BMW 528i 1997 E39 Workshop Manual

Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 181 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-5

I Cylinder Head and valvetrain1

4 Timing chain tensioner bracket (V-8)

(Tool No. BMW

11 7 380)

CYLINDER HEAD

This section provides the specifications and special recondi-

tioning information necessary to repair the cylinder heads

covered by this manual.

The disassembled cylinder head should be inspected for

warpage and cracks. Check the valve guides and valve seats

for wear before machining a warped head. Always decarbon-

ize and clean the head before inspecting it.

Visually inspect the cylinder head for craclts.

If a cracked cyl-

inder head is suspected and no

craclts are detected through

the visual Inspection, have the head further tested for cracks

by an authorized BMW dealer or an ASE certified machinist.

A cracked cylinder head must be replaced.

NOJE-

When disassembling and inspecting the cylinder head, be

sure to

checlc the camshaft carrier bearing surfaces using a

straight edge for

warpage, and check the lifter bores for wear.

A high-quality straight edge can be used to

checlc for

warpage. A warpage of 0.05 mm (0.002 in.) is acceptable

without machining. A warped cylinder head can be machined

provided no more than 0.3

mm (0.012 in.) of material is re-

moved.

If further machining is required, the head should be

replaced. Removing more than this amount will reduce the

size of the combustion chamber and adversely affect engine

performance. A 0.3 mm

thicker head gasket for machined

heads is available from an authorized BMW parts depart-

ment.

Page 182 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-6

Cylinder Head and Valvetrain

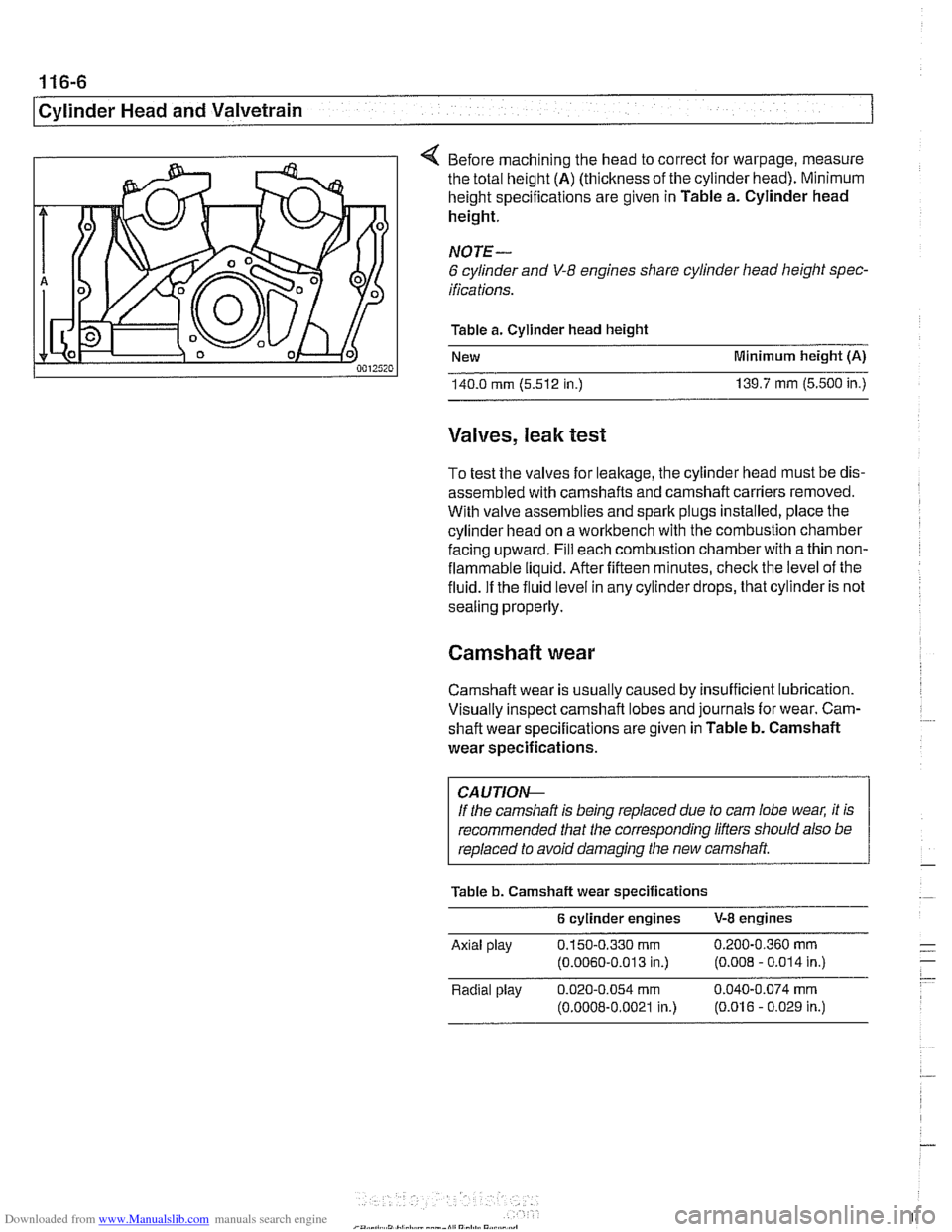

4 Before machining the head to correct for warpage, measure

the total height

(A) (thickness of the cylinder head). Minimum

height specifications are given in Table a. Cylinder head

height.

NOTE-

6 cylinder and V-8 engines share cylinder head height spec-

ifications.

Table a. Cylinder head height

New Minimum height

(A)

140.0 rnrn (5.512 in.) 139.7 rnrn (5.500 in.)

Valves, leak test

To test the valves for leakage, the cylinder head must be dis-

assembled with camshafts and camshaft carriers removed.

With valve assemblies and spark plugs installed, place the

cylinder head on a workbench with the combustion chamber

facing upward. Fill each combustion chamber with a thin non-

flammable liquid. After fifteen minutes, check the level of the

fluid. If the fluid level in any cylinder drops, that cylinder is not

sealing properly.

Camshaft wear

Camshaft wear is usually caused by insufficient lubrication.

Visually inspect camshaft lobes and journals for wear. Cam-

. ~~ shaft wear specifications are given in Table b. Camshaft

wear specifications.

CA UTIOI\C

If the camshaft is being replaced due to cam lobe wear, it is

recommended that the corresponding lifters should also be

replaced to avoid damaging the new camshaft

Table b. Camshaft wear specifications

6 cylinder engines V-8 engines

Axlal play 0.150-0.330 rnrn 0 200-0 360 rnrn - .-

(0.0060-0 013 in.) (0.008 - 0.014 in ) - - Radlal play 0.020-0.054 rnrn 0.040-0.074 rnrn

(0.0008-0.0021 in.) (0.016 - 0.029 in.)

Page 183 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and valvetrain1

Hydraulic lifters, checking and replacing

Self-adjusting hydraulic lifters (A) keep the valve clearances

within a limited working range. Hydraulic lifters are sealed

units and require no maintenance. Section view of camshaft

(6) and valve with conical valve spring (C) shown.

Under some circumstances, such as a cold start, the cam fol-

lowers may emit noise. Hydraulic lifter noise is usually a

high-

pitched tapping or chattering noise. In most instances, this is

considered normal as long as the noise goes away in a few

minutes (maximum

20 minutes). If the noise does not go

away, either the lifter is faulty or the oil pressure to the lifter is

low. Hydraulic lifter replacement requires that the camshaft

first be removed.

NOTE-

Before checking hydraulic lifters, male sure engine oil is

fresh and at the proper level.

Sticky lifters can be the result of

sludge build up in the cylinder head and lifters.

- Run engine until it reaches normal operating temperature.

Shut off engine.

- Working inside luggage compartment, disconnect negative

battery cable.

CAUTION-

Prior to disconnecting battery cable, read the baltery dls-

connection cautions given In 001 General Cautions and

Warnings.

Disconnecting the battery may erase fault

code(s)

stored in control module memory Check for fault codes

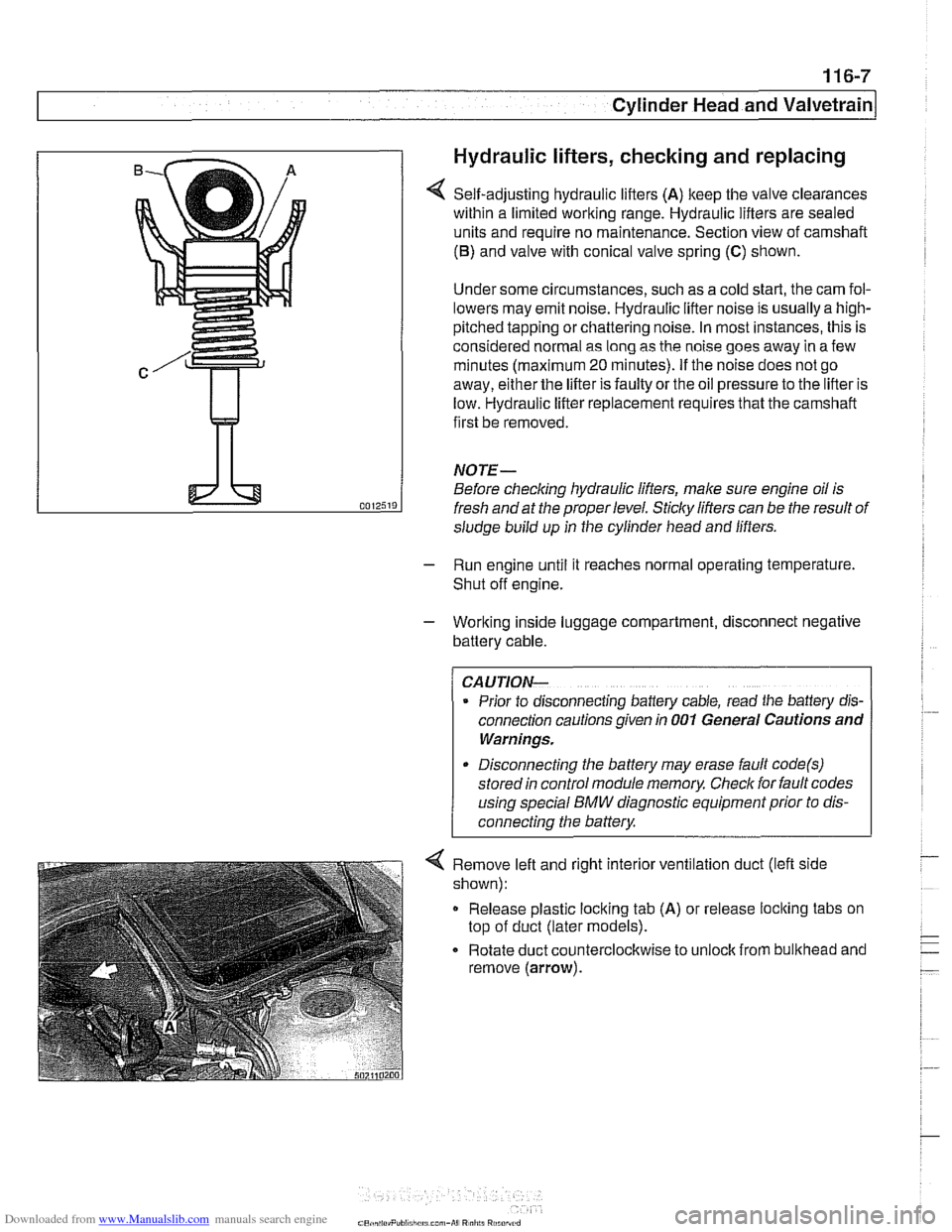

4 Remove left and right interior ventilation duct (left side

shown):

Release plastic locking tab

(A) or release loclting tabs on

top of duct (later models).

Rotate duct counterclockwise to

unloclt from bulithead and

remove (arrow).

Page 184 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

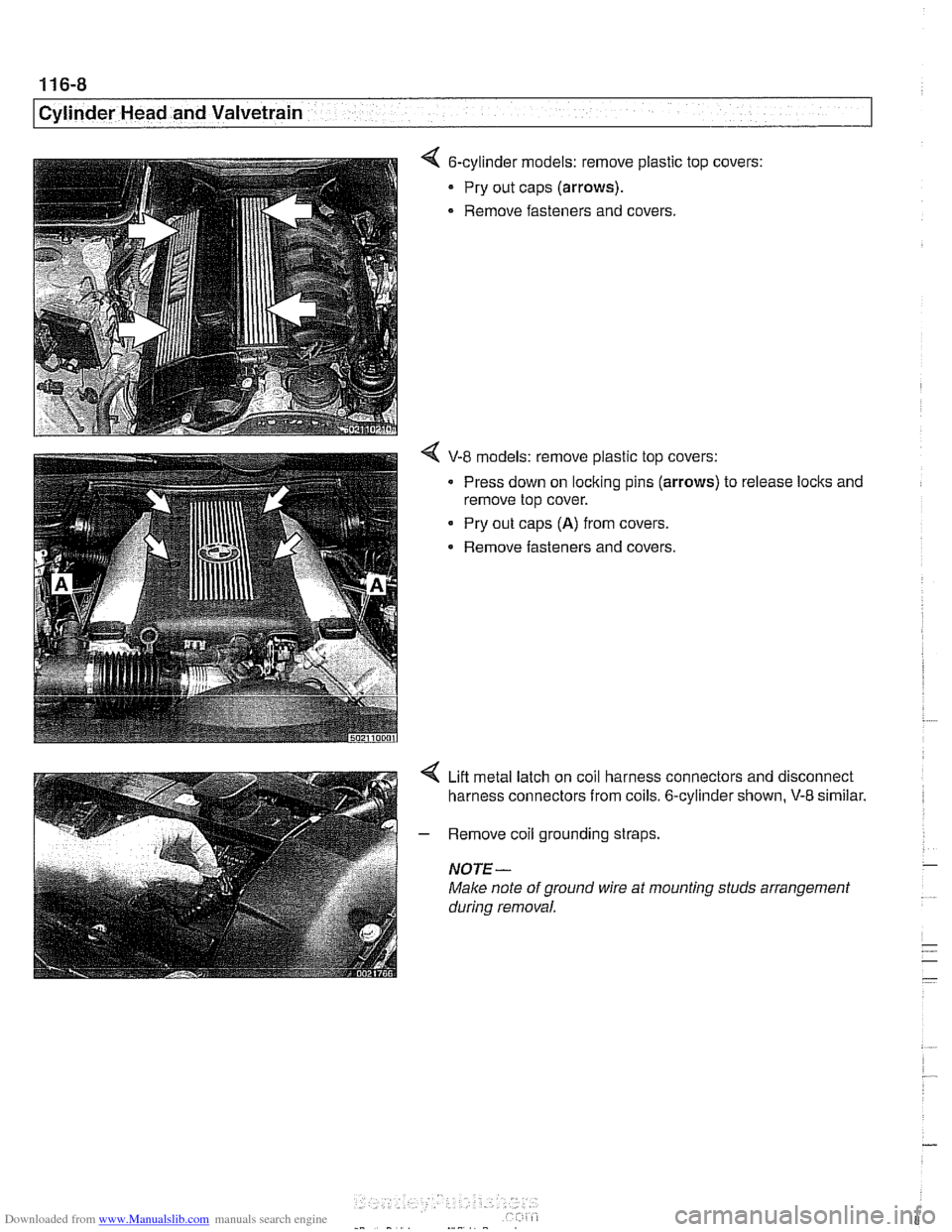

&cylinder models: remove plastic top

- Pry out caps (arrows).

- Remove fasteners and covers. covers:

4 V-8 models: remove plastic top

covers:

Press down on locking pins

(arrows) to release locks and

remove top cover.

Pry out caps

(A) from covers.

Remove fasteners and covers.

4 Lift metal latch on coil harness connectors and disconnect

harness connectors from coils. 6-cylinder shown,

V-8 similar.

- Remove coil grounding straps.

NOTE-

Make note of ground wire at mounting studs arrangement

during removal.

- -- -

-

Page 185 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 6-9

Cvlinder Head and valvetrain1

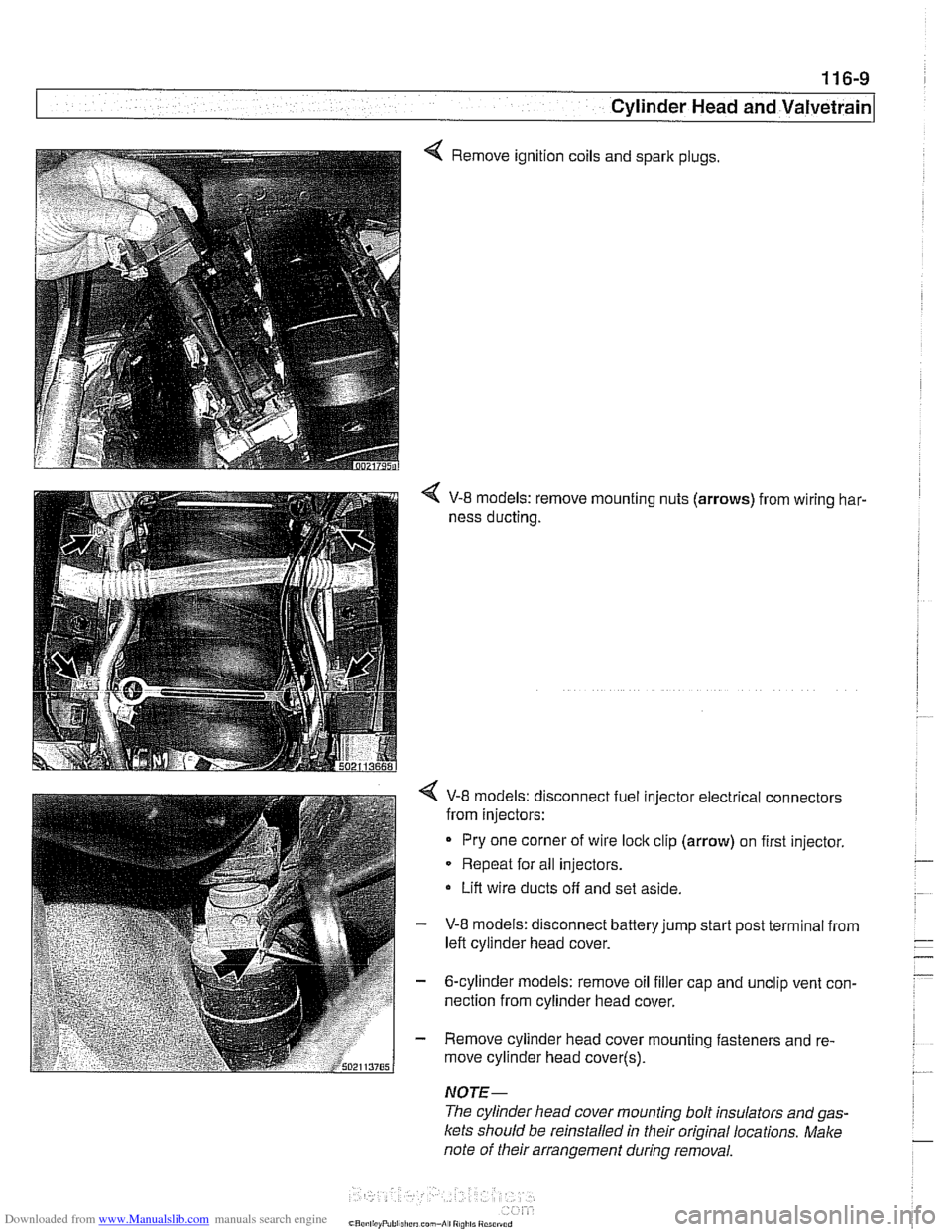

4 Remove ignition coils and spark plugs.

V-8 models: remove mounting nuts (arrows) from wiring har-

ness ducting.

< V-8 models: disconnect fuel injector electrical connectors

from injectors:

Pry one corner of wire

loclc clip (arrow) on first injector.

Repeat for all injectors.

Lift wire ducts off and set aside.

- V-8 models: disconnect battery jump start post terminal from

left cylinder head cover.

- 6-cylinder models: remove oil filler cap and unclip vent con-

nection from cylinder head cover.

- Remove cylinder head cover mounting fasteners and re-

move cylinder head cover(~).

NOTE-

The cylinder head cover mounting bolt insulators and gas-

Icets should be reinstalled in their original locations. Make

note of their arrangement

during removal.

Page 186 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

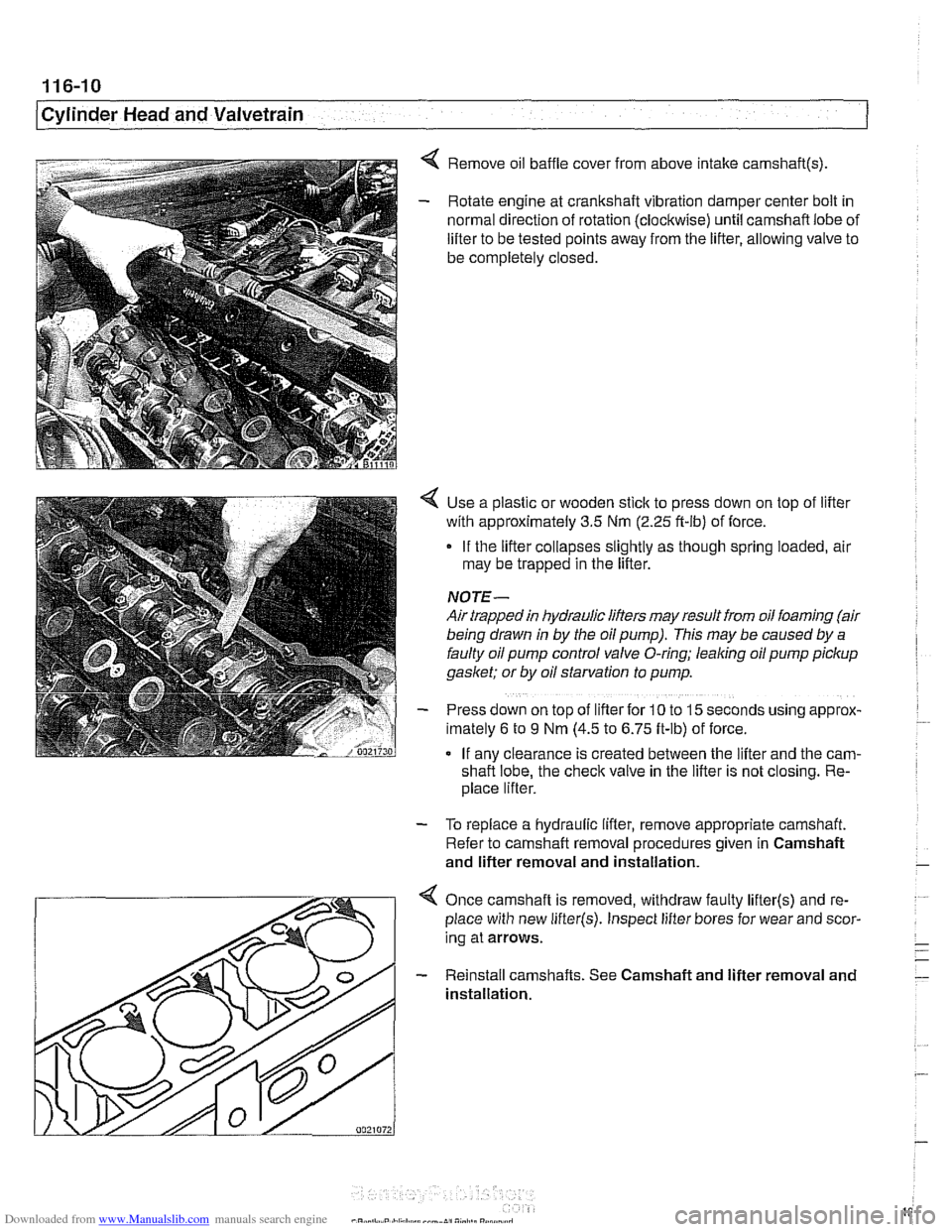

< Remove oil baffle cover from above intake camshaft(s)

- Rotate engine at crankshaft vibration damper center bolt in

normal direction of rotation (clockwise) until camshaft lobe of

lifter to be tested points away from the lifter, allowing valve to

be completely closed.

Use a plastic or wooden stick to press down on top of lifter

with approximately 3.5 Nm

(2.25 ft-ib) of force.

If the lifter collapses slightly as though spring loaded, air

may be trapped in the lifter.

NOTE-

Air trapped in hydraulic lifters may result from oil foaming (air

being drawn

in by the oil pump). This may be caused by a

faulty oil pump control valve O-ring; leaking oil pump pickup

gaslcet; or by oil starvation to pump.

Press down on top of lifter for

10 to 15 seconds uslng approx-

lmately 6 to 9 Nm (4.5 to 6.75 ft-lb) of force.

If anv clearance is created between the lifter and the

cam-

shafi lobe, the check valve in the lifter is not closing. Re-

place lifter.

- To replace a hydraulic lifter, remove appropriate camshaft.

Refer to camshaft removal procedures given in Camshaft

and lifter removal and installation.

Once camshaft is removed, withdraw faulty

lifter(s) and re-

place with new

lifter(s). Inspect lifter bores for wear and scor-

ing at arrows.

- Reinstall camshafts. See Camshaft and lifter removal and

installation.

Page 187 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

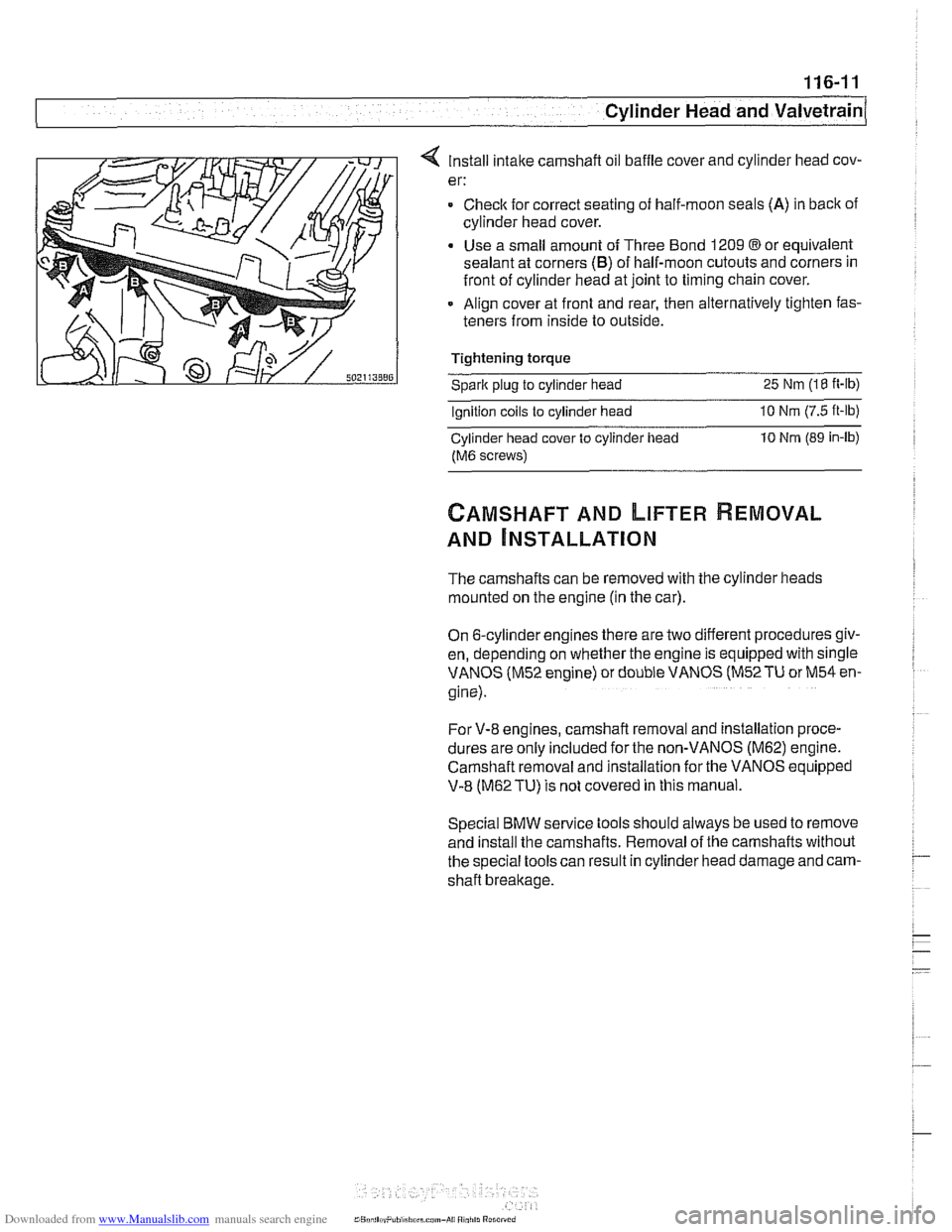

4 Install intake camshaft oil baffle cover and cylinder head cov-

er:

= Checlc for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

@or equivalent

sealant at corners

(B) of half-moon cutouts and corners in

front of cylinder head at joint to timing chain cover.

Align cover at front and rear, then alternatively tighten fas-

teners from inside to outside.

Tightening torque

Sparic plug to cylinder head 25 Nm (18 it-lb)

Ignition coils to cylinder head 10 Nrn (7.5 ft-lb)

Cylinder head cover to cylinder iiead 10 Nrn (89 in-lb)

fM6 screws)

CAMSHAFT AND LIFTER REMOVAL

AND ~NSTALLATION

The camshafts can be removed with the cylinder heads

mounted on the engine (in the car).

On 6-cylinder engines there are two different procedures giv-

en, depending on whether the engine is equipped with single

VANOS (M52 engine) or double VANOS

(M52TU or M54 en-

gine).

For V-8 engines, camshaft removal and installation proce-

dures are

only included for the non-VANOS (M62) engine.

Camshaft removal and installation for the

VANOS eq;ipped

V-8 (M62TU) is not covered in this manual.

Special BMW service tools should always be used to remove

and install the camshafts. Removal of the camshafts without

the special tools can result in cylinder head damage and cam-

shaft breakage.

Page 188 of 1002

Downloaded from www.Manualslib.com manuals search engine

116-12

I Cylinder Head and Valvetrain

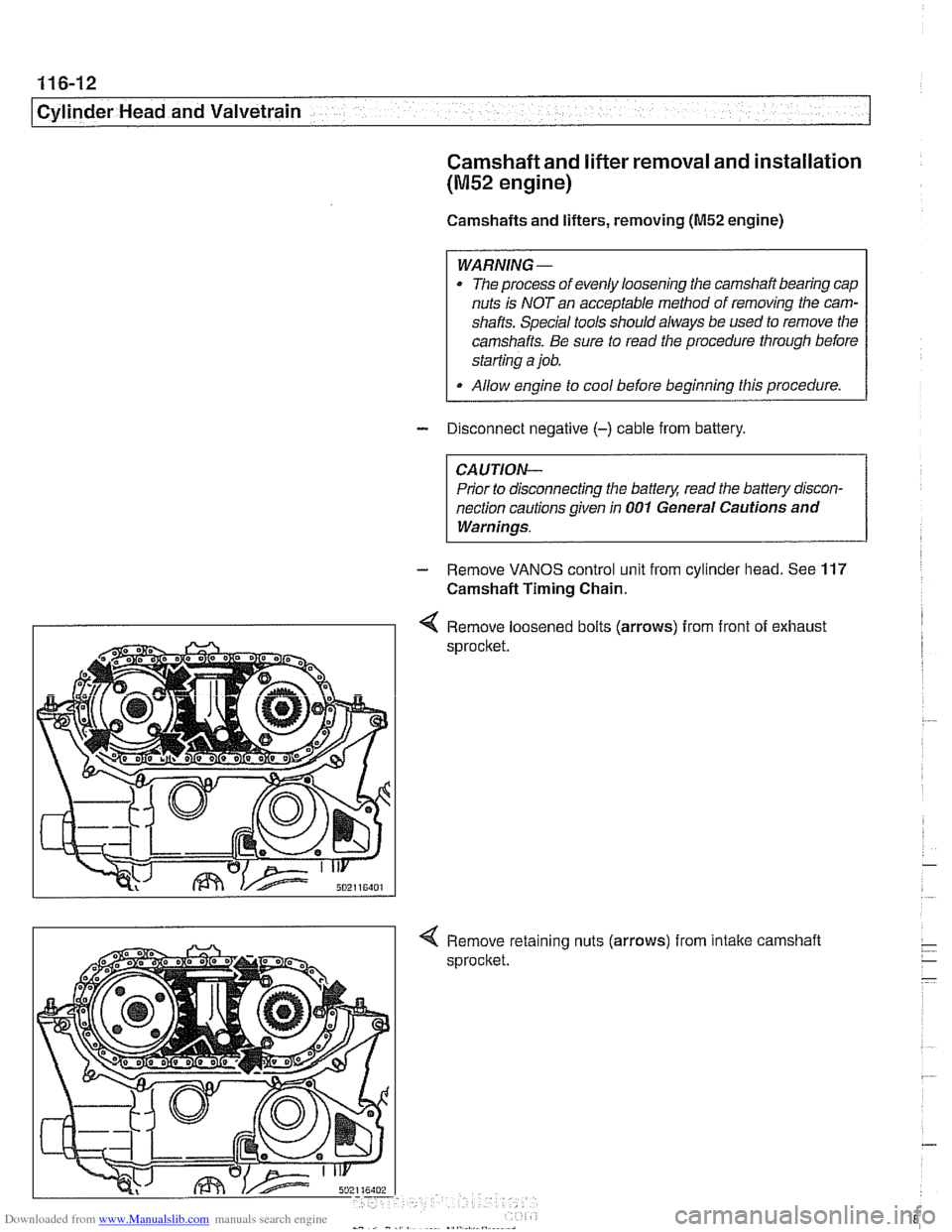

Camshaft and lifter removal and installation

(M52 engine)

Camshafts and lifters, removing (M52 engine)

WARNING

-

The process of evenly loosening the camshaft bearing cap

nuts is NOT an acceptable method of removing the cam-

shafts. Special tools should always be used to remove the

camshafts. Be sure to read the procedure

tlirough before

starting a job.

I Allow engine to cool before beginning this procedure. /

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the batfew read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove VANOS control unit from cylinder head. See 117

Camshaft Timing Chain.

I I 4 Remove loosened bolts (arrows) from front of exhaust

sprocket

nuts

(arrows) from intake camshaft

Page 189 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head and Valvetrain

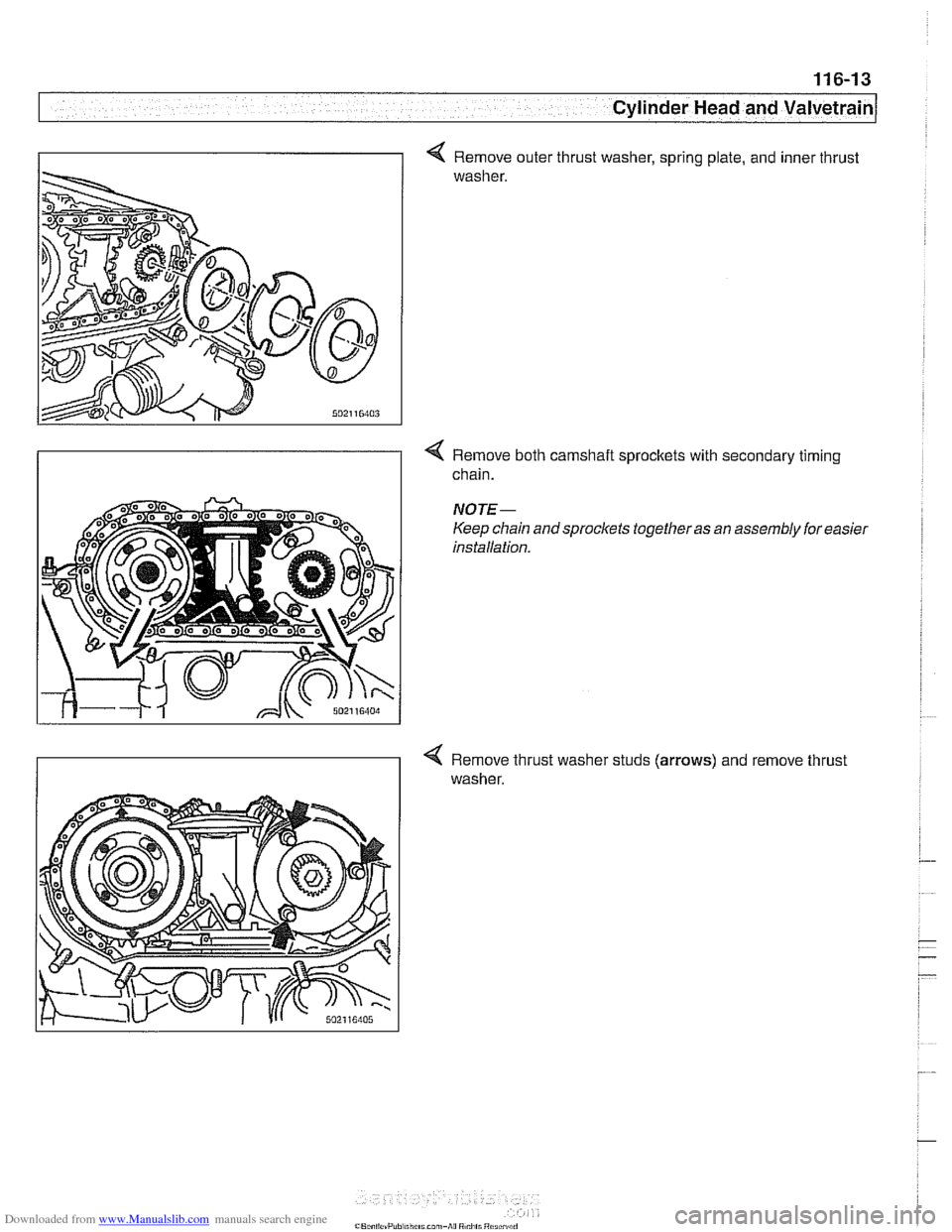

I I < Remove outer thrust washer, sprinq plate, and inner thrust

washer.

4 Remove both camshait sprockets with secondary timing

chain.

NOTE-

Keep chain and sprockets together as an assembly for easier

installation.

< Remove thrust washer studs (arrows) and remove thrust

washer.

Page 190 of 1002

Downloaded from www.Manualslib.com manuals search engine

116-14

I Cylinder Head and Valvetrain

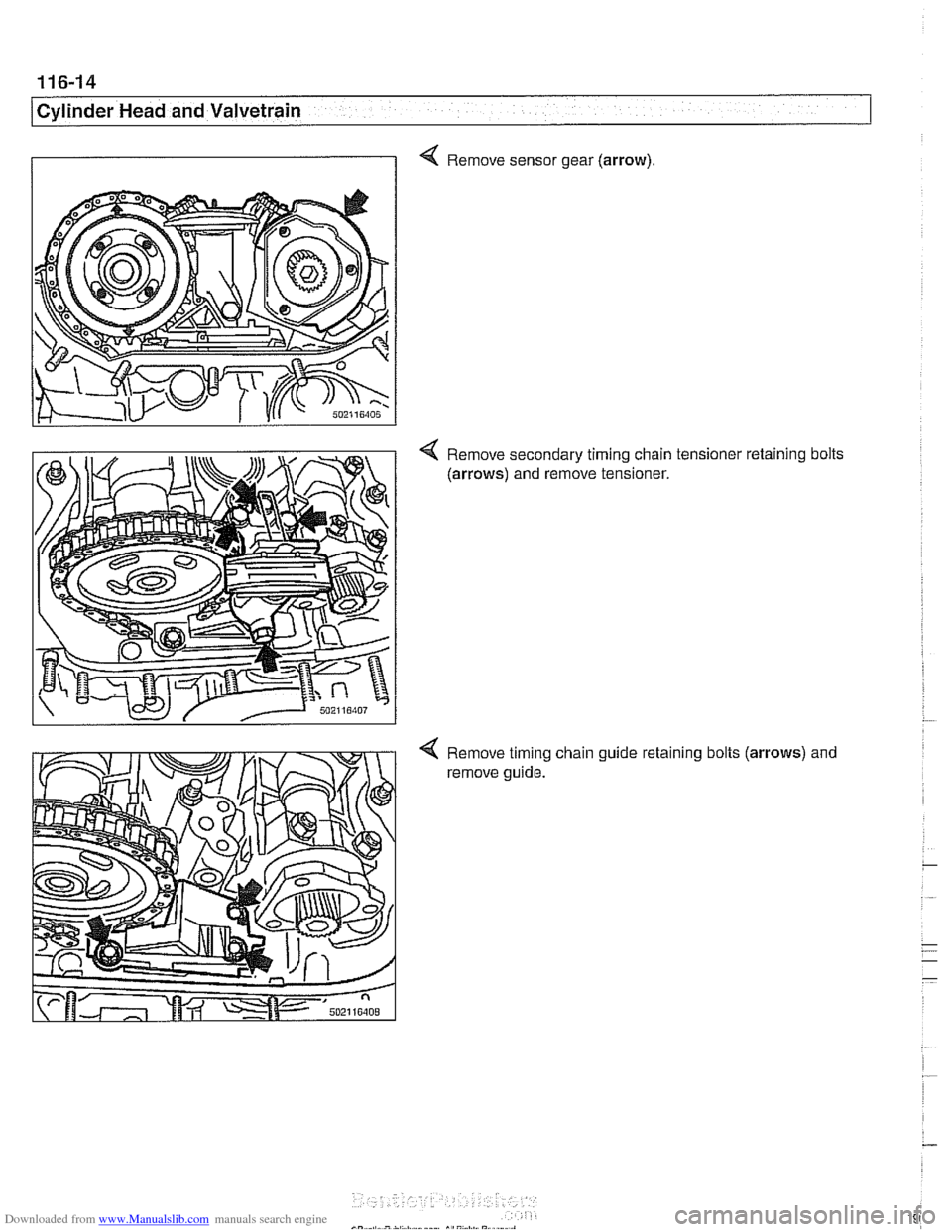

4 Remove sensor gear (arrow).

Remove secondary timing chain tensioner retaining bolts

(arrows) and remove tensioner.

Remove timing chain guide

reta~ning bolts (arrows) and

remove guide.