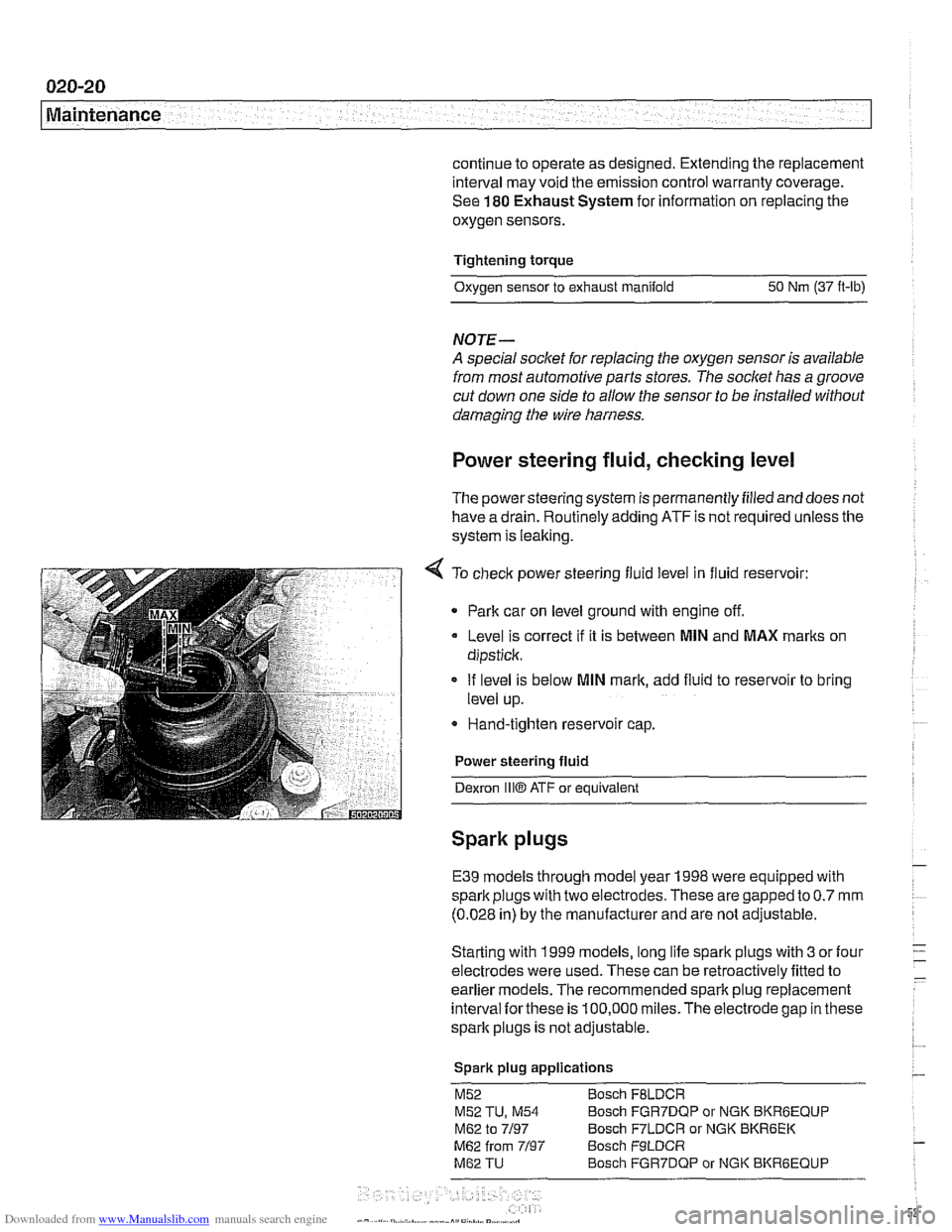

Power steering fluid, checking level

The power steering system is permanently filled and does not

have a drain. Routinely adding ATF is not required unless the

system is leaking.

4 To check power steering fluid level in fluid reservoir:

Park car on level ground with engine off.

Level is correct

if it is between MlN and MAX marks on

dipstick.

If level is below

MlN mark, add fluid to reservoir to bring

level up.

* Hand-tighten reservoir cap.

Power steering fluid

Dexron

1iiO ATF or equivalent

Spark plugs

E39 models through model year 1998 were equipped with

spark plugs with two electrodes. These are gapped to

0.7 mm

(0.028 in) by the manufacturer and are not adjustable.

Starting with 1999 models, long life spark plugs with

3 or four

electrodes were used. These can be retroactively fitted to

earlier

models. The recommended spark plug replacement

interval

forthese is 100,000 miles.The electrode gap in these

spark plugs is not adjustable.

Spark plug applications

M52 Bosch FBLDCR

M52 TU, M54 Bosch FGR7DQP or NGK BKRBEQUP

M62 to 7/97 Bosch F7LDCR or NGK BKR6EK

M62 from 7/97 Bosch F9LDCR

M62 TU Bosch FGR7DQP or NGK BKRGEQUP

Page 57 of 1002

Downloaded from www.Manualslib.com manuals search engine

7 Maintenance

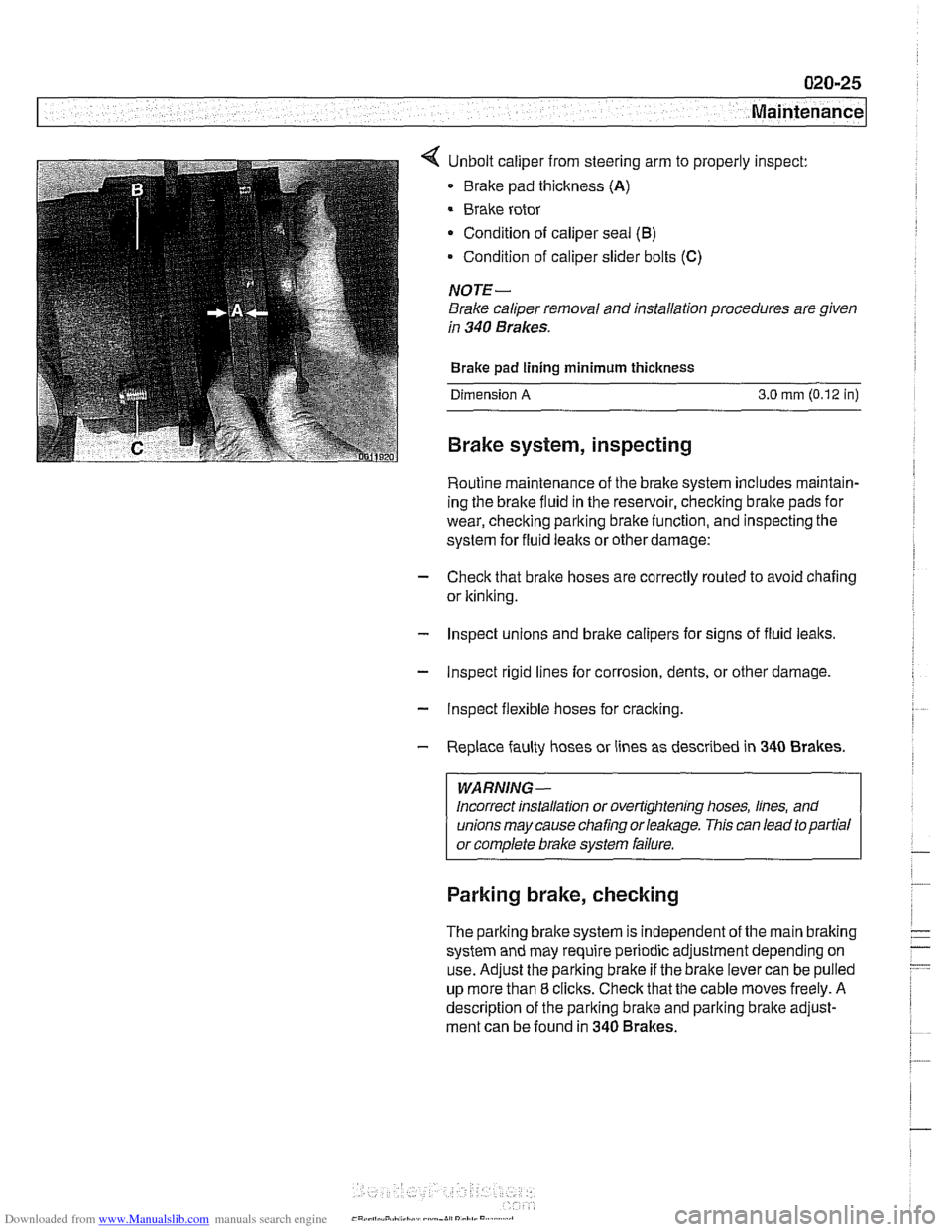

< Unbolt caliper from steering arm to properly inspect:

Brake pad thickness

(A)

Brake rotor

Condition of caliper seal

(B)

Condition of caliper slider bolts (C)

NOTE-

Brake caliper removal and installation procedures are given

in

340 Brakes.

Brake pad lining minimum thickness

Dimension

A 3.0 mm (0.12 in)

Brake system, inspecting

Routine maintenance of the brake system includes maintain-

ing the brake fluid in the reservoir,

checking bralte pads for

wear, checking parking brake function, and inspecting the

system for fluid lealts or other damage:

- Check that bralte hoses are correctly routed to avoid chafing

or

Itinking.

- lnspect unions and brake calipers for signs of fluid leaks.

- lnspect rigid lines for corrosion, dents, or other damage.

- Inspect flexible hoses for cracking

- Replace faulty hoses or lines as described in 340 Brakes.

WARNING-

Incorrect installation or overtightening hoses, lines, and

unions may cause chafing

orlealage. This can lead to partial

Parking brake, checking

The parking brake system is independent of the main braking

system and may require periodic adjustment depending on

use. Adjust the parking brake if the brake lever can be pulled

up more than

8 clicks. Check that the cable moves freely. A

description of the parking brake and

parlting bralte adjust-

ment can be found in

340 Brakes.

Page 61 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Suspension, front, inspecting

Inspection of the front suspension and steering includes a

check of all moving parts

forwear and excessive play. Inspect

ball joint and tie-rod rubber seals and boots for cracks

ortears

that could allow the entry of dirt, water, and other

contaminants. See

310 Front Suspension.

Suspension, rear, inspecting

Differential and rear drive axle service consists of checking

and changing the gear oil, inspecting for leaks, and checking

the drive axle

CV joint boots for damage.

The areas where

lealts are most likely to occurare around the

drive shaft and drive axle mounting flanges. For more infor-

mation on identifying oil leaks and theircauses, see

330 Rear

Suspension and

331 Final Drive.

Tires, checking inflation pressure

Correct tire pressures are important to handling and stability,

fuel economy, and tire wear. Tire pressures change with tem-

perature. Pressures should be

checked oRen during season-

al temperature changes. Correct inflation pressures can be

found on the driver's door pillar and in the owner's manual.

Note that tire pressures should be higher when the car is

more heavily loaded.

WARNING-

Do not inflate any tire to a pressure higher than the tire's max-

imum inflation pressure listedon the sidewall. Use care when

adding air to warm tires. Warm tire pressures can increase as

much as

4 psi (0.3 bar) over their coldpressures.

Tires, rotating

BMW does not recommend tire rotation. Due to the car's sus-

pension design, the front tires begin to wear first at the outer

shoulder and the reartires begin to wearfirst at the middle of

the tread or inner shoulder. Rotating the tires may adversely

affect road handling and tire grip.

Transmission service, automatic

The automatic transmissions installed in E39 models are

filled with special automatic transmission fluid. The transmis-

sion lubricant type can be found on the "type-plate" on the

side of the transmission. The recommended lubricants are

listed earlier in this repair group. See Fluids and lubricants.

If in doubt, consult an authorized BMW dealer for alternate

Page 62 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-30

Maintenance

fluid use and the most-up-to-date information regarding

transmission operating fluids.

The automatic transmission is not equipped with a dipstick.

Therefore, checking the ATF level is an involved procedure

which includes measuring and maintaining a specified ATF

temperature during the checking procedure.

For more complete

ATF service information, including

checking

ATF level and ATF filter replacement procedures,

see

240 Automatic Transmission.

Transmission service, manual

Manual transmission service consists of inspecting for leaks

and checking the fluid. Evidence of transmission leaks is

like-

ly to be seen around the driveshaft mounting flange and at the

bottom of the bellhousing.

NOTE-

For more information on identifying oil

leaks and their

causes, see 230 Manual Transmission and210 Clutch.

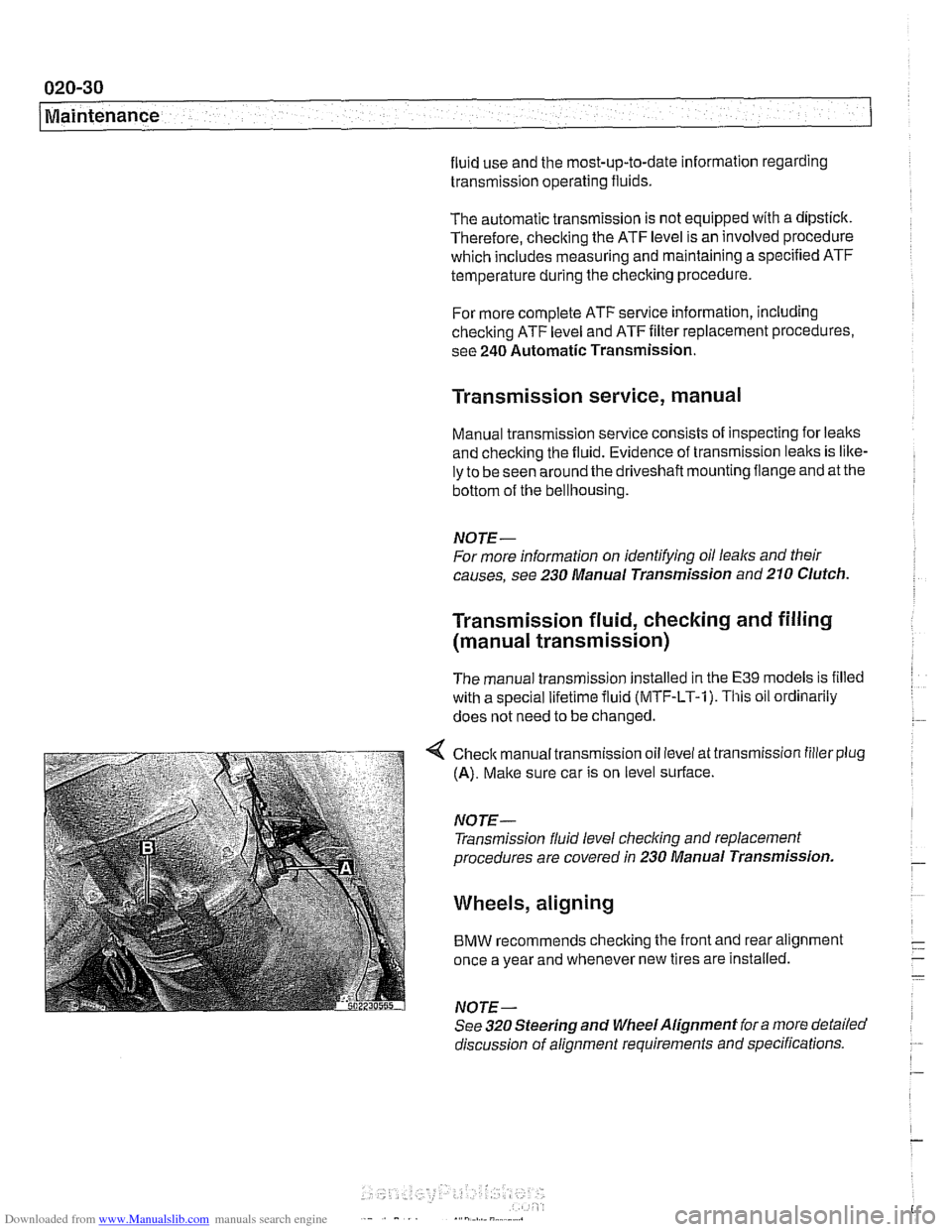

Transmission fluid, checking and filling

(manual transmission)

Tne manual transmss'on inslalleo 'n rne E39 models s f;lled

with a special liierime iluid (ivlTF-LT-I). oi. ordinarily

does

not need to be changed.

< Check manual transmission oil level at transmission filler plug

(A). Make sure car is on level surface.

NOTE- Transmission fluid level

checking and replacement

procedures are covered in 230 Manual Transmission.

Wheels, aligning

BMW recommends checking the front and rear alignment

once a year and whenever new tires are installed.

NOTE-

See 320 Steering and Wheel Alignment for a more detailed

discussion of alignment requirements and specifications.